Patents

Literature

39results about How to "Punching realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

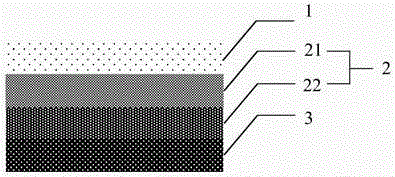

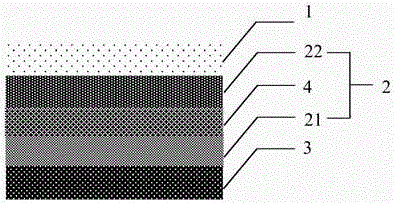

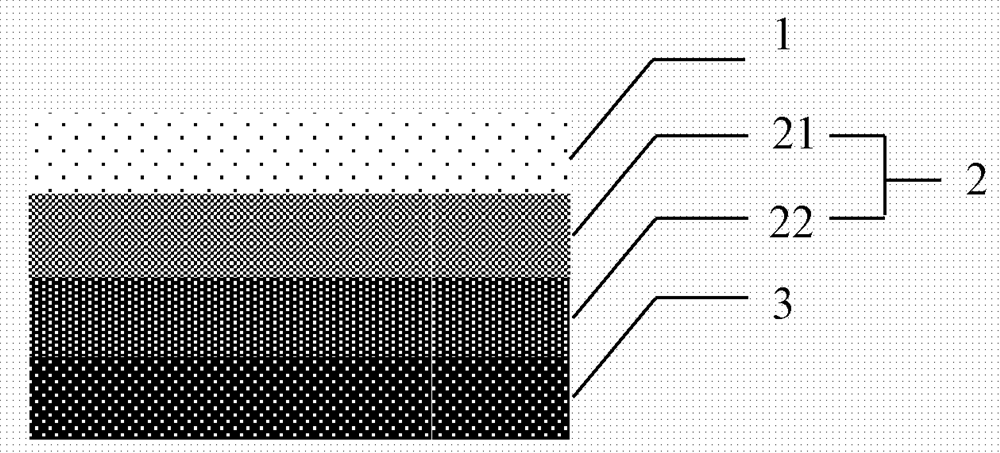

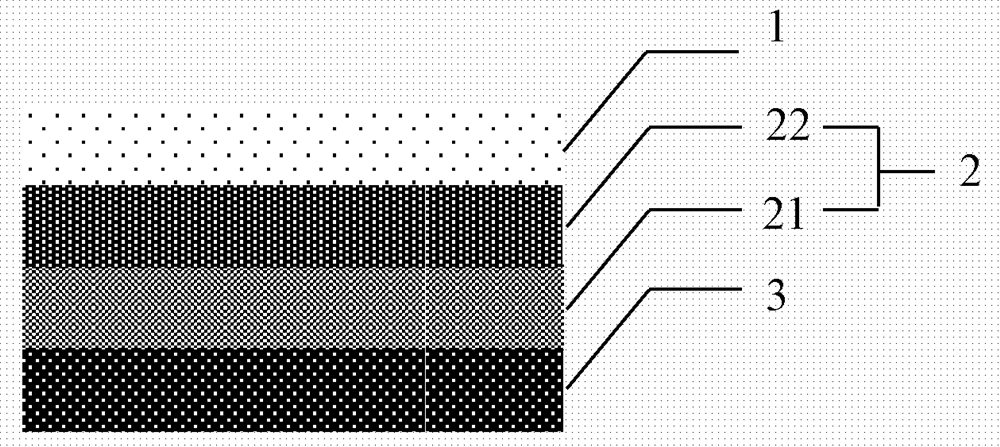

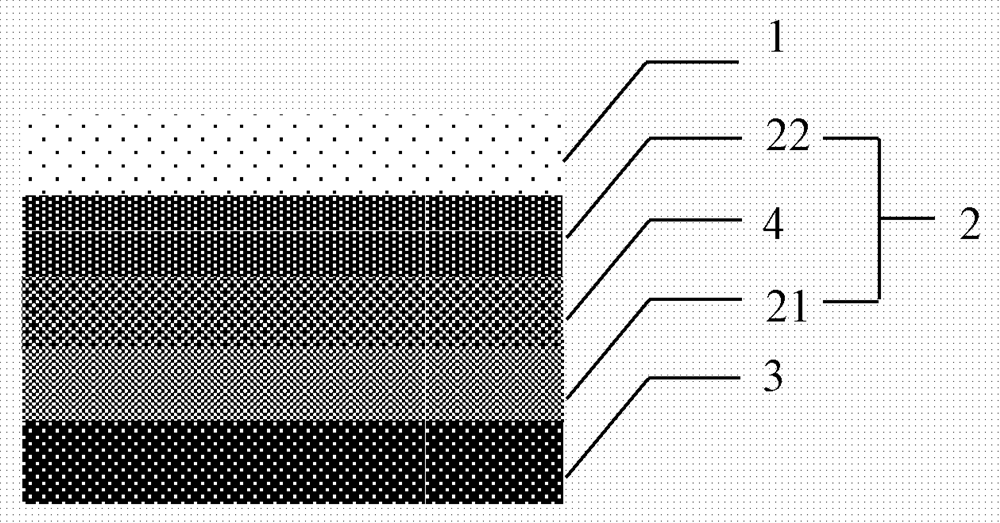

Extremely-thin flexible heat-radiation film and method for manufacturing the same

ActiveCN106531902AImprove cooling effectEasy to slimSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLayer group

The invention, which relates to the electronic material field, discloses a flexible heat-radiation film and a method for manufacturing the same. The heat-radiation film comprises a carrier film, a protection film layer, and at least one heat radiation layer group arranged between the carrier film and the protection film layer. The heat radiation layer group includes a heat-radiation adhesive film layer for horizontal heat transferring and a heat-radiation metal film layer at least being superposed on one surface of the heat-radiation adhesive film layer ad being used for longitudinal heat transferring, so that the heat radiation layer group having bidirectional heat transferring is formed. The heat-radiation adhesive film layer is made from raw materials including magnetic high-thermal-conductivity powder and resin. For the heat-radiation metal film layer, a material source is processed by a physical means to form atoms or molecules and then the atoms or molecules are deposited on the surface of the heat-radiation adhesive film layer. According to the heat-radiation film, the operation becomes simple; and the formed film layers are light, thin and compact. The flexible heat-radiation film can be applied to various electronic products and communication equipment.

Owner:广州宏庆电子有限公司

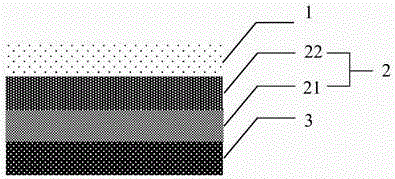

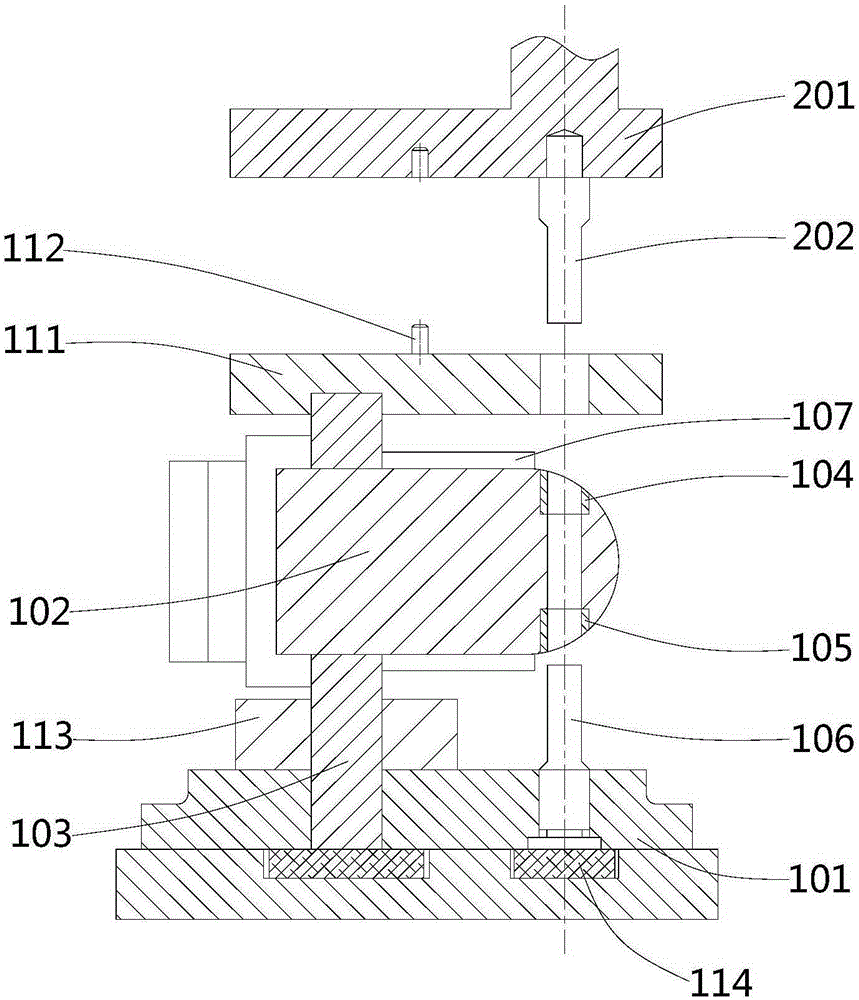

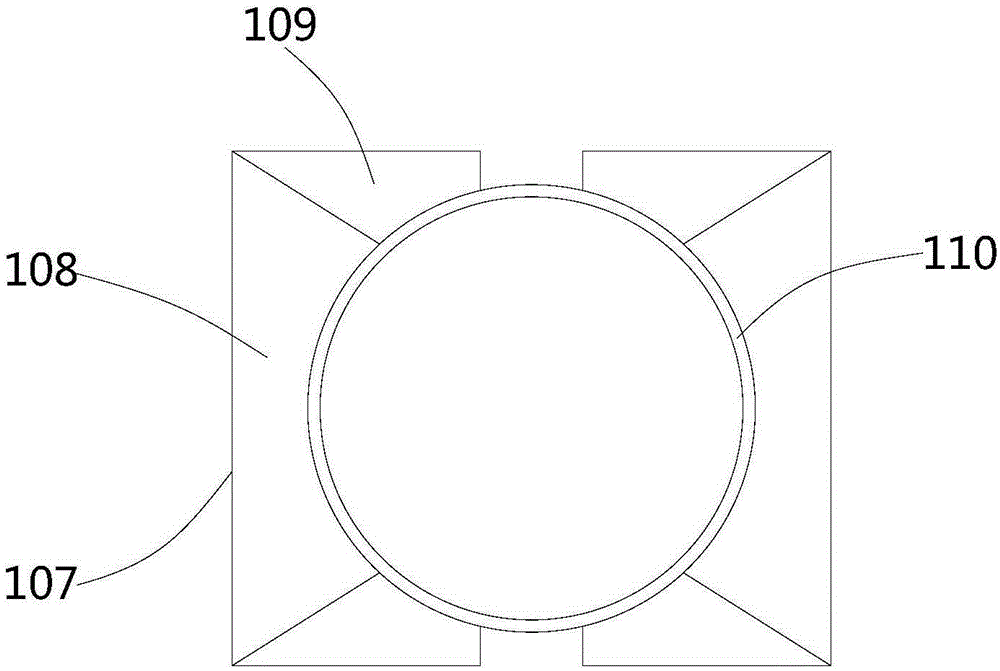

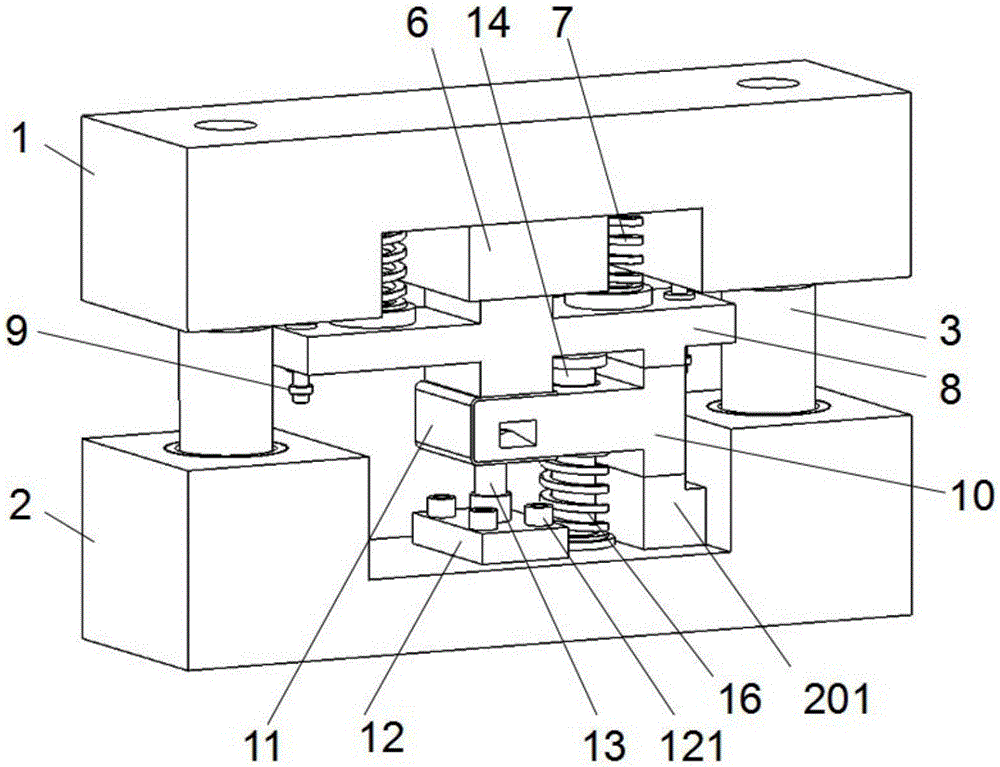

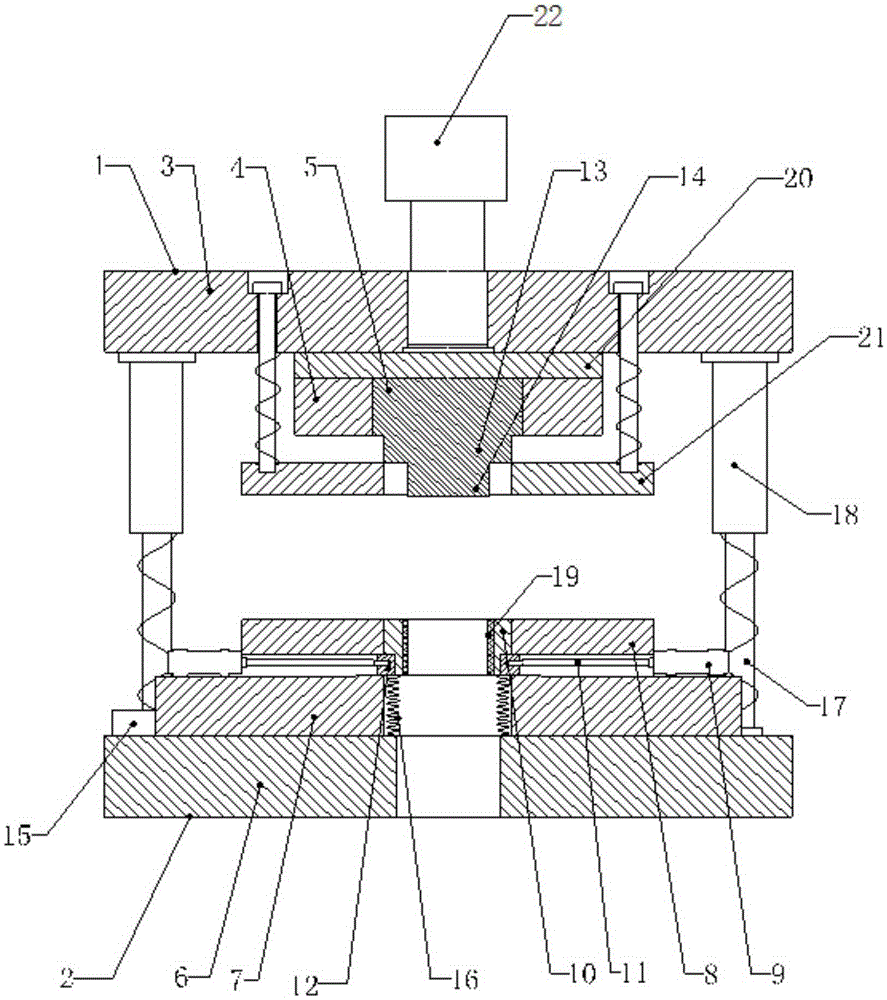

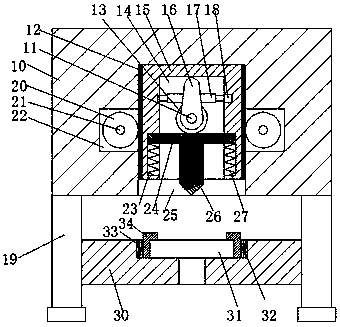

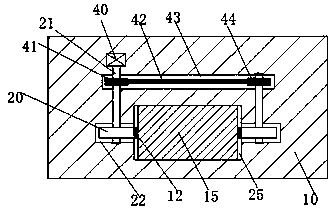

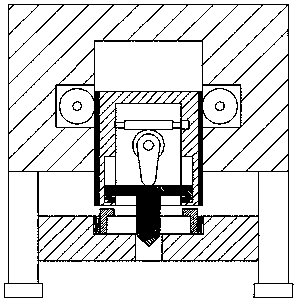

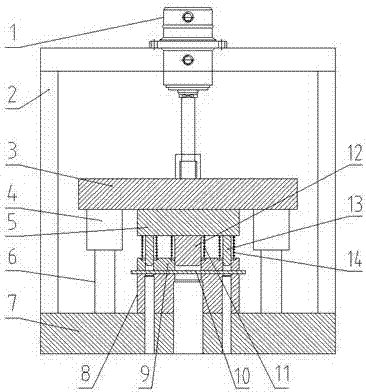

Spherical surface cantilever type bi-directional punching die

ActiveCN105215149AEasy to fixGuaranteed to proceed normallyPerforating toolsMetal-working feeding devicesPunchingSpherical shaped

The invention provides a spherical surface cantilever type bi-directional punching die and belongs to the field of punching dies. The punching die comprises a lower die base and an upper die base. The lower die base is provided with a cantilever part. One end of the cantilever part is connected with the lower die base through a female die fixing base. The other end of the cantilever part serves as a working end. The working end is provided with a spherical surface. The spherical surface is provided with an upper female die body and a lower female die body in a vertically opposite mode. The upper die base is provided with an upper male die body. The lower die base is provided with a lower male die body. The upper male die body corresponds to the upper female die body. The lower male die body corresponds to the lower female die body. Clamping blocks are arranged at the positions, close to the left side and the right side of the working end, of the lower die base respectively. The clamping blocks are detachably connected with the lower die base. The spherical surface cantilever type bi-directional punching die can punch spherical surface work-pieces synchronously in two directions, the work-pieces do not need to be punched one by one, machining efficiency is improved, punching precision is greatly improved, deformation of the spherical surface work-pieces in the punching process is reduced, and the machining quality of the manufactured work-pieces is ensured.

