Patents

Literature

72results about How to "Efficient automatic detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

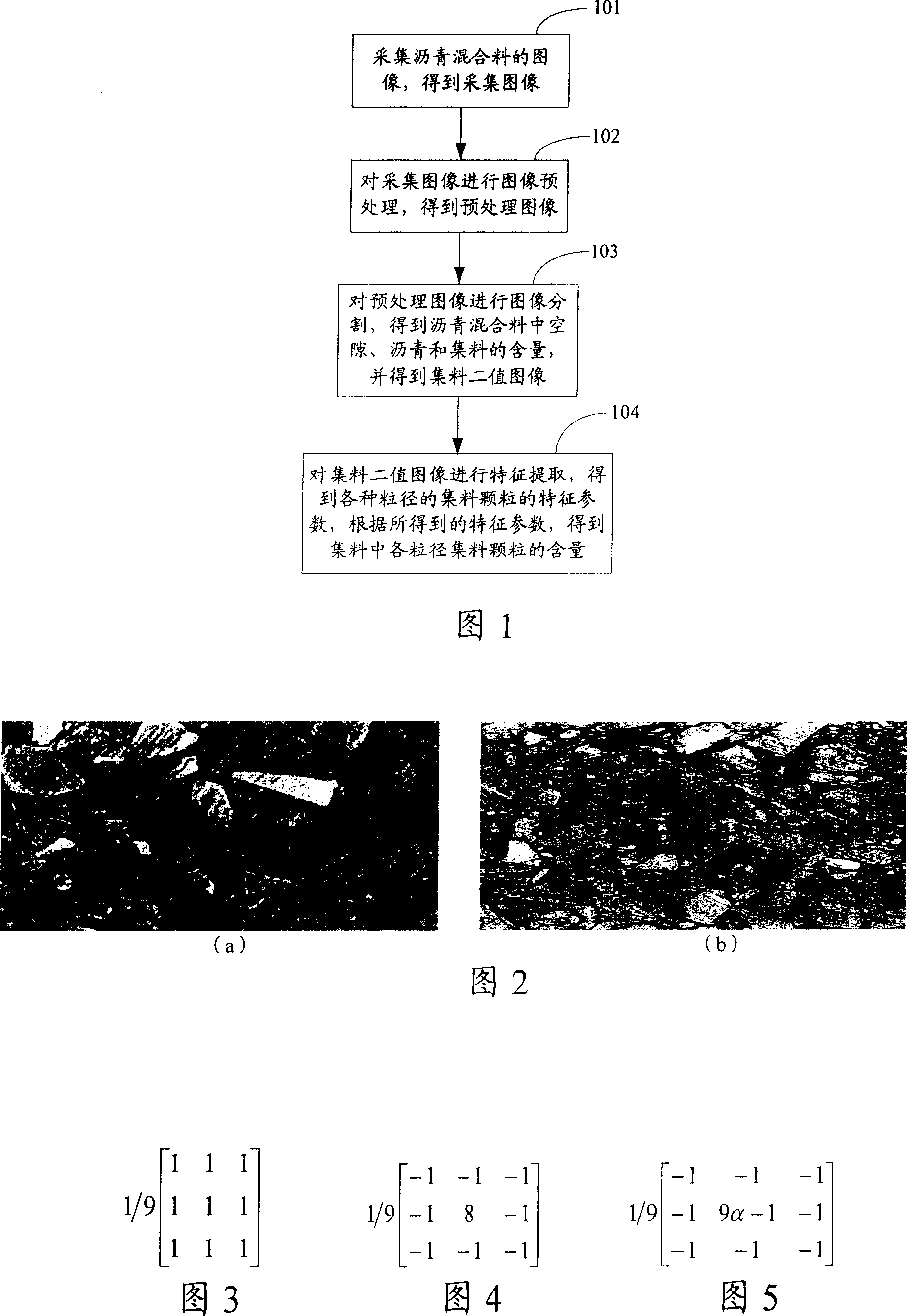

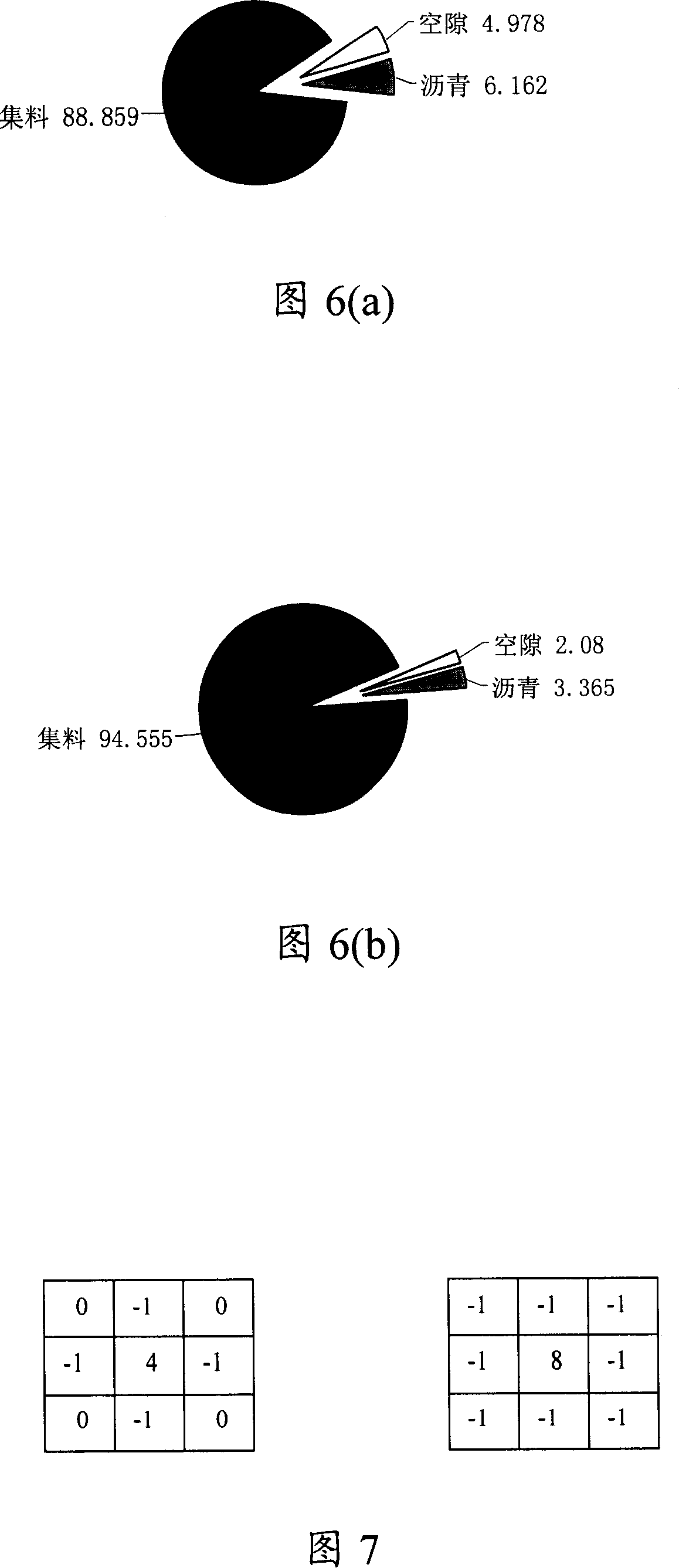

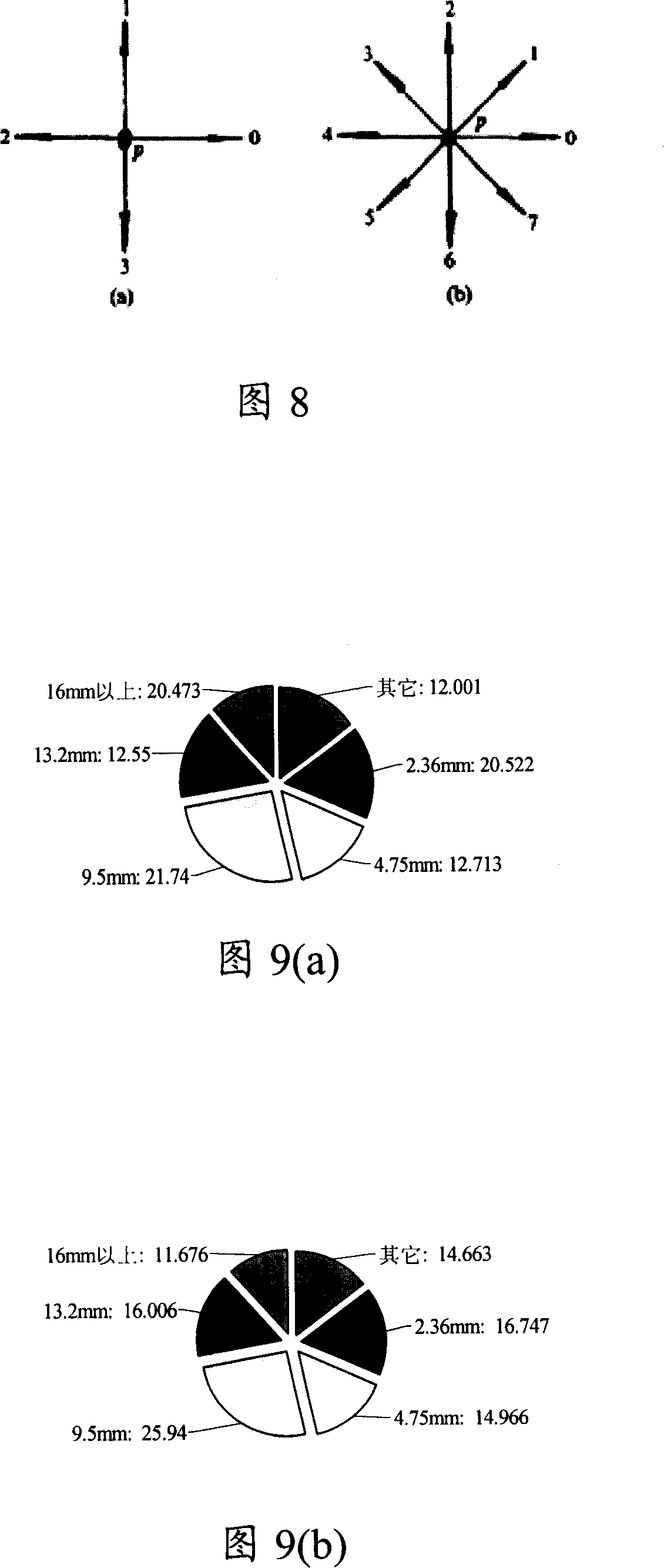

Method and system for detecting asphalt mixture

InactiveCN101153850AEfficient automatic detectionLow costImage enhancementMaterial analysis by optical meansImaging processingPavement engineering

The invention discloses a detection method of bituminous mixture, including the following steps: digital image collection of bituminous mixture is completed; image processing of the acquired digital image is completed to obtain the content of compositions of the bituminous mixture. Moreover, the invention also discloses a detection system for the bituminous mixture. Both the method and the system can complete effective separation and extraction of bitumen, airgap, aggregate and aggregate particle of different particle diameter and realize direct determination and calculation of volumetric composition characteristic parameter of the bituminous mixture through converting the obtained characteristic parameter into volume ratio; moreover, the invention improves the mechanical property of the bituminous mixture and provides reliable basis for the scientificity in bituminous pavement engineering research.

Owner:CHANGAN UNIV

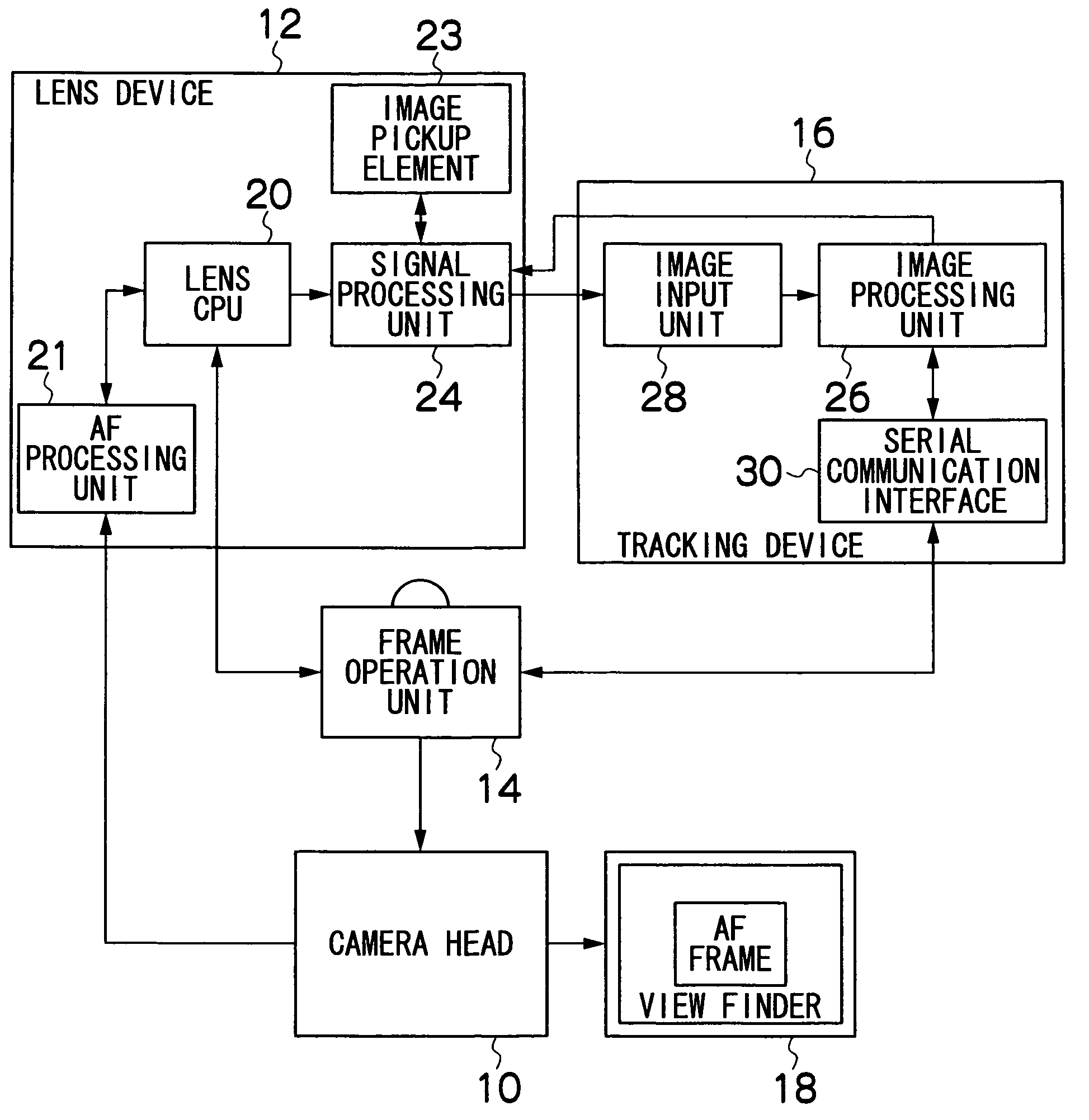

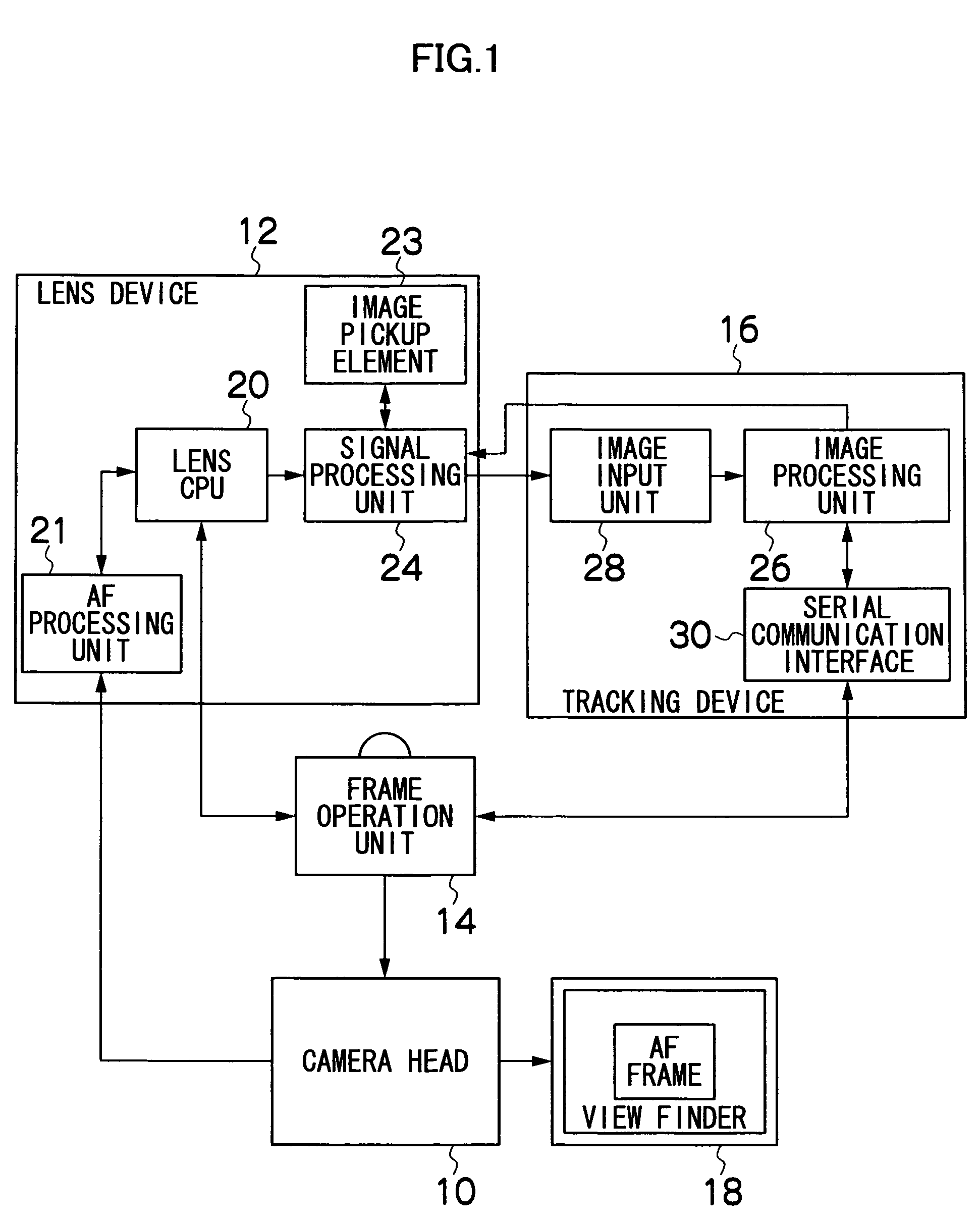

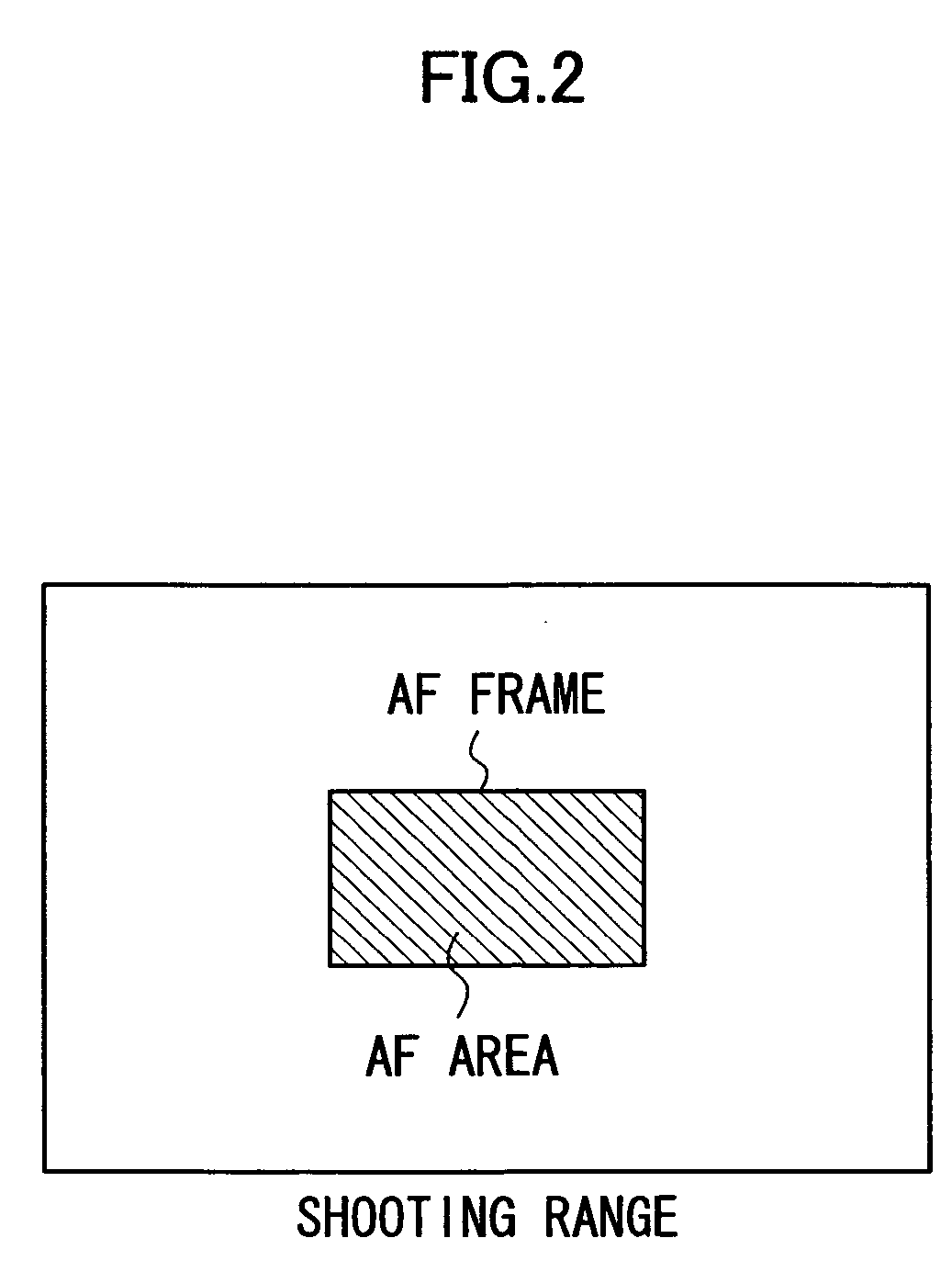

Autofocus system

InactiveUS20050264679A1Appropriate image qualityEfficient automatic detectionTelevision system detailsColor television detailsAutofocusTime signal

The autofocus system of the present invention is characterized by comprising a target subject specifying device which specifies a target subject to be put into focus, a tracking image pickup device which captures a subject image in the shooting range of the camera, and is provided in addition to an image pickup device of the camera which captures a subject image to be recorded or regenerated, a target subject movement detection device which detects a movement in the shooting range of the target subject specified by the target subject specifying device according to an image signal of a subject image captured by the tracking image pickup device, and an AF area change device which changes a range of the AF area such that the movement of the target subject detected by the target subject movement detection device is tracked.

Owner:FUJI PHOTO OPTICAL CO LTD

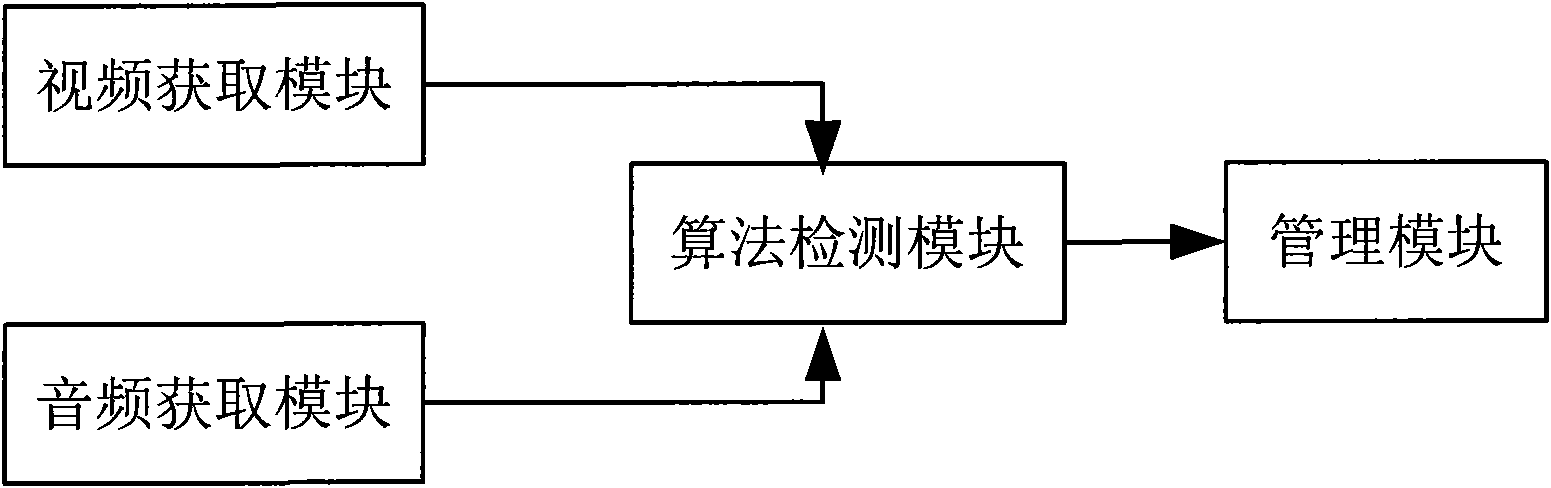

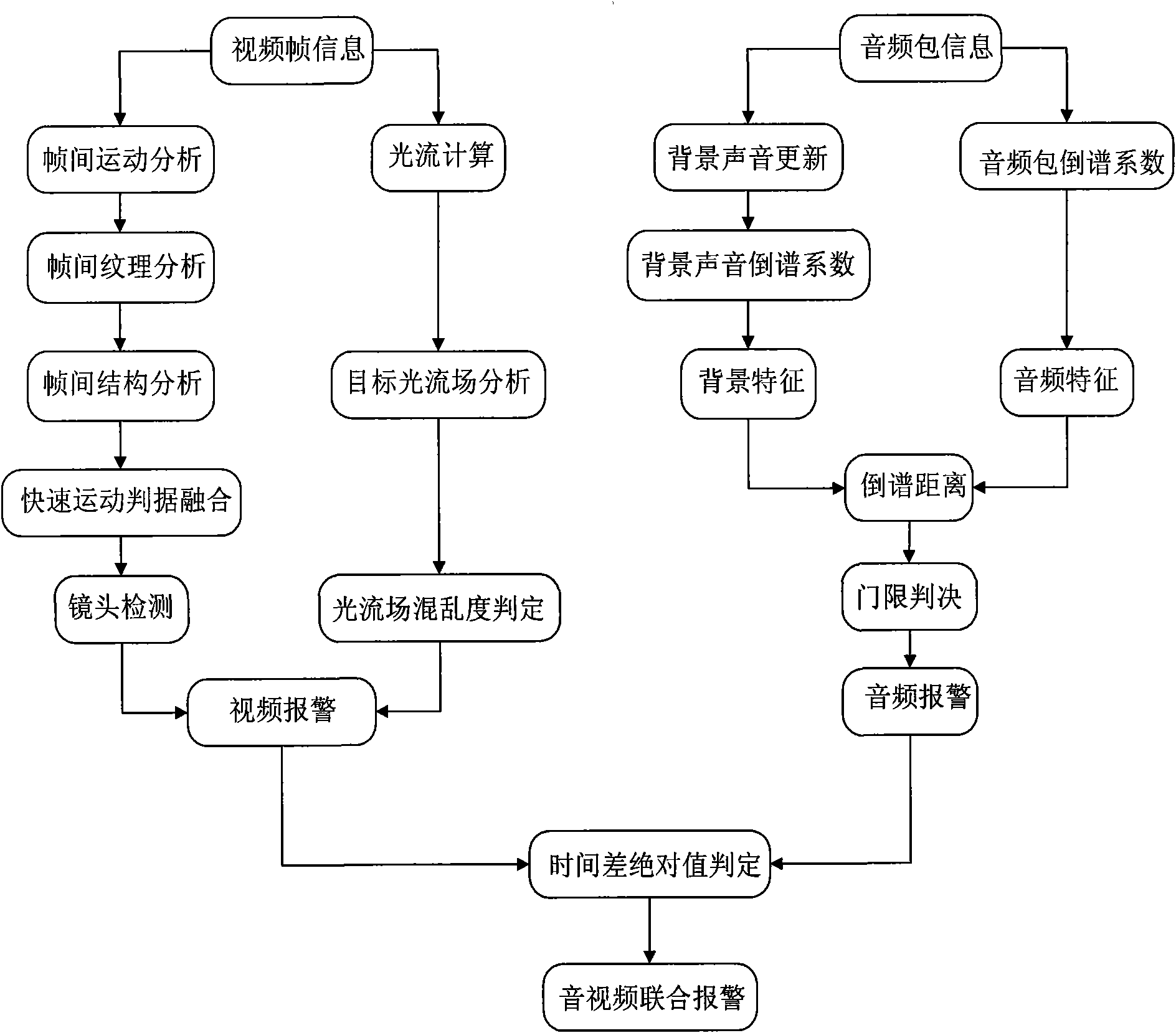

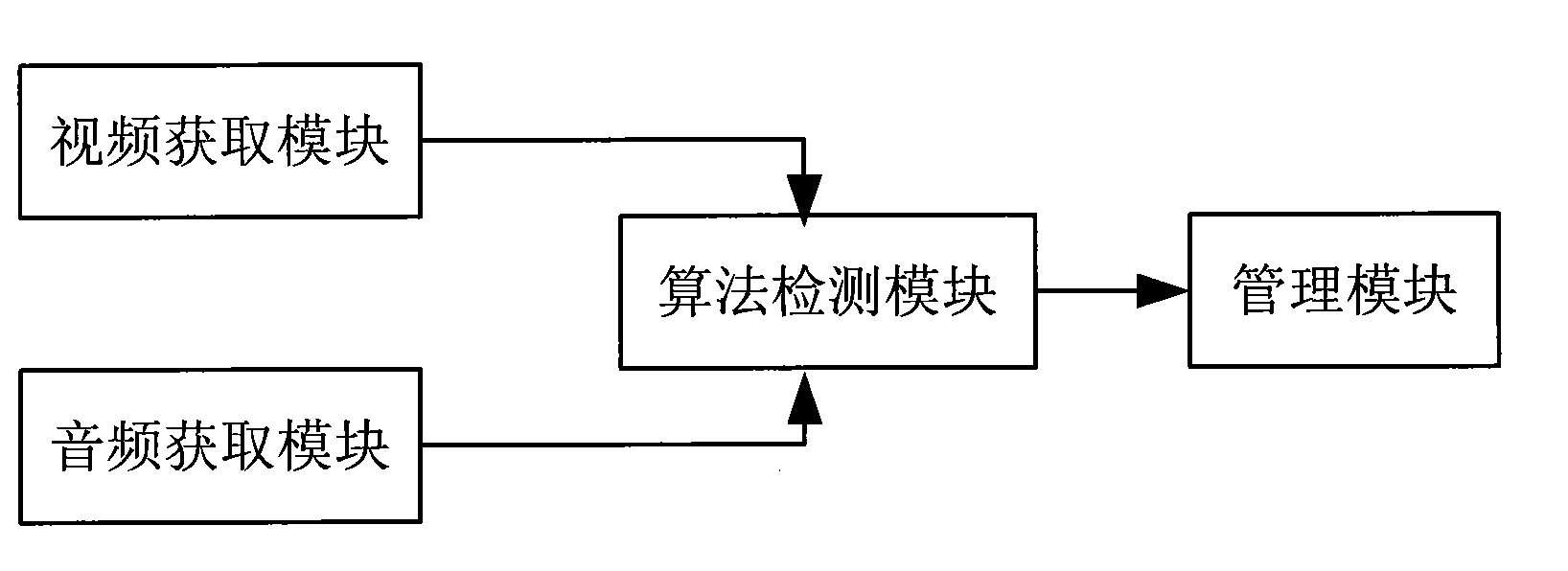

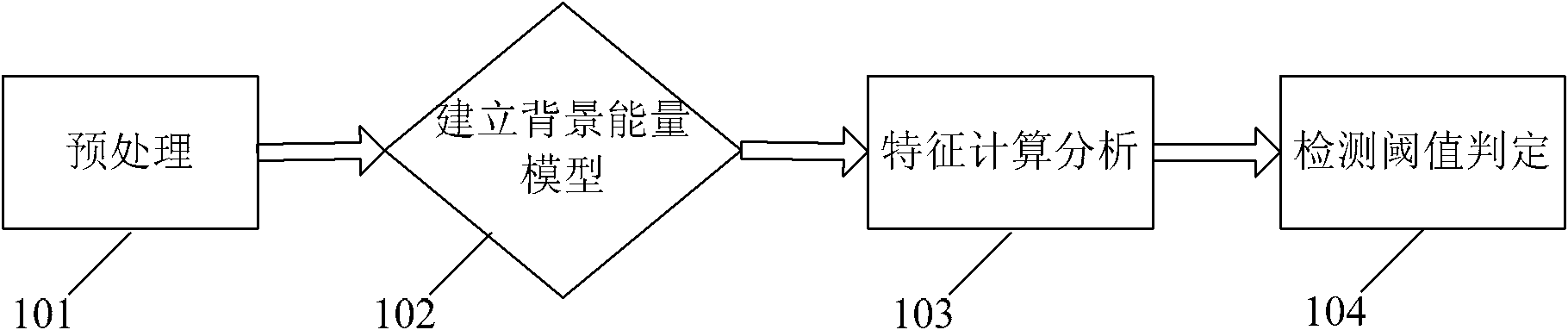

Audio and video conjoint analysis-based fighting detection system and detection method thereof

InactiveCN102098492AHigh precisionImprove analysisImage analysisClosed circuit television systemsJoint analysisCrowds

The invention discloses an audio and video conjoint analysis-based fighting detection system and an audio and video conjoint analysis-based fighting detection method thereof. The audio and video conjoint analysis-based fighting detection system comprises a video acquisition module, an audio acquisition module, an algorithm detection module and a management module, wherein each of the video acquisition module and the audio acquisition module adopts a camera, an acquisition card and a computer; the video acquisition module acquires an analogue signal of the camera to a memory of the computer by the acquisition card; the audio acquisition module acquires the analogue signal of the camera to the memory of the computer by the acquisition card; and the algorithm detection module judges the fighting of persons in a target area, judges synchronous audio and video, detects, identifies and positions the chaotic fighting of the persons in the target area, and outputs results to the management module. In the system and the method, the behaviors of the persons in a monitored scene are analyzed, identified and positioned to accurately diagnose the abnormal behaviors such as gathering, fighting and the like of the persons appearing in a video image and give an alarm.

