Punching and flanging integrated machine for rectangular pipes

A rectangular tube and integrated machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of cumbersome processing, low efficiency, and difficulty in ensuring the consistency of punching or folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below through specific examples.

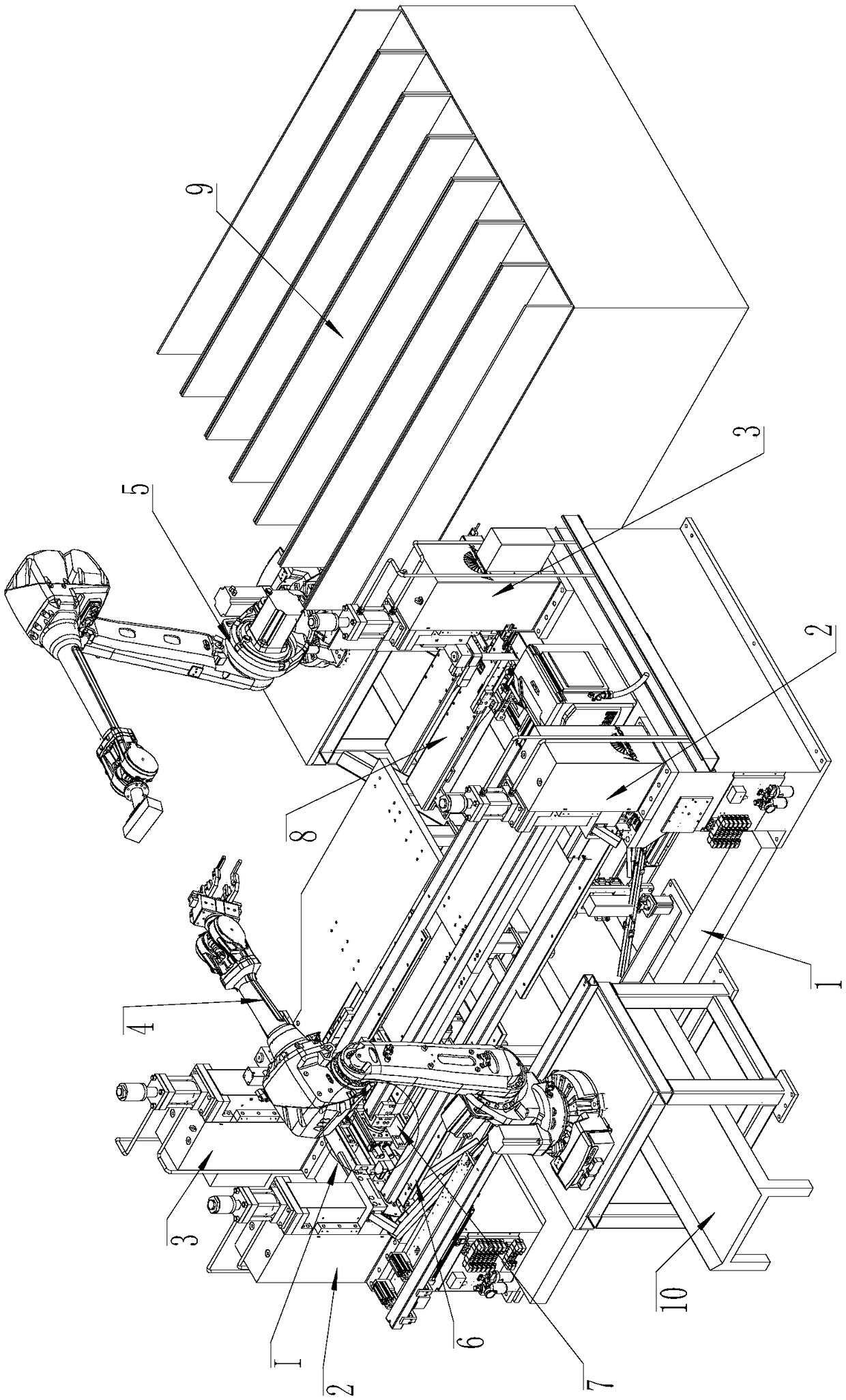

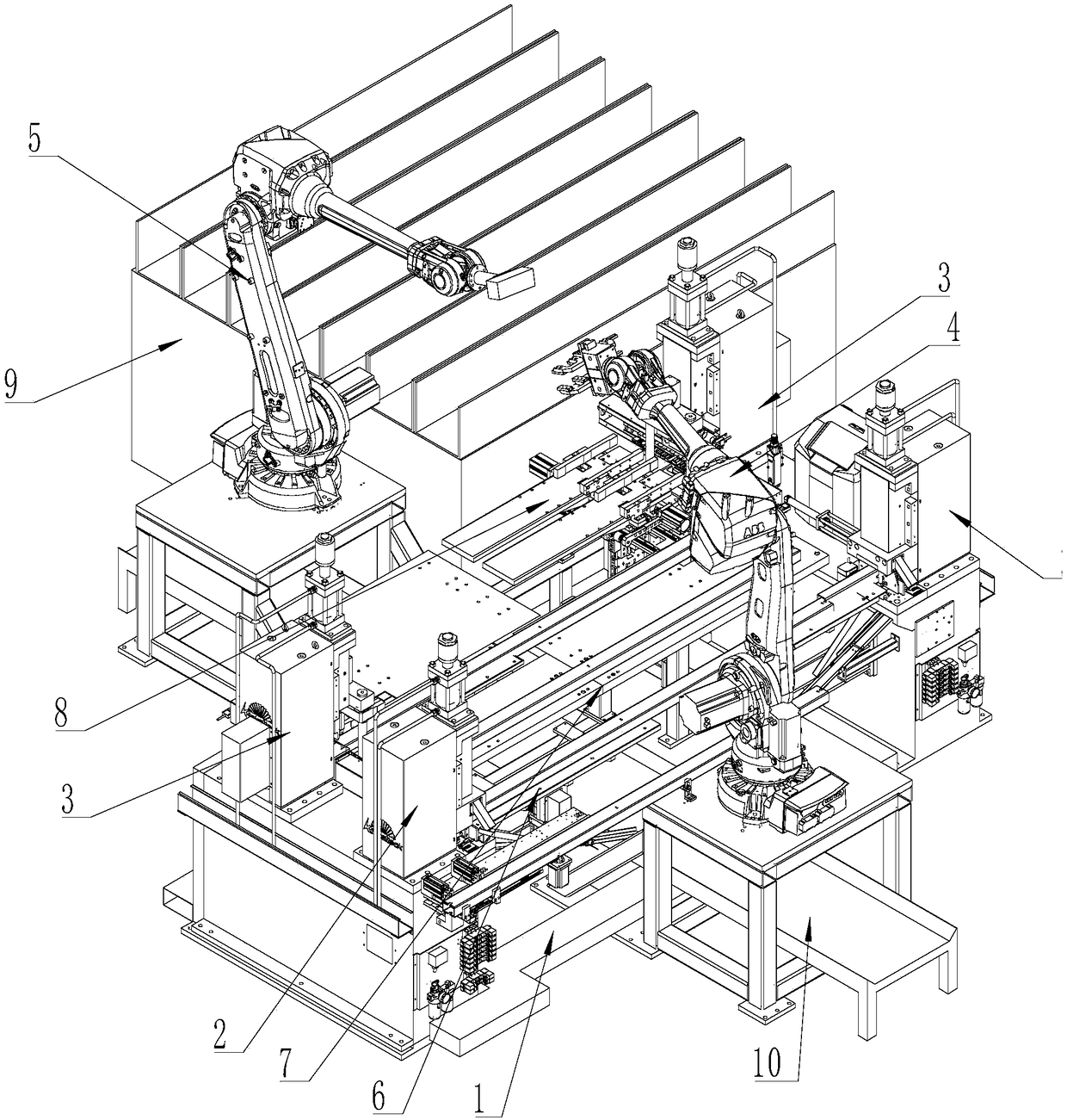

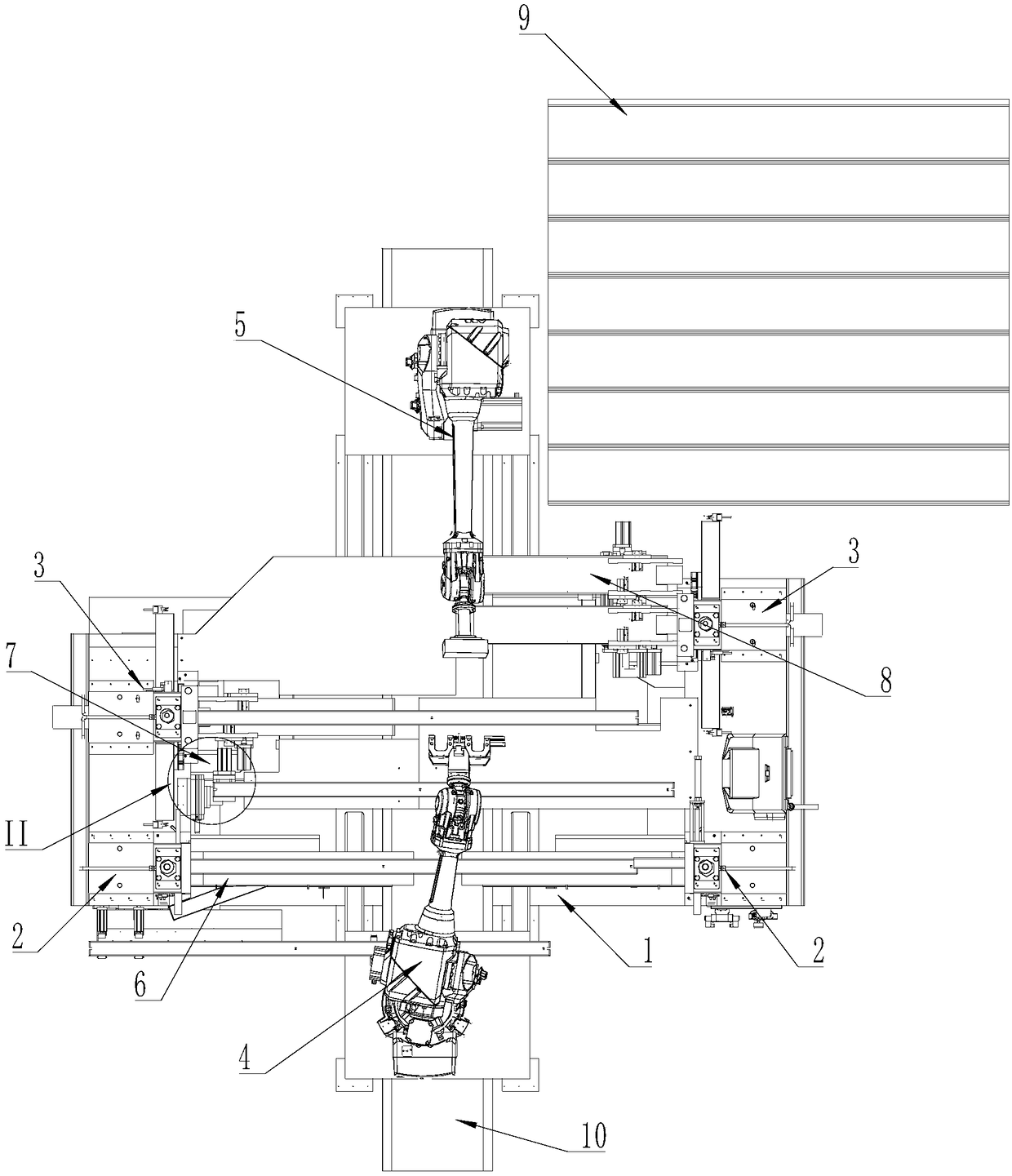

[0055] Such as Figure 1 to Figure 21 As shown, an integrated punching and folding machine for rectangular tubes includes a frame 1, which is the load-bearing support for all equipment.

[0056] The all-in-one machine also includes a punching host 2, which is arranged at the end of the frame 1, from figure 1 and figure 2 and image 3 It can be seen that in this embodiment, there are two punching main machines 2, which are respectively located at the two ends of the frame 1 for supporting use, that is to say, the all-in-one machine can be used to punch holes at both ends of a rectangular tube, Each punching main engine 2 is all cooperated with the punching lifting platform, utilizes the lifting of the punching lifting platform to switch the punching of the upper plate portion or the punching of the lower plate portion.

[0057] Such as Figure 6 to Figure 11As shown, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com