Patents

Literature

70results about How to "Flip Accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

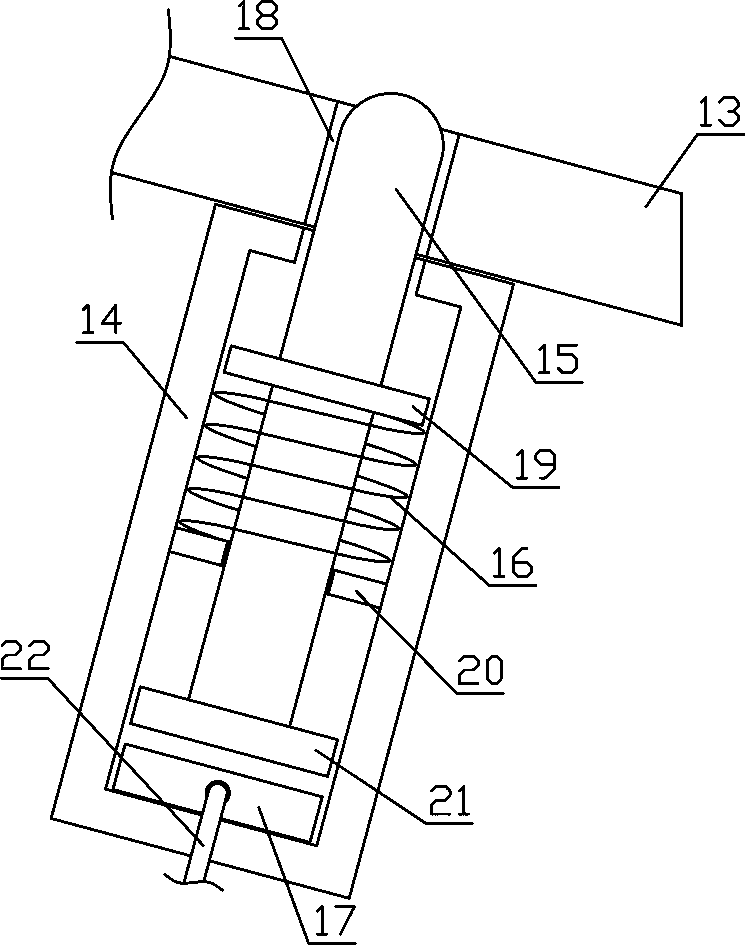

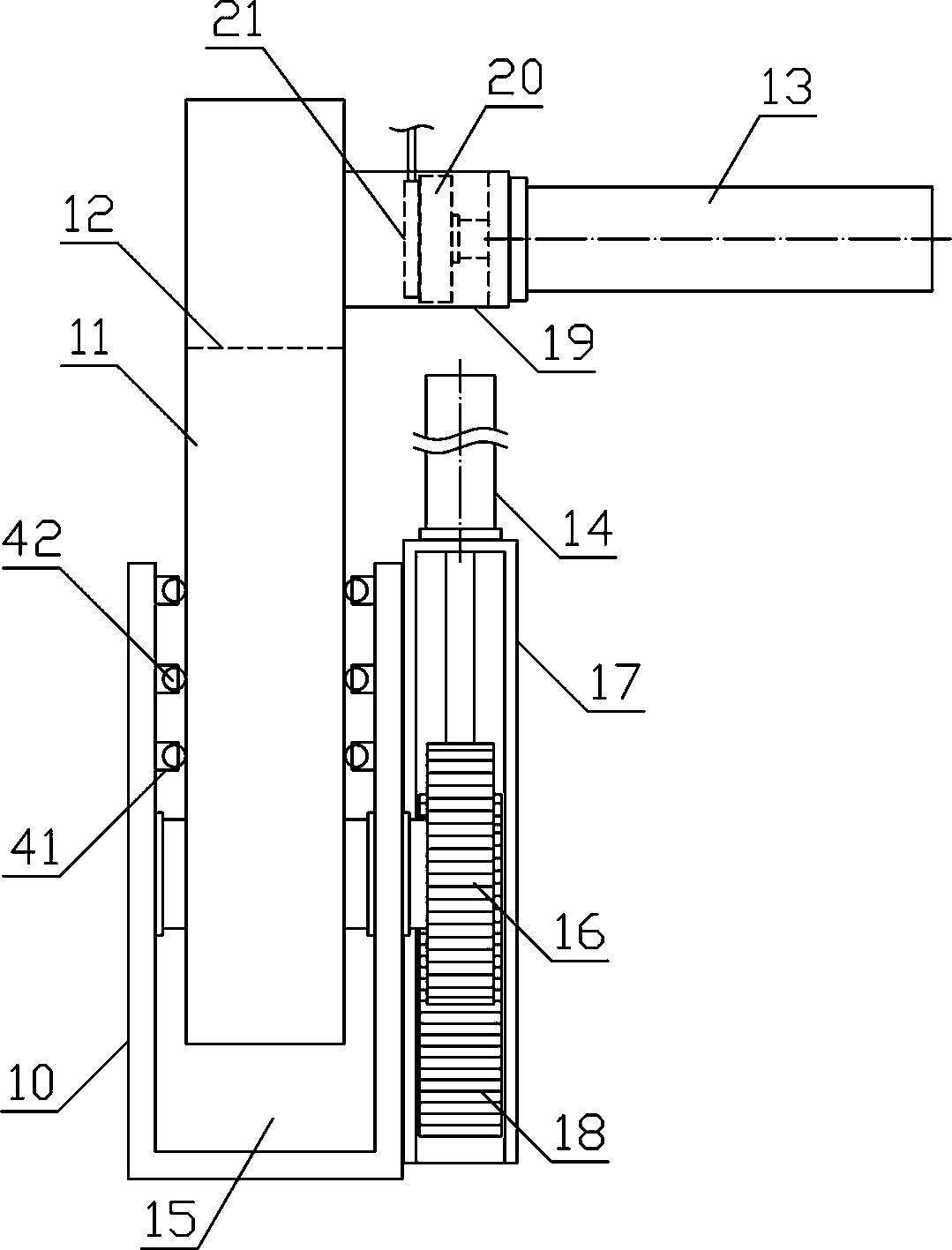

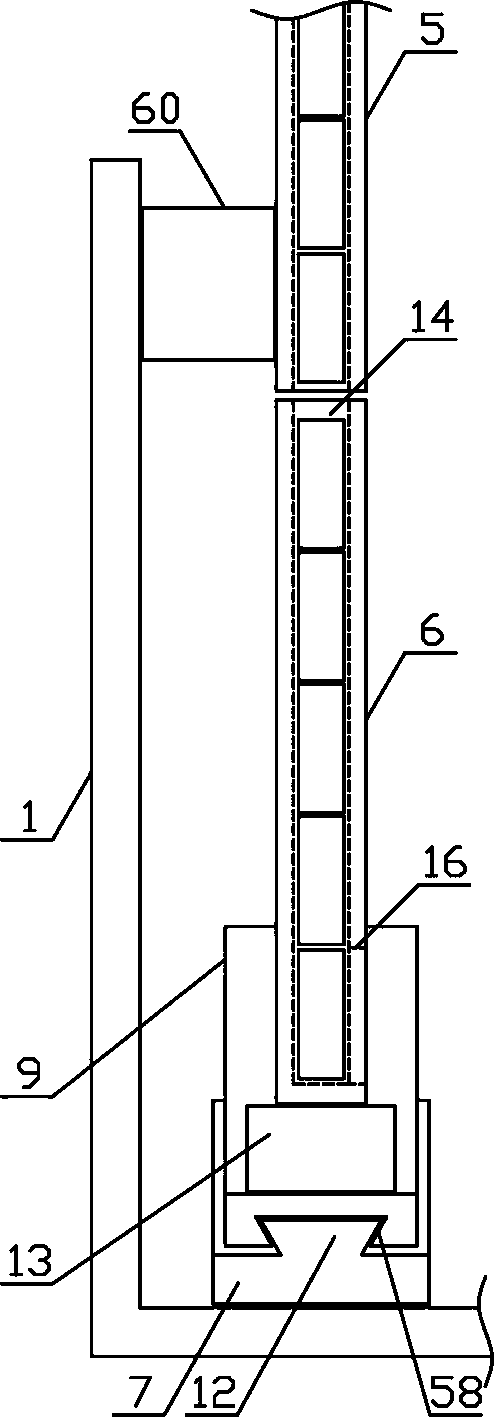

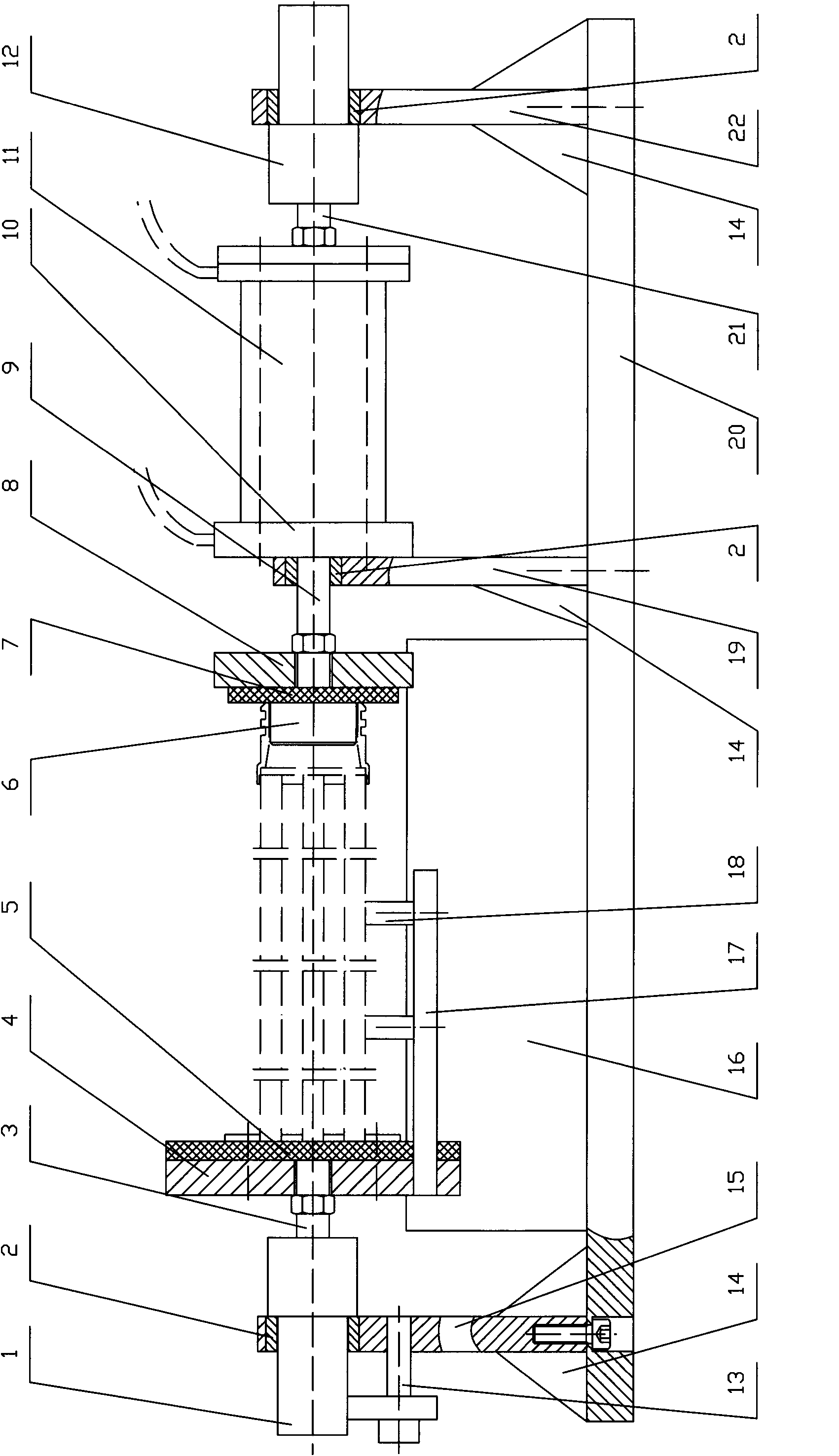

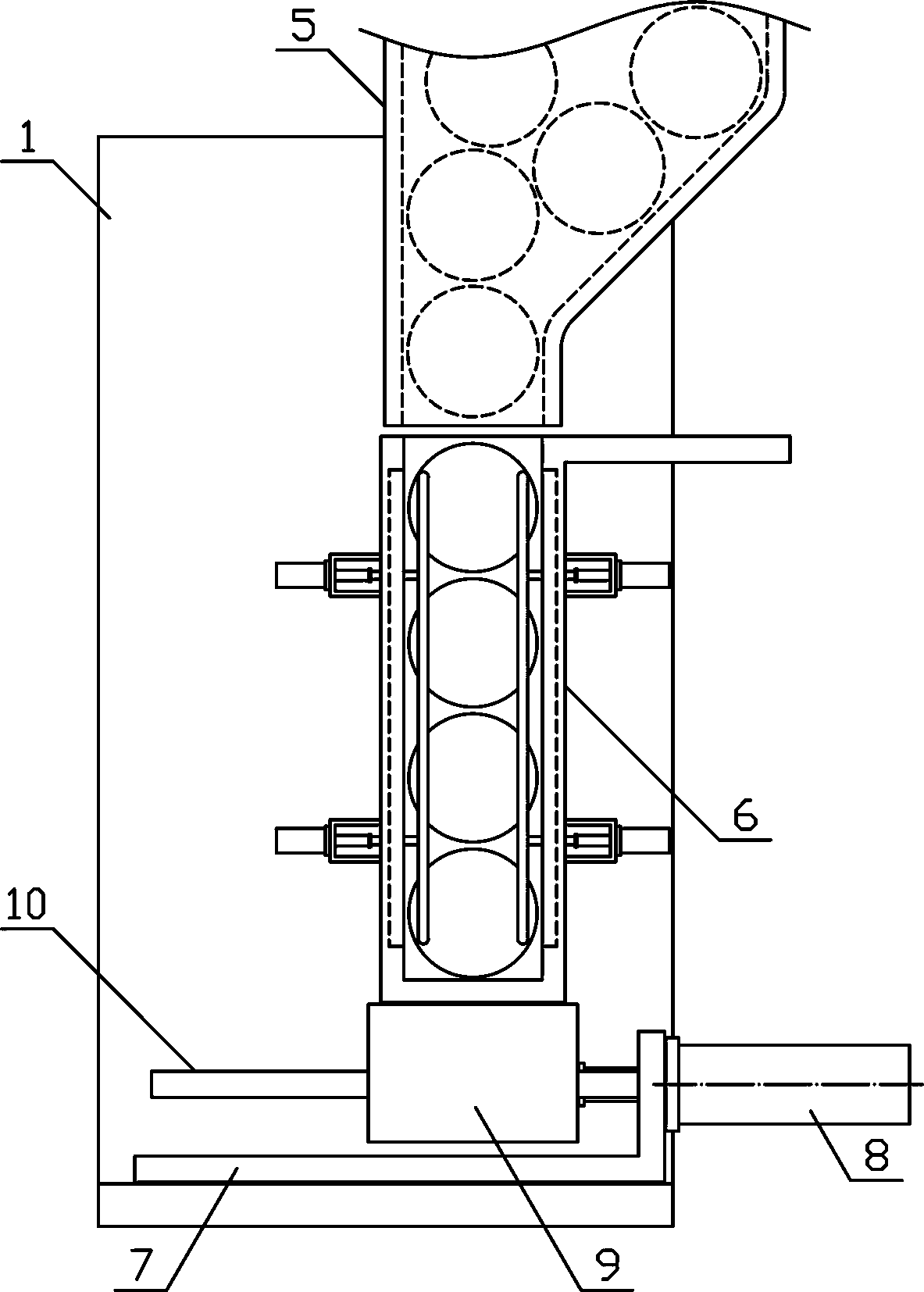

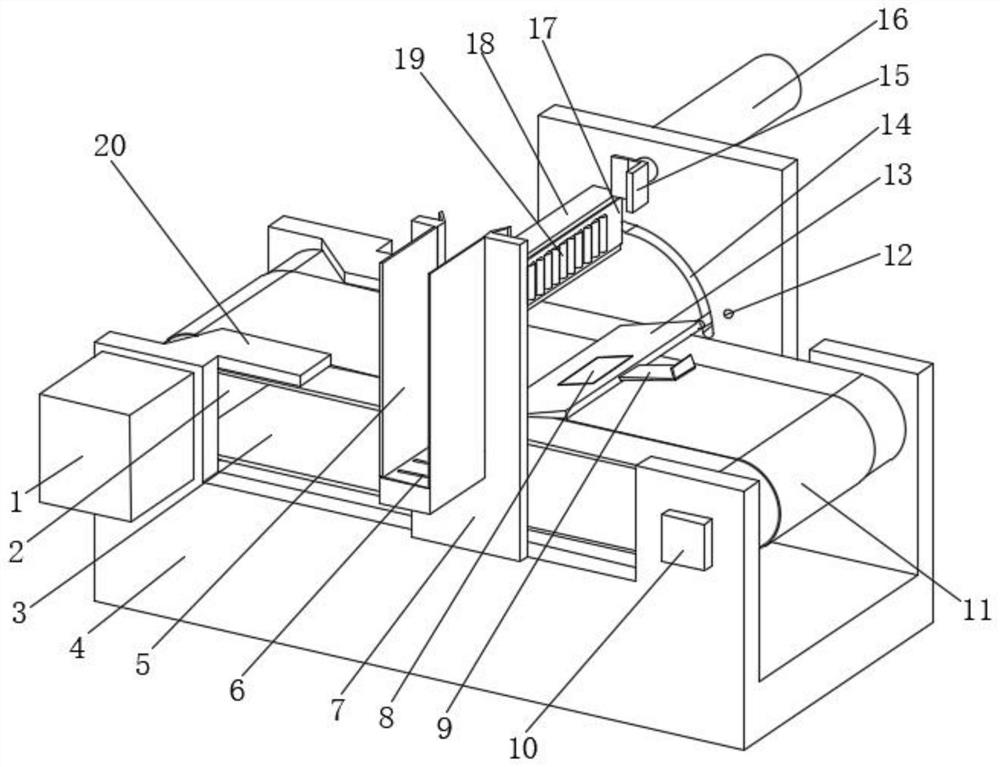

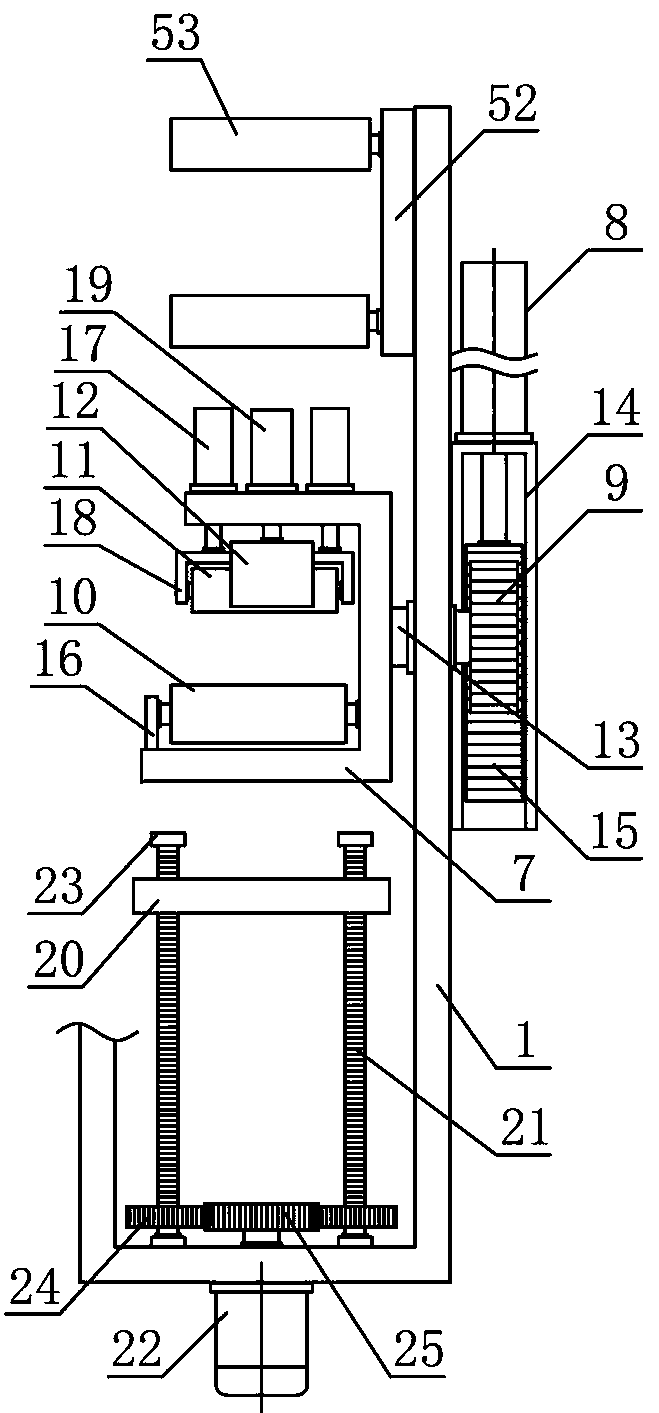

Pipe fitting reversing and feeding mechanism

InactiveCN108820802ASmooth slidingRealize automatic adjustmentConveyor partsPipe fittingMechanical equipment

The invention discloses a pipe fitting reversing and feeding mechanism, and belongs to the field of workpiece machining and conveying mechanical equipment. A reversing mechanism is vertically disposedon one side of the upper portion of a fixed bracket, and a pipe-guiding mechanism is obliquely and downwardly disposed on the fixed bracket on the lower side of the reversing mechanism; a turnover mechanism is vertically disposed on the fixed bracket on the lower side of the pipe-guiding mechanism, and a pipe-discharging charge-pipe is horizontally arranged at the lower end of a pipe-guiding charge-pipe in a communicating mode; a pipe-limiting mechanism is fixedly arranged on the lower side of a pipe-placing clamping groove in inclined and upward modes, wherein the pipe-placing clamping groove is formed in the lower end of a pipe-blocking connecting plate; a pipe-blocking fixing block is fixedly and horizontally arranged in the middle of the pipe-guiding charge-pipe, and a pipe-feeding push plate of a circular arc structure is vertically arranged at the upper end of a pipe-pushing turnover plate; and the upper end of a slide downward charge-pipe communicates with the lower end of thepipe-guiding charge-pipe, and one end of a pipe-collecting turnover plate is connected to the upper side of the slide downward charge-pipe in a hinged mode. The pipe fitting reversing and feeding mechanism is reasonable in structural design, and pipe fittings can be transferred smoothly and conveniently one by one in a reversing mode, turnover is carried out accurately during the pipe fitting feeding process, thereby the automatic adjustment of pipe fitting working stations is realized, and the needs of machining and use are met.

