Punching device preventing automobile sealing strip with skeleton from machining deformation

A technology for processing and deforming automobile sealing strips, which is applied in the field of punching devices and punching devices for automobile sealing strips with skeletons, which can solve problems such as skeleton deformation and uneven cut surface, and prevent skeleton deformation and uneven cut surface , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

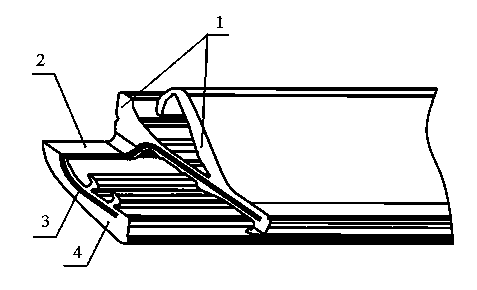

[0063] figure 1 Shown is the sealing strip to be processed in this embodiment. The sealing strip is composed of rubber 4 covered with aluminum strip 3, and can also be composed of rubber 4 covered with steel strip. The incisions required to be punched include longitudinal section 1 and transverse section. 2. An inclined angle is formed between the intersection line formed by the intersection of the longitudinal section 1 and the transverse section 2 and the extension direction of the sealing strip, and the angle can be 90° or any acute angle; the longitudinal section 1 and the transverse The intersection of the tangent planes 2 forms a tangent plane angle, and the tangent plane angle can be any angle within the range of 0° to 180° except 0° and 180°; the intersection of the longitudinal tangent plane 1 and the transverse tangent plane 2 is an arc connection, or It is a straight line connection; the surface of the longitudinal section 1 and the transverse section 2 is required ...

Embodiment 2

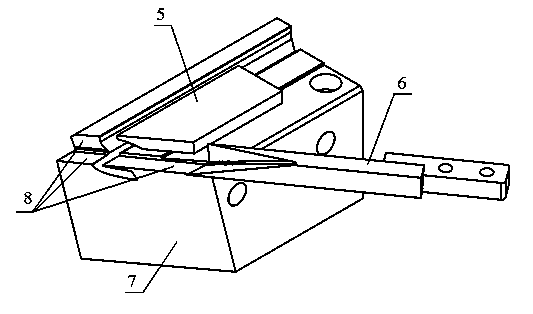

[0072] The punching device for preventing the processing and deformation of the automobile weather strip with skeleton according to the present invention includes a female mold 7, a pressing plate 5 and a cutter 6, and a groove 9 is arranged on the female mold 7 for placing the weather strip, and the The shape of the groove 9 matches the contour shape of the sealing strip to be processed;

[0073] A liftable pressing plate 5 is provided above the female mold 7 for pressing the sealing strip. The pressing plate 5 can move up and down under power drive, and the part of the pressing plate 5 in contact with the surface of the sealing strip is formed as Shape to match the profile of the weatherstrip;

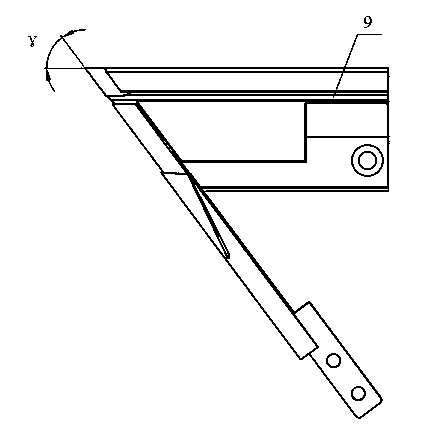

[0074] One end of the female mold 7 is provided with a guiding mechanism 8, which intersects with the groove 9 to form a guiding angle γ, and in this embodiment, the guiding angle γ is set to be 90°;

[0075] There is a sliding fit between the guide mechanism 8 and the cutter 6, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com