Efficient and reliable edging welding device for ceramic tile mold

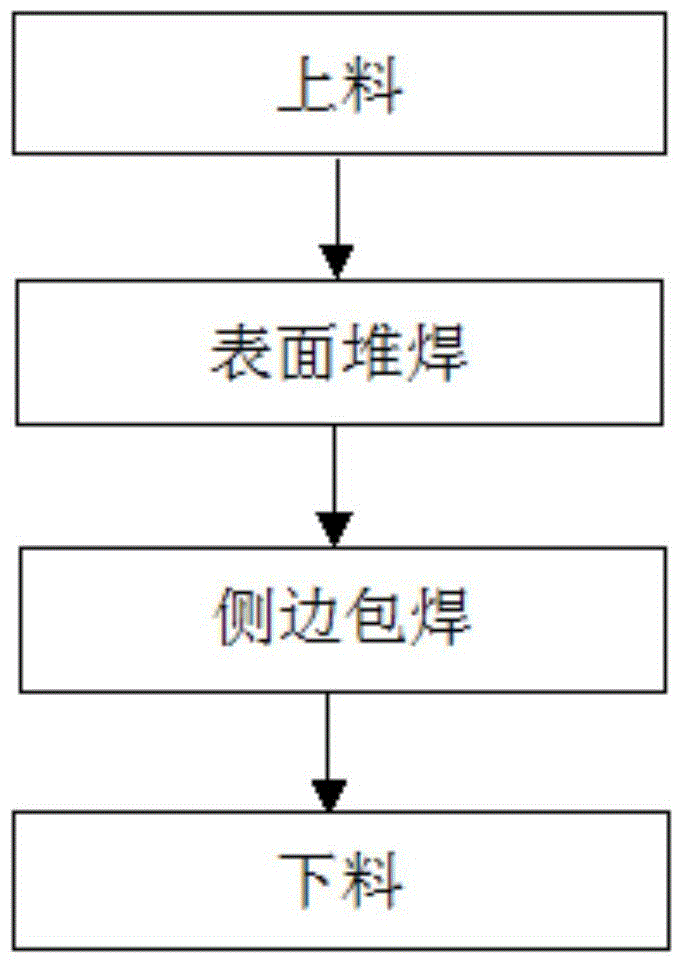

A welding device and mold technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding precision, low production efficiency, low degree of automation, etc., and meet the requirements of surfacing and welding, surfacing and welding The effect of accurate welding and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