Owner:嘉兴汉羿文化传播有限公司

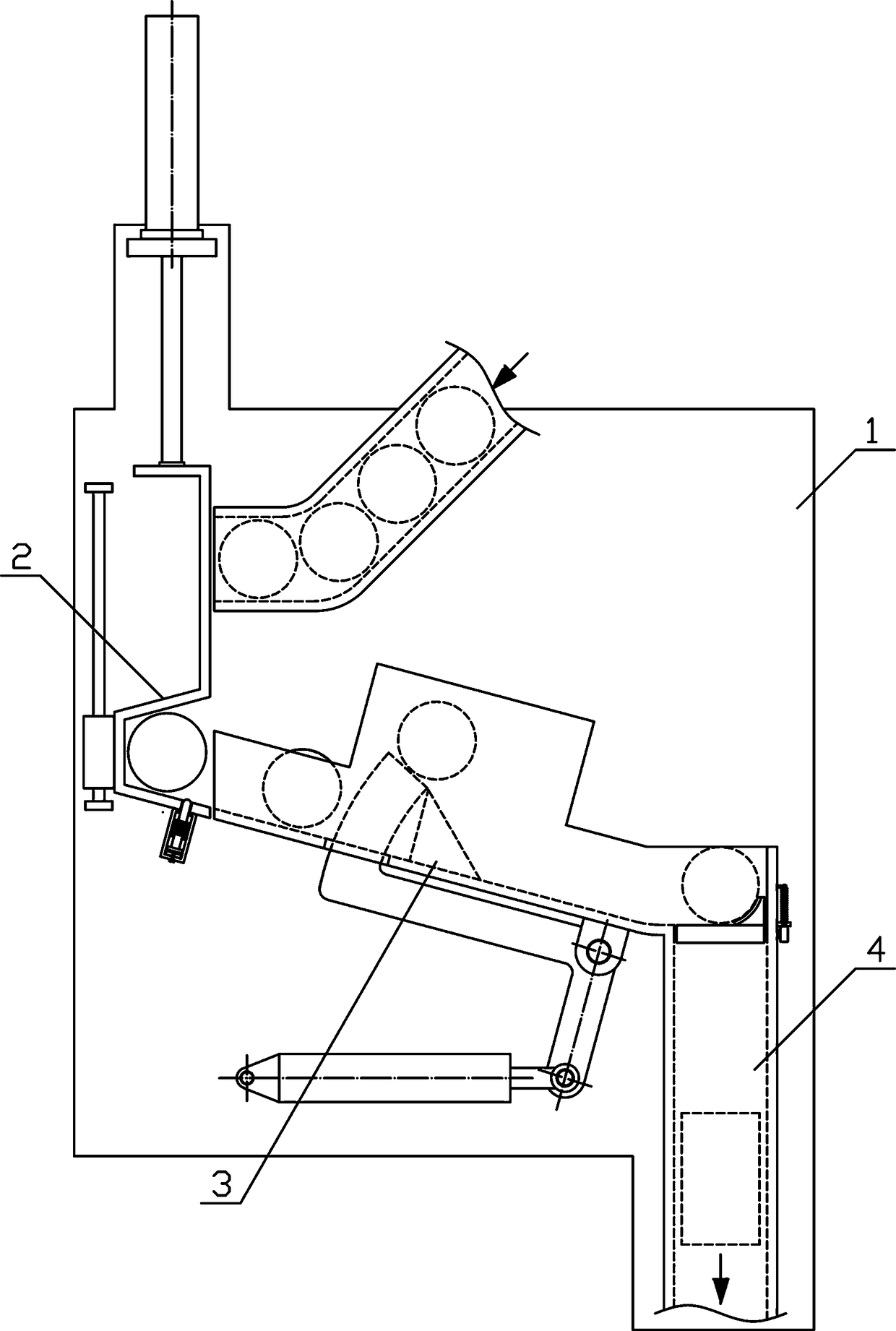

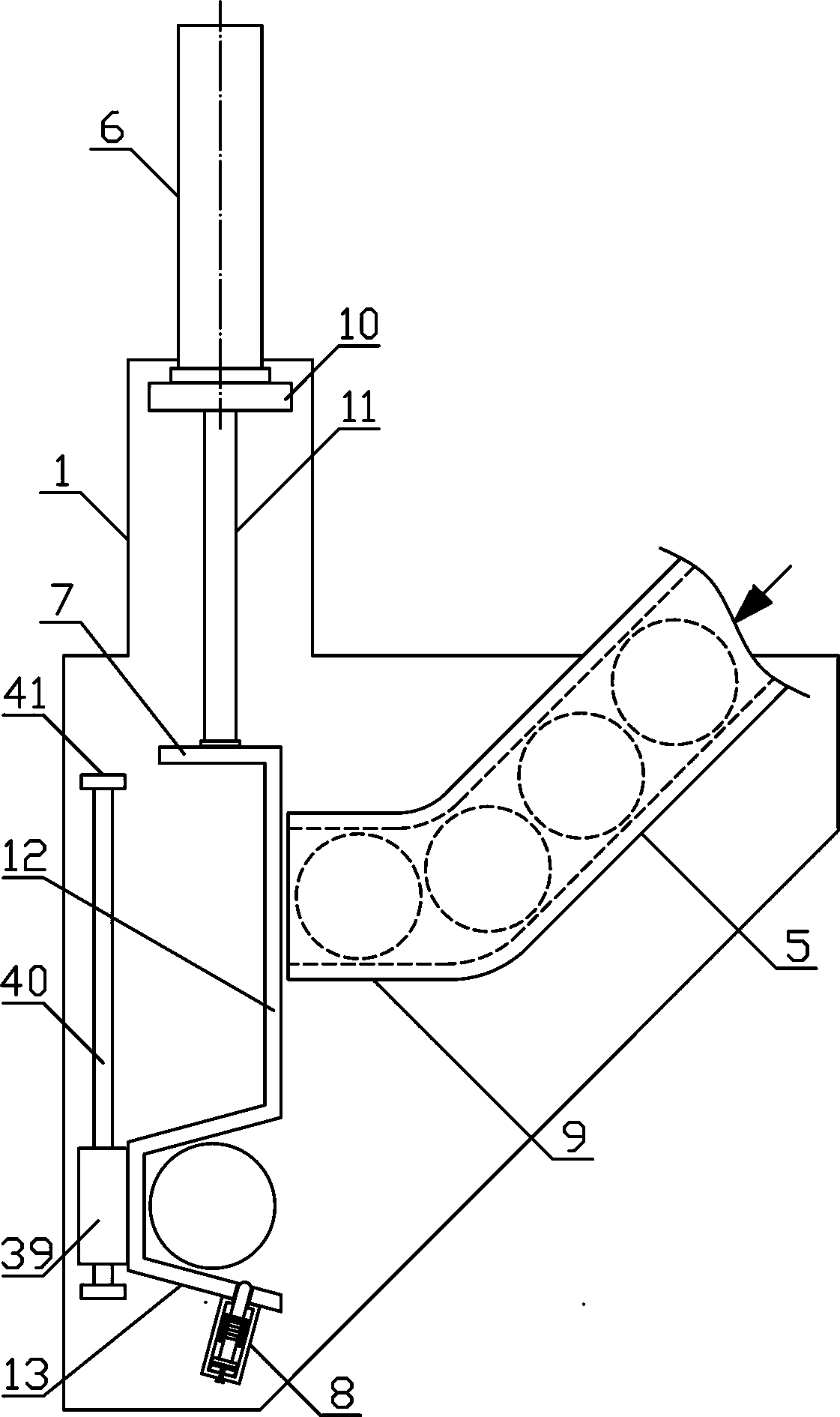

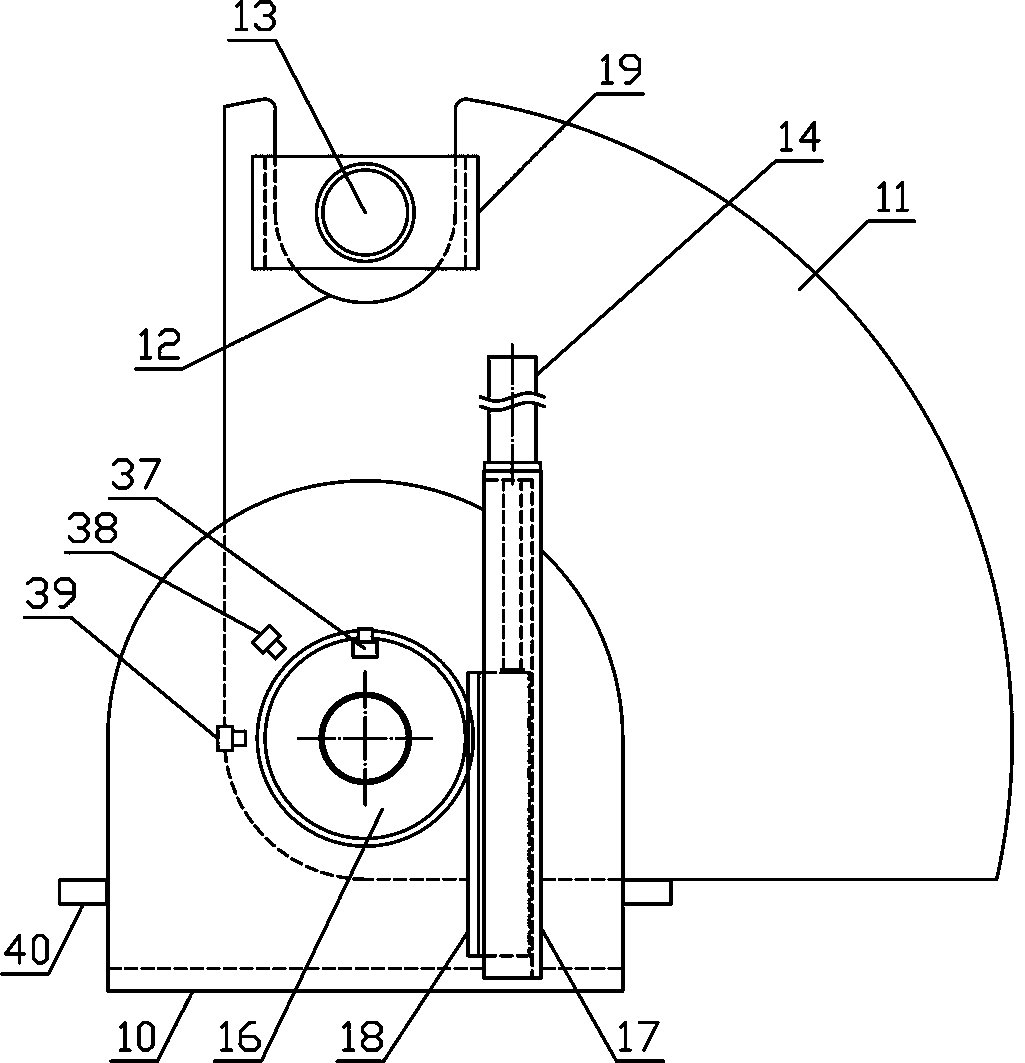

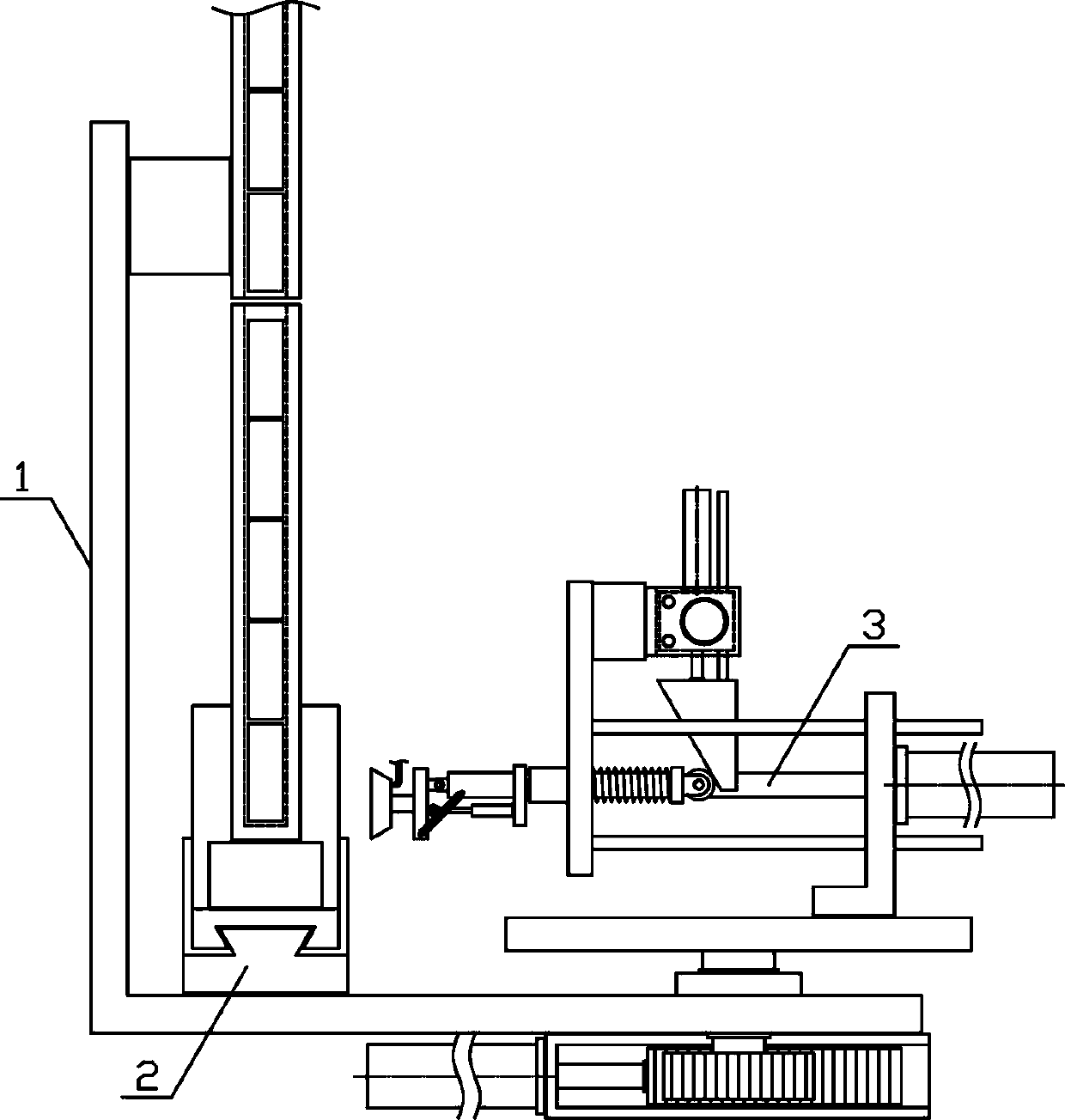

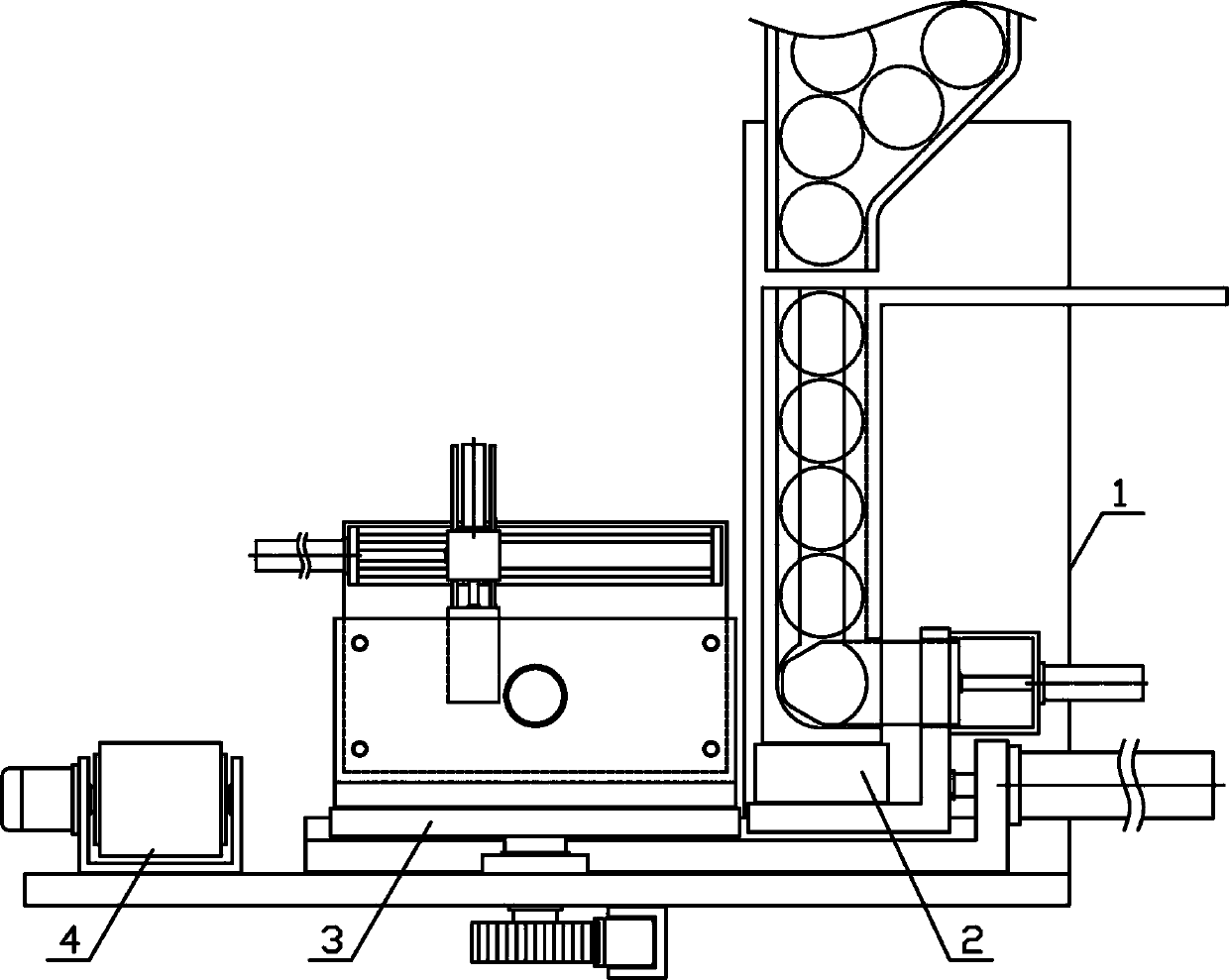

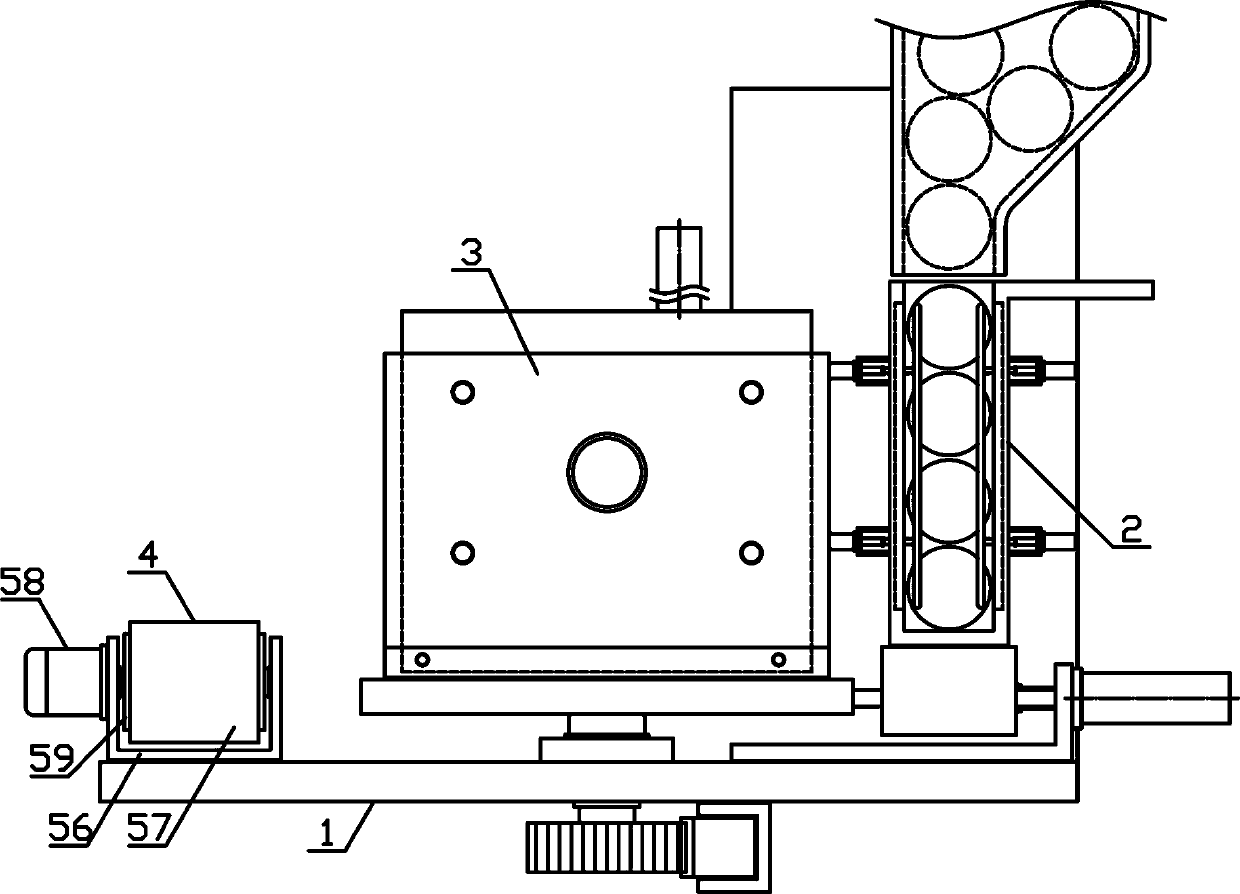

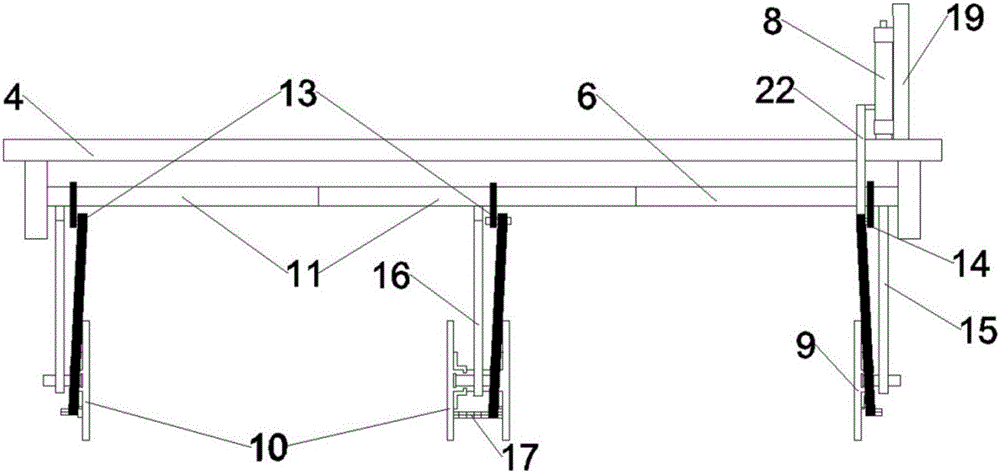

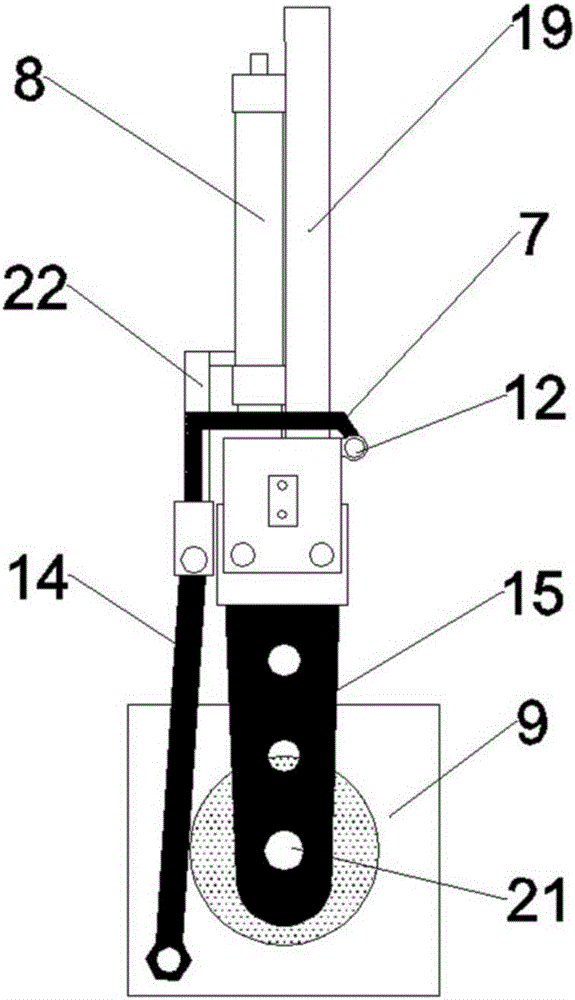

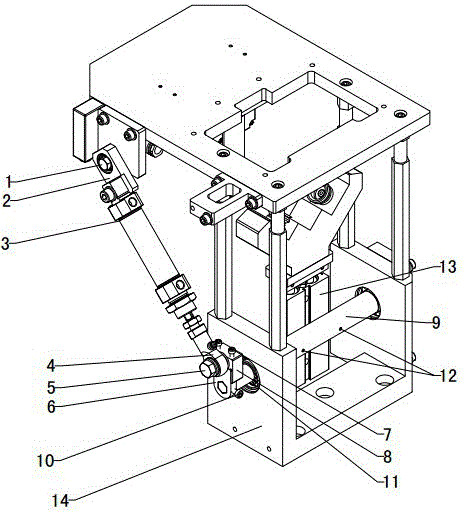

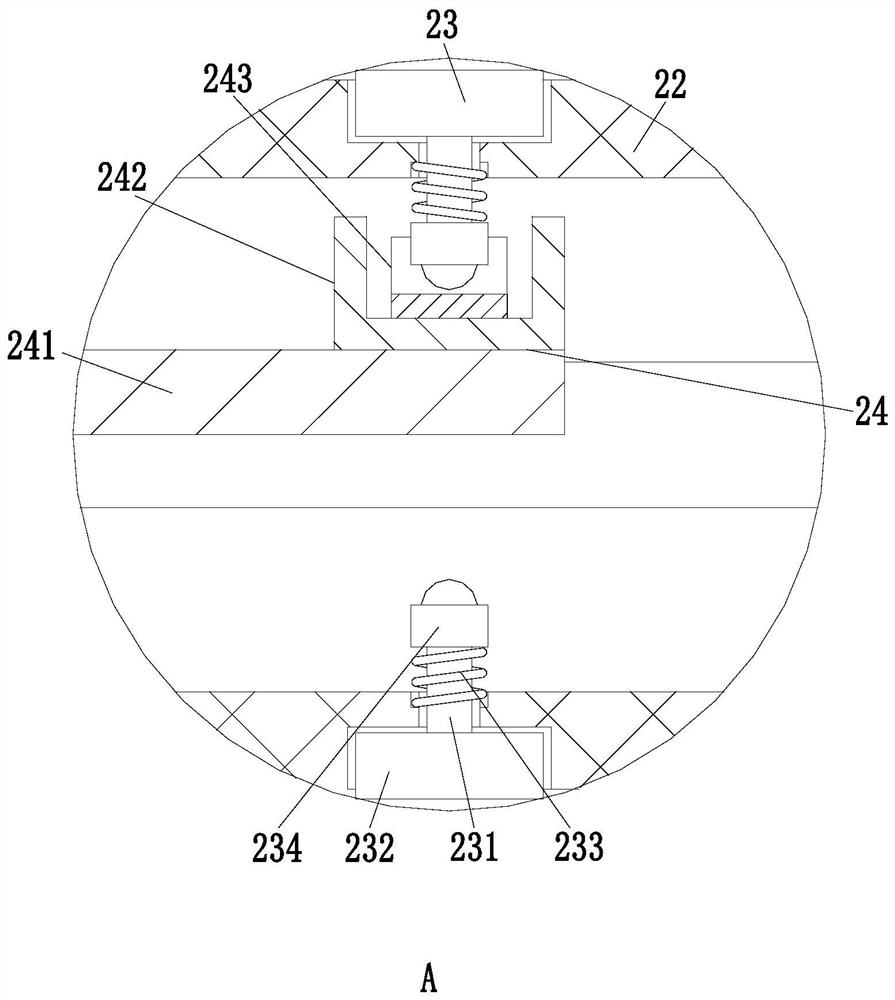

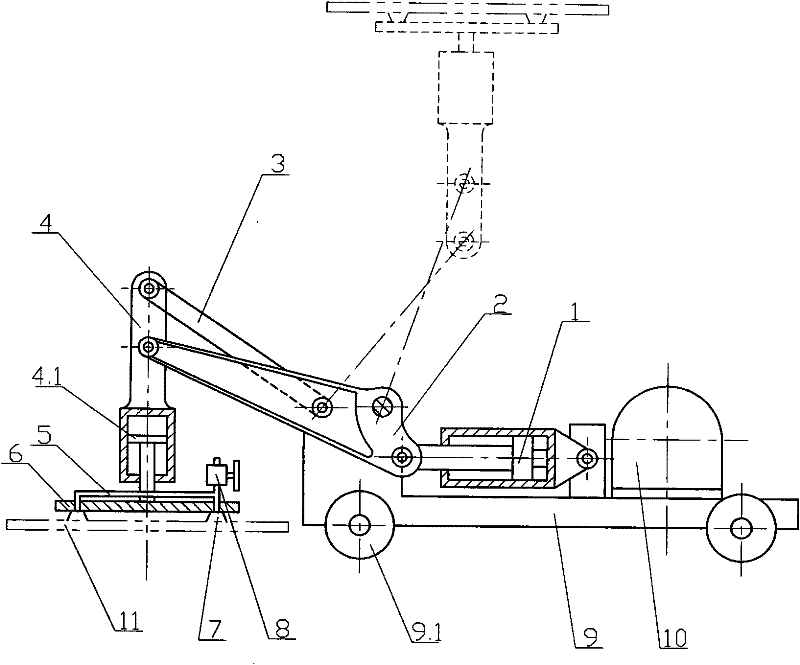

Round can shunting feeding transfer mechanism

InactiveCN108657787APrevent slidingAccurate reciprocating slidingConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a round can shunting feeding transfer mechanism, and belongs to the field of container equipment processing machinery equipment. Two can transfer mechanisms are horizontally arranged on a fixed bracket which is located on one side of the shunting mechanism from top to bottom. The middle portion of the upper part of an upper can guiding pipe communicates with the lower end of a can bearing hopper, and the upper can guiding pipe and a lower can material pipe are integrally shaped. A shunting rotary plate is vertically arranged in a rotating clamping groove of a rotating bracket, a round can clamping groove is formed in the outer side of the shunting rotary plate in the radial direction of the shunting rotary plate, and a can pushing cylinder is horizontally fixedly arranged on a can pushing bracket on one side of the round can clamping groove. A turning rotating shaft is horizontally rotatably connected to the upper side of a turning bracket. An arc-shaped grooveplate is horizontally fixedly arranged on the outer side of a turning connecting plate, and a turning can groove is formed in the arc-shaped groove plate. According to the round can shunting feeding transfer mechanism, the design is reasonable, round cans can be transported smoothly and sequentially one by one, so that the round cans be transported in a shunting mode, and the automatic turning ofthe round cans can be realized in the process of the shunting transfer of the round cans so as to meet the needs of processing and use.

