Guide rail mounting clamp for hard disk drive

A hard disk drive and installation fixture technology, which is applied in the direction of support structure installation, instruments, record carrier structural parts, etc., can solve the problems of low installation efficiency, difficult installation quality, lack, etc., to ensure quality and improve installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

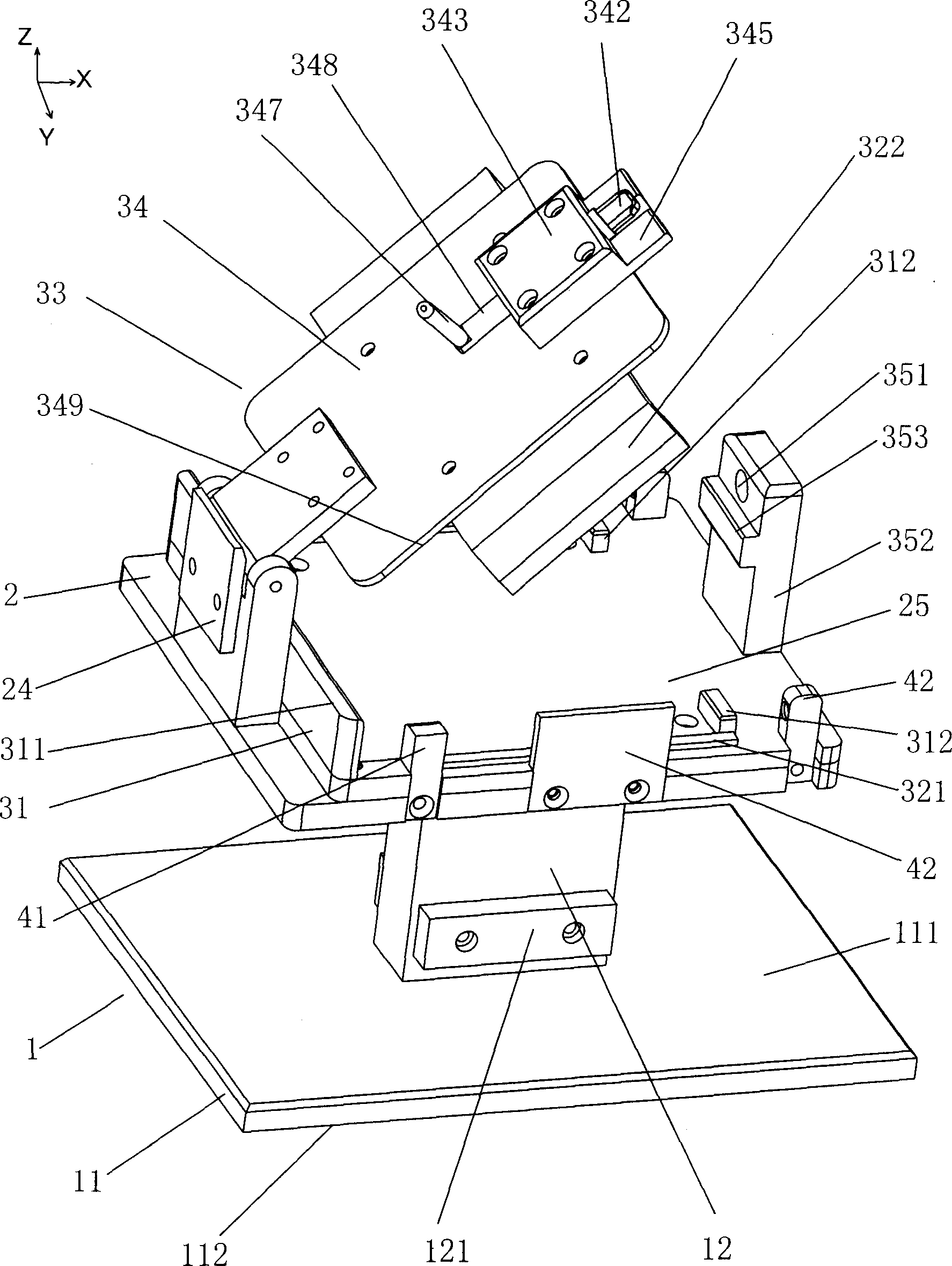

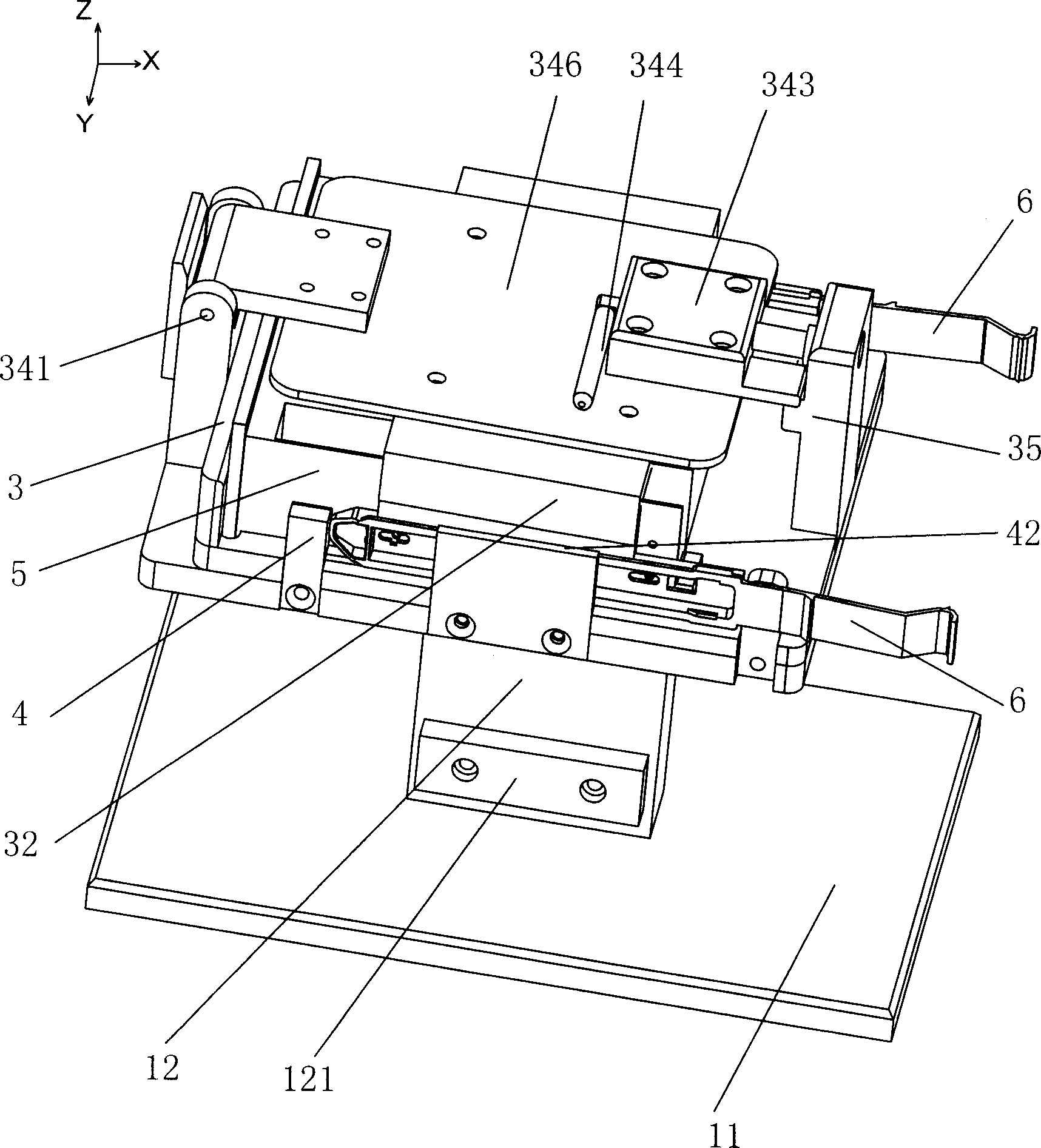

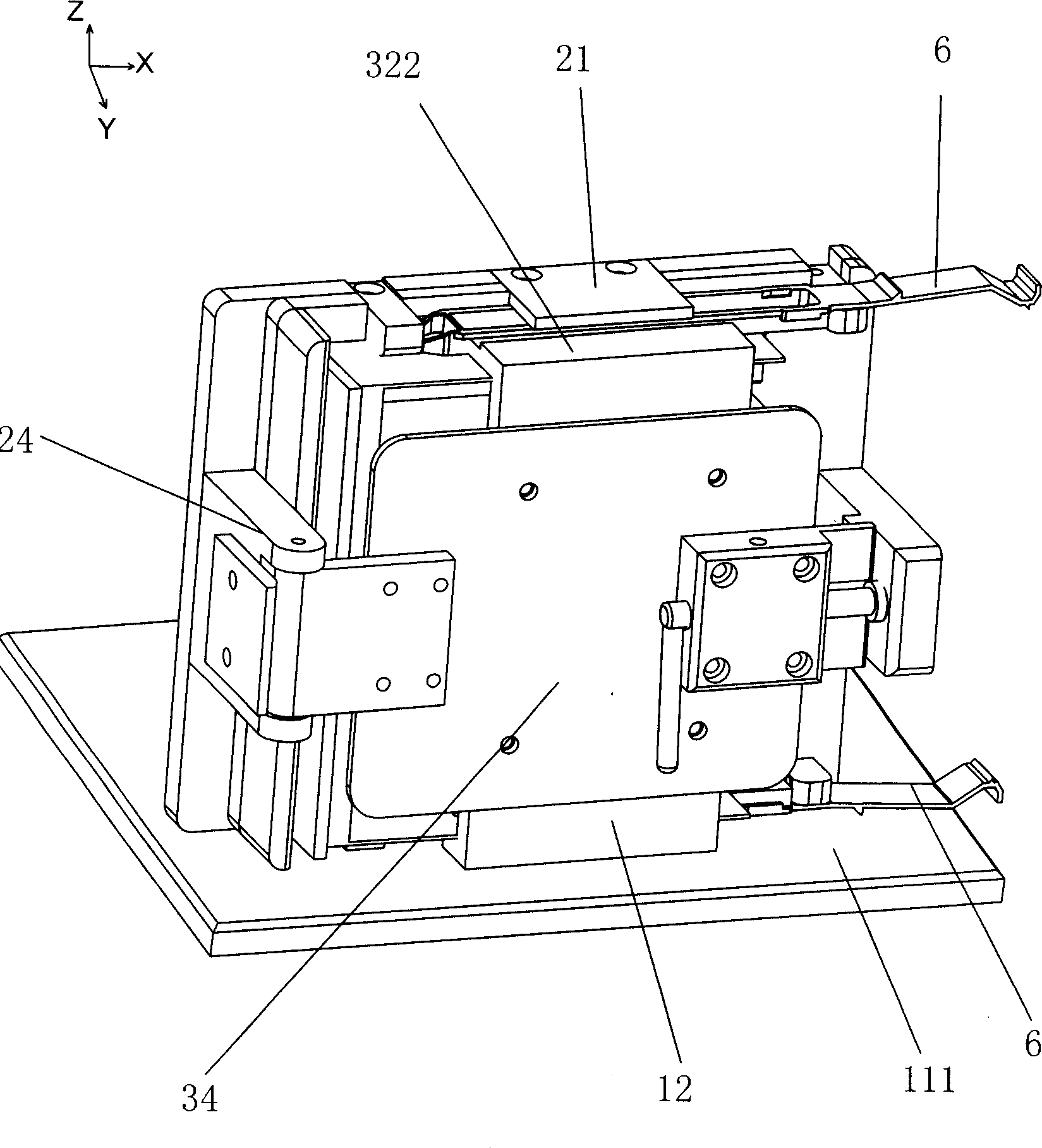

[0019] see Figure 1 to Figure 4 , The hard disk drive guide rail installation jig of the present invention includes a machine base 1 , an installation workbench 2 , a hard disk positioning member 3 and a guide rail positioning member 4 . The base 1 includes a base 11 and a rotating shaft seat 12 installed on the base 11. A first plane 21 and a second plane 22 are respectively provided on opposite sides of the installation table 2. The hard disk positioning member 3 is located on the installation workbench. In the middle position of the table 2, there are two guide rail positioning parts 4, which are respectively arranged between the hard disk positioning part 3 and the first and second planes 21 and 22. 12 , and the rotation axis of the rotating shaft 23 is located between the first and second planes 21 and 22 .

[0020] The base 1 includes a base 11 and a rotating shaft seat 12. The base 11 is flat and has a parallel upper surface 111 and a lower surface 112. The lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com