Device having counterpunching belt, for punching labels

A label and equipment technology, which is applied in the field of equipment for punching labels with matching punching belts, can solve problems such as dirty punching tools, suction air consumption interference, and quality degradation in the punching process, so as to reduce punching The effect of reducing tool wear and achieving adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

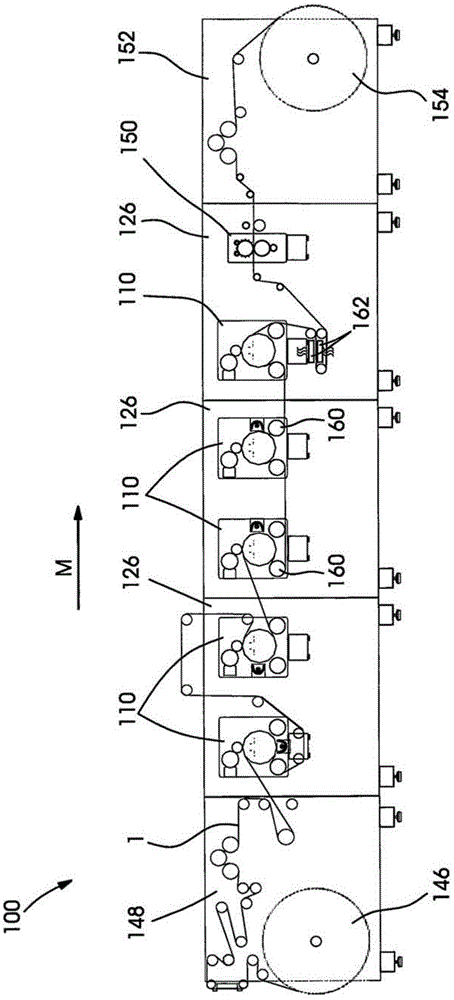

[0028] exist figure 1 A view of a preferred embodiment of a printing press 100 is shown in , which is more precisely a narrow-web label printing press in a row-and-column configuration with a printing unit 110 following in the horizontal direction. The label printing machine is used to process substrates 1 in strip form (or in web form). The substrate is unwound from a substrate roll 146 in an input 148 of the printing press 100 and is guided through the printing press 100 along a path in the machine direction M. The printing press 100 can have a plurality of frame modules 126 (in this example three frame modules 126 ). In this embodiment, respectively two printing units 110, or a printing unit 110 and a processing unit 150 (here the processing unit is a device for stamping labels on a strip-form substrate 1) are received in a rack module 126. These individual processing stations are followed by an output 152 in which the finished product is wound onto a label roll 154 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com