Owner:上海弘视通信技术有限公司

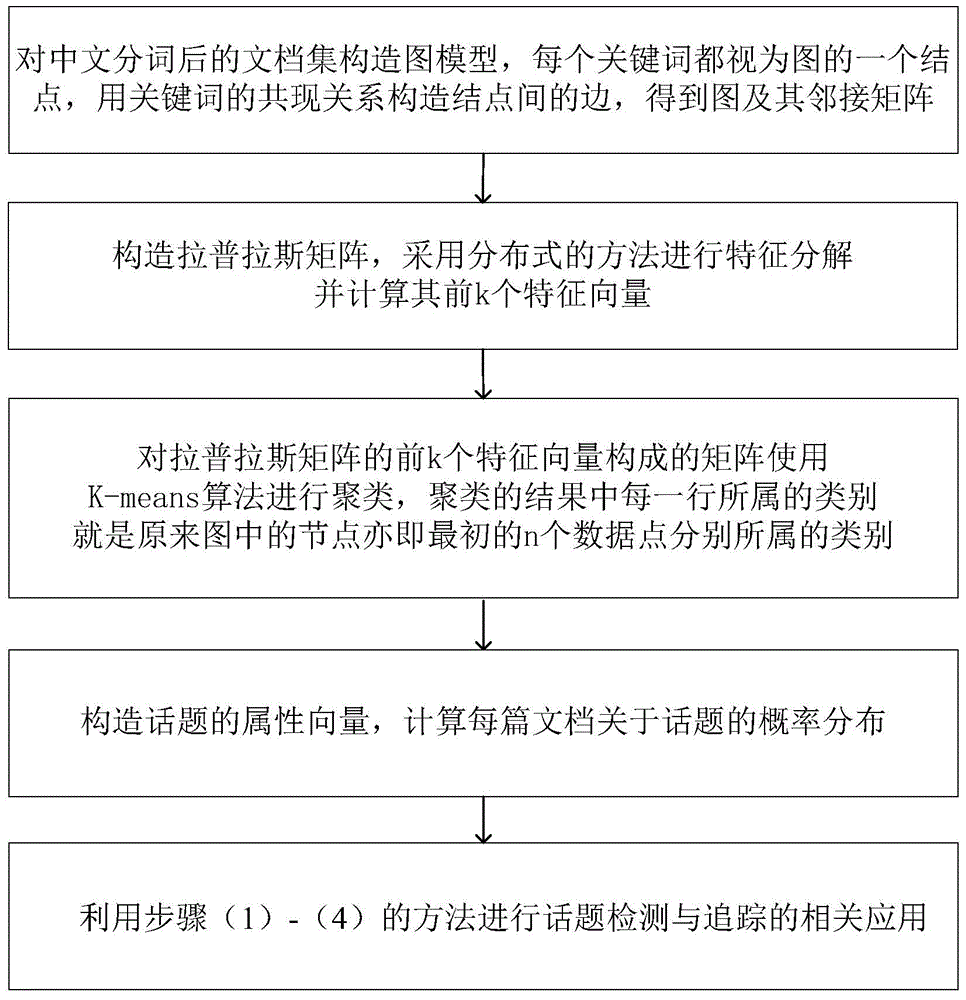

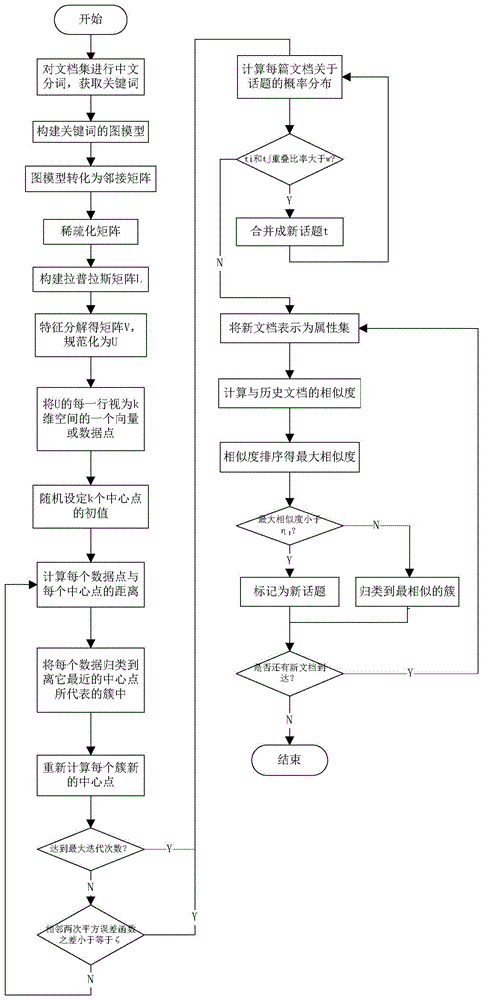

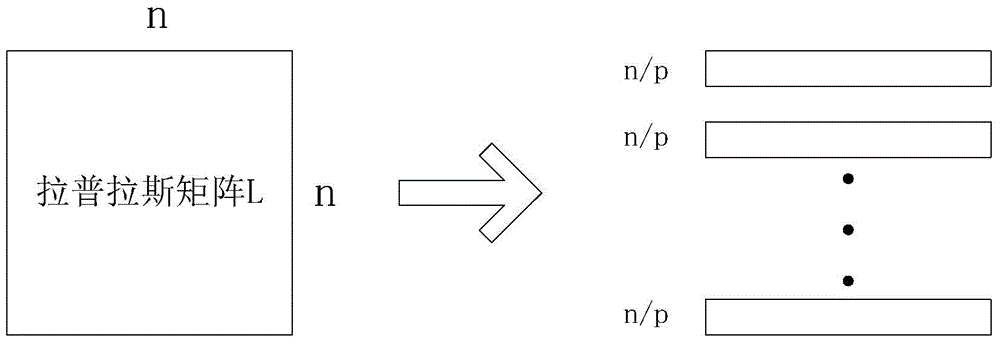

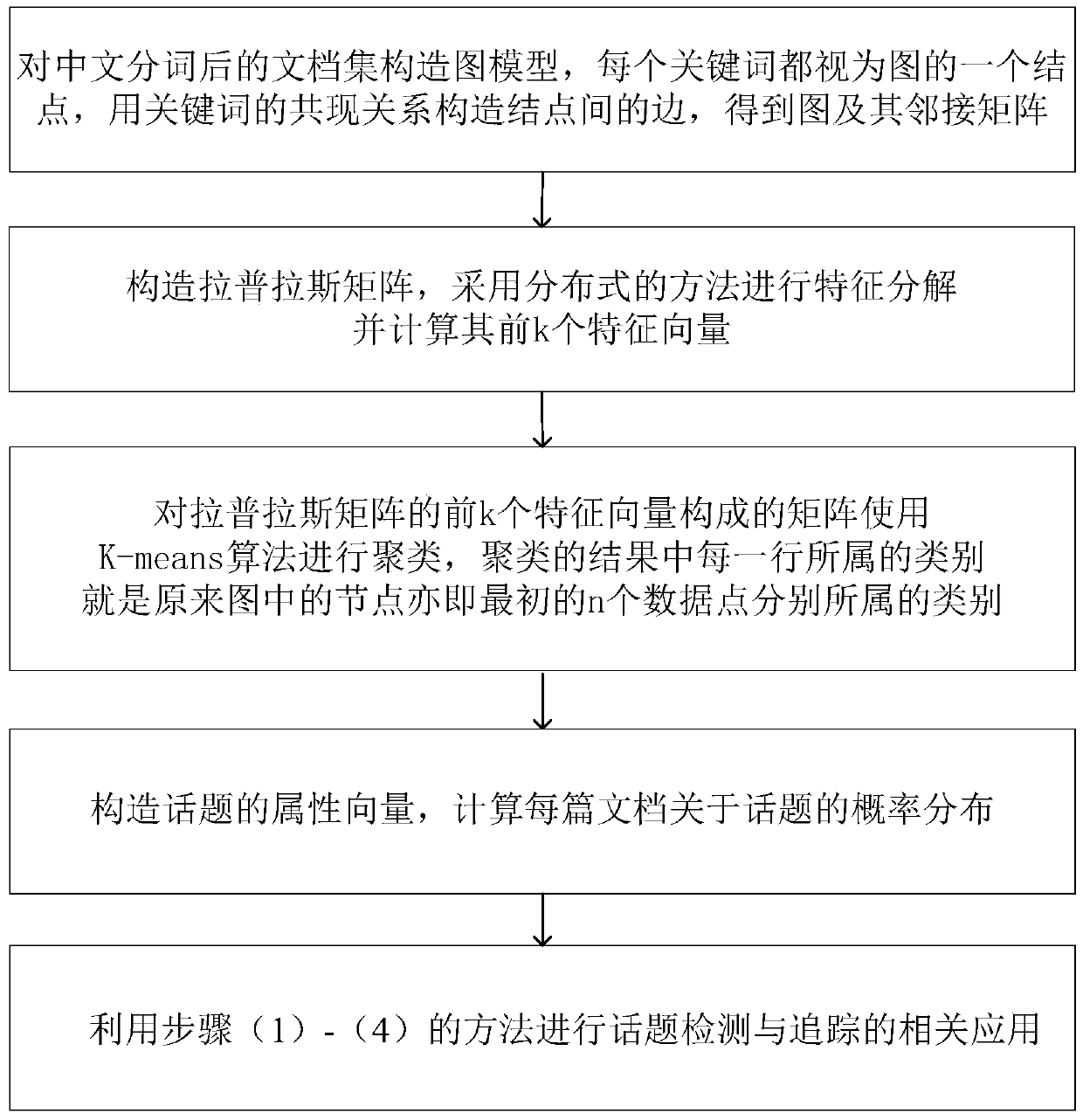

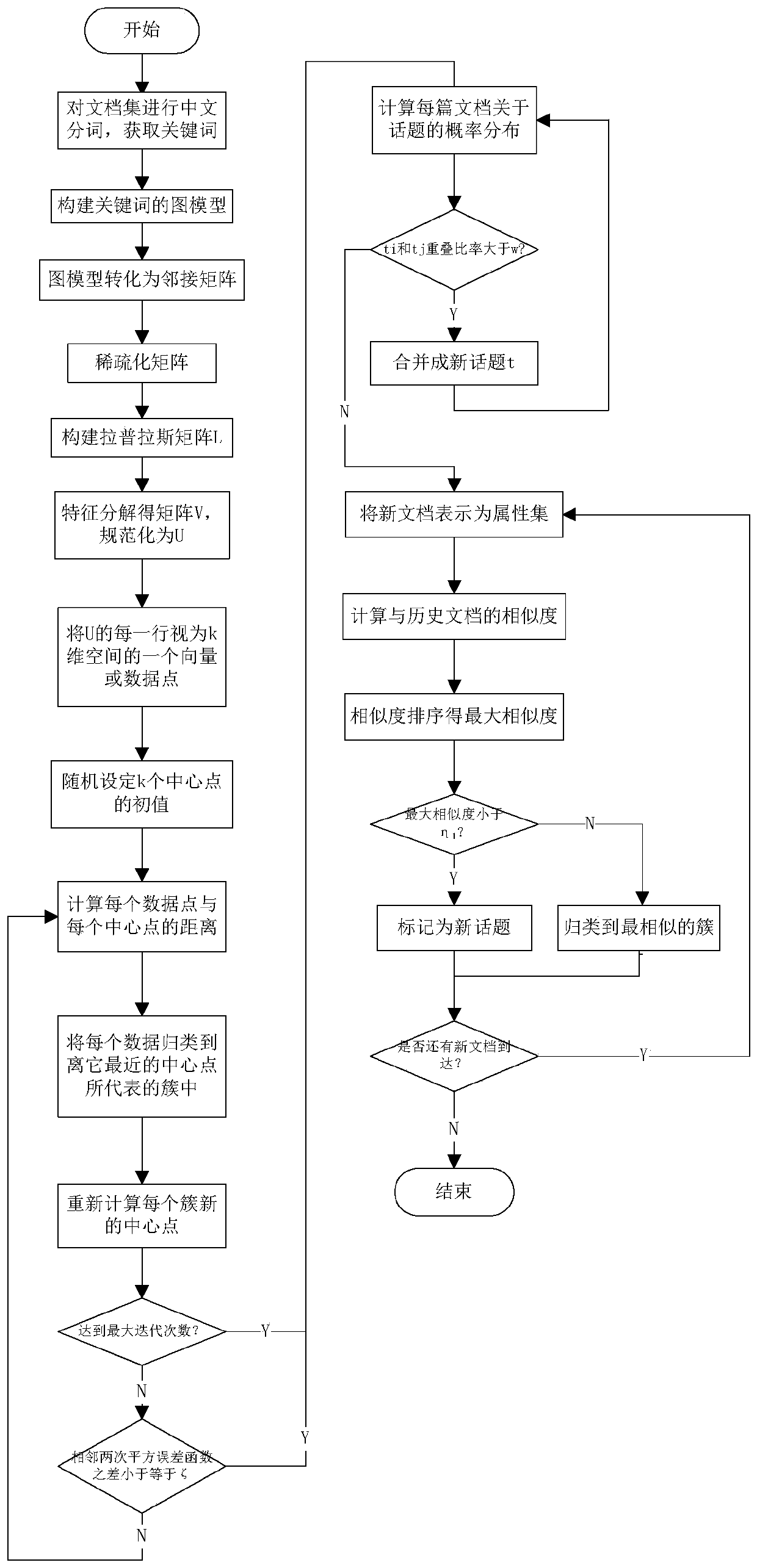

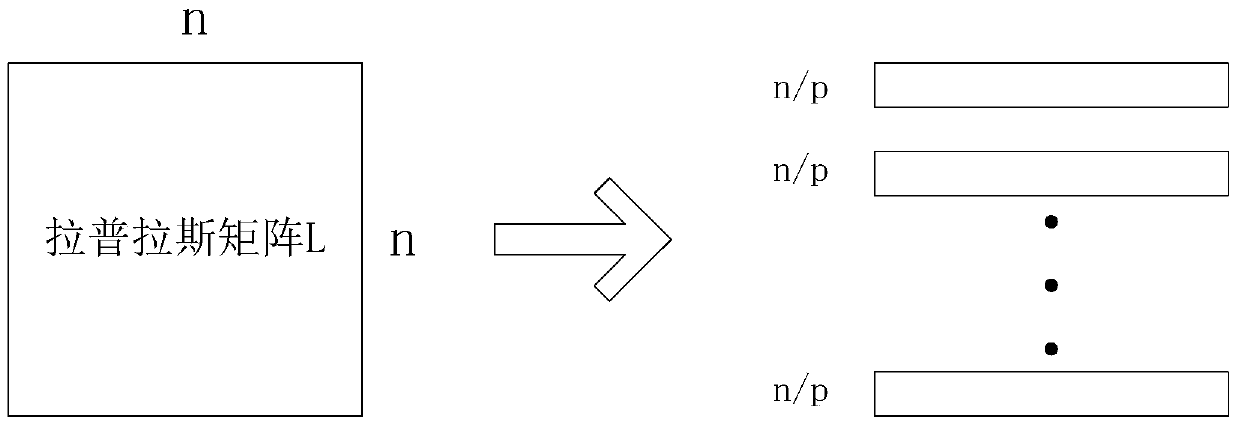

Topic detection or tracking method for network text big data

ActiveCN104462253AImprove throughputStrong scalabilitySpecial data processing applicationsText database clustering/classificationSpectral clusteringData information

The invention discloses a topic detection or tracking method for network text big data. The basic thought includes the following steps that a graph model of keywords and a corresponding adjacent matrix are built by detecting the keywords occurring in different files, the graph model and the adjacent matrix are combined with spectral clustering to provide a new topic detection model, probability distribution of each file about a topic is calculated, when a new file reaches, similarity between the new file and an attributed set represented by a historical topic is calculated, automatic detection or tracking of the topic is achieved, and a distributed method is achieved through a Map Reduce programming model. The method is characterized in that the topic is displayed and mined through the cooccurrence relation of the keywords rather than an implicit expression, the big data are calculated in a distributed mode, data information in the internet is clustered, expansibility is higher, the quantity of the data capable of being processed is larger, and the throughput rate is greatly increased.

Owner:WUHAN SHUWEI TECH

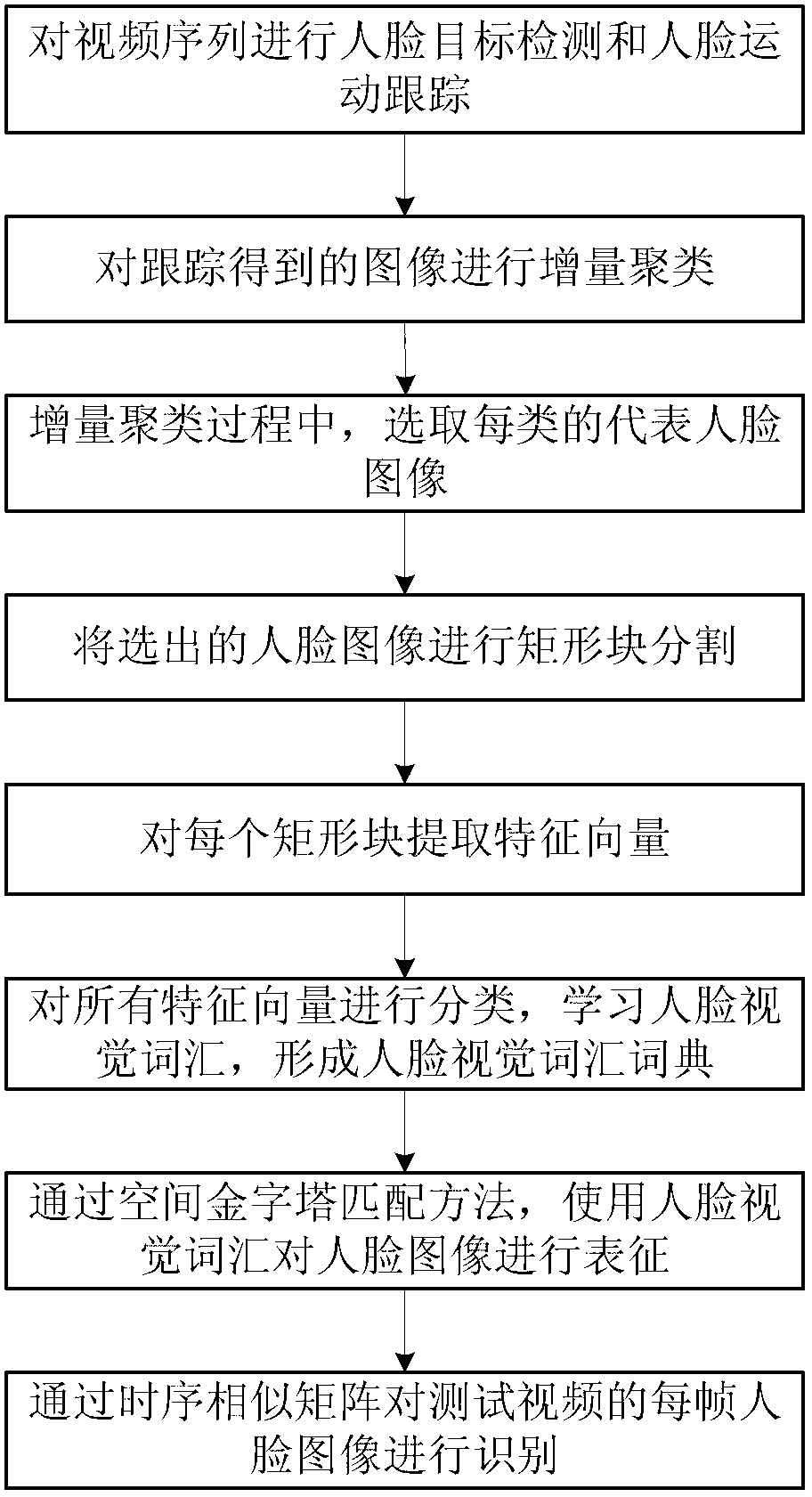

Method for identifying faces in videos based on incremental learning of face partitioning visual representations

InactiveCN103279768AEfficient automatic detectionFacilitates automatic detectionCharacter and pattern recognitionIncremental learningAdaboost algorithm

The invention provides a method for identifying faces in videos based on incremental learning of face partitioning visual representations and belongs to the field of pattern recognition. According to the method, an Adaboost algorithm is used for detecting frontal face images in a first frame of the face videos, a Camshift algorithm is used for tracking, all face images are obtained, in the process of reading the face images in the videos, incremental cluttering is carried out on the face images, and a representative image is selected from each kind of face images; the representative images are processed, and a visual dictionary based on the piece visual representations is learnt; the visual dictionary is used for carrying out the representations on the face images; finally, according to similar matrices, the videos composed of the face images are identified. According to the method, an identification rate and robustness of the video faces can be improved under the state that illumination, postures and tracking results are not ideal. The faces in the videos can be detected, tracked and identified effectively, conveniently and automatically.

Owner:BEIHANG UNIV

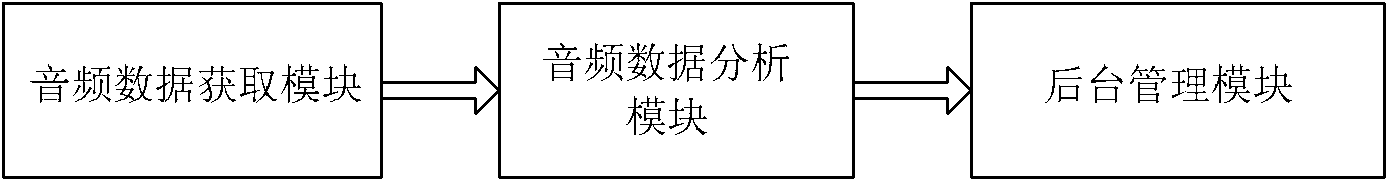

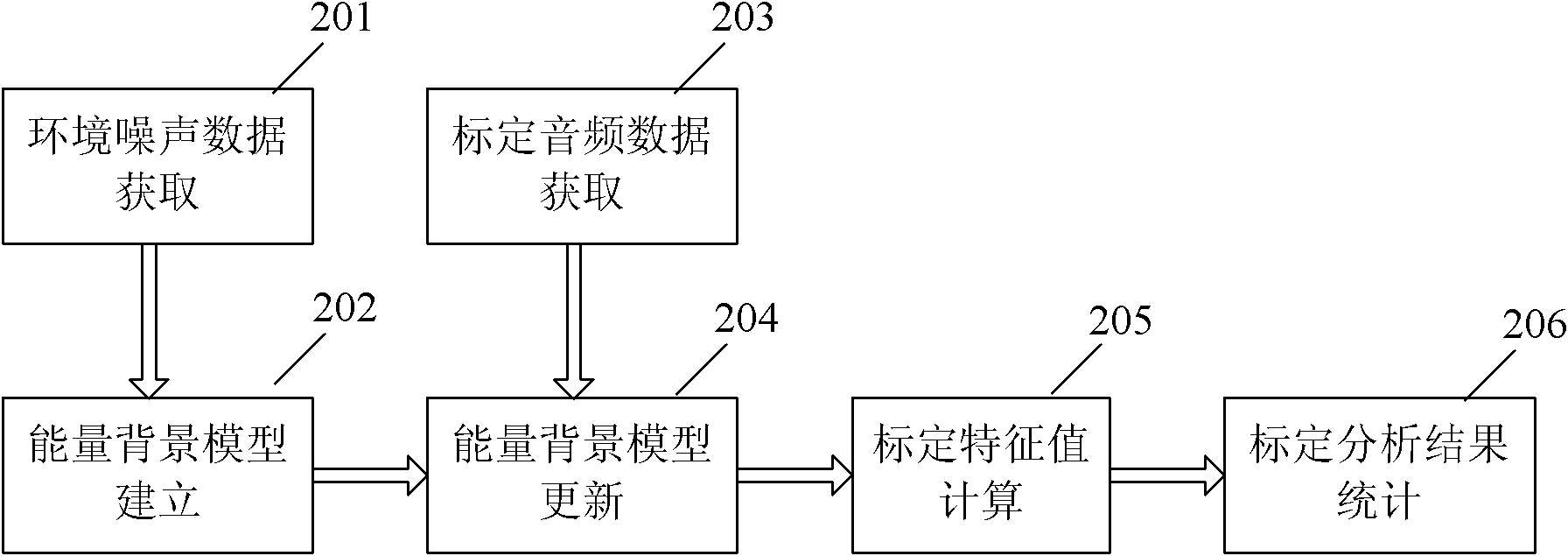

Audio exception event detection system and calibration method for the same

ActiveCN102610228AEfficient automatic detectionImprove reliabilitySpeech analysisSound input/outputData acquisitionDependability

The invention discloses an audio exception event detection system and a calibration method for the same. The audio exception event detection system comprises an audio data acquisition module, an audio data analysis module and a background management module. The audio data acquisition module comprises a sound pickup, an acquisition card and a computer, the acquisition card acquires audio data in the sound pickup and stores the acquired data in a memory of a computer; the audio data analysis module preprocesses the audio data acquired by the acquisition card, extracts analysis features, detects and judges an exception event, and outputs the detection result to the background management module; and the background management module performs alarming triggering management according to the detection result output by the audio data analysis module. The audio exception event detection system not only uses the new audio analysis features and technologies to realize the audio exception event detection and effectively improves the reliability of an intelligent security system, but also calibrates the audio receiving capability of the sound pickup, thereby simplifying the regulation of the parameters in the audio intelligent analysis technology.

Owner:上海弘视通信技术有限公司

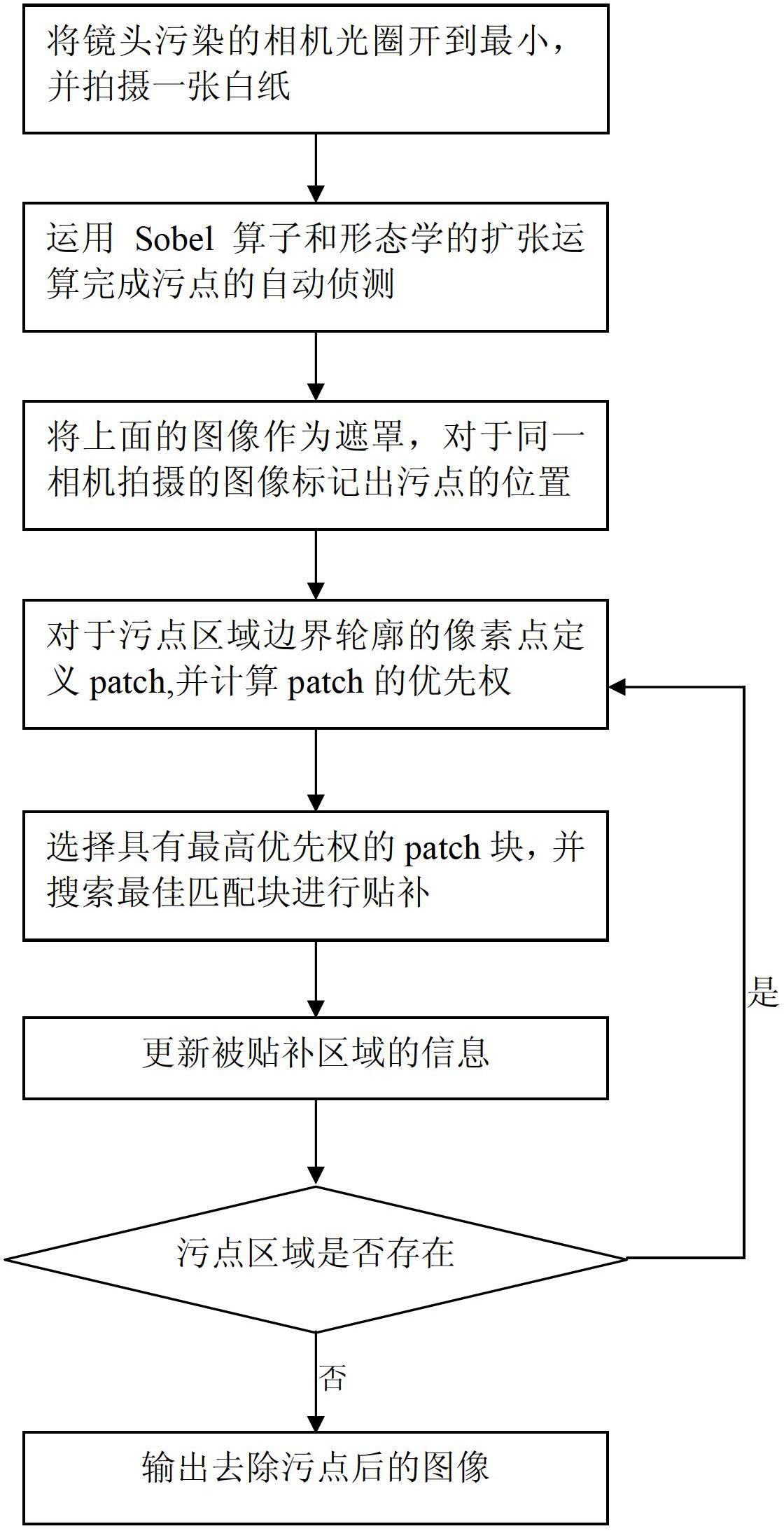

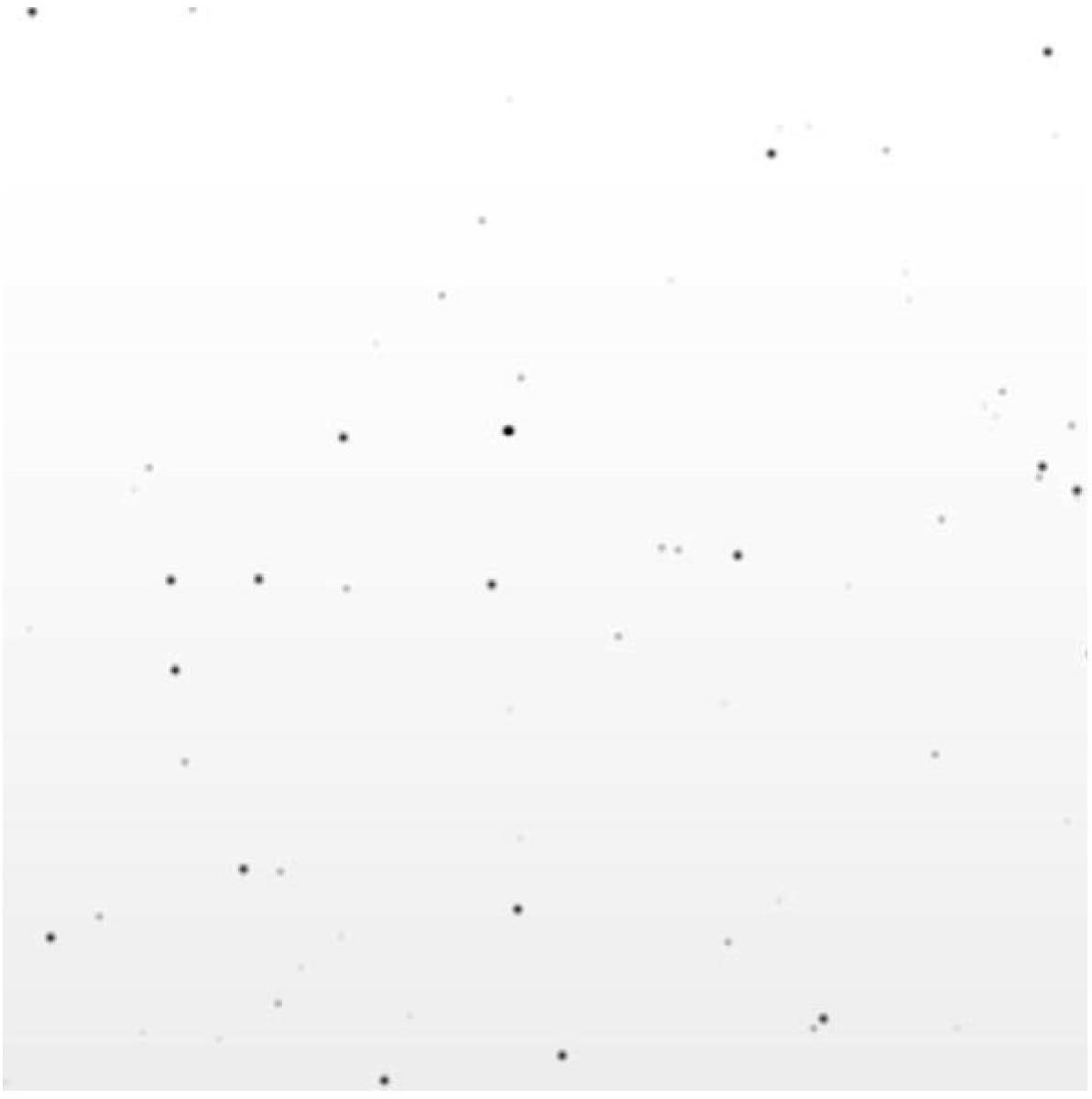

Quick image stain removing method based on image inpainting technology

InactiveCN102693534AEffective automatic detectionNarrow down the search spaceImage enhancementPattern recognitionSobel operator

The invention provides a quick image stain removing method based on the image inpainting technology. Firstly, the camera with a stained lens is used for shooting a white paper image, the Sobel operator and extensive operation are combined to detect the position of the stain, and the white paper image serves as a shade; the shade is used for covering the image shot by the same camera to mark the stain area in the image; for every pixel on the stain area contour, a patch block is defined and the priority of each patch block is calculated; the patch block with the biggest priority is selected to search and find the most matched block to replace and repair; and the repair image information is updated and re-repaired till the whole stain area of the image is repaired. Through the adoption of the image stain removing method, the stained image can be quickly and automatically repaired, and the linear structure of the image can be satisfactorily retained.

