A method of cutting and sewing men's shirt sleeves

A technology for sleeves and shirts, applied in shirts, clothing, applications, etc., can solve the problems of increased sewing difficulty, low efficiency, uneven back of sleeves, etc., to improve tailoring efficiency, ensure product quality, and shorten sewing the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

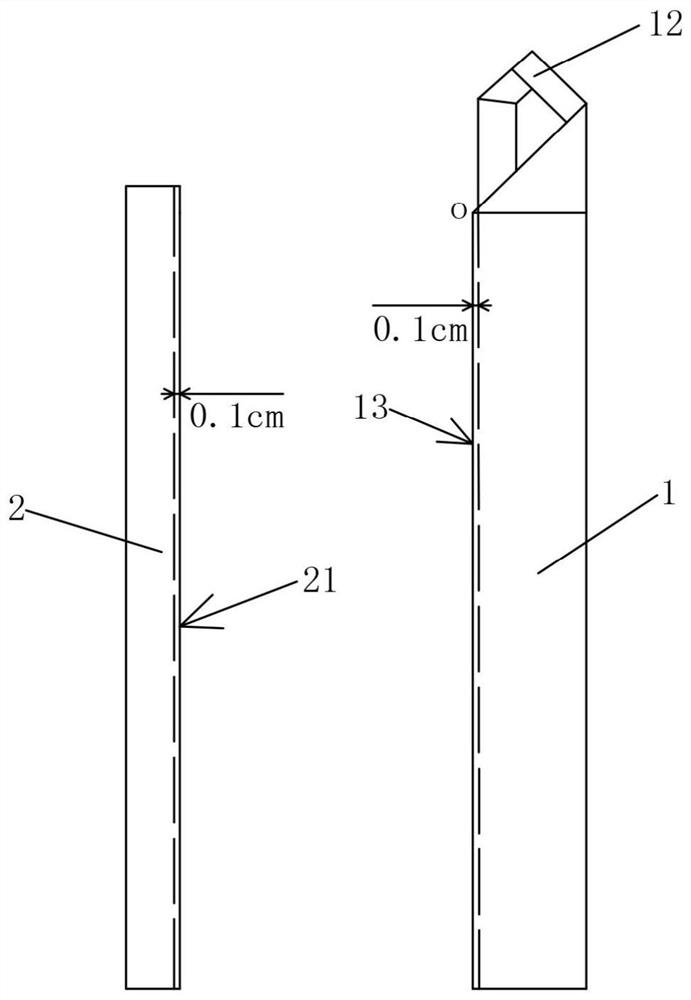

[0032] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but the description of the embodiments is not a limitation on the technical solution, and any changes in form but not in substance according to the concept of the present invention should be regarded as the protection scope of the present invention.

