A method for cutting and sewing garment sleeves

A technology for sleeves and garments, which is applied in the field of cutting and sewing of garment sleeves, can solve the problems of low flatness and many ironing links in the middle, and achieve the effects of improving production efficiency, easy operation, and improving tailoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

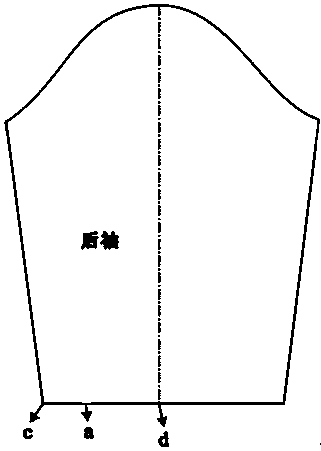

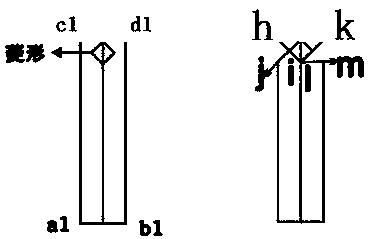

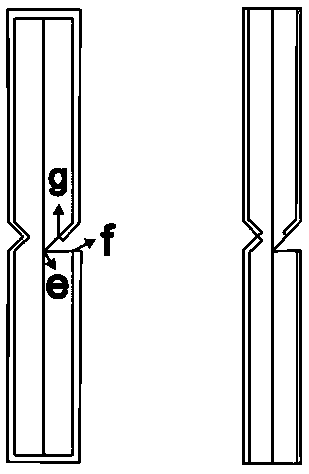

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 Shown, a kind of cutting and sewing method of garment sleeves, specific steps;

[0026] 1) According to the sleeves, draw the structure graphics of the sleeves, which mainly includes the drawing of the position of the sleeves and the structure graphics of the sleeves;

[0027] 2) Place the seam allowance and tailor it according to the drawn bag strips;

[0028] 3) Ironing according to the tailor-made bag strips, including seam allowance ironing and flip ironing, to form sword head-style sleeves;

[0029] 4) Carry out the wrapping strip process according to the ironed sleeve strips.

[0030] like figure 1 As shown, set the value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com