Micro blanking system for on-line processing of punch-die

A technology of micro-blanking and convex-concave dies, which is applied in the field of micro-blanking systems, can solve the problems of inability to process special-shaped dies, large taper of the side wall of the die, and low machining accuracy of the die, so as to reduce errors, increase the punching load, and The effect of high motion deviation absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

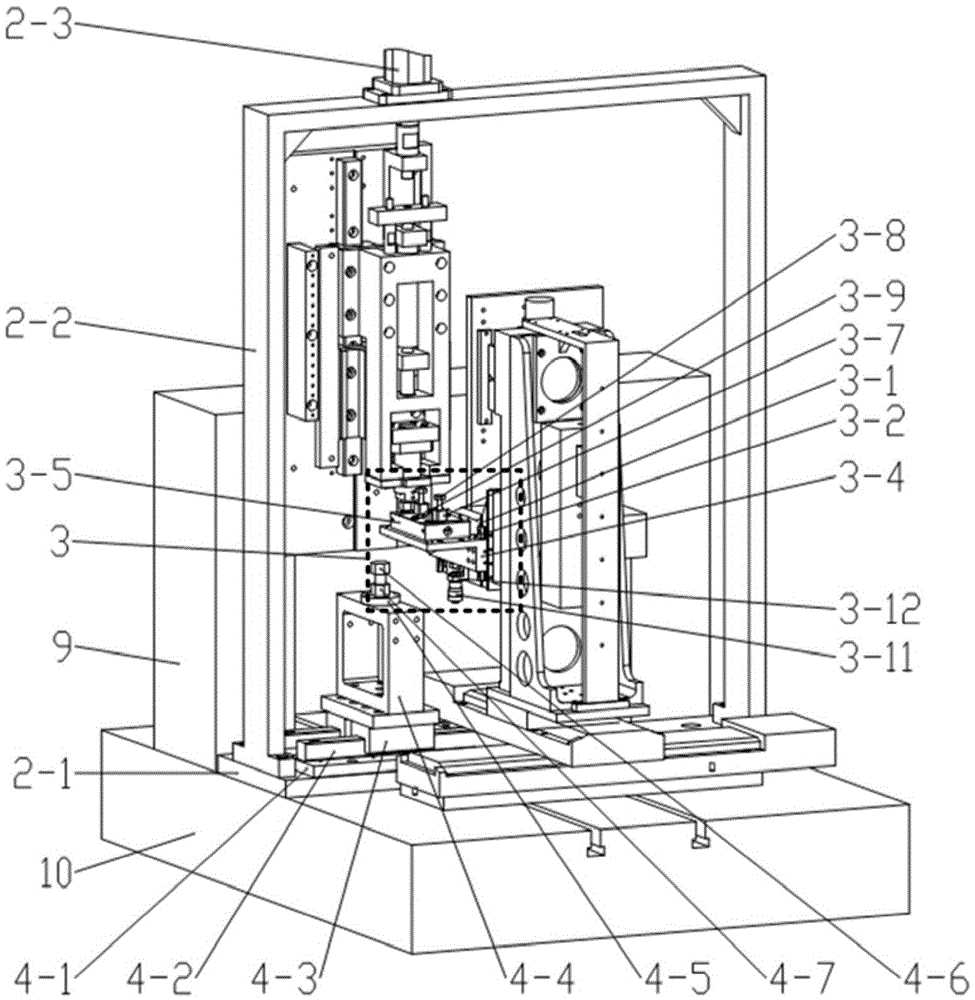

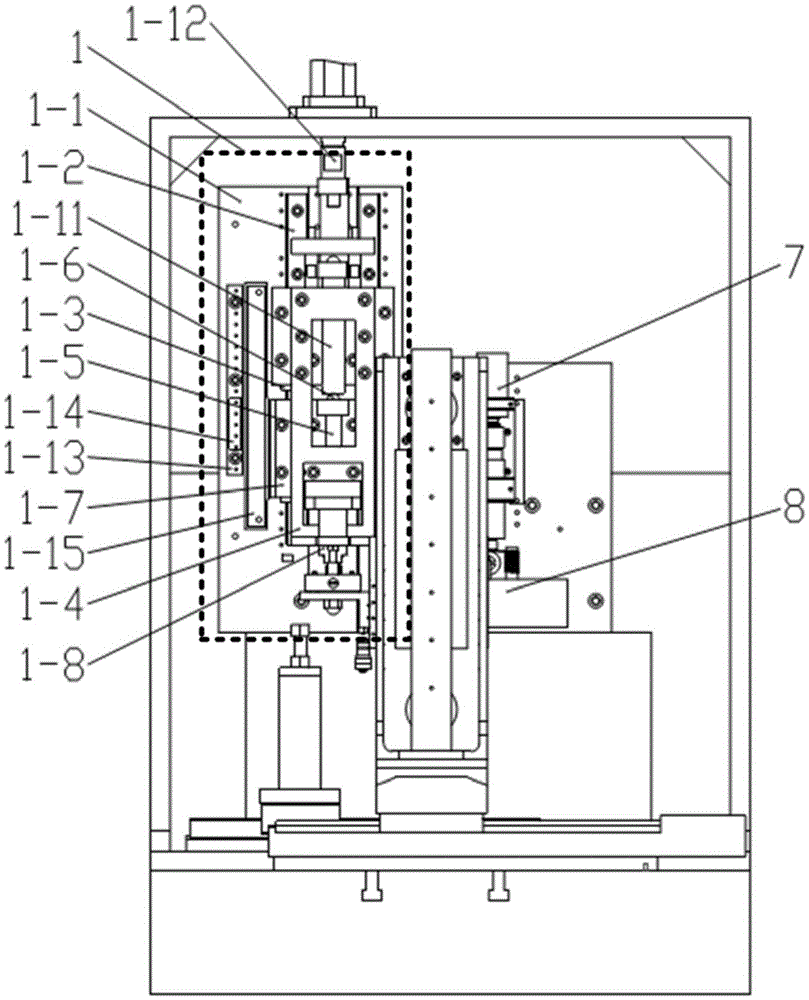

[0032] Specific embodiment one: as Figure 1-9 As shown, the micro-blanking system for online processing of punch and die described in this embodiment mainly includes a punch assembly 1, a door frame assembly 2, a die assembly 3, a bracket assembly 4, and a precision XYZ three-axis positioning assembly 5, Counterweight assembly 6, EDM spindle assembly 7, WEDG wire electrode grinding assembly 8, marble vertical board 9, marble countertop 10. The marble vertical plate 9 is a gantry structure, and is installed on the marble table 10 by screws to ensure that the verticality of the marble vertical plate 9 installation surface and the marble table 10 is 50 μm, and the punch assembly 1 and the electric spark spindle assembly 7 are respectively fixed on the On the left and right sides of the marble vertical plate installation surface, the door frame component 2 and the precision XYZ three-axis positioning component 5 are independently installed on the marble table 10, so that the X-ax...

