Pile hammer of a building construction punching pile driver

A technology for building construction and pile driver, which is applied to drill pipes, casings, drill pipes, etc., can solve the problems that the hammer head is easy to get stuck in the hole, the plum blossom hole is easy to appear, and the hammer head pile hole is inclined, etc., and the structure is ingenious, Avoid the deflection of the hammer head and reduce the effect of collapsed holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

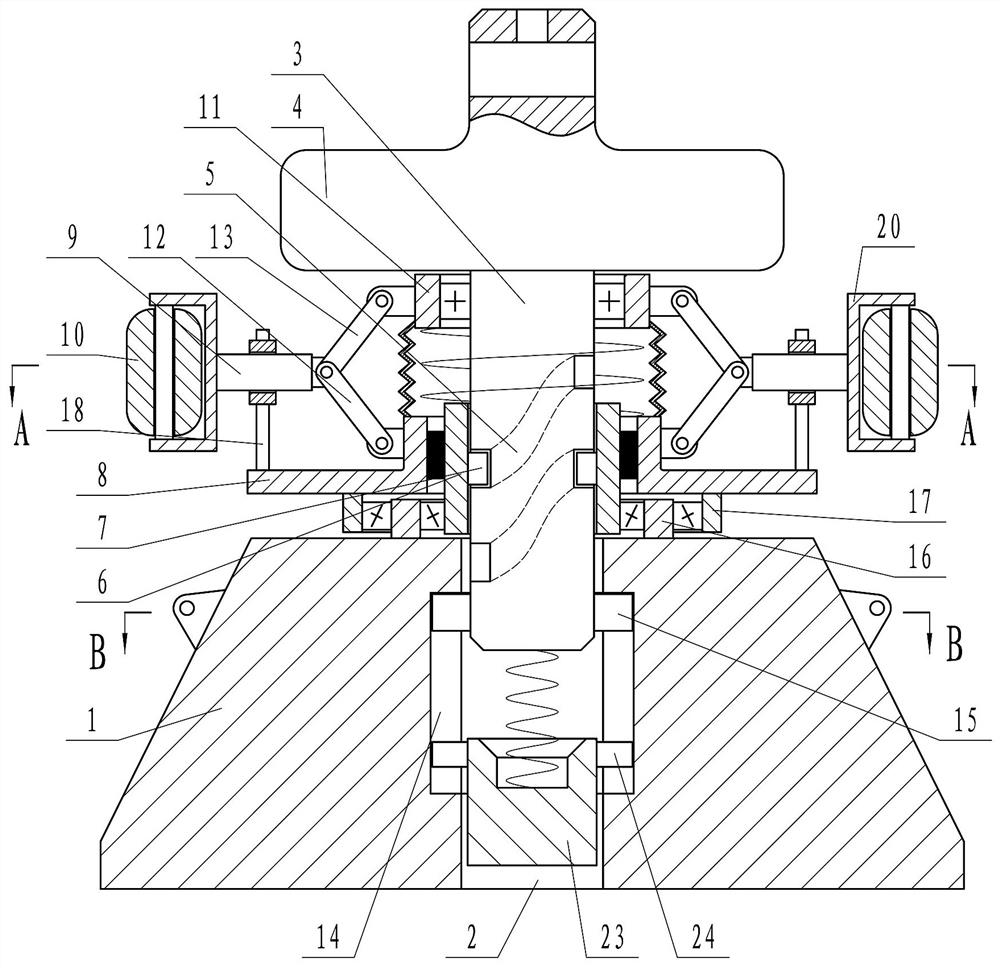

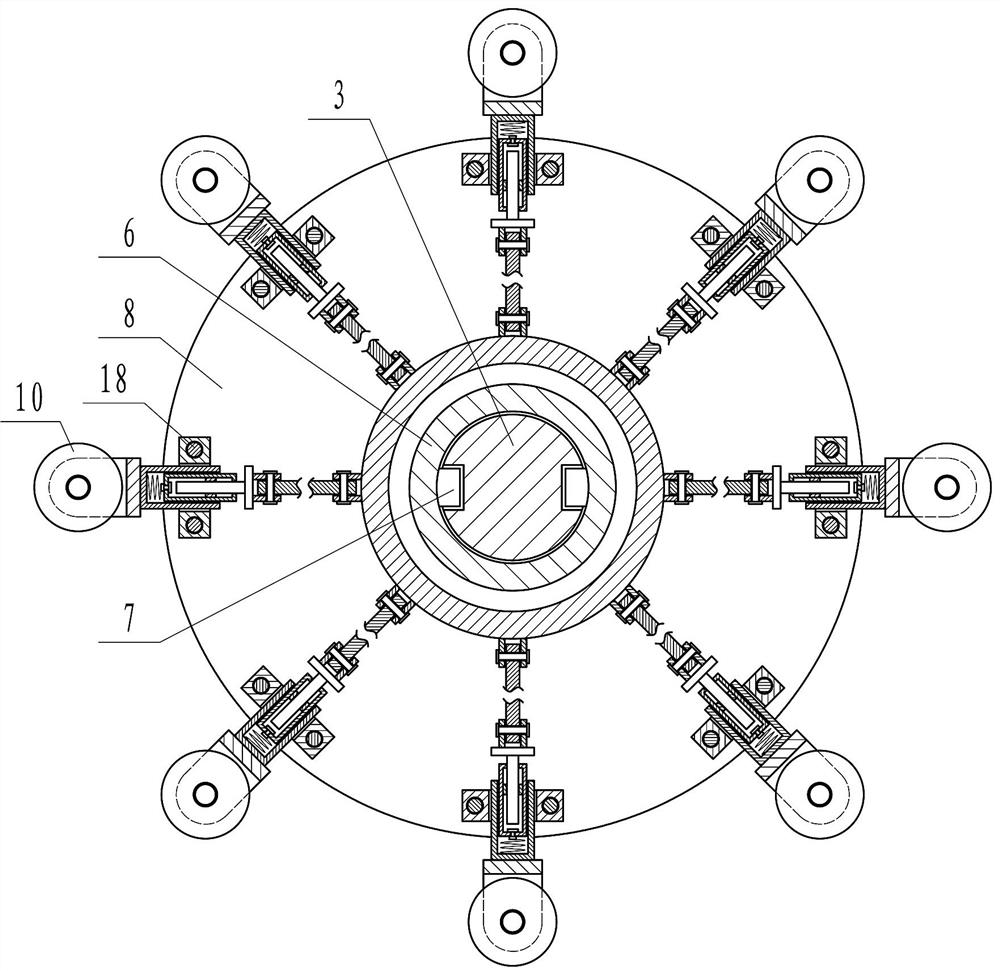

[0021] Embodiment 2, on the basis of Embodiment 1, in order to realize that the roller 10 can compact the hole wall during punching to prevent the hole from collapsing, the inner side of the annular plate 8 has an annular protrusion, and the telescopic rod 9 is close to the central axis 3 One end and the annular projection on the annular plate 8 are hinged together through the first connecting rod 12, the central shaft 3 is covered with a rotatable annular sleeve 11, and the end of the telescopic rod 9 near the central axis 3 is connected to the annular sleeve 11 through the second The connecting rod 13 is hinged, and the first connecting rod 12 and the second connecting rod 13 form a V shape with an opening inward. When the central shaft 3 moves downward to drive the annular sleeve 11 to move downward, the first connecting rod 12 and the second connecting rod 13 can push the roller 10 to move to the side away from the central axis 3 through the telescopic rod 9 and compact the...