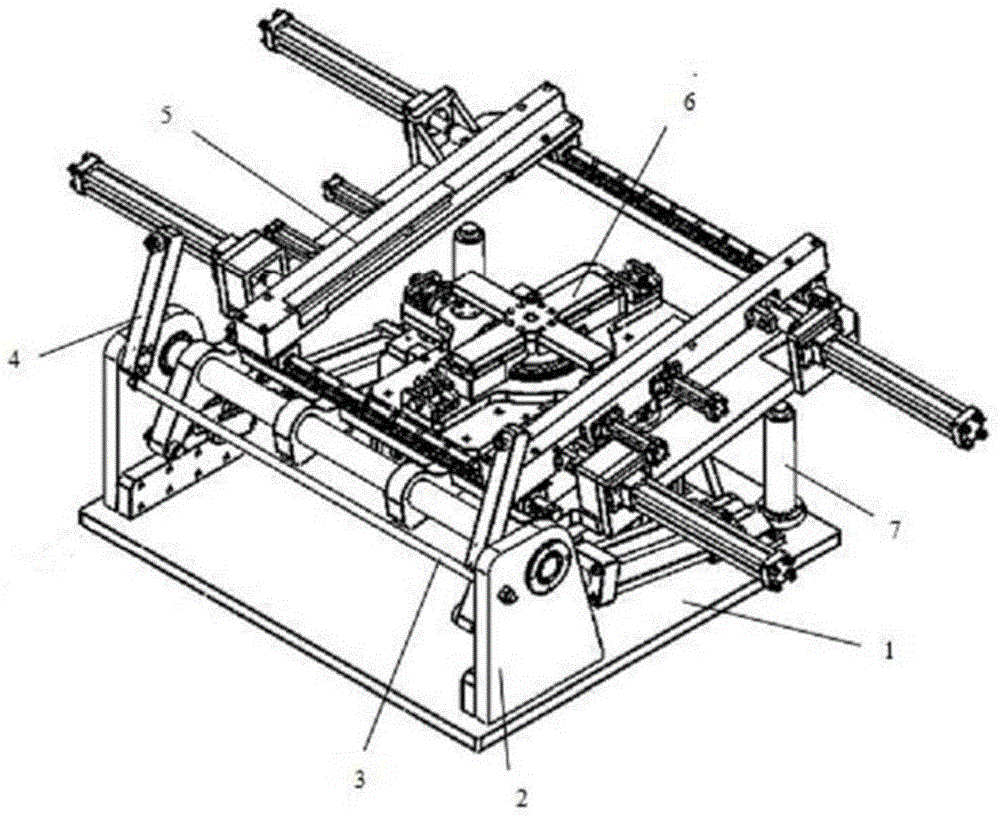

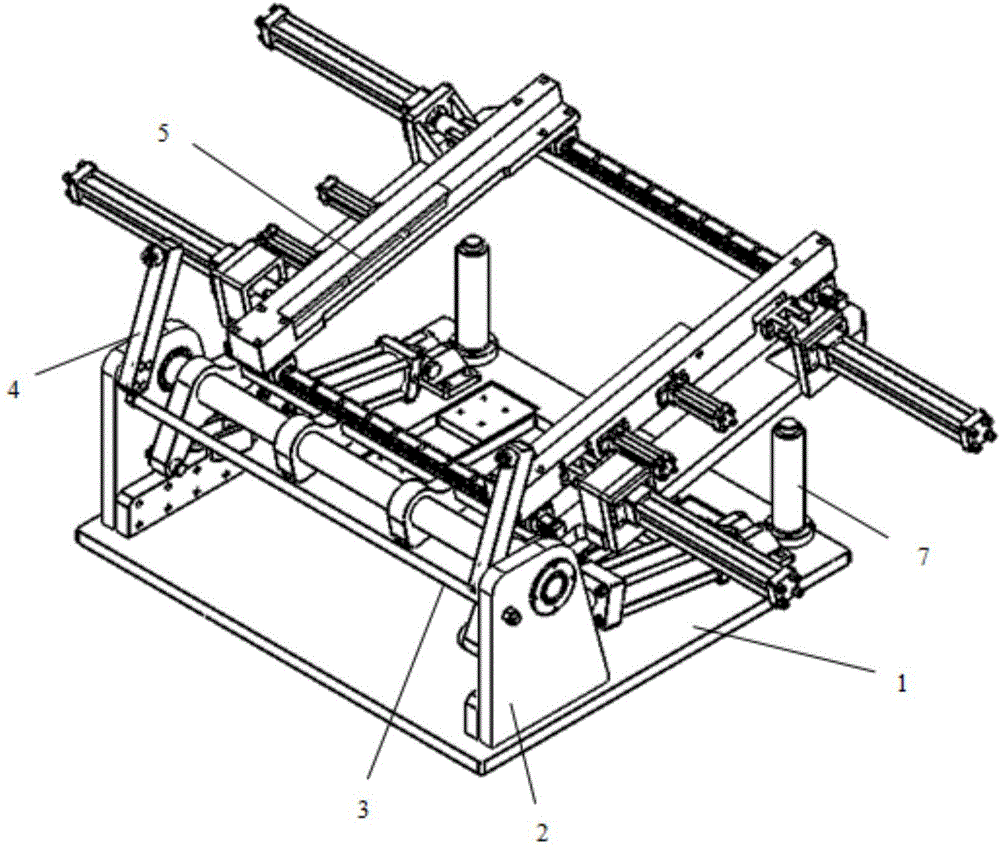

[0037]An efficient and reliable edge-wrapping welding device for ceramic tile moulds, comprising a bottom plate 1, a clamping turning mechanism 5 and a lifting and rotating mechanism 6 installed on the bottom plate 1;

[0038] The clamping turning mechanism 5 includes a clamping part for clamping the mold and a rotating part that drives the clamping part to rotate;

[0039] The lifting and rotating mechanism 6 is located below the clamping and turning mechanism 5, and the lifting and rotating mechanism 6 includes a lifting part, a rotating part and a mold carrying platform; the lifting part makes the mold move up and down in the vertical direction; The rotating part enables the mold to rotate in the horizontal direction; when the rotating part sinks, the mold carrier rises to support the mold and leaves the rotating part, preventing the clamping part from contacting the lifting and rotating mechanism. 6 produces interference.

[0040] like Figure 3-11 As shown, the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com