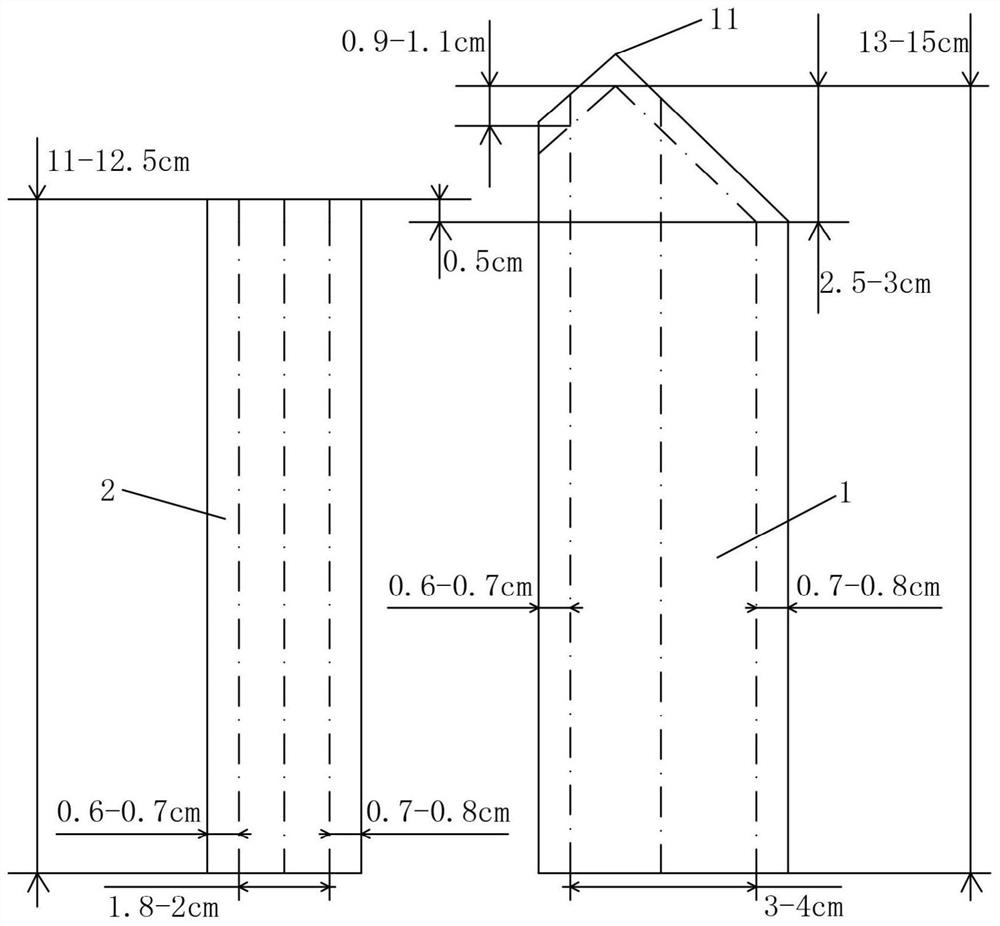

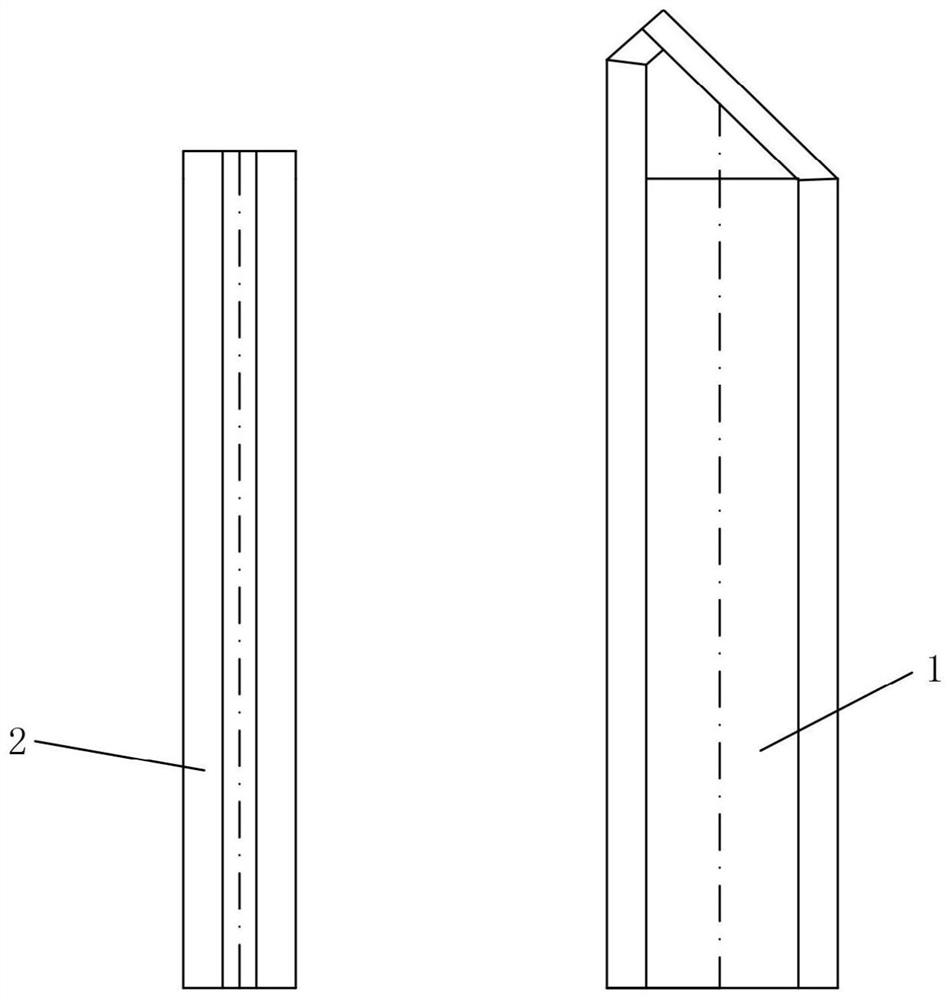

[0033] see Figure 1 to Figure 11 A method for cutting and sewing men's shirt sleeves, which is used to sew the sleeve strips to the sleeve slits to form the sword-shaped sleeves, comprising the following steps:

[0034] S1) Draw the front-facing strip 1 and the inner-front strip 2, the said front strip 1 is divided into a left half and a right half by a vertical centerline, and the upper end of the left half is drawn as equal Waist-shaped sharp corner 11, the height of sharp corner 11 is 0.9~1.1cm, preferably 1cm, the right hypotenuse of this sharp corner 11 extends to the rightmost side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com