Embodiment 3

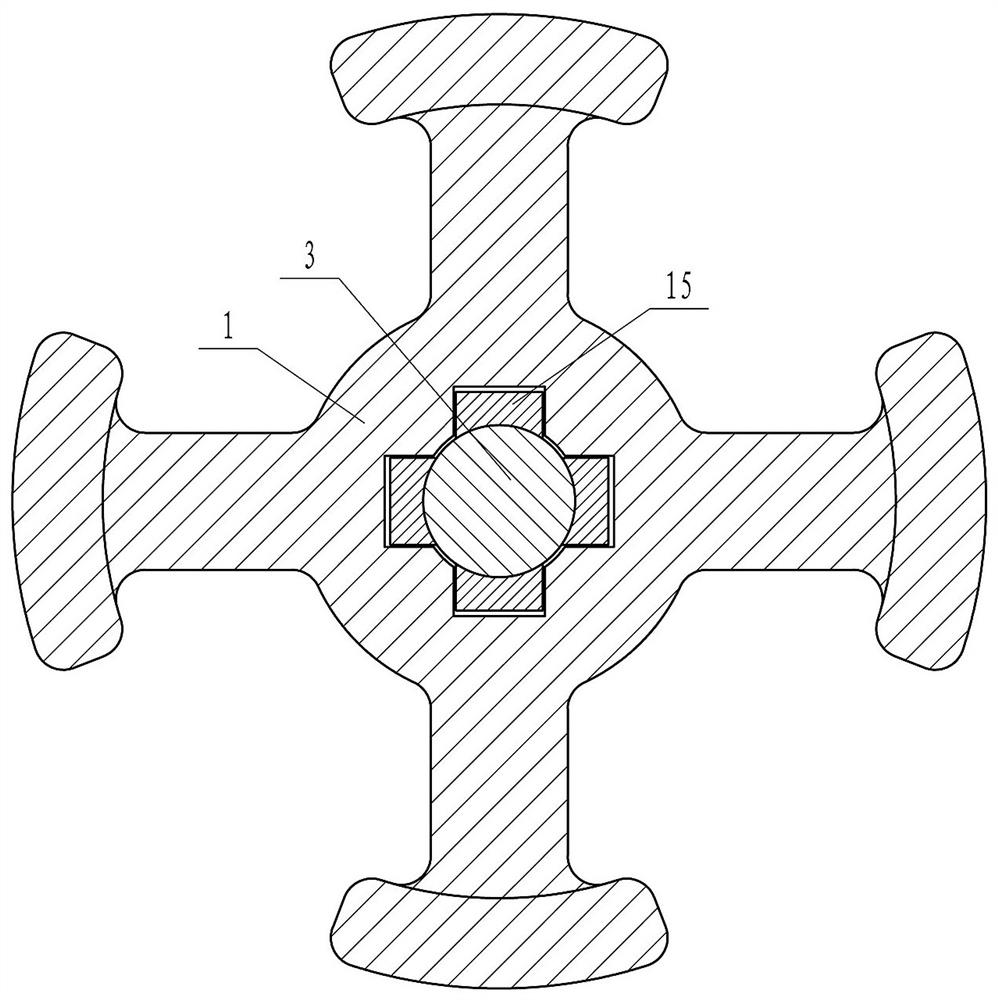

[0022] Embodiment 3, on the basis of Embodiment 1, in order to realize that the central axis 3 can move up and down along the central hole 2 but cannot rotate, the inner wall of the central hole 2 is provided with a plurality of vertical grooves 14 uniformly distributed around the circumference. The lower end of the central shaft 3 is fixed with a plurality of first protruding blocks 15 corresponding to the vertical grooves 14 one by one. The first protruding blocks 15 are placed in the vertical grooves 14 and can move up and down along the vertical grooves 14. The vertical grooves 14 are located in the center. The middle part of the hole 2 and the upper and lower ends of the vertical groove 14 are not connected, so that the first protruding piece 15 does not separate from the vertical groove 14 .

Embodiment 4

[0023] Embodiment 4, on the basis of Embodiment 1, in order to realize that the cylinder 6 can drive the ring plate 8 to rotate in one direction, a one-way clutch is installed between the cylinder 6 and the ring plate 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com