Owner:海宁市波菲特进出口有限公司

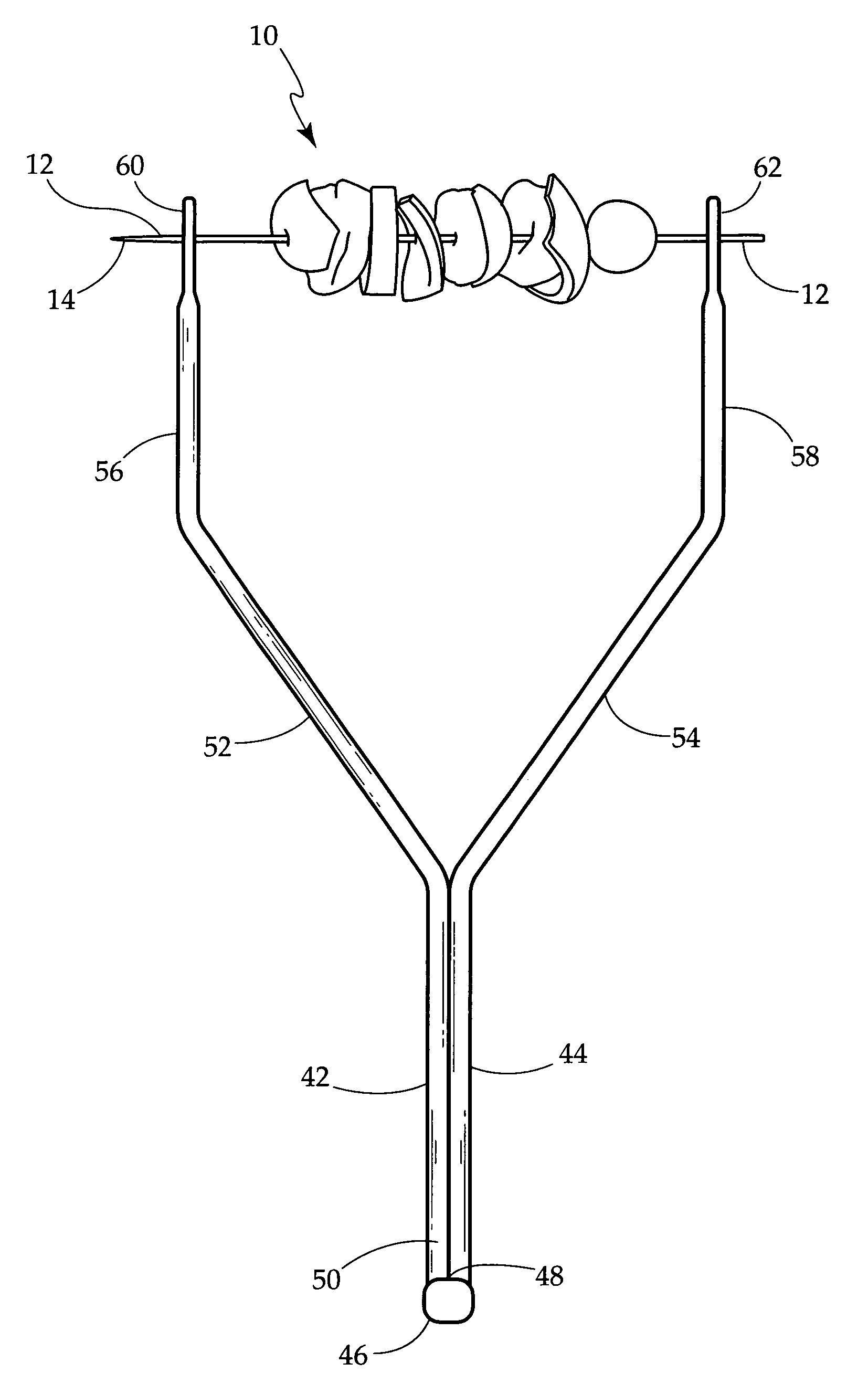

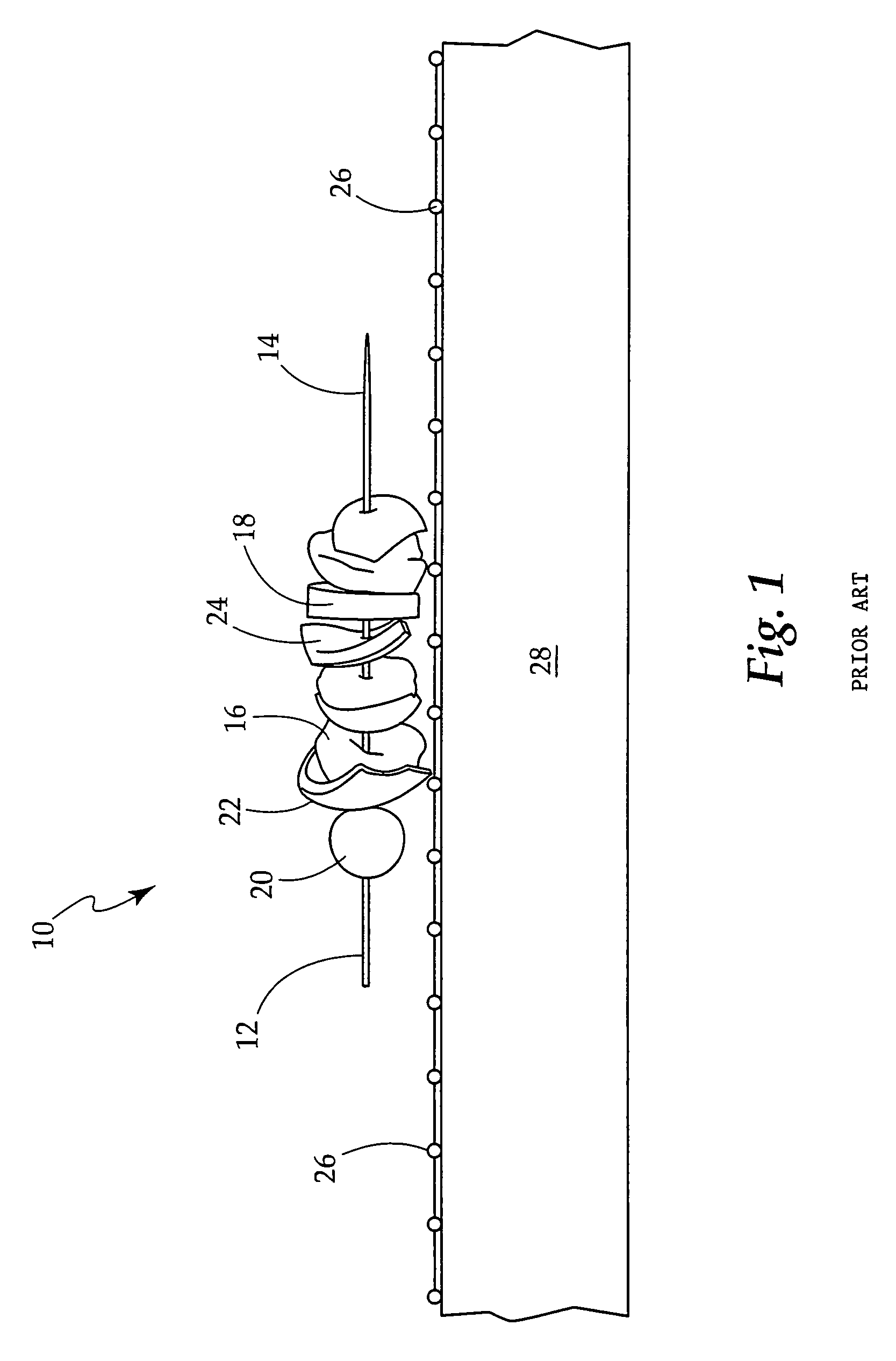

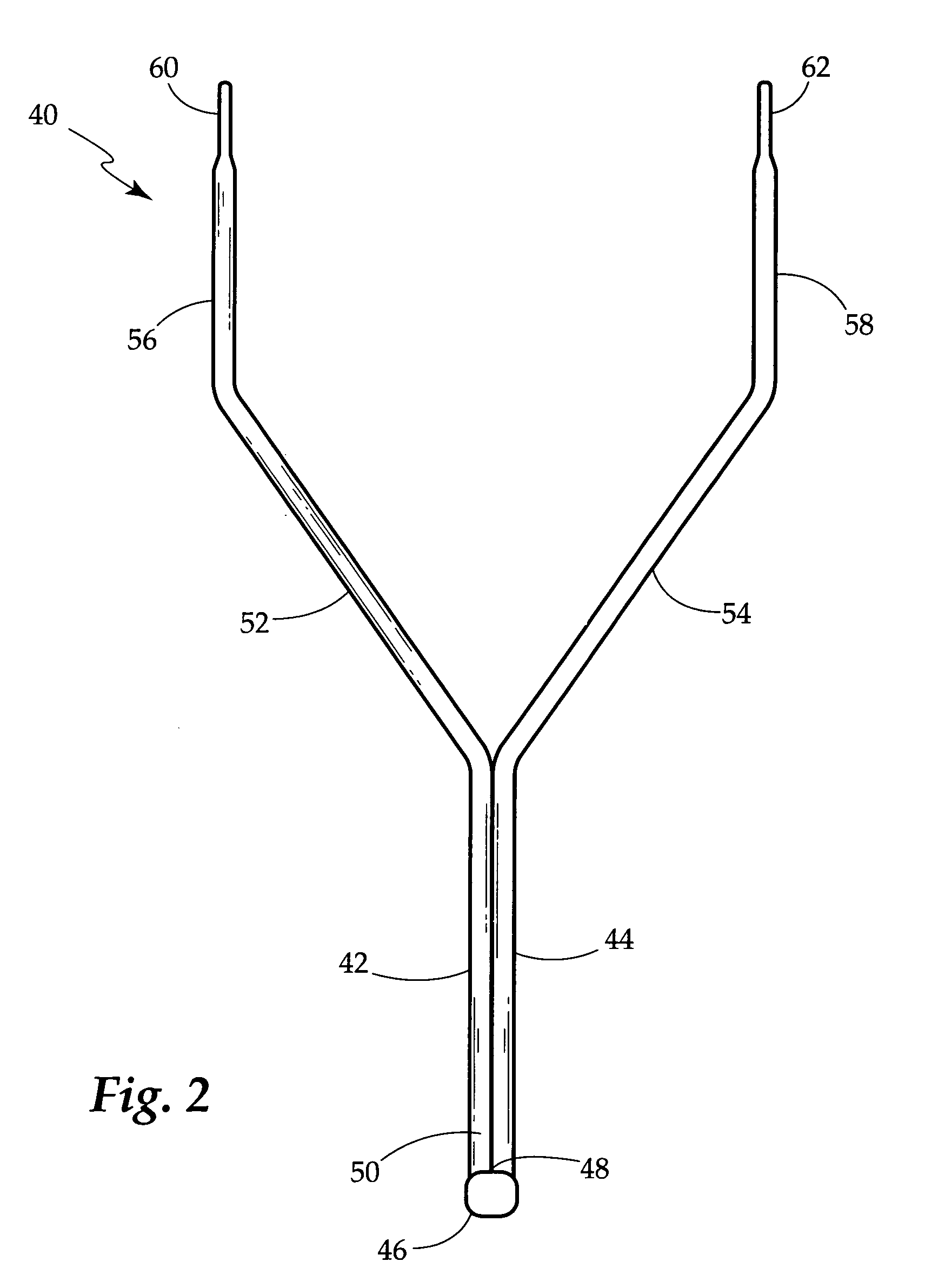

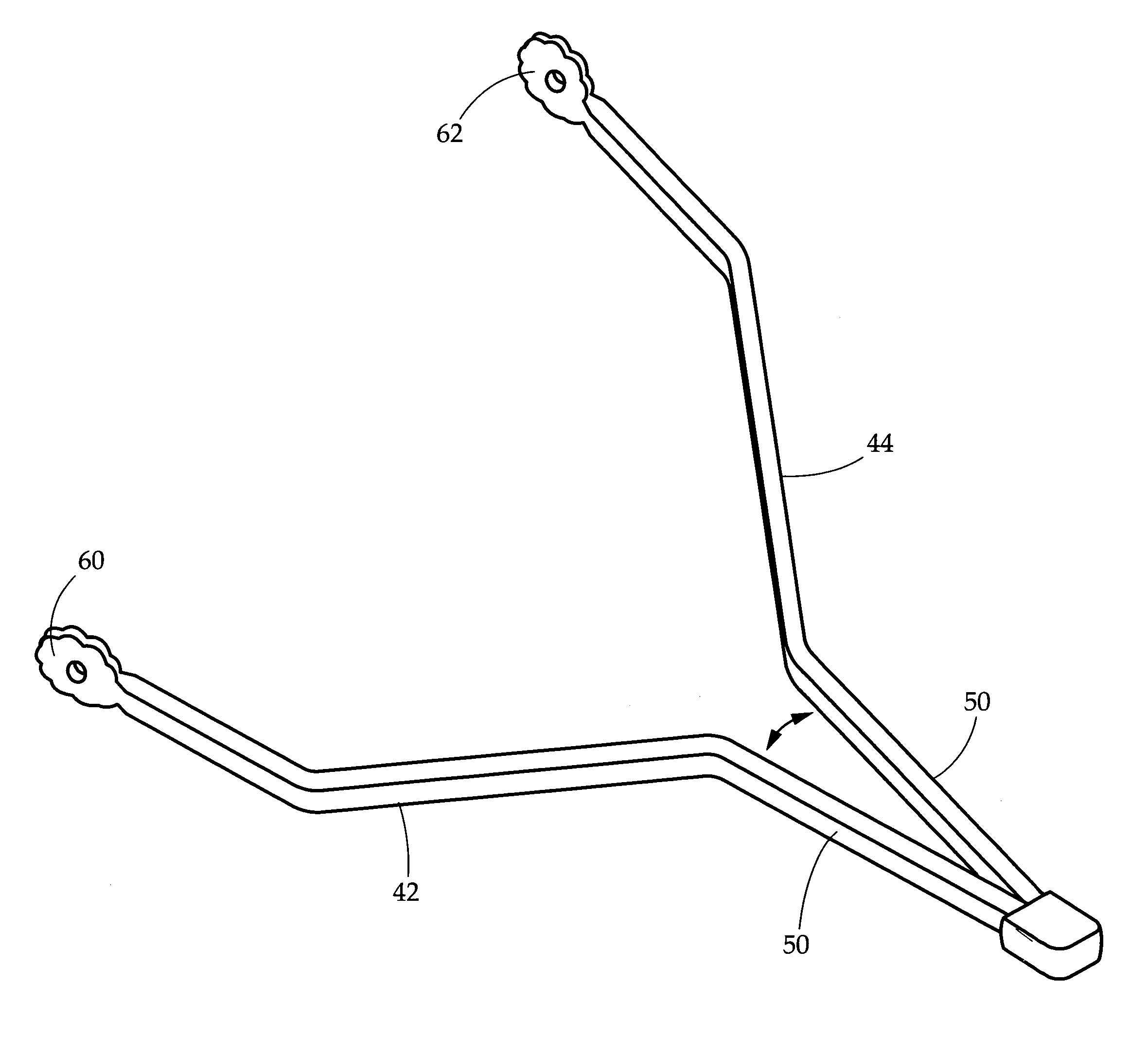

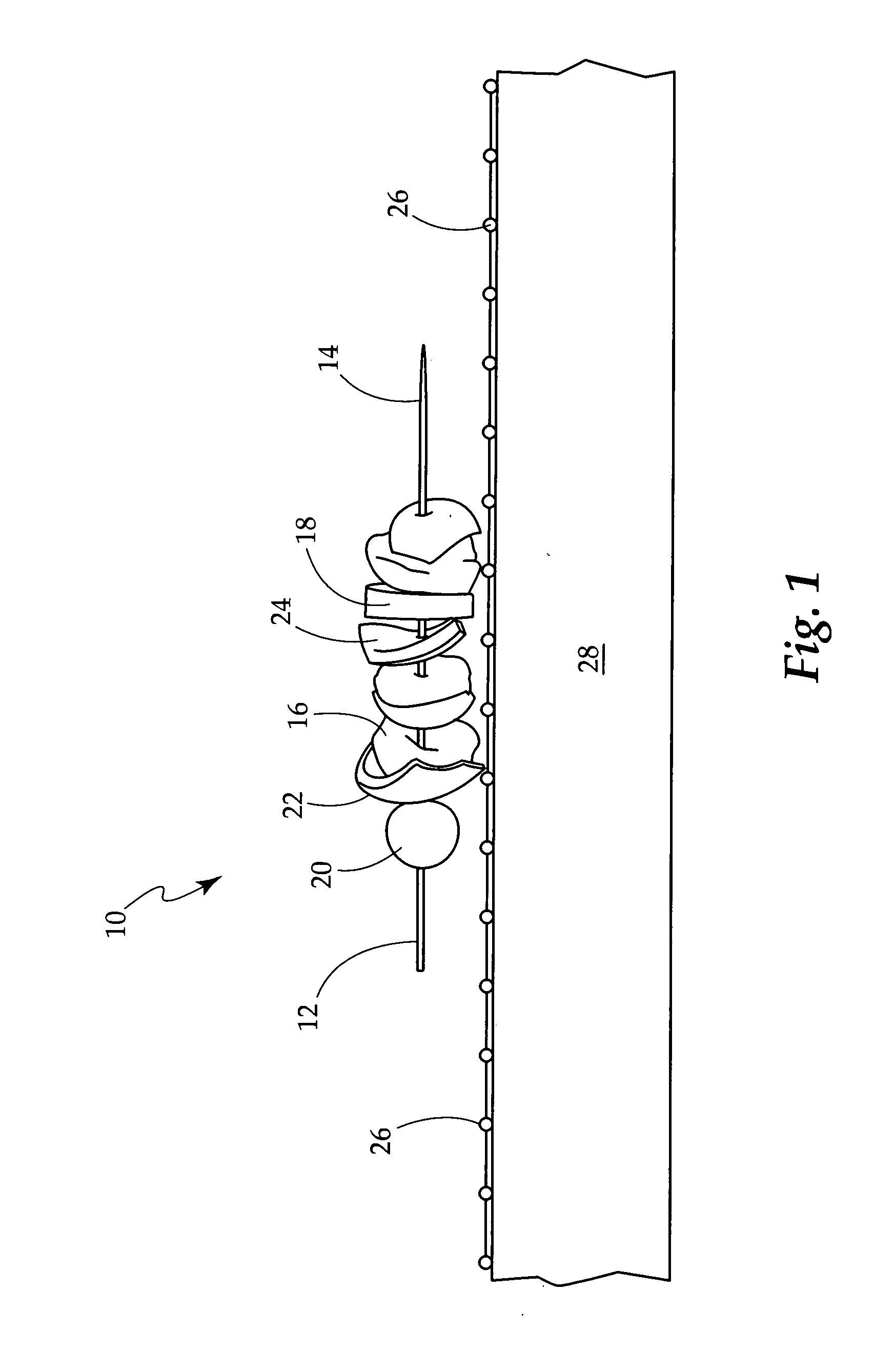

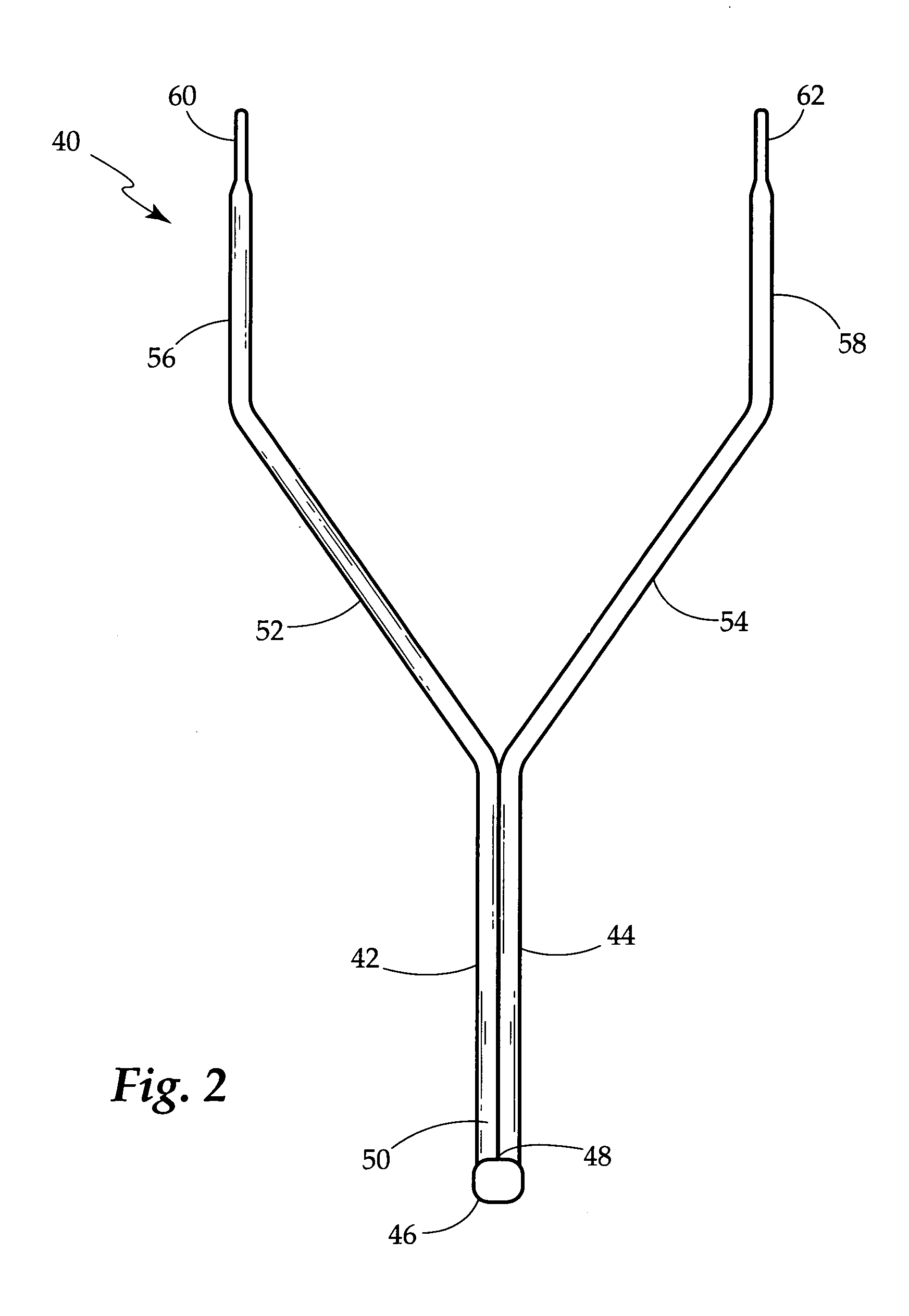

Kebob tongs

Tongs for manipulating shish-kebob on a barbeque grill, the tongs having two arms, the two arms being in parallel relationship at an insulated handle end which includes the pivot point at one end, the arms diverging at the opposing end of the handle end, to form two opposing spaced apart arms having kebob engaging ends, each end having an aperture there through, the apertures engaging the ends of the skewer, the tongs then being compressed so that the kebob engaging ends engage the outer food items on the skewer preventing their rotation so that the kebob may be either flipped for even cooking on the opposing side, or removed from the grill for consumption without endangering the fingers of the user.

