Patents

Literature

1056 results about "Data graph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

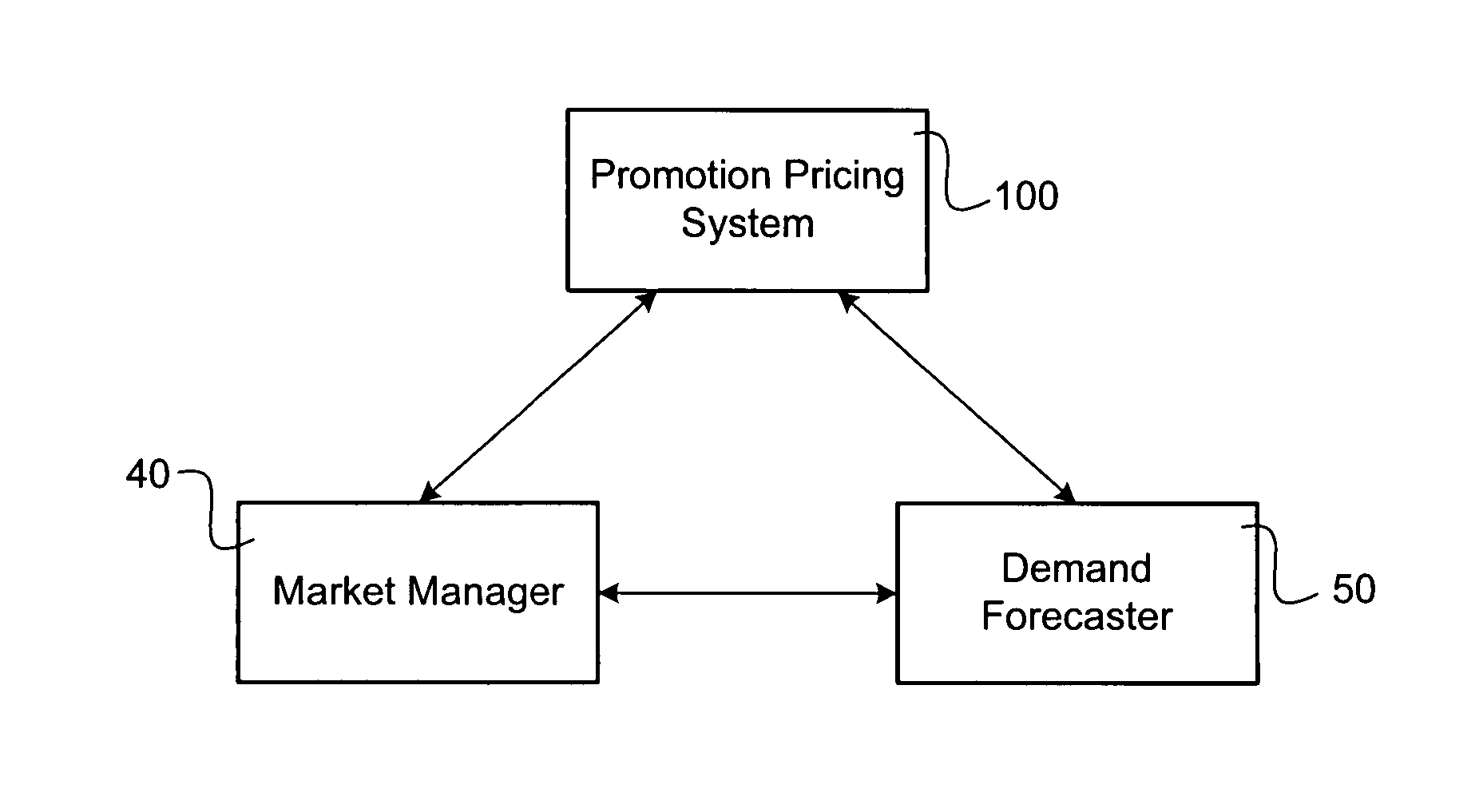

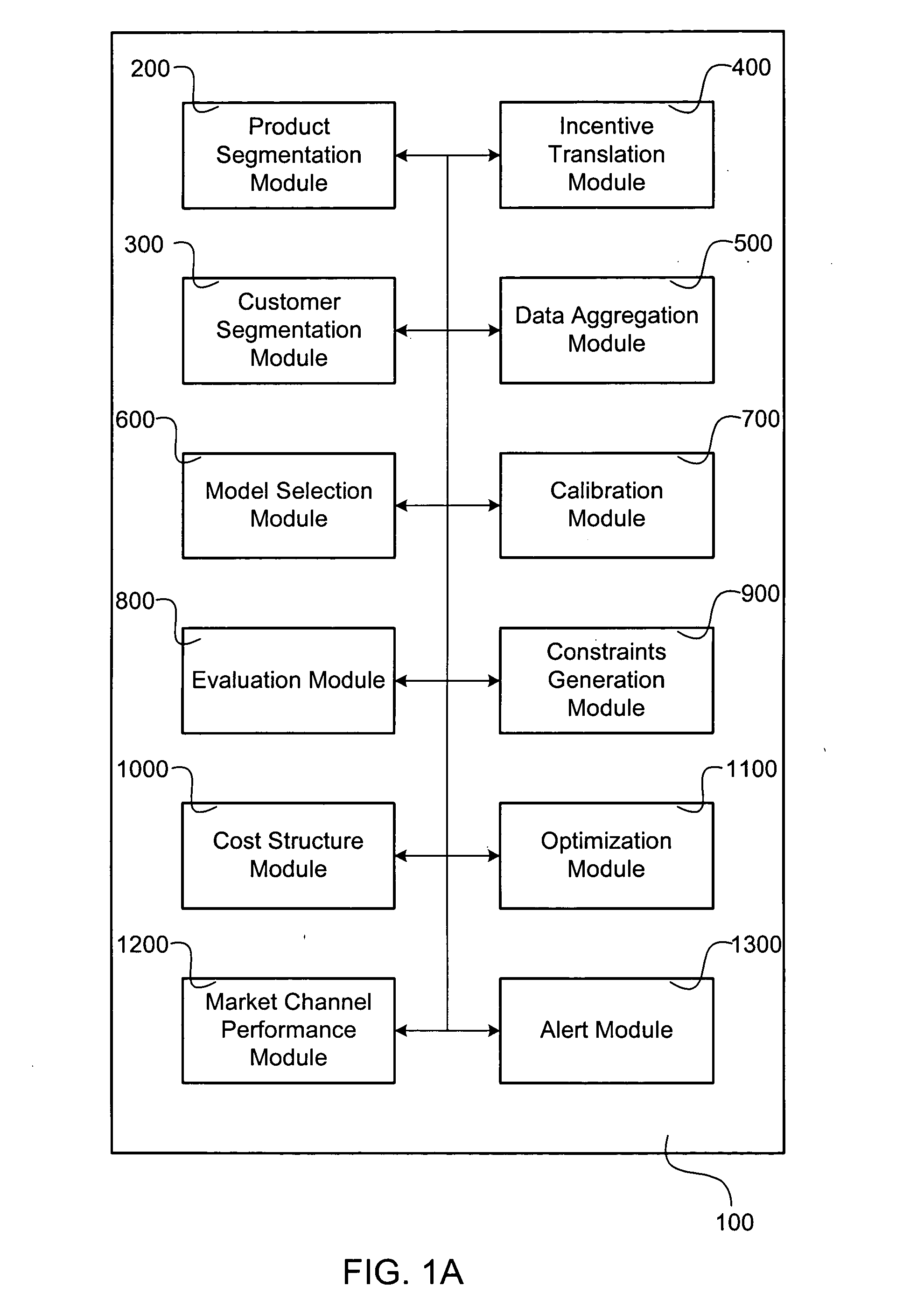

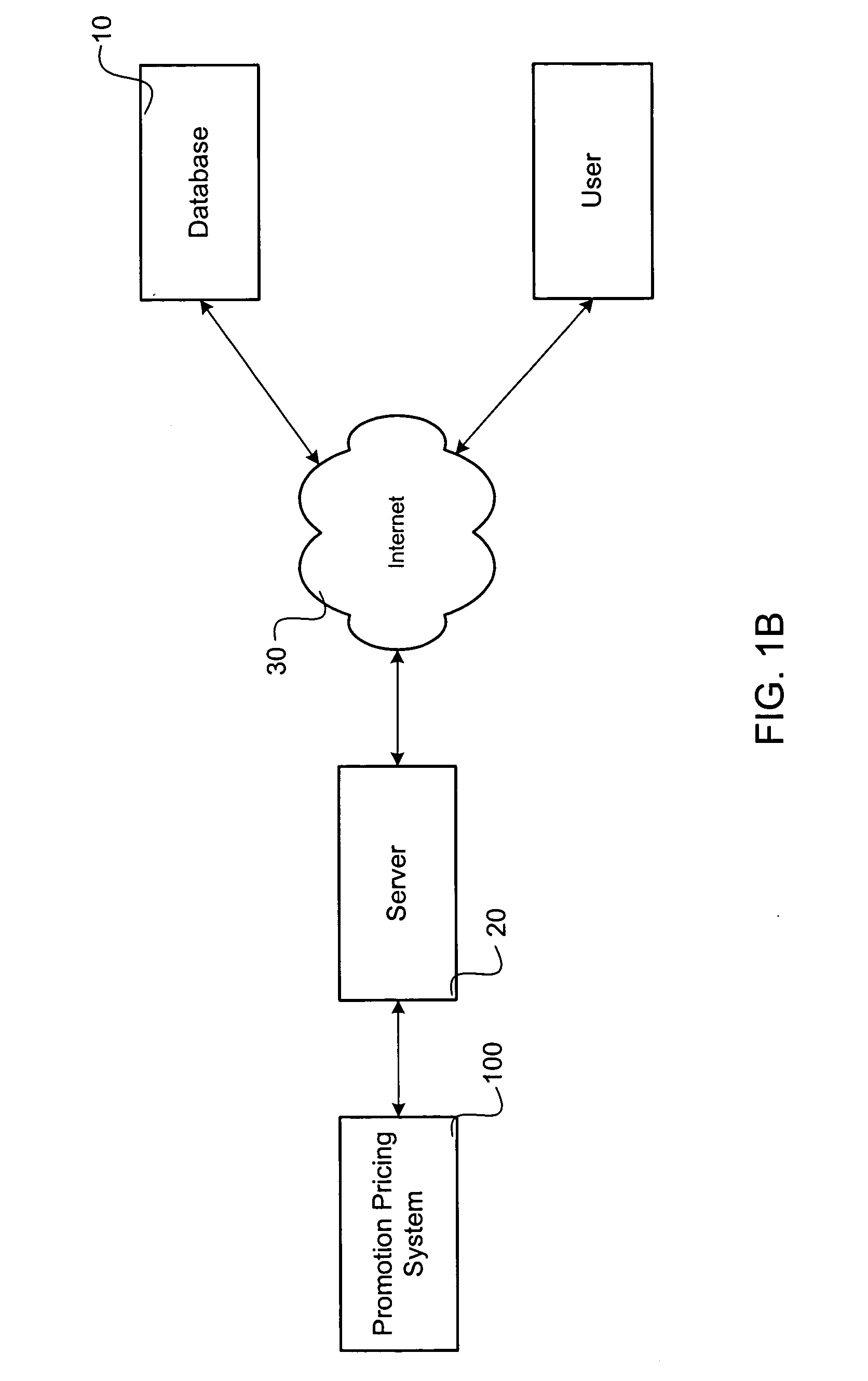

Configurable pricing optimization system

InactiveUS20050256778A1OptimizationEasy to deployMarket predictionsBuying/selling/leasing transactionsGraphicsGraphical user interface

The present invention provides a configurable pricing system that allows users to define or modify data used to analyze, evaluate, improve, and design pricing changes according to the user's need. A Graphical user interface or some other type of user interface allows the user to access and review various data to be used during pricing optimization. The user may then modify this data as needed to improve the pricing evaluation, such as defining sales or pricing trends, or relationships between the product of interest and other competing items. The user interface may further display changes in pricing and the effects of the pricing changes, as caused by the user's changes. The interface may also allow the user to modify the mathematical model to be used during price optimization, as well as define variables, constraints, and boundaries to be considered during the price optimization.

