Battery steel shell metal plate punching tool

A battery steel shell and sheet metal technology, applied in the field of stamping tooling, can solve the problems of prolonging production time, reducing production efficiency, and many stamping processes, and achieve the effect of reducing production time, improving efficiency, and less stamping processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

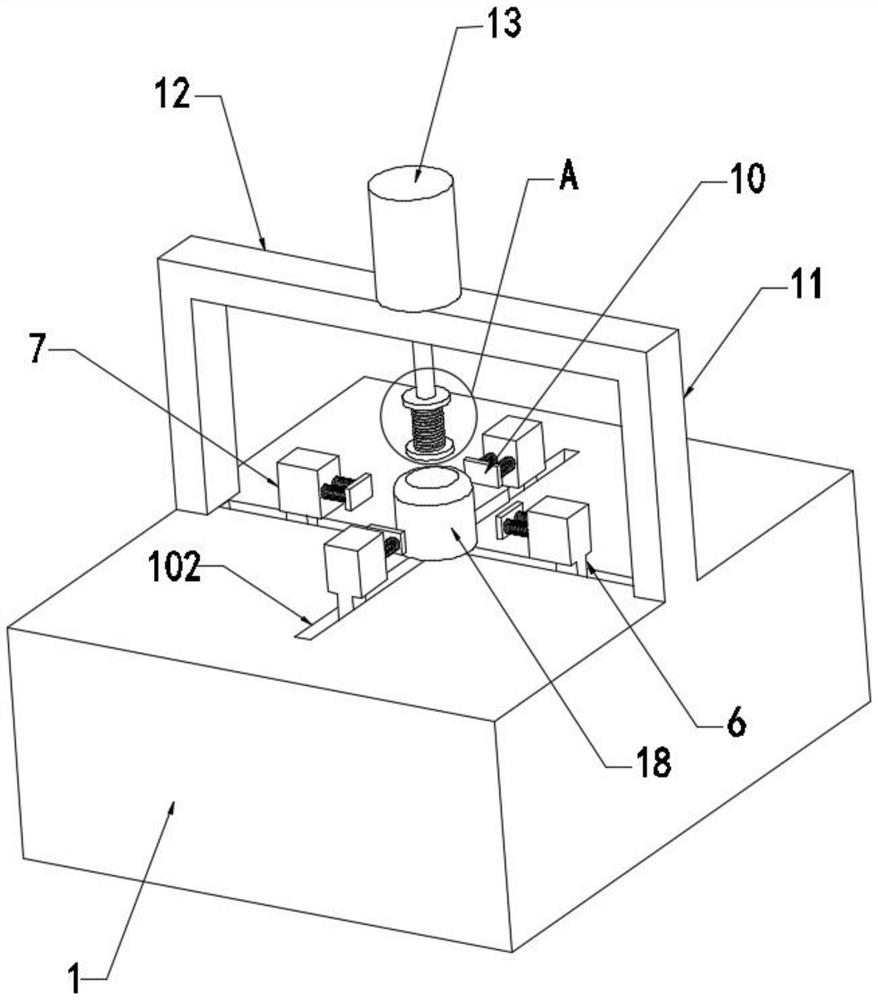

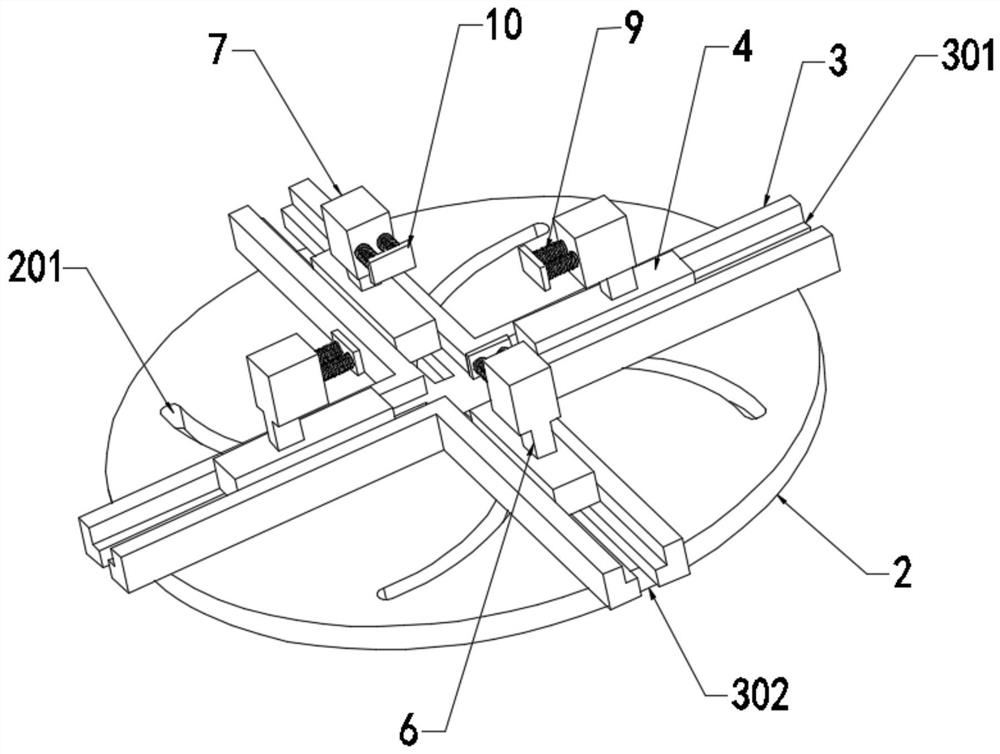

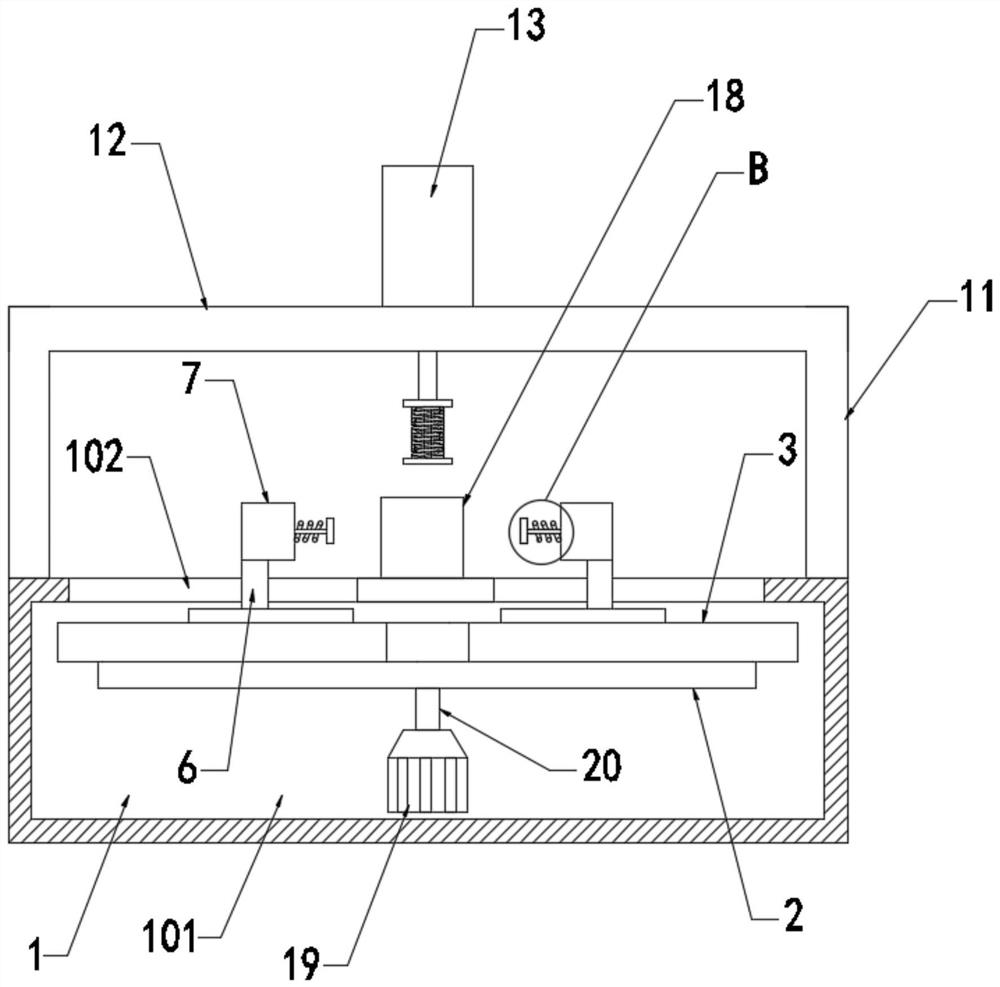

[0042] see Figure 1-8 , the present invention provides a technical solution: a battery steel shell sheet metal stamping tool, including a base 1, a first installation groove 101 is opened in the base 1, a rotating disk 2 is installed in the first installation groove 101, and the rotating disk 2 There are four arc grooves 201 arranged obliquely on the top, and the four arc grooves 201 are arranged at equal angles around the axis of the rotating disk 2 on the rotating disk 2. The cross block 3 is fixedly installed in the first installation groove 101, and the cross block 3 is provided with a sliding groove 301, the sliding block 4 is slidably connected in the sliding groove 301, the cross block 3 is provided with a slot 302 communicating with the sliding groove 301, and the bottom of the sliding block 4 is fixedly connected with a sliding rod passing through the slot 302 5. The sliding rod 5 slides in the arc groove 201, the first installation groove 101 is provided with a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com