Owner:STERN ROBERT

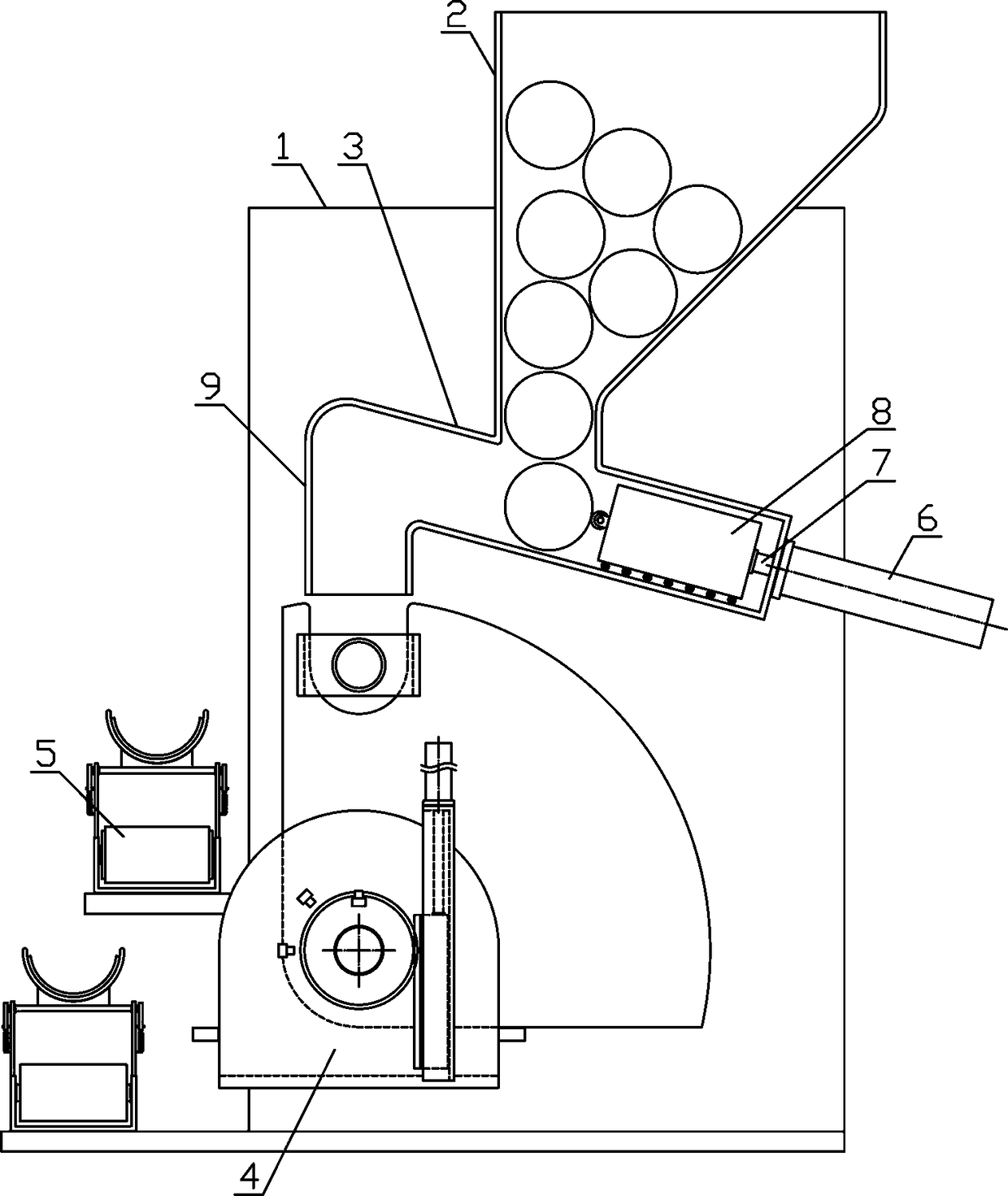

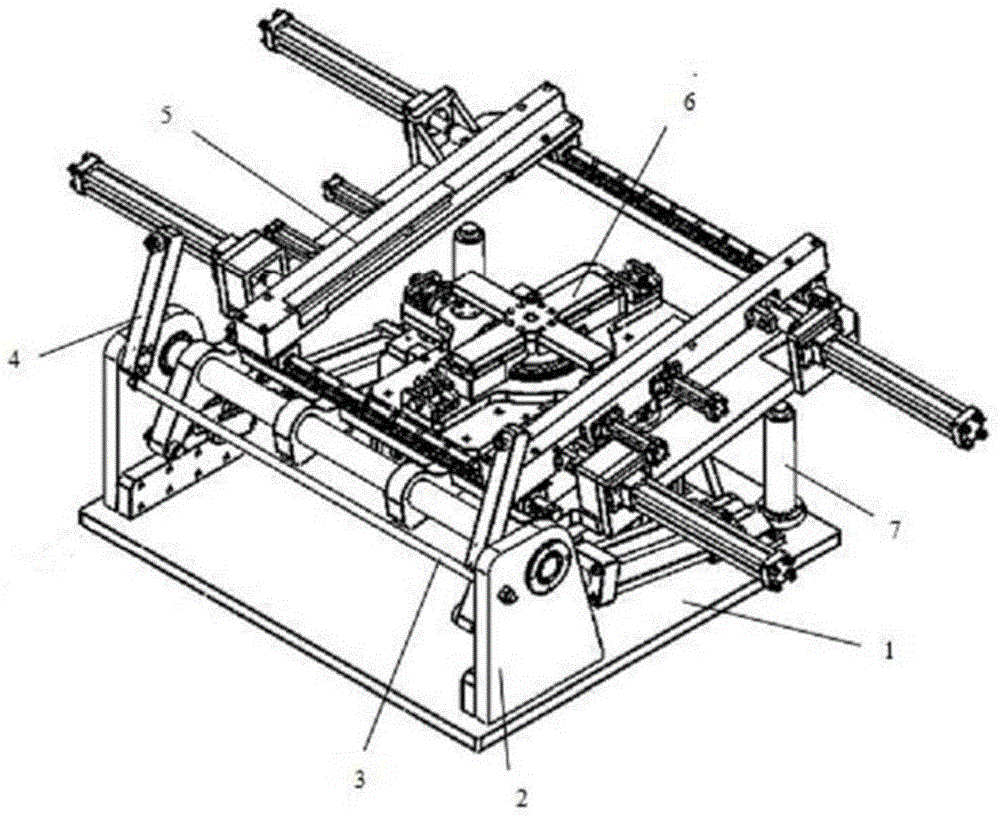

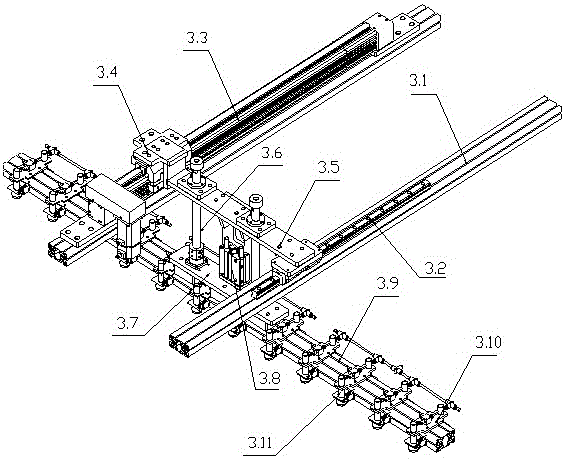

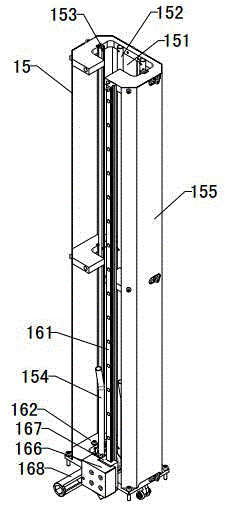

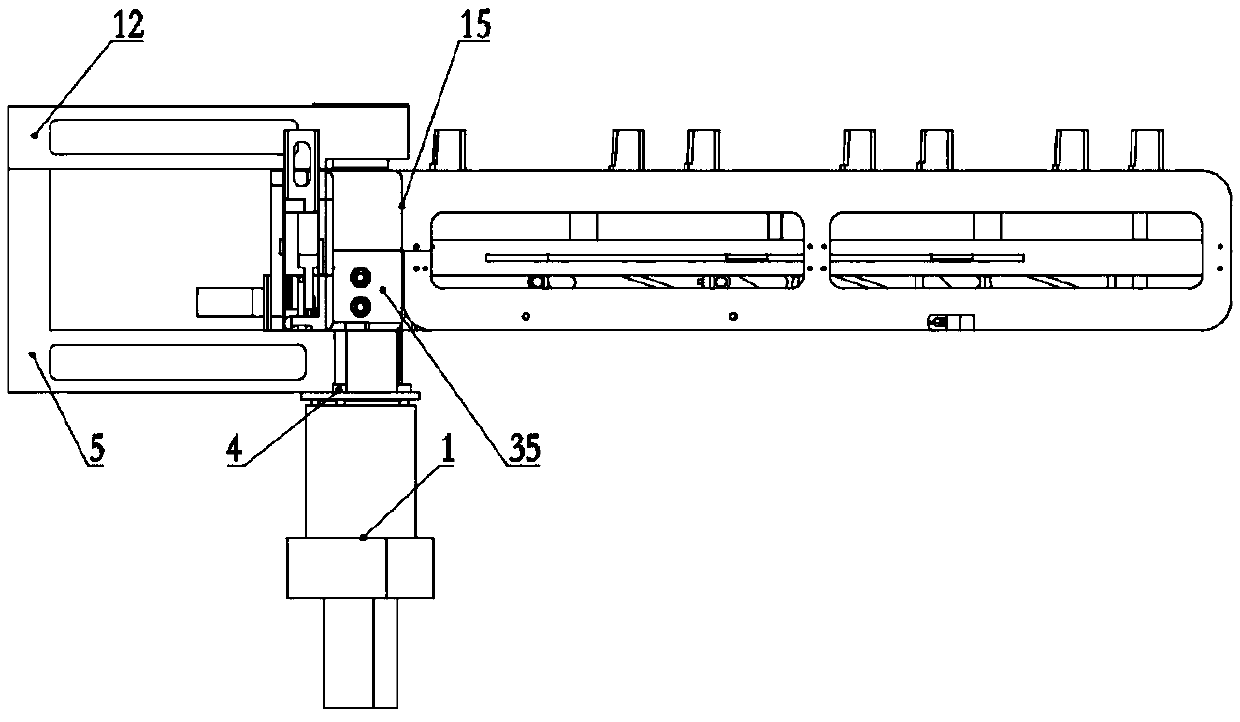

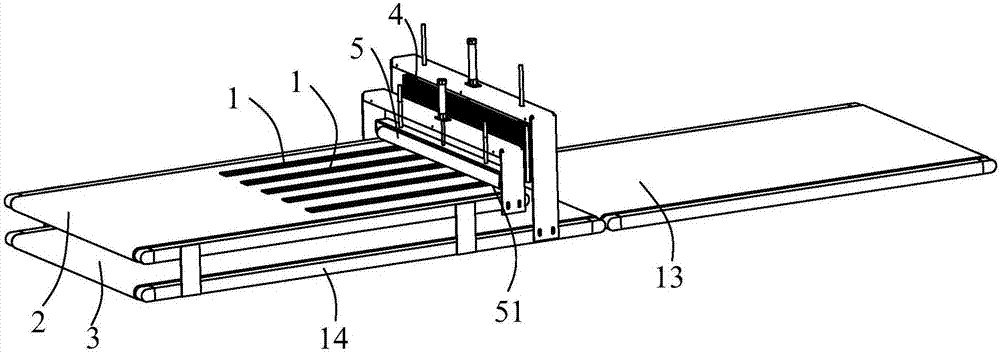

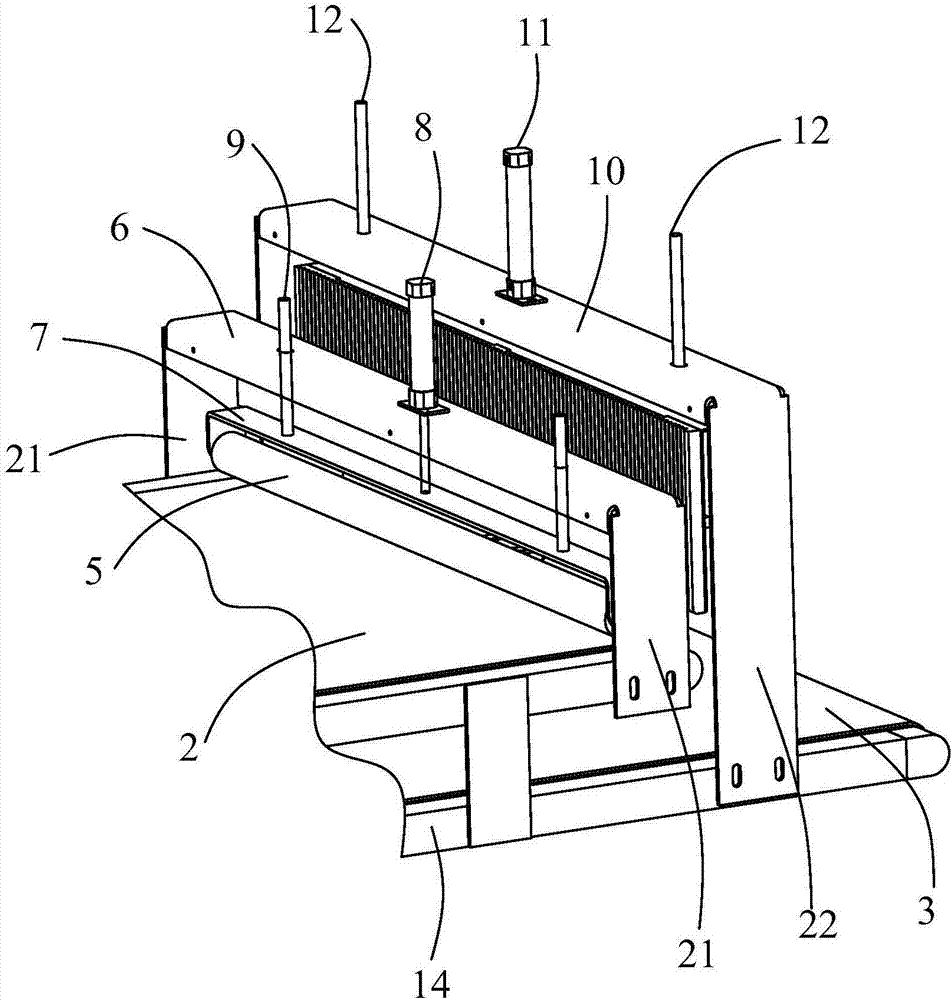

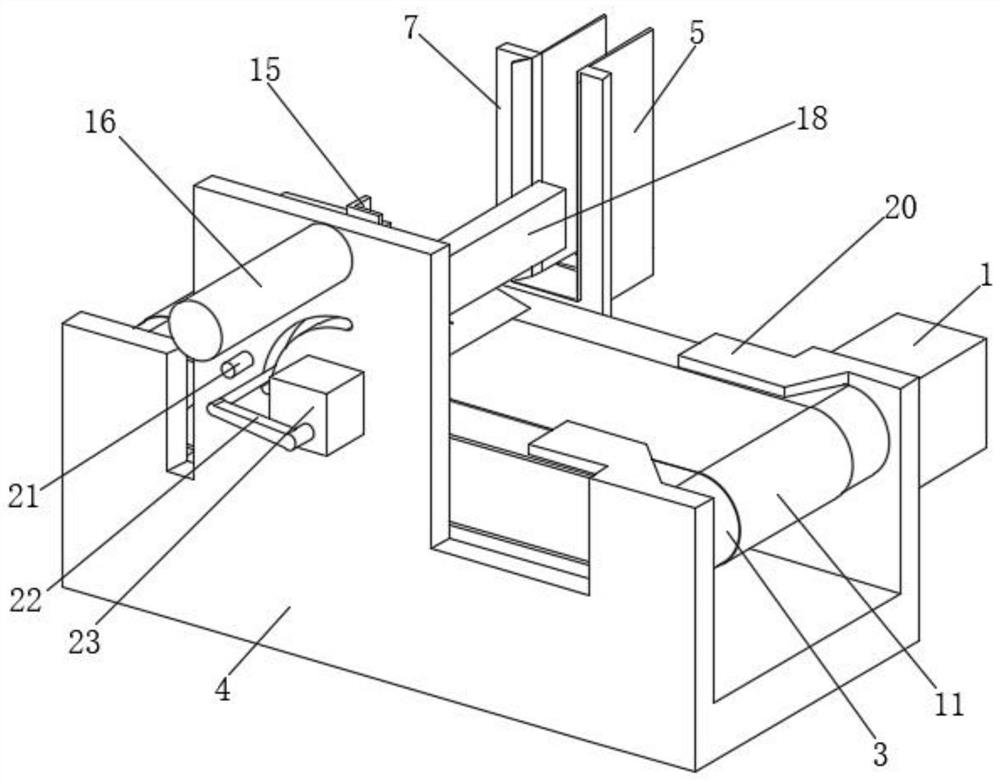

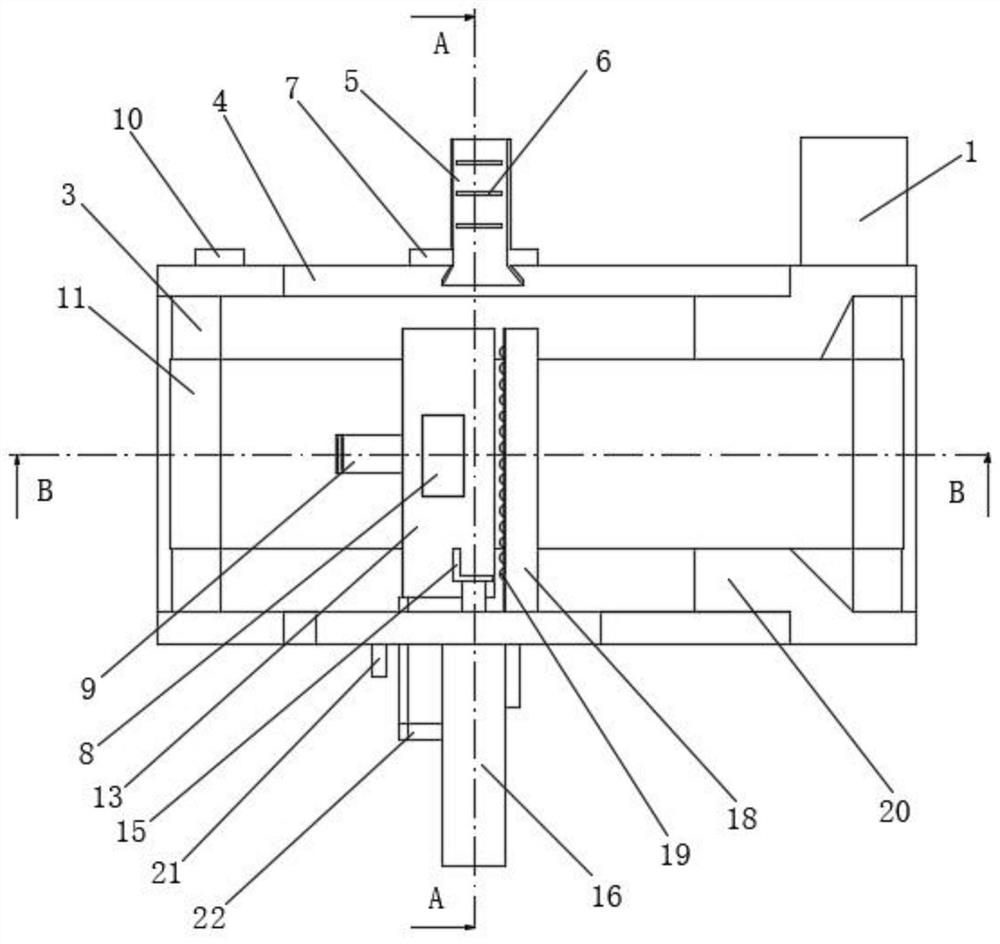

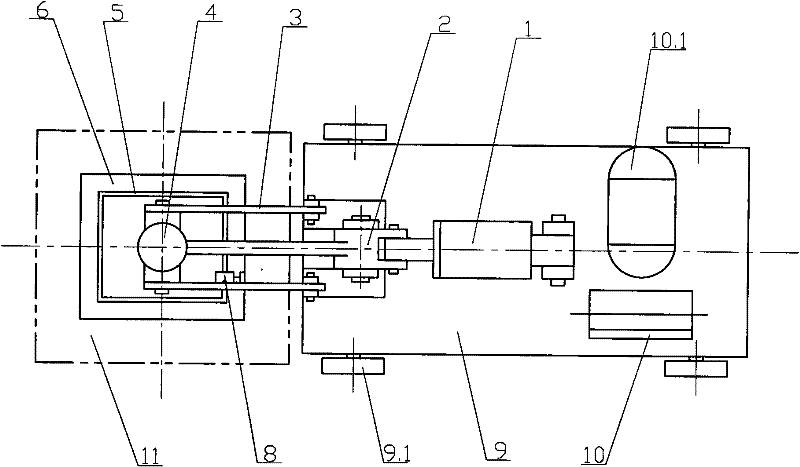

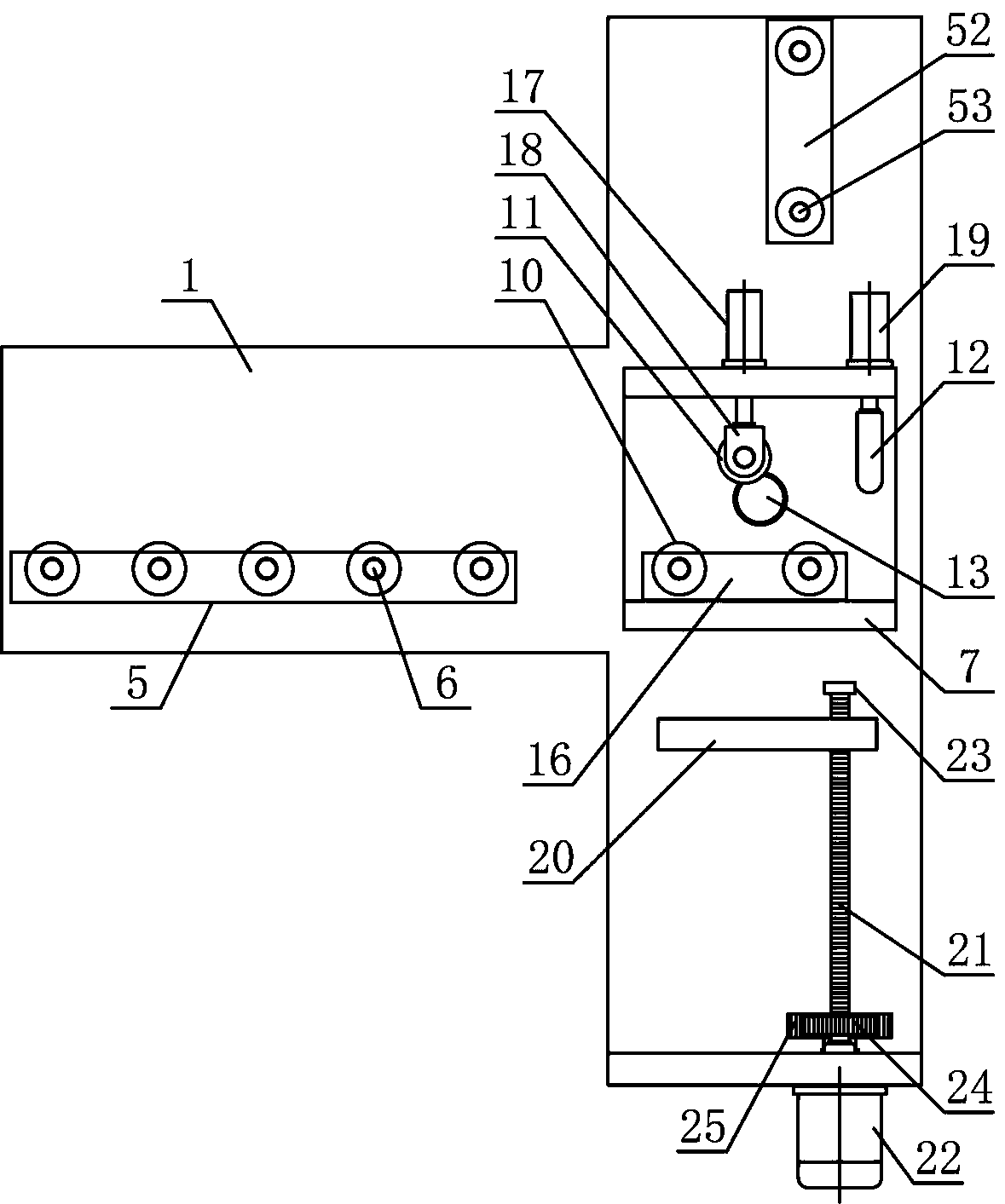

Sheet workpiece continuous feeding mechanism

InactiveCN109648378AReasonable structural designRealize continuous feedingMetal working apparatusEngineeringMechanical equipment

The invention discloses a sheet workpiece continuous feeding mechanism and belongs to the field of workpiece machining and conveying mechanical equipment. A feeding mechanism body and a material conveying mechanism of the feeding mechanism are sequentially arranged on the part, on one side of a material guiding mechanism, of a fixing bracket in the horizontal direction; a translation bracket is horizontally arranged on the part, on the lower side of a storage hopper, of the fixing bracket; a translation connecting plate is slidably arranged on a translation guide bar in the horizontal direction; the middle of the lower side of a rotating disc is fixedly connected with the upper end of a feeding rotating shaft; a material suction guiding plate is vertically arranged on one side of a material suction bracket; the output end of a material suction air cylinder is fixedly connected with the middle of one side of the material suction guiding plate; a plurality of material suction mechanismsare sequentially and uniformly arranged on the material suction guiding plate in the horizontal direction; and a material conveying belt is arranged on the upper side of a material conveying bracket.The feeding mechanism is reasonable in structure design, a plurality of sheet workpieces can be sequentially sucked and fixed, and the multiple sucked and fixed sheet workpieces can be synchronously transferred and conveyed, so that the sheet workpiece feeding automation degree is increased, and the machining demands are met.

Owner:嘉兴汉羿文化传播有限公司

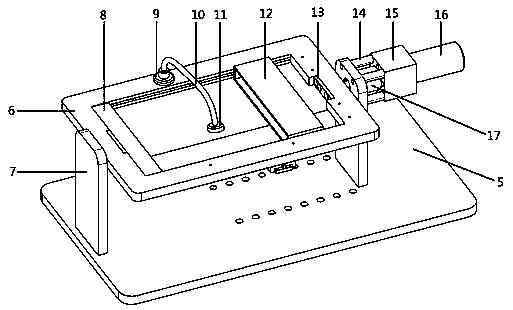

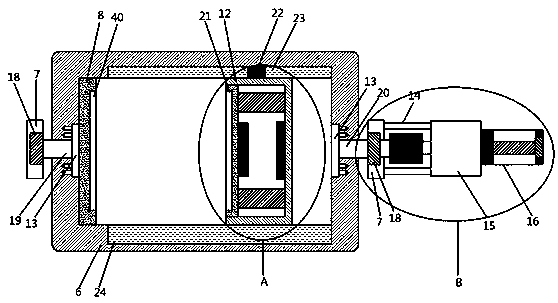

Clamp for detecting gas tightness of automobile cooling pipe

ActiveCN101666699AReduce labor intensityImprove work efficiencyDetection of fluid at leakage pointEngineeringAir tightness

Owner:NINGBO YUANDONG AUTOMOBILE PARTS MFG

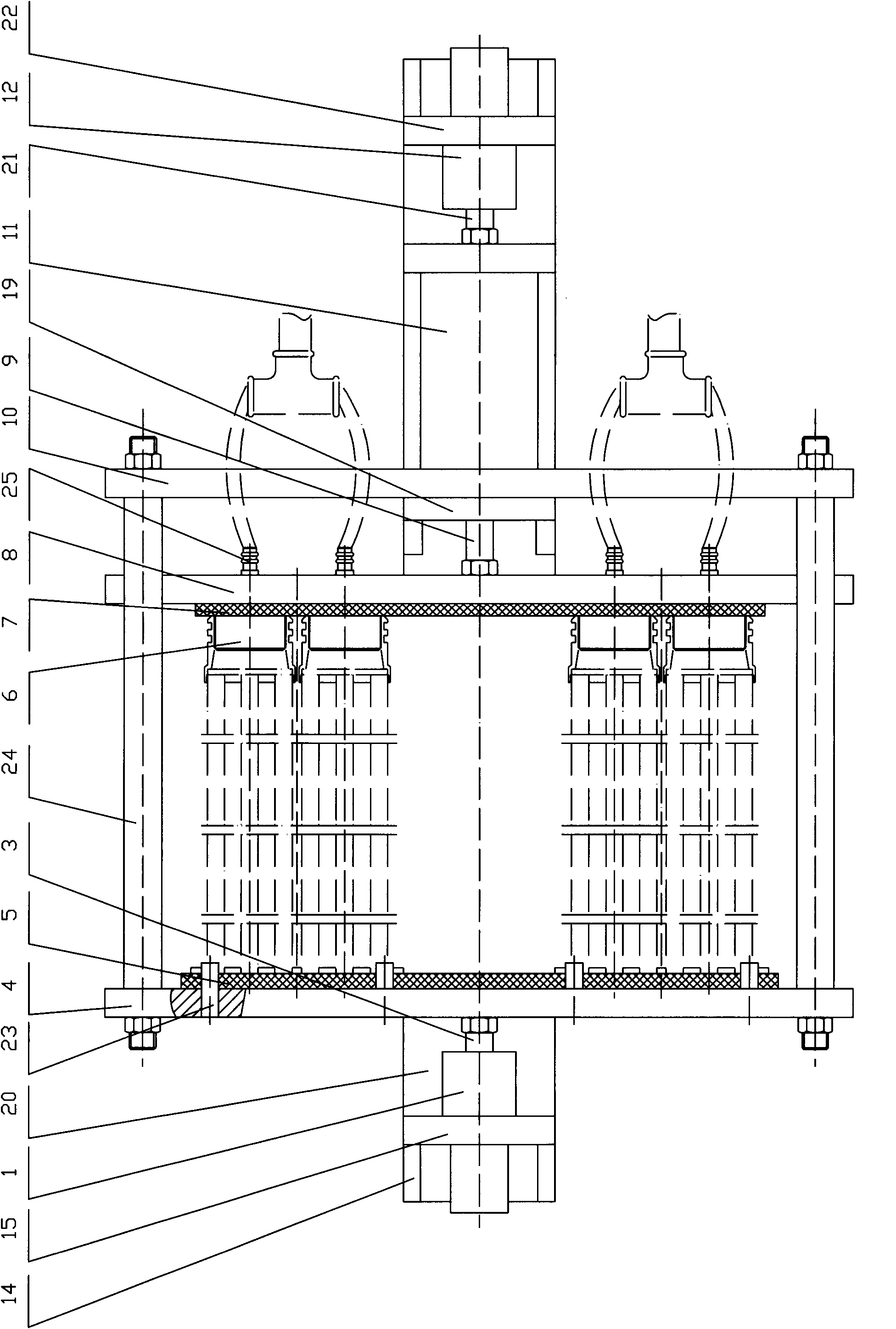

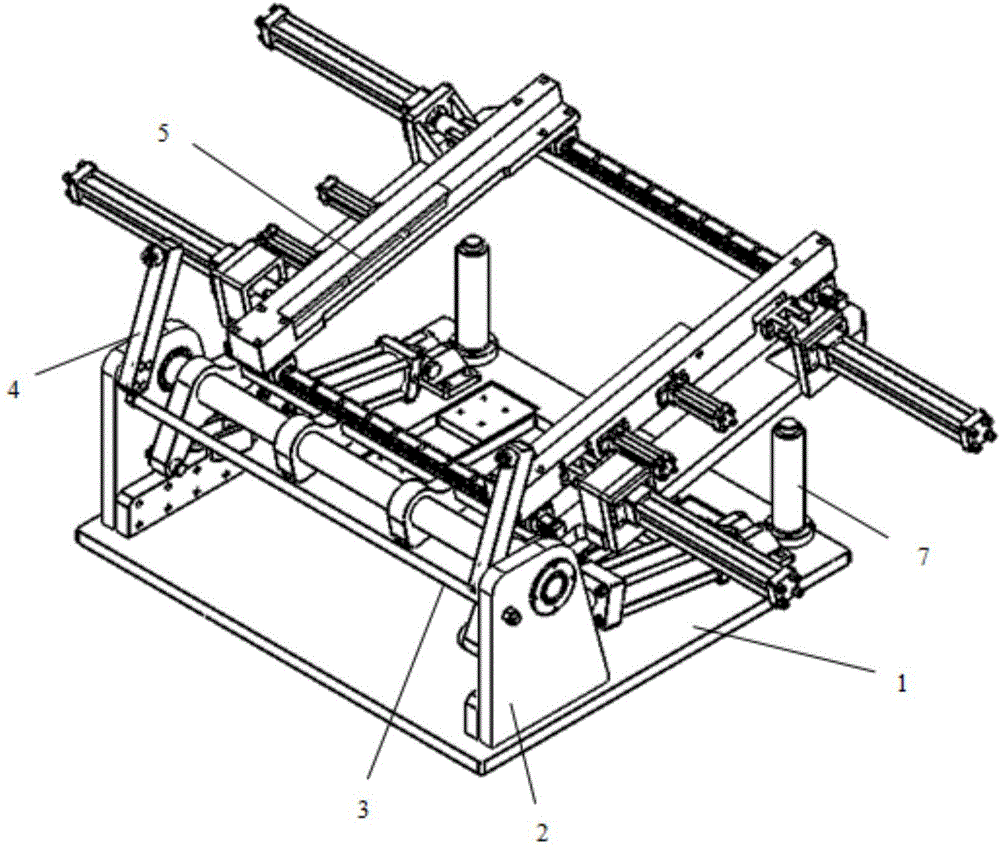

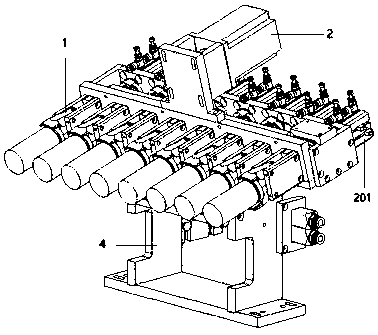

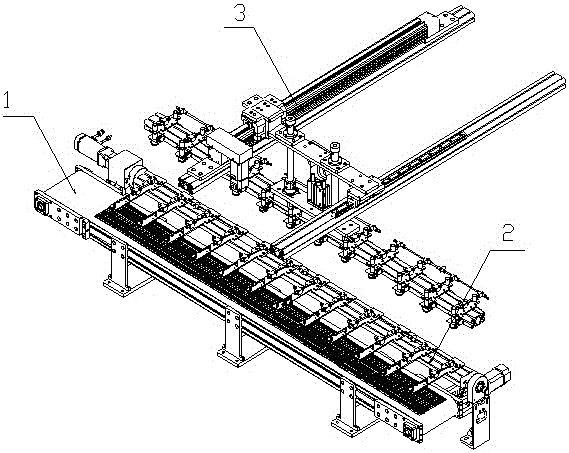

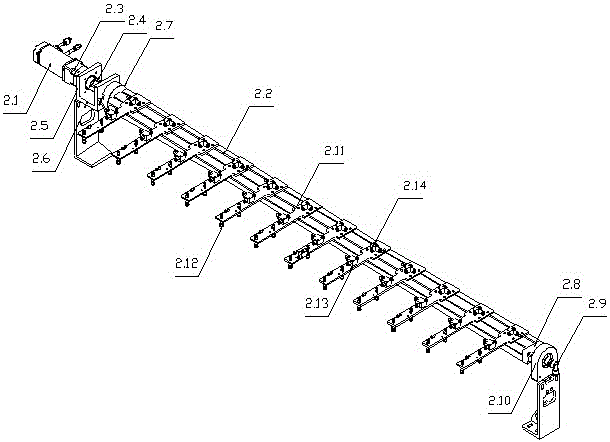

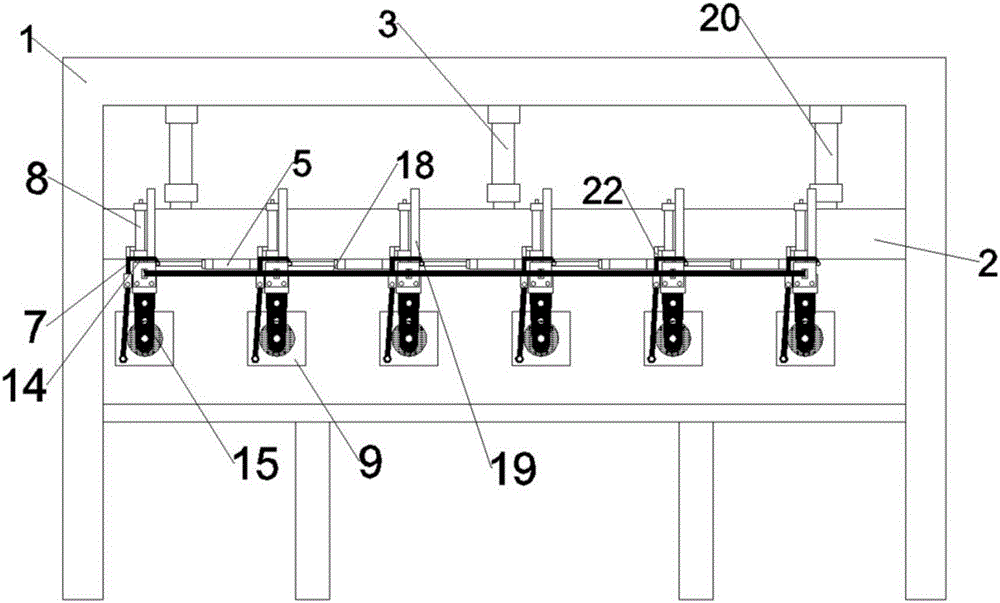

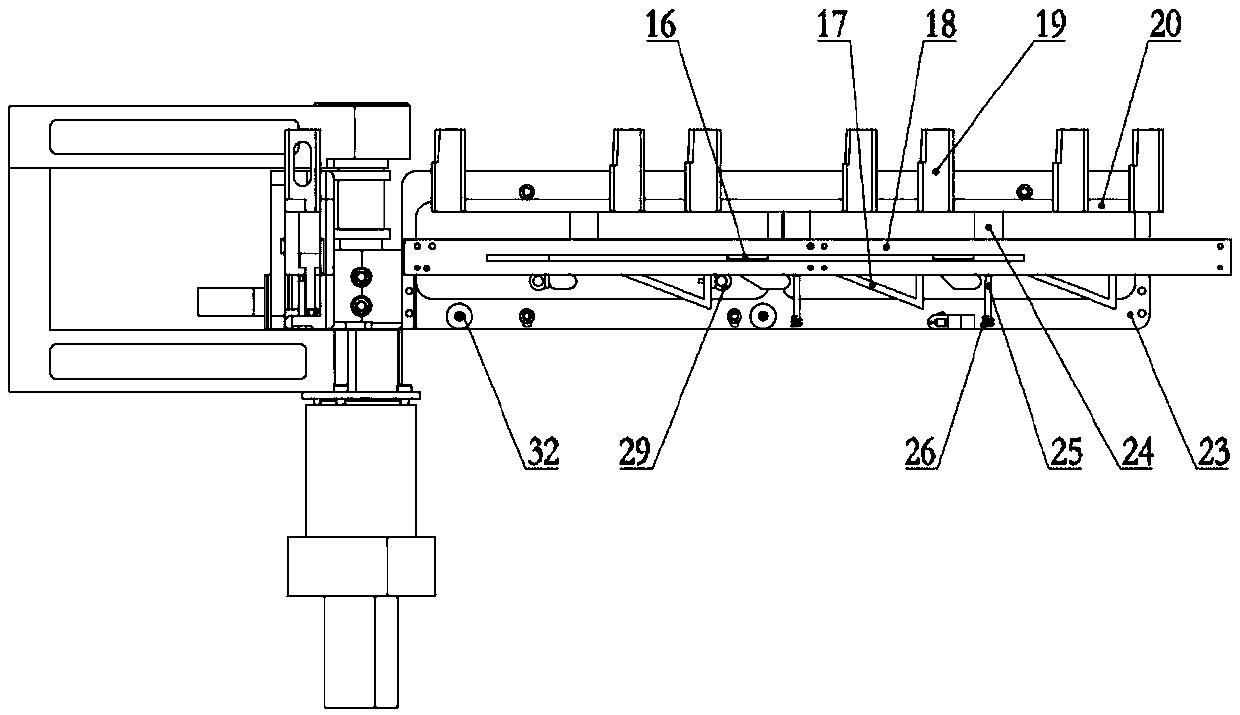

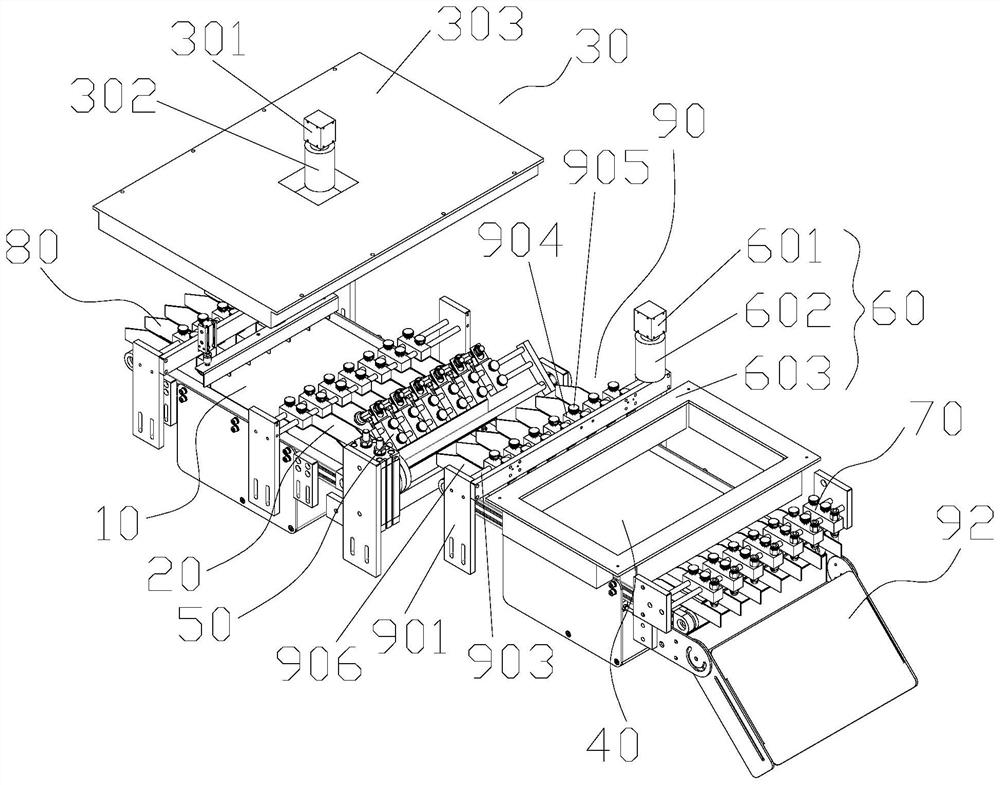

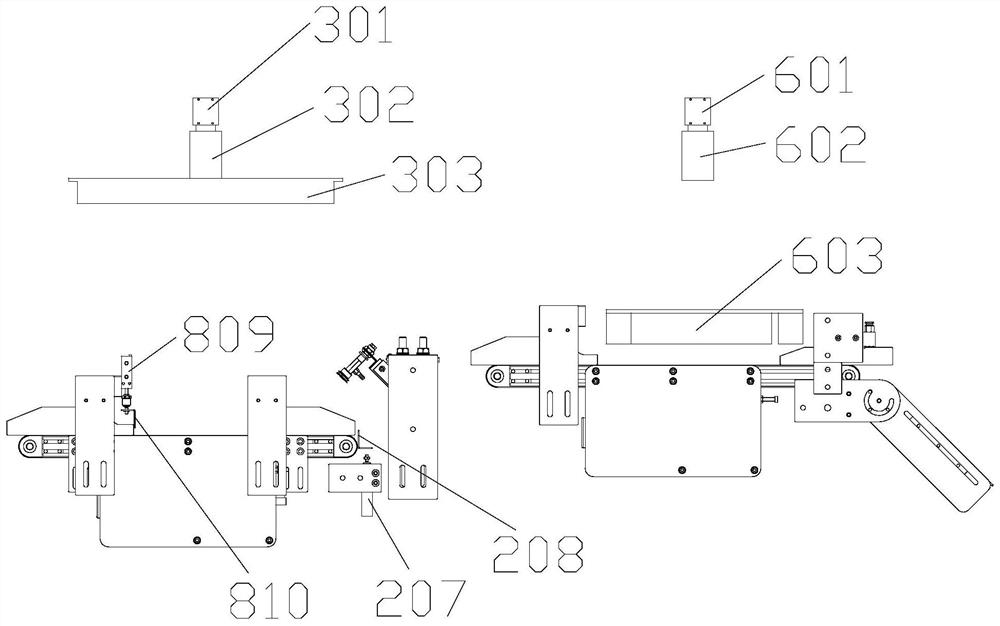

Mechanism for synchronously feeding multiple workpieces

InactiveCN109704063ARealize continuous feedingReasonable structural designConveyor partsEngineeringMechanical equipment

The invention discloses a mechanism for synchronously feeding multiple workpieces, and belongs to the field of workpiece machining and conveying mechanical equipment. According to the mechanism, the output end of a translation air cylinder is fixedly connected with one side of a translation bearing plate; a discharging pipe is vertically and fixedly arranged at the position, on the lower side of astorage hopper, of the translation bearing plate; the middle of the lower side of a rotating disc is fixedly connected with the upper end of a feeding rotating shaft; the output end of a push plate air cylinder is fixedly connected with the middle of one side of a horizontal push connecting plate; the middle of one side of a suction support is fixedly connected with the end of an adjusting rotating shaft; the output end of the suction air cylinder is fixedly connected with the upper side of a lifting push plate; a push plate bevel is arranged on one side of the lower portion of the lifting push plate; multiple suction mechanisms are sequentially and evenly arranged on the lower side of the suction support in the horizontal direction; and a conveying belt is arranged on the upper side of aconveying support. According to the mechanism, structural design is reasonable, multiple thin workpieces can be synchronously adsorbed and fixed, the multiple adsorbed and fixed thin workpieces can be synchronously transferred and conveyed, the feeding automation degree of the thin workpieces can be improved, and the requirements of machining and use can be met.