Owner:BEIHANG UNIV

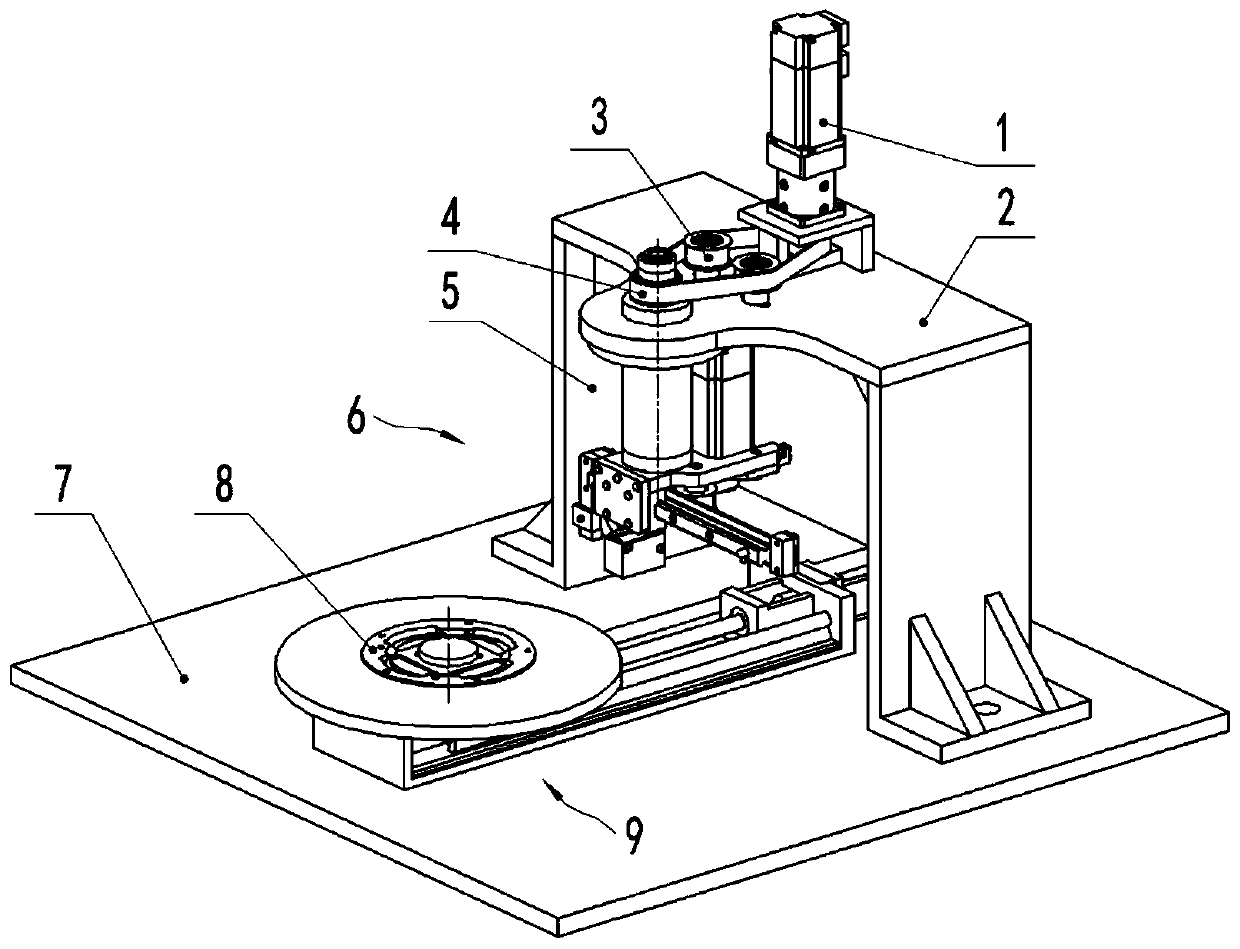

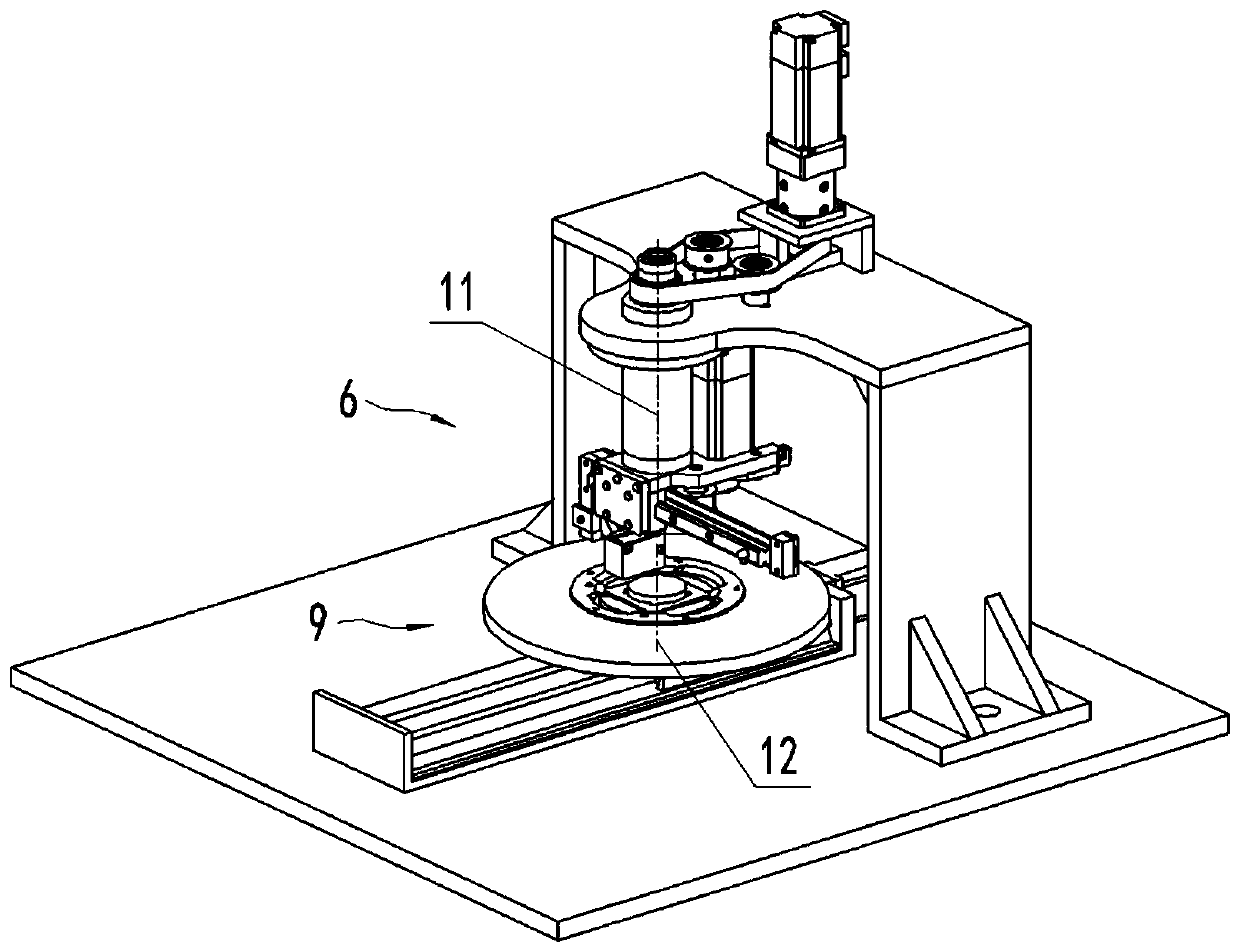

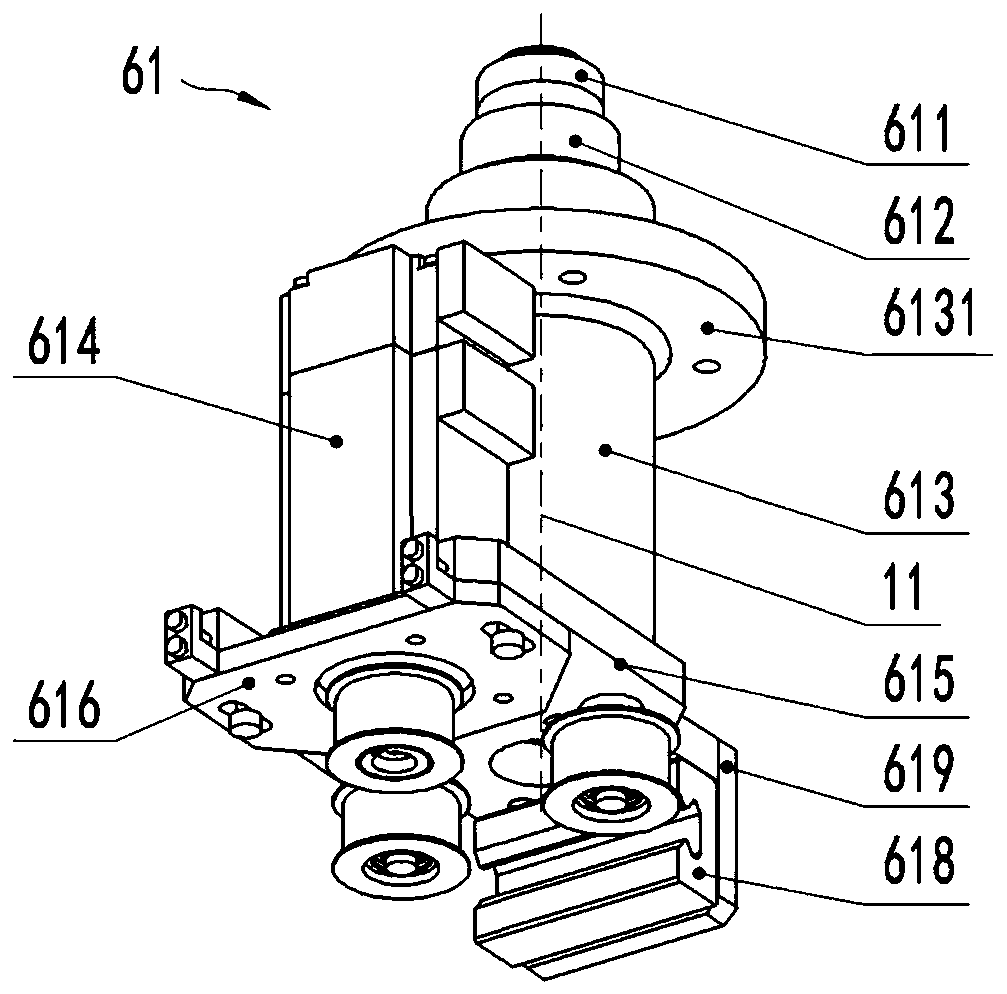

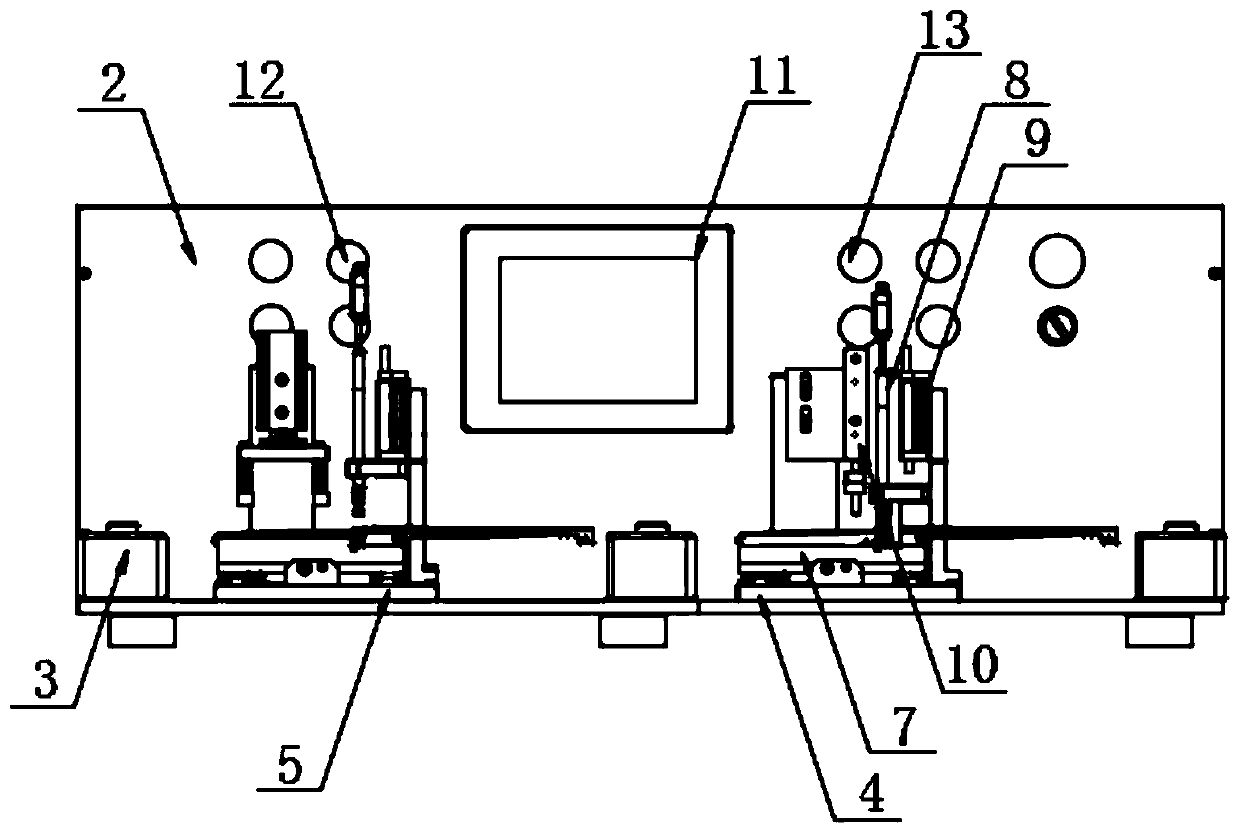

Disc-shaped part flatness detecting device, automatic detecting table and detecting method thereof

InactiveCN109916364AEasy accessFast detection operationMeasurement devicesEngineeringSurface flatness

The invention discloses a disc-shaped part flatness detecting device, an automatic detecting table and a detecting method thereof. The device comprises a bottom plate; a bracket, a detecting mechanism, a displacement sensor and a slip assembly, wherein the bracket is fixedly disposed on the bottom plate; the detecting mechanism is fixedly disposed on the bracket and comprises a rotary assembly anda guide rail assembly which are vertically connected in sequence, the rotary assembly is fixedly disposed on a support and the output end rotates around a Z axis, and the guide rail assembly is horizontally fixed to the output end of the rotary assembly to provide linear movement in a horizontal direction; the displacement sensor is fixedly disposed at one end of the guide rail assembly; and theslip assembly is fixed on the bottom plate and located below the detecting mechanism for mounting and transporting a to-be-detected part. The cost is moderate, the occupied space is small, a disc-shaped part can be taken and placed conveniently, the detecting operation is quick, an executing mechanism is accurately controlled, the automation degree is high, manual product surface flatness measurement can be replaced, the detecting efficiency and the accuracy can be effectively improved, and the requirements of the daily detection quantity can be met.

Owner:SOUTH CHINA UNIV OF TECH

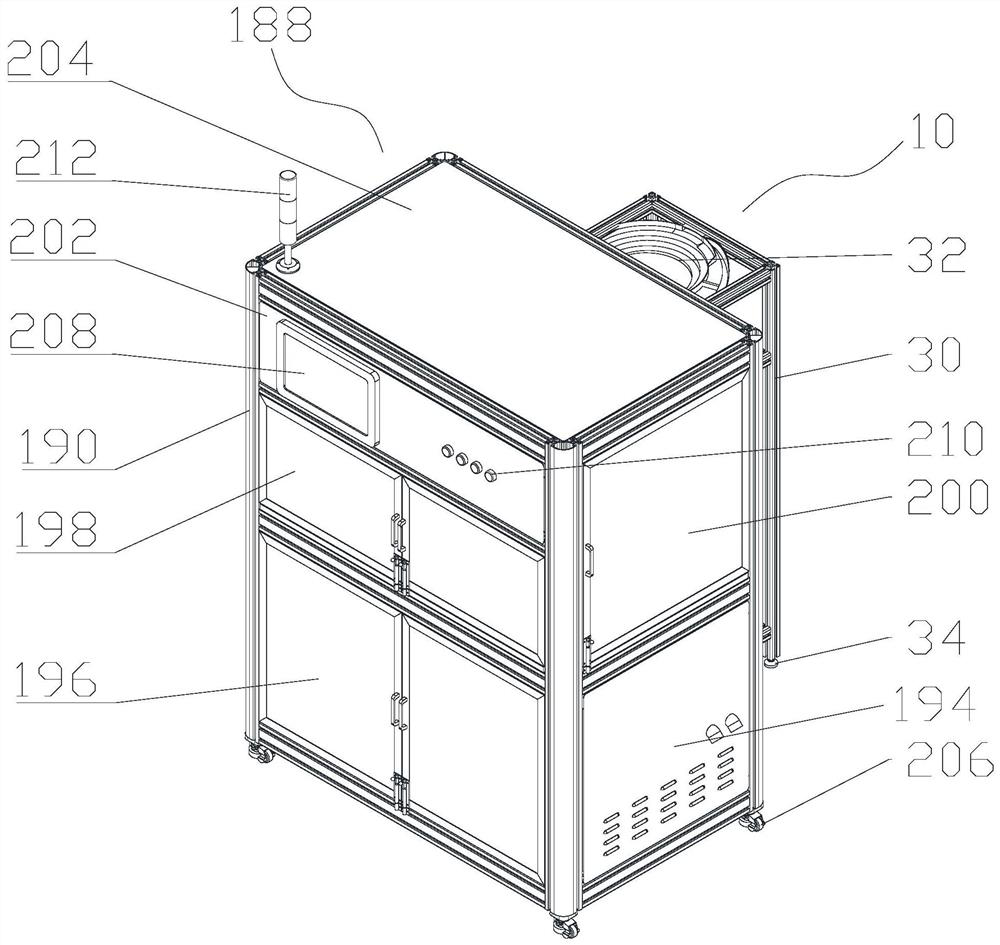

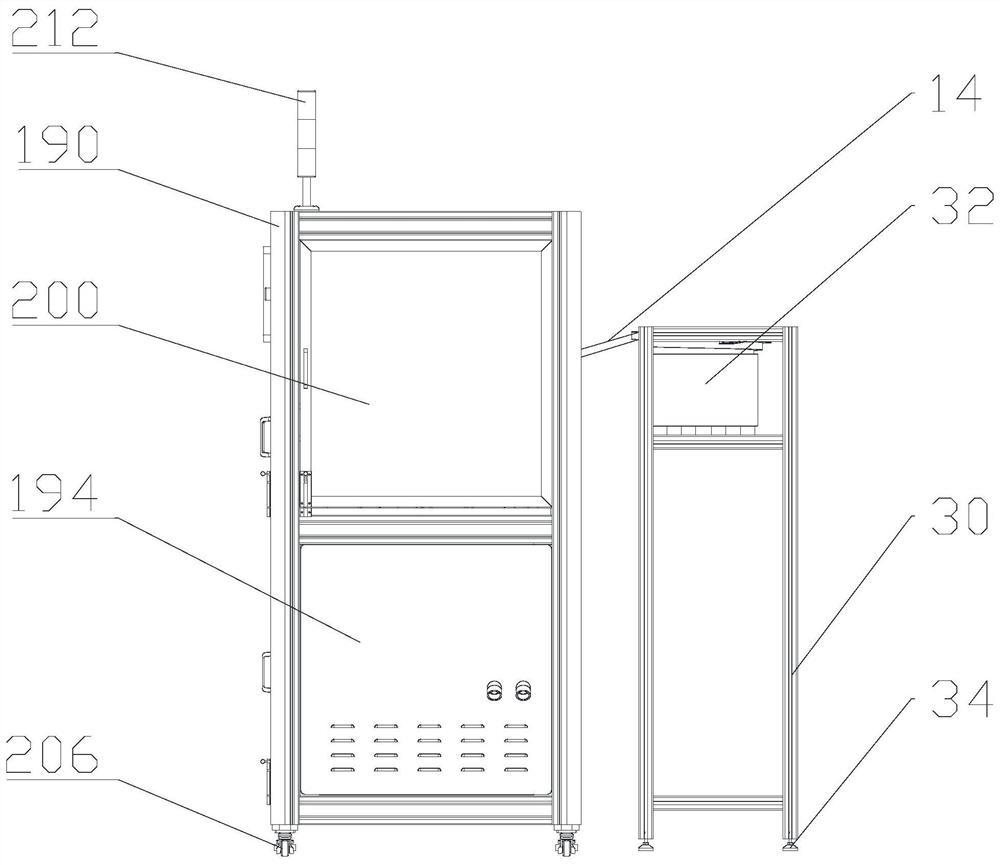

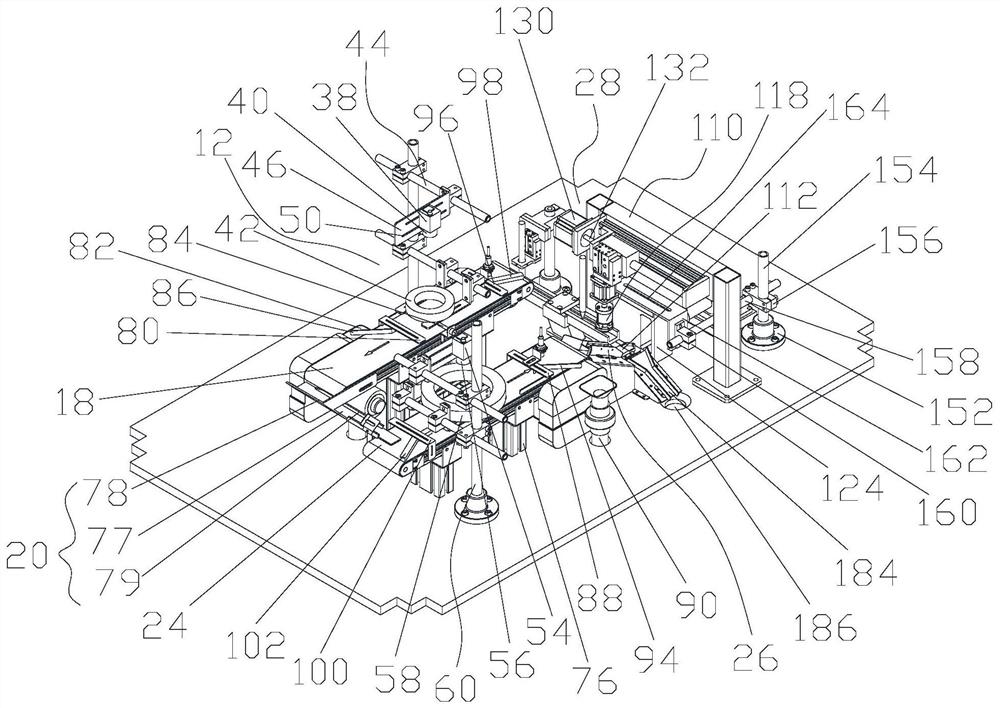

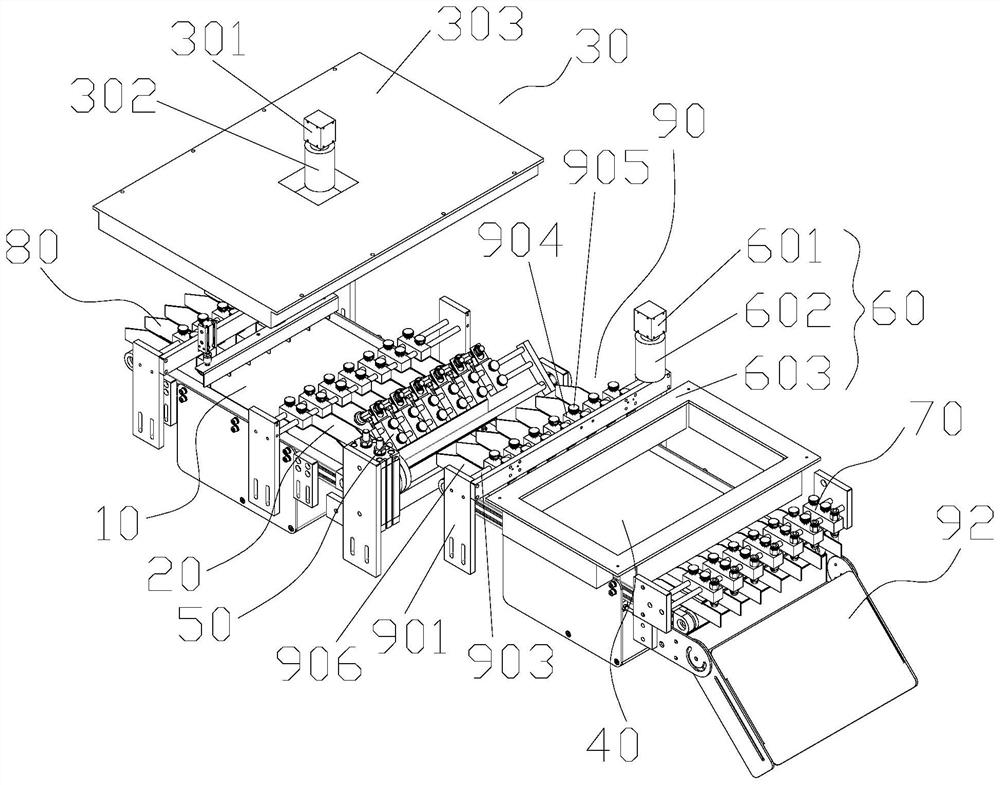

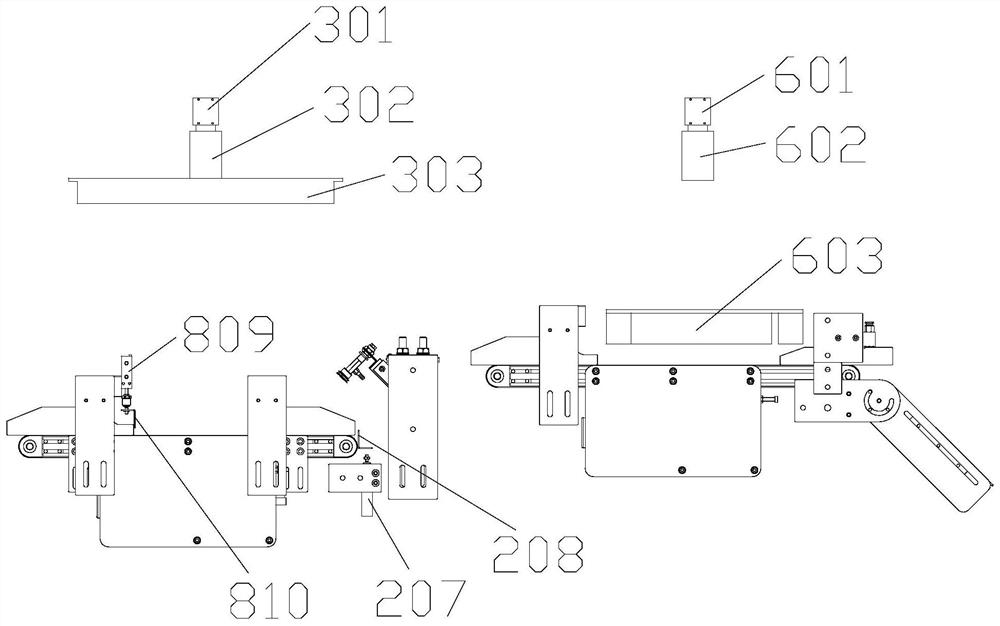

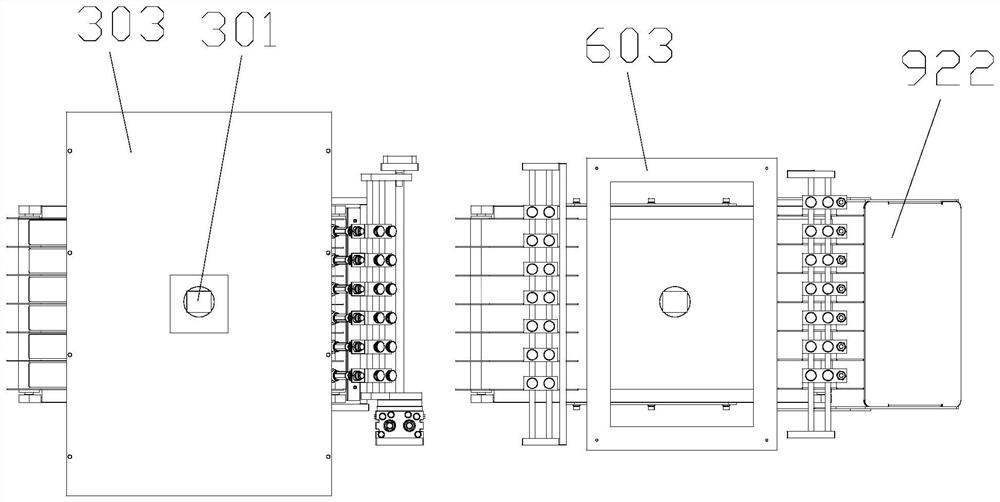

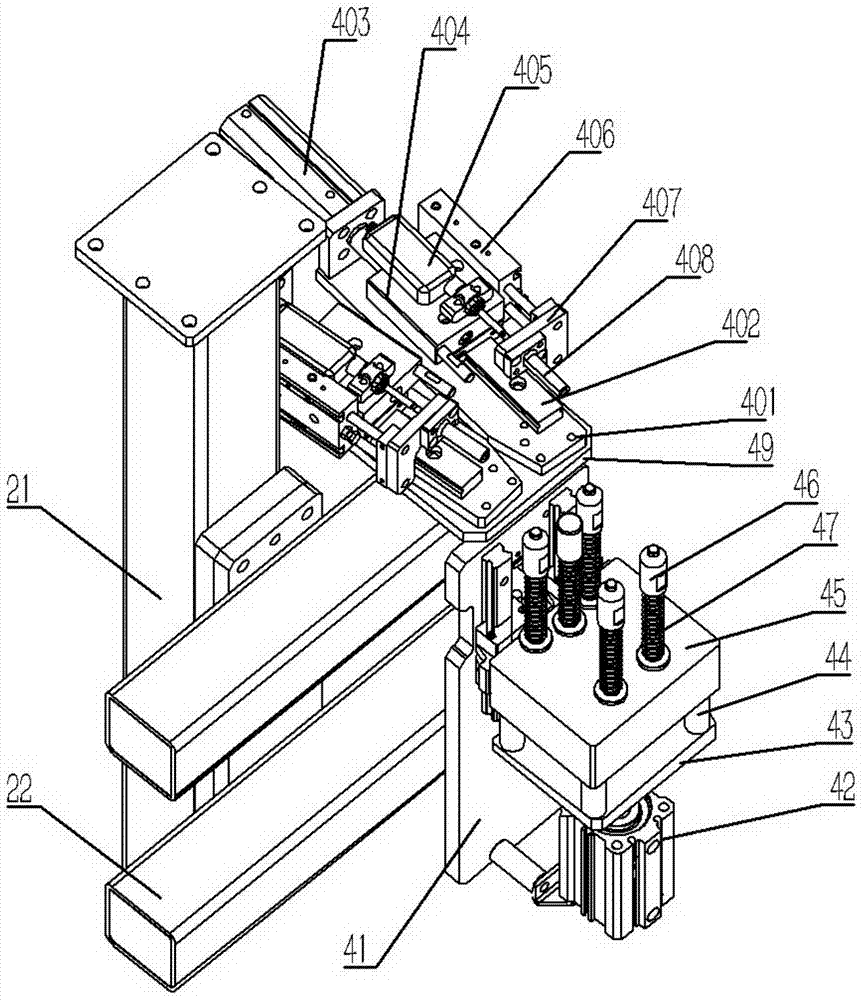

Full-automatic machine part visual flaw detection equipment and method

PendingCN111804601AEfficient automatic detectionReduce false detection rateSortingMachine partsMechanical components

The invention discloses full-automatic machine part visual flaw detection equipment. The equipment comprises a feeding device and a detection device, the feeding device is connected with a feeding rail, the detection device comprises a first view finding mechanism, a first conveyor, a turnover mechanism, a second view finding mechanism, a second conveyor, an arrangement mechanism and a third viewfinding mechanism, an output end of the feeding rail faces the first conveyor, the first conveyor is positioned above the second conveyor, the turnover mechanism faces the second conveyor, and the arrangement mechanism is positioned between the second conveyor and the third view finding mechanism. The invention also discloses a full-automatic machine part visual flaw detection method. According tothe equipment and the method, through the cooperation of a vibration disc, the first view finding mechanism, the first conveyor, the turnover mechanism, the second view finding mechanism, the secondconveyor and the third view finding mechanism, comprehensive, efficient and rapid detection on the front surface, the back surface and the side wall of a part is realized, the false detection rate isreduced, the correct and reliable detection result is ensured, the detection efficiency is accelerated, and the cost is effectively reduced.