Owner:启东市鸿洋润滑产品有限公司

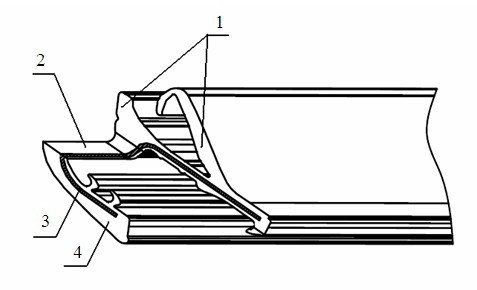

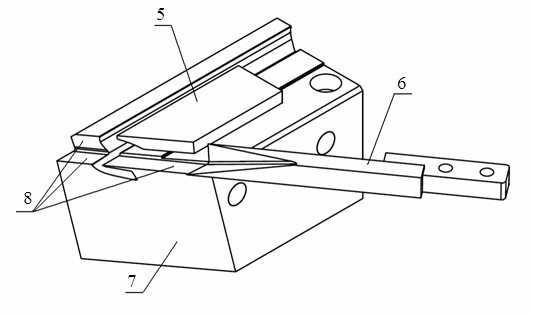

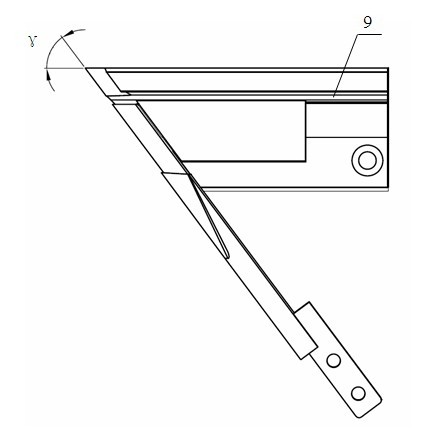

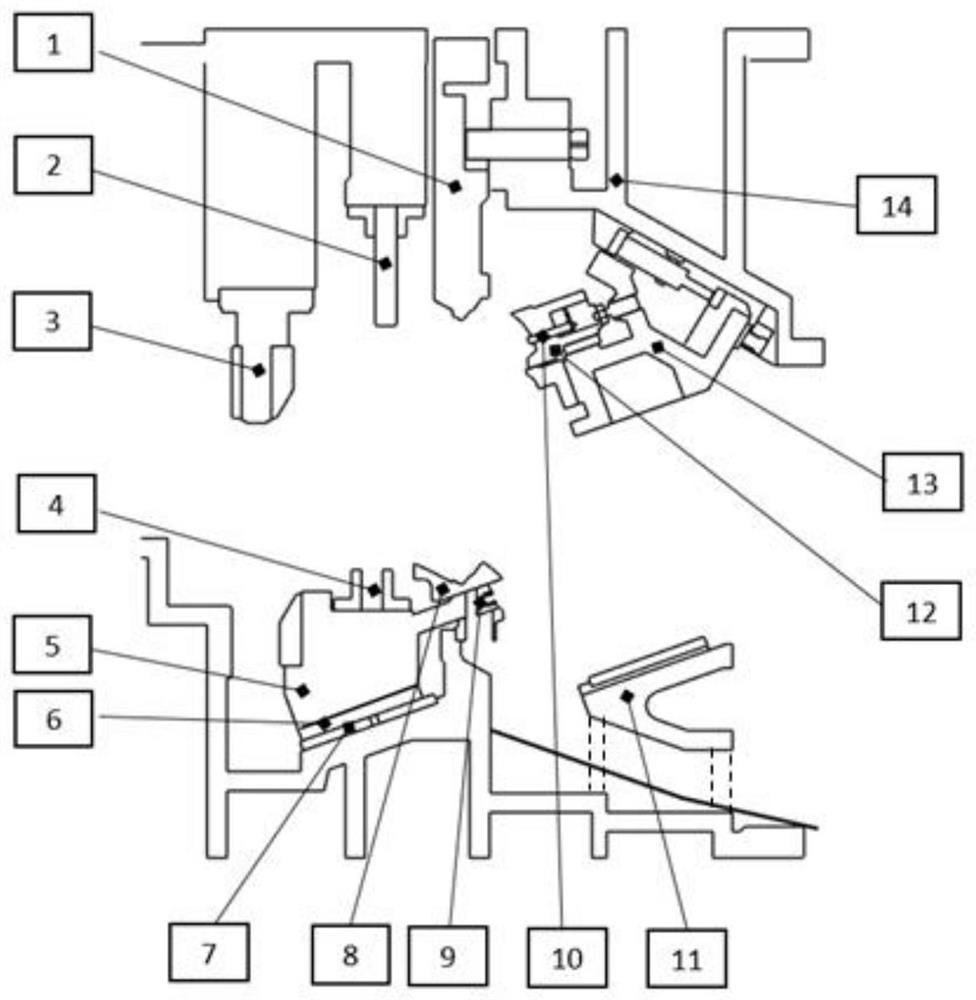

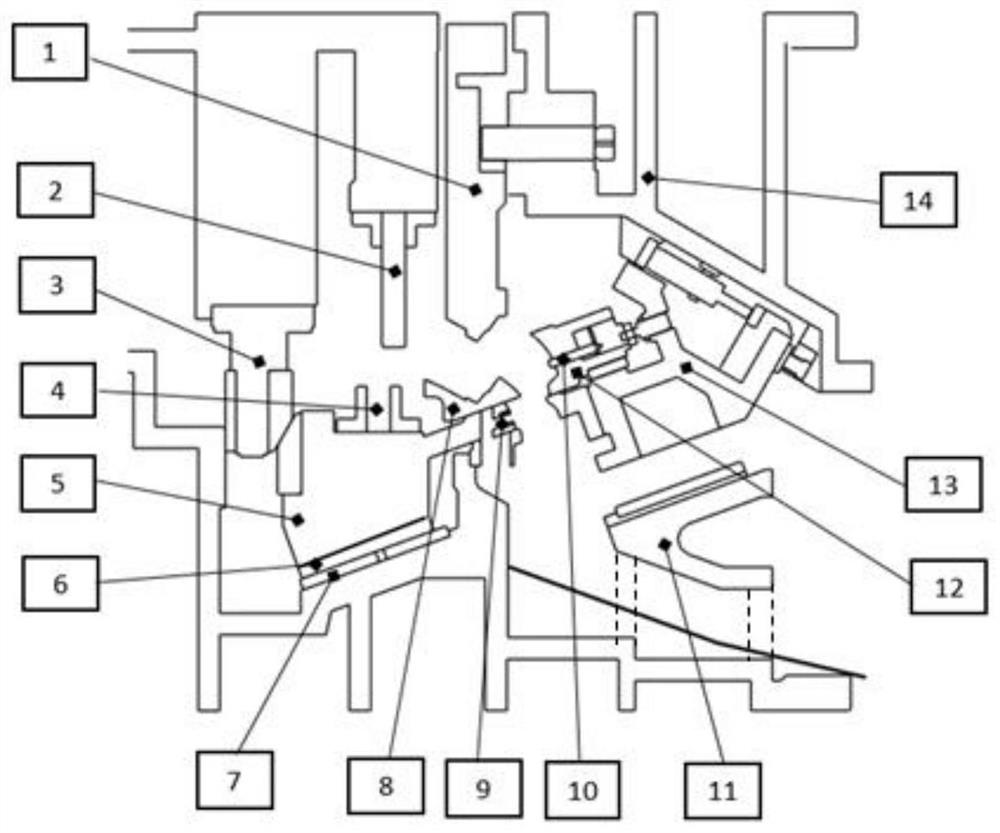

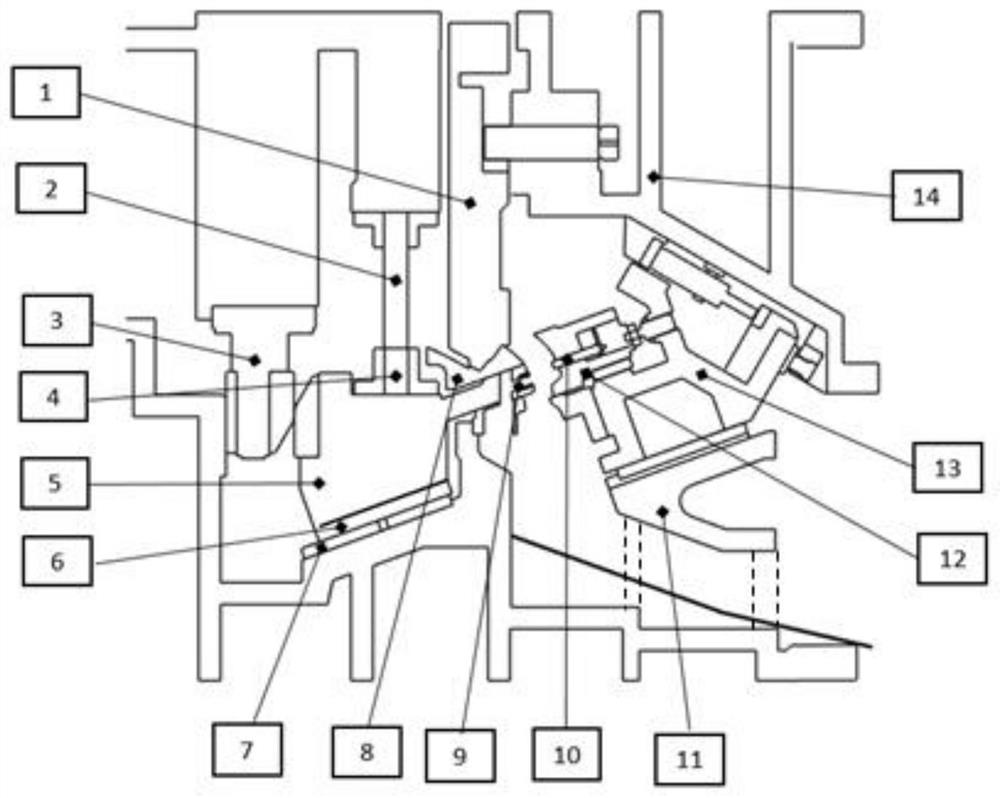

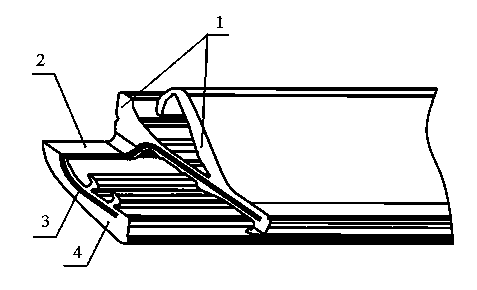

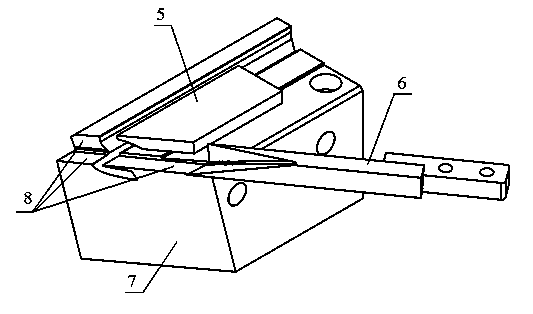

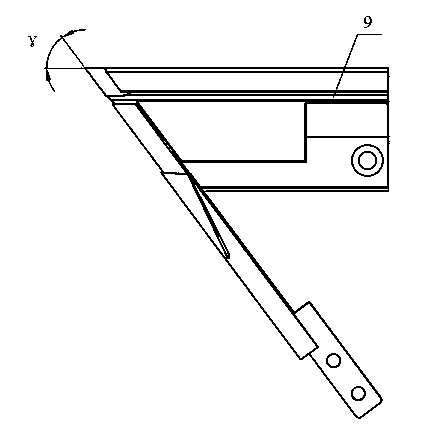

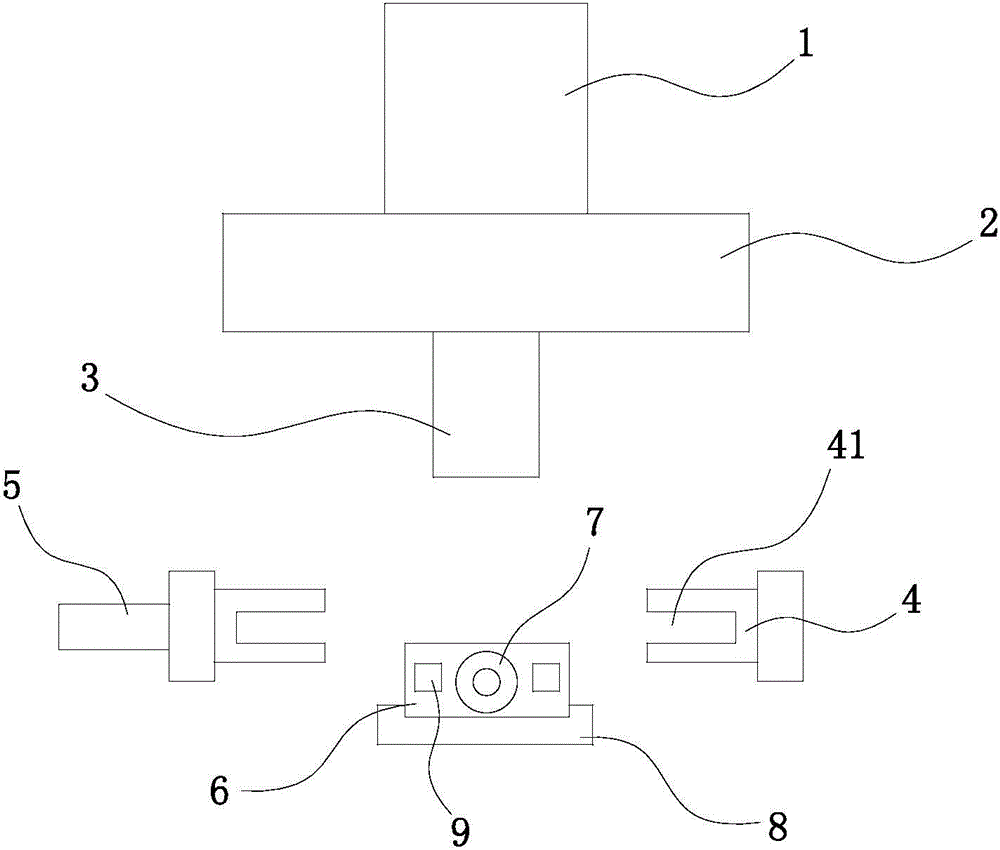

Punching device preventing automobile sealing strip with skeleton from machining deformation

A punching device preventing an automobile sealing strip with a skeleton from machining deformation comprises a female die 7, a pressure plate 5 and a cutter 6, and is characterized in that a groove 9 for placing the sealing strips and a guide mechanism 8 for guiding the cutter 6 to finish the punching operation are arranged on the female die 7; the guide mechanism 8 is intersected with the groove 9 to form a guiding included angle Gamma; the cutter 6 is provided with a horizontal cutting edge 12 and a vertical cutting edge 10; the moving direction of the horizontal cutting edge 12 and the moving direction of the cutter 6 form a cutting edge included angle Beta 1; one end, far from the pressure plate 5, of the horizontal cutting edge 12 inclines towards the punching advance direction of the cutter 6; the cutting edge included angle Beta 1 is smaller than the guiding included angle Gamma; in punching, the sealing strips are cut step by step by the horizontal cutting edge 12 at first, then are cut by the vertical cutting edge 10, so that the impulsive force of the cutter 6 on the sealing strips is reduced, and the deformation of the sealing strips is further reduced, the incision surfaces of the sealing strips are smooth, and the skeleton deformation is avooided.

Owner:瀚德(中国)汽车密封系统有限公司

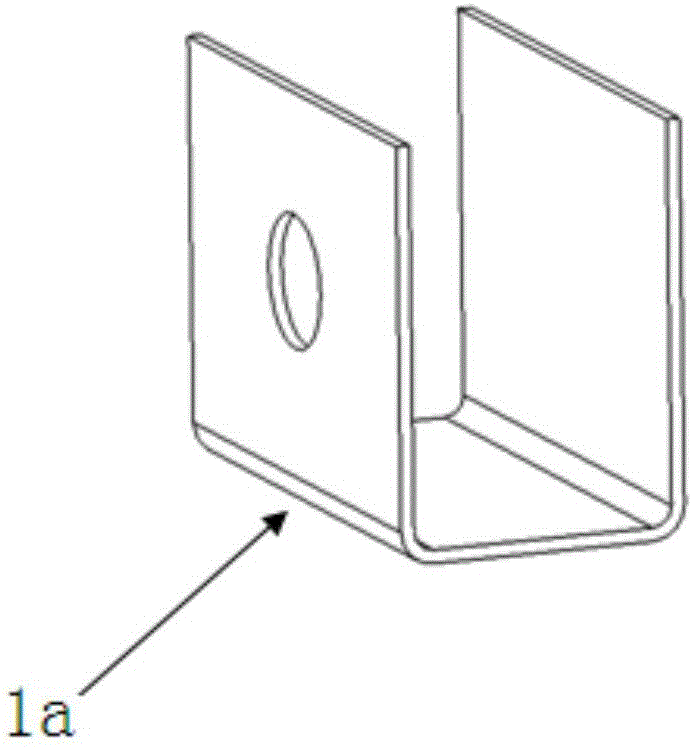

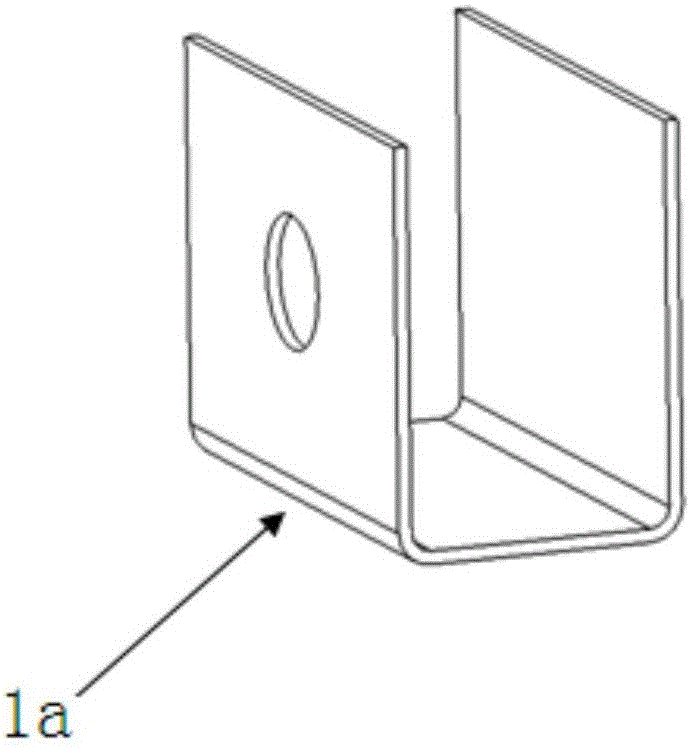

Hole-punching mold

The invention discloses a hole-punching mold. The U-shaped parts punching include lower die base and upper die base. The fixed block is fixed at the bottom of upper die base and the lower fixed block is installed on the top of the lower die base. The piercing die extends outside along the middle of the lower fixed block. There is one location hole longitudinally set on the piercing die. The hole-piercing punch is vertically set by directly facing the location hole at the bottom of the upper fixed block. The hole-piercing punch is of cylindrical structure matched with the location hole. In the invention, several U-shaped parts match with piercing die. The upper die base moves downwards, the hole-piercing punch goes through punched parts and location hole successively, thus punching U-shaped parts. The device is of simple structure and can be used easily.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

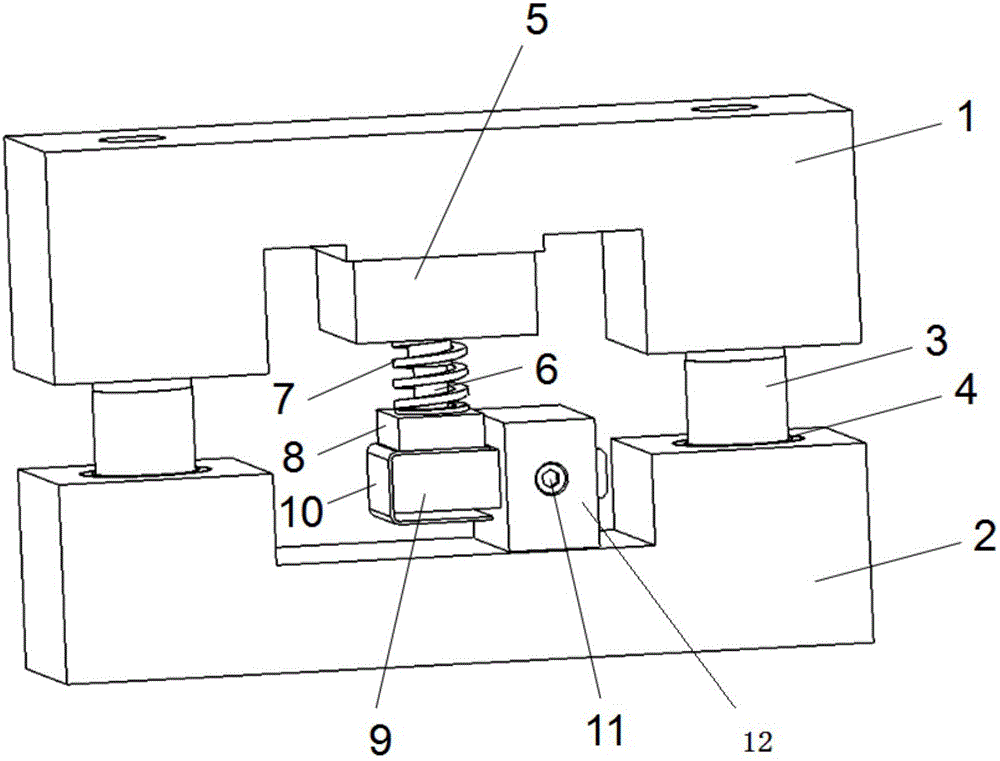

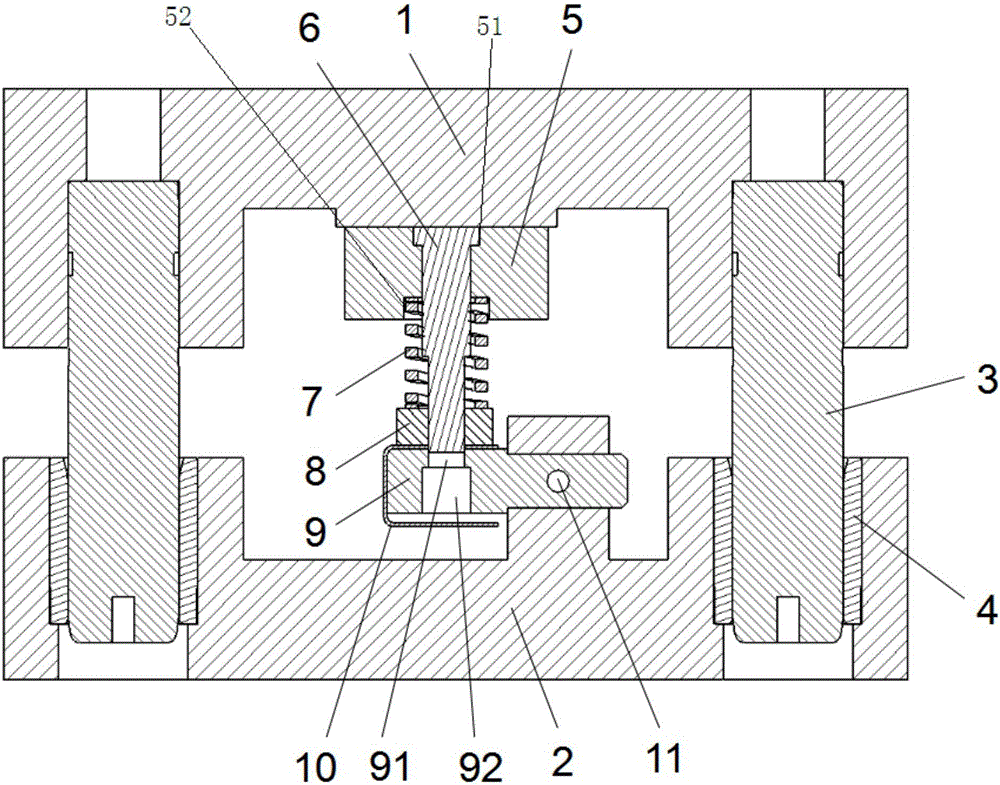

Punching die

The invention discloses a punching die which is punching holes in a part shaped like a Chinese character 'ji'. The punching die comprises a lower die base, an upper die base, an upper fixing block and a lower fixing block, wherein the upper fixing block is fixed to the bottom face of the upper die base, and provided with an upper punching head, and the lower fixing block is installed on the top face of the lower die base and provided with a lower punching head; the punching die further comprises a punching female die which is of a T-shaped structure, and the punching female die comprises a head and a fixing part horizontally extending out along the middle of the head; and the head is vertically installed on the lower die base, the fixing part is suspended between the upper punching head and the lower punching head, and a guide hole is formed in the fixing part. According to the scheme, the punching female die is of the T-shaped structure, the part shaped like the Chinese character 'ji' is matched with the punching female die, the upper die base drives the upper punching head to downwards move, and punching of the part shaped like the Chinese character 'ji' is achieved. The punching die is simple in structure and convenient to use.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automatic compounding equipment for coiled RFID hang tags

PendingCN113276534AFast automatic processingGlue to achieveLiquid surface applicatorsLamination ancillary operationsMechanical engineeringEmbedded system

The invention discloses automatic compounding equipment for coiled RFID hang tags. According to the technical scheme, the automatic compounding equipment for the coiled RFID hang tags is characterized in that the automatic compounding equipment for the coiled RFID hang tags comprises a rack, the rack is provided with a surface paper air swelling shaft used for conveying surface paper, a surface paper gluing mechanism used for gluing the surface paper, a chip air swelling shaft used for rolling an RFID chip, a chip cutting and conveying mechanism used for cutting and attaching the RFID chip to the surface of the surface paper, a backing paper air swelling shaft used for conveying backing paper, a backing paper gluing mechanism used for gluing the backing paper, a compounding assembly used for compounding the glued backing paper and the glued surface paper, and a shearing assembly is used for cutting the compounded backing paper and the compounded surface paper into the RFID hang tag, wherein the structure of the backing paper gluing mechanism is consistent with that of the surface paper gluing mechanism. According to the invention, automatic combined processing of the RFID tags is achieved, the convenience of processing the RFID tags is improved, and the processing efficiency of the RFID tags is improved.