Owner:嘉兴汉羿文化传播有限公司

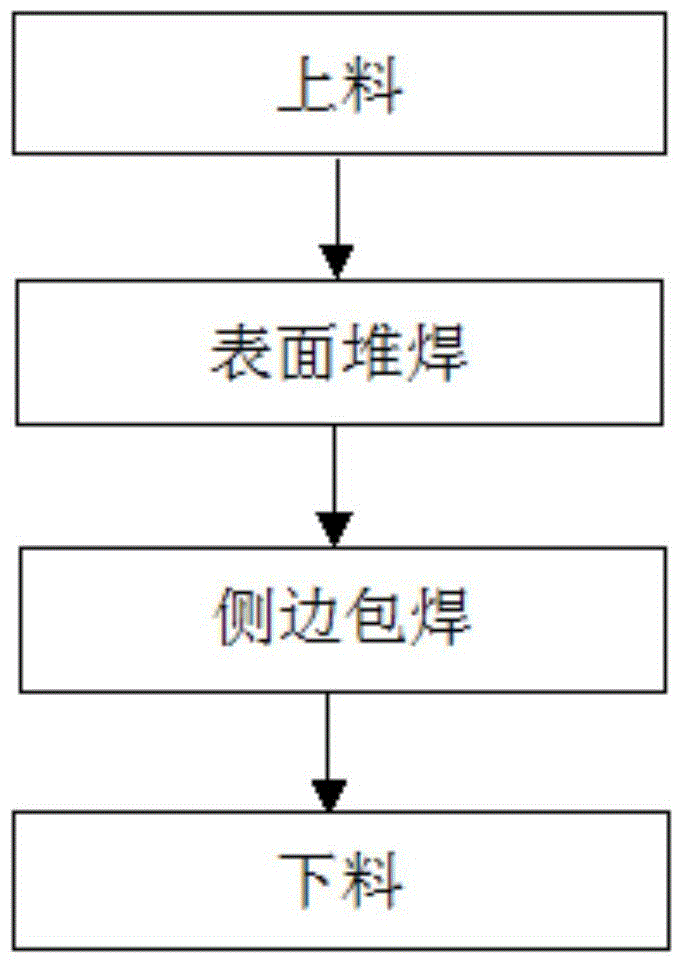

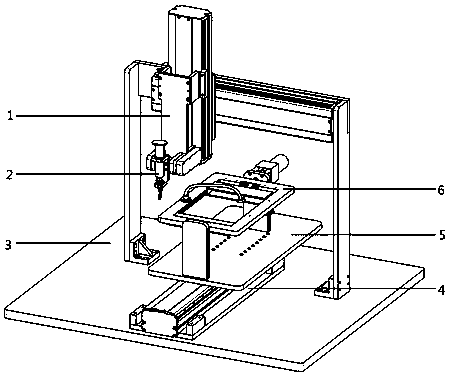

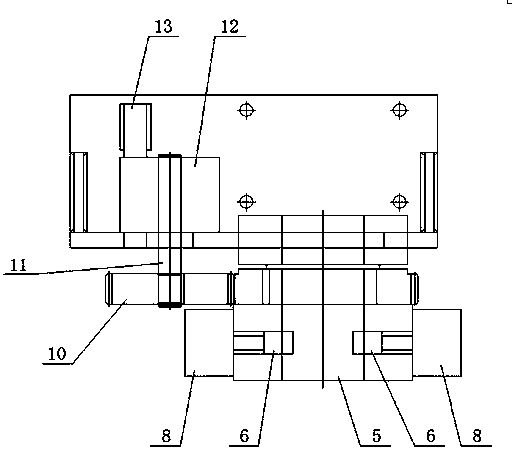

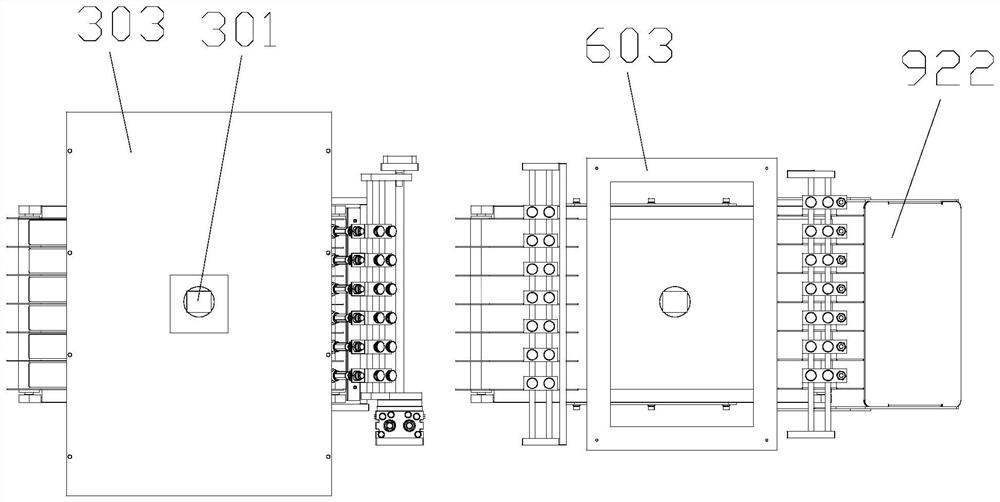

Efficient and reliable edging welding device for ceramic tile mold

ActiveCN104607856AFlip AccurateEasy flipWelding/cutting auxillary devicesAuxillary welding devicesModular designEngineering

The invention discloses an efficient and reliable edging welding device for a ceramic tile mold. The edging welding device comprises a base plate, a clamping overturning mechanism and a lifting rotating mechanism, wherein the clamping overturning mechanism and the lifting rotating mechanism are installed on the base plate. The clamping overturning mechanism comprises a clamping part used for clamping the mold and a rotating part for driving the clamping part to rotate. The lifting rotating mechanism is located below the clamping overturning mechanism and comprises a lifting part, a rotating part and a mold bearing table. The mold performs up-and-down movement in the vertical direction through the lifting part and performs rotation in the horizontal direction through the rotating part. When the rotating part sinks, the mold bearing table ascends to support the mold and is separated from the rotating part, and interference between the clamping part and the lifting rotating mechanism is prevented. According to the edging welding device, the modular design thought is adopted, the problem that surface overlaying and edging welding of the ceramic tile mold can not be carried out at the same time is solved, and the automation degree is high.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

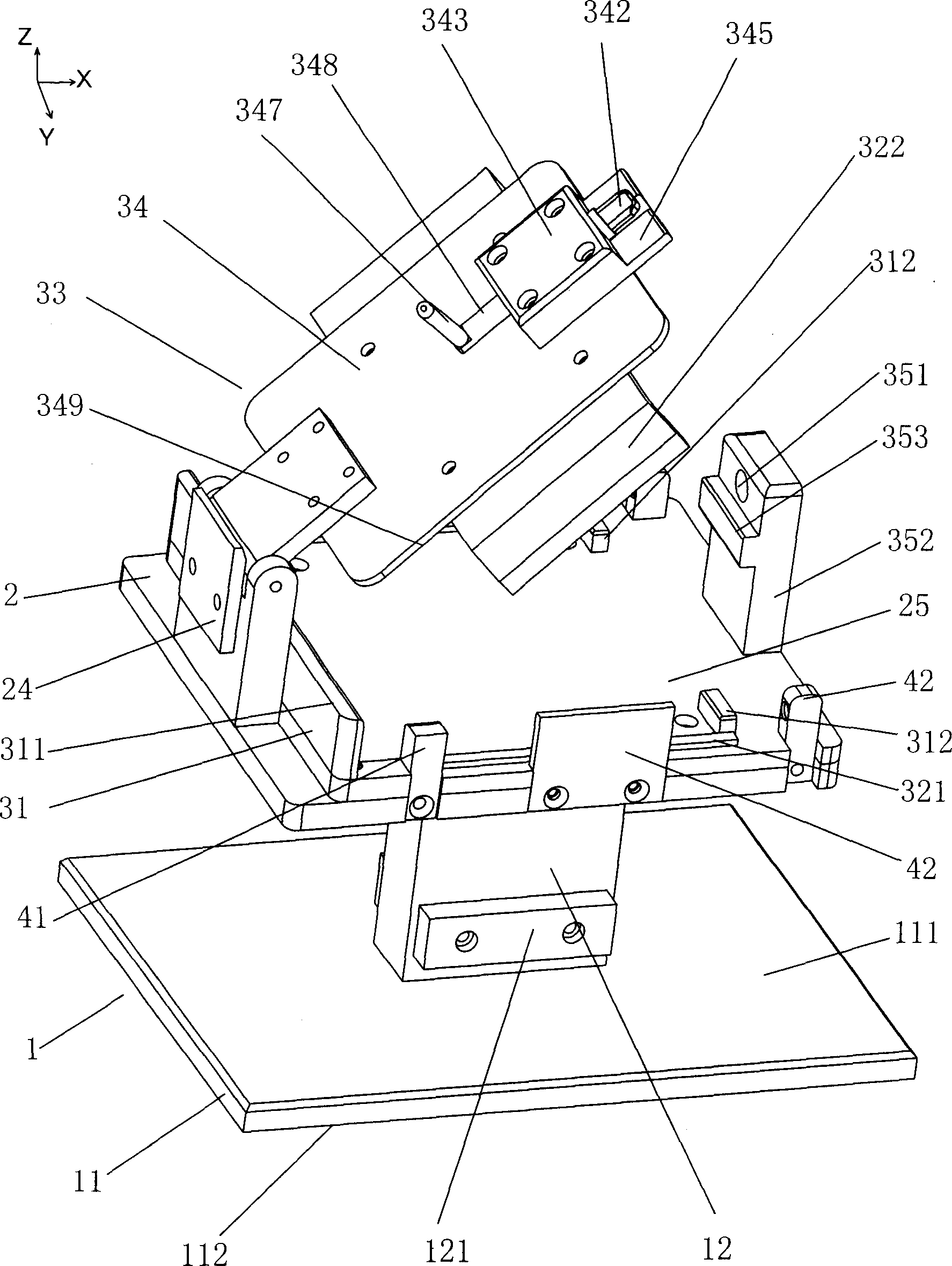

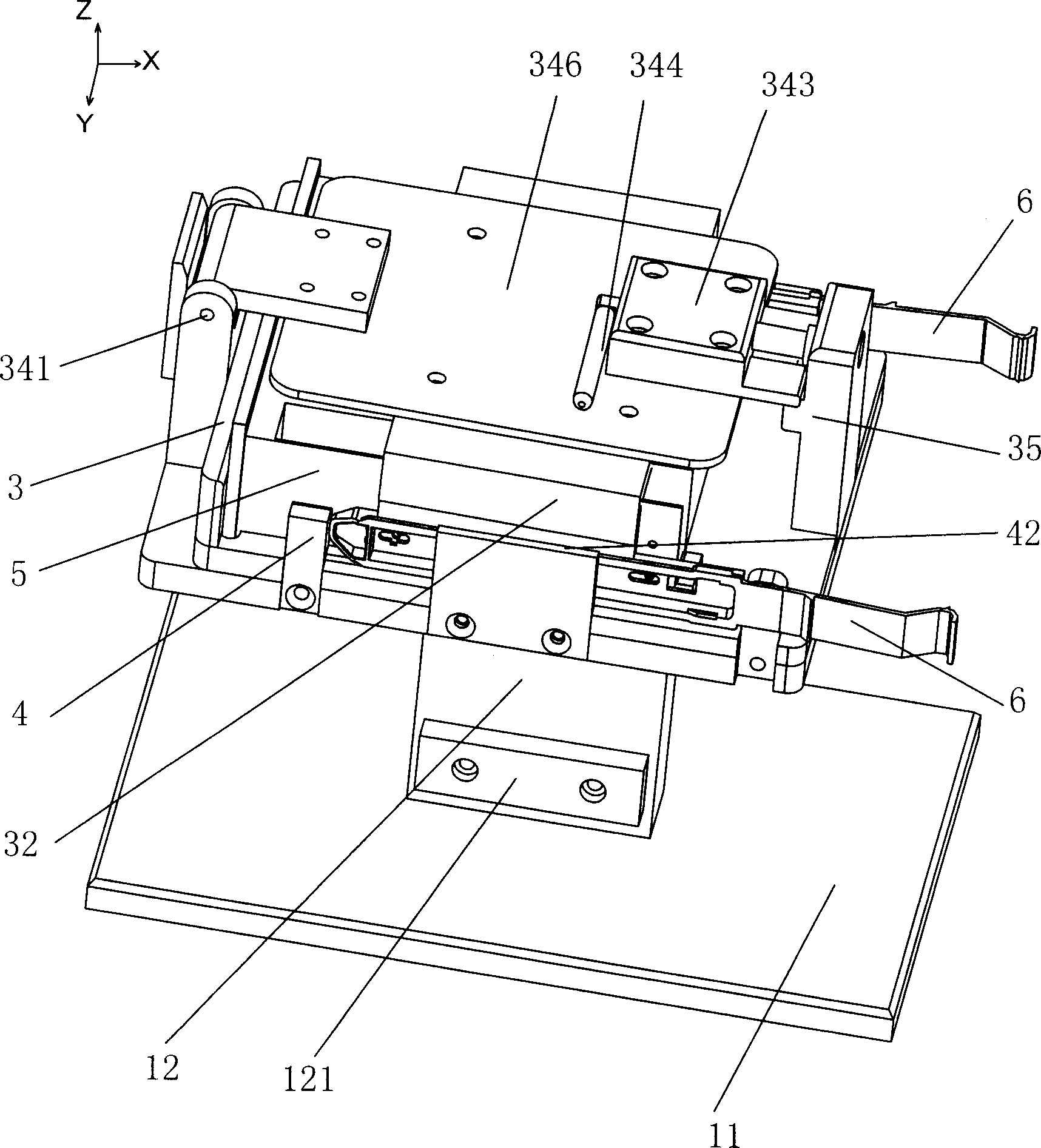

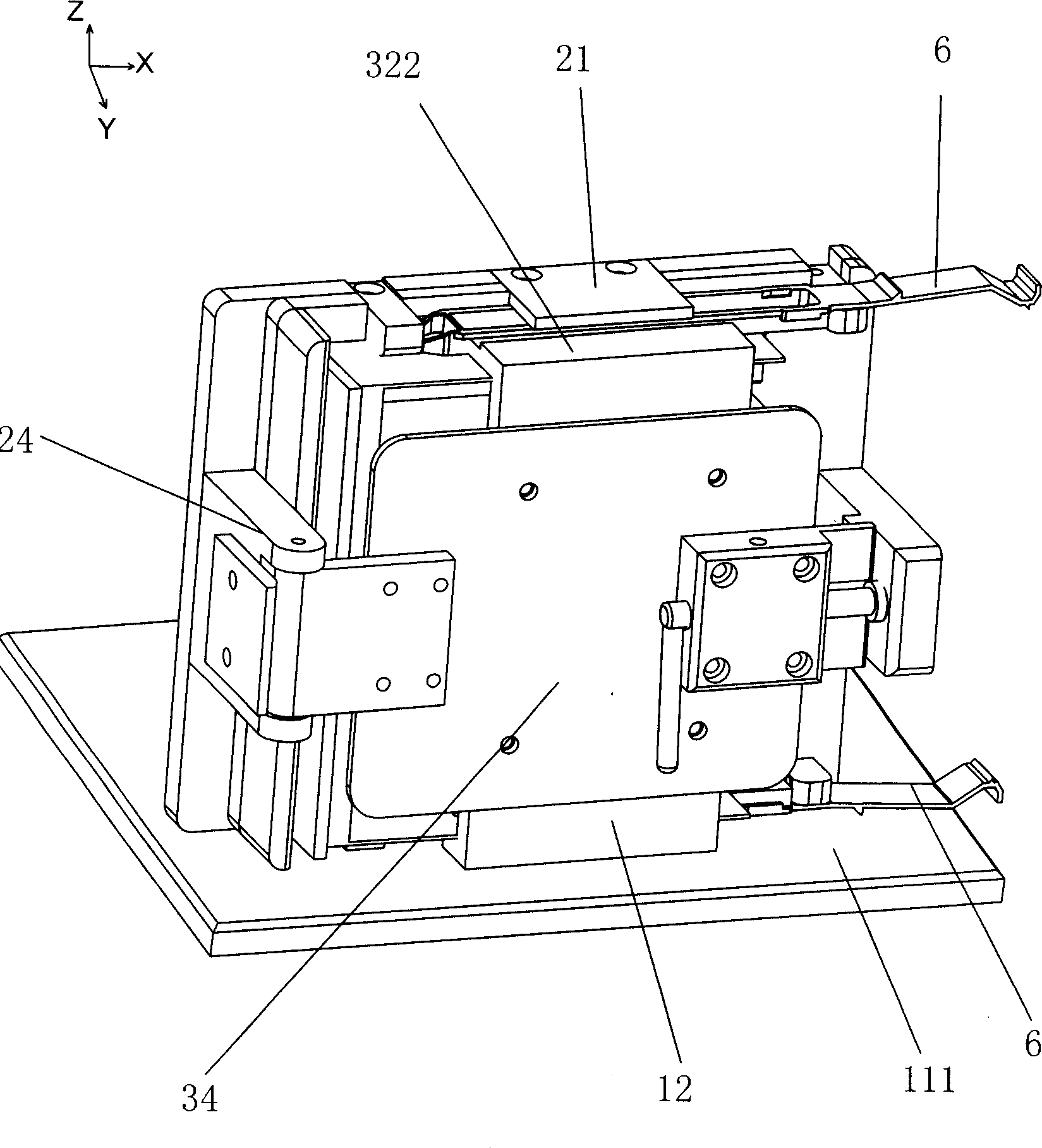

Guide rail mounting clamp for hard disk drive

InactiveCN1881461AImprove installation efficiencyQuality assuranceRecord information storageRecord carrier contruction detailsHard disc driveEngineering

The invention relates to a track mounting clamper of hard disk driver, which comprises a base and a mounting console, wherein said base comprises a base and a rotation axle base mounted on the base; said mounting console has opposite first and second surfaces; the center of mounting console is arranged with a hard disk positioning element which both has the track positioning element between it and the first and second surfaces; the console via the rotation axle can be turned over to be supported on the rotation axle base; the rotation axis of rotation axle is between the first and second surfaces; via the hard disk positioning element and the track positioning element, the hard disk and the track can be positioned on the clamper; via the turn-over mounting console, the hard disk and the track can be turned over to the mounting position, to improve the efficiency and the quality.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

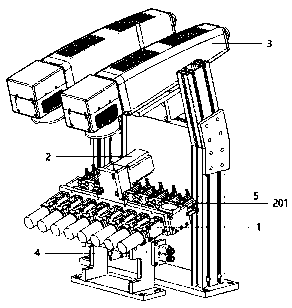

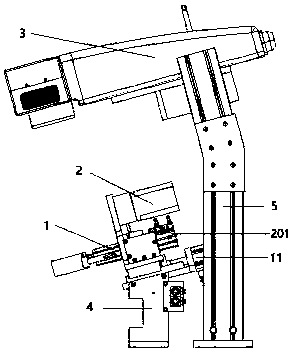

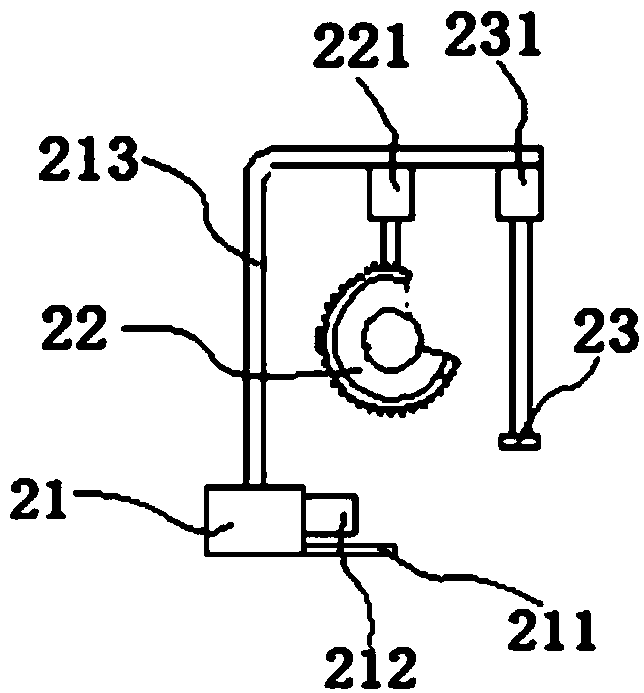

Automatic turning system for battery cells

ActiveCN107597778AFlip flexibleFlip AccurateFinal product manufactureSecondary cells manufactureEngineeringAutomatic testing

The invention discloses an automatic turning system for battery cells. The automatic turning system for the battery cells comprises a turning mechanism used for turning the battery cells and a clamping mechanism used for clamping the battery cells when the battery cells are turned. The clamping mechanism comprises one or more clamping assemblies and a driving assembly used for controlling the clamping assemblies to stretch and retract. Each clamping assembly comprises a connecting rod and a clamping jaw, wherein one end of the connecting rod is connected with the clamping jaw, and the other end of the connecting rod is connected with the driving assembly. As the turning mechanism and the clamping mechanism are arranged, when the automatic turning system for the battery cells is applied toelectrode cleaning equipment, the turning mechanism can automatically turn the battery cells by 180 degrees, the clamping mechanism can clamp the battery cells in the turning process, and thus omnibearing cleaning of electrodes is achieved.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

Cell string automatic unloading mechanism

PendingCN106449497AAvoid human contactQuick flipFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a cell string automatic unloading mechanism which comprises a conveying mechanism used for conveying a cell string to a preset position, a turning device used for turning a cell string on the conveying device, and a handling device used for putting a cell string on the turning device into a material box. The turning device is disposed between the conveying device and the handling device. After the turning device adsorbs a cell string on the conveying device, the turning device turns the cell string 180 degrees to the handling device on the other side, and the handling device adsorbs the cell string, moves the cell string to a target position and puts the cell string into a material box. Through cooperation of the three devices, automatic unloading of cell strings is realized. The problem that the hand touches cells in the checking process is avoided, cells can be quickly and accurately turned in batches, the efficiency is improved, and cell breakage, pollution and other loss caused by hand touch are prevented effectively.

Owner:JIANGSU ZHONGQIRUICHI IND ROBOT AUTOMATION CO LTD

Installation device of embedded controller

PendingCN109862717AEasy to operateHigh degree of automationPrinted circuit assemblingSoldering auxillary devicesEmbedded systemMagnet

The invention discloses an installation device of an embedded controller. The installation device of the embedded controller comprises a base, a tin welder, a driving mechanism, a control host, a worktable and a clamping frame. A circuit board can be quickly and safely clamped through the contact process of a power supply sheet and a conductive sheet in a moving clamp, and a permanent magnet sliding block is simultaneously attracted to move in the direction of an electromagnetic driving coil, so that a screw rod drives the clamping frame to rotate, secondly, through the arrangement of a laserirradiation lamp and a magnetic grid ruler, operators can conveniently and accurately record the specific positions of welding spots, and controllers with different specifications can be installed; the installation device of the embedded controller is convenient to operate, high in automation degree, capable of safely completing automatic clamping work, and capable of ensuring that the circuit board is always parallel to a horizontal plane during welding; and the installation device of the embedded controller breaks away from the traditional manual welding process, improves the working efficiency and simultaneously ensures the safety of workers.