Owner:太仓中科信息技术研究院

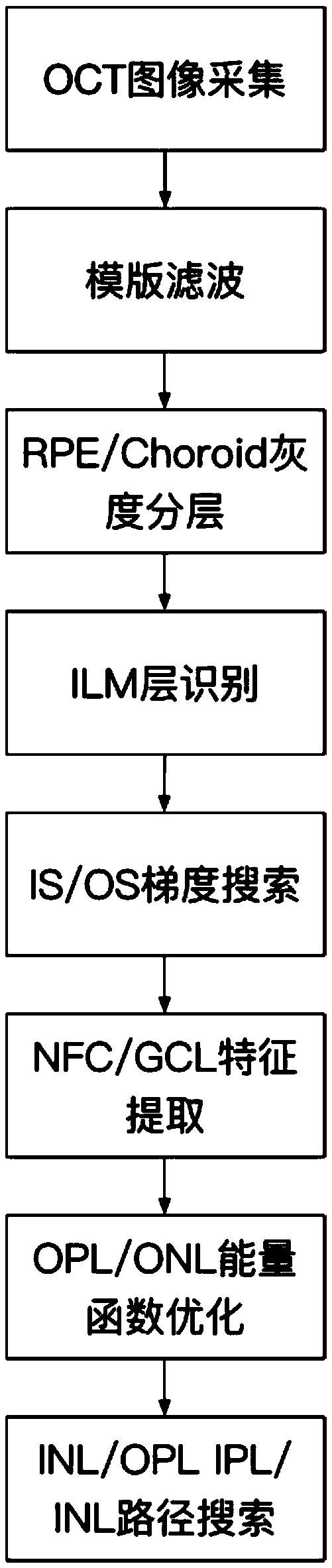

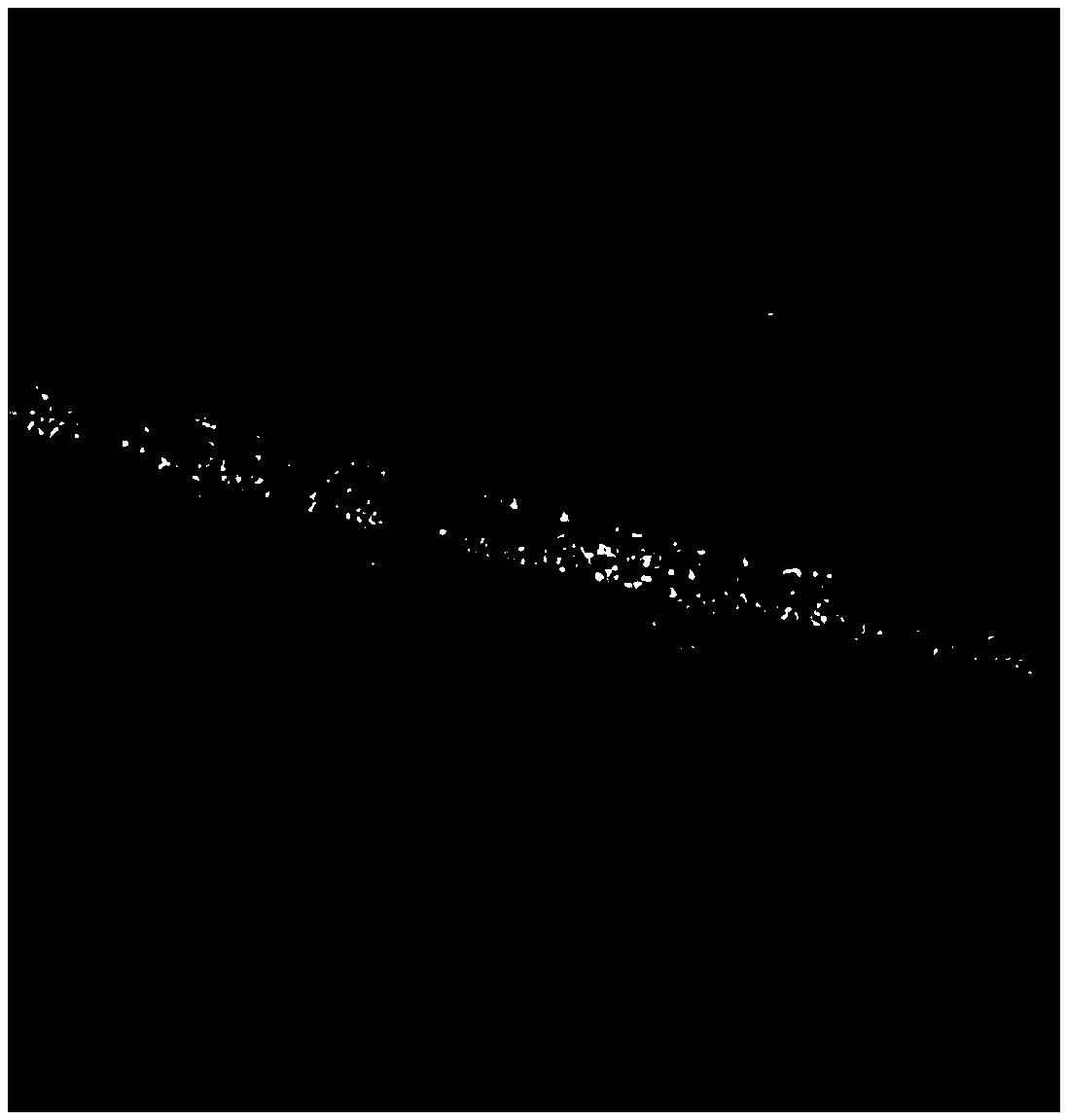

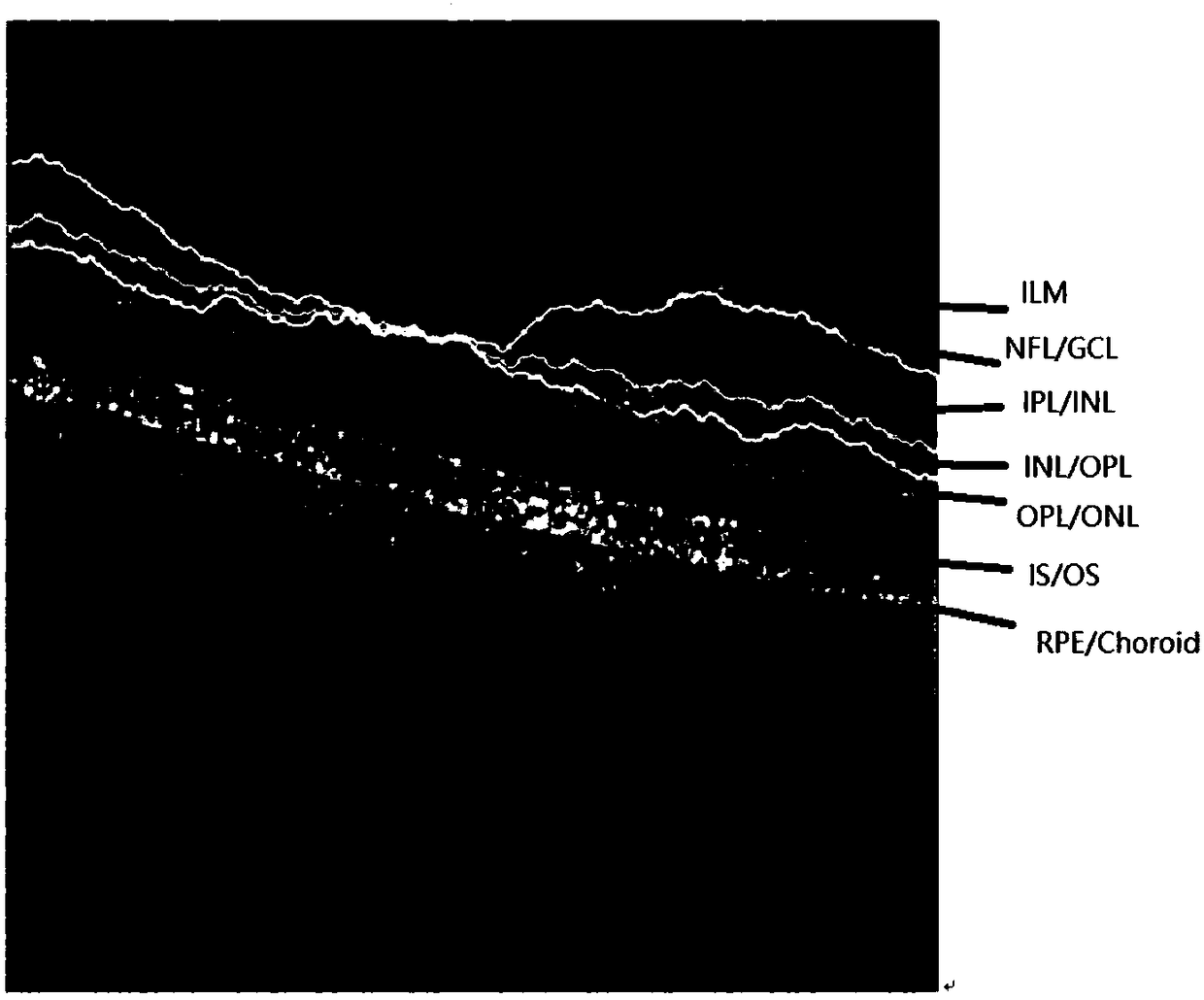

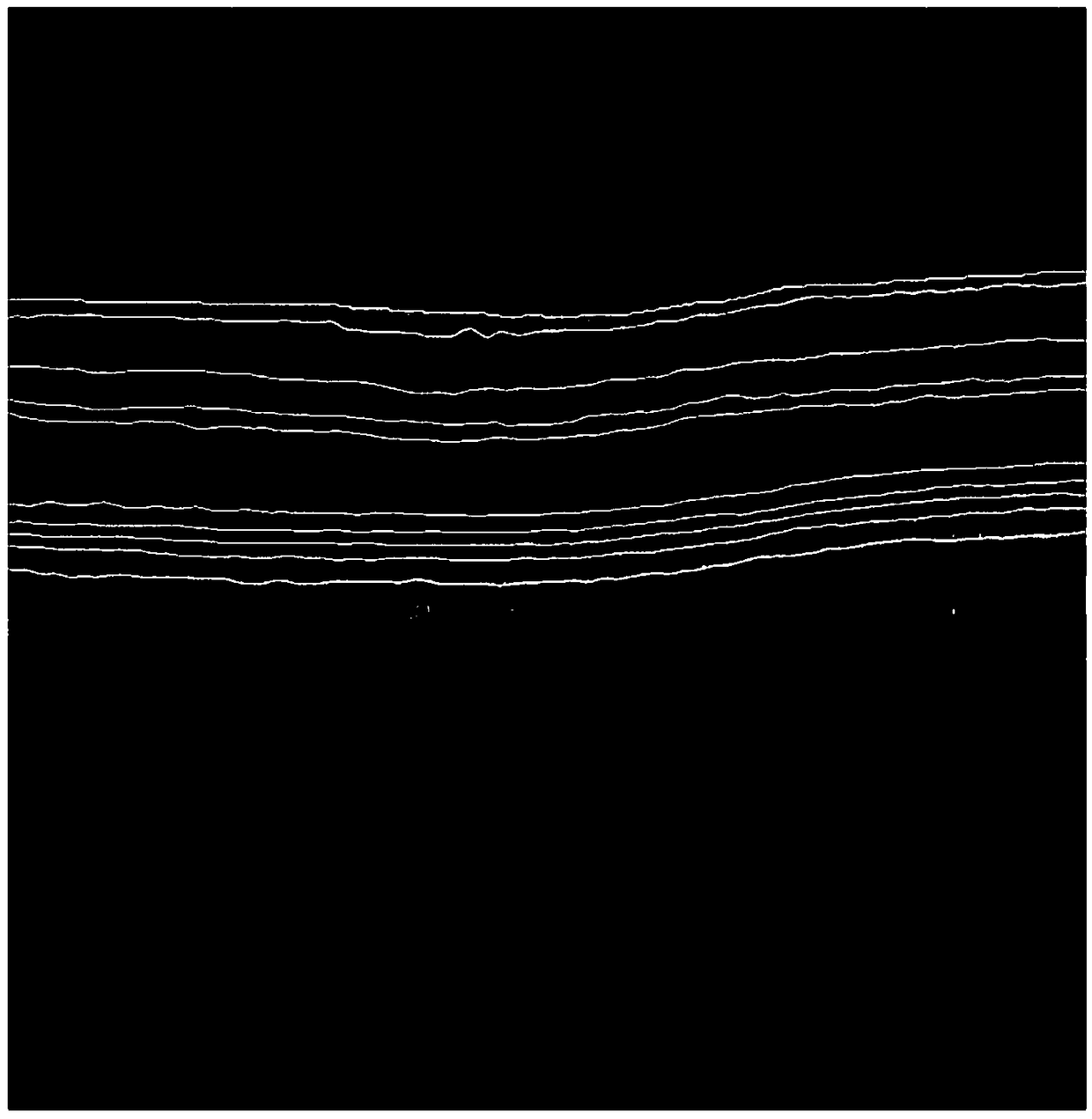

Retina stratification method in eye ground OCT (Optical Coherence Tomography) image

ActiveCN108836257AEfficient automatic detectionVerify accuracyImage enhancementImage analysisGanglion cell layerEpithelium

The invention discloses a retina stratification method in an eye ground OCT (Optical Coherence Tomography) image. The eye ground OCT image is acquired as an original image; the integral original imageis traversed by using a weight coefficient matrix template to carry out template filtering; and then RPE (Retina Pigment Epithelium) / Choroid gray scale stratification, ILM (Internal Limiting Membrane) layer identification, IS / OS (Inner Segment / Outer Segment) gradient search, NFC / GCL (Nerve Fiber Layer / Ganglion Cell Layer) feature extraction, OPL / ONL (Outer Molecular Layer / Outer Nuclear Layer) energy function optimization and INL (Inner Nuclear Layer) / OPL and IPL (Inner Molecular Layer) / INL path search are carried out, and finally, segmentation on different layers of the retina in the OCT image is completed. The retina stratification method in the eye ground OCT image, which is disclosed by the invention, can implement automatic segmentation on multiple layer structures by utilizing a computer which is commonly configured, implements effective automatic detection on a complex disease stratified structure of the retina, adopts serialized stratification, has few original processing stepsfor the image, and has a certain advantage in detection efficiency.

Owner:杭州富扬科技有限公司

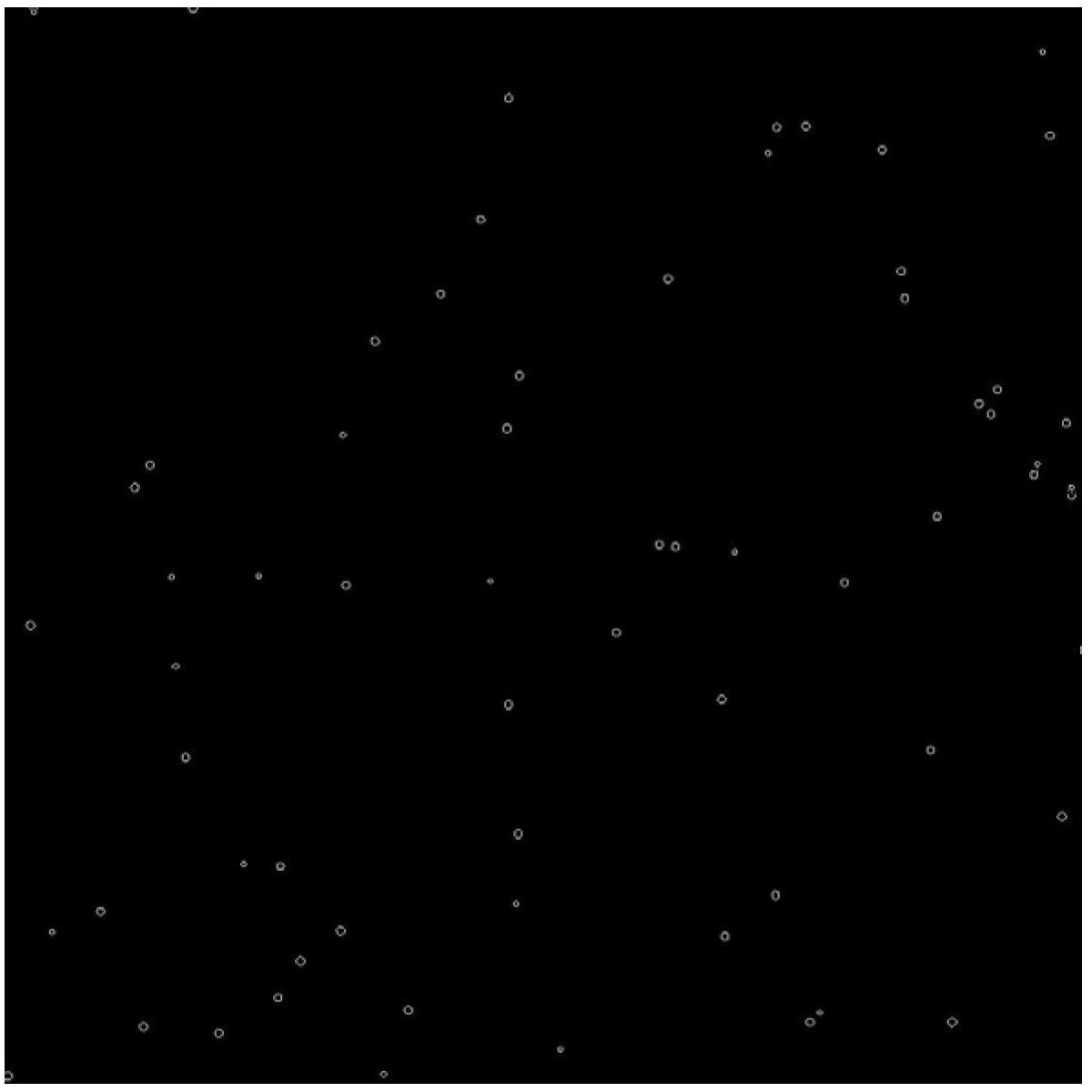

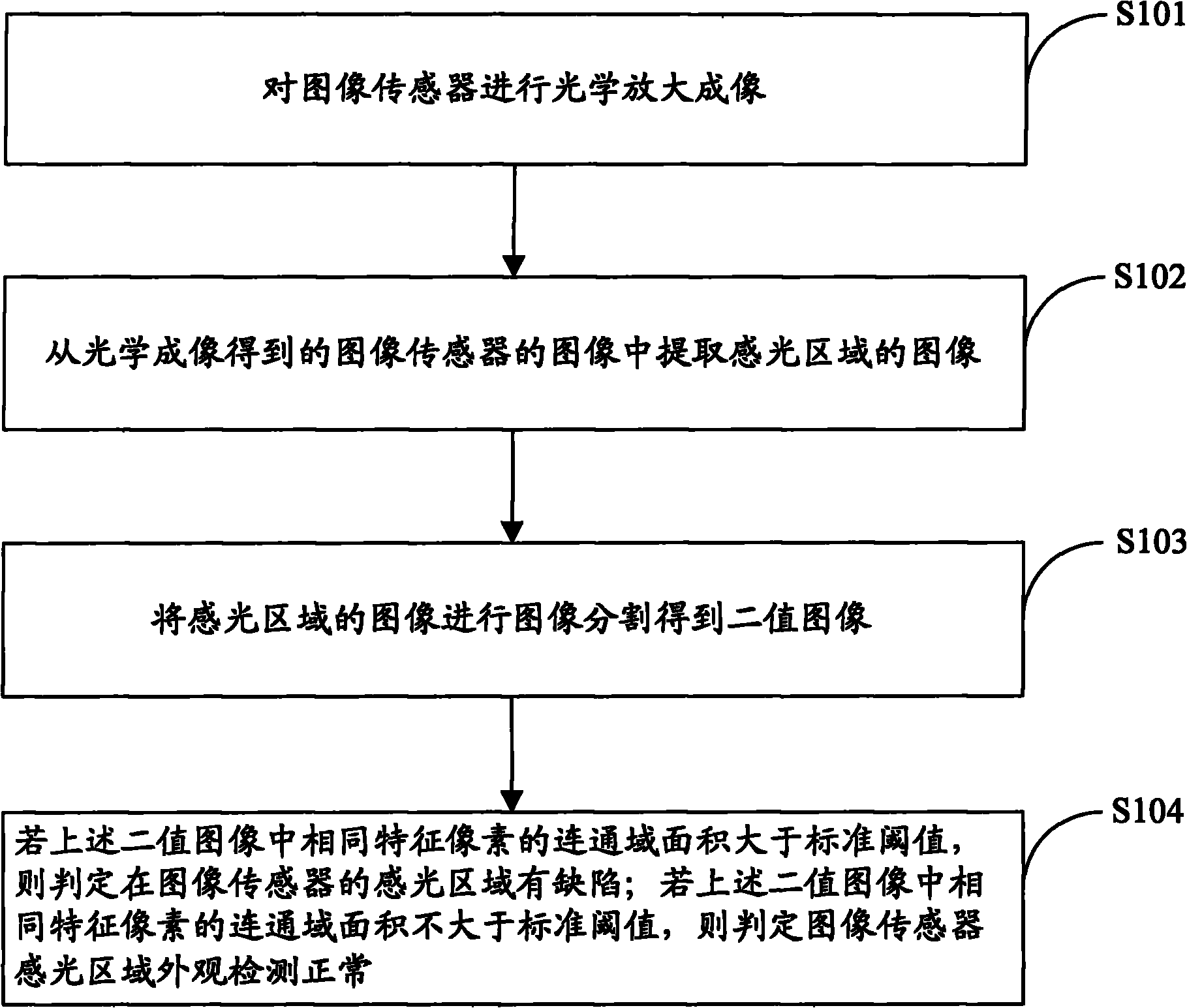

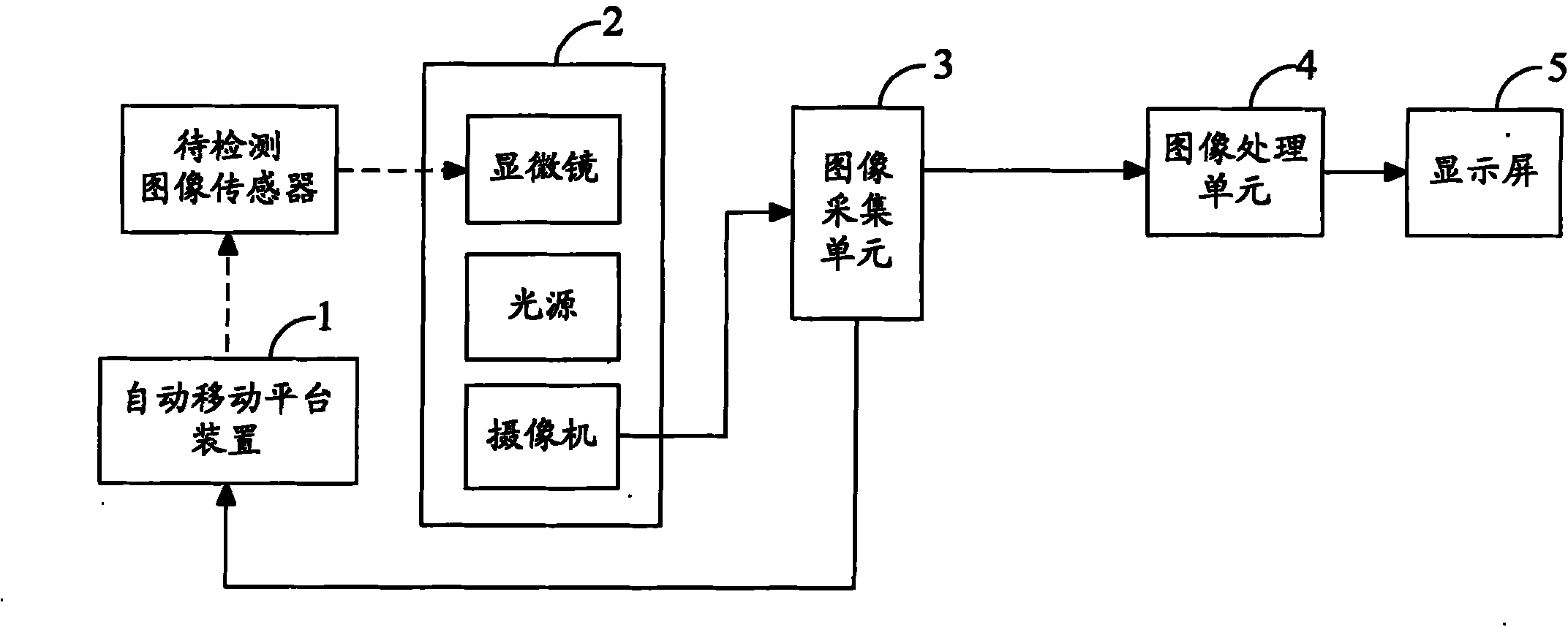

Appearance detection method and system of image sensor

InactiveCN101995325AEfficient automatic detectionAccurate automatic detectionOptical apparatus testingLight sensingAutomation

The invention provides appearance detection method and system of an image sensor, which is applicable to the technical field of chip manufacture procedures. The method comprises the following steps of: carrying out optical amplification imaging on the image sensor; extracting images of light sensing regions of the image sensor from images obtained through optical application imaging, and further obtaining binary images; judging that the light sensing region of the image sensor has defects if the value of the communication region area of the identical character pixels in the binary images is greater than a standard threshold value; and judging that the appearance of the light sensing region of the image sensor is normal if the value of the communication region area is not greater than the standard threshold value, wherein the pixels corresponding to the standard threshold values have the same color characteristics as the pixels in the communication region. The invention can efficiently and accurately carry out automatic detection on the light sensing region defects on the image sensor, the whole process can be conveniently integrated into the existing automation manufacture procedures, the manual participation is not needed in judgment, and the consistency of the detection standard can be ensured, so the detection quality is improved.