Owner:君爱智能标签科技(浙江)有限公司

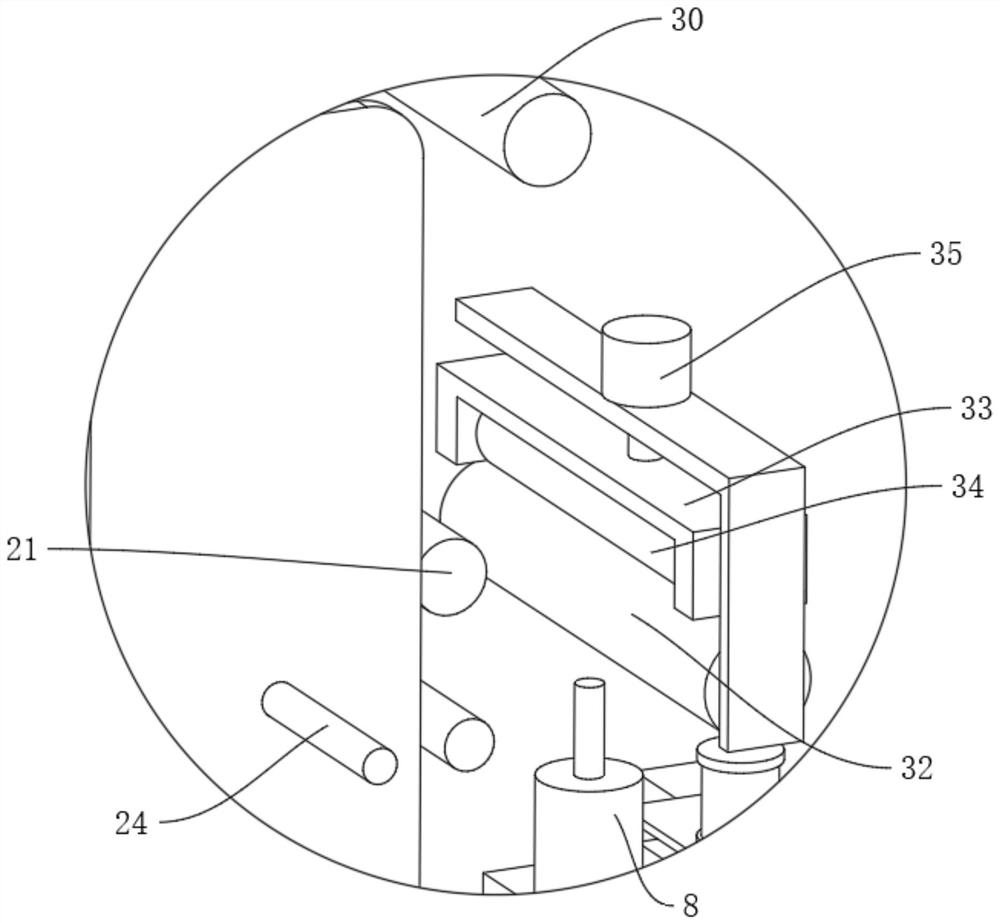

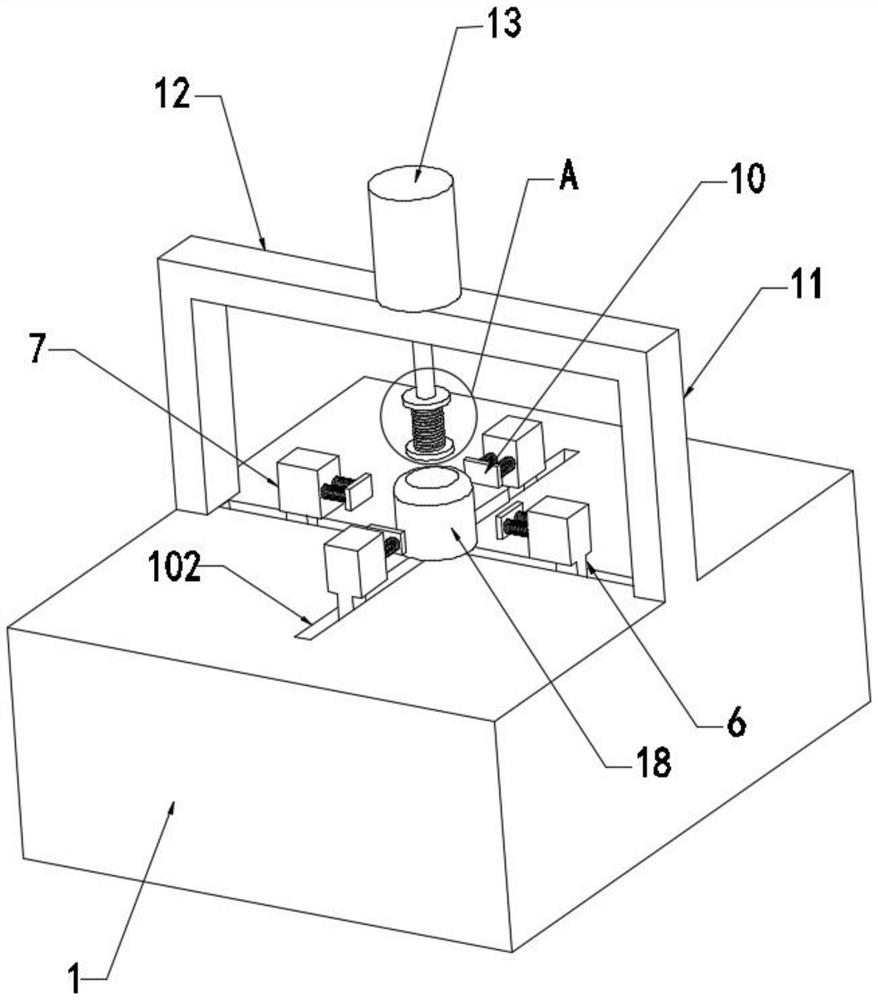

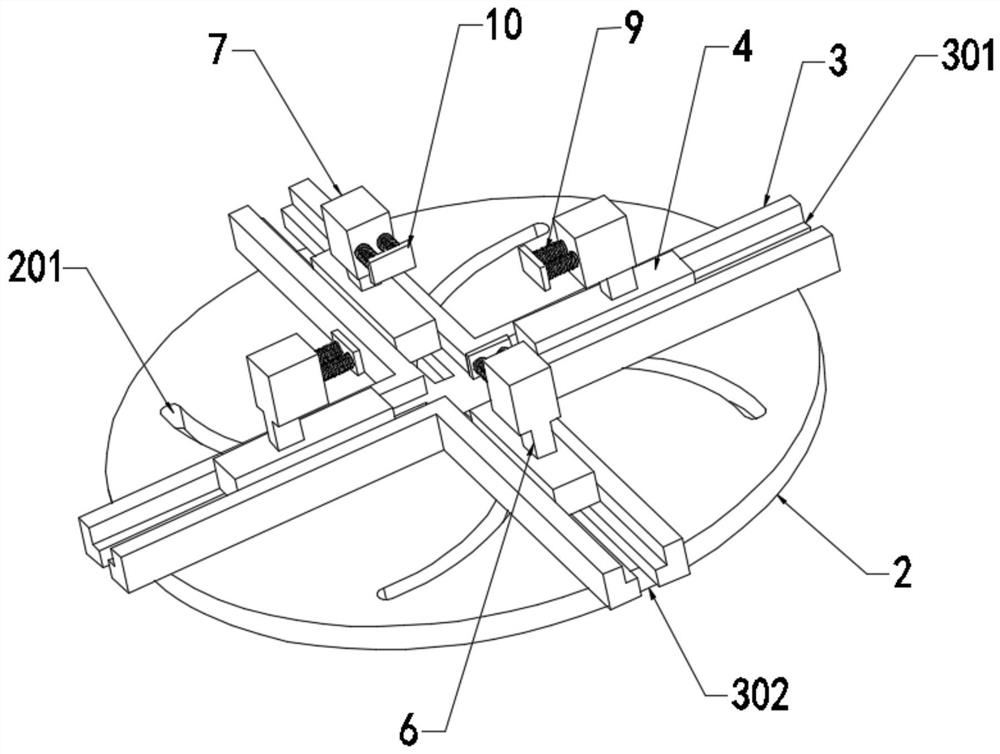

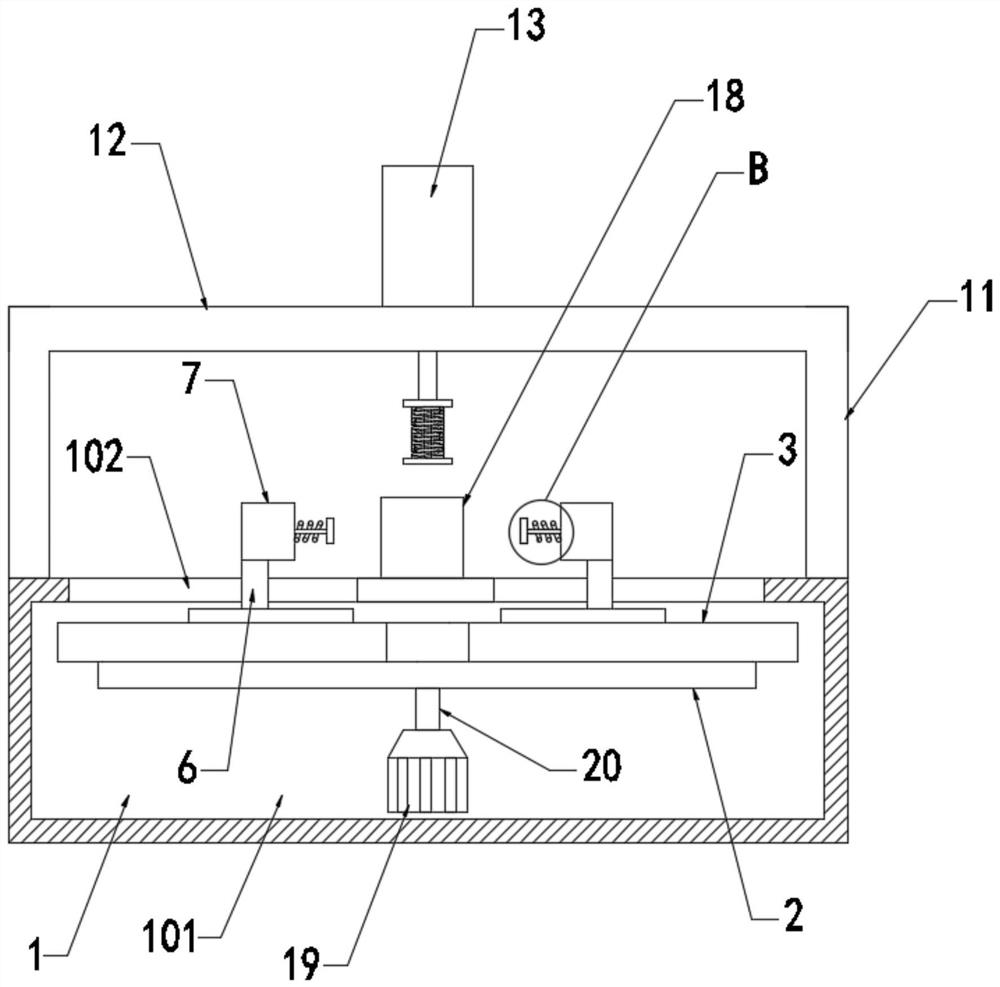

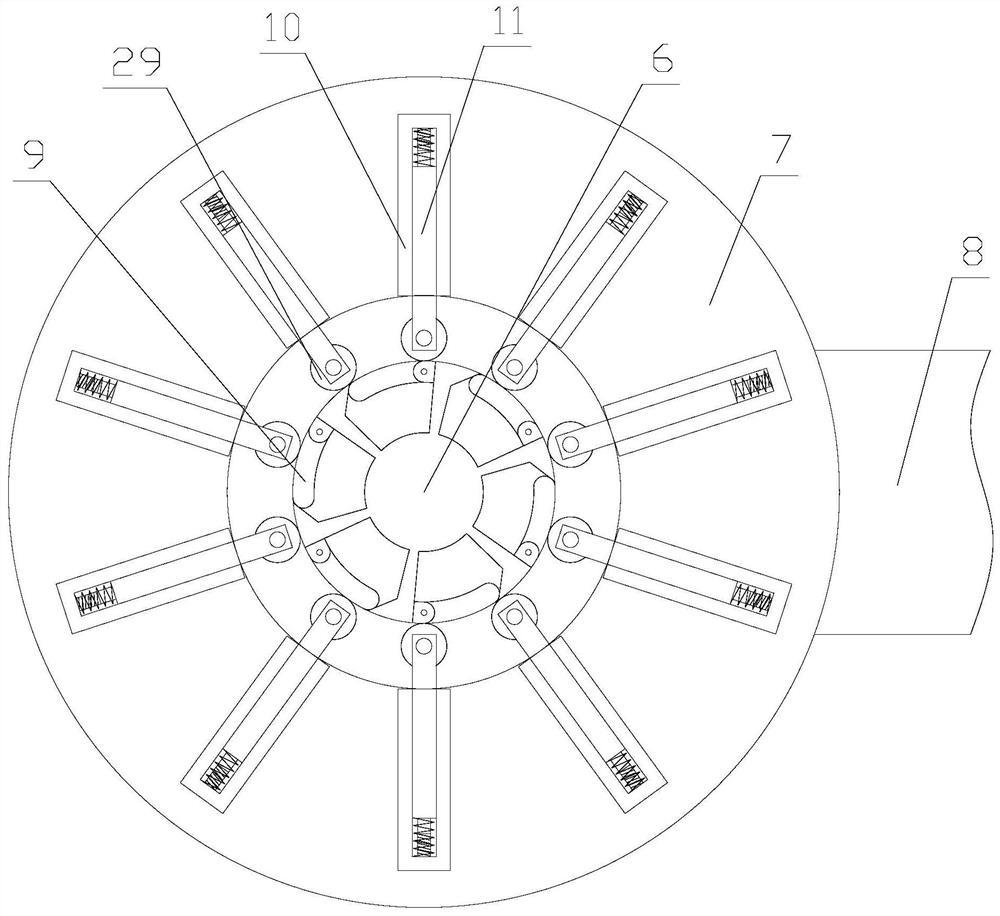

Battery steel shell metal plate punching tool

PendingCN113351736APunching realizationEasy to operateVibration suppression adjustmentsPunchingElectrical battery

The invention discloses a battery steel shell metal plate punching tool. The battery steel shell metal plate punching tool comprises a base, a first mounting groove is formed in the base, a rotating disc is rotationally mounted in the first mounting groove, four arc grooves which are obliquely formed are formed in the rotating disc, and the four arc grooves are formed in the rotating disc around the axis of the rotating disc at equal angles. According to the battery steel shell metal plate punching tool, a battery steel shell is placed on a convex block, a piston rod of an air cylinder is started to stretch out, a baffle is driven to move downwards, a buffer plate is pressed on the battery steel shell to fix the battery steel shell, a driving motor is started to rotate, a transmission shaft is driven to rotate, the rotating disc is driven to rotate, sliding rods slide in the arc grooves to drive sliding blocks to slide in sliding grooves, then four mounting bases are driven to move inwards, four stamping blocks are driven to move inwards to punch the battery steel shell, therefore, punching of the battery steel shell is achieved, operation is easy, the number of punching processes is small, the production time is shortened, and the production efficiency is improved.

Owner:安徽捷盛科技有限公司

Corrugated paper punching machine

InactiveCN112248099APunching realizationTo achieve switchingMetal working apparatusStructural engineeringManufacturing engineering

The invention relates to the technical field of punching equipment, in particular to a corrugated paper punching machine which has the advantage of preventing a punch from being blocked after punchingcorrugated paper for a long time. The corrugated paper punching machine comprises a punching assembly, a transverse moving assembly, a stamping assembly, an intermittent feeding assembly, a frameworkdrive assembly and fixed-length cutting assemblies, wherein the punching assembly is rotatably connected onto the transverse moving assembly; the punching assembly and the transverse moving assemblyare in engaged transmission; the transverse moving assembly is connected on the stamping assembly in a sliding mode; the transverse moving assembly and the stamping assembly are in threaded transmission; the stamping assembly is fixedly connected on the intermittent feeding assembly; the framework drive assembly is fixedly connected on the intermittent feeding assembly; rear moving plates of the two fixed-length cutting assemblies are connected on the framework drive assembly in a sliding mode; and both the fixed-length cutting assemblies are in engaged drive with the framework drive assembly.

Owner:詹恒荣

Panel stamping molding device

ActiveCN108526303APunching realizationAvoid mobilityMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to the field of machining and manufacturing, in particular to a panel stamping molding device which comprises a rack; the rack is provided with a stamping table; molding groovesare symmetrically formed in the stamping table; the side wall of the outer side of each molding groove forms an inclined surface; a molding hole is formed between the molding grooves; a stamping headis arranged above the stamping table; clamping jaws capable of being inserted into the molding grooves respectively are hinged to the stamping head and are provided with wedged surfaces matched with the corresponding inclined surfaces respectively; first liquid storage pipes are symmetrically arranged between the clamping jaws and are internally provided with pistons in a sliding manner respectively; a pressure rod is arranged below each piston in the sliding manner; a first spring is connected between each pressure rod and the corresponding piston; the stamping head is provided with a limiting mechanism used for fixing the pistons; a second liquid storage pipe is communicated between the first liquid storage pipes and is internally provided with a punching cutter capable of being insertedinto the corresponding molding hole in the sliding manner; and the stamping head is internally provided with a drive mechanism. The panel stamping molding device solves the problem that the existingstamping mechanism cannot perform stamping at the same time.

Owner:SHANDONG STREET MOBILE SHOP NEW ENERGY TECH CO LTD

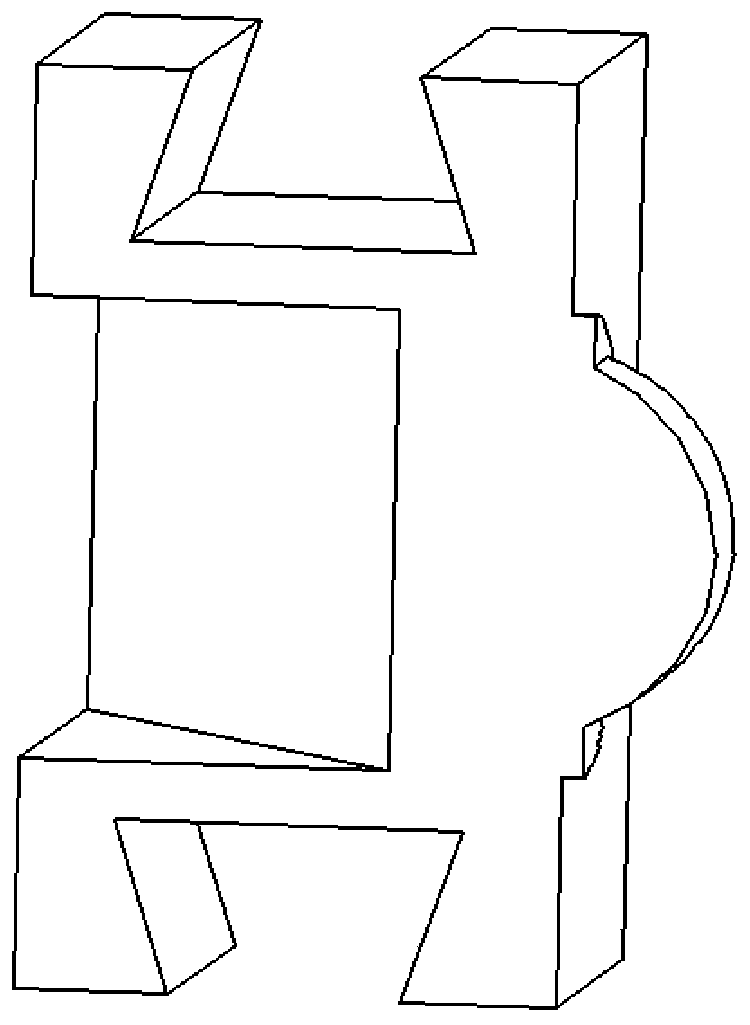

Steel channel punching die

InactiveCN105499373APunching realizationAchieve interchangePerforating toolsStripping-off devicesPunchingEngineering

The invention discloses a steel channel punching die, comprising a die body; the die body is in an H-shape; steel channel machining positions are arranged on two ends of an upper transverse edge of the H-shape; a lower transverse edge of the H-shape is mounted on a worktable; punching through holes are formed in the middles of the two steel channel machining positions; the steel channel machining positions on the two ends are different in thickness and used for machining steel channels different in specification. According to the steel channel punching die, the die body is arranged into the H-shape and two steel channel punching positions different in thickness are arranged on the two ends of the upper transverse edge of the H-shape, and in such a manner, during machining, the die body is just rotated by 180 degrees to realize interchange of the two punching positions and punching of steel channels different in specification; replacement is facilitated and the punching efficiency is improved; further, the steel channel punching die is simple in structure and low in cost.

Owner:GUANGDONG DISHENG ELECTRIC POWER STEEL EQUIP

punching die

ActiveCN103722083BPunching realizationRealize multi-purposeShaping toolsPerforating toolsPunchingEngineering