Owner:SHANGQIU NORMAL UNIVERSITY

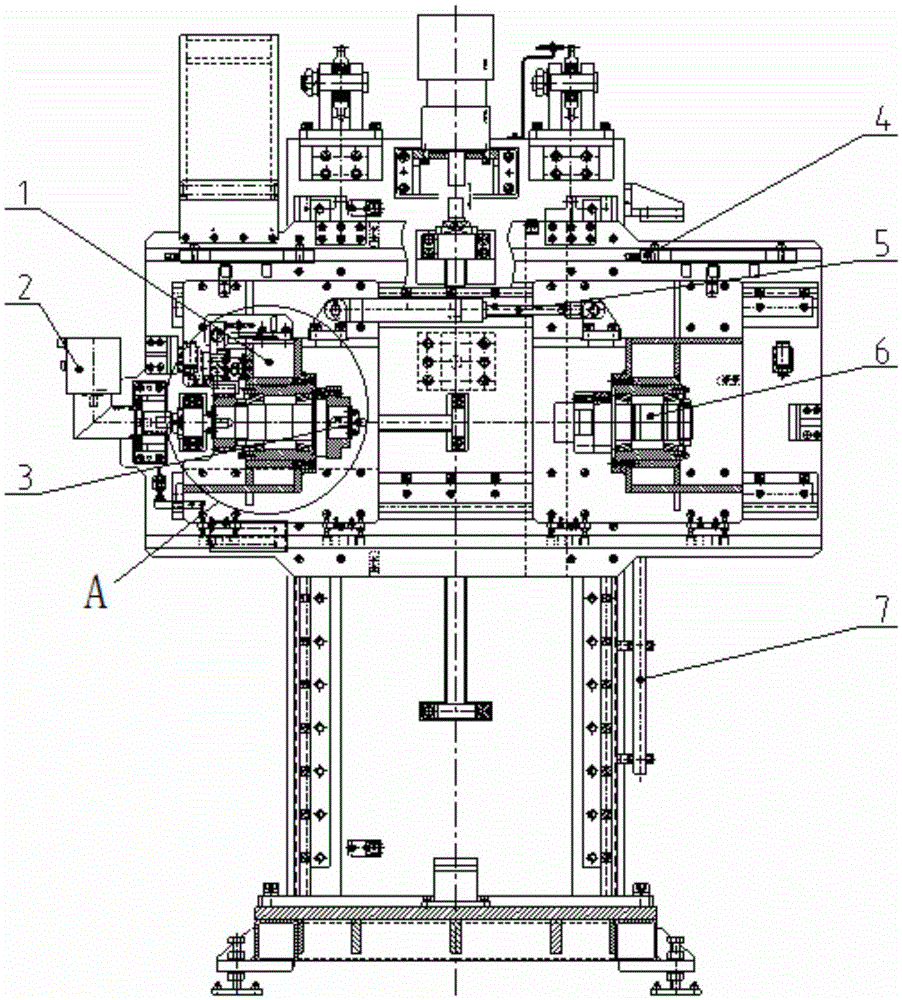

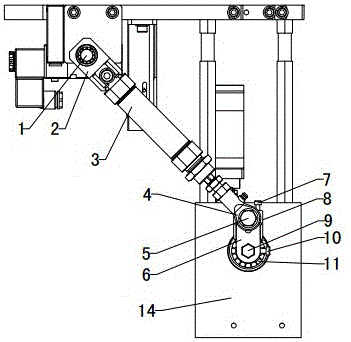

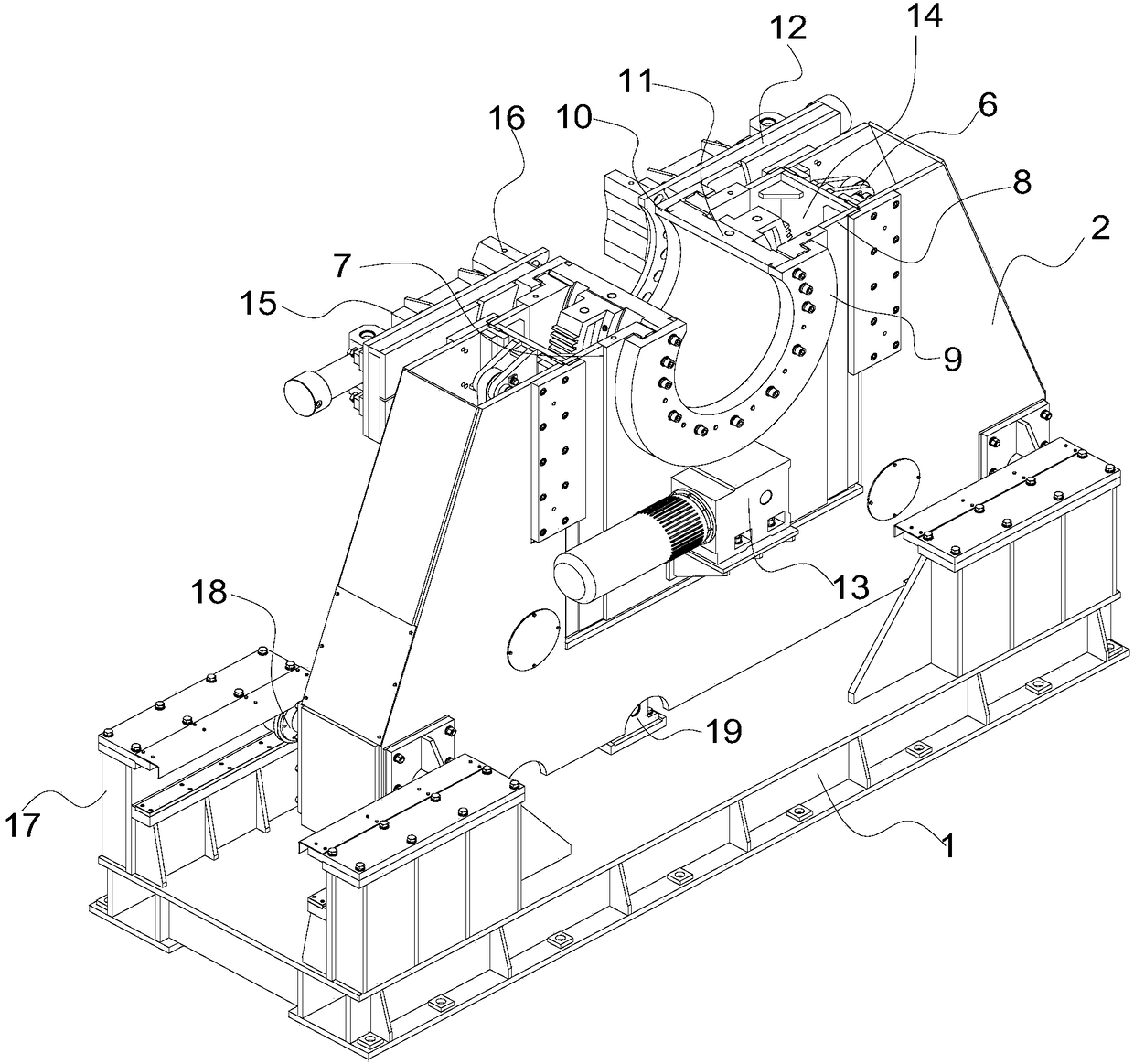

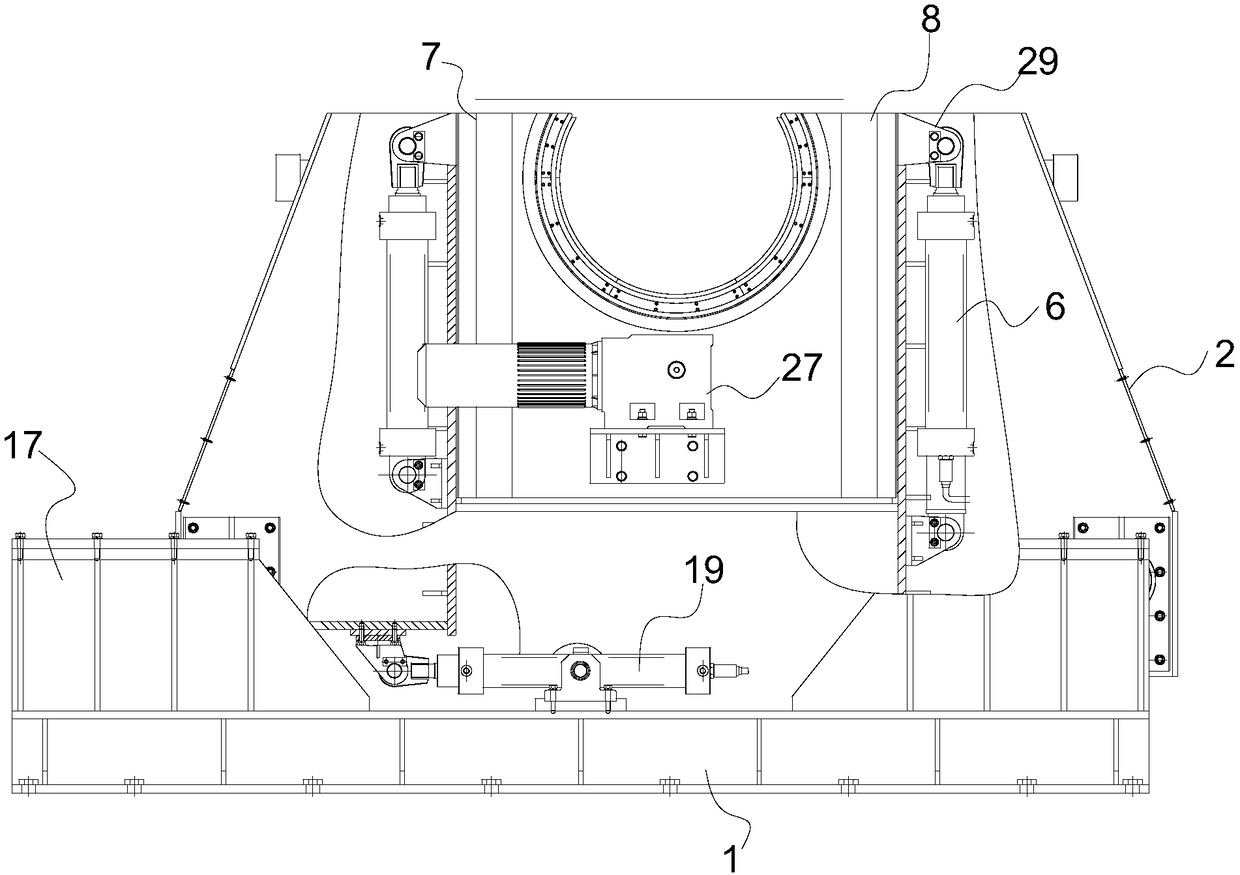

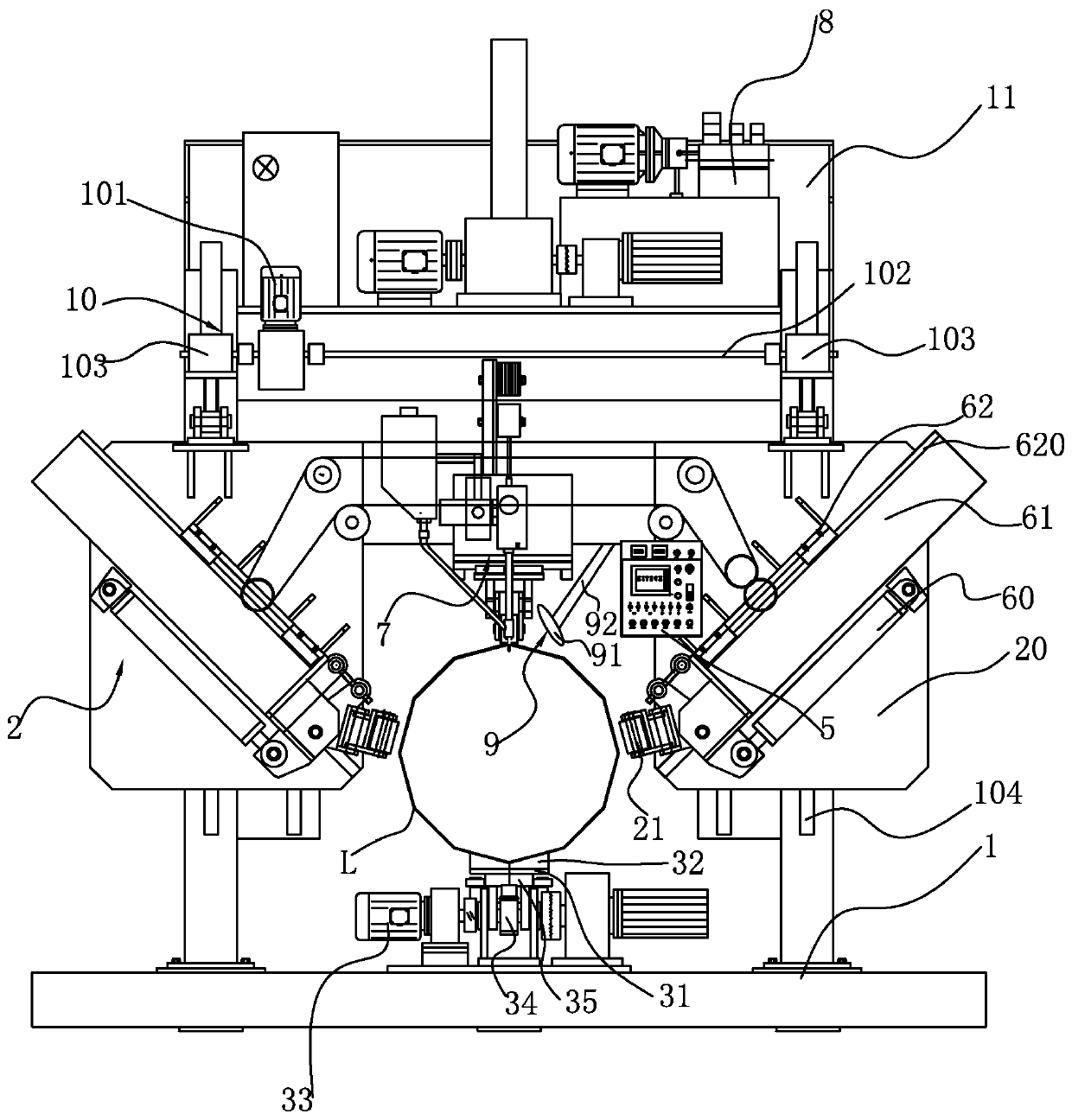

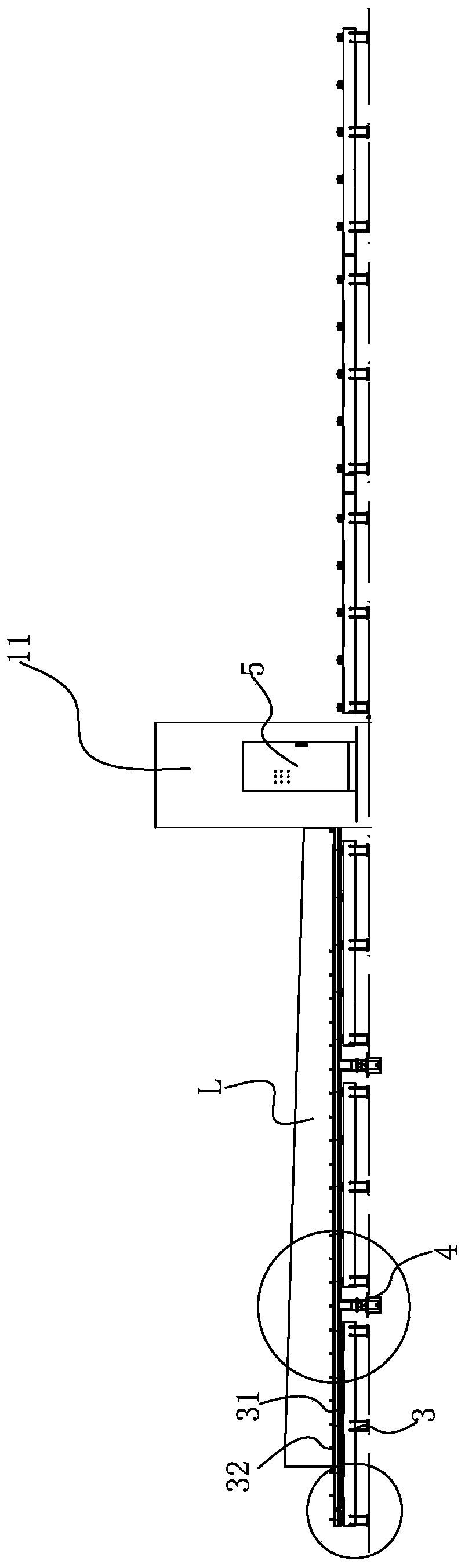

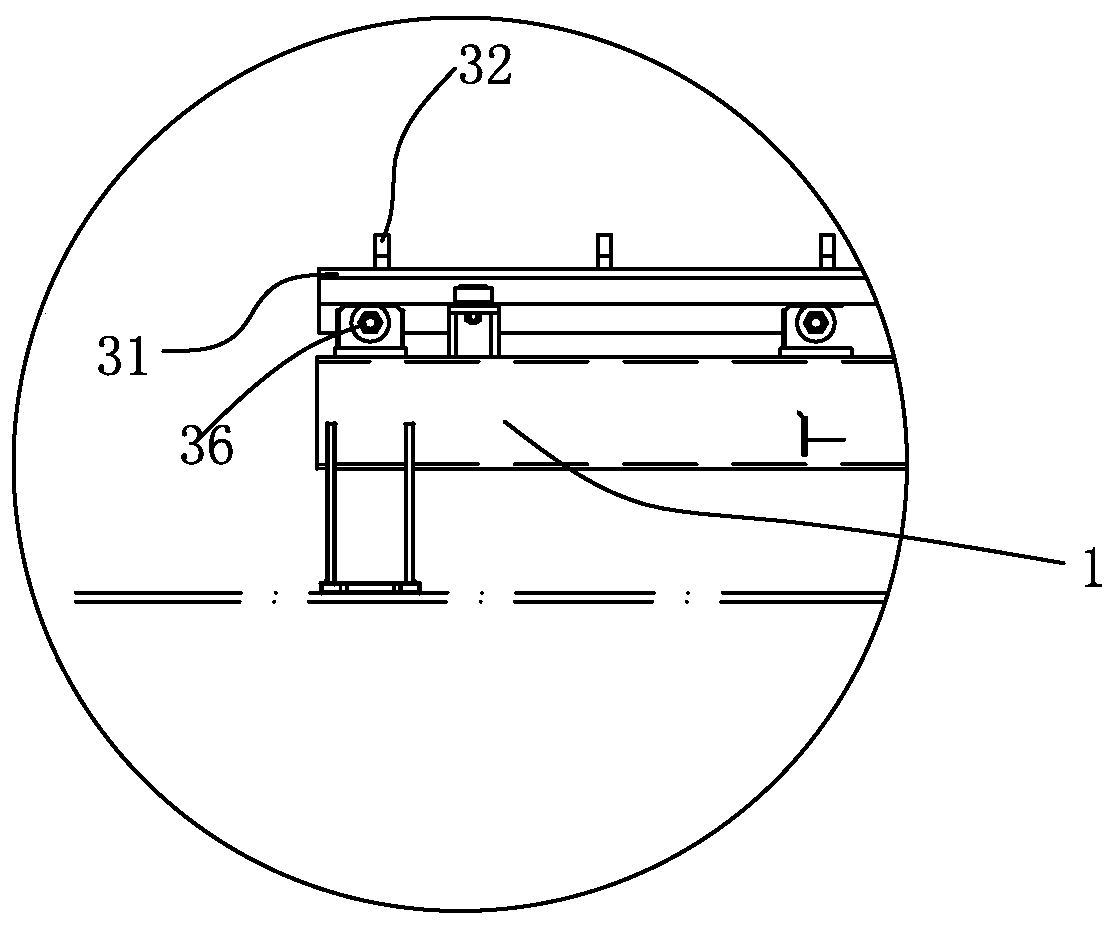

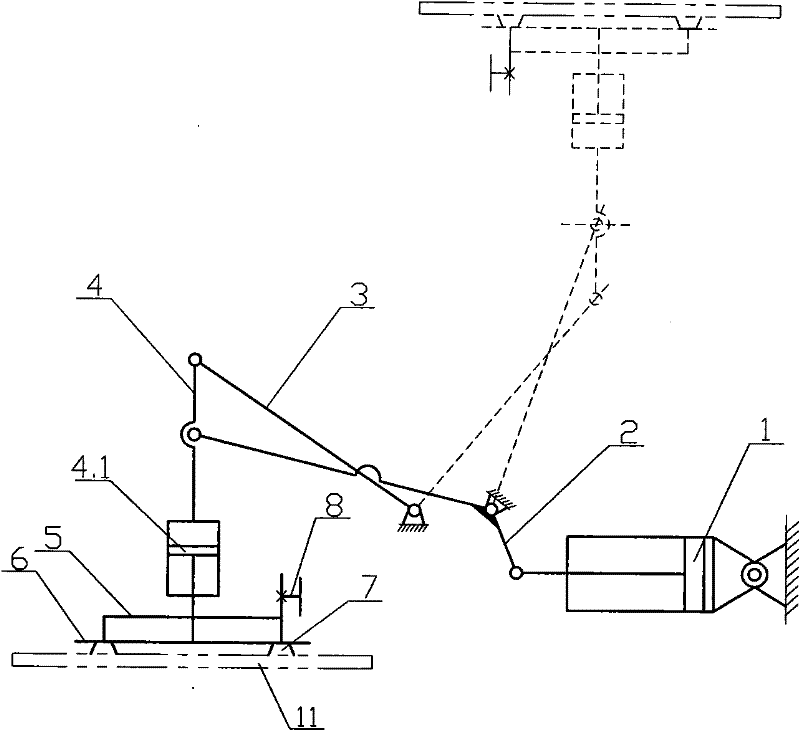

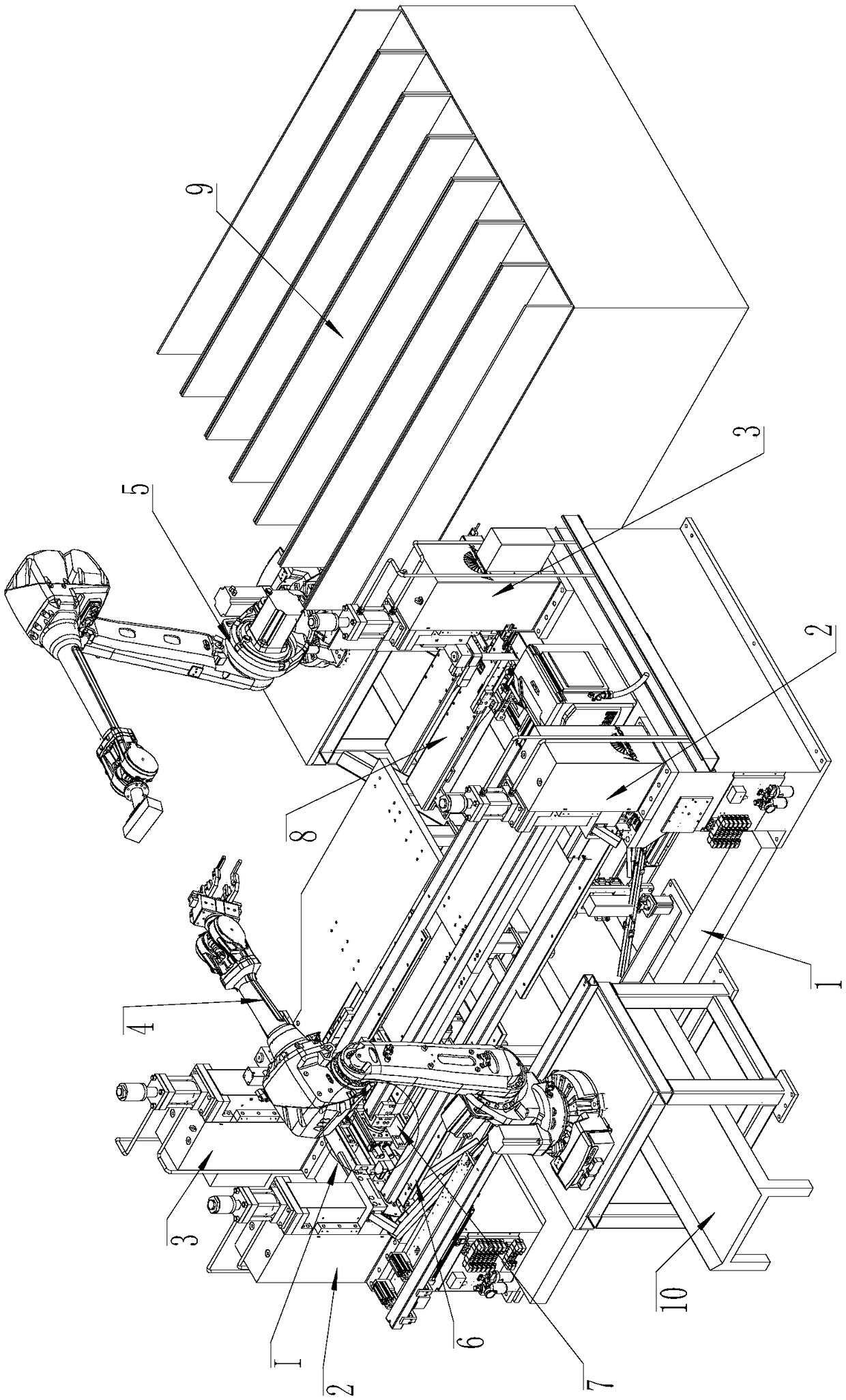

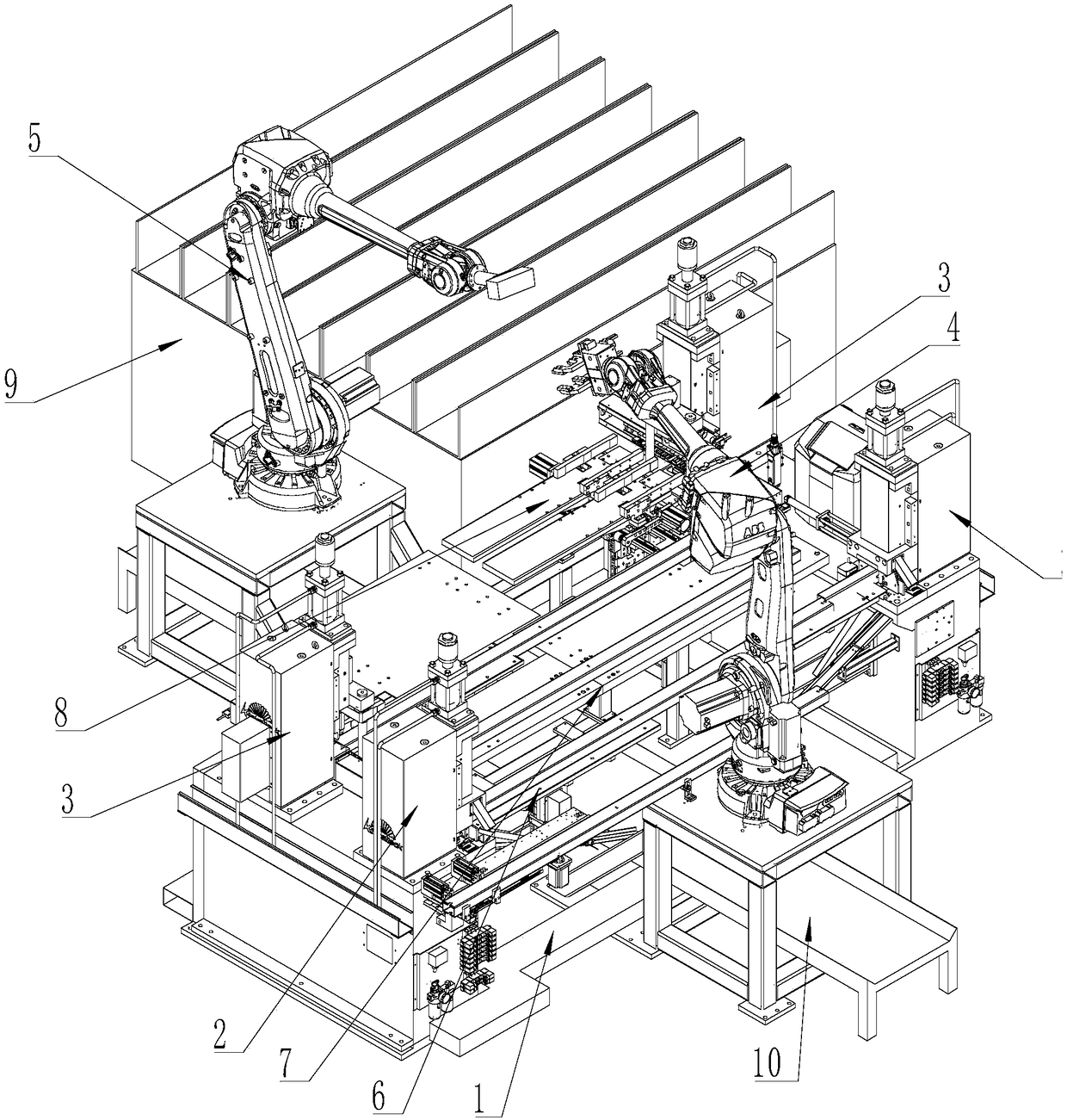

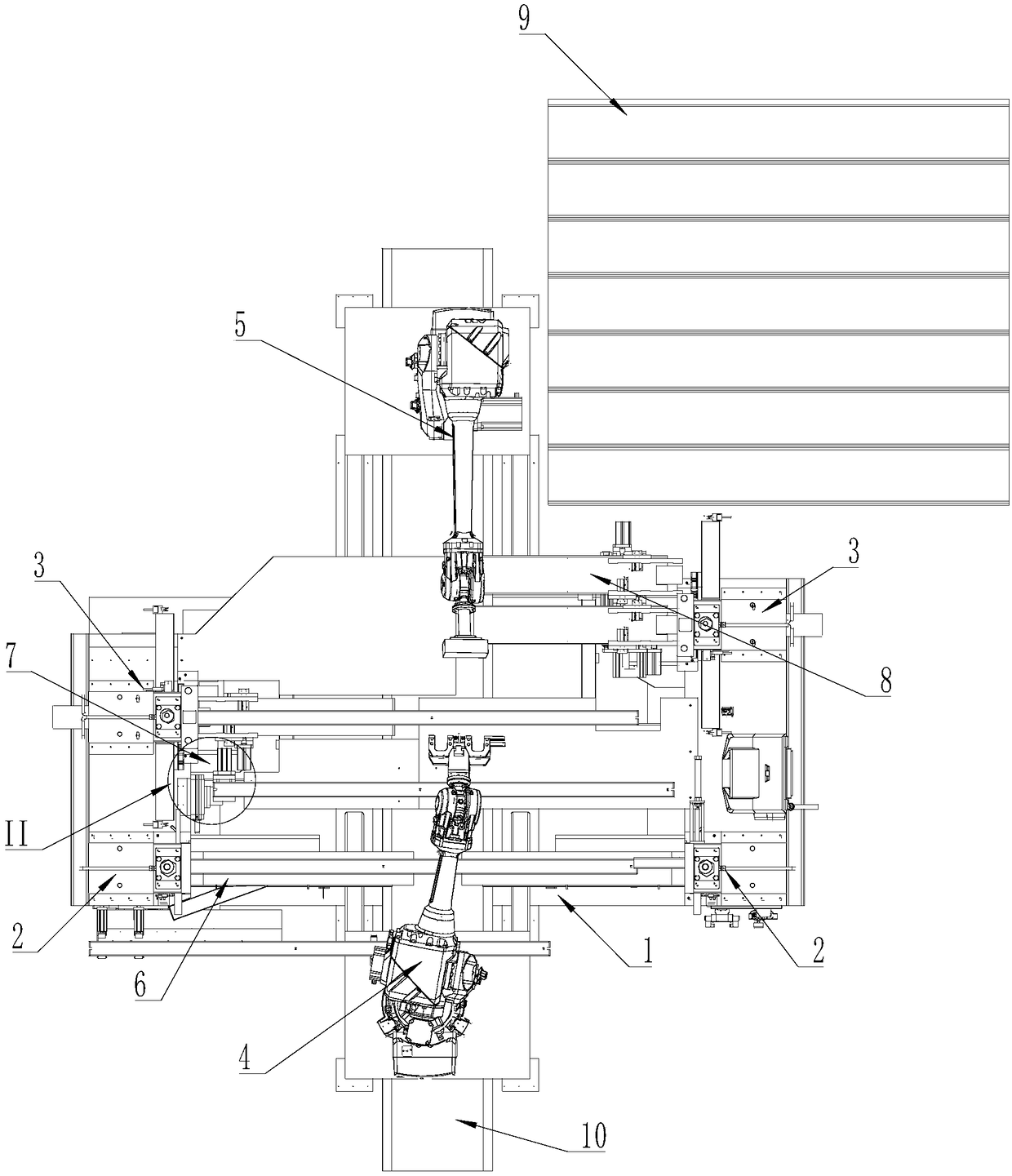

Automatic accurate overturning machine for heavy truck speed changing box assembling

ActiveCN106882746AFlip AccurateMeet precise positioning requirementsLifting devicesHoisting equipmentsEngineeringTruck

The invention relates to the field of heavy truck speed changing box assembling, in particular to an automatic accurate overturning machine for heavy truck speed changing box assembling. The automatic accurate overturning machine comprises a machine body, a clamping lifting mechanism, an overturning clamping claw, a clamp clamping claw, a positioning lifting mechanism, a positioning rotating mechanism and a positioning bearing disc. The clamping lifting mechanism is arranged on a first support of the machine body. The overturning clamping claw and the clamp clamping claw are arranged on the clamping lifting mechanism. A workpiece is movably clamped through the overturning clamping claw and the clamp clamping claw, and after the workpiece is clamped, overturning is conducted through the overturning clamping claw. The positioning lifting mechanism is arranged on a second support of the machine body and provided with the positioning rotating mechanism, the positioning rotating mechanism is provided with the positioning bearing disc, the positioning bearing disc is driven to rotate through the positioning rotating mechanism, a tray bearing the workpiece is supported and positioned through the positioning bearing disc, and a machine body base between the first support and the second support is provided with a floating bearing. The automatic accurate overturning machine can automatically overturn a heavy truck speed changing box shell assembly, and the precision positioning requirement is met after overturning.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

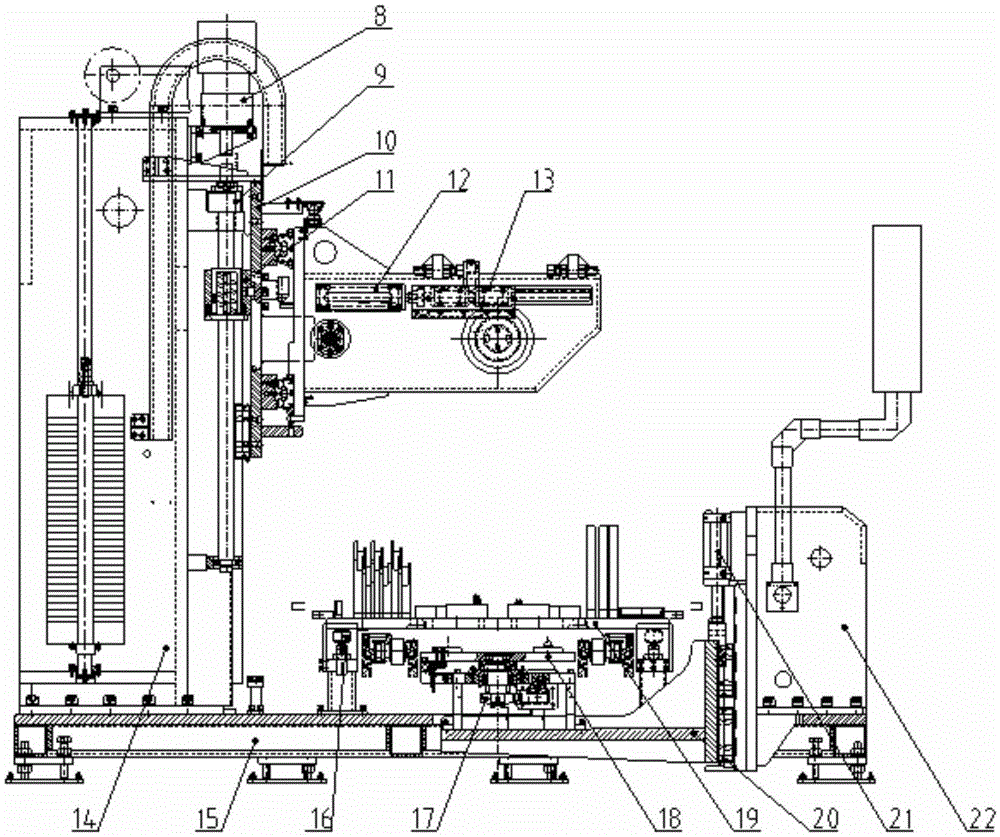

Green brick overturning machine achieving accurate overturning of green bricks

The invention relates to the field of green brick manufacturing and provides a green brick overturning machine achieving accurate overturning of green bricks. The green brick overturning machine achieving accurate overturning of the green bricks comprises a basic frame, a main frame, main cylinders arranged between a transmission device basic frame and the main frame, a plurality of cross beams arranged below the main frame and capable of sliding along the main frame, and telescopic cylinders arranged between the multiple cross beams and capable of moving the cross beams; each cross beam is provided with a main clamping plate and auxiliary clamping plates; each transmission device comprises a rotating shaft arranged on the cross beams; the positions, corresponding to the auxiliary clamping plates or the main clamping plates, on the rotating shafts are fixedly provided with cranks a or cranks b; the cranks a or the cranks b are movably connected with the corresponding auxiliary clamping plates or the corresponding main clamping plates; and clamping cylinders and overturning cylinders are both magnetic cylinders without piston rods. When the green brick overturning machine achieving accurate overturning of the green bricks is used for overturning the green bricks, synchronous overturning is achieved, the clamping cylinders and the overturning cylinders are both the magnetic cylinders without the piston rods, the accuracy degree can be improved when the green bricks are overturned and clamped, damage to the green bricks is reduced, the green bricks can also be evenly separated, and work procedures are saved for a setting machine.