Owner:BYD CO LTD

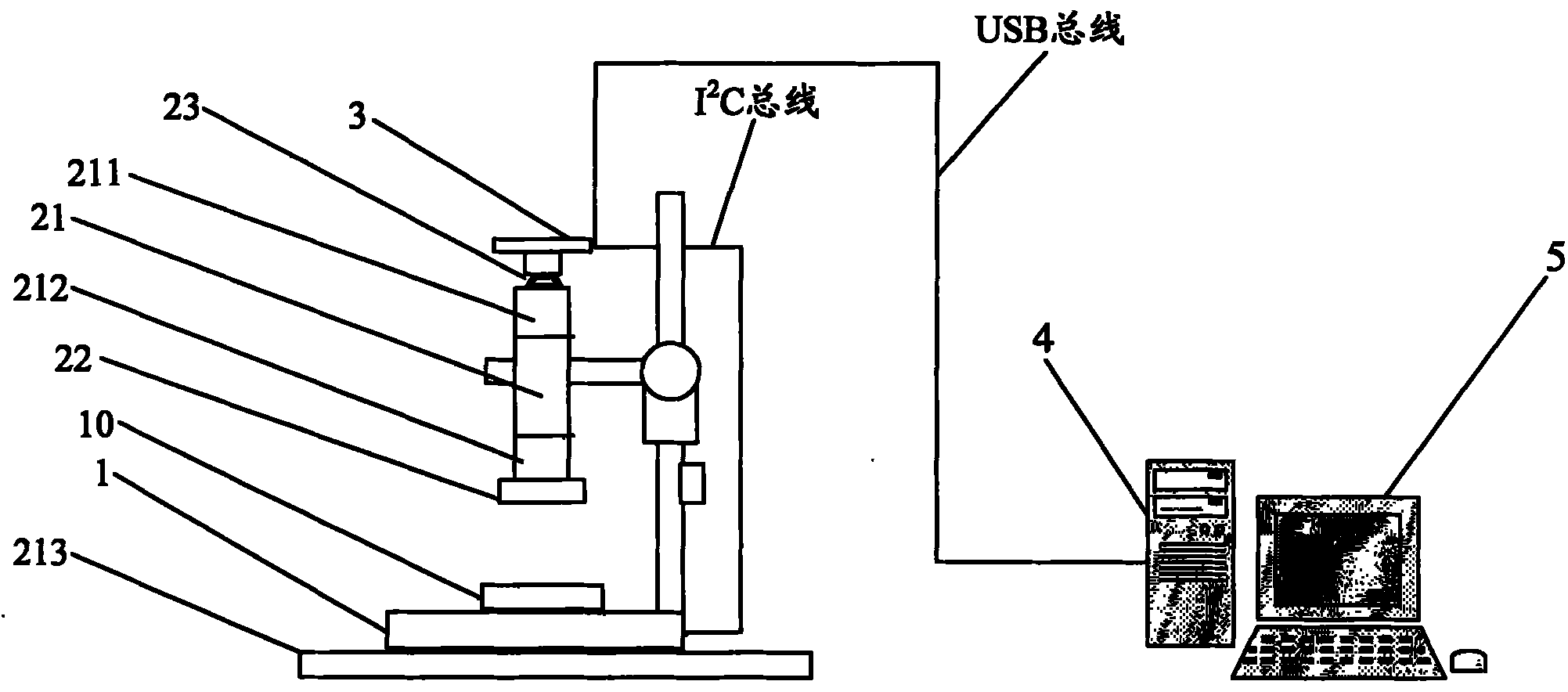

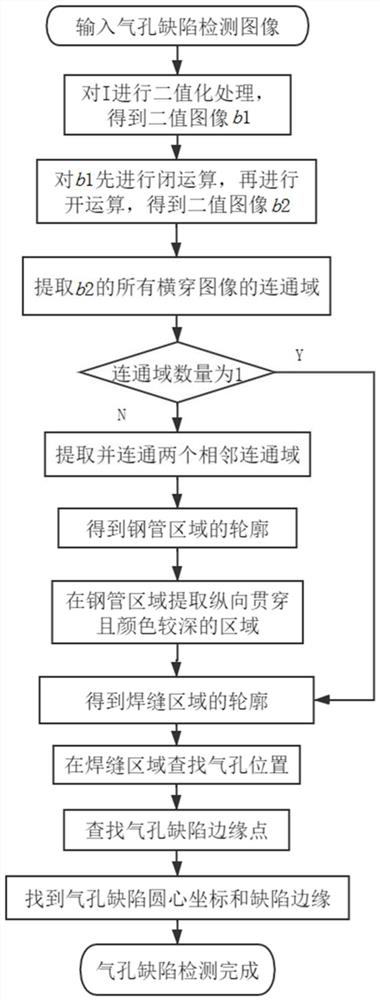

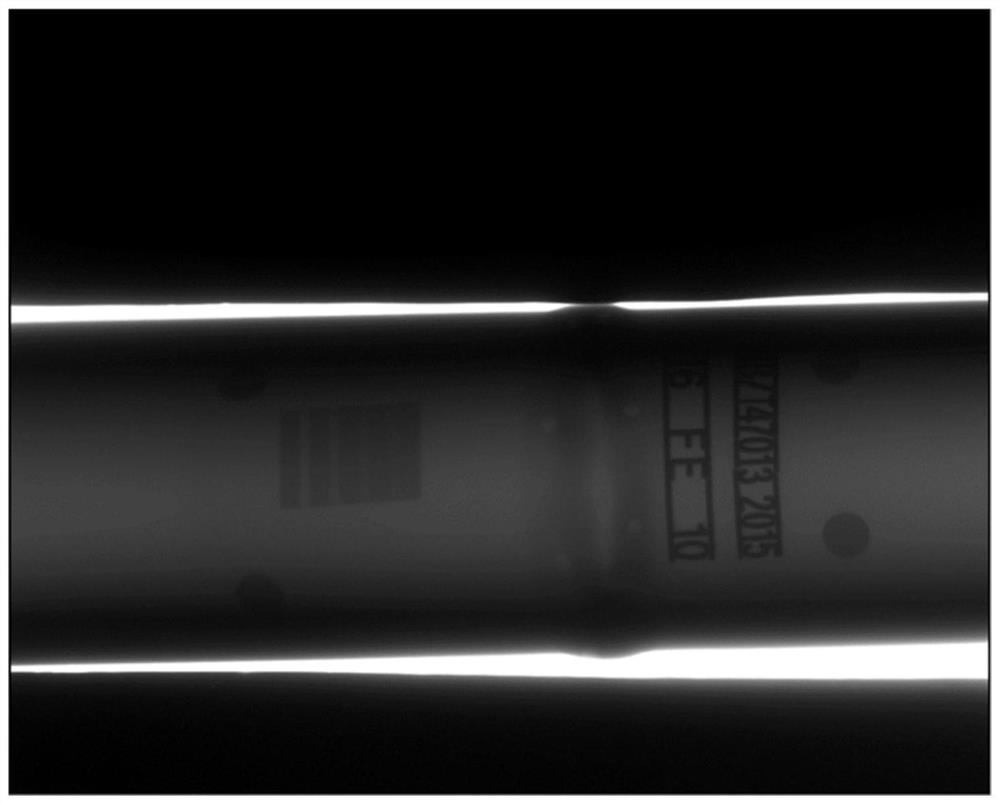

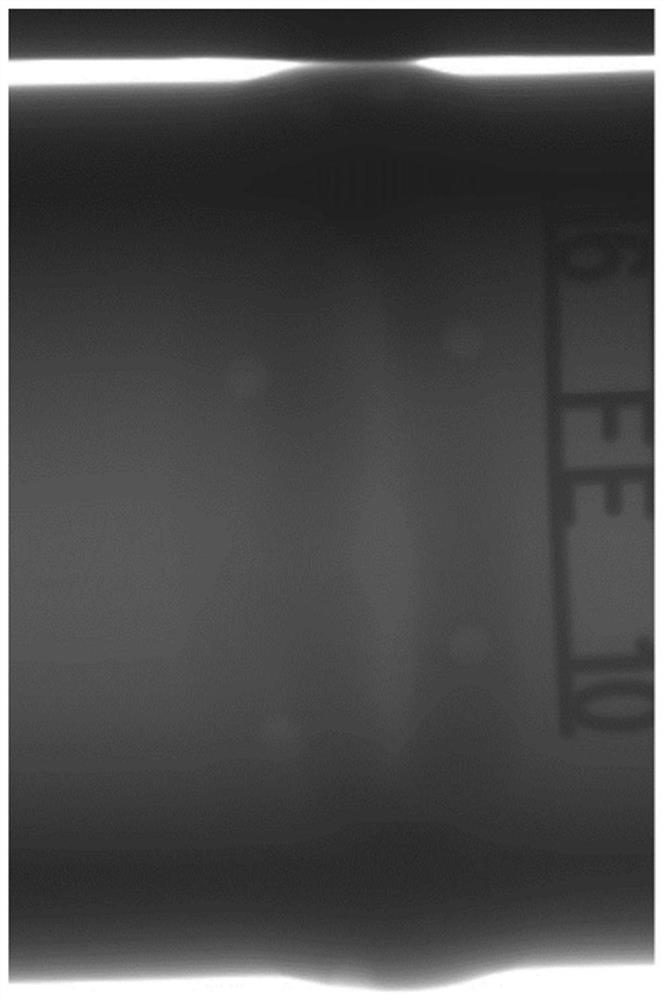

Weld joint pore defect detection method based on image processing

ActiveCN113496483AAccurate automated detectionEfficient automatic detectionImage enhancementImage analysisPattern recognitionImaging processing

The invention discloses a weld joint pore defect detection method based on image processing. The method comprises the following steps: carrying out binarization processing on an input pore defect to-be-detected image to obtain a binary image imgb1; performing closing operation and opening operation on the binary image imgb1 in sequence to obtain a binary image imgb2; extracting and putting all connected domains of the binary image imgb2 into a summary set; traversing the summarized set, extracting a connected domain which transversely passes through the image, and putting the connected domain into a first screening set; if only one element exists in the first screening set, taking the connected domain as the contour of the welding joint area, and searching the pore defect area directly; otherwise, searching a steel pipe area; extracting a target welding seam area; searching an air hole defect area; and extracting all pore defect areas based on edge detection, and fitting the contour by adopting a least square method. According to the invention, the to-be-detected image of the pore defect is directly processed, the weld pore defect is detected by combining connected domain searching and edge detection, and the method has good precision and accuracy.

Owner:SOUTH CHINA UNIV OF TECH

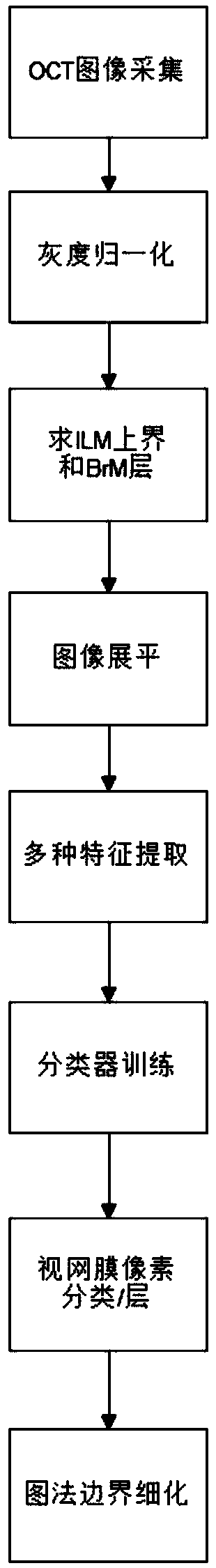

A retinal stratification method based on OCT images

ActiveCN109325955AQuick layeringAccurate retinal layer structureImage enhancementImage analysisAutomatic segmentationAverage filter

The invention discloses a retinal layering method based on an OCT image. The OCT image of the fundus of the eye is collected as a sample image, the gray-scale normalization processing is carried out on the collected sample images, and then the sample image is flattened. The average filter is used to solve the longitudinal gradient, and then the upper and lower retinal boundaries are determined bycomparison. The calculated features are inputted to the training classifier to obtain the probability that pixels are located at the boundary of different layers. Finally, the optimal boundary and itsposition of the training classifier are optimized by using a graph theory algorithm through the probability. The method of the invention can realize the automatic segmentation of a plurality of layerstructures by using a commonly configured computer, and adopts the multi-level probability classification decision and optimization, and at the same time adopts serialization layering, has fewer original processing steps for the image, and improves detection accuracy certainly.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

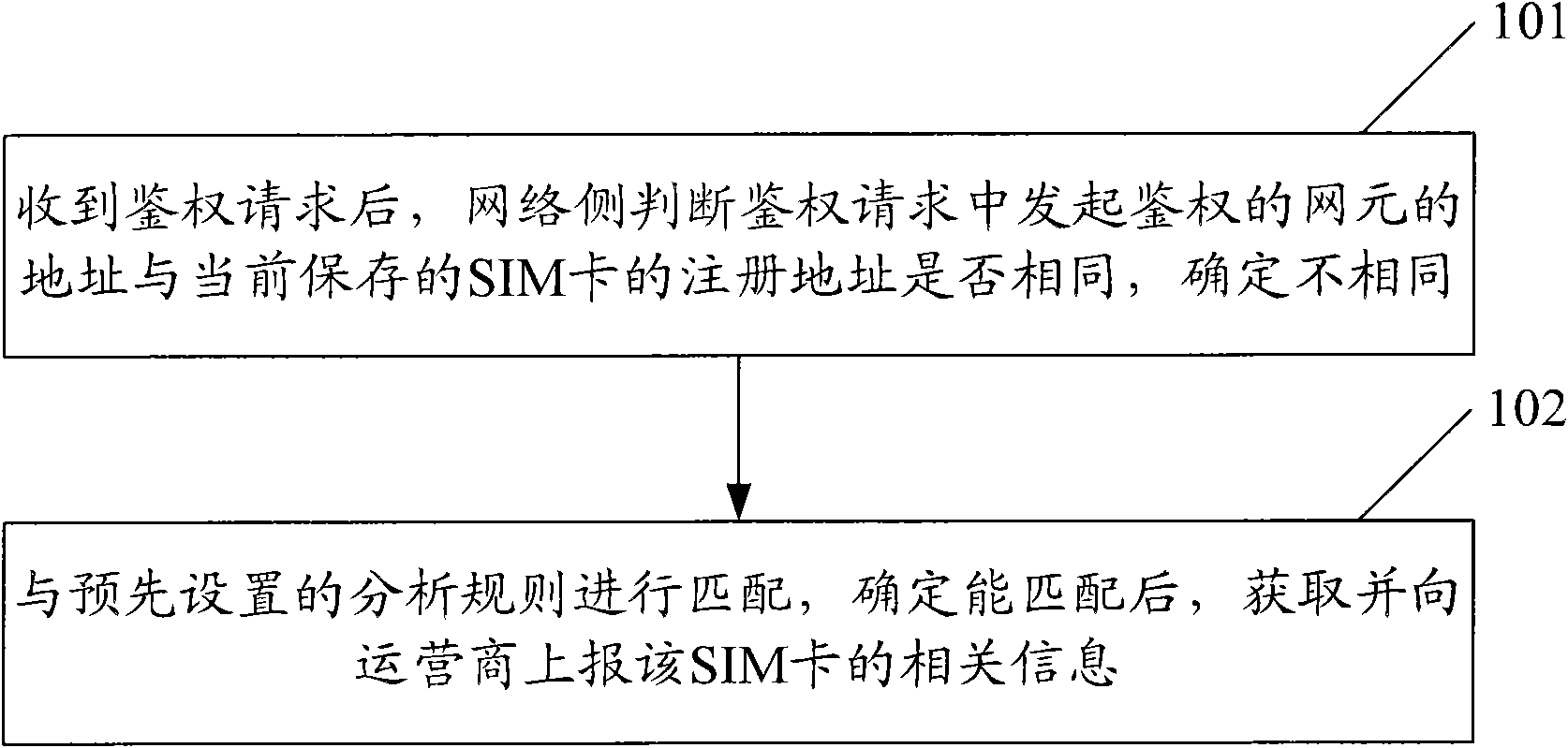

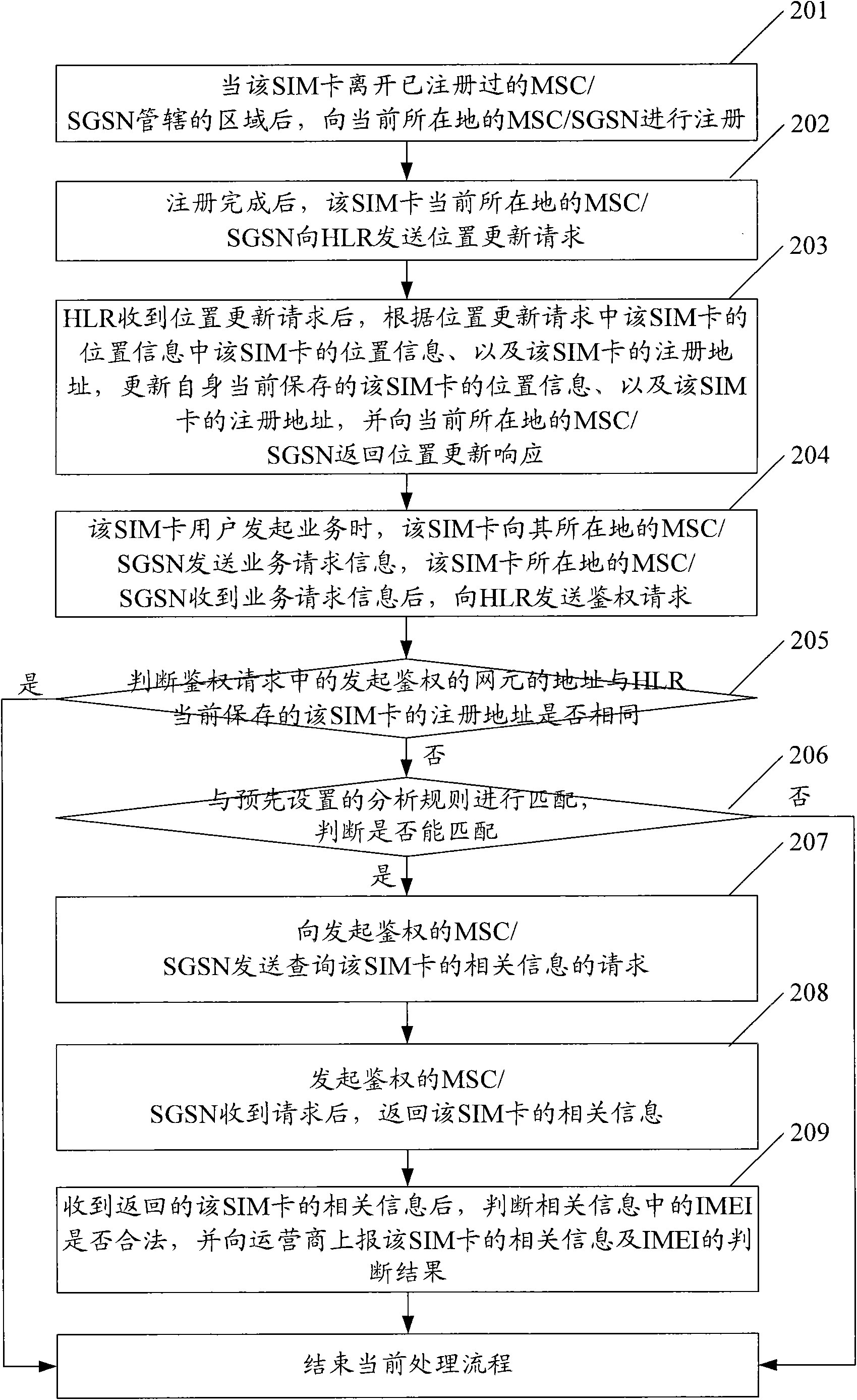

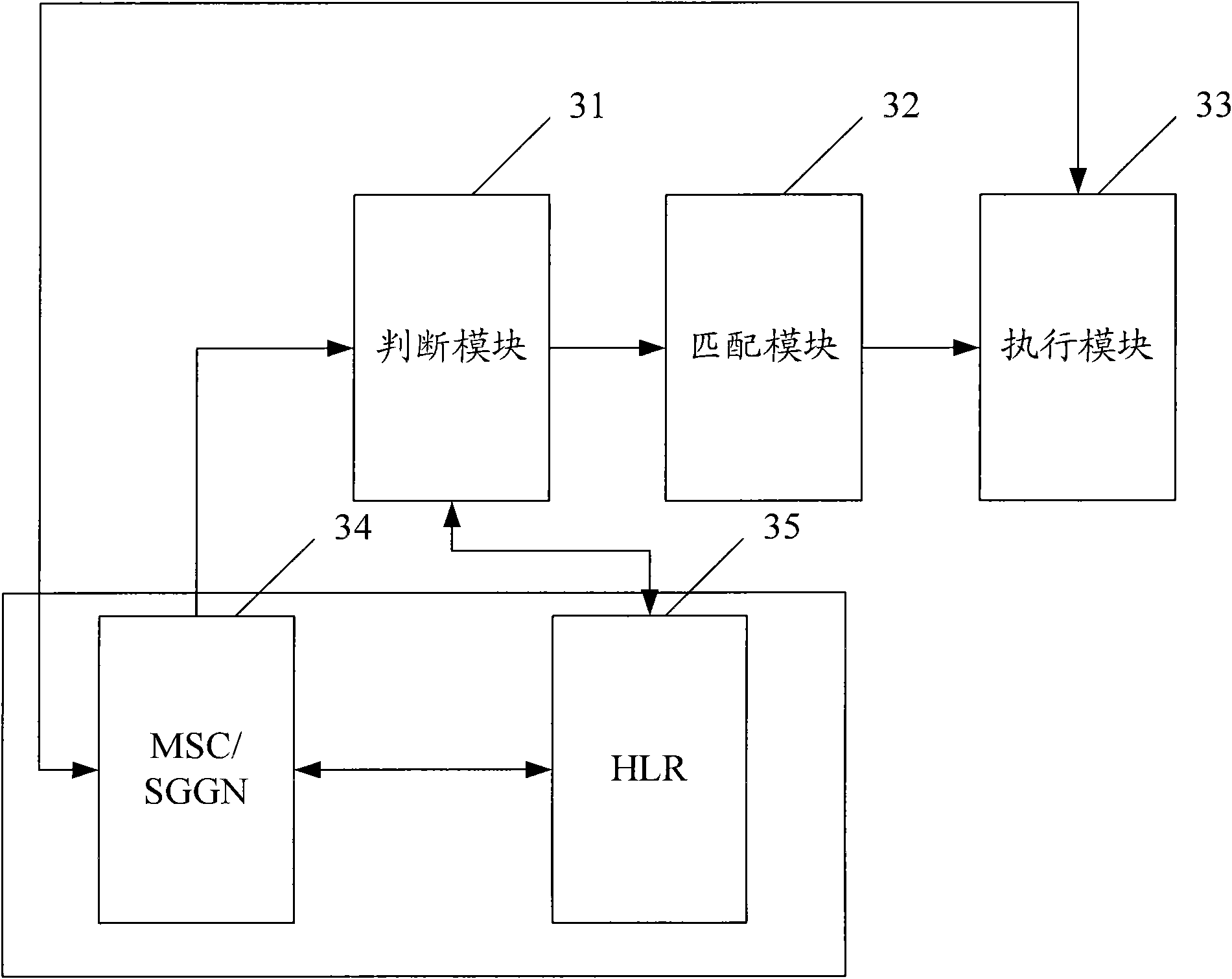

Cloned subscriber identity module card test method and system

ActiveCN101860847AEfficient automatic detectionReduce labor costsSecurity arrangementNetwork data managementRelevant informationSubscriber identity module

The invention discloses a cloned subscriber identity module (SIM) card test method, which comprises the following steps that: after authentication requirement is received, whether the address of a network element initiating authentication in the authentication requirement is the same as the registered address of the currently stored SIM card or not is judged, if the two addresses are not the same, a preset analysis rule is matched, and if the matching works, the relative information of the SIM card is obtained and reported to the operator. The invention discloses a cloned SIM card test system at the same time. The method and the system can detect the cloned SIM card in mobile communication network efficiently and automatically and then save labor cost.

Owner:ZTE CORP

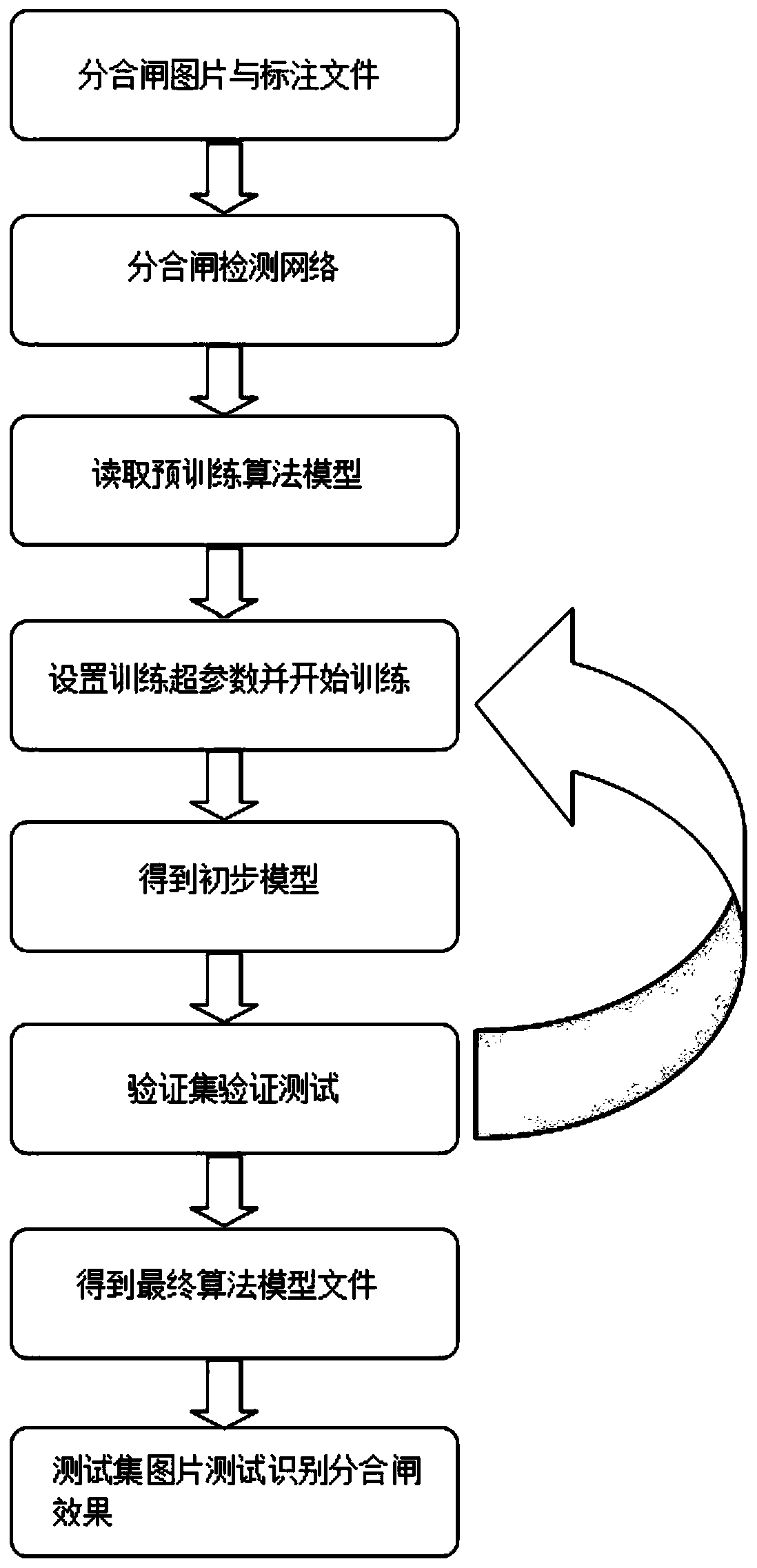

Transformer substation equipment detection method and device based on deep learning

PendingCN111209958AImprove accuracyEfficient automatic detectionCharacter and pattern recognitionNeural architecturesData setAlgorithm

The invention discloses a transformer substation equipment detection method and device based on deep learning. The method comprises the following steps: collecting a plurality of images comprising thephysical opening and closing positions of transformer substation equipment, carrying out the labeling and preprocessing of the images, making a standard data set, and dividing the data set into a training set, a verification set and a test set in proportion; and training a substation equipment detection neural network model by using a py master rcnn deep convolutional network, and testing by using the trained network model to obtain an equipment category and a physical opening and closing position recognition result of the substation equipment. According to the transformer substation equipment detection method and device based on deep learning, the transformer substation equipment category and the physical opening and closing state can be efficiently and automatically detected, the recognition result accuracy is high, and the practicability and operability are high.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

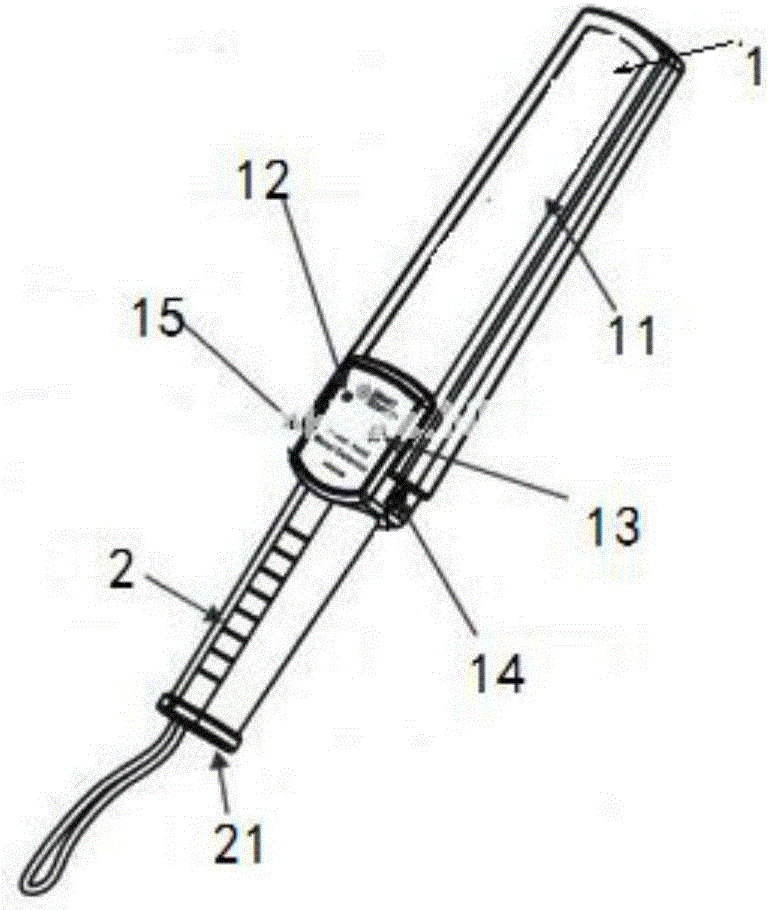

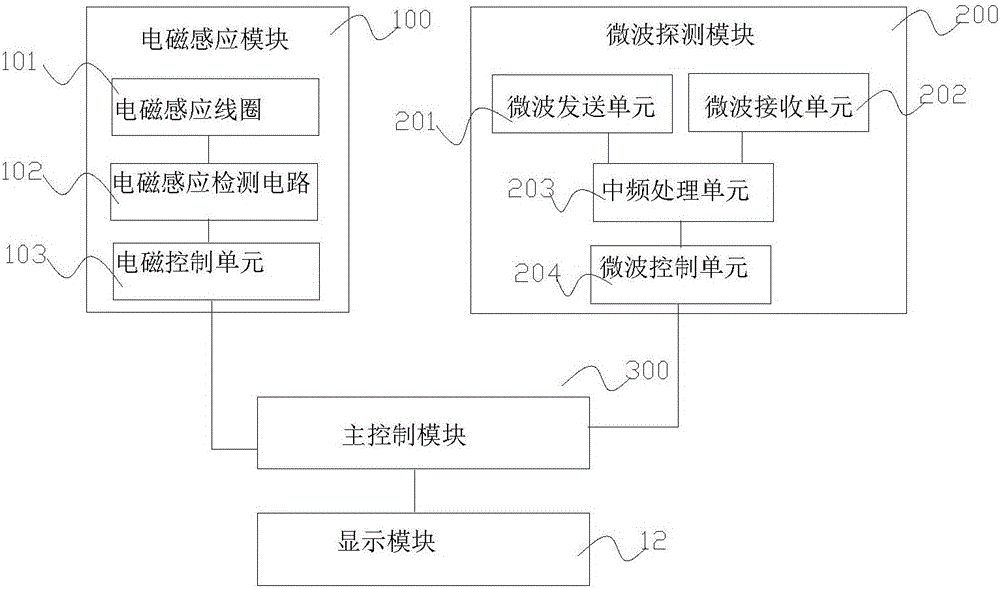

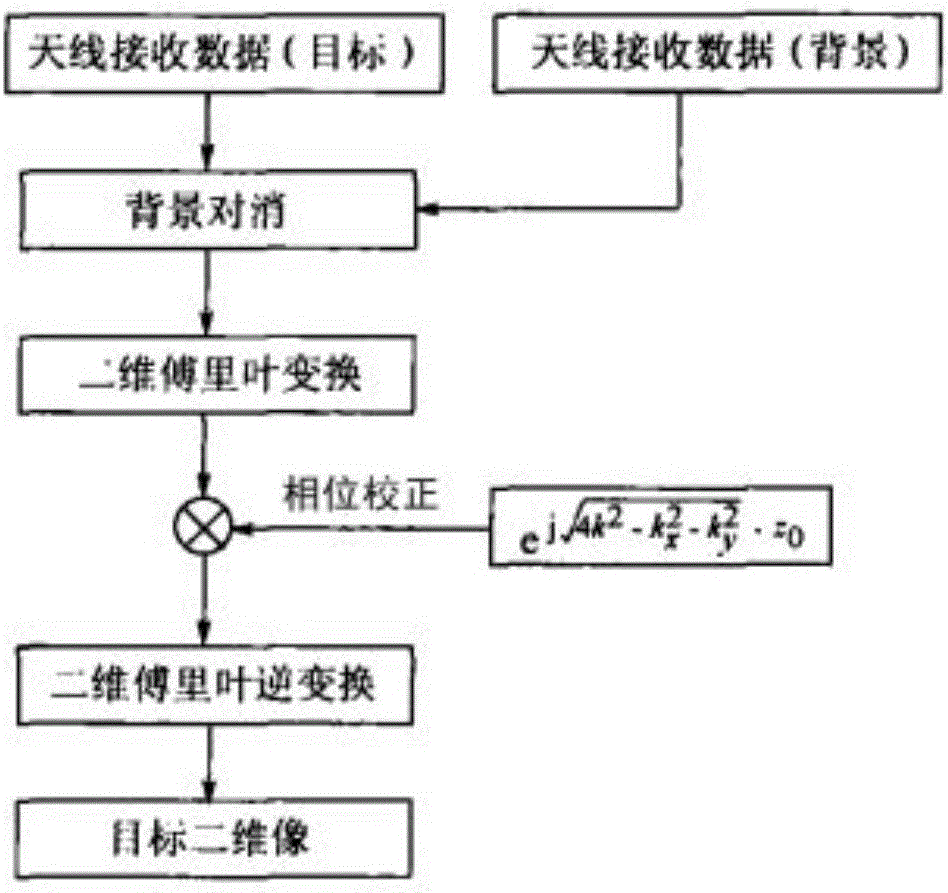

Hand-held safety-check device and safety-check method

InactiveCN106405661AHigh sensitivityHigh-efficiency automated detectionDetection using electromagnetic wavesElectromagnetic inductionEngineering

The invention discloses a hand-held safety-check device and a safety-check method. The hand-held safety-check device comprises a detection main body, the detection main body is provided with a display module and a detection surface, the detection main body also comprises an electromagnetic induction module, a microwave detection module and a master control module, the electromagnetic induction module and the microwave detection module are connected with the master control module, the master control module makes an analytical comparison between an electromagnetic detection signal result output by the electromagnetic induction module and a microwave detection signal result output by the microwave detection module to obtain a detection analysis result, the master control module is then connected with a display unit and performs displaying and early warning on the detection analysis result, and the microwave detection module comprises a microwave scattering imaging algorithm unit.

