Spherical surface cantilever type bi-directional punching die

A two-way punching and cantilever type technology, applied in the field of punching dies, can solve problems such as difficulty in guaranteeing the processing quality of the workpiece, difficulty in ensuring the coaxiality of the two holes, and unsatisfactory quality of the workpiece, so as to achieve reliable spherical workpieces and improve processing Efficiency and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

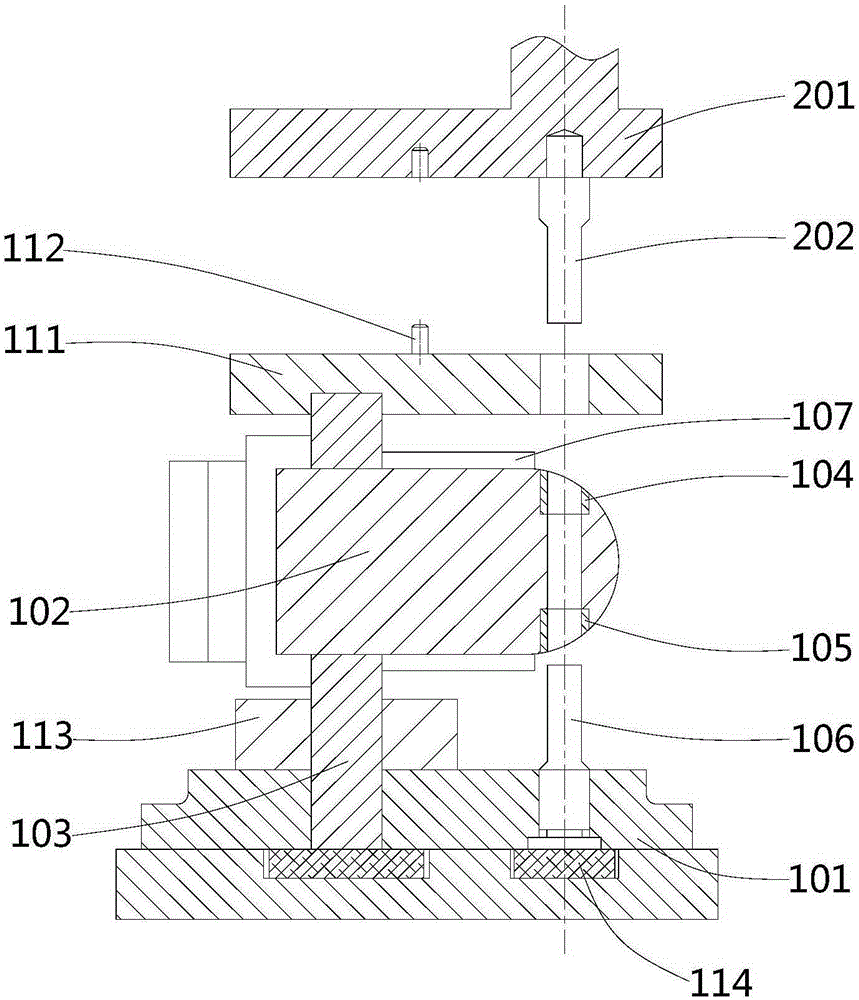

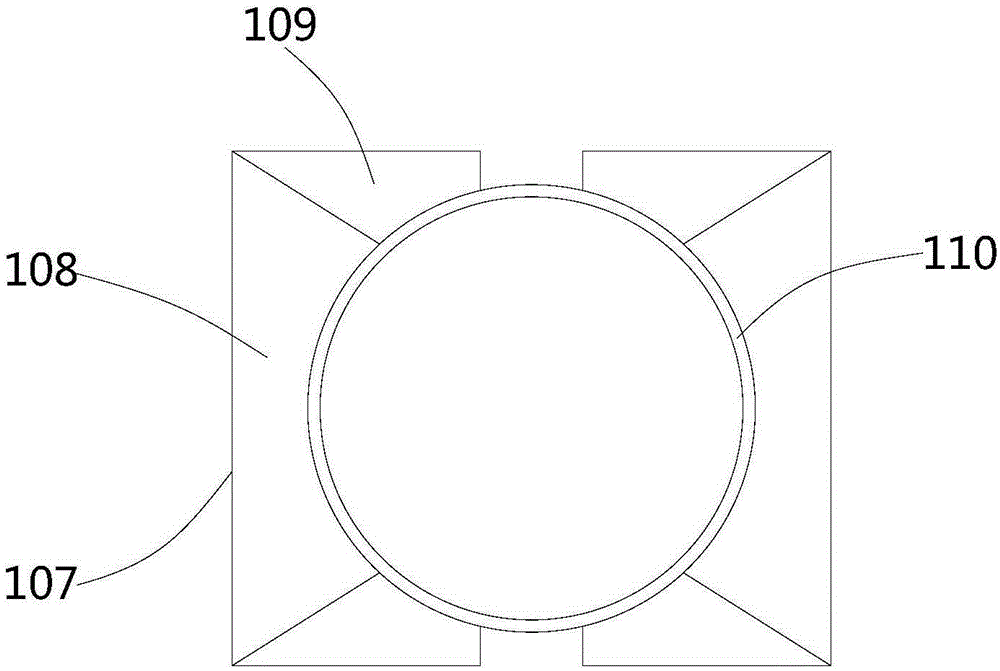

[0034] see figure 1 with figure 2 , this embodiment provides a spherical cantilever type bi-directional punching die, which is used for bi-directional punching of spherical workpieces. This spherical cantilever type bidirectional punching die comprises a lower die base 101 and an upper die base 201, the lower die base 101 is provided with a cantilever portion 102, and one end of the cantilever portion 102 is connected with the lower die base 101 through a die holder 103, the cantilever portion The other end of 102 is a working end, and the working end is provided with a spherical surface, and an upper die 104 and a lower die 105 are relatively arranged on the spherical surface up and down, the upper die holder 201 is provided with an upper punch 202, and the lower die holder 101 is provided There is a lower punch 106, the upper punch 202 corresponds to the upper die 104, the lower punch 106 corresponds to the lower die 105, and the lower die base 101 is respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com