Owner:四川联腾电子科技有限公司

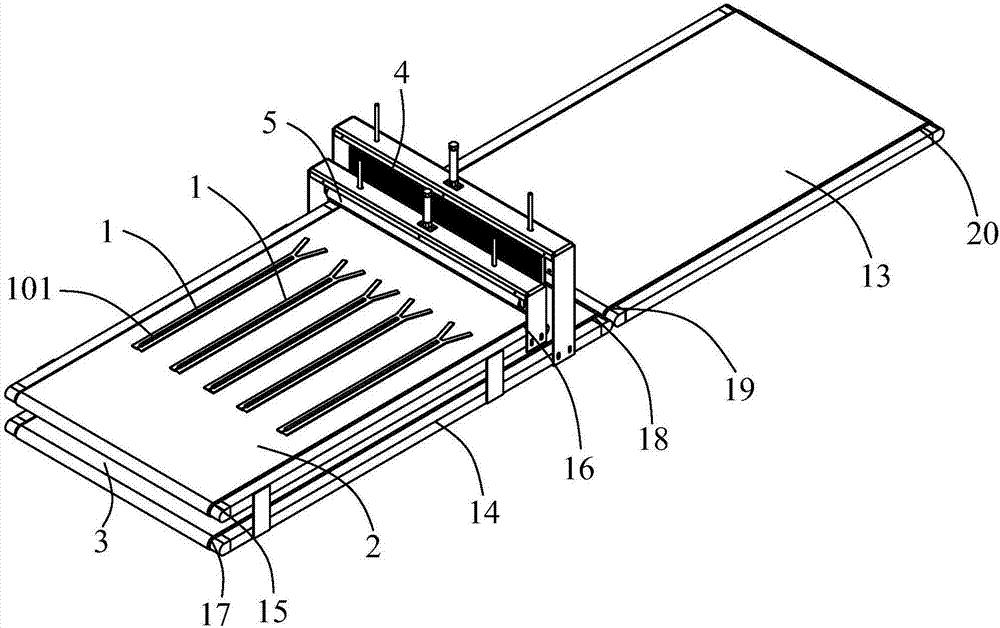

Automatic and accurate page turning and paper picking device

The invention discloses an automatic and accurate page turning and paper picking device, and belongs to the field of auxiliary tools of reading. The automatic and accurate page turning and paper picking device comprises a base, a cylindrical page turning mechanism and a book pressing mechanism, wherein a supporting rod is mounted at the upper part of the base; a first pushing cylinder and a second pushing cylinder are arranged on a cross beam of the supporting rod; a page turning motor is mounted at the tail end of a pushing rod of the first pushing cylinder; the cylindrical page turning mechanism is arranged on a main shaft of the page turning motor; and the book pressing mechanism is mounted at the tail end of a pushing rod of the second pushing cylinder. According to the automatic and accurate page turning and paper picking device, the cylindrical page turning mechanism is an incomplete cylinder, an air blowing plate blows air into a clearance to fill the clearance, when a page guide rod enters the space between the first-layer paper and a book from the clearance, the first-page paper is accurately turned during the process where the page guide rod overturns the first-layer paper to the other side, and a reader can turn the book to the assigned position according to the self requirements.

Owner:菏泽中能电子科技有限公司

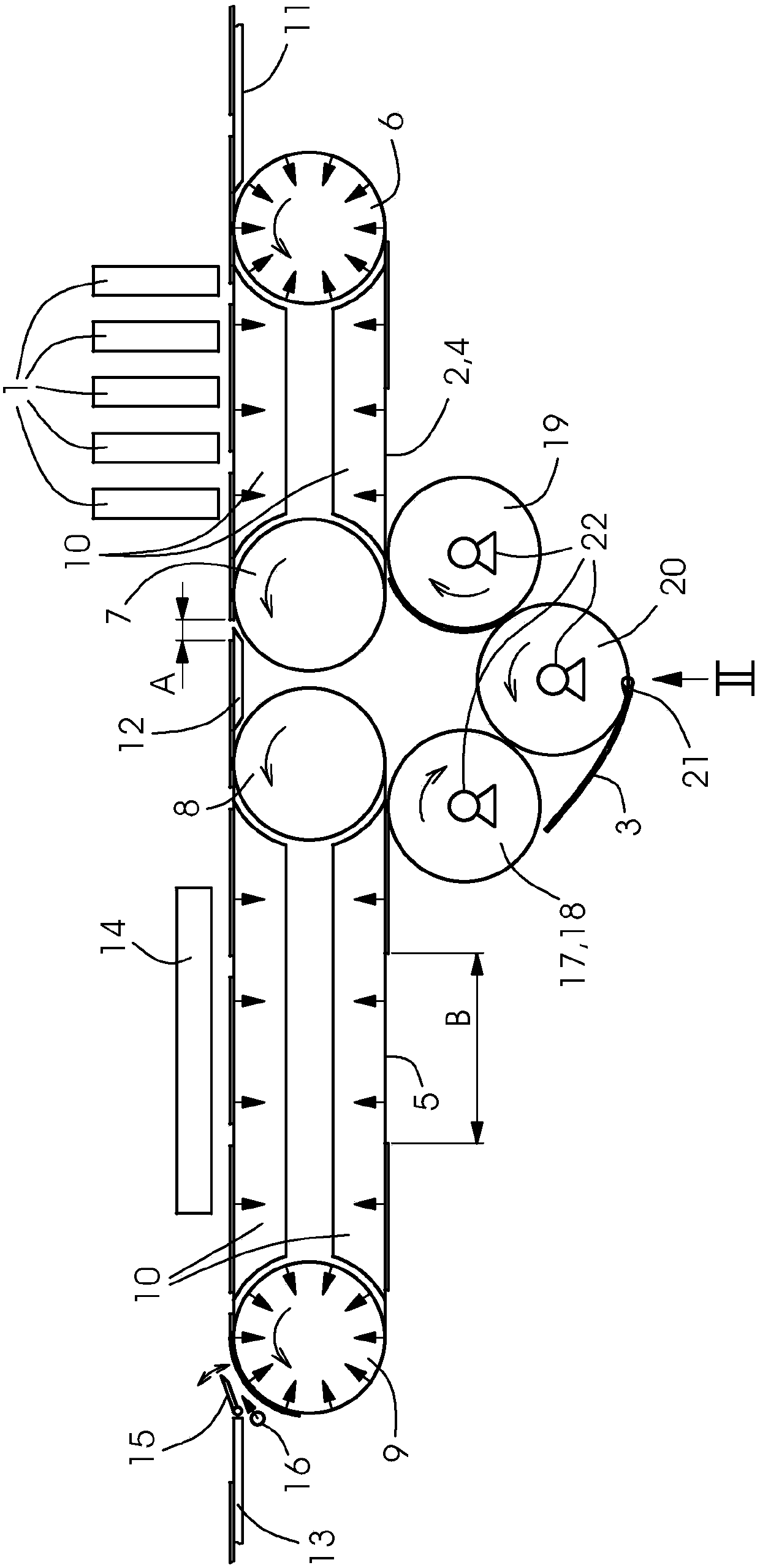

Digital printing machine

ActiveCN107813620AFlip AccurateEliminate damageTypewritersOther printing apparatusEngineeringPrinting press

The invention relates to a digital printing machine comprising a printing head (1) for printing the front and back sides of a printing sheet (3), a conveyor belt device (2) for feeding the printing sheet (3), and an overturning device (17) for flipping a printing sheet (3) between a printing front side and a printing back side, wherein the overturning device (17) has a first vacuum drum (18), a second vacuum drum (19) and an overturning drum (20) having a folder-type picker (21) for holding the printing sheet (3).

Owner:HEIDELBERGER DRUCKMASCHINEN AG

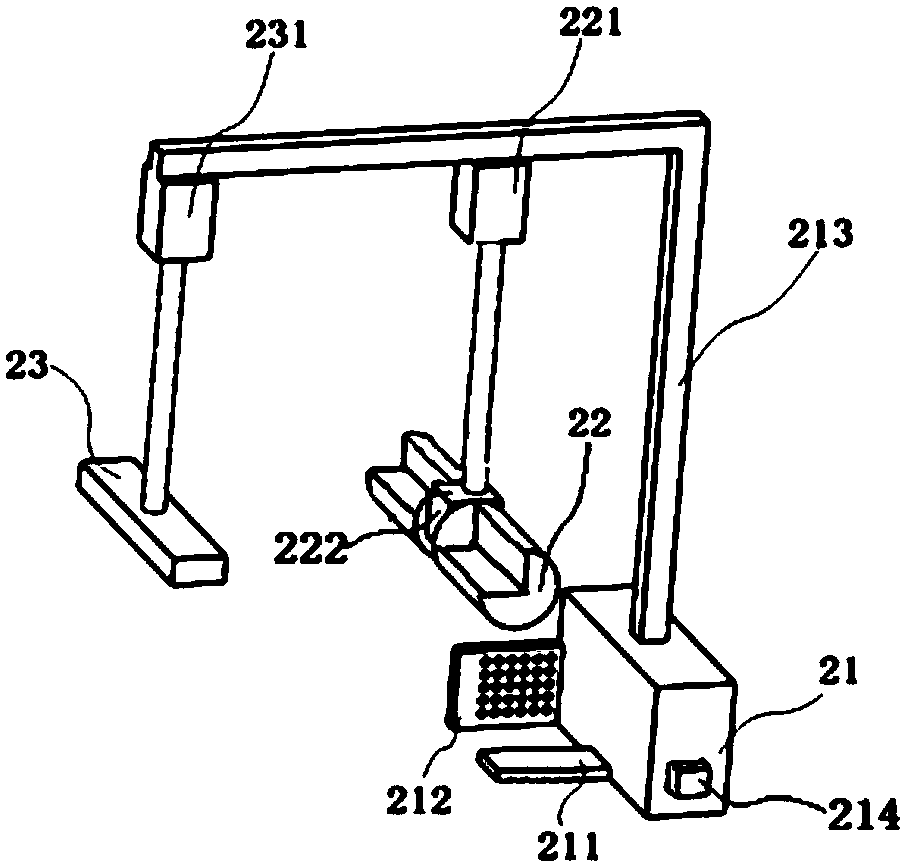

An automatic and accurate page turning device

ActiveCN106240189BReduce mutual frictionReduce frictionBook markersEngineeringMechanical engineering

The invention discloses an automatic and accurate page turning and paper picking device, and belongs to the field of auxiliary tools of reading. The automatic and accurate page turning and paper picking device comprises a base, a cylindrical page turning mechanism and a book pressing mechanism, wherein a supporting rod is mounted at the upper part of the base; a first pushing cylinder and a second pushing cylinder are arranged on a cross beam of the supporting rod; a page turning motor is mounted at the tail end of a pushing rod of the first pushing cylinder; the cylindrical page turning mechanism is arranged on a main shaft of the page turning motor; and the book pressing mechanism is mounted at the tail end of a pushing rod of the second pushing cylinder. According to the automatic and accurate page turning and paper picking device, the cylindrical page turning mechanism is an incomplete cylinder, an air blowing plate blows air into a clearance to fill the clearance, when a page guide rod enters the space between the first-layer paper and a book from the clearance, the first-page paper is accurately turned during the process where the page guide rod overturns the first-layer paper to the other side, and a reader can turn the book to the assigned position according to the self requirements.

Owner:菏泽中能电子科技有限公司

Right-angle overturning mechanism of ceramic tile corner wrapping machine and ceramic tile corner wrapping machine

InactiveCN106144075AFlipFlip AccurateShock-sensitive articlesConveyor partsPerpendicular directionMaterials science

The invention provides a right-angle overturning mechanism of a ceramic tile corner wrapping machine and the ceramic tile corner wrapping machine and belongs to the field of ceramic tile packaging equipment. The right-angle overturning mechanism of the ceramic tile corner wrapping machine is characterized in that overturning bodies (13) are rotationally installed in an overturning support (14) through overturning shafts (9), one end of each overturning shaft (9) penetrates the overturning support (14) and is connected with a linear pushing mechanism driving the overturning shaft (9) to rotate by 90 degrees, and the linear pushing mechanisms are arranged outside the overturning support (14) in an inclined manner. According to the right-angle overturning mechanism of the ceramic tile corner wrapping machine, the one or two groups of linear pushing mechanisms are used for pushing the overturning shafts to turn over by 90 degrees; meanwhile, the linear pushing mechanisms are arranged outside the overturning support in the inclined manner, the movement path of each inclined linear pushing mechanism in the pushing process is a linear movement path along the inclined angle of the inclined linear pushing mechanism, and therefore the overturning shafts are forced to turn over by 90 degrees through the linear movement characteristic of the linear pushing mechanisms; in this way, it is guaranteed that the overturning shafts can drive the overturning bodies to accurately turn over by 90 degrees, and then the purpose that the overturning bodies rotate from the perpendicular direction to the horizontal direction is achieved.

Owner:山东爱而生智能科技有限公司

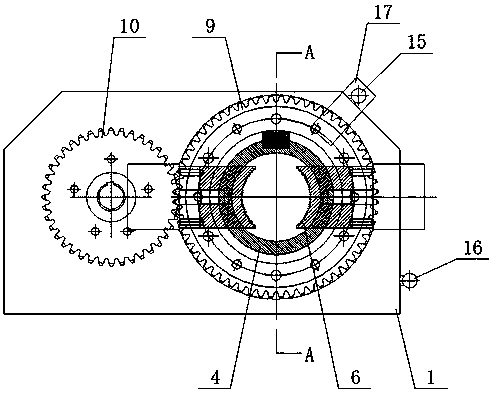

Turnover machine

PendingCN108580588ARealize automatic control operationStable performanceMetal-working feeding devicesPositioning devicesAutomatic controlVehicle frame

The invention discloses a turnover machine. The turnover machine comprises a base, a machine frame, a lifting mechanism, a rotary mechanism and a clamping mechanism, wherein the lifting mechanism comprises a first lifting frame, a second lifting frame, a first backing ring and a second backing ring; the rotary mechanism is connected between the first backing ring and the second backing ring in a sliding manner and comprises a rotary part, a rotary support and a driving mechanism which is arranged in the machine frame and is used for driving the rotary part to rotate; rotary space for the rotation of the rotary part is formed between the rotary part and the first lifting frame and between the rotary part and the second lifting frame; the clamping mechanism comprises clamping oil cylinders arranged at the two ends of a circular arc opening of the rotary support, and clamping heads connected to the ends, close to the circular arc opening, of the clamping oil cylinders; and two clamping heads are oppositely arranged. The accurate overturning of straightening materials is realized through the transverse movement, lifting, rotation and clamping of the turnover machine. The turnover machine integrates machinery, electricity and liquid, can realize automatic control operation, is safe and reliable, has stable performances and high result intensity and is simple to operate.

Owner:成都莱克冶金机械设备制造有限公司

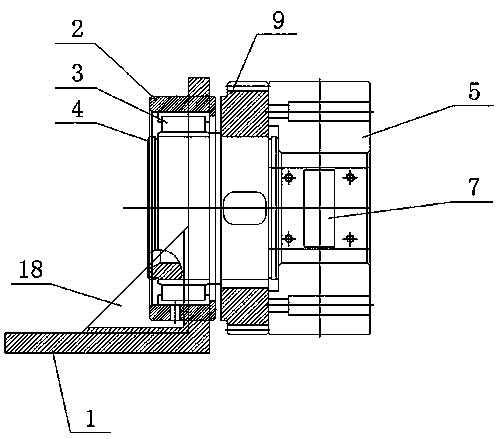

High-precision copper pipe milled surface automatic overturning device based on motor drive

InactiveCN109434518AEasy to cleanQuick washFeeding apparatusLarge fixed membersMotor driveCylinder head

The invention relates to a high-precision copper pipe milled surface automatic overturning device based on motor drive. The device comprises a supporting bottom plate; a bearing sleeve is embedded inthe vertical surface of the supporting bottom plate; the bearing sleeve is fixed on the supporting bottom plate; a bearing is mounted in the bearing sleeve; one end of a central shaft is connected with the bearing; the other end of the central shaft penetrates through the bearing and then is fixedly connected with a rotating bracket; the central shaft is in a cylindrical shape; a channel for pulling a pipe blank is reserved in the central shaft; the end, connected to the rotating bracket, of the central shaft is provided with a mounting hole for mounting a clamping jaw; an air cylinder is mounted on the rotating bracket; an air cylinder head of the air cylinder is connected with the clamping jaw arranged on the inner wall of the rotating bracket; the clamping jaw is mounted in the centralshaft telescopically after penetrating the mounting hole; and the air cylinder head drives the clamping jaws to tighten when the air cylinder acts. The overturning device can automatically clamp and overturn copper pipes, thus, cleaning can be carried out more conveniently and quickly, and the production efficiency is improved advantageously.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

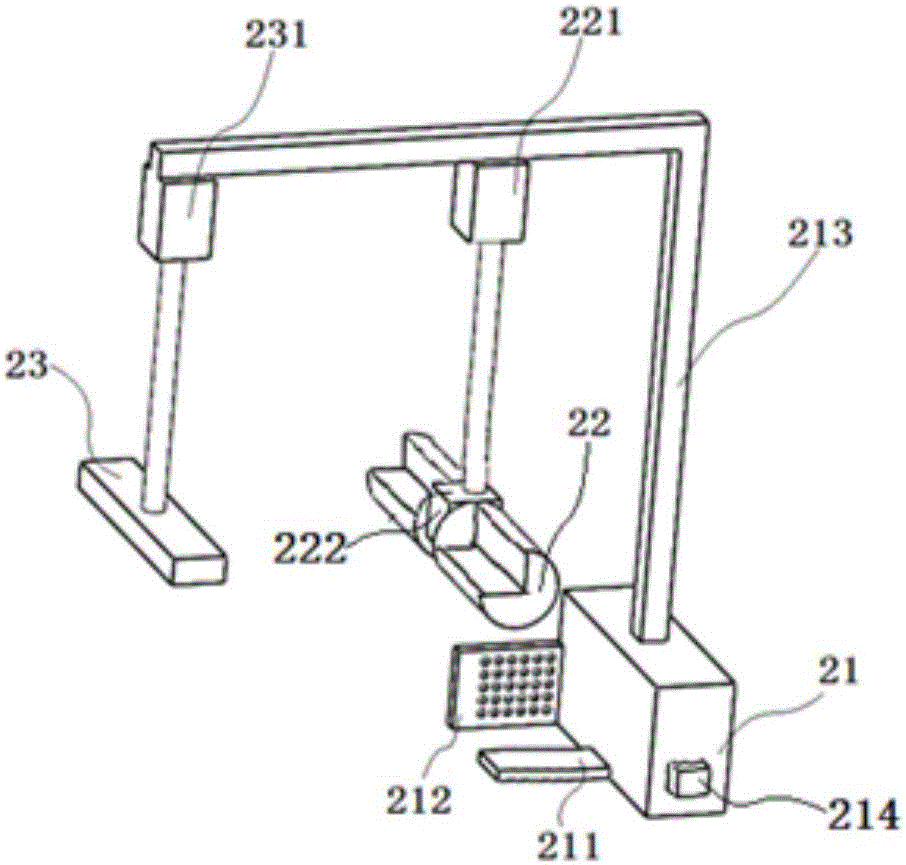

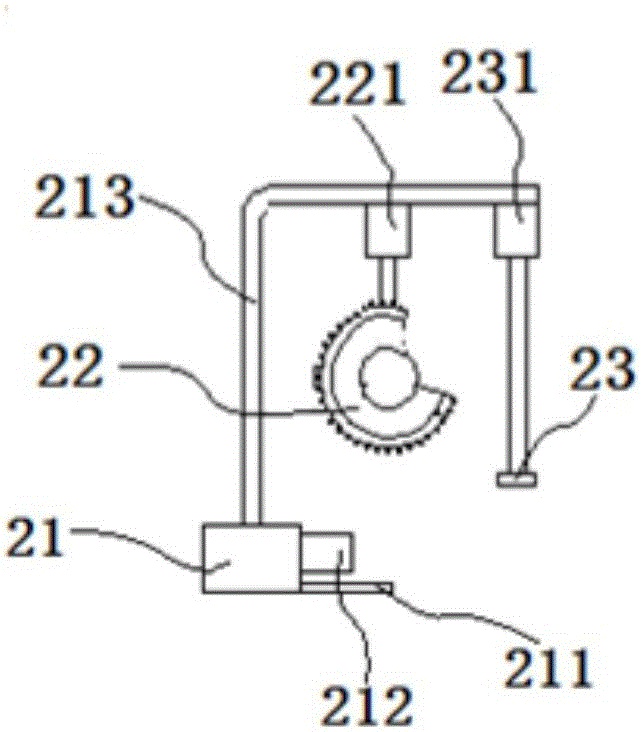

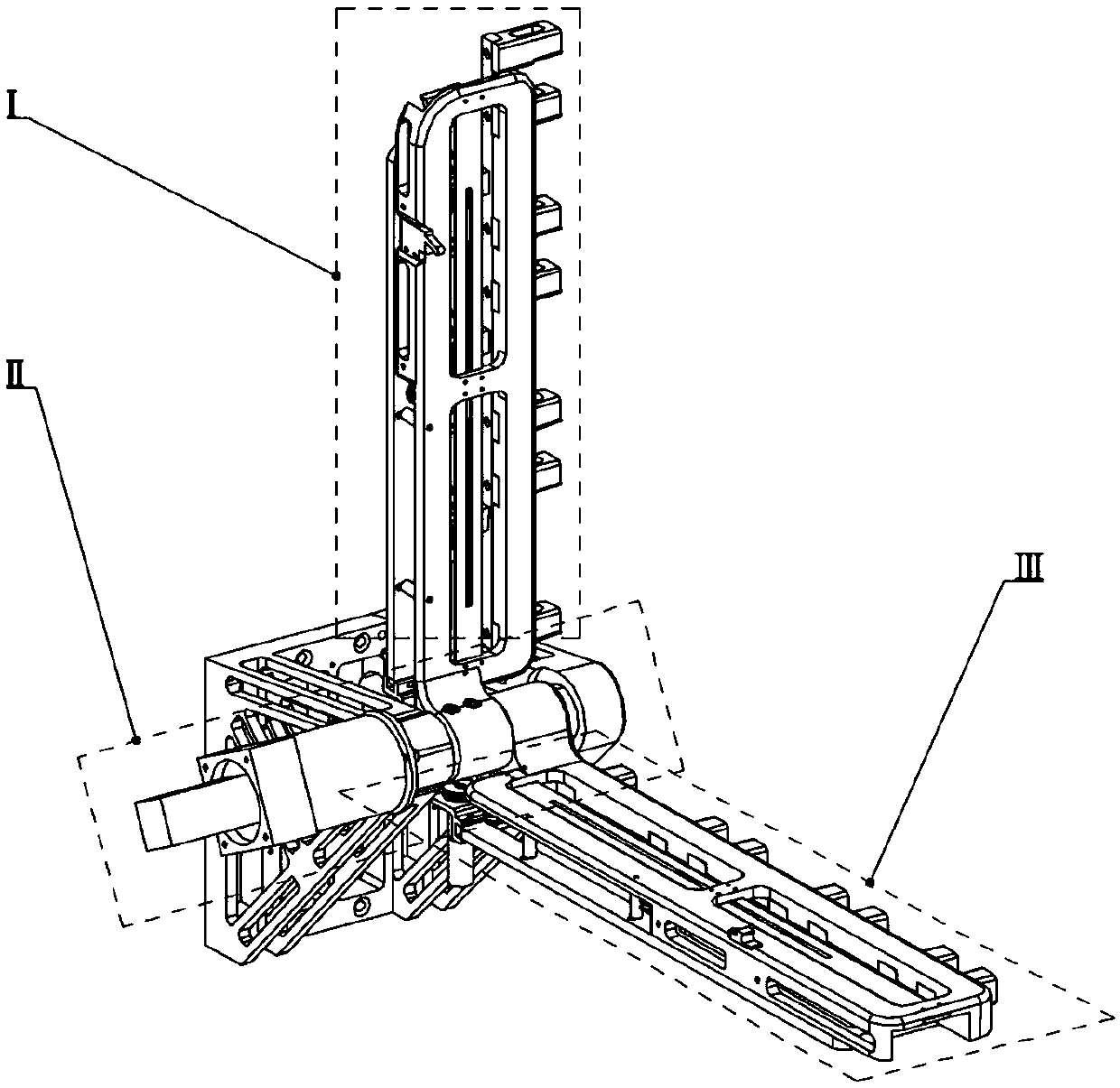

High-precision multi-butt-joint-locking-plane antenna auxiliary unfolding mechanism

ActiveCN109638405AFlip AccurateAchieve stretch outCollapsable antennas meansAntenna supports/mountingsSatellite antennasButt joint

The invention discloses a high-precision multi-butt-joint-locking-plane antenna auxiliary unfolding mechanism, and belongs to the technical field of satellite antennas. The mechanism comprises an overturning module I, a rotation connection module II and a fixing module III, the module I and the module III comprise wedge telescoping mechanisms, the rotation connection module II comprises a large motor, a transmission shaft fixedly combined with a motor shaft of the large motor, and a first installation plate and a second installation plate supporting connection of the large motor and the transmission shaft, and the overturning module I and the rotation connection module II are separately connected with the transmission shaft. By employing the mechanism, the whole process of antenna unfolding is reversible, when an antenna needs to be withdrawn, wedges of the auxiliary mechanism can perform accurate butt joint with a reflection plane and are then vertically overturned to an original position, the antenna reflection plane with greater length can be carried in a segmented manner, a fixing effect is achieved during folding of the reflection plane, and the problem of simultaneous and accurate overturning of multiple groups of reflection planes is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Overturning device and front face and back face overturning method of articles

The invention provides an overturning device. The overturning device comprises a first conveyor belt and a second conveyor belt which are distributed in parallel and are both used for conveying a plurality of bodies to be overturned. In the direction that the first conveyor belt forwards conveys the multiple bodies to be overturned, a baffle is arranged in front of the first conveyor belt; and when the multiple bodies to be overturned are forwards conveyed by the first conveyor belt and make contact with the baffle, the baffle enables the multiple bodies to be overturned to bend towards the second conveyor belt, the multiple bodies to be overturned are conveyed to the second conveyor belt, and the conveying direction of the second conveyor belt is opposite to the conveying direction of thefirst conveyor belt. By means of the overturning device, the multiple bodies to be overturned can be overturned by 180 degrees at a time, the distribution manner of the multiple overturned bodies isconsistent with the distribution manner of the multiple bodies to be overturned before overturning, and therefore the requirements of production occasions or other occasions are met, such as the quality testing of the front faces and back faces of the overturned bodies in the last of the production link of the bodies to be overturned.

Owner:YKK ZIPPERSHENZHEN CO LTD

Full-automatic aluminum-plastic bubble cap detection equipment

PendingCN113680678AEfficient automatic detectionReduce false detection rateConveyorsControl devices for conveyorsStructural engineeringMechanical engineering

The invention discloses full-automatic aluminum-plastic bubble cap detection equipment, which comprises a first conveying mechanism; a material blocking mechanism which is arranged at the discharging end of the first conveying mechanism; a first detection mechanism which is arranged above the first conveying mechanism; a second conveying mechanism which is arranged behind the first conveying mechanism; an overturning mechanism which is used for overturning aluminum-plastic bubble caps located at the material blocking mechanism on the first conveying mechanism and then placing the aluminum-plastic bubble caps on the second conveying mechanism; a second detection mechanism which is arranged above the second conveying mechanism; and a sorting mechanism which is arranged at the discharging end of the second conveying mechanism. According to the full-automatic aluminum-plastic bubble cap detection equipment provided by the invention, efficient, rapid and automatic detection of the front and back surfaces of the aluminum-plastic bubble caps and fillers in the bubble caps is realized; the full-automatic aluminum-plastic bubble cap detection equipment greatly reduces the false detection rate of subjective manual visual detection, guarantees the correctness and reliability of a detection result, accelerates the detection efficiency, and effectively reduces the labor cost of detection; the equipment is simple in structure, convenient to install and debug, capable of turning over and adjusting speed and accurate in resetting; the shooting accuracy is high; and the time cost is greatly saved.