Owner:廊坊事达同泰汽车零部件有限公司

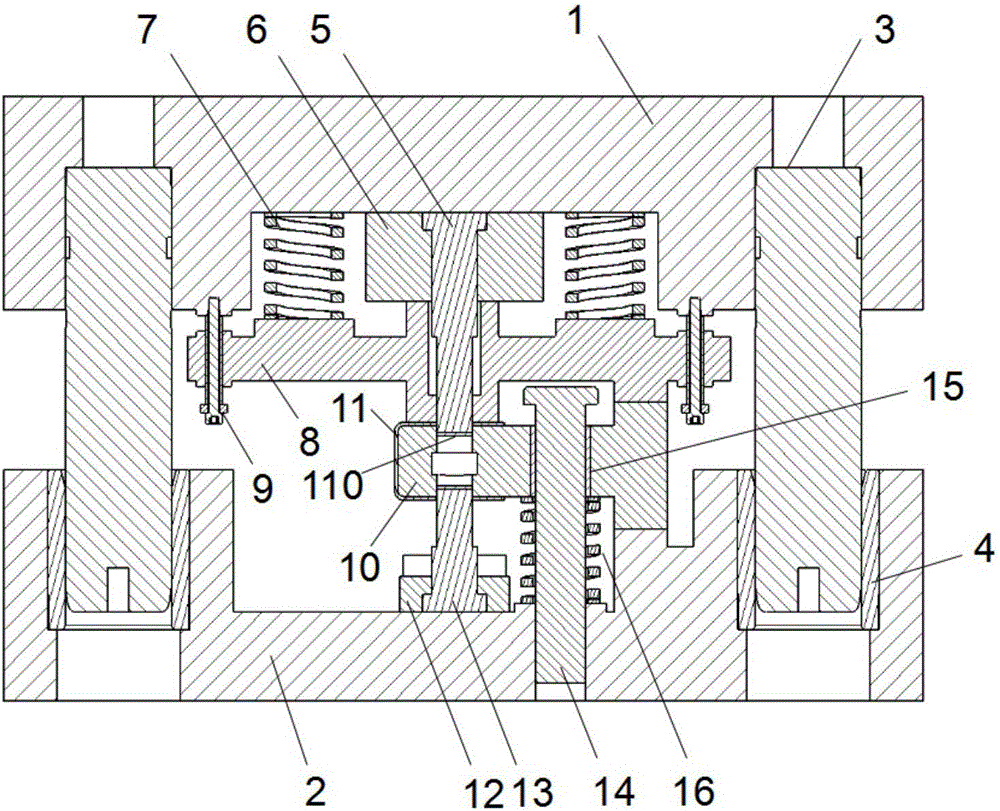

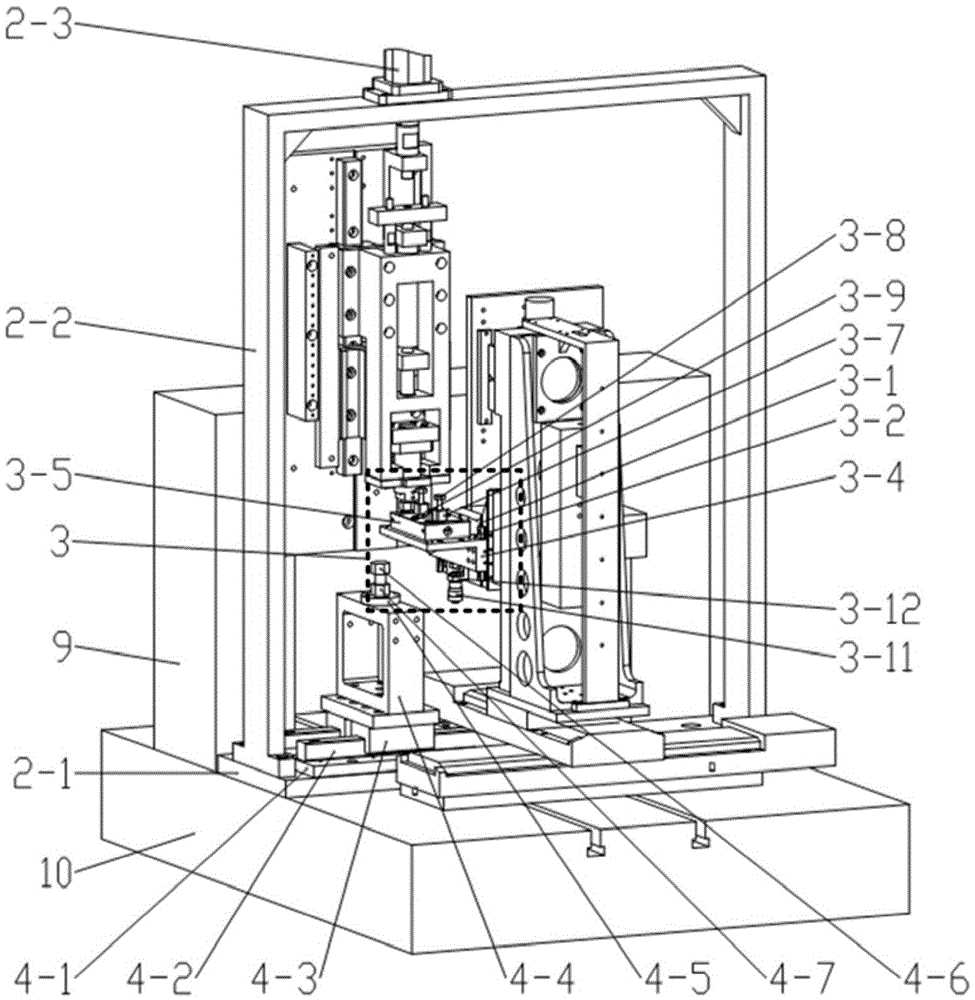

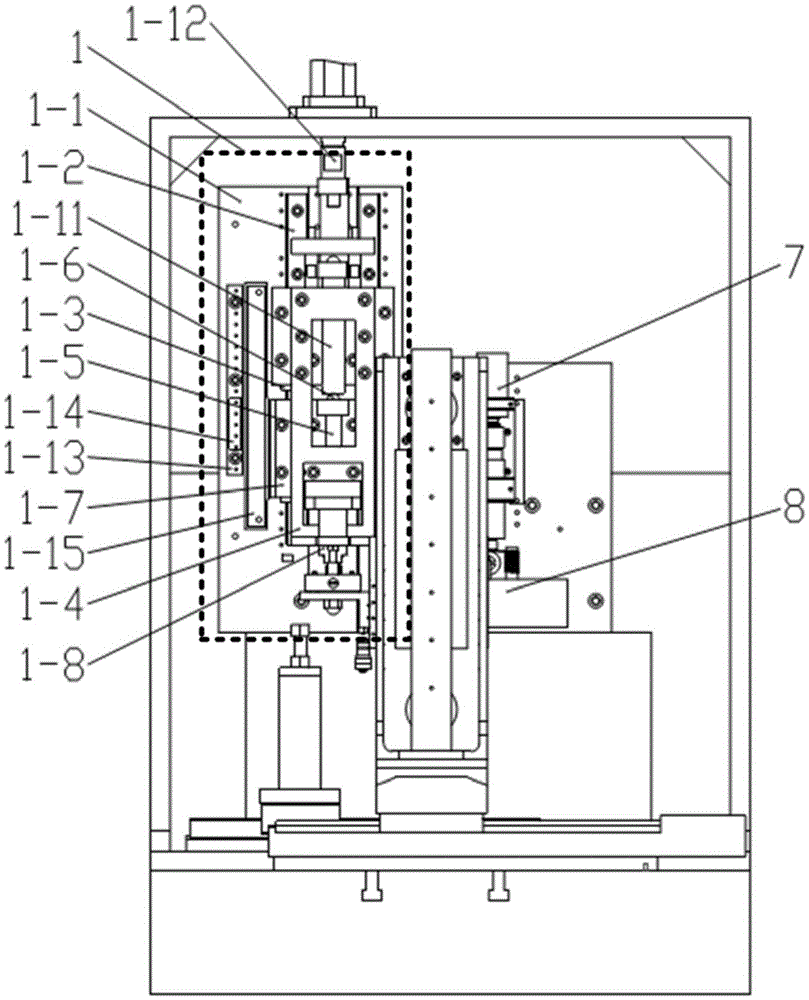

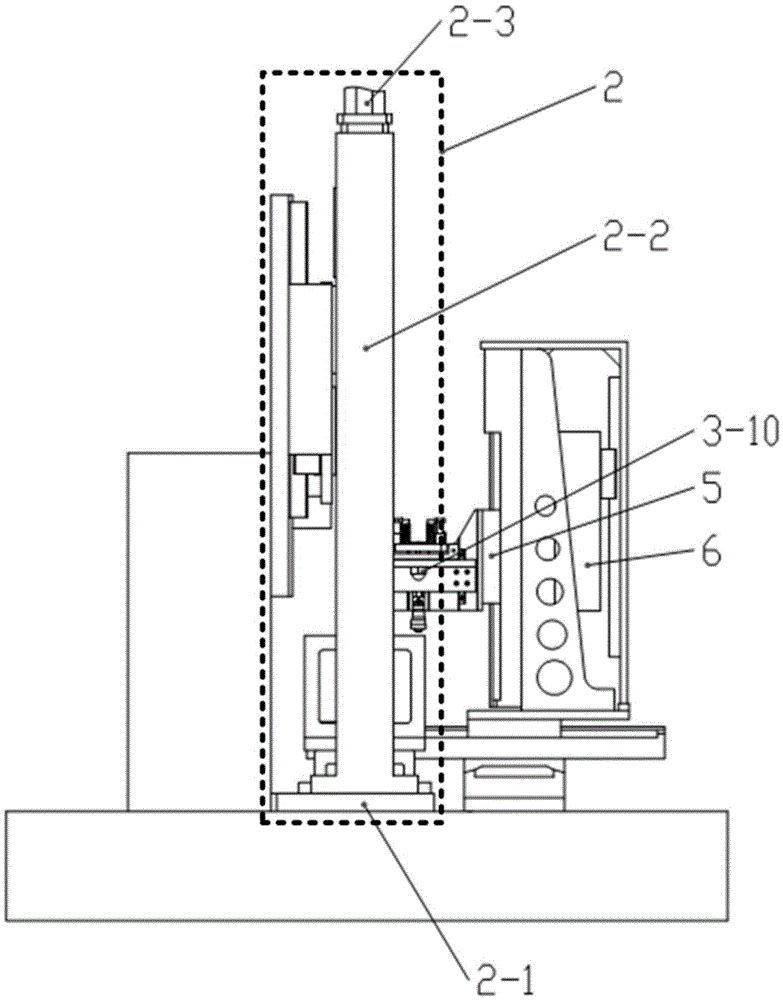

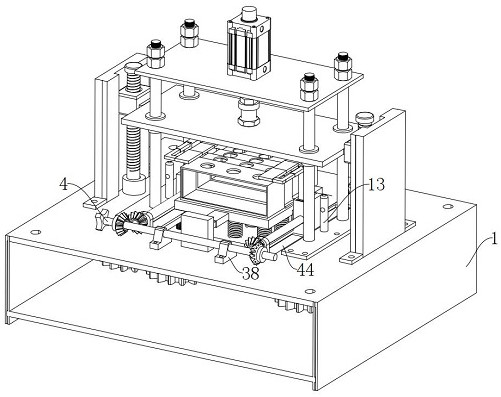

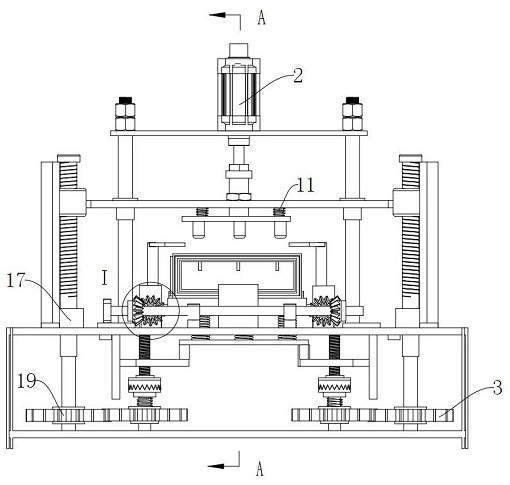

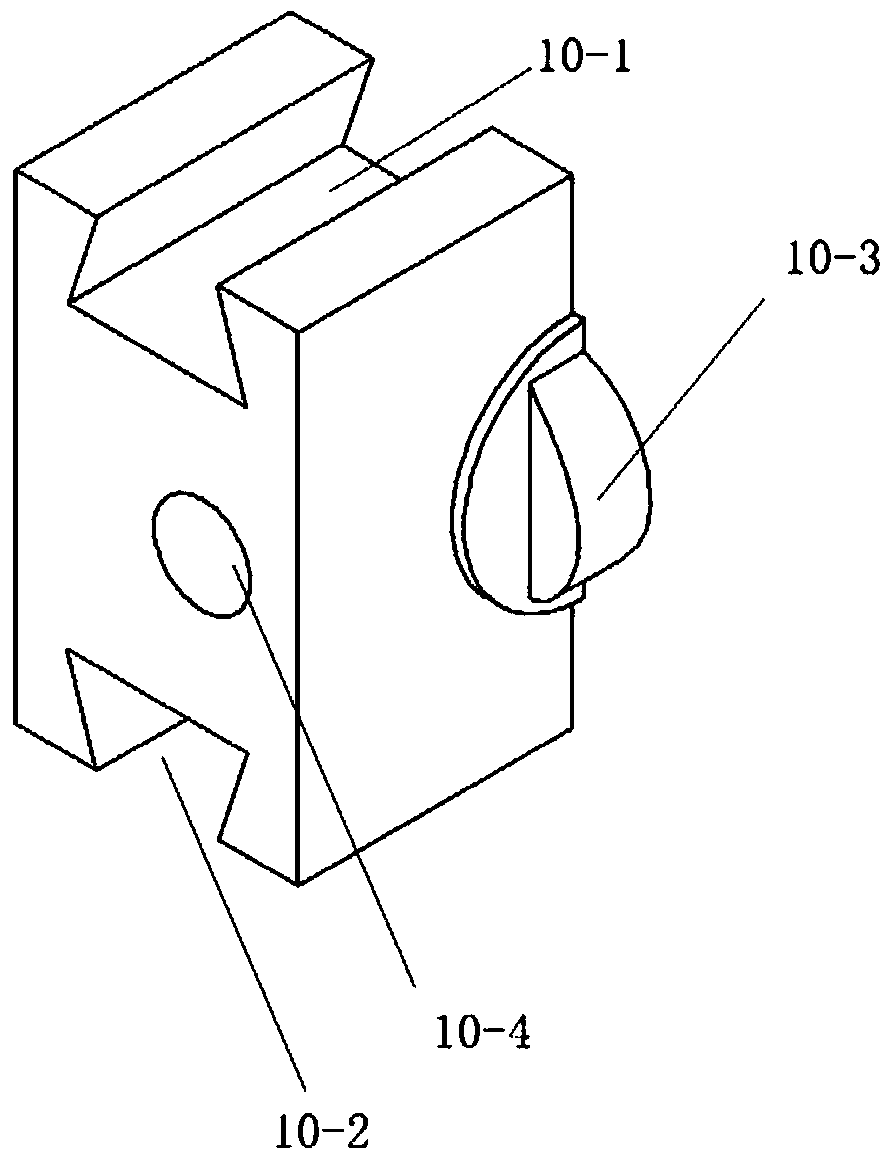

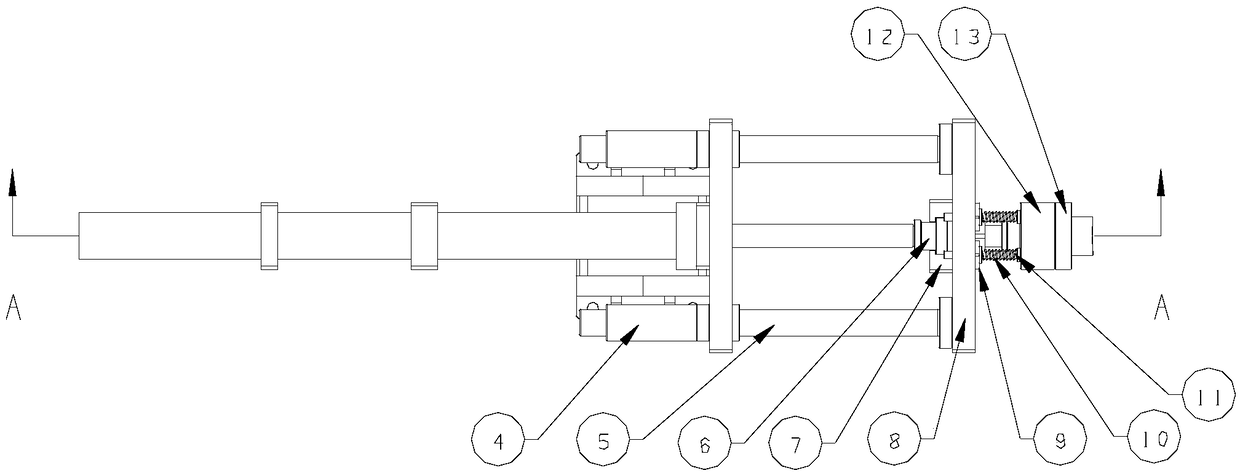

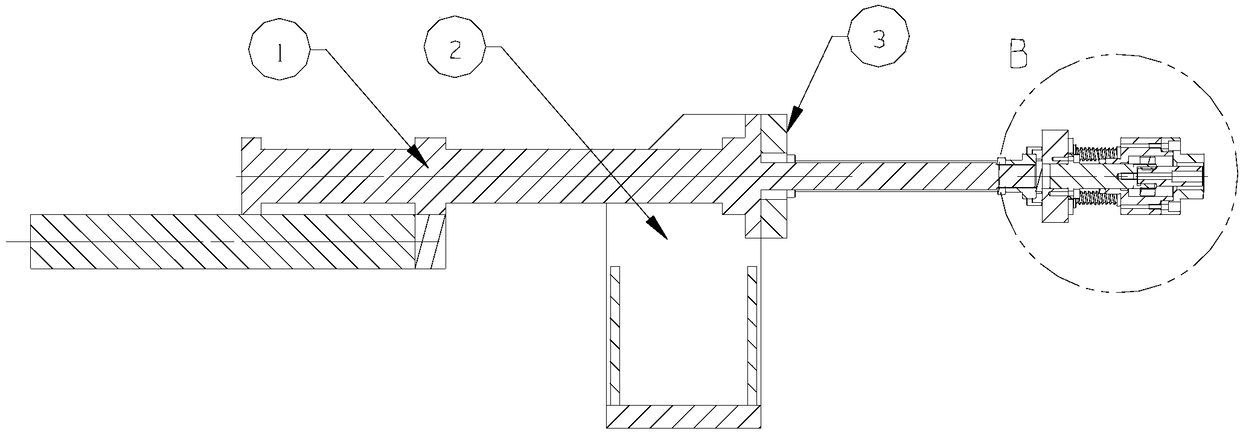

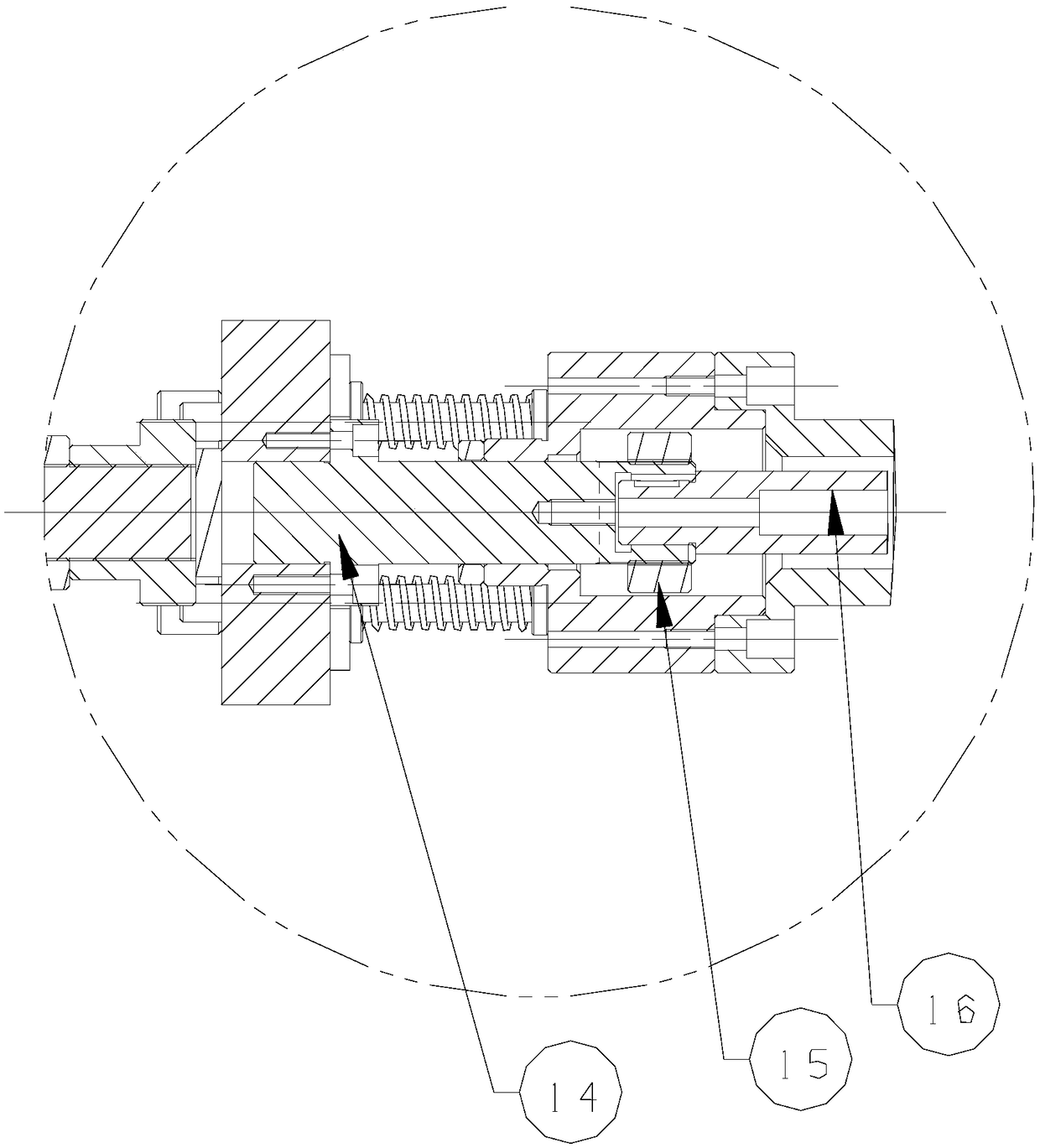

Micro blanking system for on-line processing of punch-die

ActiveCN105642734AHigh guiding precisionLarge punching loadElectrical-based machining electrodesElectrical-based auxillary apparatusLinear actuatorEngineering

The invention belongs to the field of manufacturing of precision machinery and provides a micro blanking system for on-line processing of a punch-die. A punch assembly and an electric spark spindle assembly are fixed on a vertical marble plate; a power source portal frame assembly is separately mounted on a marble platform surface and connected to the punch assembly; a support frame assembly for bearing force is mounted on a portal frame base plate of the portal frame assembly; a precise XYZ three-axis positioning assembly is mounted on the marble platform surface; a die assembly and a wire electrical discharge grinding (WEDG) assembly are mounted on a z axis of the precise XYZ three-axis positioning assembly; and a counterweight assembly is mounted on the Z axis and balanced with the die assembly and the WEDG assembly in weight. The punch assembly adopts a spherical surface contact rigid connection structure of an ultraprecise linear guide rail and a high-load linear actuator, and the die assembly adopts a floating structure based on a precise linear guide rail. The micro blanking system realizes on-line processing, trimming and center alignment of special-shaped punch-dies as well as blanking, high-load blanking, stretching and other various processes of micro special-shaped parts.

