Lead frame plate placing and pushing-out equipment for semiconductor cutting

A lead frame and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of increasing the work intensity of operators and reducing the efficiency of semiconductor tailoring, so as to improve the tailoring Efficiency, the effect of avoiding manual picking and placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

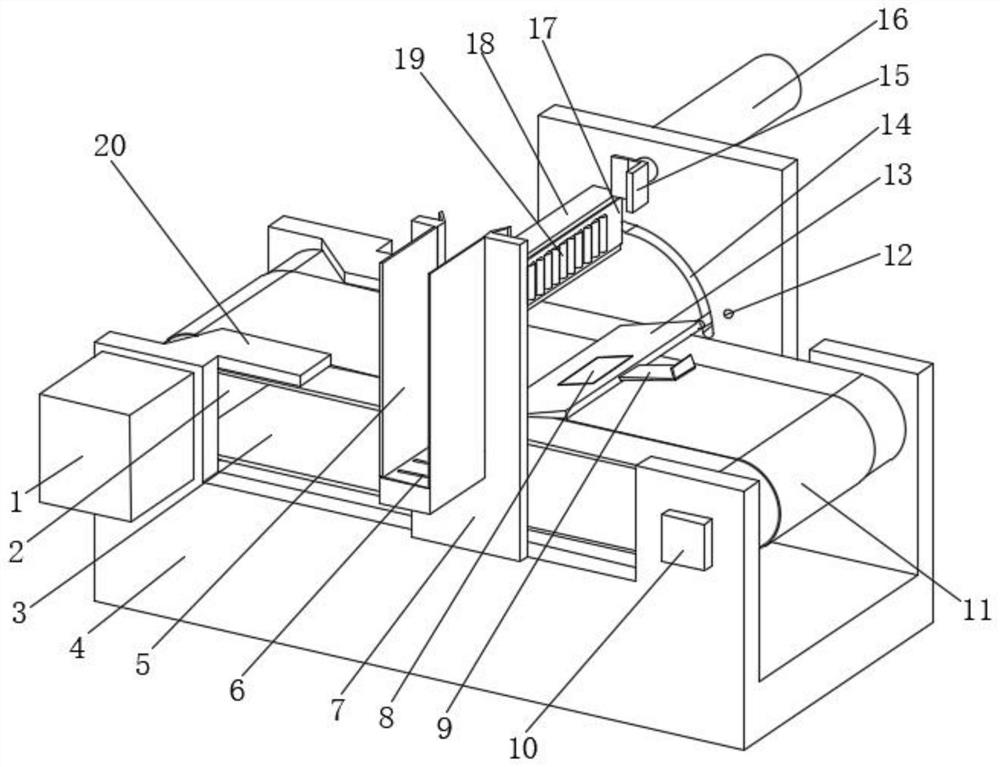

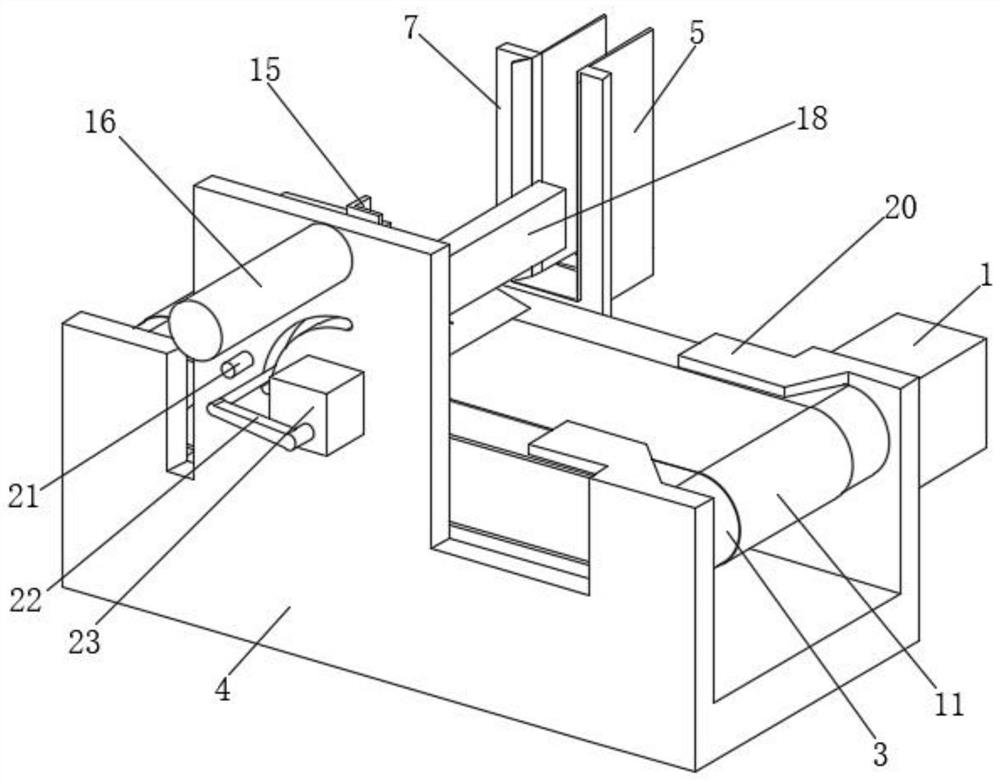

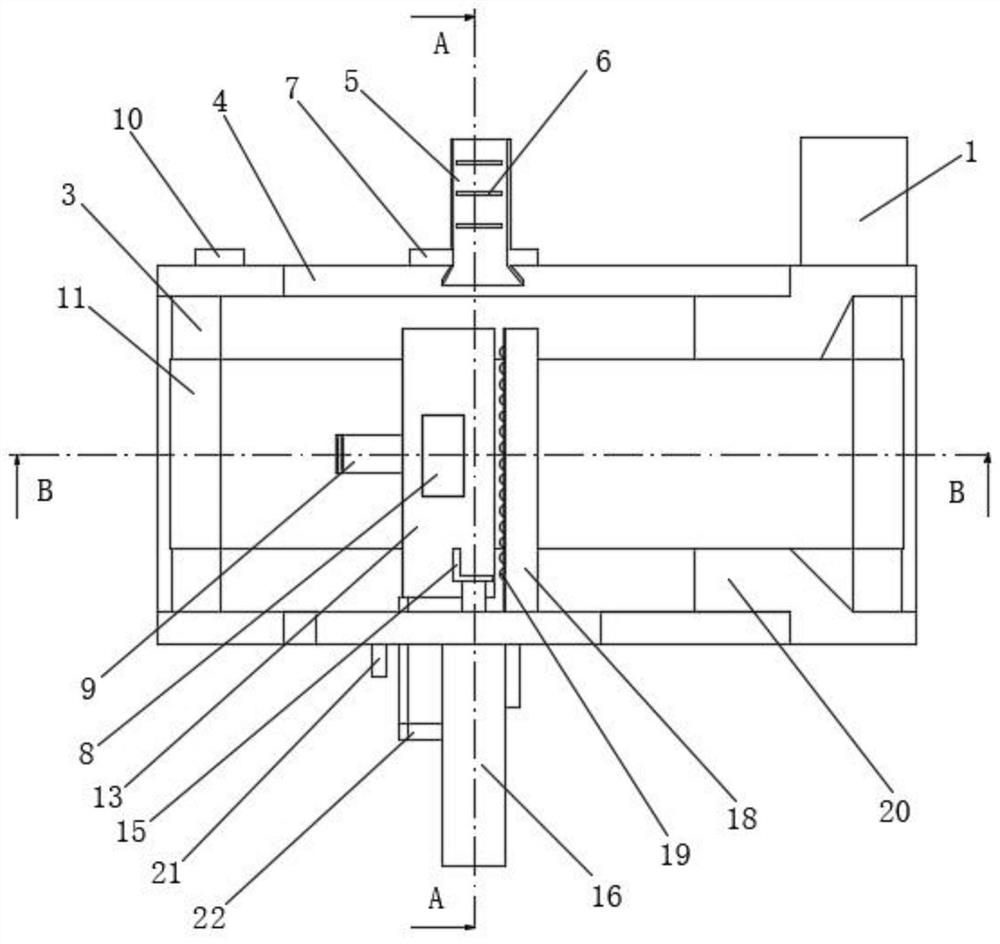

[0028] Embodiment 1: A semiconductor tailoring lead frame plate placing and pushing out device includes a base 4, a top frame 18 and a second motor 23;

[0029] Base 4: its back side is provided with arc hole 14, and its back side is provided with detection hole 12, and detection hole 12 is positioned at the right side of the lower end of arc hole 14, and the back side of base 4 is fixed with sensor 21, and sensor 21 and detection The holes 12 are arranged in front and back correspondingly. There are two transmission rollers 2 rotating inside the base 4, and the two transmission rollers 2 are connected by a belt 3. The front side of the base 4 is fixed with a first motor 1, and the output end of the first motor 1 passes through the The front side of the base 4 is fixed on the front end of one of the driving rollers 2, the rear side of the base 4 is fixed with an electric push rod 16, and the output end of the electric push rod 16 passes through the rear side of the base 4 and i...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is:

[0035] In this embodiment, it also includes a discharge frame 5 and a support plate 7, the lower end of the support plate 7 is fixed on the upper side of the front end of the base 4, the discharge frame 5 passes through the support plate 7, and the discharge frame 5 and the push seat 15 front and back Corresponding to the setting, the lead frame board can be pushed into the designated equipment through the discharge frame 5, and the first built-in roller 6 is also included, which is rotated in the inner lower side of the discharge frame 5 through the rotating shaft, and its linear array is arranged on the In the inner lower side of the discharge frame 5, its upper half side is located above the inner lower side of the discharge frame 5, and the friction between the lower end of the lead frame plate and the discharge frame 5 is reduced by the first embedded roller 6, and the friction between the lower end of th...

Embodiment 3

[0037] The difference between this embodiment and embodiment two is:

[0038] In this embodiment, a magnet 8 is also included, which is interspersed in the upper side of the turnover plate 13, and the lead frame plate is attracted by the magnet 8, so as to prevent the lead frame plate from slipping when the turnover plate 13 is turned over, and a baffle plate 9 is also included, which is fixed on The right end of turnover plate 13, prevents lead frame plate from rushing out of turnover plate 13 to the right by baffle plate 9, also includes increasing friction strip 11, is fixed on the outer surface of belt 3, prevents lead frame plate from being on belt 3 by increasing friction strip 11 Glide on.

[0039] When in use: the lead frame plate is sent to the friction-increasing strip 11 from the external production equipment, the single-chip microcomputer 10 is turned on, the first motor 1 starts to work, the first motor 1 drives the driving roller 2 to rotate, and the driving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com