Owner:北京澳丰源科技有限公司

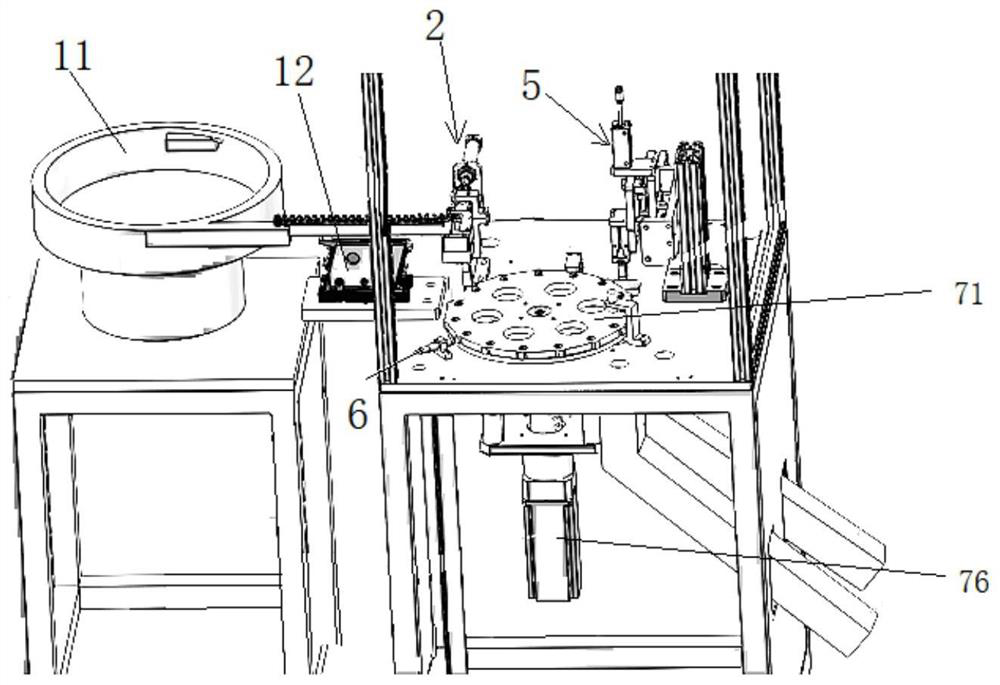

Automatic electrode detection device

PendingCN111958238ARealize automatic feeding processQuick Auto DetectAssembly machinesTransmissivity measurementsEngineeringManipulator

The invention discloses an automatic electrode detection device. The automatic electrode detection device comprises an automatic feeding component, an automatic mounting component, a hafnium wire detection component, a brass core detection component and a knurling detection manipulator. The automatic feeding component is used for conveying an electrode to be mounted to the automatic mounting component; the automatic mounting component is used for mounting the electrode in a station hole of a multi-station turntable; the hafnium wire detection component is used for detecting whether a hafnium wire is mounted on the electrode; the brass core detection component is used for detecting whether a brass core is mounted on the electrode; and the knurling detection manipulator is used for detectingwhether the surface of the electrode is knurled. According to the device, automatic feeding can be achieved, and a PLC system is combined with a mechanical structure, so that rapid, efficient and accurate automatic detection is achieved; and the installation condition or qualified condition of knurls, brass cores and hafnium wires can be detected at a time, and qualified products and unqualifiedproducts can be automatically classified.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

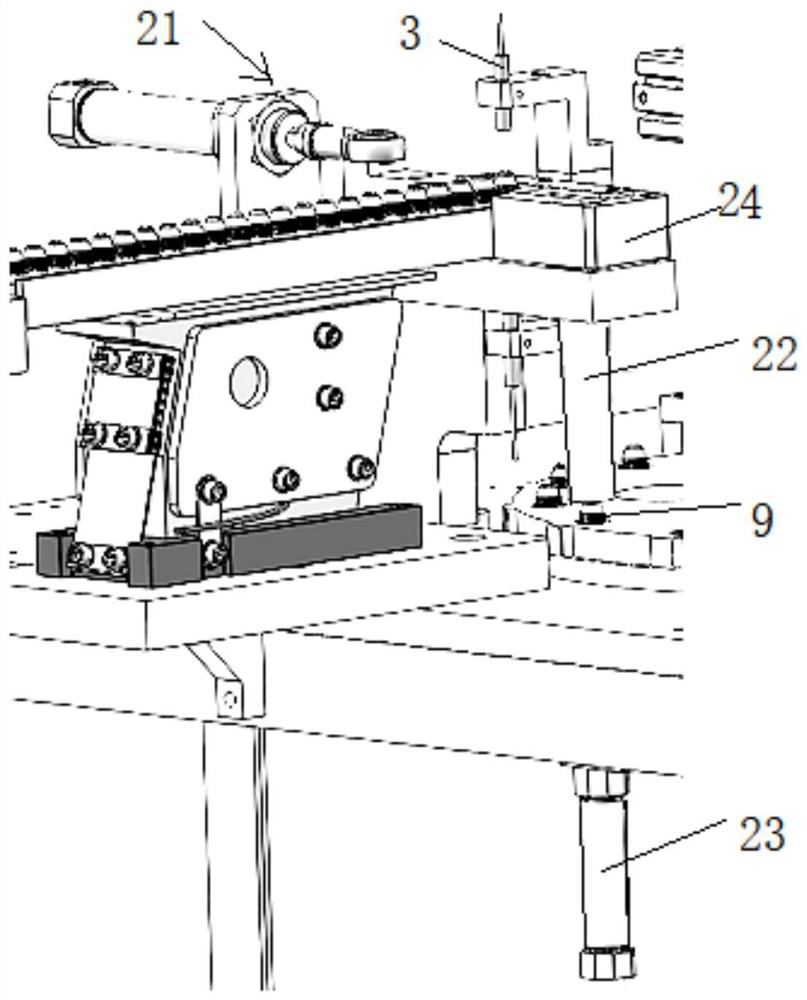

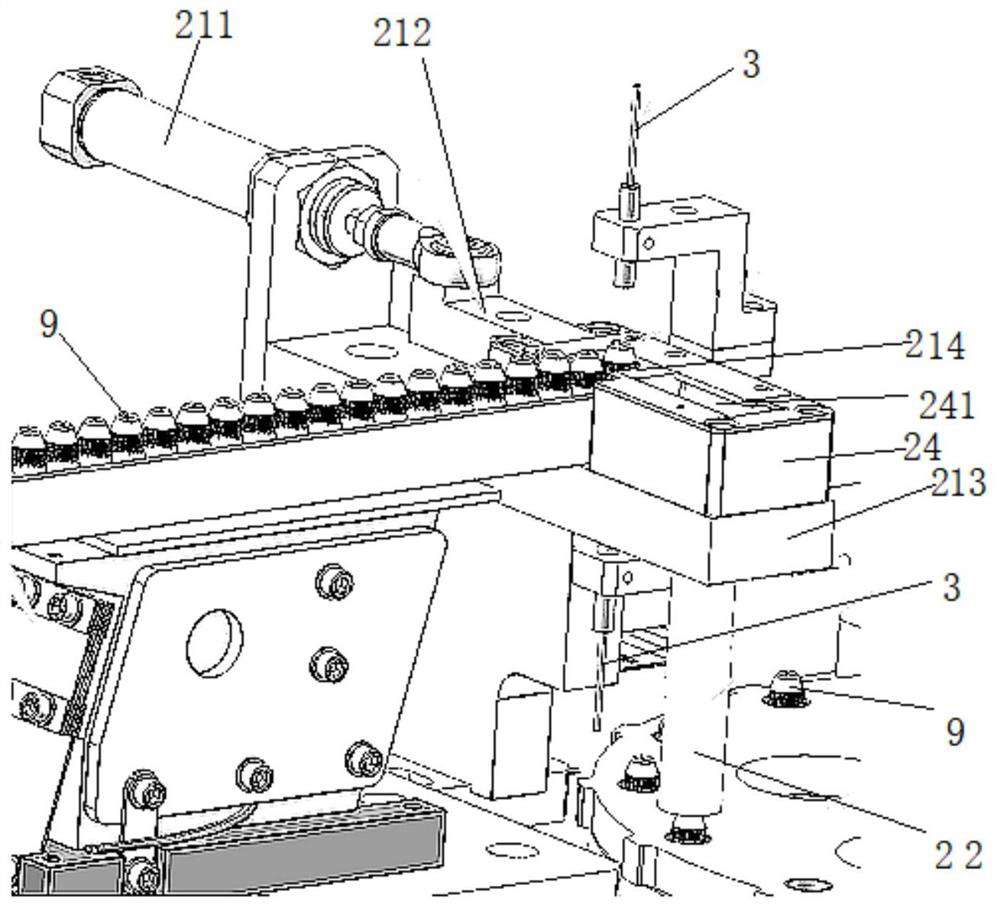

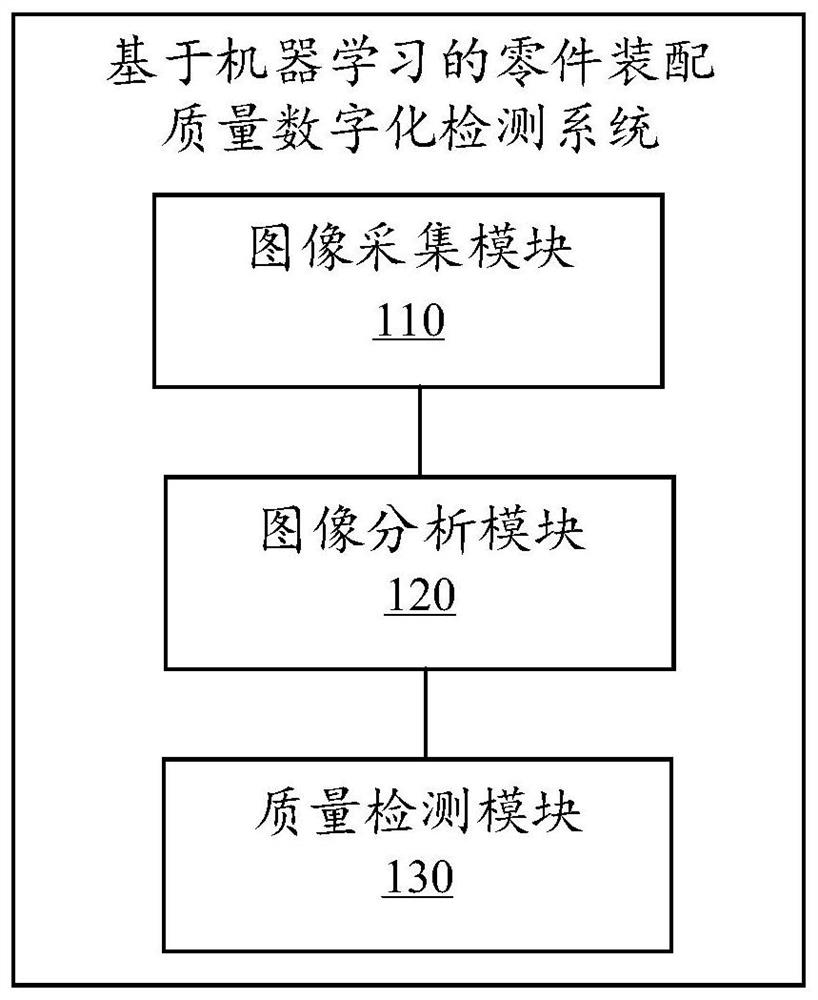

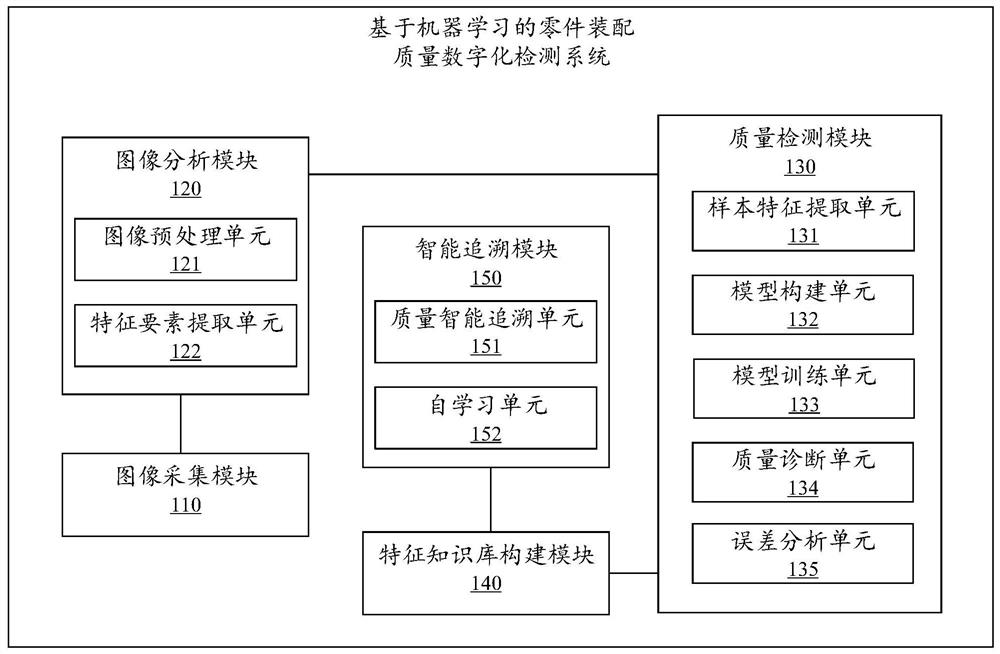

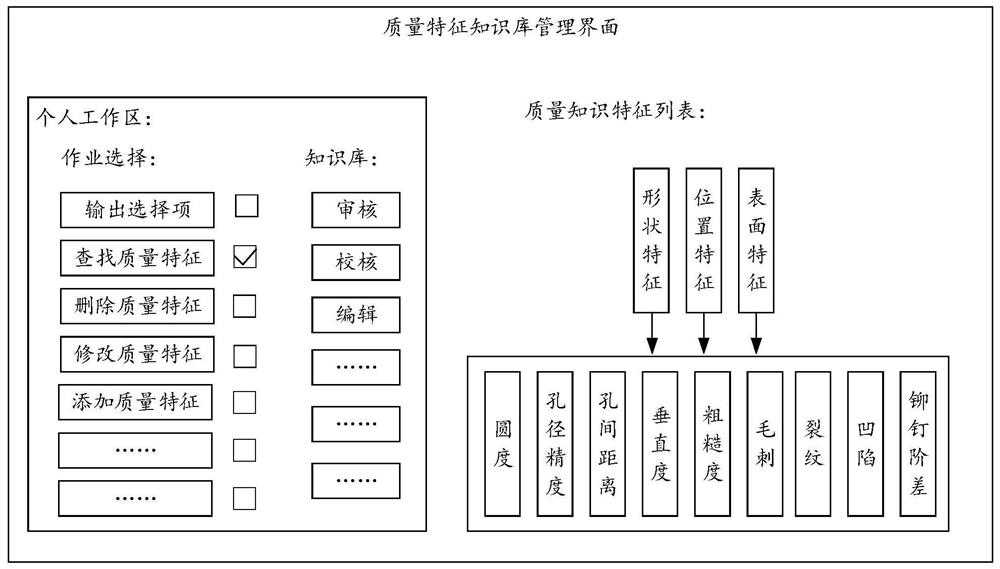

Part assembly quality digital detection system and method based on machine learning

PendingCN113487533AReduce error rateImplement diagnosticsImage enhancementImage analysisPattern recognitionData graph

The invention provides a part assembly quality digital detection system and method based on machine learning. The system comprises an image collection module which is used for obtaining the image data of at least one part, an image analysis module which is used for performing image information analysis on the image data to obtain a plurality of quality feature elements corresponding to the image data, and a quality detection module which is used for constructing a target quality detection model based on particle swarm parameter optimization, and performing drilling and / or riveting quality detection on the part by using the target quality detection model according to quality characteristic elements to obtain a quality detection result of the part. According to the part assembly quality digital detection system and method based on the machine learning of the invention, the quality detection of hole making and riveting in the part assembling process is realized in a process-oriented, modularized, automatic and efficient manner, the accuracy of a quality detection result is improved, and the manpower and time cost is greatly saved.

Owner:NORTHEASTERN UNIV

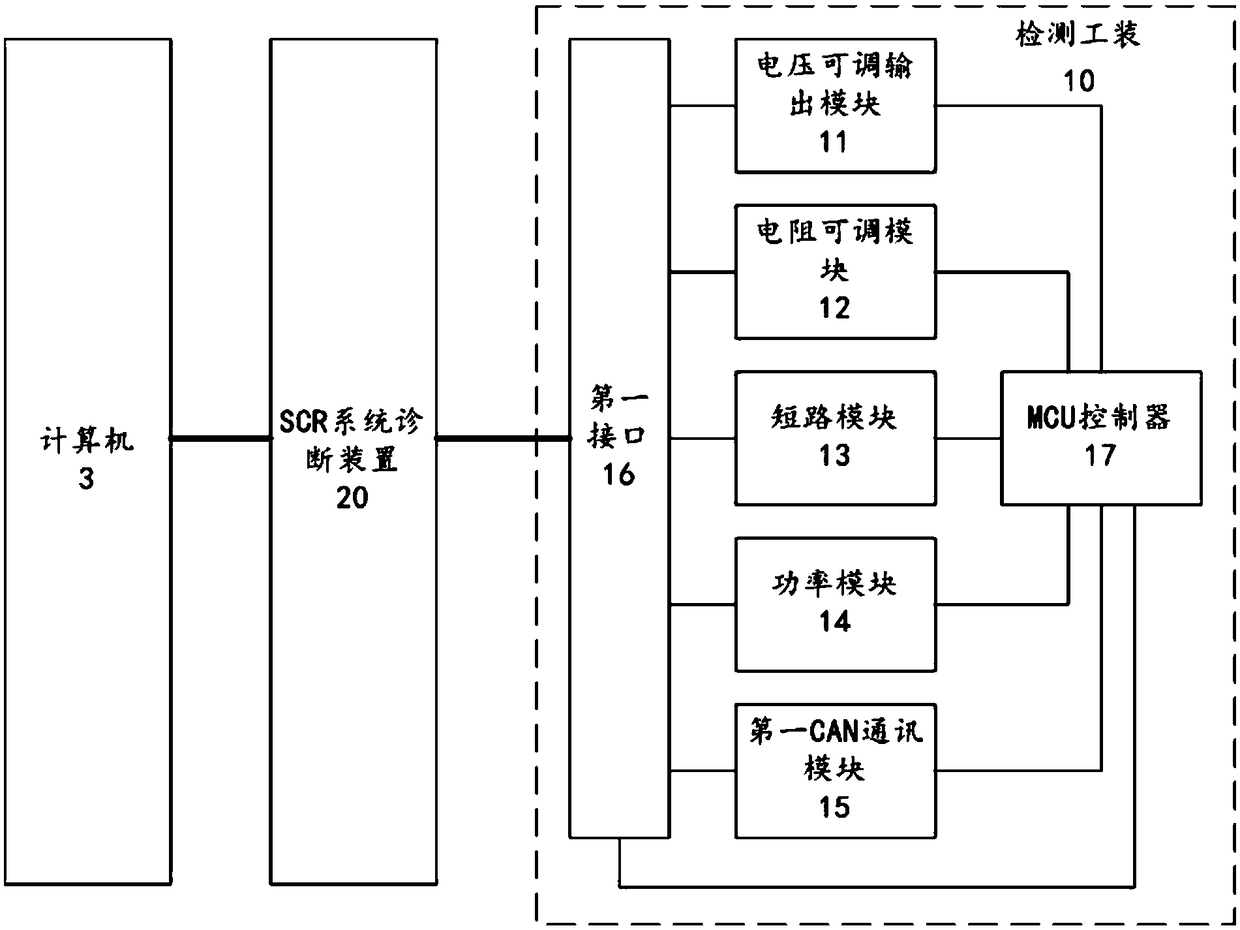

Detection tool and method of SCR system diagnostic device

PendingCN109406906AImprove detection accuracyEfficient automatic detectionTesting electric installations on transportComputer moduleEngineering

A detection tool of a SCR system diagnostic device comprises a voltage adjustable output module as load modules, a resistance adjustable module, a short circuit module, a power module, a first CAN communication module, a first interface and an MCU controller, wherein the voltage adjustable output module, the resistance adjustable module, the short circuit module, the power module, the first CAN communication module and the first interface are all connected to the MCU controller; the voltage adjustable output module, the resistance adjustable module, the short circuit module, the power module and the first CAN communication module are all connected to the first interface; and the first interface has a plurality of pins corresponding to respective load modules to form detection channels corresponding to respective load modules. The detection tool can efficiently and automatically achieve detection, saves detection time and manpower input, can achieve batch detection, has high detection precision, covers various working conditions, avoids misjudgment caused by human factors, and eliminates the influence of early failed components on equipment.

Owner:SHANGHAI XINGRONG AUTOMOBILE TECH CO LTD

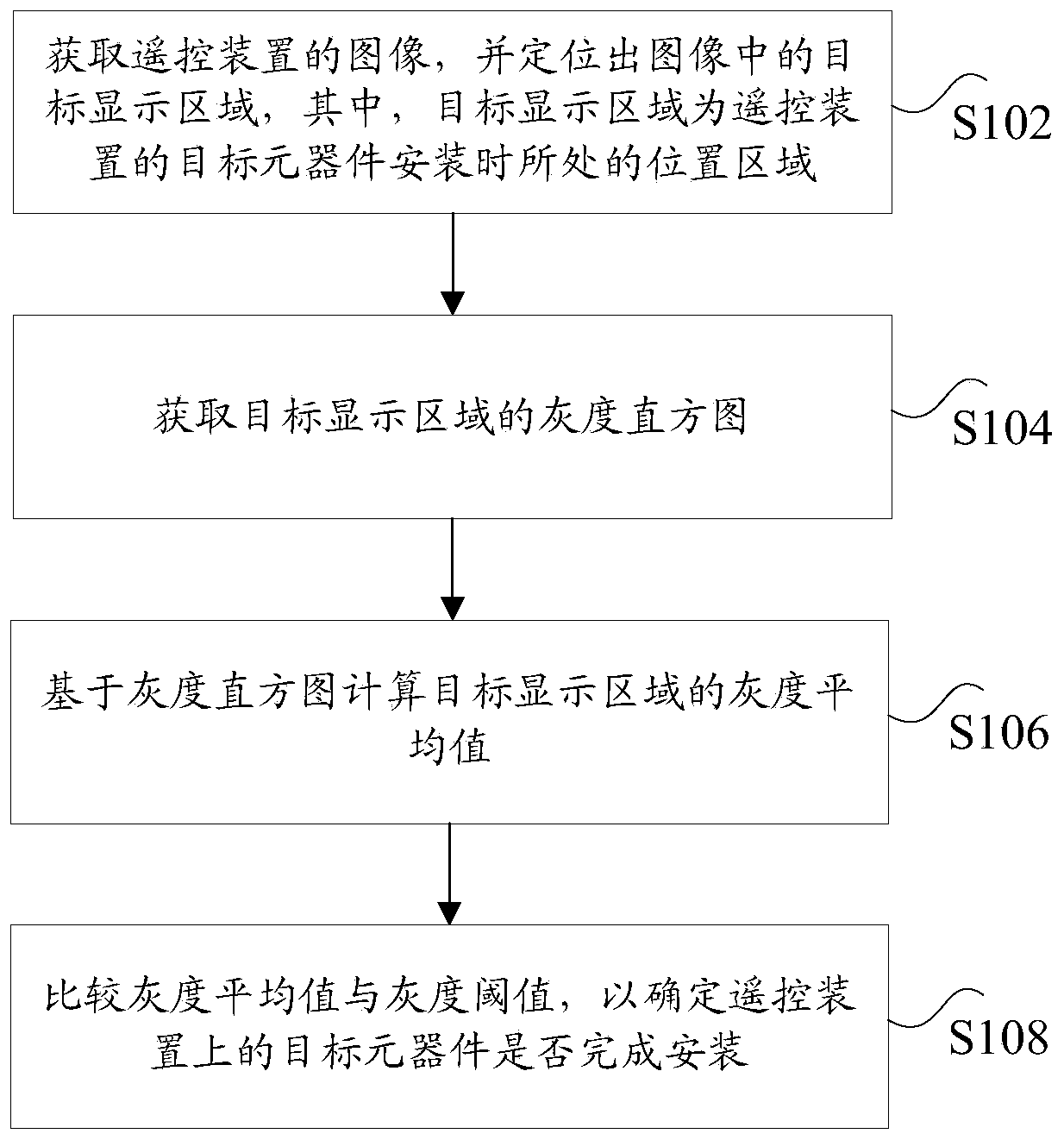

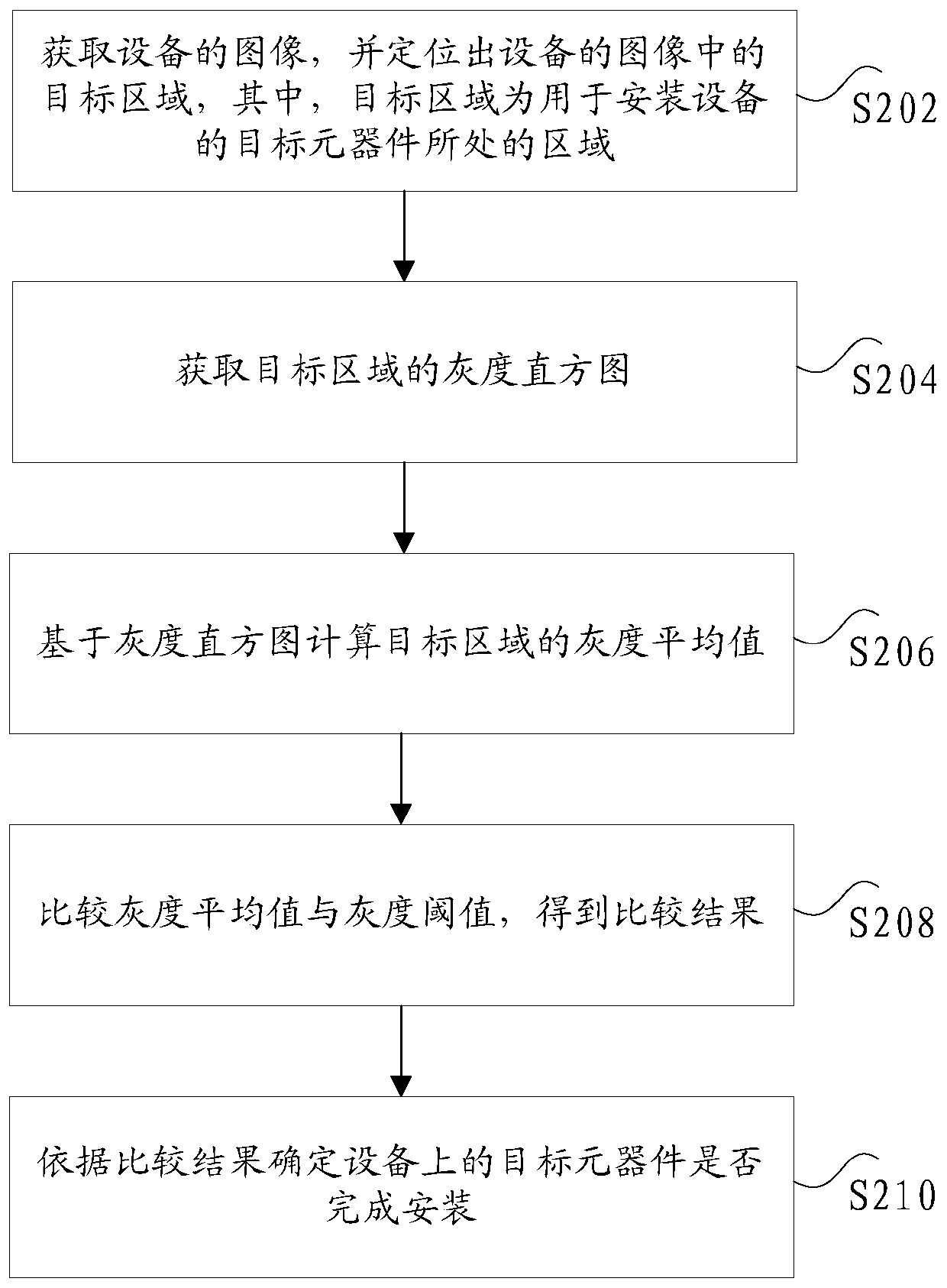

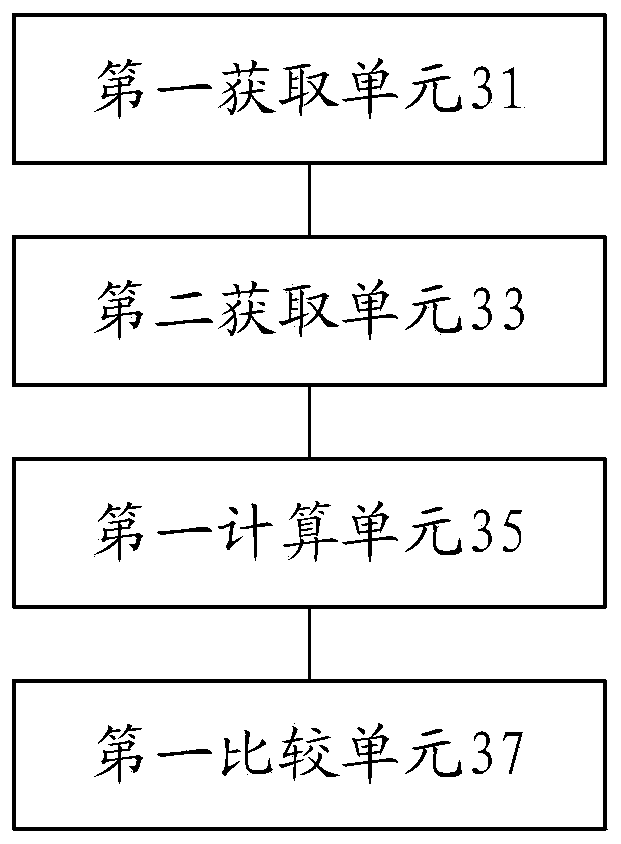

Installation detection method and device for remote control device

PendingCN111325731AEfficient automatic detectionEfficient detectionImage enhancementImage analysisComputer graphics (images)Remote control

The invention discloses an installation detection method and device for a remote control device. The method comprises the steps that an image of the remote control device is acquired, a target displayarea in the image is positioned, and the target display area is a position area where a target component of the remote control device is located when the target component is installed; obtaining a gray histogram of the target display area; calculating a gray average value of the target display area based on the gray histogram; and comparing the gray scale average value with a gray scale thresholdvalue to determine whether the target component on the remote control device is installed or not. According to the invention, the technical problems that the installation and detection efficiency ofthe remote controller liquid crystal screen is low and the shielded part cannot be effectively detected in the prior art are solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