Owner:DALIAN UNIV OF TECH

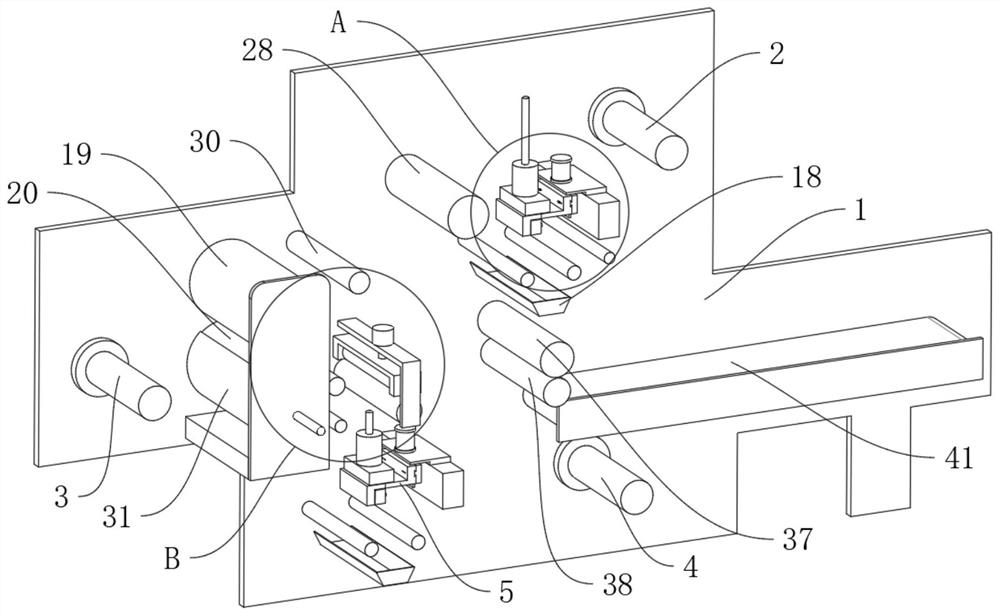

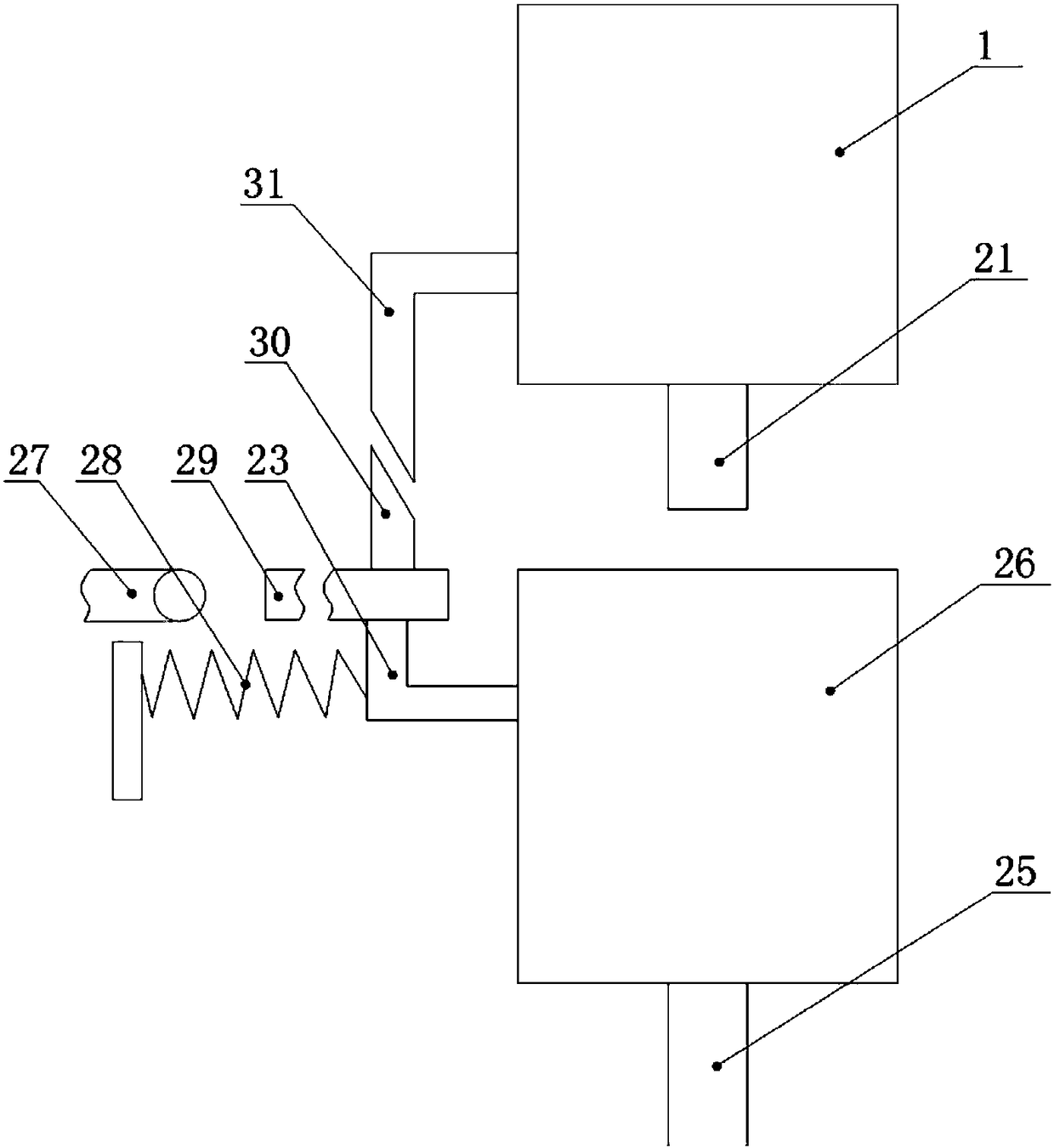

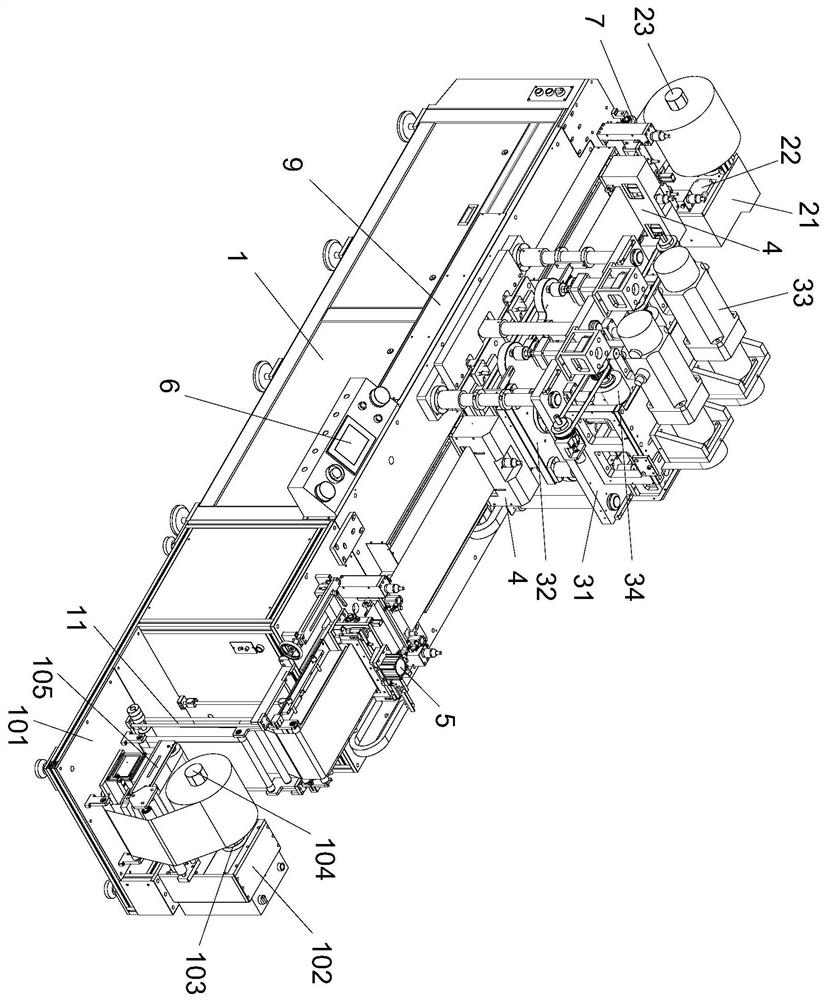

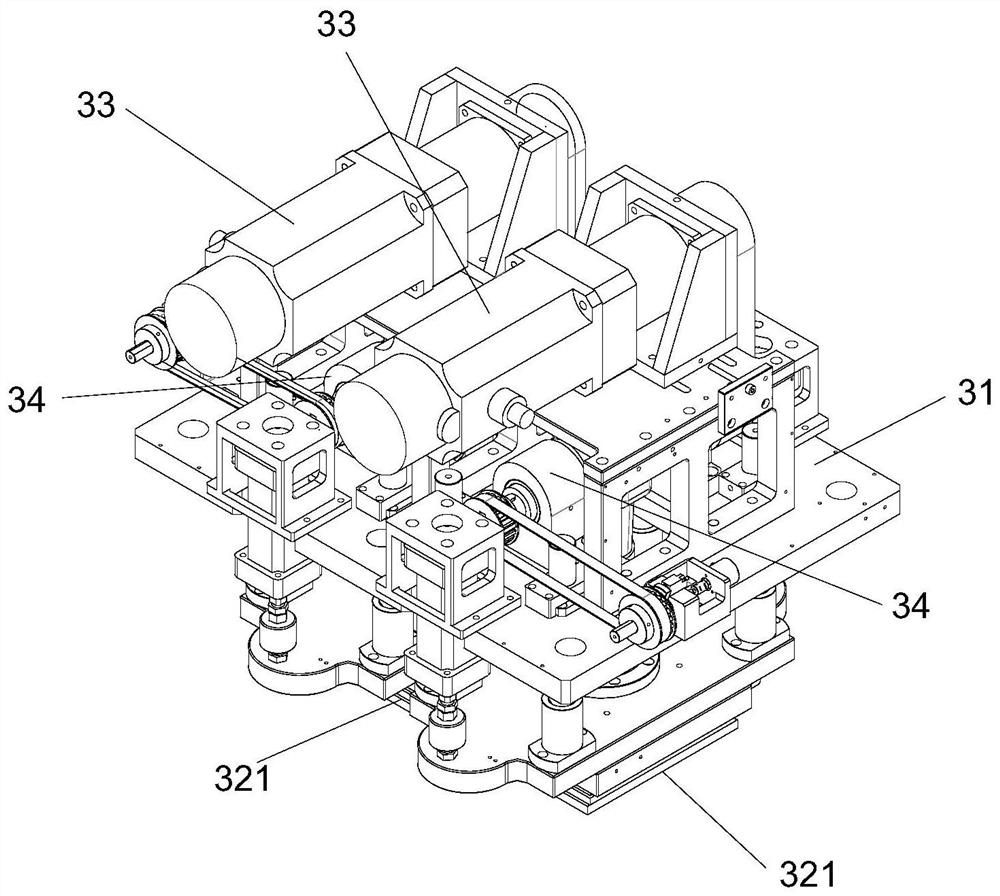

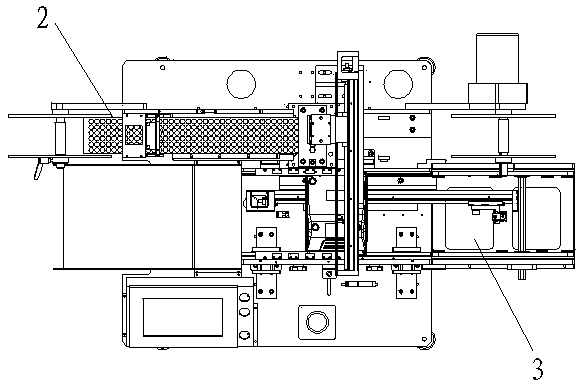

Coil stock dual-pressure automatic punching all-in-one machine

PendingCN111844218APunching realizationRealize automatic feedingMetal working apparatusElectric machineryStructural engineering

The invention discloses a coil stock dual-pressure automatic punching all-in-one machine, and relates to the technical field of punching. The coil stock dual-pressure automatic punching all-in-one machine comprises a rack, a coil stock feeding device, a dual-pressure punching device, a dual-clamping carrying device, a cutting device and an LPF controller are fixedly arranged above the rack, and the coil stock fe device, the dual-pressure punching device and the cutting device are sequentially arranged from left to right in a separated manner; the dual-pressure punching device comprises a punching frame, punching dies, punching motors and lifters; the two punching dies are arranged in a left-right separated manner, each punching die comprises an upper die and a lower die, the two punching motors and the two lifters are arranged in a left-right separated manner, the punching frame and the lower dies are fixedly arranged at the upper end of the rack, the punching motors and the lifters are fixedly arranged at the upper end of the punching frame, and the punching motors correspondingly drive the upper dies to vertically move through the lifters; the LPF controller correspondingly controls the coil stock feeding device, the punching motors, the dual-clamping carrying device and the cutting device to work; and the punching precision is higher, and the efficiency is higher.

Owner:深圳市欣荣自动化智能设备有限公司

Hardware product punching device with power-off protection function

InactiveCN112588940AAchieve protectionRealization of metal product punching with protection functionShaping safety devicesPunchingStructural engineering

The invention relates to a hardware product punching device with a power-off protection function. The hardware product punching device comprises a base, a supporting rod, a transverse rod, a driving mechanism, a punching mechanism and a protection mechanism. According to the hardware product punching device with the power-off protection function, a rotating rod is driven by the driving mechanism to rotate, and the rotating rod drives the punching mechanism to move, so that punching of a workpiece is achieved; when power is off, the rotating rod is locked through the protection mechanism, so that the positions of the driving mechanism and an impact mechanism are locked, the position of a drill bit is locked, and therefore the workpiece and an operator are protected; compared with an existing protection mechanism, the mechanism not only supports and fixes a lantern ring, but also locks the lantern ring, so that practicability is improved; and compared with an existing limiting assembly,the mechanism not only limits the movement of a movable rod, but also lubricates the movement of the movable rod, so that the movement of the movable rod is more stable, and the punching precision isimproved.

Owner:南京思达捷信息科技有限公司

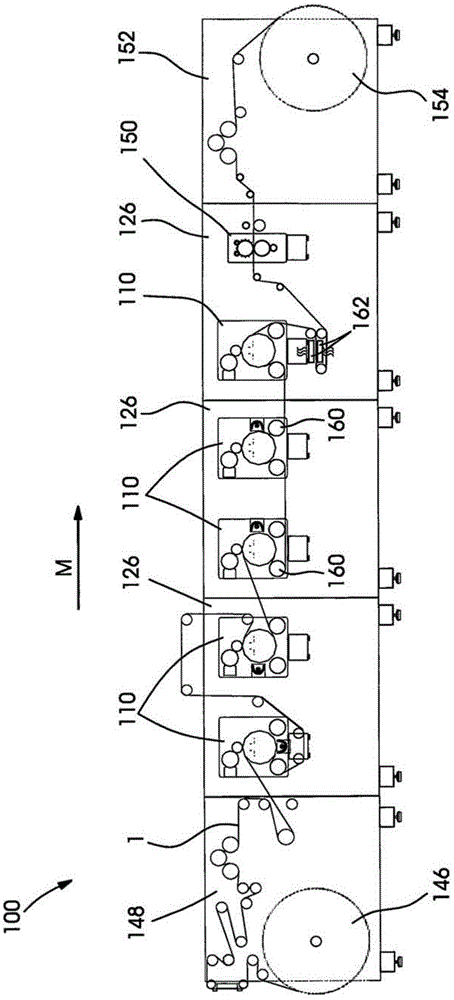

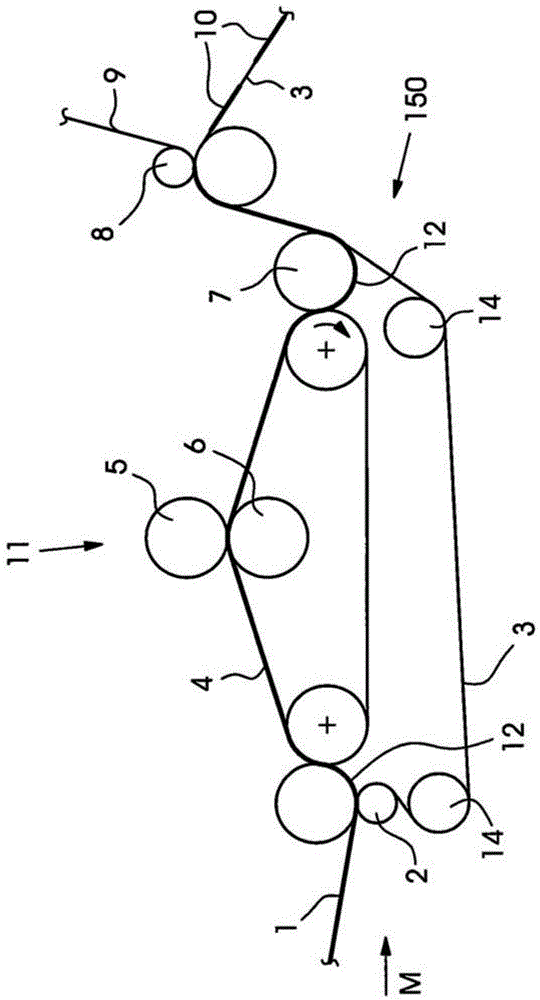

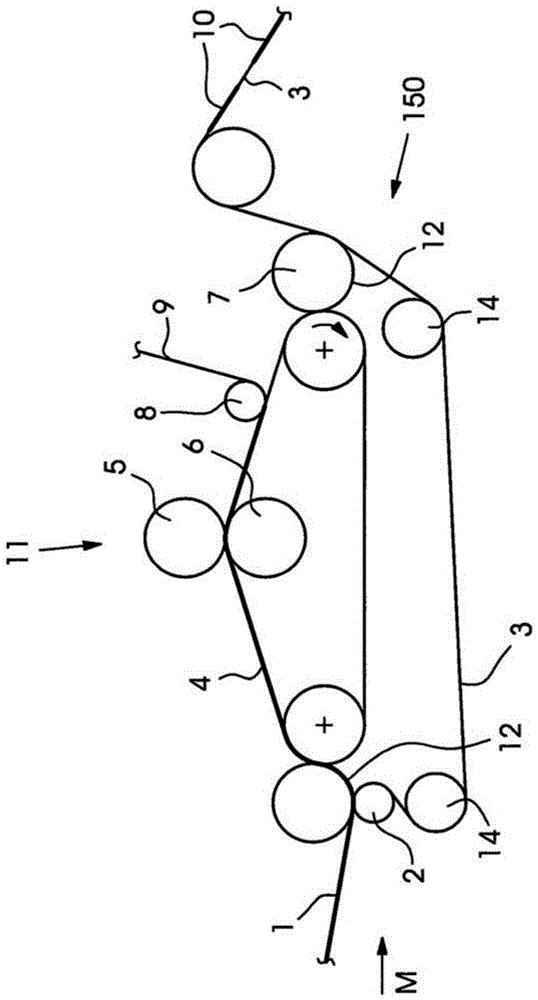

Device having counterpunching belt, for punching labels

InactiveCN104441783AReduce lossEasy to peelLamination ancillary operationsPaper/cardboard articlesAdhesiveStructural engineering

The invention relates to a device (150) for punching labels (10) from a substrate web (1), wherein the substrate web (1) is provided with a carrier layer (3) and a label layer (12). The device includes a punching installation (11) for punching the labels. The punching installation (11) has a delaminating installation (2) for separating the label layer (12) from the carrier layer (3), a metallic non-suction revolving counterpunching belt (4) for conveying the label layer (12) during a punching operation, and a relaminating installation (7) for reconnecting the label layer (12), provided with punchings, to the carrier layer (3). The invention also relates to a method for punching self-adhesive labels (10) is also provided. By the device and the method, the thin carrier layer (3) can be used, and the carrier layer is not damaged during punching.

Owner:GALLUS DRUCKMASCHINEN GMBH

An ultra-thin flexible heat dissipation film and its manufacturing method

ActiveCN106531902BImprove cooling effectEasy to slimSolid-state devicesSemiconductor/solid-state device manufacturingMetal membraneElectronic materials

The invention discloses a flexible heat dissipation film and a preparation method thereof, and the invention relates to the field of electronic materials. The heat dissipation film includes a carrier film and a protective film layer, and at least one heat dissipation layer group between the carrier film and the protective film layer; The heat dissipation metal film layer on one surface of the heat dissipation adhesive film layer is used for longitudinal heat transfer, thereby forming a heat dissipation layer group with two-way heat transfer; wherein, the raw materials of the heat dissipation adhesive film layer include magnetized high thermal conductivity powder and Resin; wherein, the heat dissipation metal film is formed by depositing the material source on the surface of the heat dissipation adhesive film layer after forming atoms or molecules by physical means. The heat dissipation film of the present application is easy to operate, and the formed film layer is thin and dense, and is suitable for various electronic products and communication equipment.

Owner:广州宏庆电子有限公司

Advanced mold designing and manufacturing technical equipment

InactiveCN108500128APunching realizationPlay a protective effectPerforating toolsMetal-working feeding devicesPunchingManufacturing technology

The invention discloses advanced mold designing and manufacturing technical equipment which comprises a fixing machine body and supporting legs arranged on the bottom face of the fixing machine body in a left-right symmetry mode. A fixing base platform is fixedly arranged between two supporting legs on the left and right. A fixing device is arranged in the fixing base platform. A sliding cavity with an opening formed in the bottom is arranged at the middle portion of the fixing machine body and the sliding cavity is internally provided with a sliding machine body. The sliding machine body is connected to the sliding cavity in a sliding-fit mode. Sliding racks which extend vertically are fixedly arranged at middle portions of the left and right side faces of the sliding machine body. A cavity with an opening formed in the bottom is arranged at the middle portion of the sliding machine body. The advanced mold designing and manufacturing technical equipment is simple in structure, convenient to use, and firm in mold fixing; during the punching process, lifting of the sliding machine body is controlled according to the required depth of punching; after the punching process, the slidingmachine body completely retracts into the sliding cavity and a punching head is protected.