Owner:太仓中科信息技术研究院

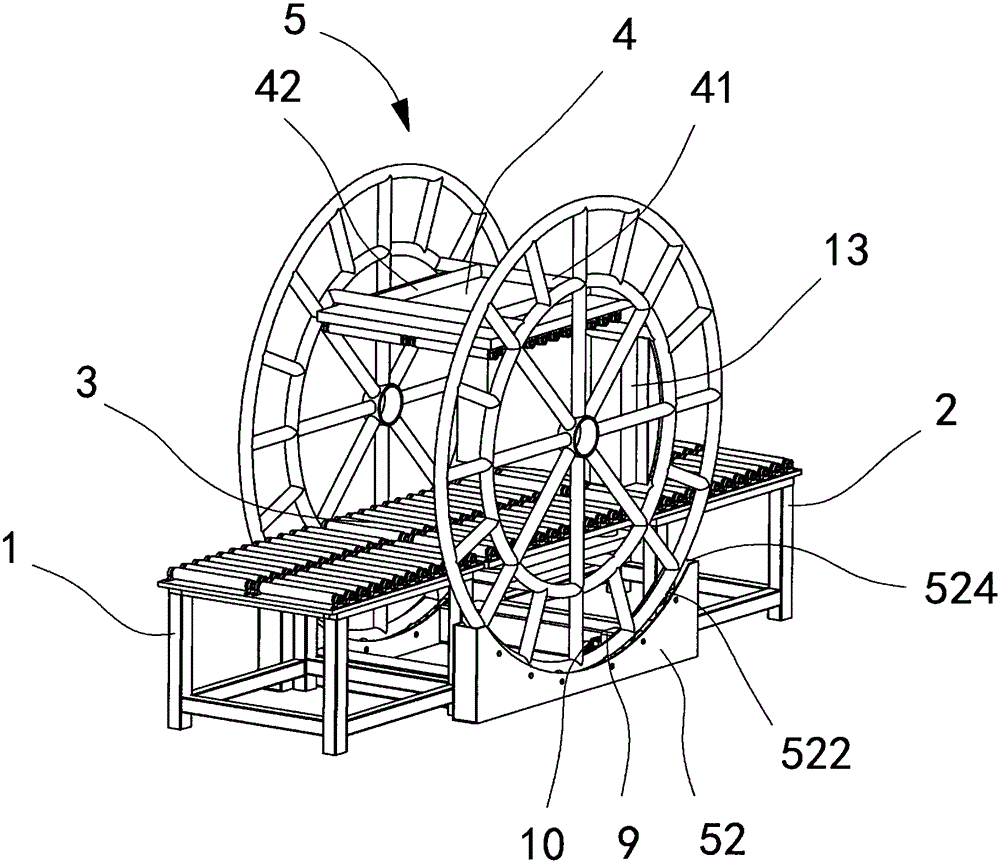

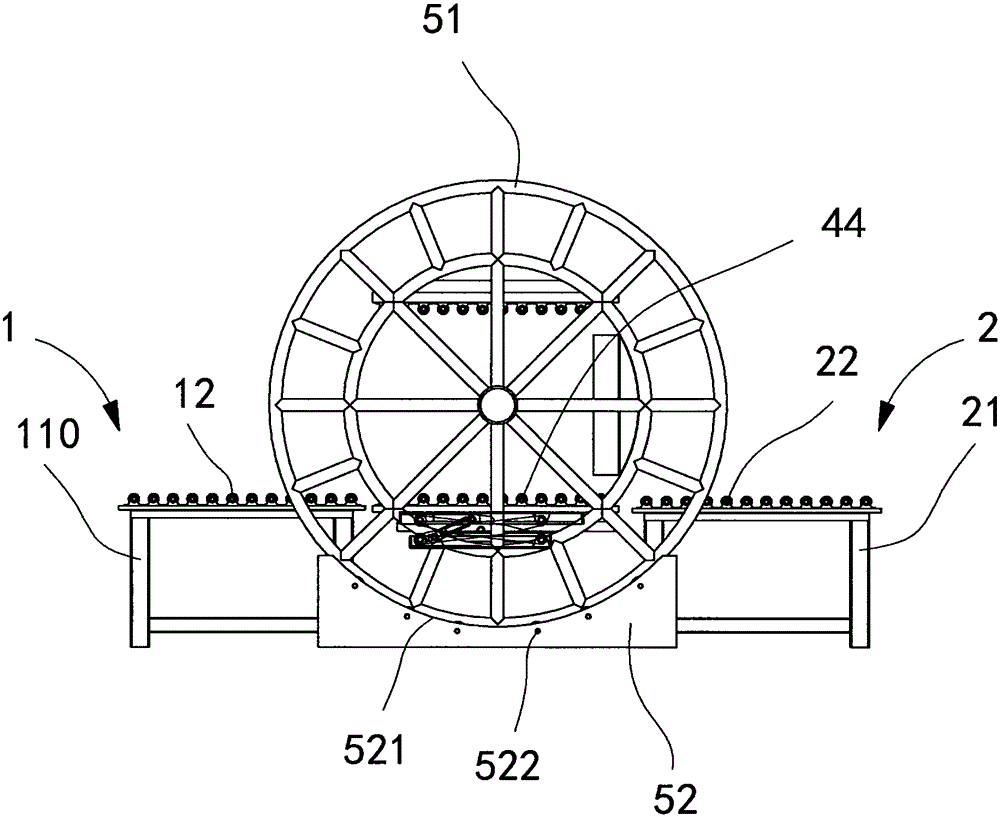

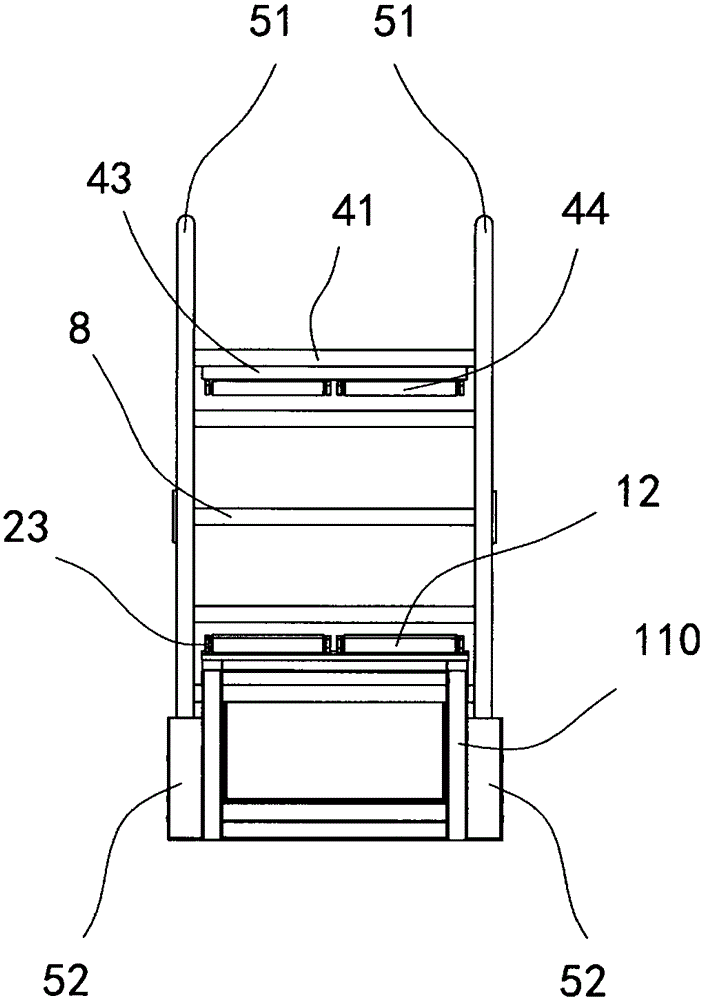

Wheel-type automatic turnover equipment with lifting mechanism

InactiveCN105173650AImprove turnover efficiencyFlip process safetyConveyor partsEngineeringMechanical engineering

The invention discloses wheel-type automatic turnover equipment with a lifting mechanism. The wheel-type automatic turnover equipment comprises an inlet conveying mechanism and an outlet conveying mechanism. A turnover mechanism is arranged between the inlet conveying mechanism and the outlet conveying mechanism and provided with a first intermediate conveying mechanism and a second intermediate conveying mechanism. The first intermediate conveying mechanism and the second intermediate conveying mechanism are arranged on the turnover mechanism in parallel. The lifting mechanism is arranged below the first intermediate conveying mechanism. The turnover mechanism is further provided with a clamping mechanism which is a hydraulically-driven plane-type clamping mechanism. According to the wheel-type automatic turnover equipment, the turnover efficiency is improved, and the turnover process is safer and more accurate; meanwhile, the wheel-type automatic turnover equipment has the characteristic of being simple in structure.

Owner:KENMEC MECHA TRONICS (SUZHOU) CO LTD

Intelligent environment-friendly welding machine

ActiveCN111482674AReduce workloadGuarantee product qualityWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeManufacturing engineering

The invention discloses an intelligent environment-friendly welding machine. A conveying device used for conveying pyramidal steel pipes, a clamping device used for clamping the steel pipes, a weldingdevice located above the conveying device, a power device used for driving the clamping device and a control device are arranged on the rack. The clamping device comprises two sets of symmetrically-arranged clamping assemblies acting at the same time. Each set of clamping assembly is provided with a mounting rack, a clamping wheel and a clamping drive assembly driving the clamping wheel to clampthe pyramidal steel pipes. The clamping drive assemblies are arranged on the mounting racks. The clamping wheels are rotationally arranged on the clamping drive assemblies. During clamping, the clamping wheels roll relative to the length direction of the pyramidal steel pipes. The welding device comprises a taper adjusting assembly, a welding joint, a welding wire and a probe. During welding, theprobe guides the welding joint and the welding wire to cooperatively weld a to-be-welded clearance. The taper adjusting assembly adjusts the height of the welding joint and the height of the probe soas to adapt to the taper of the pyramidal steel pipes. The production efficiency and quality of steel pipes in polygonal pyramid shapes are improved, manpower is reduced, and the production cost and pollution to the environment are reduced.

Owner:WEIFANG HIGHLIGHT TAPERED STEEL TUBE

Kebob tongs

InactiveUS20140339840A1Flip AccurateCook evenlyKitchen equipmentLoad-engaging elementsEngineeringMechanical engineering

Tongs for manipulating shish-kebob on a barbeque grill, the tongs having two arms, the two arms being in parallel relationship at an insulated handle end which includes the pivot point at one end, the arms diverging at the opposing end of the handle end, to form two opposing spaced apart arms having kebob engaging ends, each end having an aperture there through, the apertures engaging the ends of the skewer, the tongs then being compressed so that the kebob engaging ends engage the outer food items on the skewer preventing their rotation so that the kebob may be either flipped for even cooking on the opposing side, or removed from the grill for consumption without endangering the fingers of the user.

Owner:STERN ROBERT

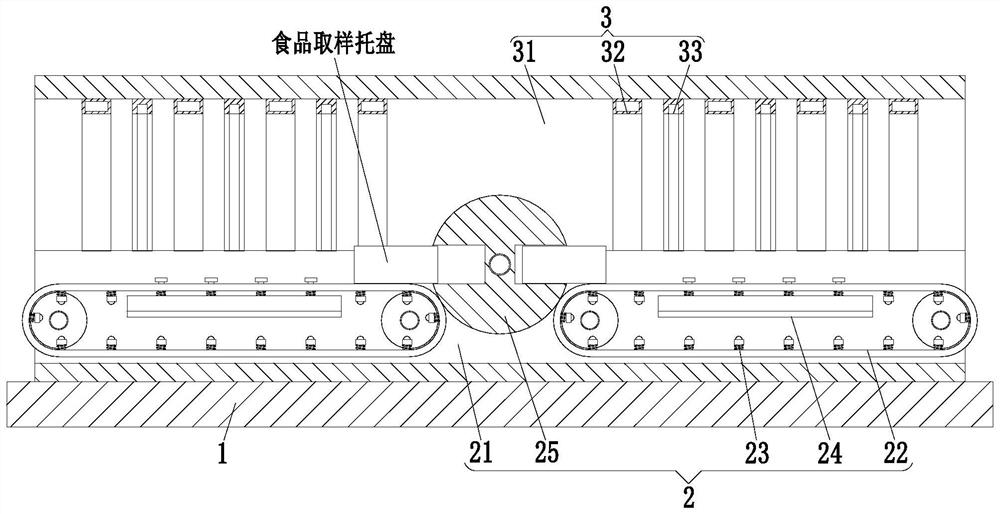

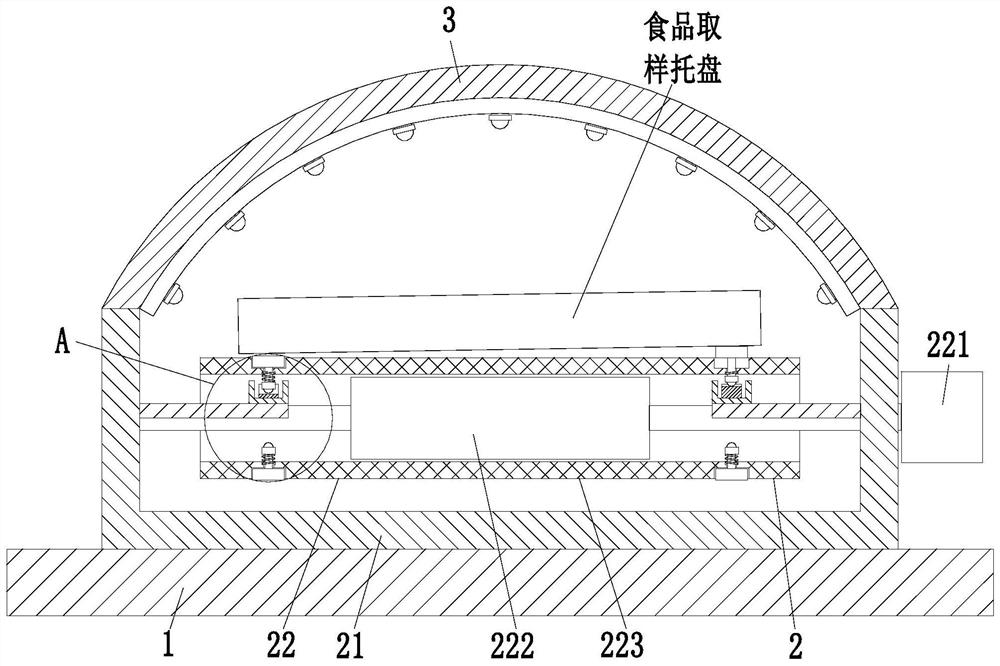

Food sampling tool disinfection device

ActiveCN113060516AEfficient deliveryImprove the bactericidal effectConveyorsConveyor partsEnvironmental engineeringFood products

The invention relates to a food sampling tool disinfection device. The device comprises a bottom plate, a conveying device and a disinfection device, the conveying device is installed in the middle of the upper end of the bottom plate, the disinfection device is installed at the upper end of the conveying device, and the cross section of the disinfection device is of an arc-shaped structure. The device can solve the problems that when existing equipment is used for disinfecting and processing a food sampling tool, the food sampling tool cannot be driven to swing left and right, so that the side face of the food sampling tool is not in complete contact with disinfectant fluid, the disinfection effect of the food sampling tool is poor, and disinfection is insufficient. Meanwhile, the problems that when the existing equipment is used for disinfecting and processing the food sampling tool, the food sampling tool cannot be effectively overturned, so that impurities such as food residues, wastes and the like remain at the bottom of the food sampling tool, the surface of the food sampling tool is easily polluted when the food sampling tool is stacked, the follow-up detection effect of foods is influenced and the like are solved.

Owner:芜湖国泰数字检测认证研究院有限公司

Lead frame plate placing and pushing-out equipment for semiconductor cutting

InactiveCN112086389AAvoid manual handling and placementImprove tailoring efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringStructural engineering

The invention discloses lead frame plate placing and pushing-out equipment for semiconductor cutting. The lead frame plate placing and pushing-out equipment comprises a base, a top frame and a secondmotor. An arc-shaped hole is formed in the rear side of the base, a detection hole is formed in the rear side of the base, the detection hole is located in the right of the lower end of the arc-shapedhole, a sensor is fixed to the rear side of the base, the sensor and the detection hole are arranged in a front-back corresponding mode, and two transmission rollers are rotationally arranged in thebase and are in transmission connection through a belt. A first motor is fixed to the front side of the base, the output end of the first motor penetrates through the front side of the base to be fixed to the front end of one of the transmission rollers, and an electric push rod is fixed to the rear side of the base. According to the lead frame plate placing and pushing-out equipment for semiconductor cutting, the lead frame plates can be placed into the equipment without stop, then the lead frame plates are turned over to be placed and pushed into the cutting device, manual taking and placingare avoided, and the cutting efficiency is improved.

Owner:李锋

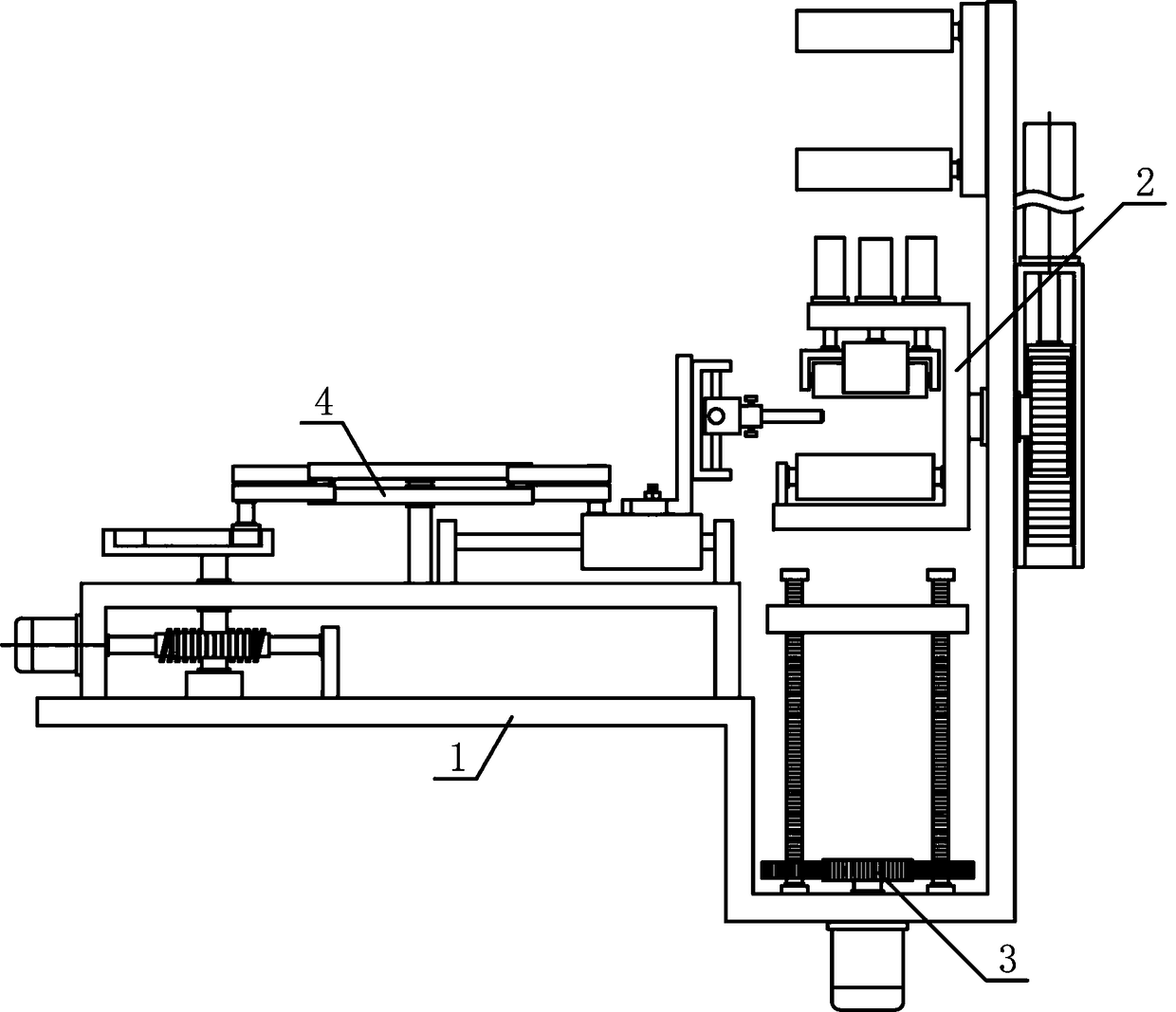

Ceramic floor tile paving device

InactiveCN101832019BSimple structureFlip AccurateBuilding constructionsVehicle framePneumatic circuit

The invention discloses a ceramic floor tile paving device. The device comprises a frame, a turnover mechanism, a lifting mechanism and a power system, wherein the frame comprises a bottom plate and universal wheels, the positioning ends, corresponding to a crank and a rocker, at the left end of the bottom plate are provided with protruding platforms used for hinged connection, the middle sectionof the bottom plate is hinged with a main air cylinder, and the power system is arranged at the right end of the bottom plate; the turnover mechanism is provided with a connecting bar, the rocker andthe crank, which are connected in sequence to form a four-bar mechanism which takes the positioning end of the crank as the shaft and can be driven by the main air cylinder to repeatedly overturn 180degrees; the lifting mechanism uses a secondary air cylinder at the bottom end of the connecting bar as a power component, wherein an extending end of a piston rod is centered and connected with a flat plate; 4 to 9 suction disks, which are connected in series and controlled to be connected or disconnected by a valve, are uniformly distributed on the outer end surface of the flat plate; and the power system is provided with an air compressor and air storage tank, and the main air cylinder and the secondary air cylinder are connected by an air supply tube to form a pneumatic circuit. When the device is used, the ceramic floor tiles which are horizontally placed and wait for paving overturn 180 degrees for vertical descent paving, and because the floor tiles are in parallel contact with a base material, the paving quality is good, the working efficiency is high and the labor intensity of workers is lowered.

Owner:JINCHEN GROUP

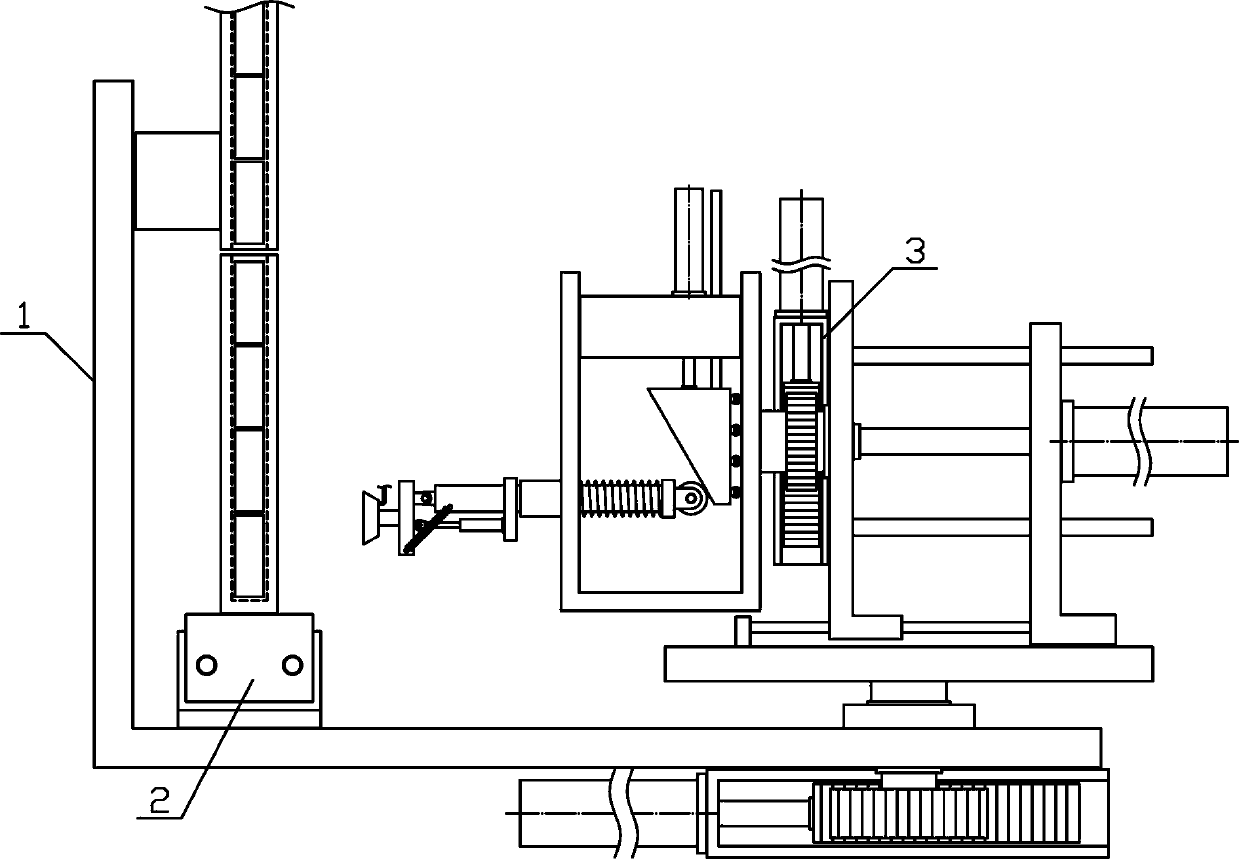

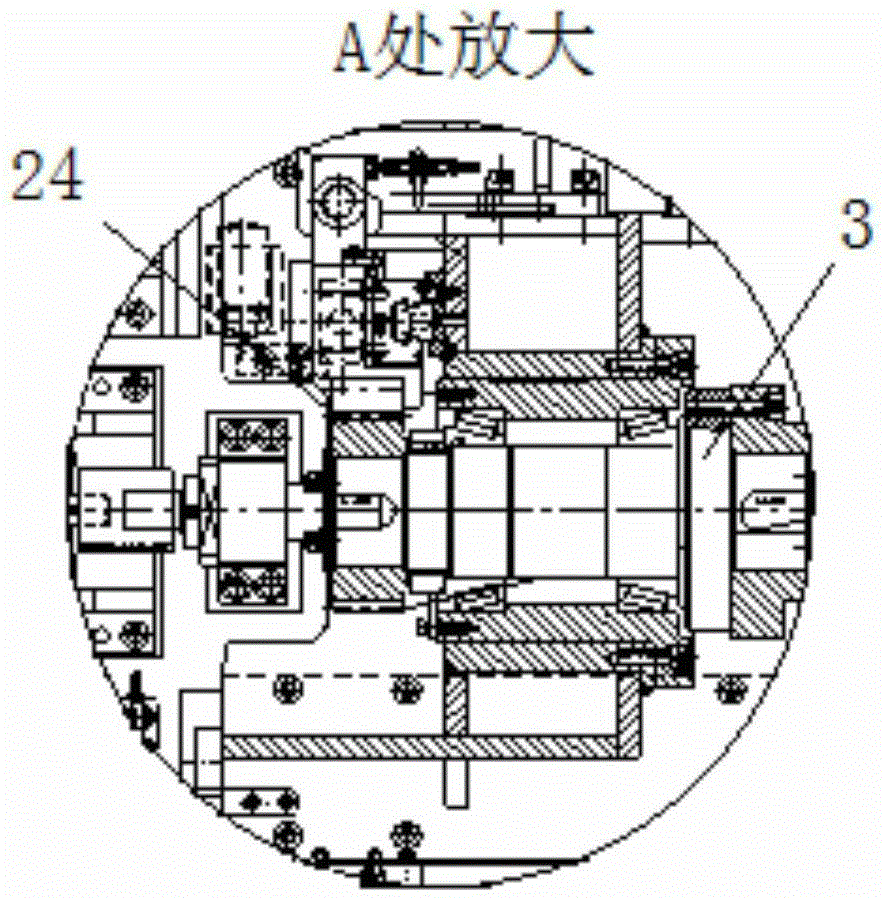

Turnover guiding machining mechanism for aluminium profile

PendingCN109262023AHigh degree of automationReasonable structural designMetal working apparatusBoring/drilling componentsPunchingMechanical equipment

The invention discloses a turnover guiding machining mechanism for an aluminium profile, and belongs to the field of profile machining mechanical equipment. A profile turnover mechanism and a profileguiding mechanism are successively arranged on one side of a fixed base from top to bottom, a profile punching mechanism is horizontally arranged on the portion, on one side of the profile turnover mechanism, of the fixed base, and a plurality of material conveying rotary rollers are successively arranged on a material conveying bracket horizontally; material bearing guide rollers are horizontallyand rotatably connected to the two sides of a material bearing bracket on the lower side of a turnover bracket respectively, the two sides of a profile bearing plate are in threaded connection with material guiding lead screws on the two sides of the fixed base respectively, an adjusting connecting plate is vertically arranged on the upper side of a translation connecting plate, and a punching pressing rod is horizontally arranged on one side of an adjusting guide plate. The mechanism is reasonable in structural design, the aluminium profile horizontally conveyed can be perpendicularly turnedover stably and accurately so that the aluminium profile can be continuously punched and machined in the successive material guiding process in the vertical direction, the automation degree of machining the aluminium profile is improved, and the requirements of machining and using are met.

Owner:ZHEJIANG ZHUOYI ALUMINUM

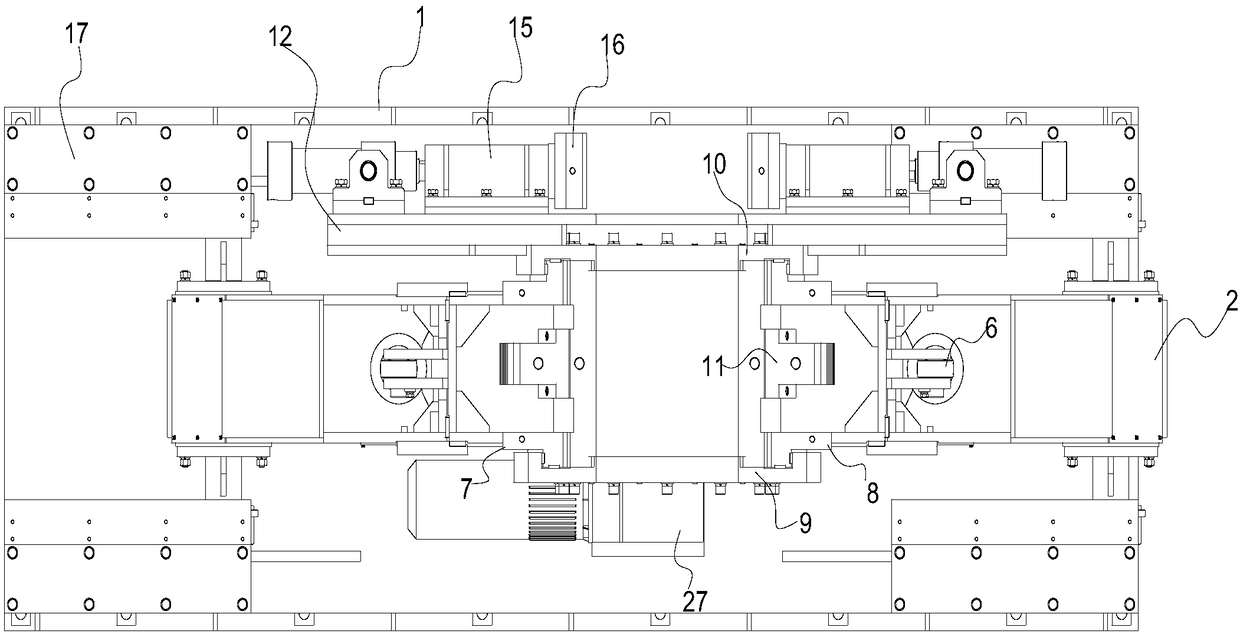

Punching and flanging integrated machine for rectangular pipes

PendingCN108580718APunching realizationImprove adaptabilityMetal-working feeding devicesVehicle componentsPunchingFlanging

The invention discloses a punching and flanging integrated machine for rectangular pipes. The machine comprises a rack; a punching main machine capable of realizing punching from top to bottom or frombottom to top; a punching lifting support platform for placing and lifting the rectangular pipes to selecting the upper plate parts or the lower plate parts of the rectangular pipes to be punched; aflanging main machine for flanging the upper plate parts or the lower plate parts of the rectangular pipes; a flanging feeding platform which is used for clamping the rectangular pipes on the platformand feeding to ensure that the ends of the rectangular pipes are matched with the flanging main machine for flanging; a 90-degree flipping device comprising a flipping support platform which is fixedon the rack and located at a flipping station, wherein a 90-degree flipping mechanism for clamping the rectangular pipes to rotate by 90 degrees is arranged at one end of the flipping support platform; a first manipulator; and a second manipulator. The punching and flanging integrated machine has the advantages that the punching of two opposite plate parts at the ends of the rectangular pipes andthe flanging of the other two opposite plate parts can be completed, so that the automation of punching and flanging is realized and the processing accuracy and the processing efficiency are increased.

Owner:金凯达(佛山)智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com