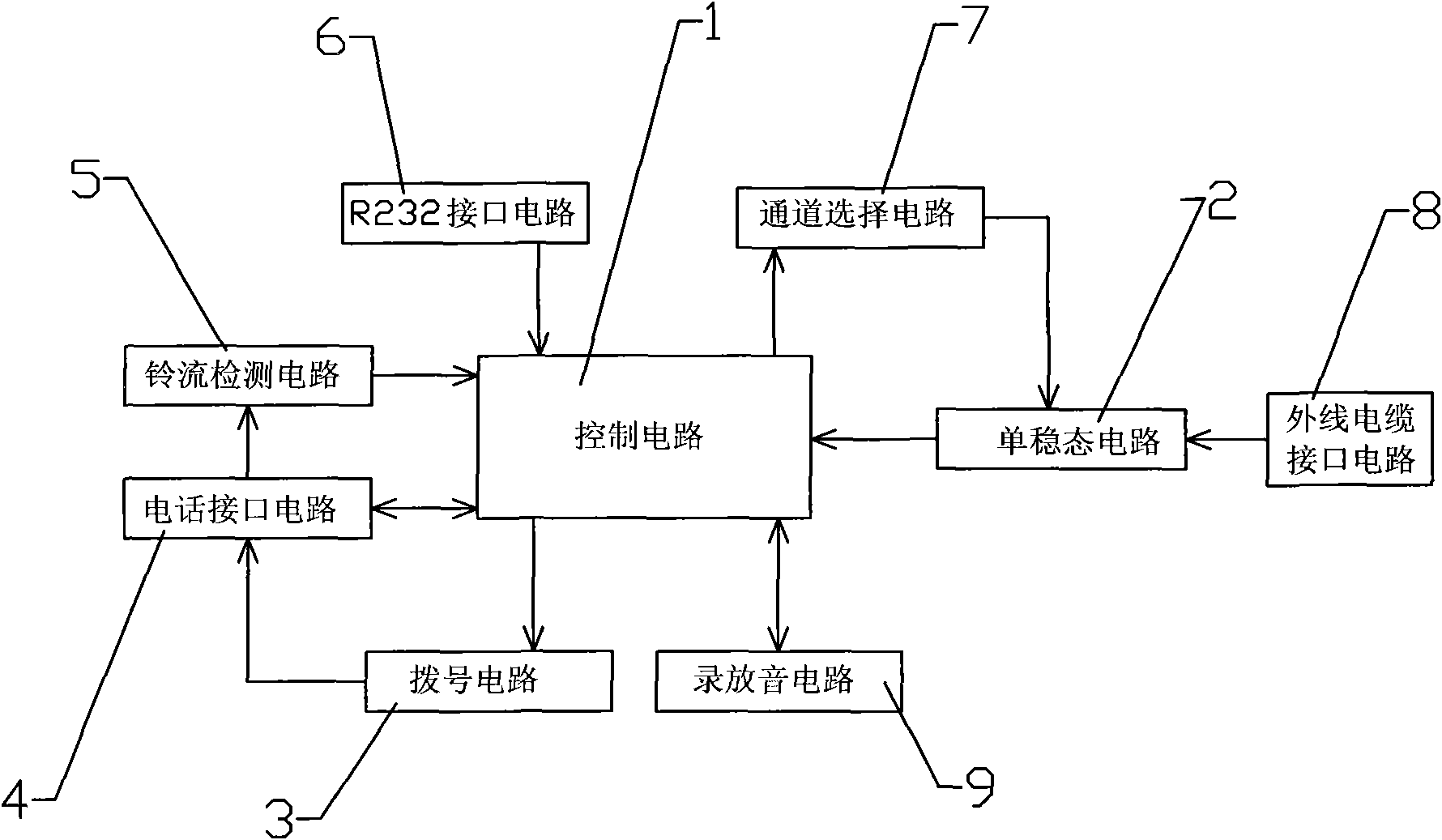

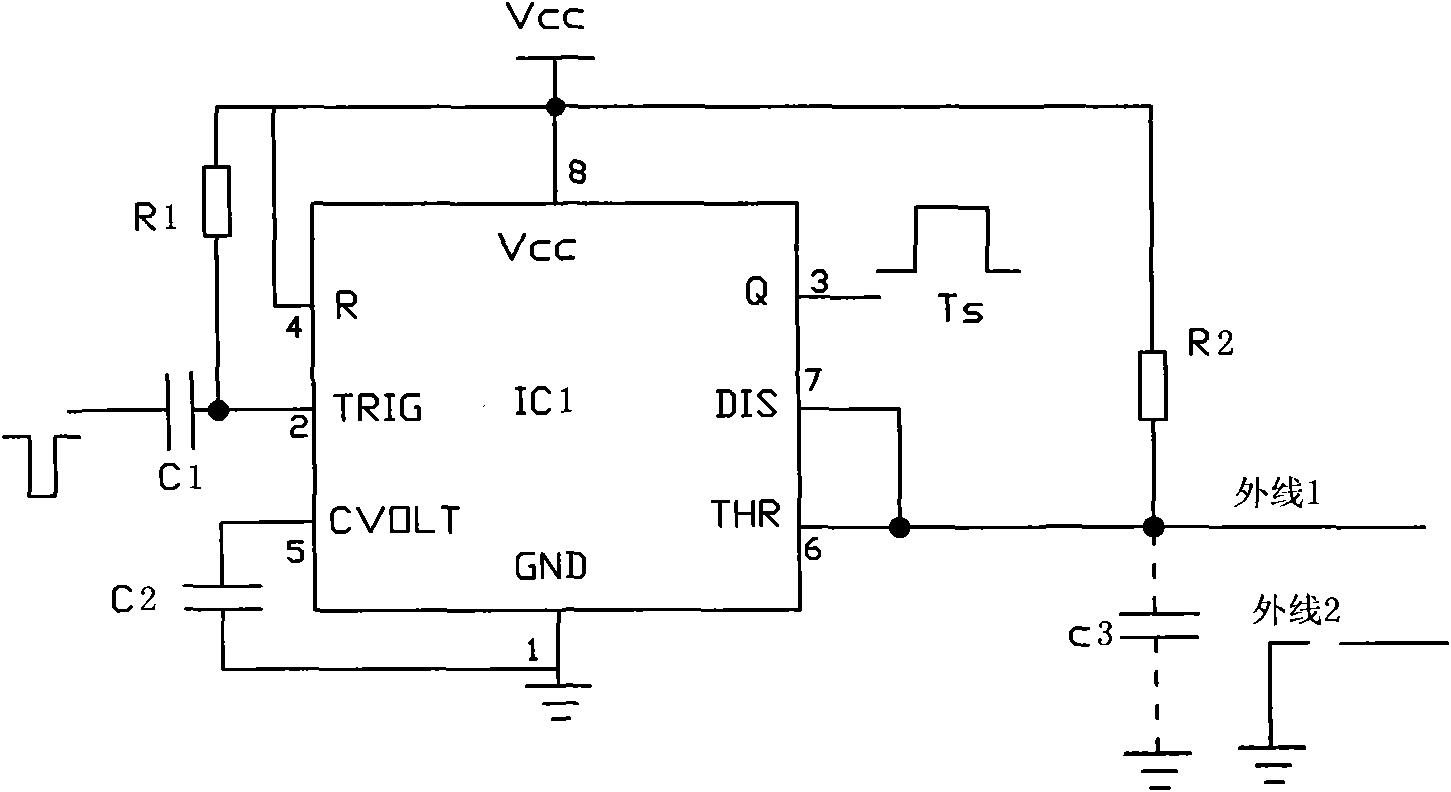

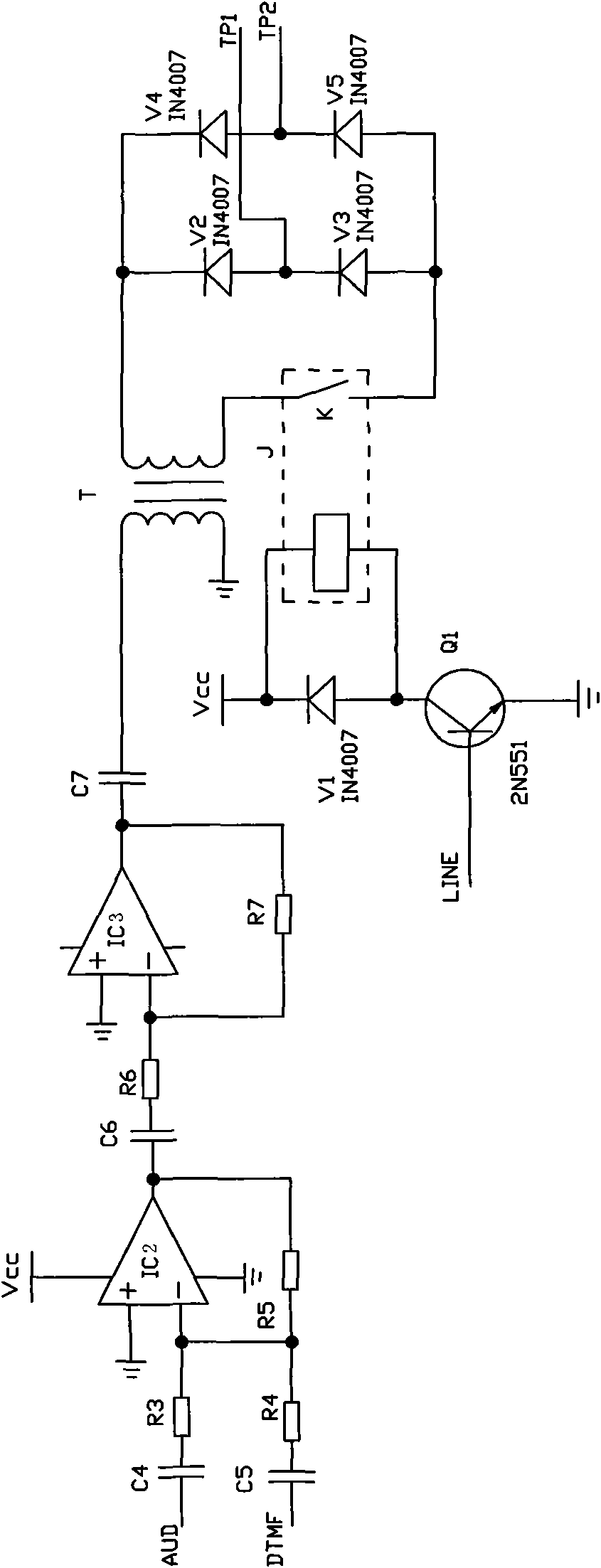

Automatic detection alarm of breakpoints of communication cable

InactiveCN101865965AQuick distance measurementEfficient automatic detectionSubscriber signalling identity devicesFault locationCapacitanceAudio power amplifier

The invention relates to an automatic detection alarm of breakpoints of a communication cable, which comprises a control circuit, a dialing circuit and a telephone interface circuit, wherein the telephone interface circuit comprises an amplifying circuit and a trigger circuit; the amplifying circuit comprises a computing amplifier IC2, a computing amplifier IC3, a resistor R3, a resistor R4, a resistor R5, a resistor R6, a resistor R7, a capacitor C4, a capacitor C5, a capacitor C6 and a capacitor C7; the inverted input end of the computing amplifier IC2 is connected with one end of the resistor R3, one end of the resistor R4 and one end of the resistor R5; the other end of the resistor R3 is connected with an AUD audio signal through the capacitor C4; and the other end of the resistor R4 is connected with the dialing circuit through the capacitor C5. A monostable circuit is utilized to be matched with the control circuit to carry out real-time detection on the breakpoints of the cable to judge the distance of the breakpoints; when the cable is cut and stolen or generates faults, the distances of the breakpoints of the cable can be rapidly measured, and simultaneously, a telephone number saved in advance is dialled to give a voice alarm.

Owner:SHANDONG UNIV OF SCI & TECH

Full-automatic aluminum-plastic bubble cap detection equipment

PendingCN113680678AEfficient automatic detectionReduce false detection rateConveyorsControl devices for conveyorsStructural engineeringMechanical engineering

The invention discloses full-automatic aluminum-plastic bubble cap detection equipment, which comprises a first conveying mechanism; a material blocking mechanism which is arranged at the discharging end of the first conveying mechanism; a first detection mechanism which is arranged above the first conveying mechanism; a second conveying mechanism which is arranged behind the first conveying mechanism; an overturning mechanism which is used for overturning aluminum-plastic bubble caps located at the material blocking mechanism on the first conveying mechanism and then placing the aluminum-plastic bubble caps on the second conveying mechanism; a second detection mechanism which is arranged above the second conveying mechanism; and a sorting mechanism which is arranged at the discharging end of the second conveying mechanism. According to the full-automatic aluminum-plastic bubble cap detection equipment provided by the invention, efficient, rapid and automatic detection of the front and back surfaces of the aluminum-plastic bubble caps and fillers in the bubble caps is realized; the full-automatic aluminum-plastic bubble cap detection equipment greatly reduces the false detection rate of subjective manual visual detection, guarantees the correctness and reliability of a detection result, accelerates the detection efficiency, and effectively reduces the labor cost of detection; the equipment is simple in structure, convenient to install and debug, capable of turning over and adjusting speed and accurate in resetting; the shooting accuracy is high; and the time cost is greatly saved.

Owner:太仓中科信息技术研究院

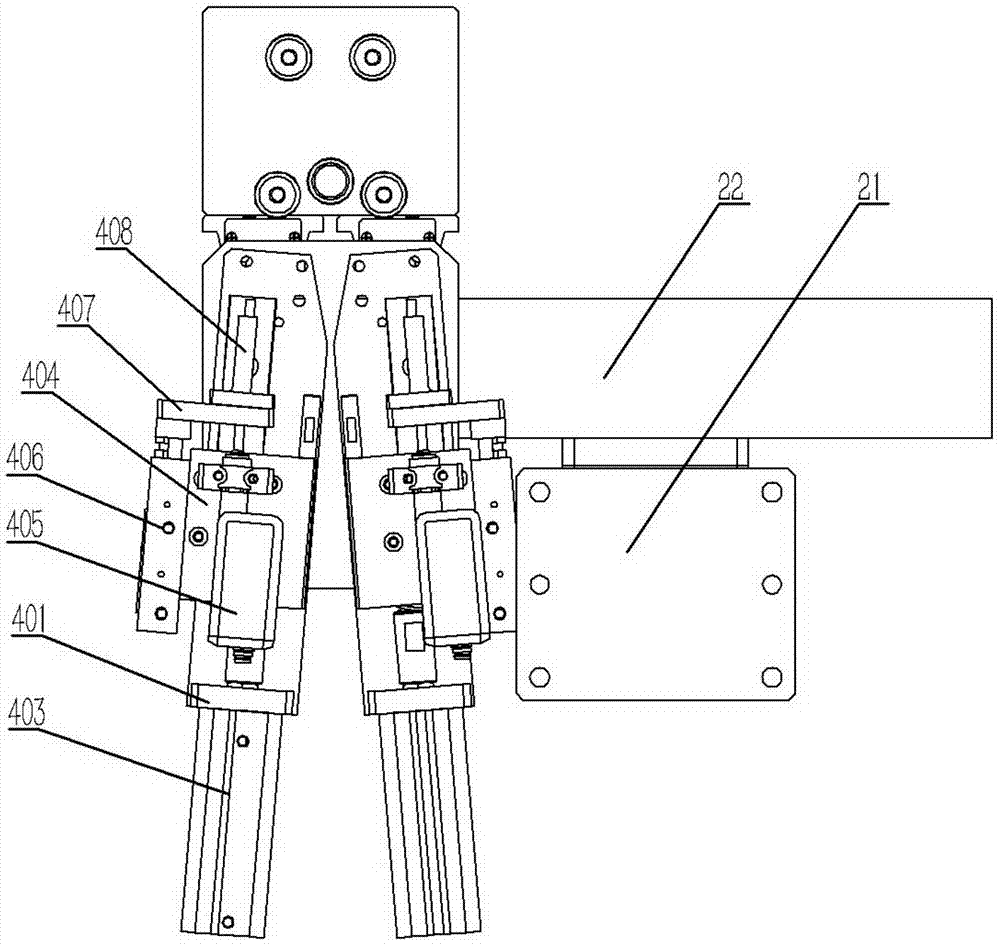

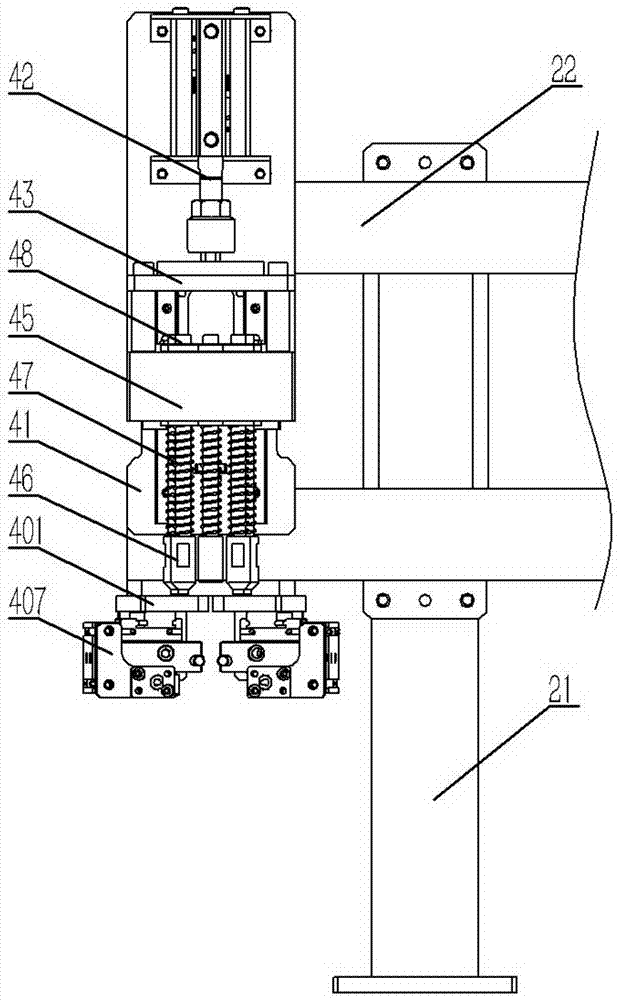

Detecting mechanism of automatic assembling and detecting machine for door locks

ActiveCN103591921AReduce configurationEfficient automatic detectionMeasurement devicesWork holdersEngineering

The invention discloses a detecting mechanism of an automatic assembling and detecting machine for door locks. The detecting mechanism of the automatic assembling and detecting machine for the door locks comprises a vertical stand column. An upper transverse supporting rod and a lower transverse supporting rod are fixed on the vertical stand column, a vertical mounting plate is fixed on the transverse supporting rod at the upper end, a vertical air cylinder is fixedly arranged at the upper end of the vertical mounting plate, the piston rod of the vertical air cylinder is fixed on a supporting plate, a plurality of vertical supporting columns are fixedly arranged on the lower end face of the supporting plate, the lower ends of the vertical supporting columns are fixed on a square mounting block, a plurality of T-shaped locating rods are inserted in the square mounting block in a penetrating mode, the locating rods are sleeved with compression springs, the upper ends of the compression springs press and butt against the lower end face of the square mounting block, and the upper ends of the locating rods penetrate through the square mounting block and then are fixedly provided with limiting blocks. The detecting mechanism of the automatic assembling and detecting machine for the door locks is capable of effectively carrying out automatic detection and needless for manual detection, reduces detecting errors and allocated operating personnel, and saves labor cost. Meanwhile, the detecting speed is improved through automatic detection, and thus production efficiency is improved.

Owner:湖州奇奇机电科技有限公司

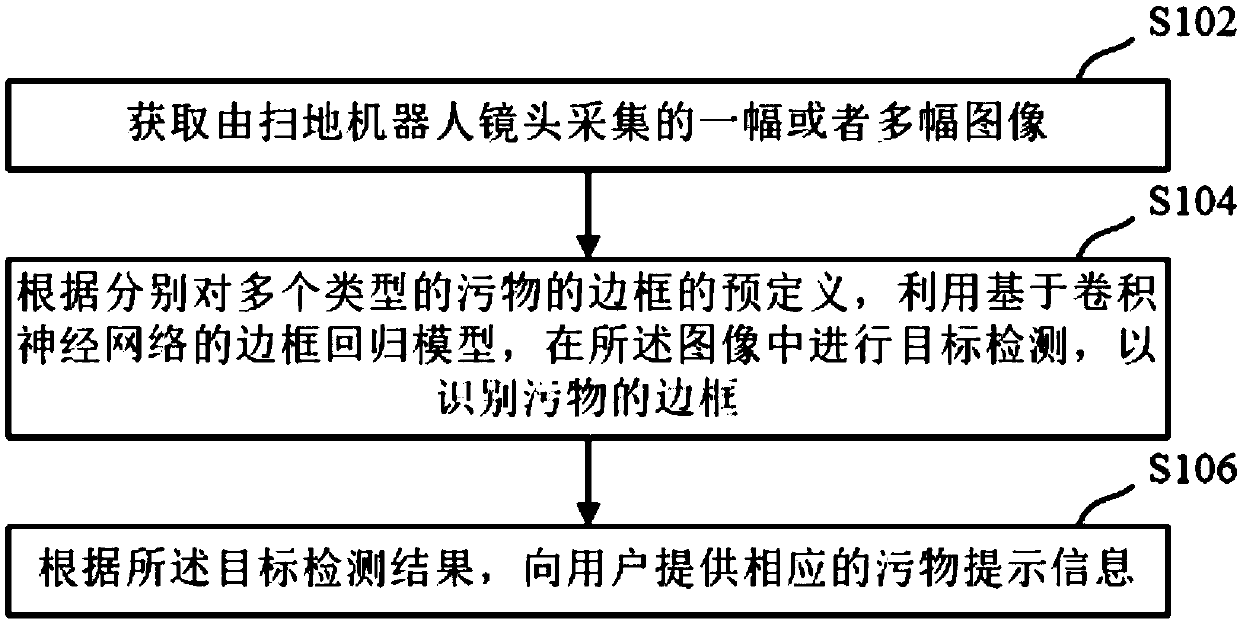

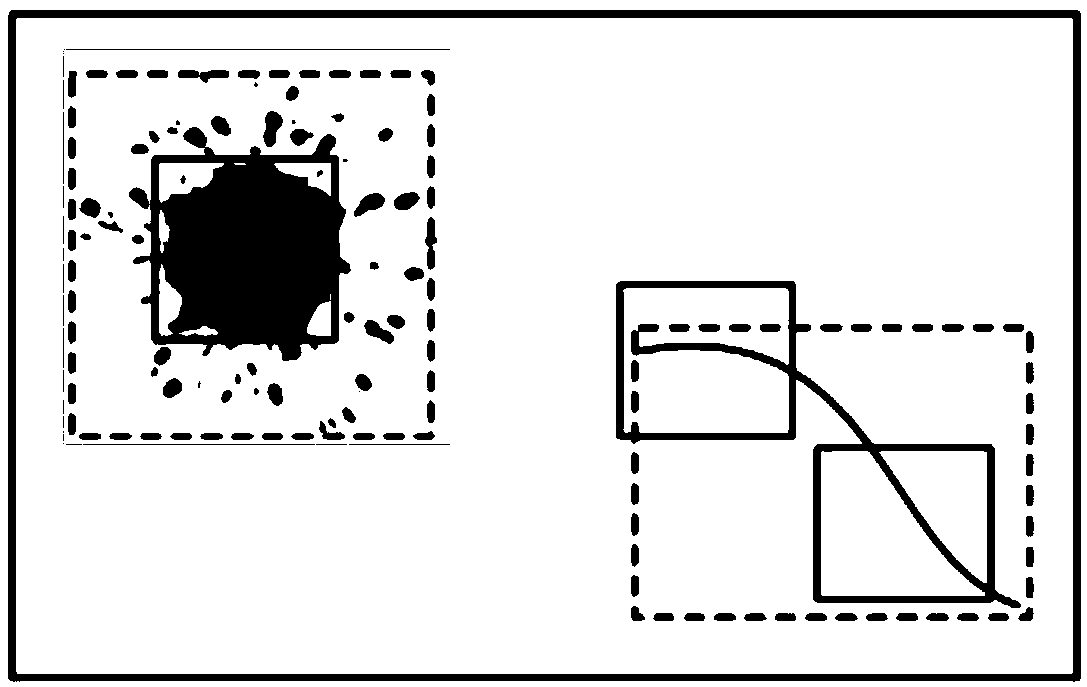

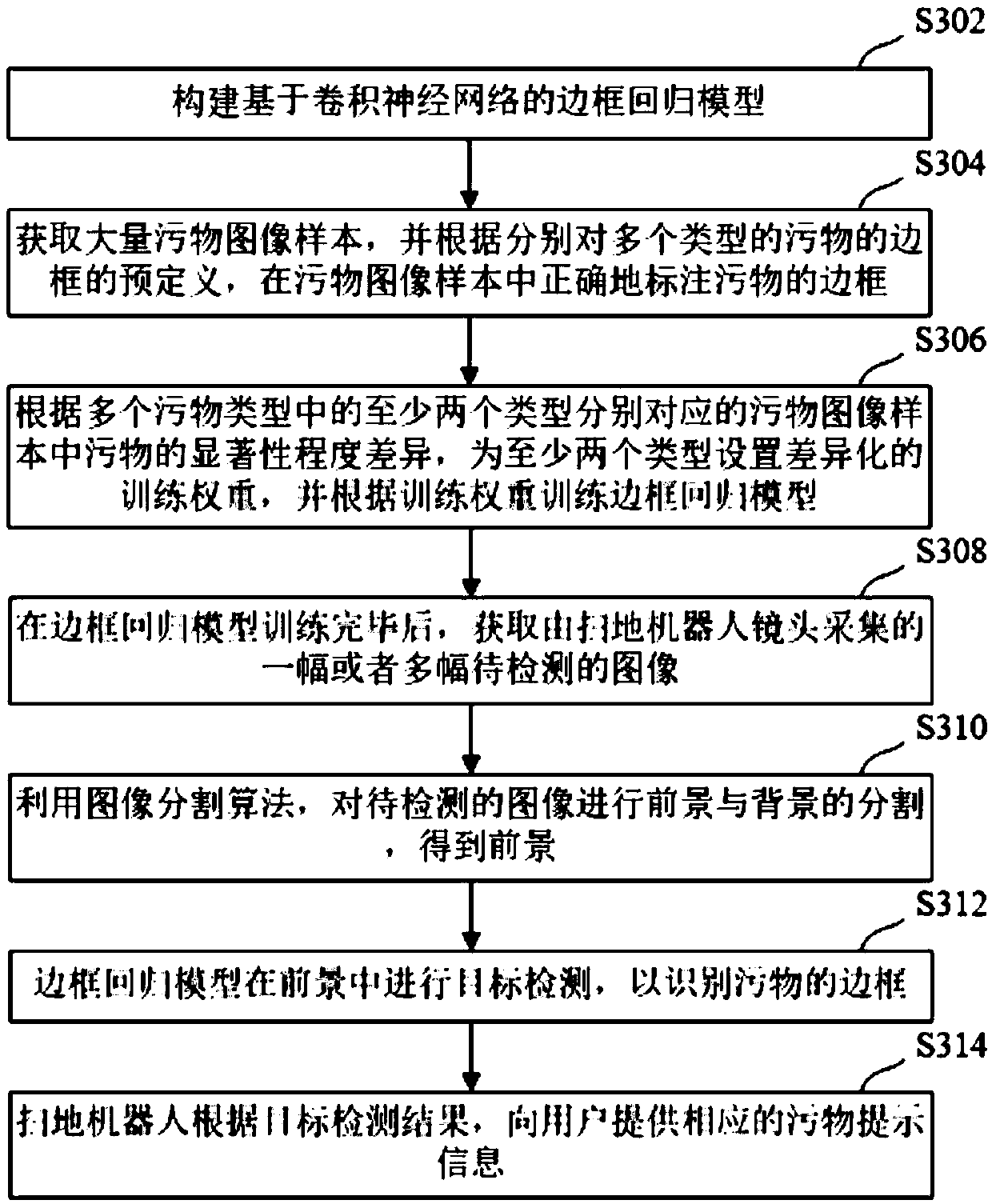

Dirt detection method and device for lens of sweeping robot, equipment and medium

ActiveCN111374608AEfficient automatic detectionPrecise NavigationCarpet cleanersFloor cleanersComputer graphics (images)Vision based

The invention discloses a dirt detection method and device for a lens of a sweeping robot, equipment and a medium. The method at least comprises the following steps: acquiring one or more images acquired by a lens of the sweeping robot; performing target detection in the image by using a convolutional neural network-based frame regression model according to the predefinitions of the frames of theplurality of types of dirt so as to identify the frames of the dirt; and providing corresponding dirt prompt information for the user according to the target detection result. According to the invention, the sweeping robot navigated based on visual analysis can effectively and automatically detect dirt on the lens and prompts a user to clean the dirt in time, so more accurate navigation is facilitated.

Owner:SHARKNINJA CHINA TECH CO LTD

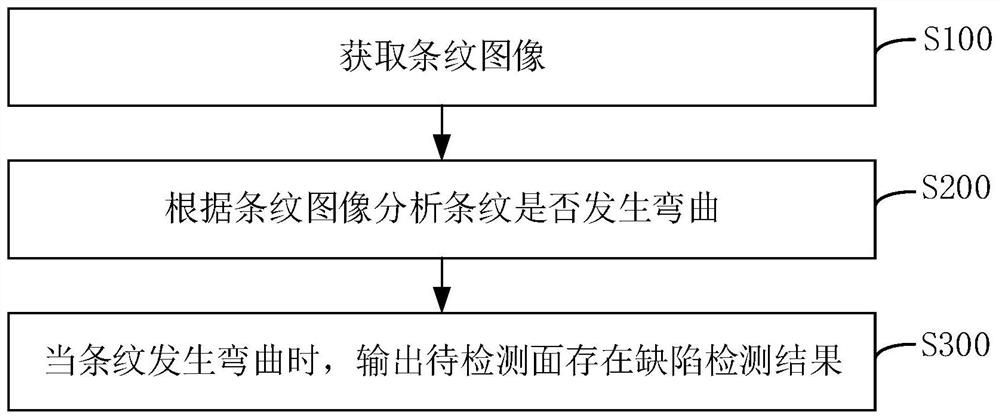

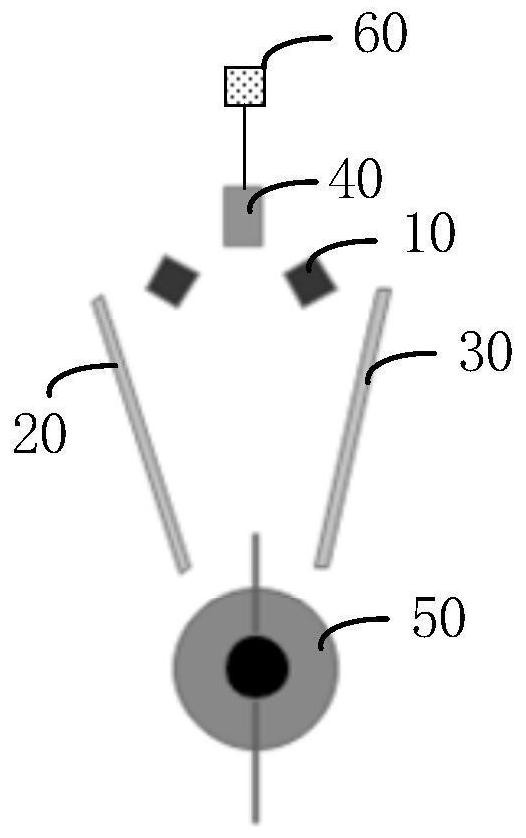

Surface defect detection method, device and system

PendingCN111855671AEfficient automatic detectionReduce missed detection rateOptically investigating flaws/contaminationOptical pathEngineering

The invention relates to a surface defect detection method, device and system, and the method comprises the steps: forming spaced stripes on a mirror surface by reflection of a light path, concretely,enabling strip light emitted by a strip light source to be reflected by a first reflector and a second reflector, finally projecting the strip light to a to-be-detected surface of a to-be-detected object, and forming stripes on the to-be-detected surface; and then analyzing by acquiring a stripe image of the to-be-detected surface, and indirectly obtaining a detection result of whether the to-be-detected surface has defects by judging whether stripes formed on the to-be-detected surface are bent or not. By means of the scheme, whether the concave-convex defects exist on the cylindrical surface or the to-be-detected surfaces in other shapes or not can be effectively and automatically detected, the omission ratio is extremely low, manual detection can be replaced, and high detection efficiency is achieved. The scheme has the advantage of high detection reliability when being used for detecting the surface defects of the lithium battery.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