Owner:陈城

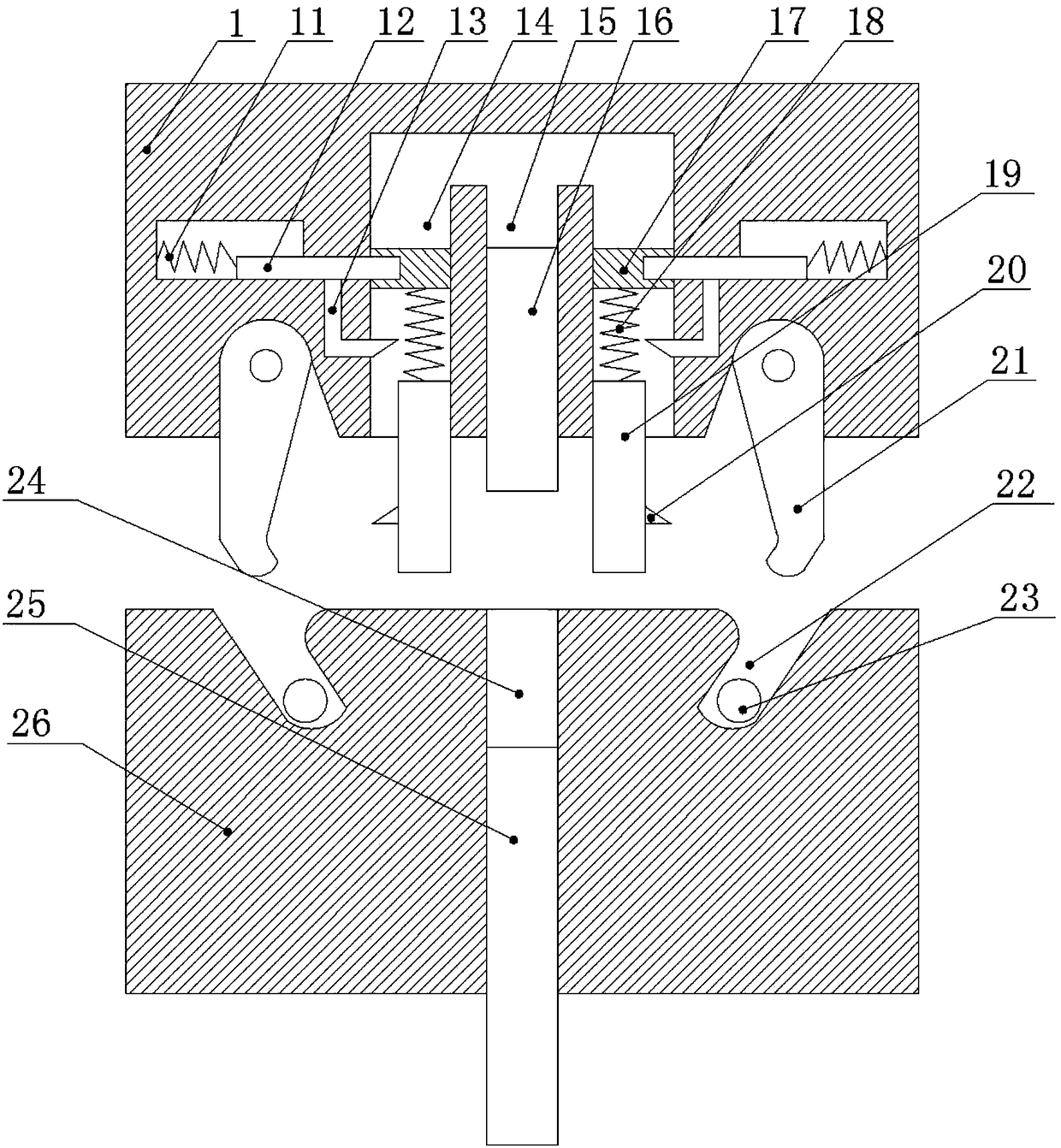

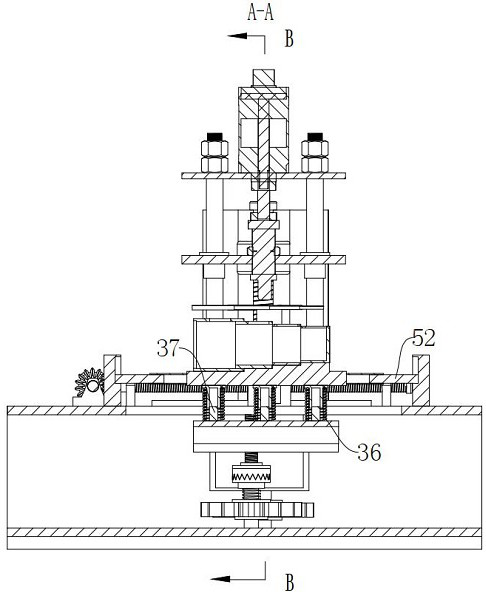

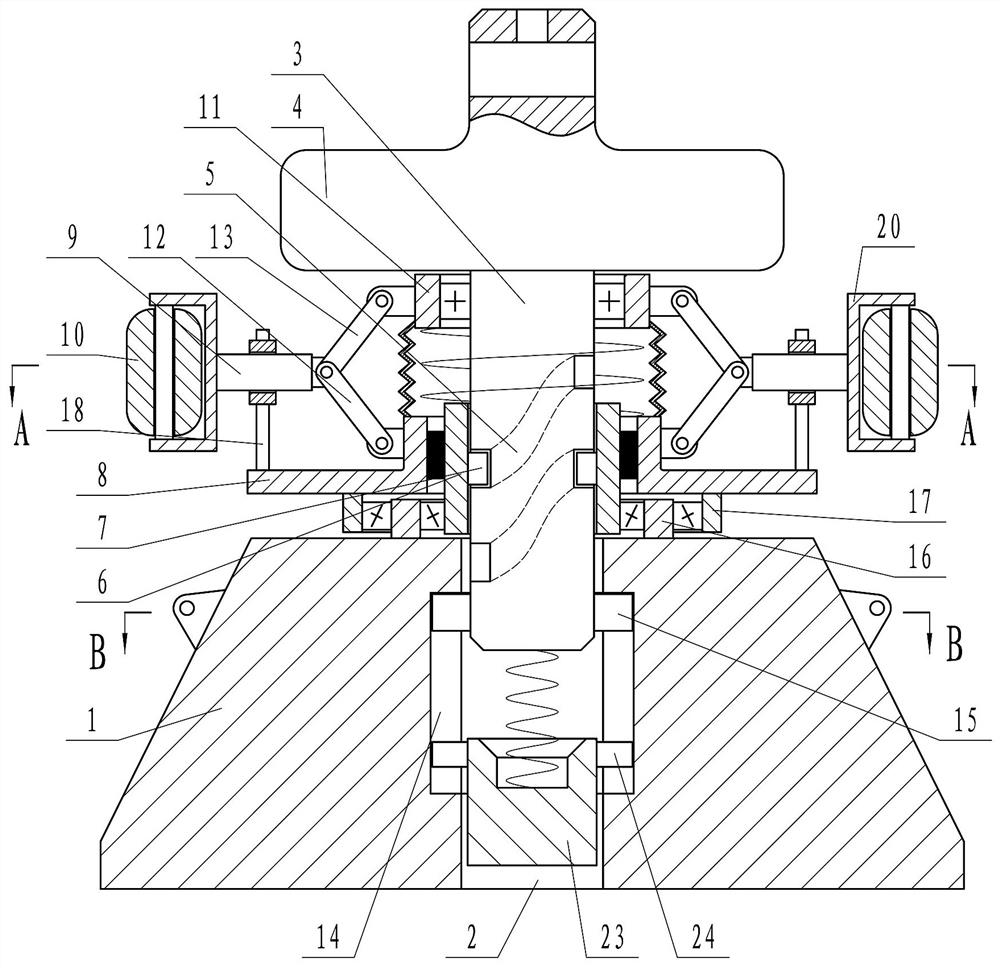

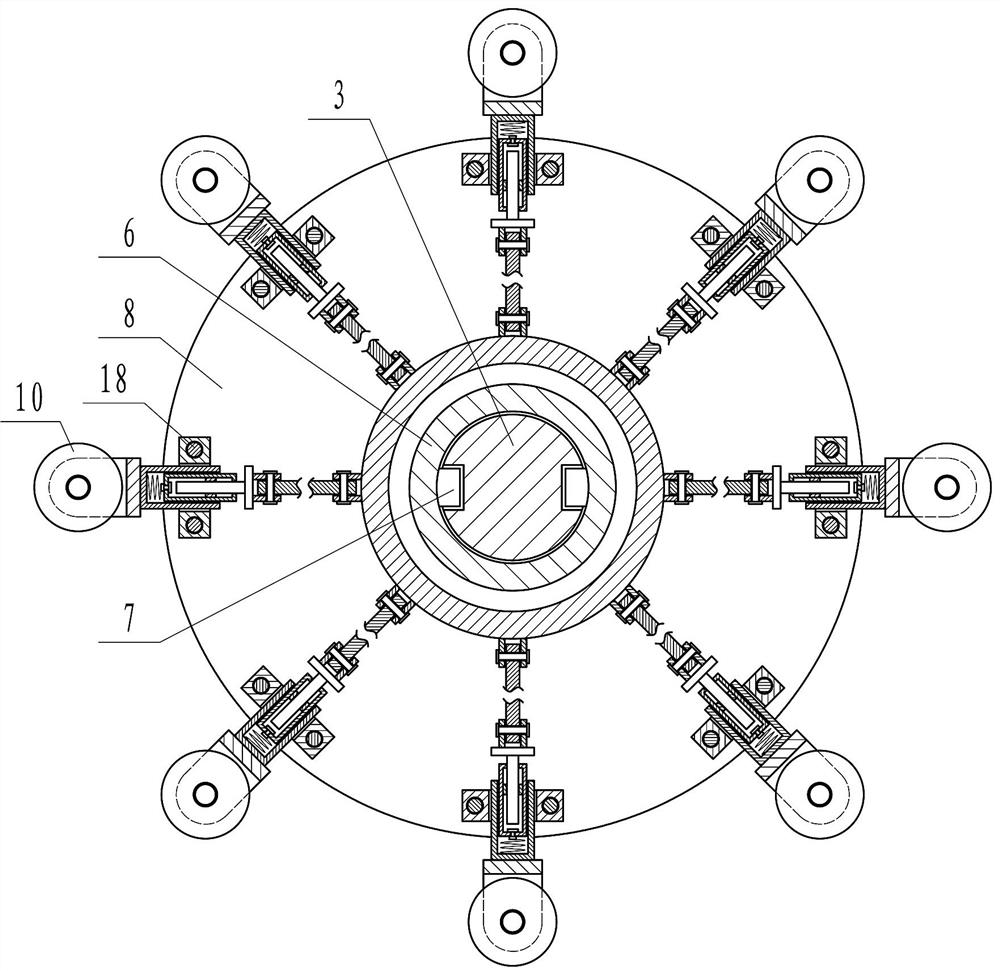

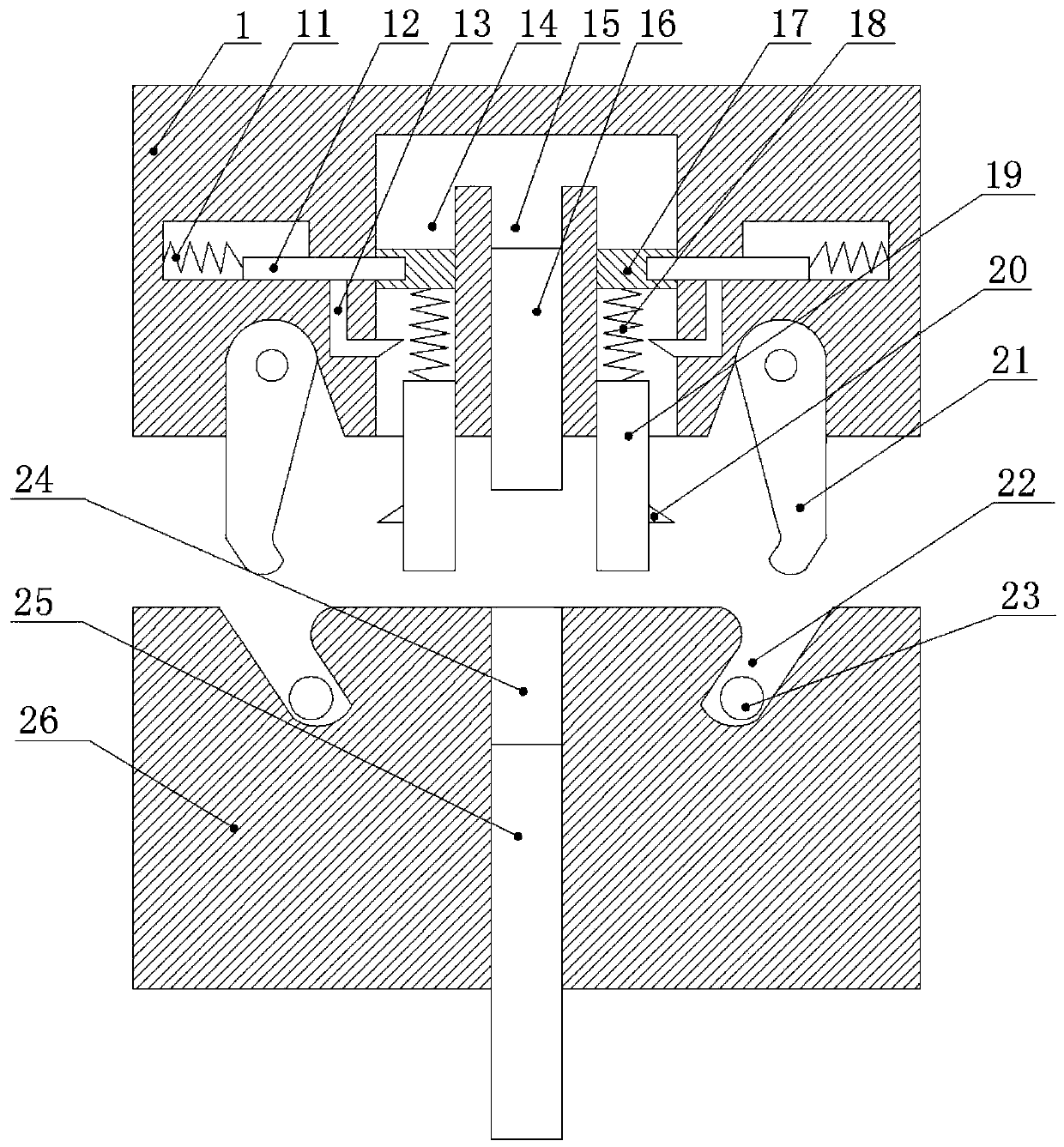

Hierarchical floating locking type power component punching device

PendingCN114769419AImprove applicabilitySecure locking to avoidPerforating toolsMetal-working feeding devicesStructural engineeringPunching

The invention discloses a hierarchical floating locking type punching device for power components. The hierarchical floating locking type punching device comprises a punching device body, a pressing punching assembly, a fastening anti-shake mechanism and a multi-dimensional adaptive adjusting assembly. The invention belongs to the technical field of electric power component punching devices, and particularly relates to a hierarchical floating locking type electric power component punching device. The punching device can adjust the adaptive placement position and the punching position according to the shapes of the power components through the arranged multi-dimensional adaptive adjusting assembly, and in order to lock the power components with different thicknesses, through the arrangement of the fastening anti-shake mechanism, the characteristics of punched holes are utilized, and the punching precision is improved. Therefore, an independent sensing mechanism and an independent locking driving mechanism do not need to be arranged, the locking process and the punching process are synchronous, the locking process and the punching finishing resetting process are synchronous, stable locking of the power component is achieved, meanwhile, the contradiction between the punching displacement difference and the thickness difference of the power component is avoided, and the punching quality of the power component is improved. And the automation level of the punching device is increased.

Owner:江阴市查克拉科技有限公司

Punching tool and stamping and punching method

PendingCN113894203ASmooth and precise movementPrecise position controlShaping toolsPerforating toolsPunchingButt joint

The invention discloses a punching tool and a stamping and punching method. The punching tool comprises an upper base body, a base, a first guide structure, a male die, a female die sleeve and a punch arranged on the upper base body, a guide inclined plane is arranged on the base, and the male die is in sliding fit with the guide inclined plane; the female die sleeve is arranged on the male die and matched with the punch; and the first guide structure comprises a guide column and a guide sleeve which are matched, one of the guide column and the guide sleeve is arranged on the upper base body, the other one is arranged on the male die, and after the upper base body moves by a set distance in the stamping direction, the male die moves along the guide inclined plane till the guide column is in butt joint with the guide sleeve in a sleeved mode. According to the punching tool and the stamping and punching method, part taking and placing can be prevented from being interfered, and punching in the punching process can be achieved; and meanwhile, the guide inclined plane and the first guide structure are additionally arranged, so that the operation precision of the male die is ensured, positioning deviation is avoided, and the precision and stability of punching on a movable part can be ensured.

Owner:VOYAH AUTOMOBILE TECH CO LTD

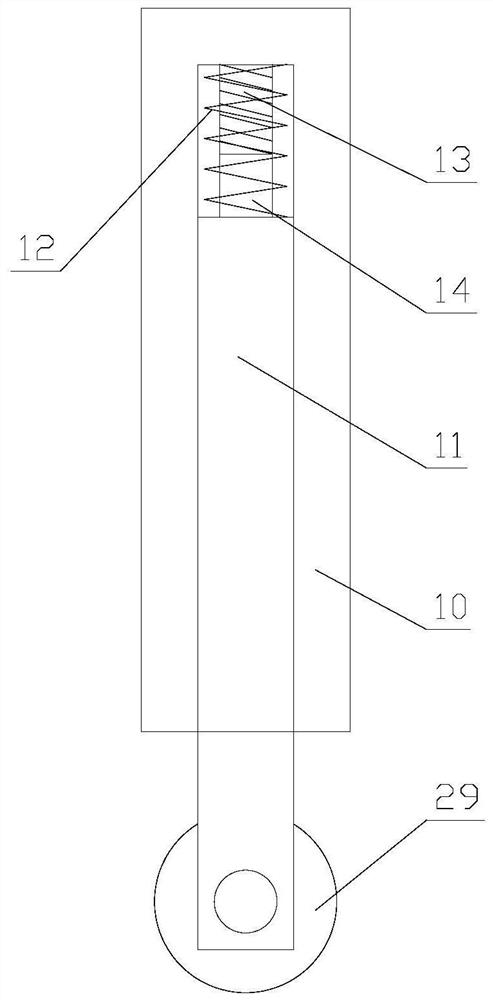

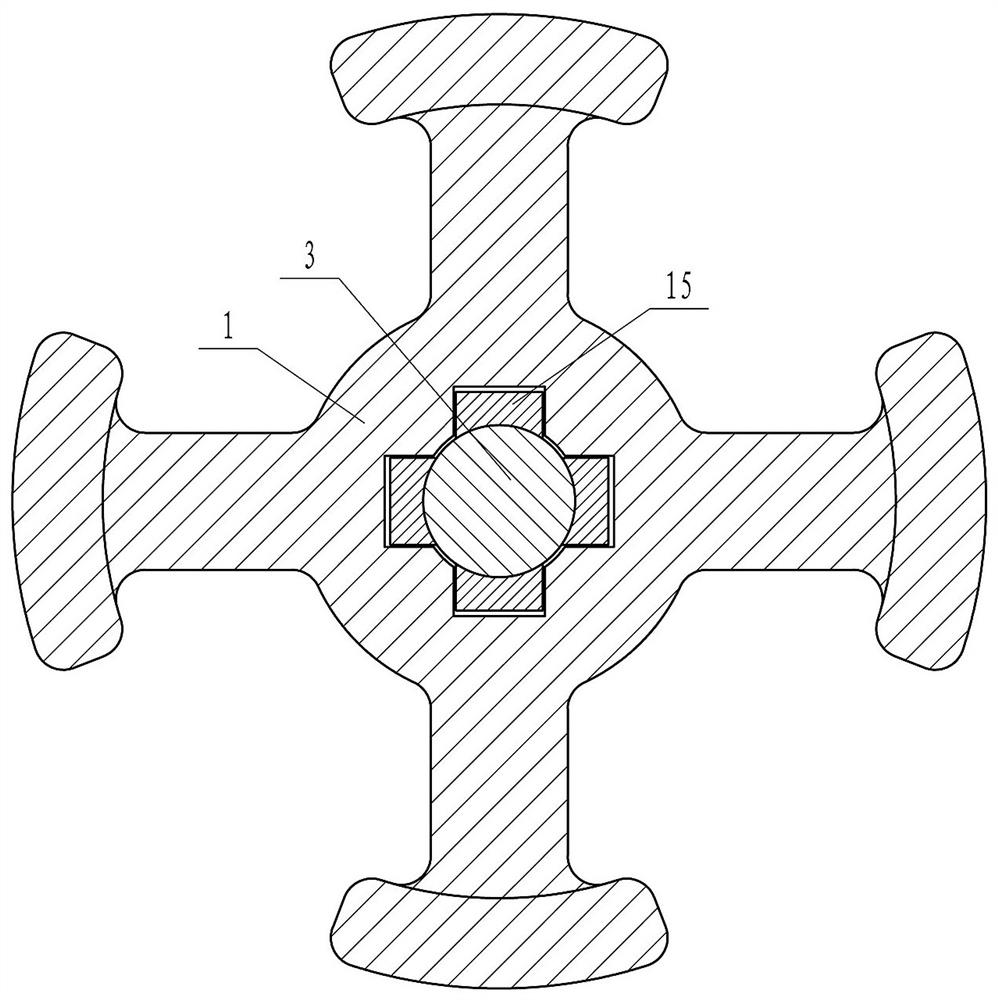

Pile hammer of a building construction punching pile driver

The invention provides a pile hammer of a construction punching pile driver, which effectively solves the problem that the hammer head of the existing punching pile driver is prone to inclination of the pile hole, the hammer head is easy to be stuck in the hole, and the plum blossom hole is easy to appear. The problem of hole collapse; the technical solution is to include the main body of the hammer head of the punching pile driver, the center of the main body has a central hole, the central hole has a central shaft, the upper end of the central shaft has a counterweight, and there is a groove on the central shaft. There is a cylinder on the central axis, a slider on the inner wall of the cylinder, an annular plate is set on the cylinder, and a telescopic rod is arranged on the annular plate, which can drive the telescopic rod to rotate, and a cylinder is installed on the end of the telescopic rod away from the central axis. shaped roller, and the central shaft is fitted with a rotatable annular sleeve; the invention has an ingenious structure, which can also compact the side wall of the pile hole to build the wall during the punching process, reducing the occurrence of hole collapse and effectively avoiding the hammer The head is deflected to prevent the hammer head from being stuck in the pile hole, realize punching and reaming, and improve the bearing capacity of the pile foundation.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

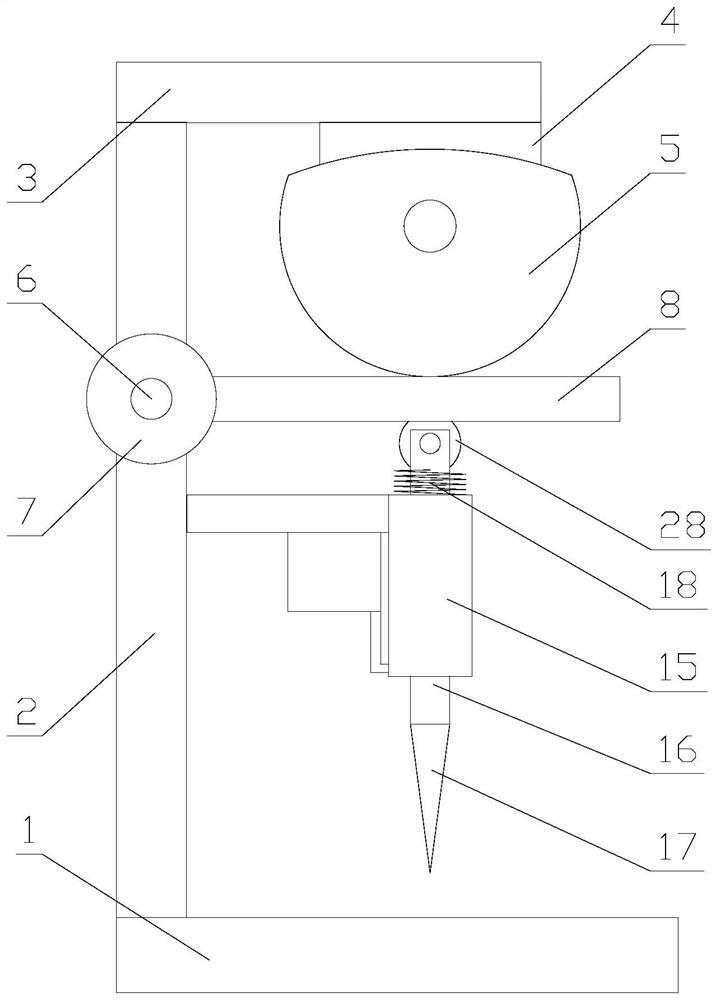

Teacup filter side edge perforating device

PendingCN112570555APunching realizationImplement automatic rolloutMetal-working feeding devicesPress ramStructural engineeringWorkbench

The invention relates to a perforating device, in particular to a teacup filter side edge perforating device. The teacup filter side edge perforating device is easy to operate and capable of automatically discharging a filter. The teacup filter side edge perforating device comprises a bottom plate, a transmission mechanism, a punching mechanism, an intermittent rotating mechanism, a feeding mechanism and a pushing mechanism, and a plurality of workbenches are arranged at the top of the bottom plate. The transmission mechanism is arranged between the workbenches on one side and the bottom plate. The punching mechanism is arranged on the workbenches on one side. The intermittent rotating mechanism is arranged on the workbenches on one side. The feeding mechanism is arranged between the workbenches. The pushing mechanism is arranged on the workbenches on the other side. According to the teacup filter side edge perforating device, the punching action on a filter is achieved through the punching mechanism, then, under cooperation of the transmission mechanism, the intermittent rotating mechanism, the feeding mechanism and the pushing mechanism, punching on the filter can be efficientlyand stably achieved, and the intermittent rotating mechanism can drive the filter to intermittently rotate.