specific Embodiment 2

[0033] Specific embodiment 2: The punch linear guide 1-2 used in the punch assembly 1 can choose the HGH30HA ultra-precision linear guide in Taiwan HIWIN, and the grating ruler used for the linearity up to 2 μm can choose the LS400170 produced by Germany Heidenhain .

specific Embodiment 3

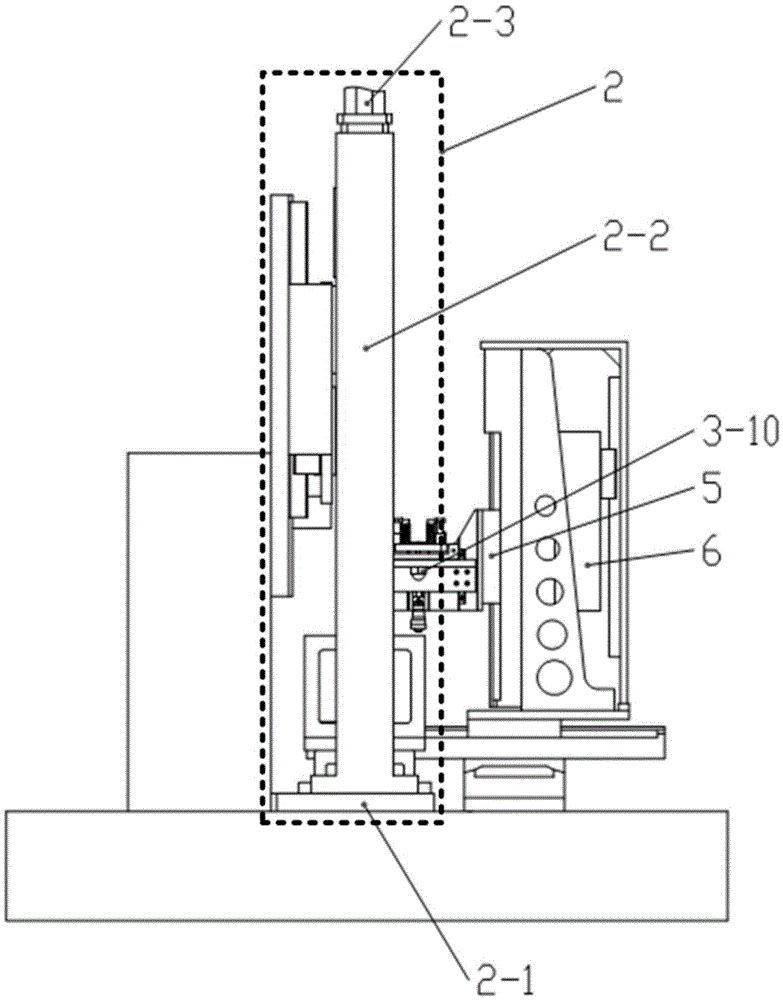

[0034] Specific embodiment three: as Figure 1~3 As shown, the gantry assembly 2 of the micro-blanking system in this embodiment includes a gantry bottom plate 2-1, a gantry main body 2-2 and a linear actuator 2-3; wherein the gantry bottom plate 2-1 is installed on a marble table 10, the door frame main body 2-2 is a door-shaped frame structure, which is spliced by two vertical plates and a horizontal plate. The main body of the door frame 2-2 is fixed to the door frame bottom plate 2- 1 and make the main body 2-2 of the door frame straddle the marble table 10, the installation surface of the top horizontal plate is basically parallel to the marble vertical board 9 and the marble table 10, and the linear actuator 2-3 is installed on the top of the main body 2-2 of the door frame. and make the execution feed direction of the linear actuator 2-3 perpendicular to the marble table top 10, the execution end of the linear actuator 2-3 is connected and fastened with the push rod c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com