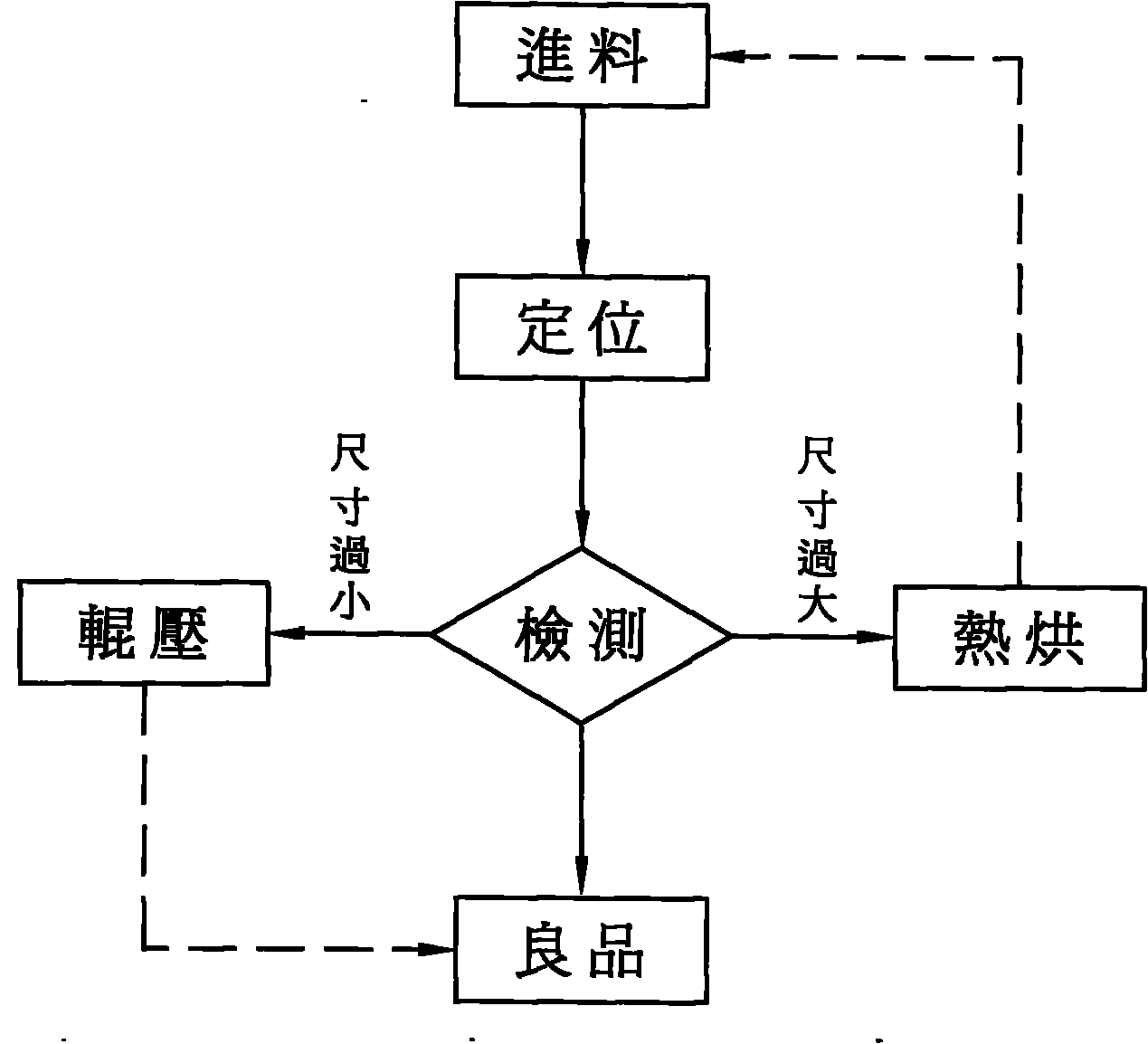

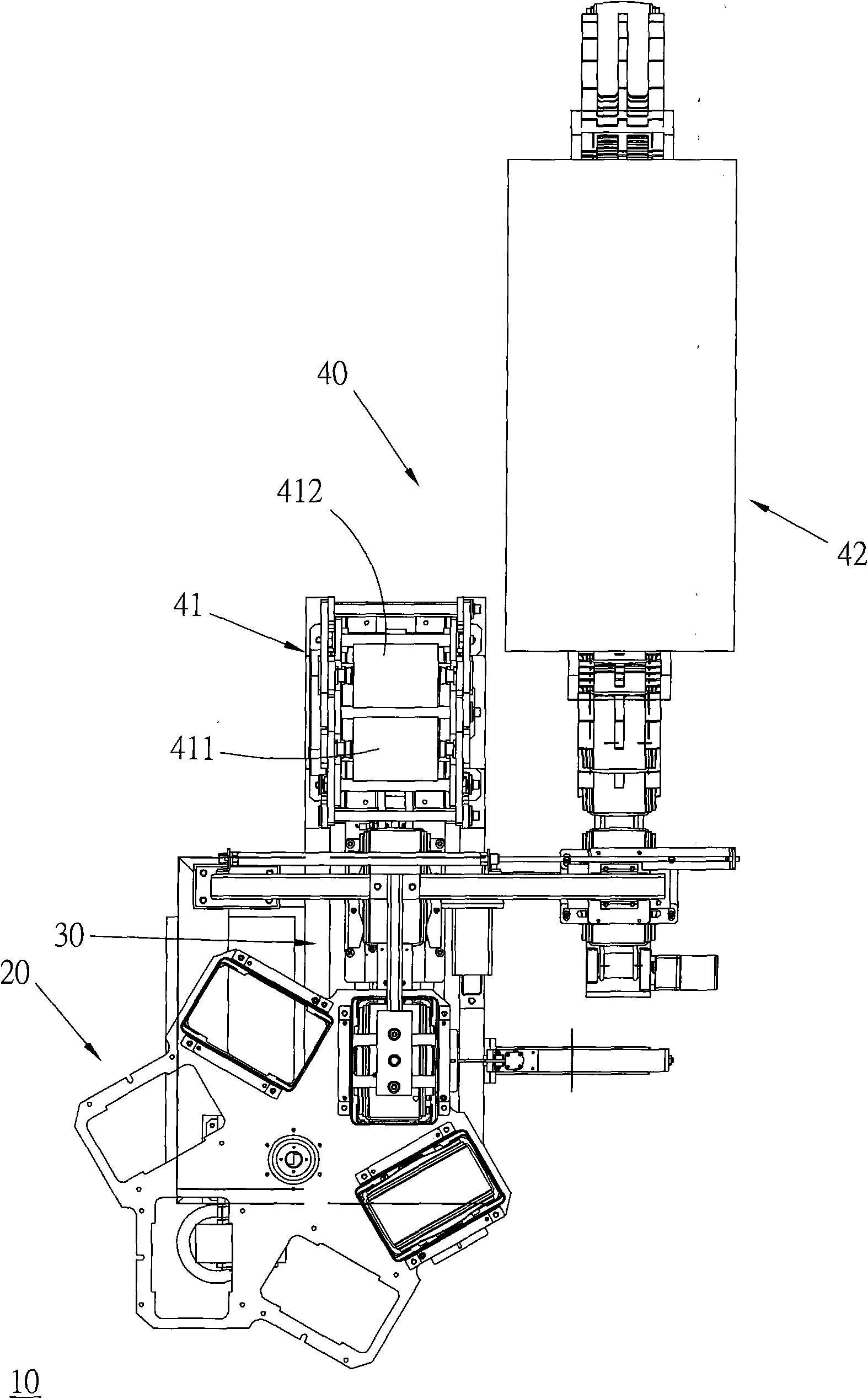

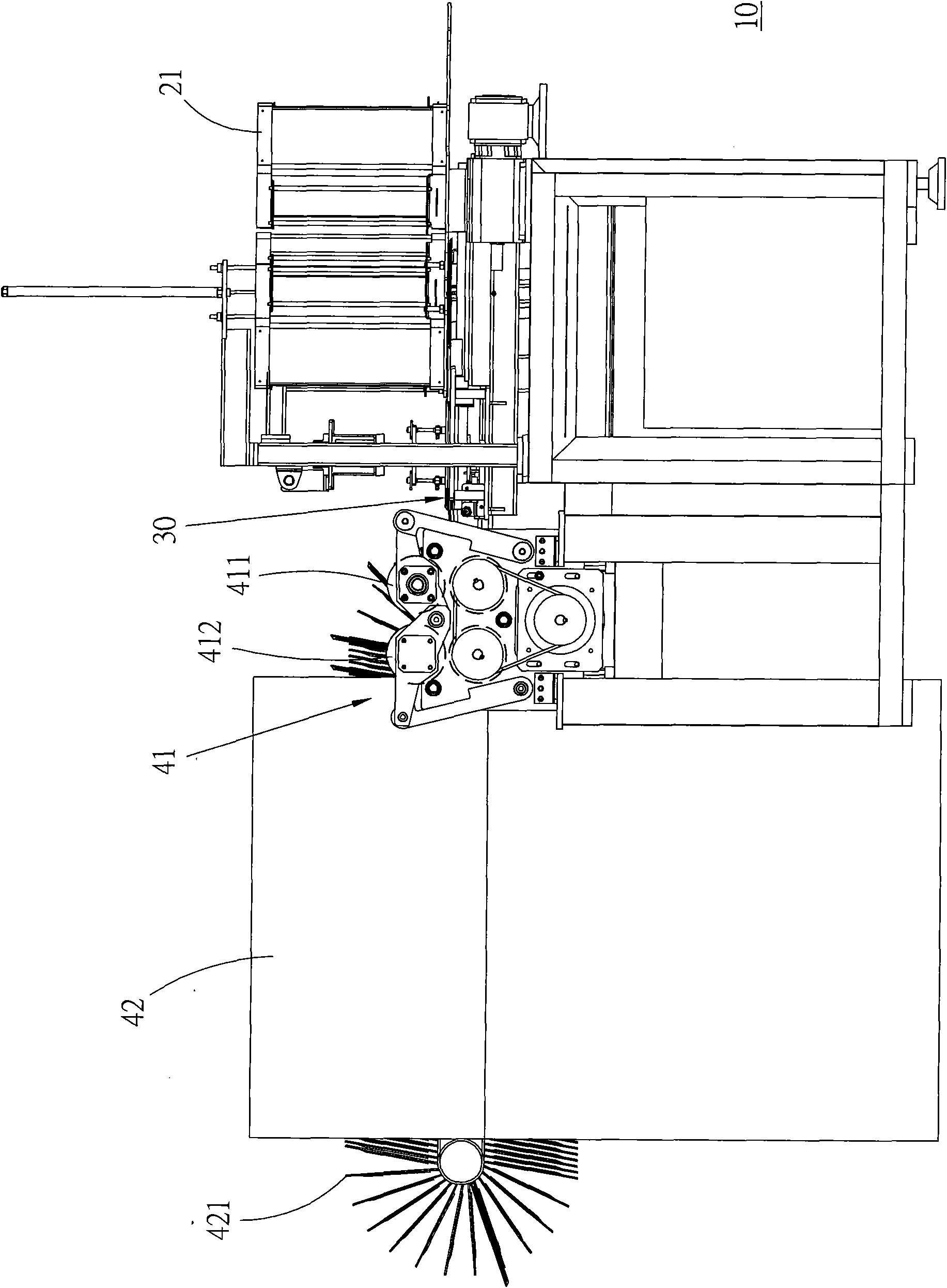

Method for size detection and post-treatment of sheeted molded polymer material and detection and post-treatment machine for implementing method

InactiveCN102072743AEfficient automatic detectionMeasurement apparatus bearings/suspensionsBiomedical engineeringPolymer

The invention provides a method for the size detection and post-treatment of a sheeted molded polymer material, which comprises the following steps of: positioning the sheeted molded polymer material to be detected in a predetermined detection space in a way that the sheet end of one side of the sheeted molded polymer material is positioned at a detection reference point, sensing the position of the other sheet end by using a sensing device to obtain the size of the material, further judging whether the material is oversized or undersized, and performing corresponding post-treatment procedures respectively to increase or decrease the size of the material to a range of allowable error of a good product. In addition, the invention simultaneously provides a detection and post-treatment machine for implementing the method. The method and the machine have the advantages that: automatic detection can be rapidly and highly-efficiently performed on the size of the sheeted molded polymer material, and automatic treatment can be performed according to the size.

Owner:陈法胜

A Topic Detection or Tracking Method for Network Text Big Data

ActiveCN104462253BImprove throughputEfficient automatic detectionSpecial data processing applicationsText database clustering/classificationMap reduceData information

Owner:WUHAN SHUWEI TECH

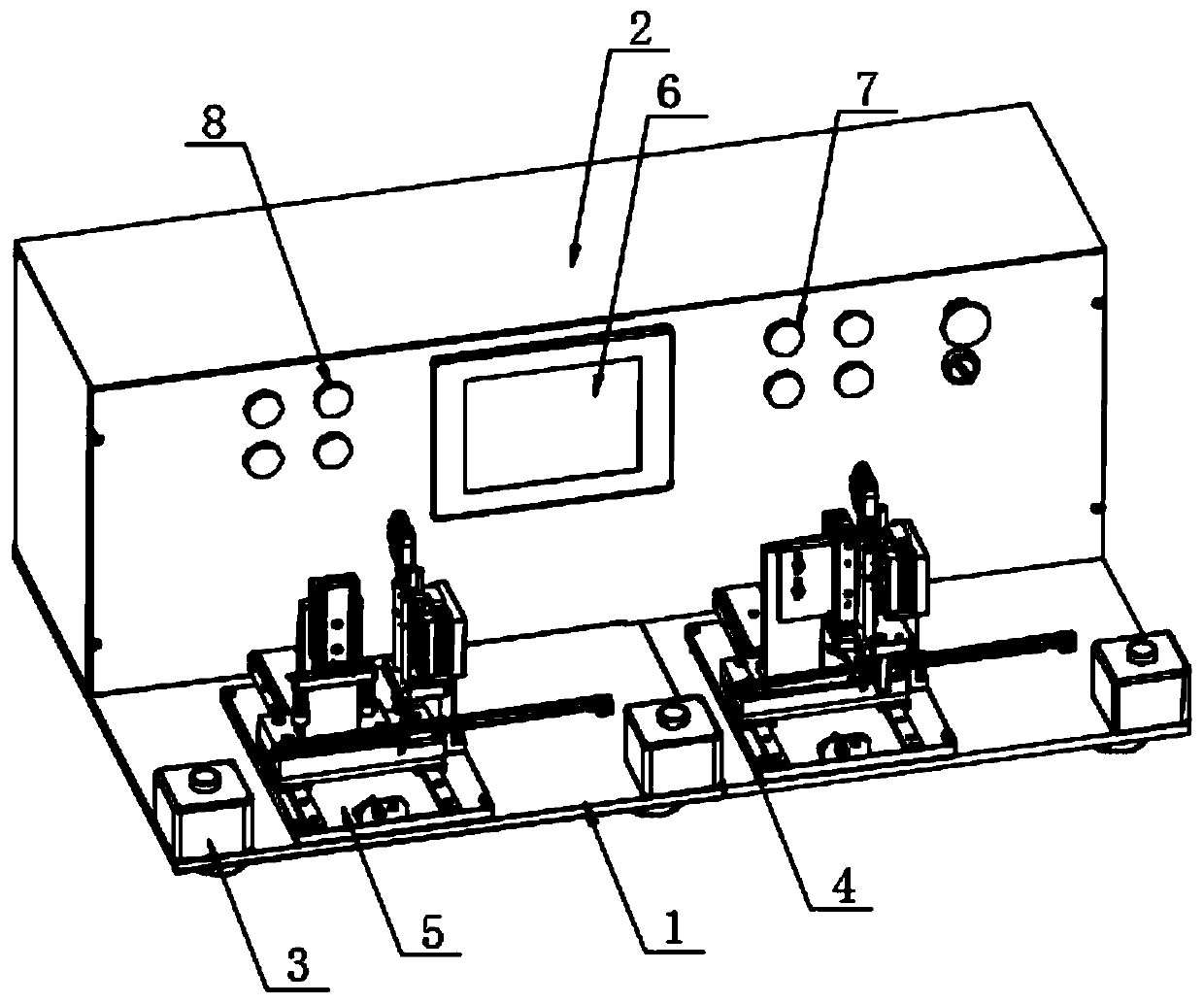

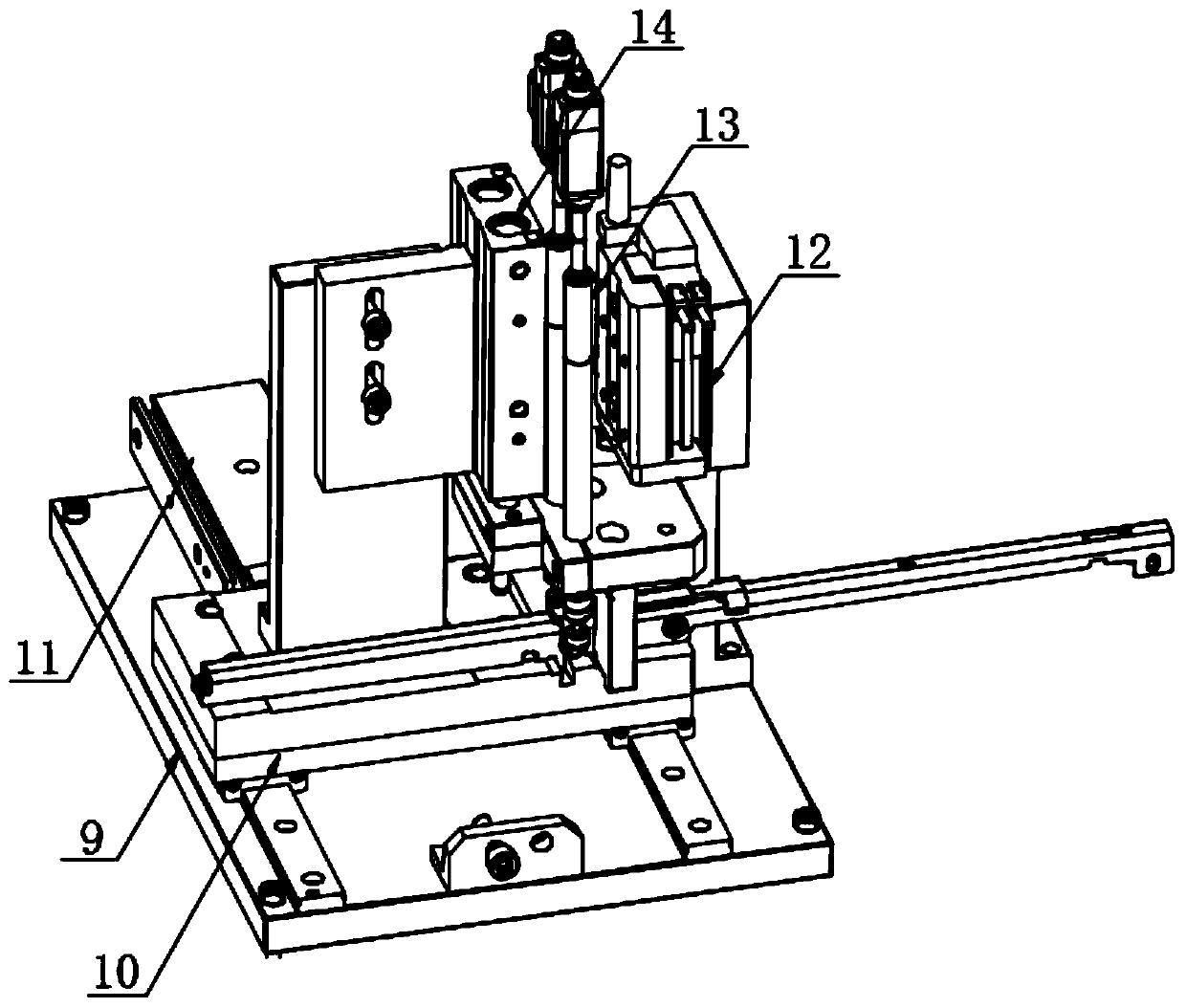

Medical part height detector and detection method

PendingCN111336971AReduce manual labor intensityIncrease productivityMeasurement devicesControl systemAnalog signal

The invention discloses a medical part height detector and a detection method, and particularly relates to the technical field of automatic detection equipment. The medical part height detector comprises a workbench, a rack is fixedly arranged on the workbench, and a first clamping part and a second clamping part are arranged on the upper surface of the workbench. According to the invention, a left-right double-station design is adopted, one set of control system and one display screen are shared, and two kinds of workpieces can be switched for use; workpieces are manually placed, ta clamp isdriven to move on a bottom plate, a pressing cylinder automatically presses down and presses the workpieces, a sensor pressing air cylinder drives a displacement sensor to downwards contact with a measured point, retreating is carried out after a preset position is reached, and a result is output to a display screen; the whole system completes action control over all air cylinders through a PLC, analog signal conversion between the displacement sensor and the display screen is achieved, the labor intensity of workers is reduced, the production efficiency is improved, the labor cost is saved, the detection result is accurate and reliable, automatic detection is achieved, and the detector is more efficient and reliable than manual detection.

Owner:贝联特种金属制品(上海)有限公司

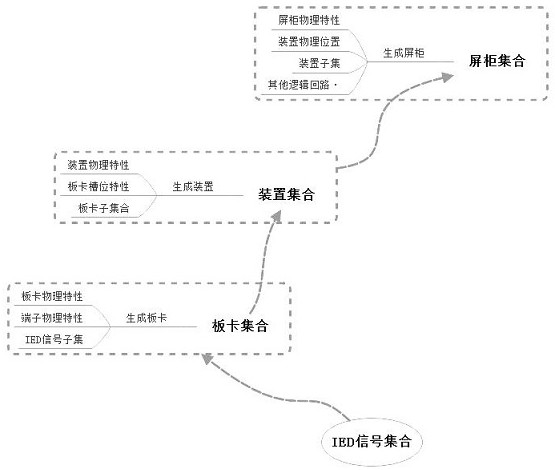

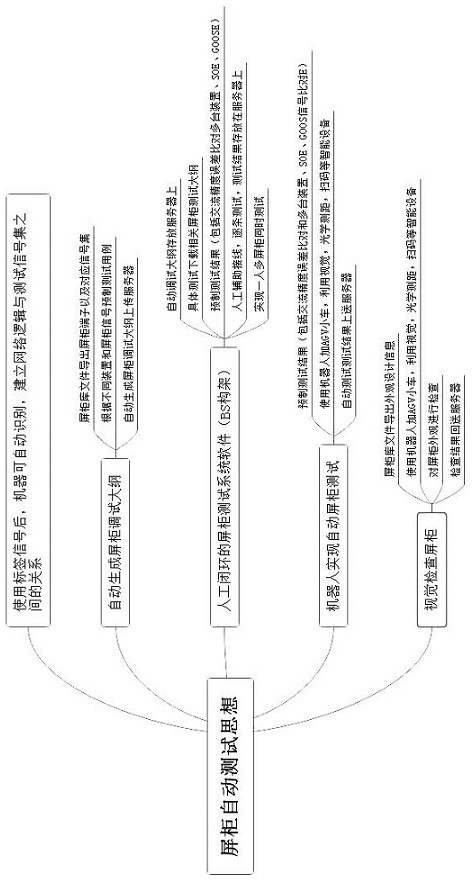

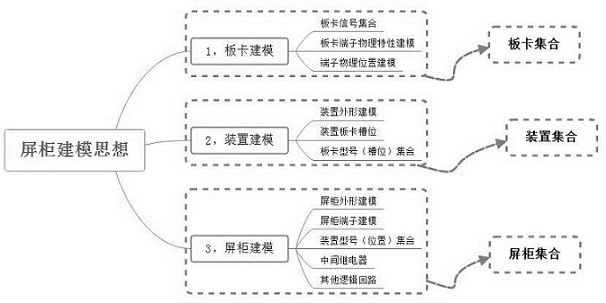

Modeling design method of digital screen cabinet for production test and matched test generation method

PendingCN114036733AImplement automatic detectionExtension collectionGeometric CADSoftware testing/debuggingModelSimSoftware engineering

The invention discloses a digital screen cabinet modeling design method for production test and a matched test generation method. According to the overall design, components, connector terminals, board cards, devices and logic loops in a simulated real environment in a software virtual environment establish a machine-recognizable digital model for a screen cabinet, a design modeling system establishes a digital model board card through a professional signal digital simulation set of tags, and then a digital device model is established; and finally, establishing a digital screen cabinet model; after modeling, generating a tested screen cabinet label signal set which can be recognized by a machine, and a topological network structure and a logic connection relation between the screen cabinet terminal model and the device terminal model. Therefore, a screen cabinet debugging outline is generated and used for carrying out production testing on the screen cabinet produced by a secondary manufacturer, and the tested screen cabinet which is actually produced after modeling is connected to a detection system through broadband network communication and a modern sensor technology to form a complete closed-loop manual semi-automatic detection system or an intelligent automatic detection system.

Owner:NANJING IAT SOFTWARE & TESTING CO LTD

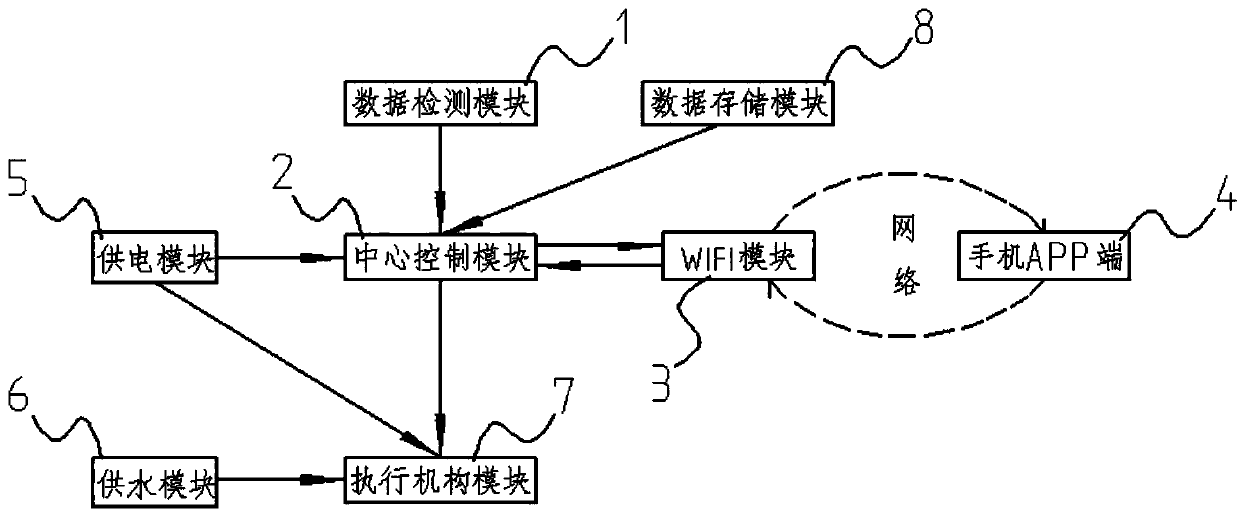

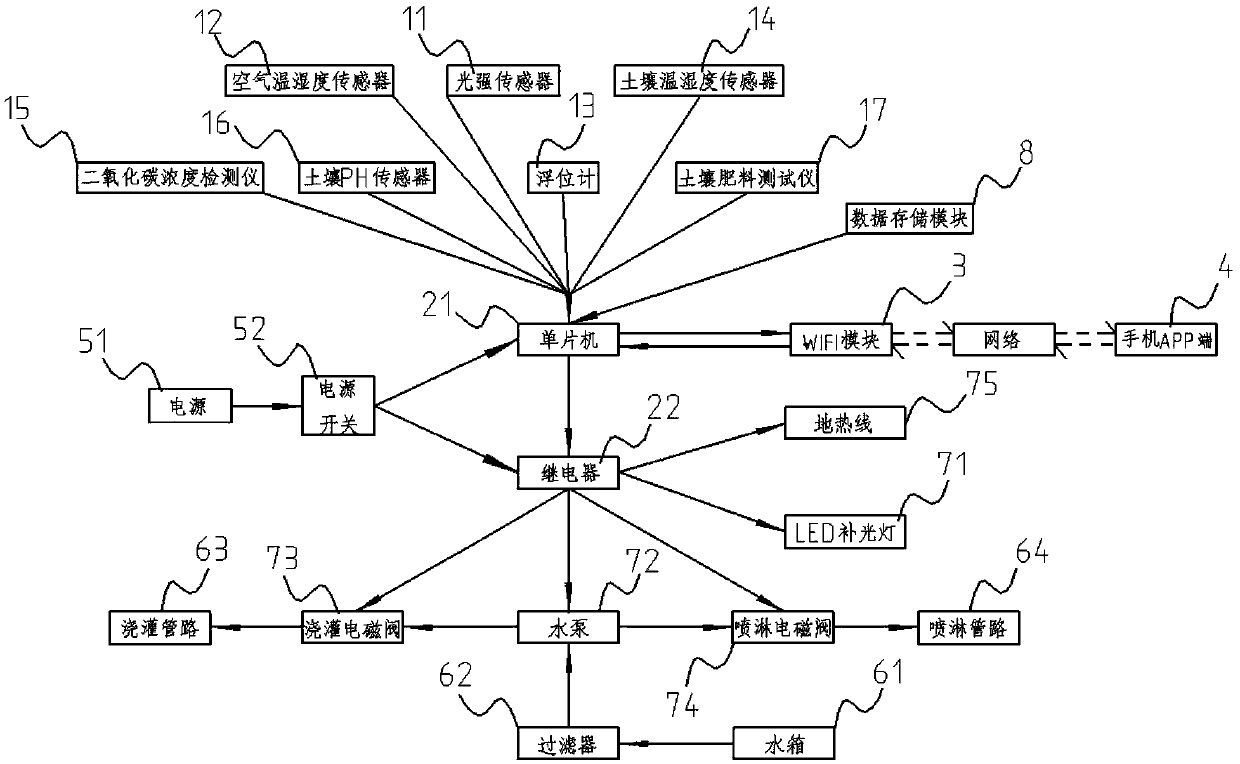

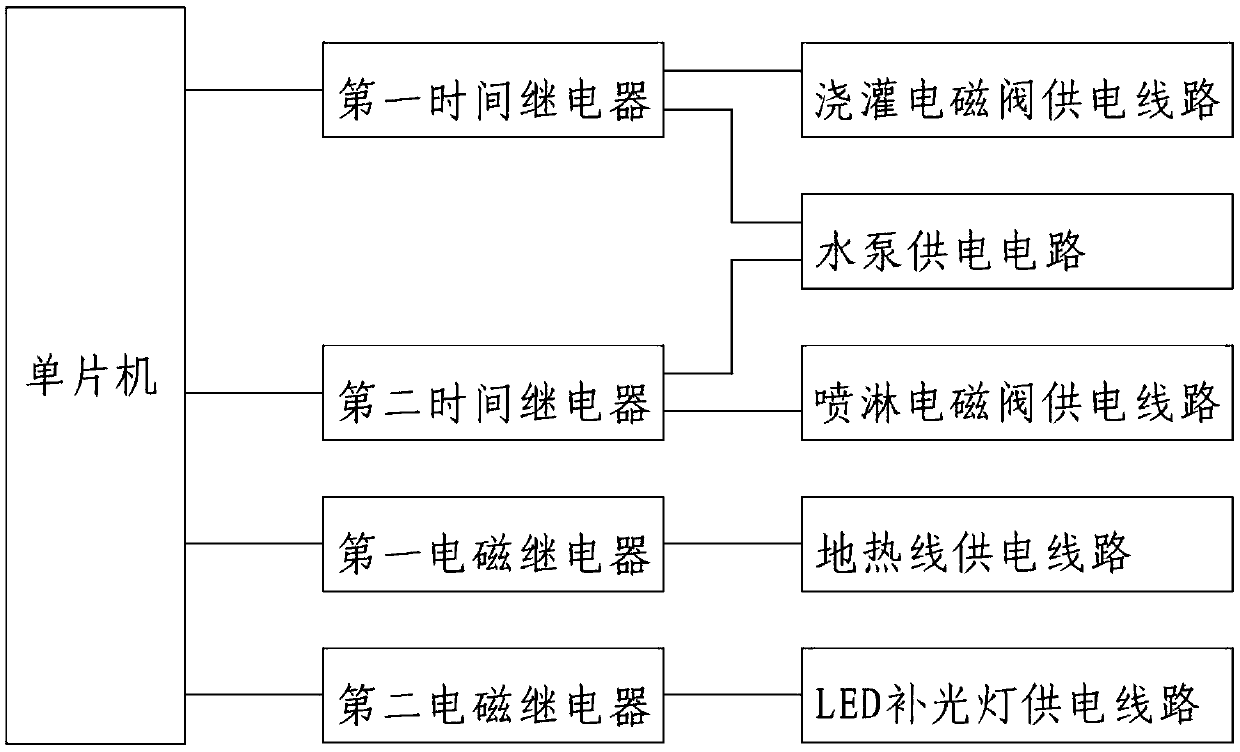

An intelligent management and control system for greenhouse planting

ActiveCN106708143BEfficient automatic detectionConvenient intelligent setting managementSimultaneous control of multiple variablesGreenhouseIntelligent management

The invention relates to an intelligent management and control system for greenhouse planting. The system comprises a mobile phone APP terminal carried with management personnel and a central control module, a data storage module, a data detection module, a power supply module, a water supply module and an executing mechanism module which are arranged in a greenhouse; the central control module is accessed to a network to be connected to the mobile phone APP terminal, the data storage module is connected to the central control module, the data detection module is connected to the central control module, the power supply module is separately connected to the central control module and the executing mechanism module for providing a working power supply, and the water supply module, the control terminal of the executing mechanism module and the central control module are connected, so that the problem that the intelligent degree of the greenhouse vegetable planting is not high is solved, intelligent settings and management can be performed on different optimum parameters required by various vegetables through the mobile phone APP conveniently, crops can be automatically detected in a planting process of the greenhouse to take measures, and vegetables efficiently and quickly grow.

Owner:上海蔬悦农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com