Owner:邓利成

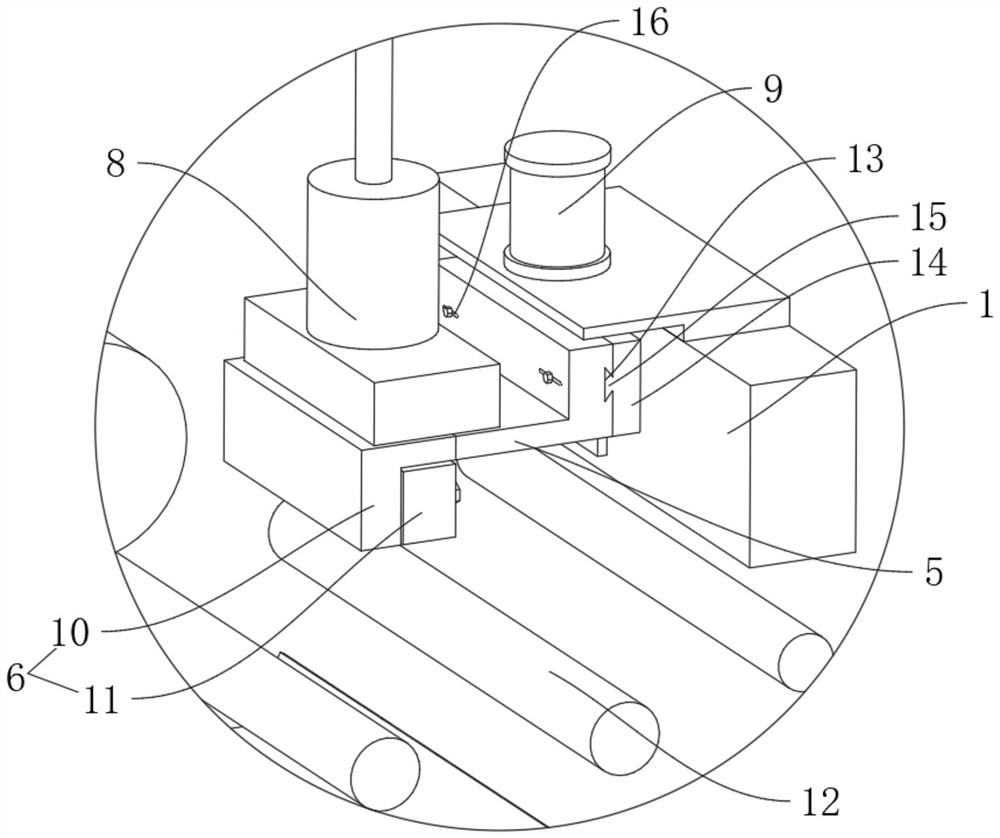

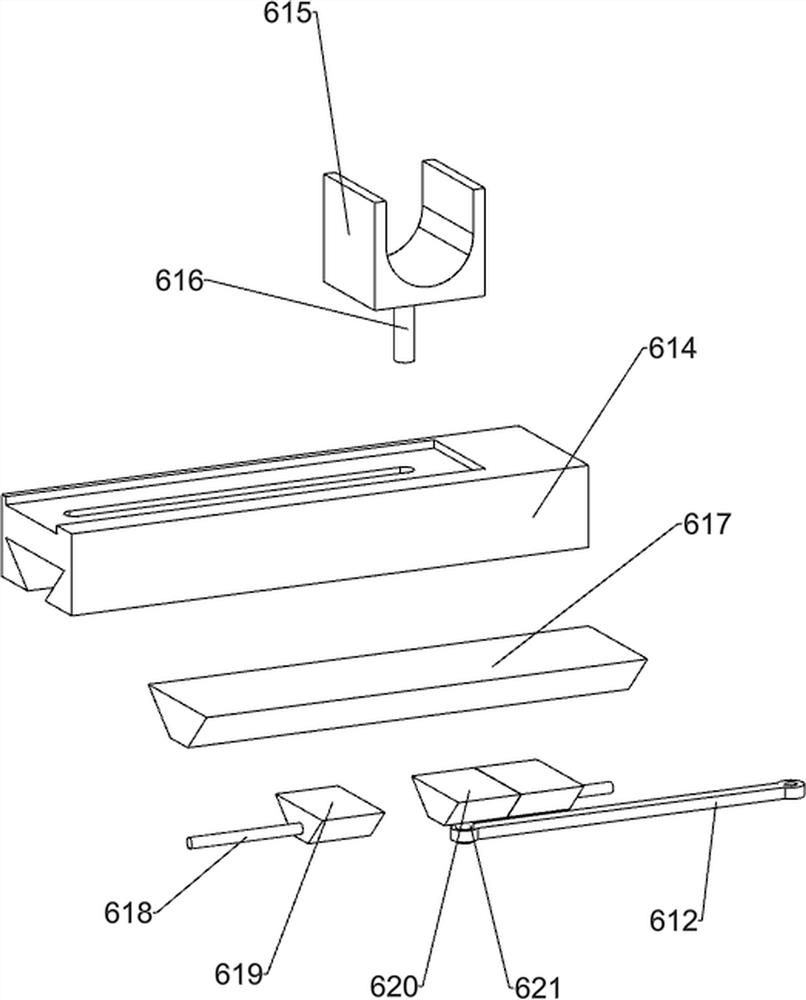

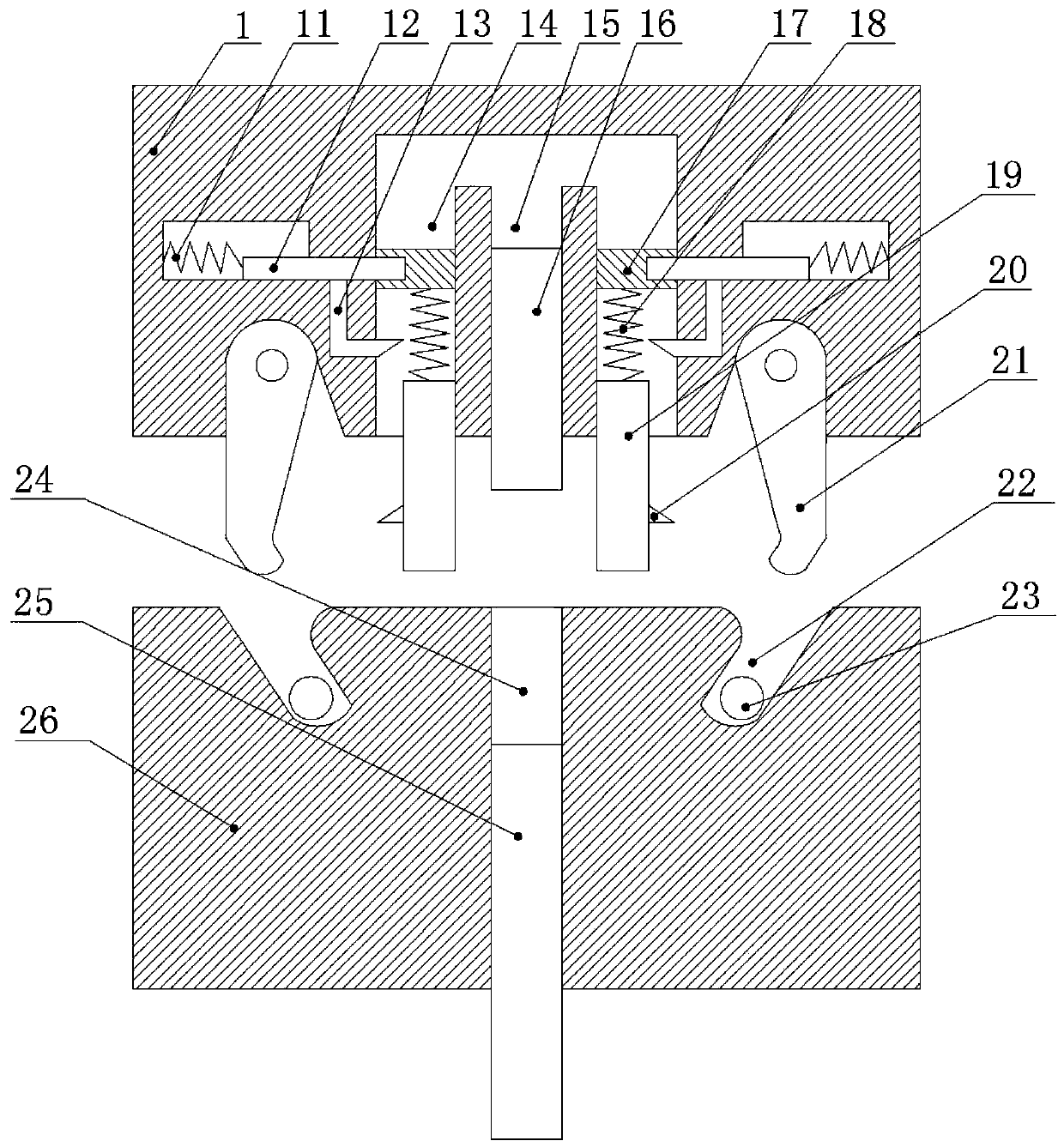

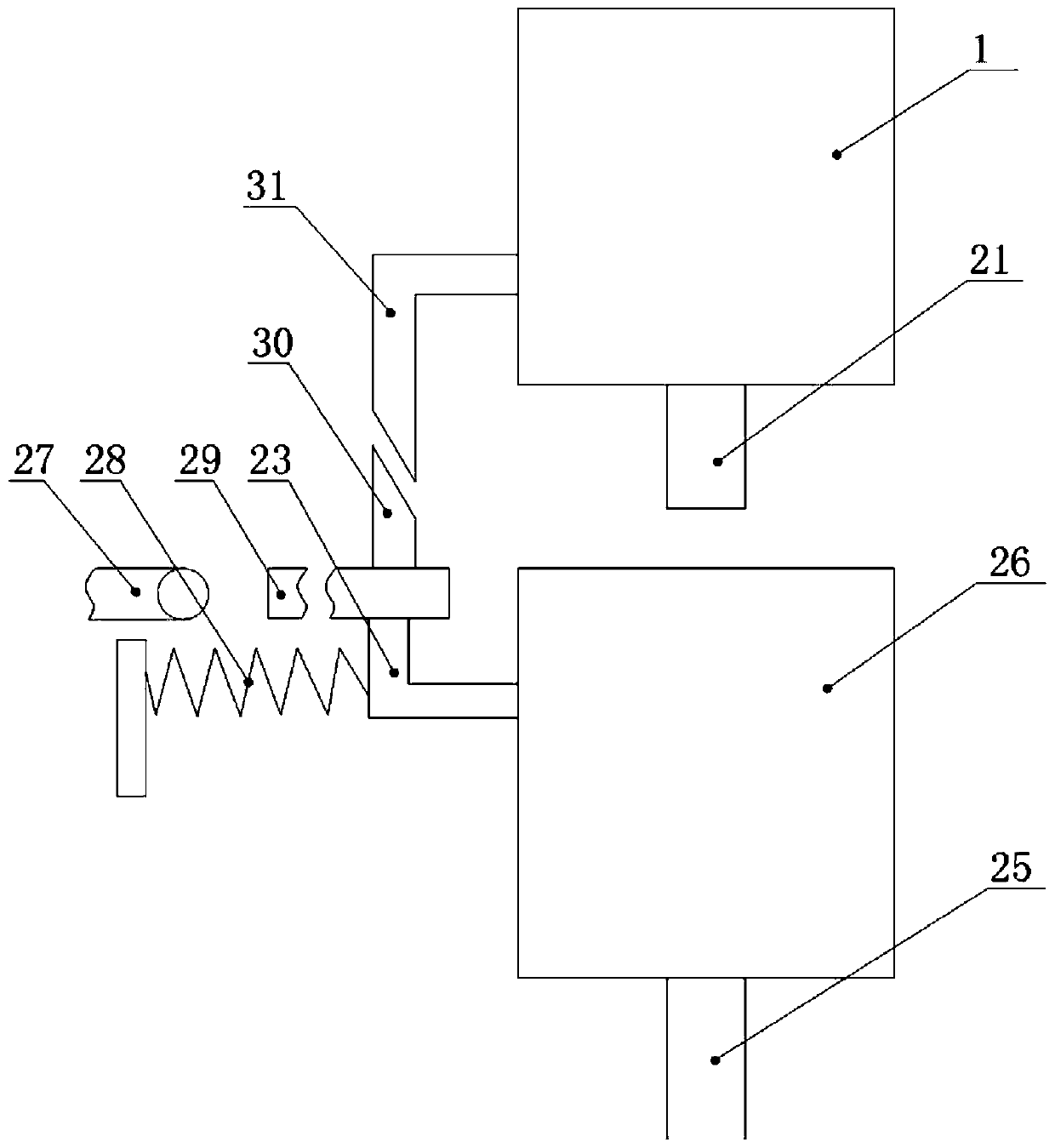

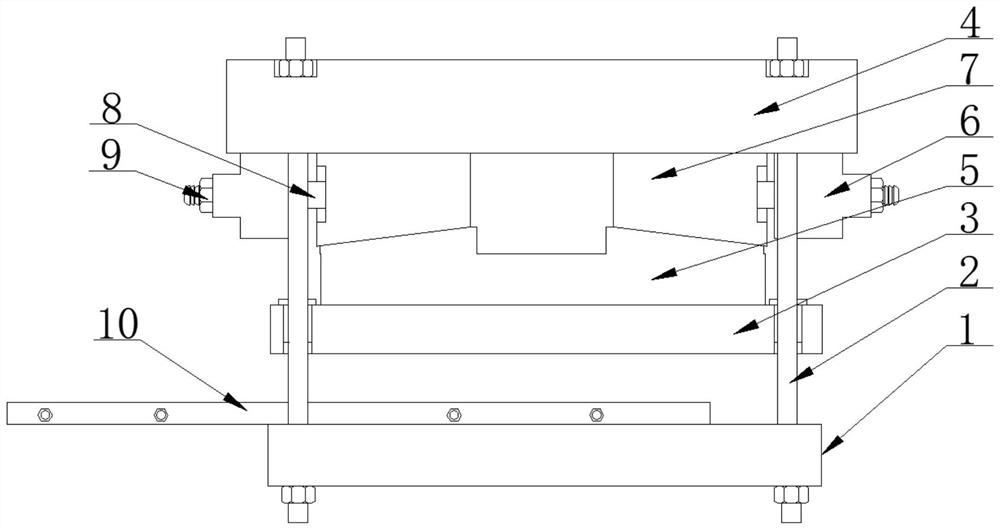

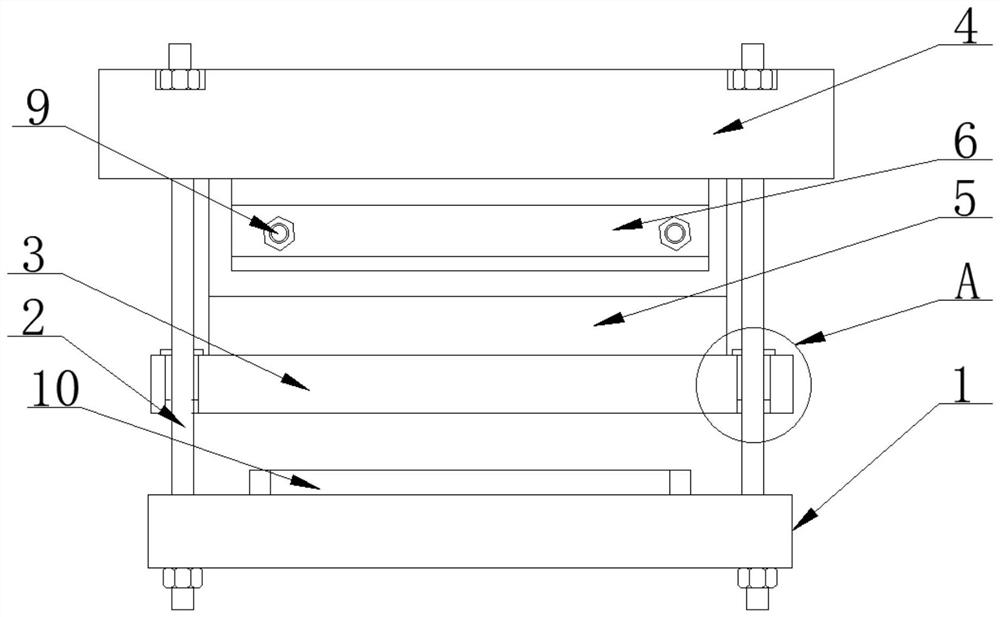

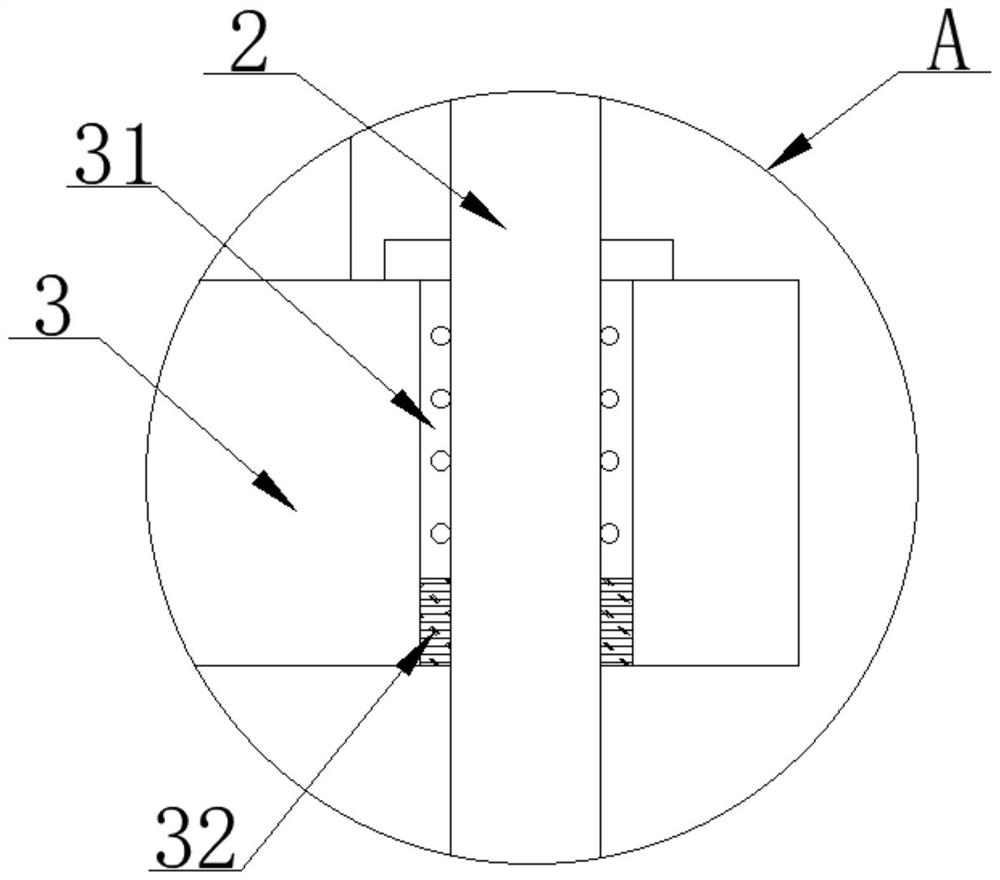

Circular tube symmetric distribution bilateral intersecting line one-time blanking forming device and method

InactiveCN109821964AGuaranteed normal movementEven by forceBilateral symmetryElectrical and Electronics engineering

The invention discloses a circular tube symmetric distribution bilateral intersecting line one-time blanking forming device and method. The device comprises a driving device and a composite die, wherein the composite die comprises a stamping die, a trapezoid die and a positioning die; the trapezoid die is arranged on the driving device; the stamping die comprises a first sub stamping die and a second sub stamping die; the first sub stamping die and the second sub stamping die are the same in structure and are mounted in a mounting seat in bilateral symmetry; the first sub stamping die is driven by a first returning device to automatically return; the second sub stamping die is driven by a second returning device to automatically return; the motion direction of the first sub stamping die and the second sub stamping die is perpendicular to that of the trapezoid die; and a die cavity is formed in the positioning die for fixing a to-be-processed workpiece.

Owner:SHANDONG UNIV

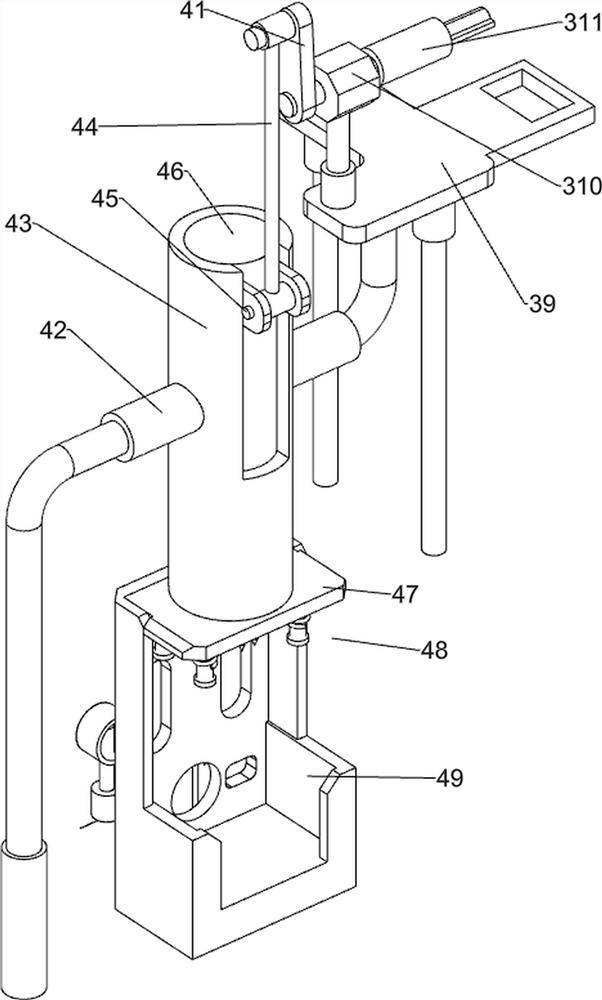

Novel punching mechanism

The invention provides a novel punching mechanism which comprises a gas-liquid pressure cylinder, a mounting support, a profiling convex mold and a guide mechanism. During punching, the profiling convex mold is driven by the gas-liquid pressure cylinder, the gas-liquid pressure cylinder presses a to-be-punched product to the profiling convex mold, then pressurization work is carried out, and therefore product punching is achieved. The gas-liquid pressure cylinder is used as a power source for punching, enough punching force is achieved, and under the guide action of the guide mechanism, precise locating can be achieved; and the product surfaces are prevented from being damaged, and therefore process requirements are met, and product quality is guaranteed.

Owner:LIUZHOU WULING MOTORS +1

Plate punching device

InactiveCN106914530APunching realizationSimple structurePerforating toolsEjection devicesPunchingEngineering

The invention discloses a plate punching device. The plate punching device comprises an upper die, an unloading plate, a center punch, side punches and a female die. The center punch is fixed to the center position of the bottom of the upper die. The multiple sets of side punches are fixed to the side portion of the bottom of the upper die. Center springs are arranged on the outer side of the center punch, and side springs are arranged on the outer sides of the side punches. The upper ends and the lower ends of the center springs and the side springs are connected with the upper die and the unloading plate. The female die is arranged at the bottom of the unloading plate and is fixed to a base. Center holes aligned with one another are formed in the center positions of the unloading plate, the female die and the base. The center holes and the center punch have the common center line. Side holes which are aligned with one another are formed in the side portions of the unloading plate, the female die and the base. The side holes and the side punches have the common center line. The upper die is fixed to the bottom of an upper die plate, and the upper portion of the upper die plate is connected with a piston rod of a hydraulic oil cylinder. The plate punching device has the beneficial effects of being simple in structure, high in efficiency and capable of achieving automatic unloading and is suitable for punching of various plates.

Owner:CHAOHU UNIV

Punching device preventing automobile sealing strip with skeleton from machining deformation

ActiveCN102689330BPunching realizationReduce impactMetal working apparatusPunchingMachining deformation

A punching device preventing an automobile sealing strip with a skeleton from machining deformation comprises a female die 7, a pressure plate 5 and a cutter 6, and is characterized in that a groove 9 for placing the sealing strips and a guide mechanism 8 for guiding the cutter 6 to finish the punching operation are arranged on the female die 7; the guide mechanism 8 is intersected with the groove 9 to form a guiding included angle Gamma; the cutter 6 is provided with a horizontal cutting edge 12 and a vertical cutting edge 10; the moving direction of the horizontal cutting edge 12 and the moving direction of the cutter 6 form a cutting edge included angle Beta 1; one end, far from the pressure plate 5, of the horizontal cutting edge 12 inclines towards the punching advance direction of the cutter 6; the cutting edge included angle Beta 1 is smaller than the guiding included angle Gamma; in punching, the sealing strips are cut step by step by the horizontal cutting edge 12 at first, then are cut by the vertical cutting edge 10, so that the impulsive force of the cutter 6 on the sealing strips is reduced, and the deformation of the sealing strips is further reduced, the incision surfaces of the sealing strips are smooth, and the skeleton deformation is avooided.

Owner:HENNIGES (CHINA) AUTOMOTIVE SEALING SYST CO LTD

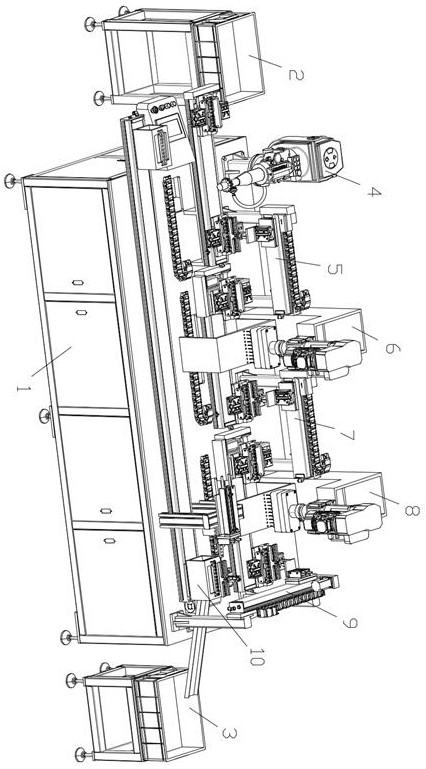

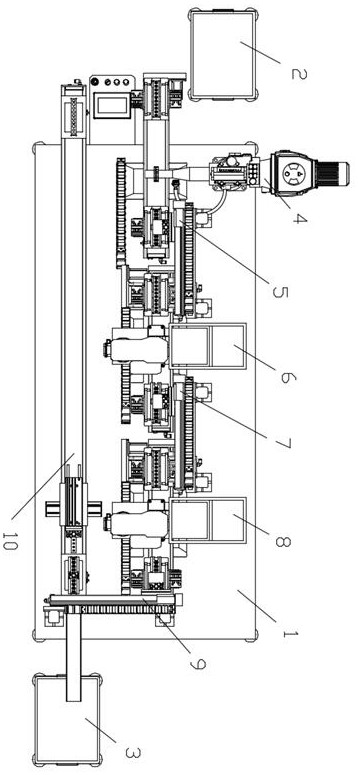

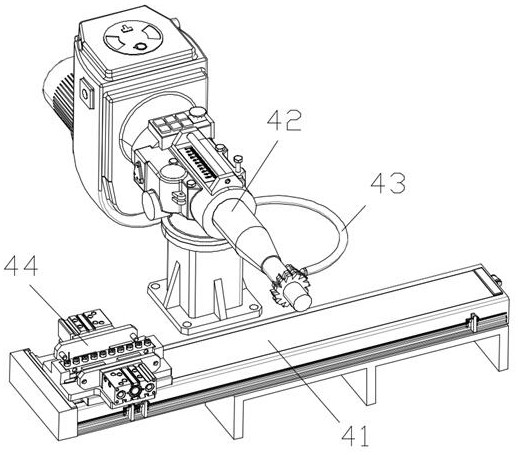

Automatic surface milling and drilling equipment used for machining

InactiveCN112238352APunching realizationImprove machining accuracyOther manufacturing equipments/toolsPunchingManipulator

The invention discloses automatic surface milling and drilling equipment used for machining. The automatic surface milling and drilling equipment comprises a worktable, a feeding box and a collectingbox; the feeding box and the collecting box are located at the left side and the right side of the worktable correspondingly; the automatic surface milling and drilling equipment further comprises a lock cylinder surface milling mechanism, a manipulator part taking mechanism I, a lock cylinder punching mechanism, a manipulator part taking mechanism II, a lock cylinder tapping mechanism, a manipulator part taking mechanism III and a product jig reflux mechanism; the lock cylinder surface milling mechanism, the lock cylinder punching mechanism and the lock cylinder tapping mechanism are fixed tothe middle part of the upper surface of the worktable in sequence from left to right; the manipulator part taking mechanism I and the manipulator part taking mechanism II are both fixed to the rear side of the upper surface of the worktable; and the manipulator part taking mechanism I delivers a to-be-machined product to the position of the lock cylinder punching mechanism from the position of the lock cylinder surface milling mechanism. The automatic surface milling and drilling equipment is high in automation degree, effectively improves the machining precision of a lock cylinder, greatly increases the working efficiency and reduces the labor cost, and has good market application value.

Owner:新乡创想自动化科技有限公司

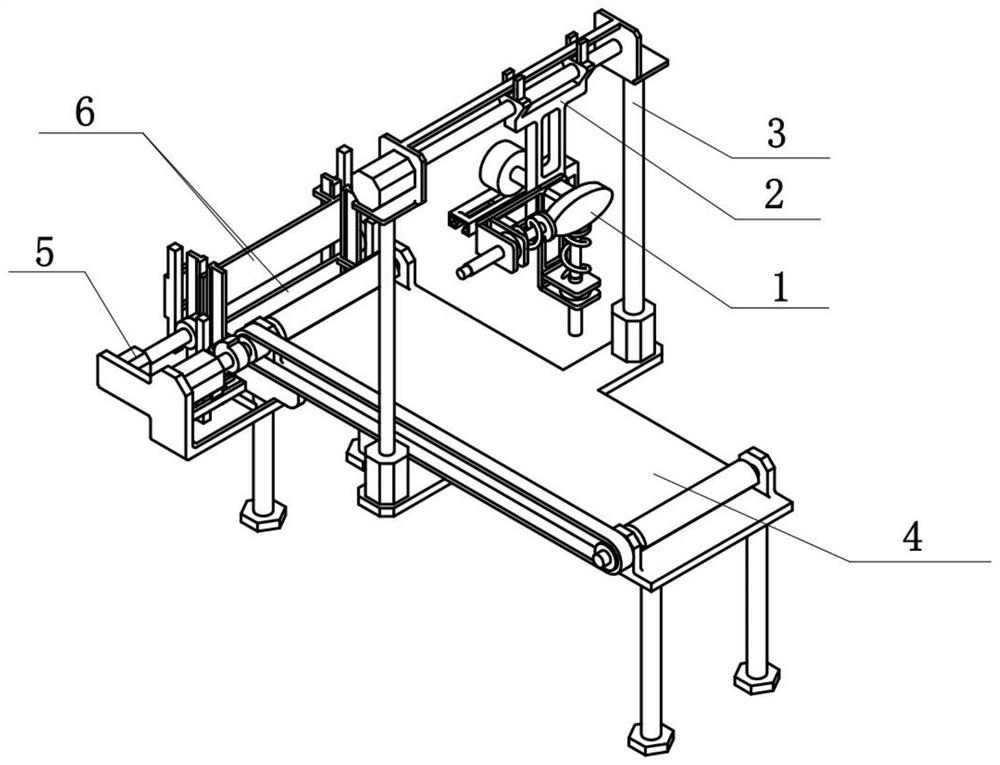

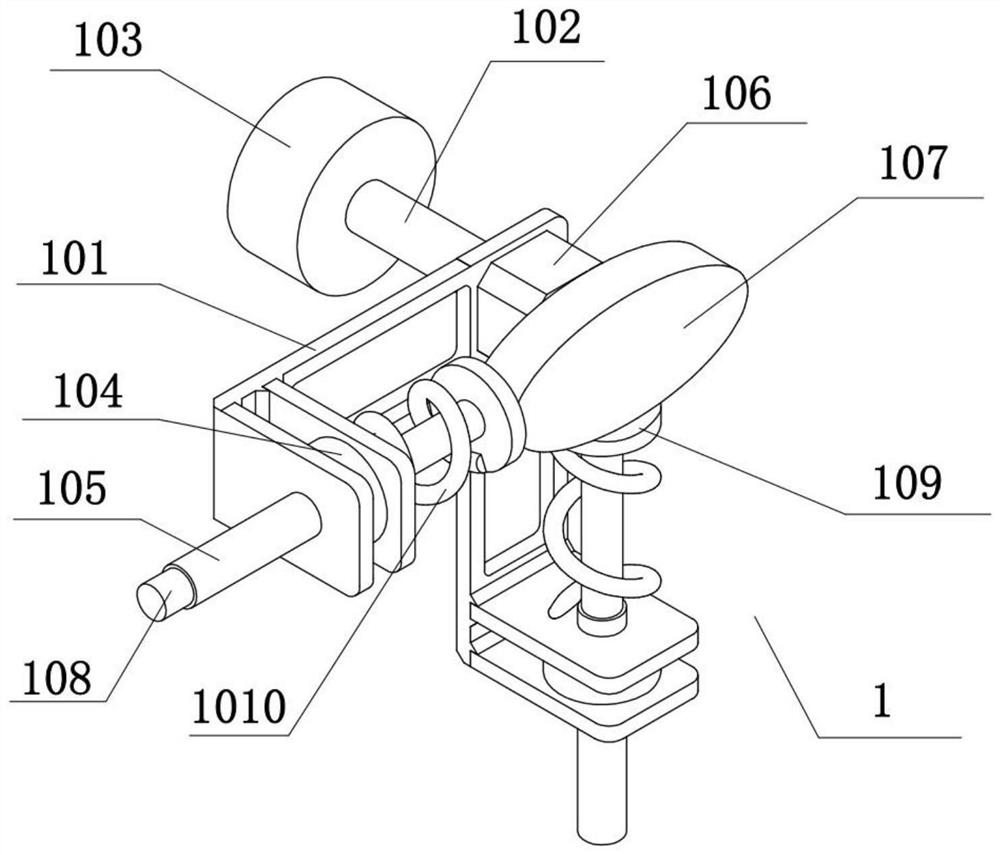

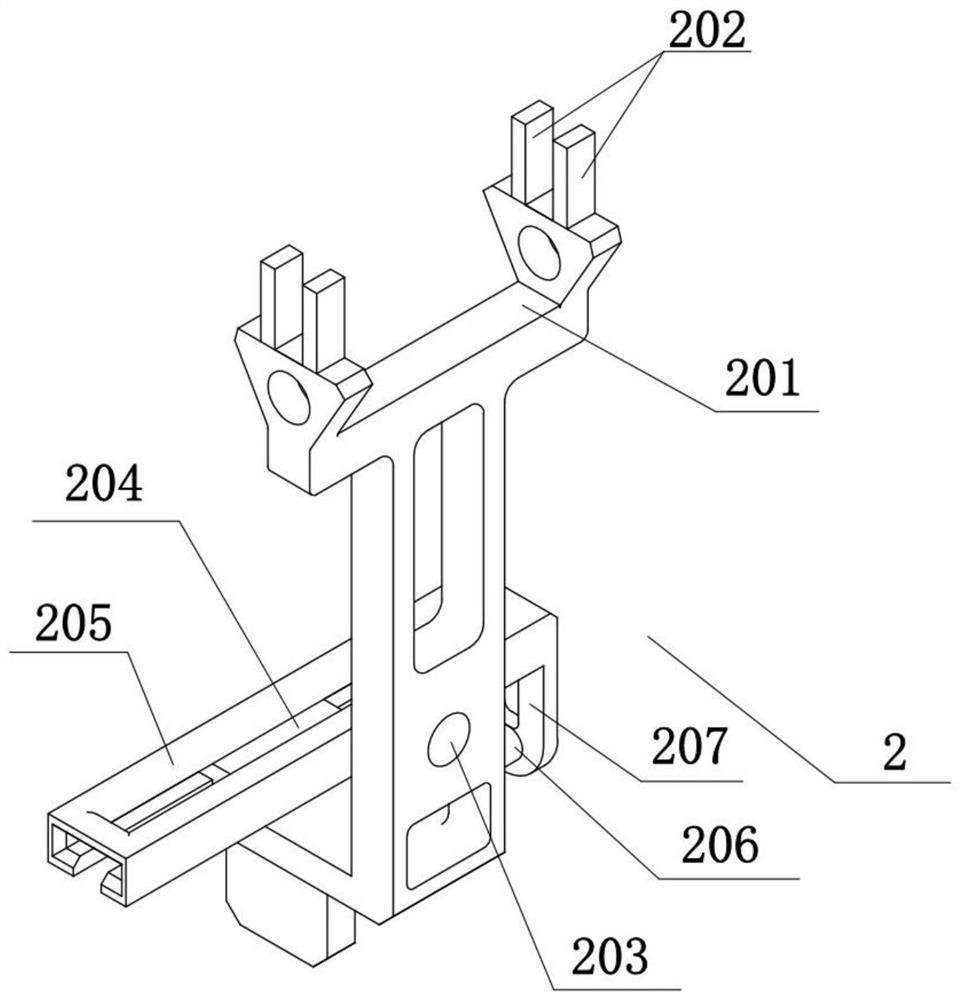

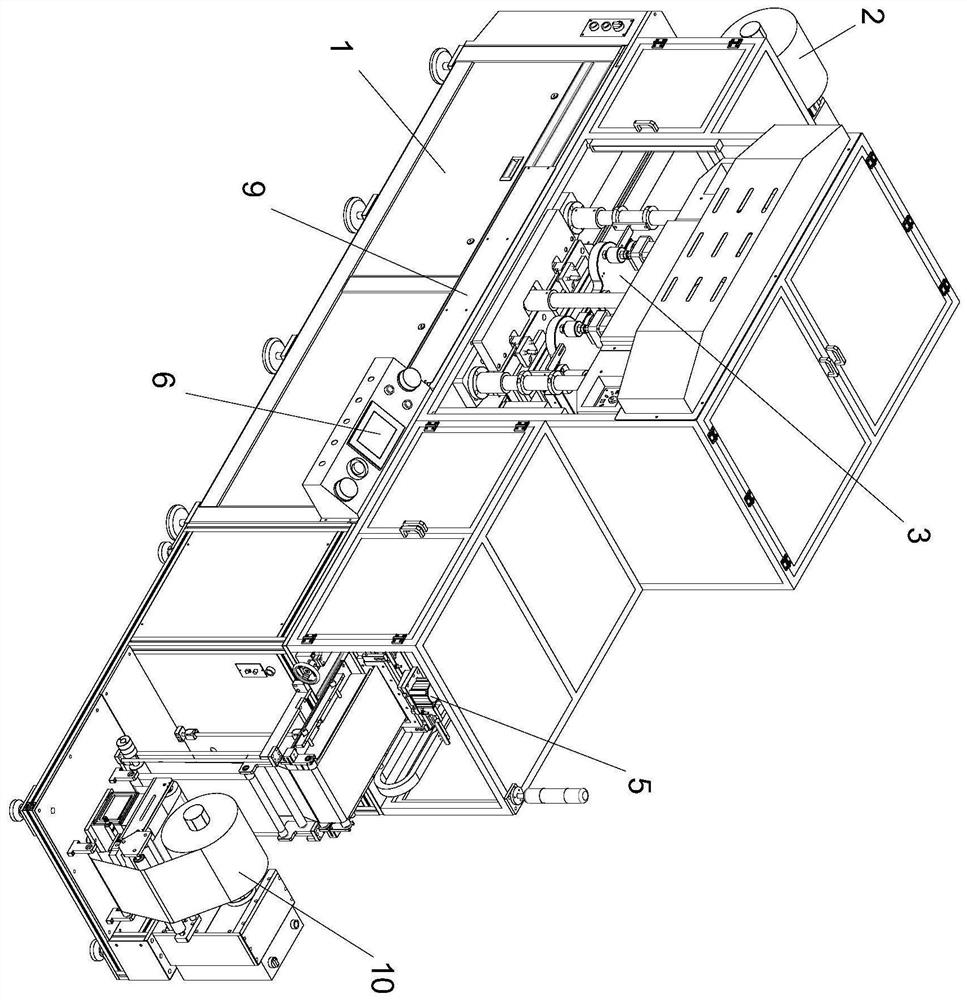

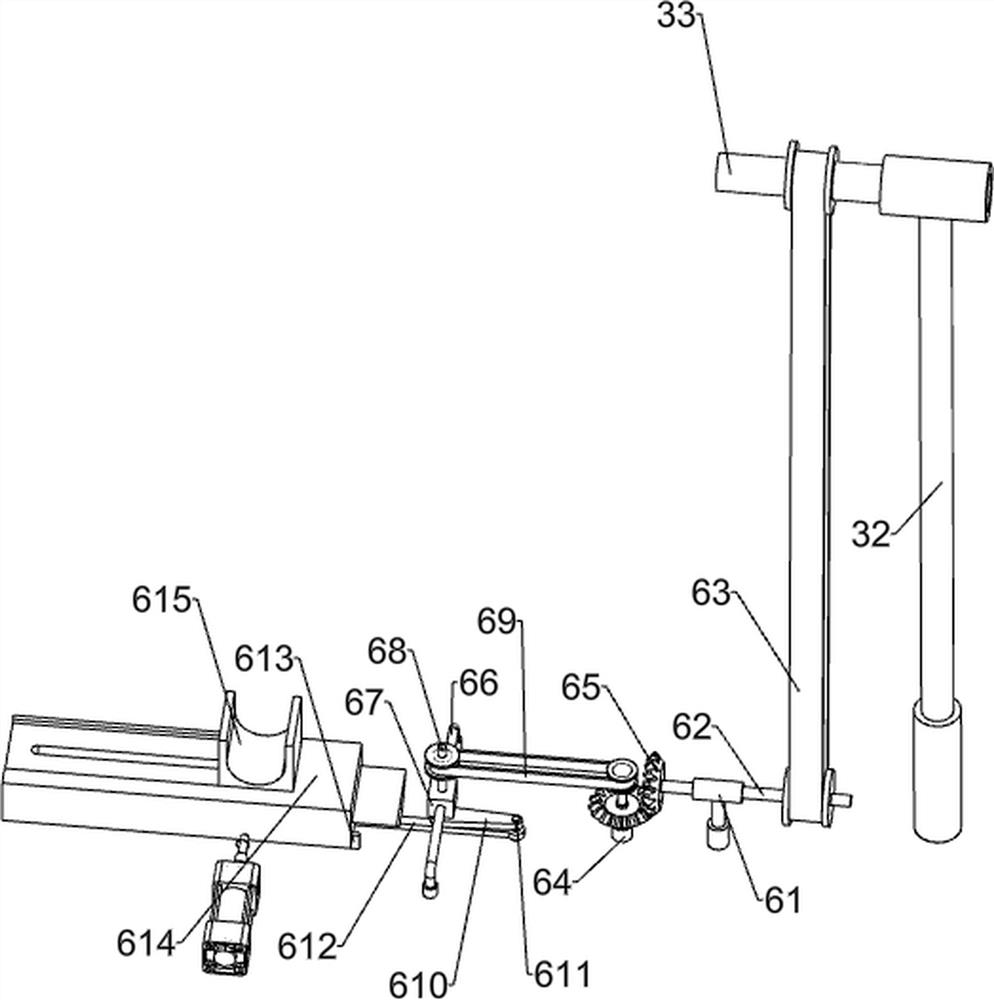

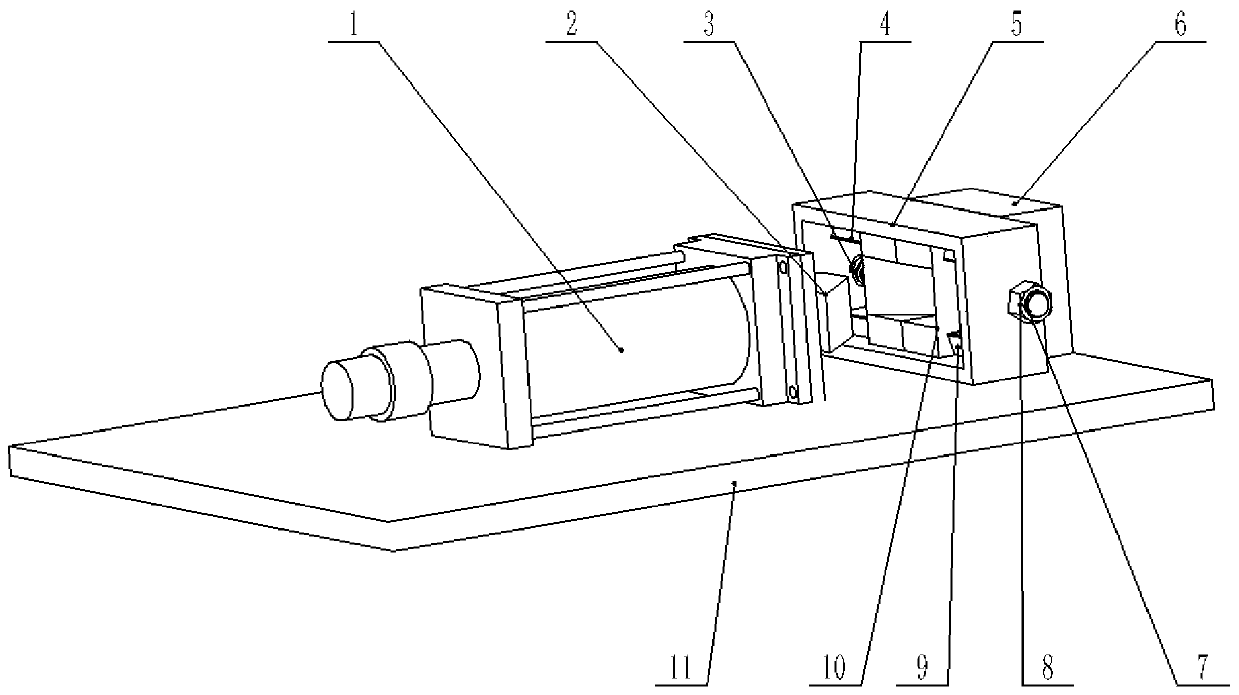

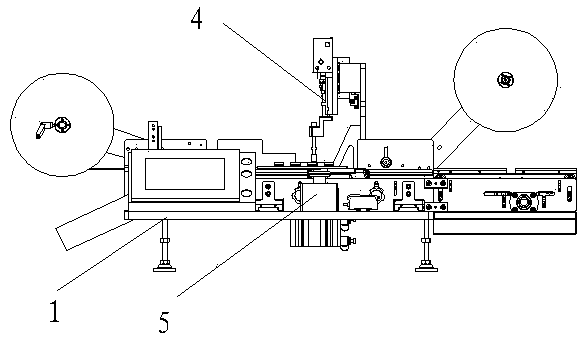

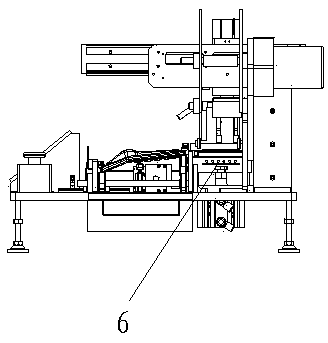

Calculator foot pad attaching machine

InactiveCN103775453AQuick and easy attachmentPunching realizationMetal working apparatusFastening meansPunchingEngineering

The invention discloses a calculator foot pad attaching machine which comprises a rack (1), wherein a foot pad feeding module (2), a product feeding module (3), an absorbing module (4), a product positioning module (5) and a punching module (6) are arranged on the rack; the foot pad feeding module and the product feeding module are adjacently arranged; the punching module is located at one end of the foot pad feeding module; the absorbing module is located above the punching module; and the product positioning module is located above the product feeding module. By the aid of the scheme, the accurate product positioning module and the punching module are arranged, so that foot pads can be attached to any types of calculators rapidly and simply, feed punching of the foot pads can be realized, the punching cost of the raw material is saved, and the machine has the advantages that the manufacturing cost is low and the production efficiency is high.

Owner:JIANGSU COWAIN AUTOMATION TECH

A panel punching and shaping device

ActiveCN108526303BPunching realizationMetal-working feeding devicesPositioning devicesPunchingStructural engineering

The invention relates to the field of machining and manufacturing, in particular to a panel stamping molding device which comprises a rack; the rack is provided with a stamping table; molding groovesare symmetrically formed in the stamping table; the side wall of the outer side of each molding groove forms an inclined surface; a molding hole is formed between the molding grooves; a stamping headis arranged above the stamping table; clamping jaws capable of being inserted into the molding grooves respectively are hinged to the stamping head and are provided with wedged surfaces matched with the corresponding inclined surfaces respectively; first liquid storage pipes are symmetrically arranged between the clamping jaws and are internally provided with pistons in a sliding manner respectively; a pressure rod is arranged below each piston in the sliding manner; a first spring is connected between each pressure rod and the corresponding piston; the stamping head is provided with a limiting mechanism used for fixing the pistons; a second liquid storage pipe is communicated between the first liquid storage pipes and is internally provided with a punching cutter capable of being insertedinto the corresponding molding hole in the sliding manner; and the stamping head is internally provided with a drive mechanism. The panel stamping molding device solves the problem that the existingstamping mechanism cannot perform stamping at the same time.

Owner:SHANDONG STREET MOBILE SHOP NEW ENERGY TECH CO LTD

Intelligent automatic die adjusting mechanism based on oil press principle

InactiveCN111644505APunching realizationThe punching process is stablePress ramEngineeringStructural engineering

The invention discloses an intelligent automatic die adjusting mechanism based on an oil press principle, and particularly relates to the field of machining. The intelligent automatic die adjusting mechanism based on the oil press principle comprises a punching bottom plate, a linear guide rod, a punching die and a feeding mechanism, a fixed seat is installed at the top end of the linear guide rod, a tapered wedge moving block is slidably connected to the bottom face of the fixed seat, and a hydraulic jacking mechanism is installed on the bottom face of the fixed seat; and the output end of the hydraulic jacking mechanism is connected with a jacking rod, the top face of the punching die is connected with a tapered wedge pressing die in a clamped mode, and the input end of the hydraulic jacking mechanism is connected with a hydraulic driving mechanism. According to the intelligent automatic die adjusting mechanism, a tapered wedge lifting mechanism is arranged, the tapered wedge movingblock transversely moves on the surface of the tapered wedge pressing die, and the transverse jacking force driven hydraulically is converted into lifting power of the punching die through the taperedwedge lifting mechanism, so that punching of a workpiece is achieved; and compared with a traditional lead screw lifting structure, the tapered wedge lifting mechanism is more stable and higher in structural strength, the tapered wedge lifting mechanism is suitable for punching high-hardness workpieces, the fault rate is low, and the service life is greatly prolonged.

Owner:嘉兴久珥科技有限公司

Magnetic type positioning punching device

InactiveCN105689525APunching realizationImprove reliabilityMetal-working feeding devicesPositioning devicesPunchingThick plate

The invention relates to a magnetic type positioning punching device. The magnetic type positioning punching device comprises a punching driving device, an upper die plate and a punching head and further comprises a supporting device and a clamping device, wherein the supporting device and the clamping device are located below the punching head. The supporting device comprises a base provided with a sliding groove. A cushion block is slidably arranged in the sliding groove of the base and driven by an air cylinder. Positioning magnets are arranged in the cushion block. The clamping device comprises clamping blocks which are symmetrically arranged. Clamping grooves are formed in the inner sides of the clamping blocks. One clamping block is connected with a motor. The magnetic type positioning punching device further comprises a controller used for controlling the punching driving device, the air cylinder and the motor. According to the magnetic type positioning punching device, hole machining is achieved in a turning type double-sided punching way, and punching of thick plates is achieved; and the magnets are used for primary positioning, deviation in the turning process is prevented, and thus the punching reliability is improved.

Owner:无锡市通协物资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com