Owner:BLUE YONDER GRP INC

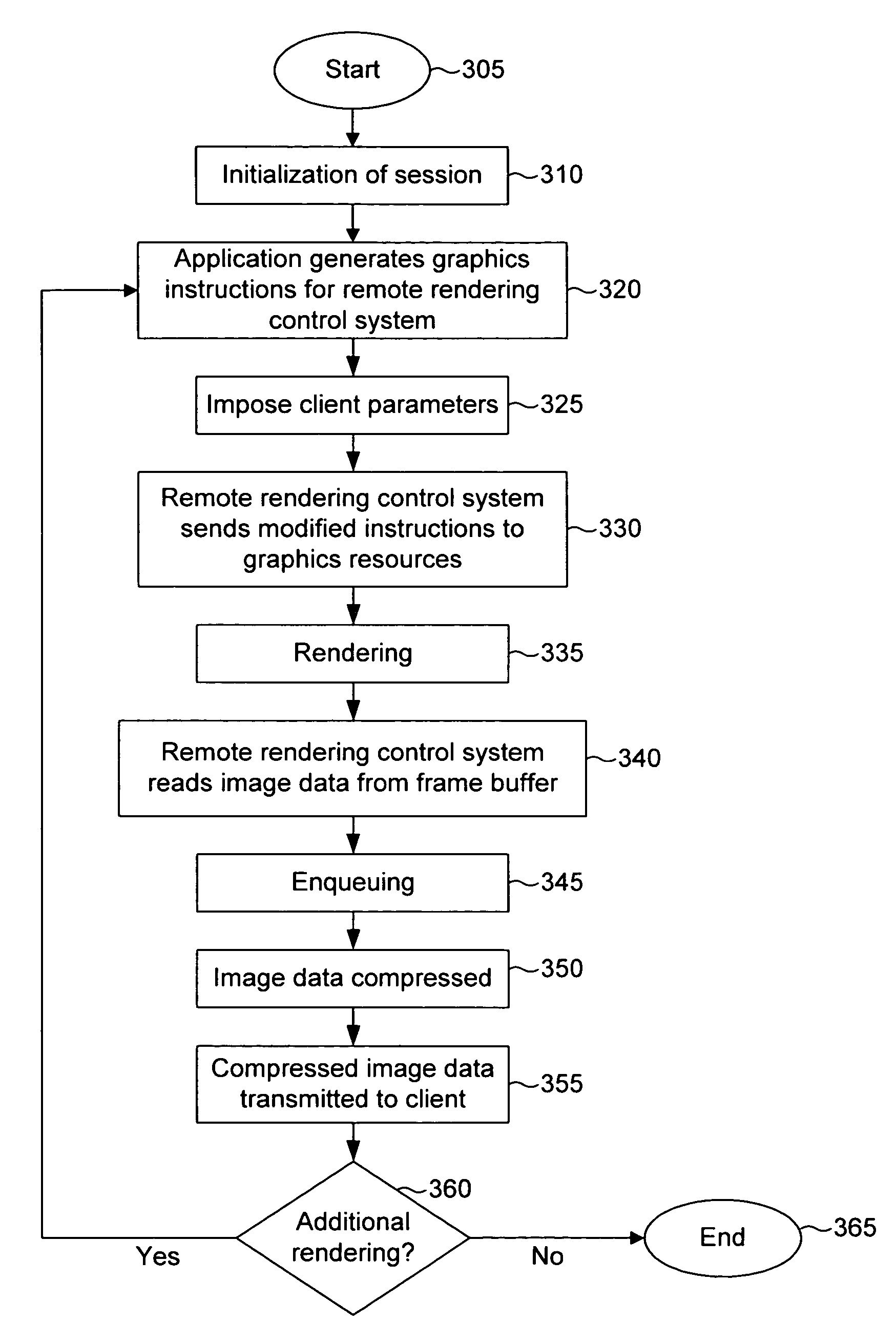

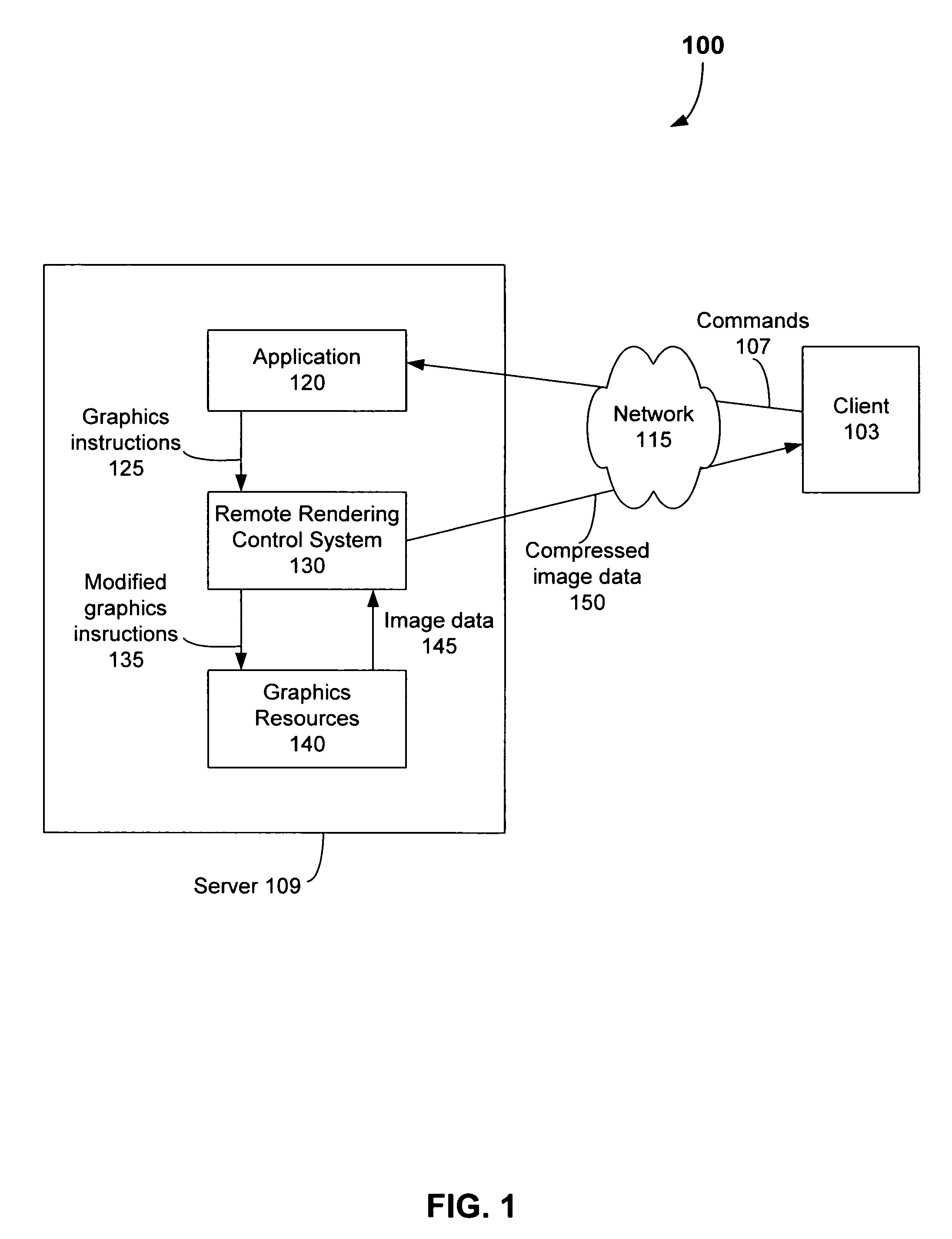

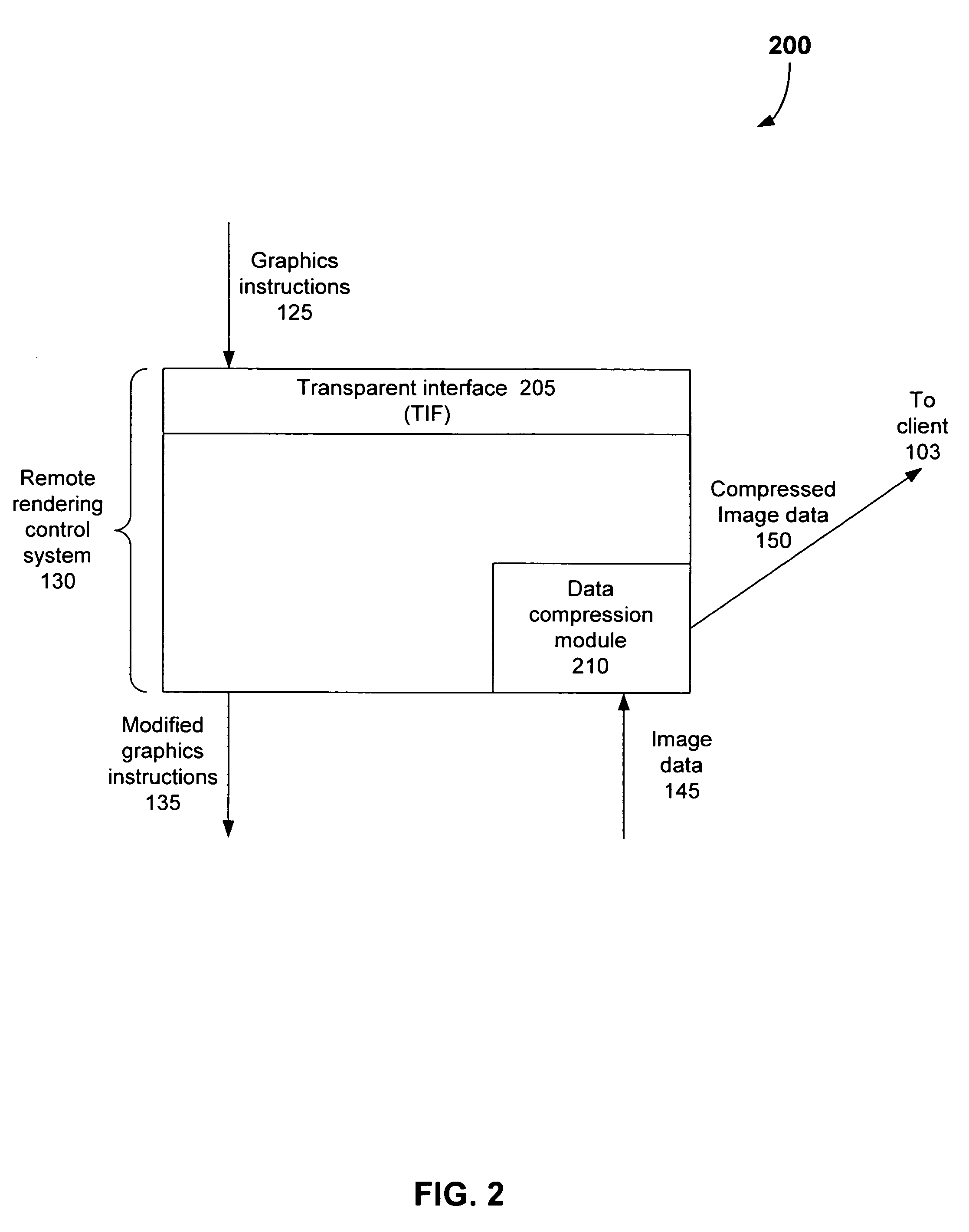

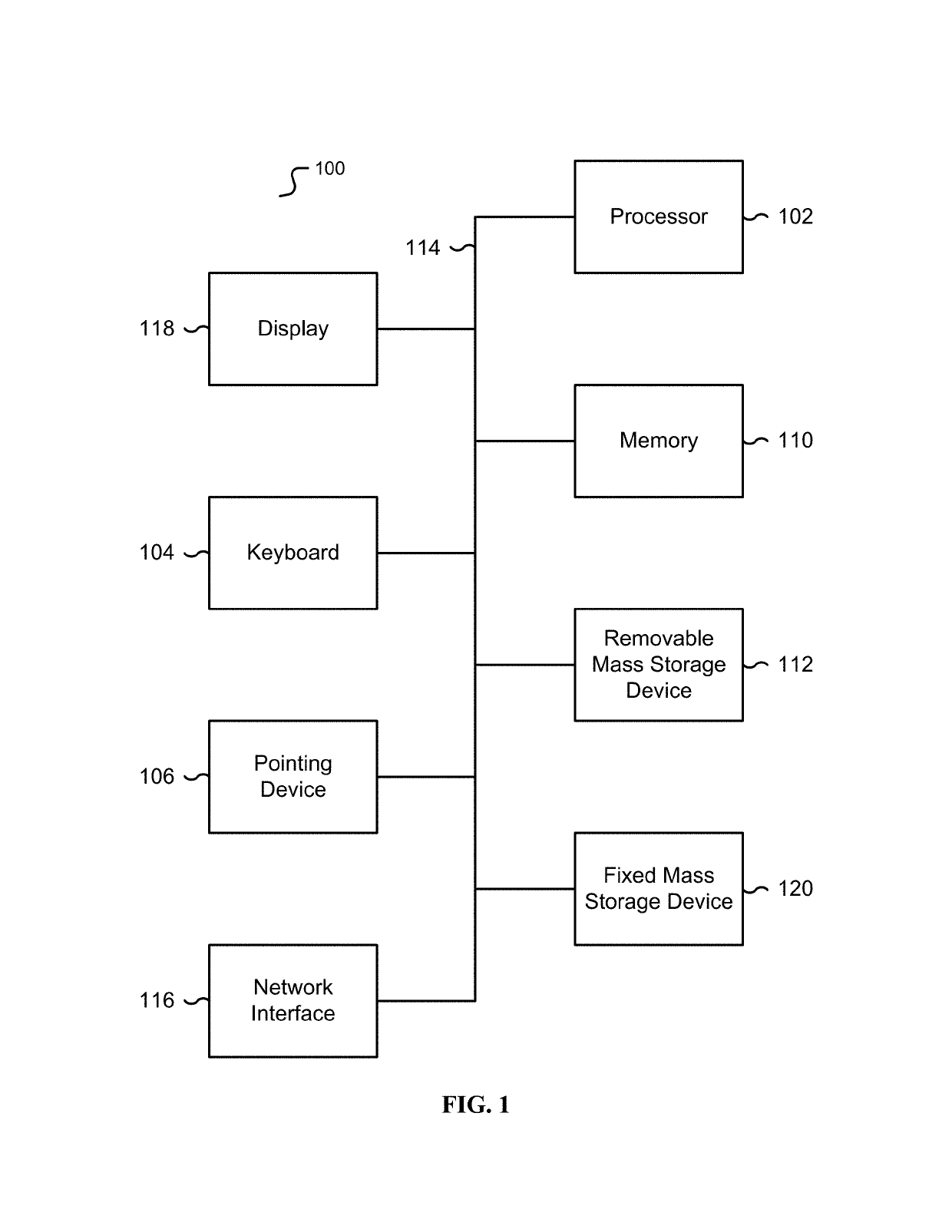

System method and computer program product for remote graphics processing

InactiveUS7274368B1Great utilityCathode-ray tube indicatorsMultiple digital computer combinationsClient-sideFramebuffer

A system, method, and computer program product are provided for remote rendering of computer graphics. The system includes a graphics application program resident at a remote server. The graphics application is invoked by a user or process located at a client. The invoked graphics application proceeds to issue graphics instructions. The graphics instructions are received by a remote rendering control system. Given that the client and server differ with respect to graphics context and image processing capability, the remote rendering control system modifies the graphics instructions in order to accommodate these differences. The modified graphics instructions are sent to graphics rendering resources, which produce one or more rendered images. Data representing the rendered images is written to one or more frame buffers. The remote rendering control system then reads this image data from the frame buffers. The image data is transmitted to the client for display or processing. In an embodiment of the system, the image data is compressed before being transmitted to the client. In such an embodiment, the steps of rendering, compression, and transmission can be performed asynchronously in a pipelined manner.

Owner:GOOGLE LLC +1

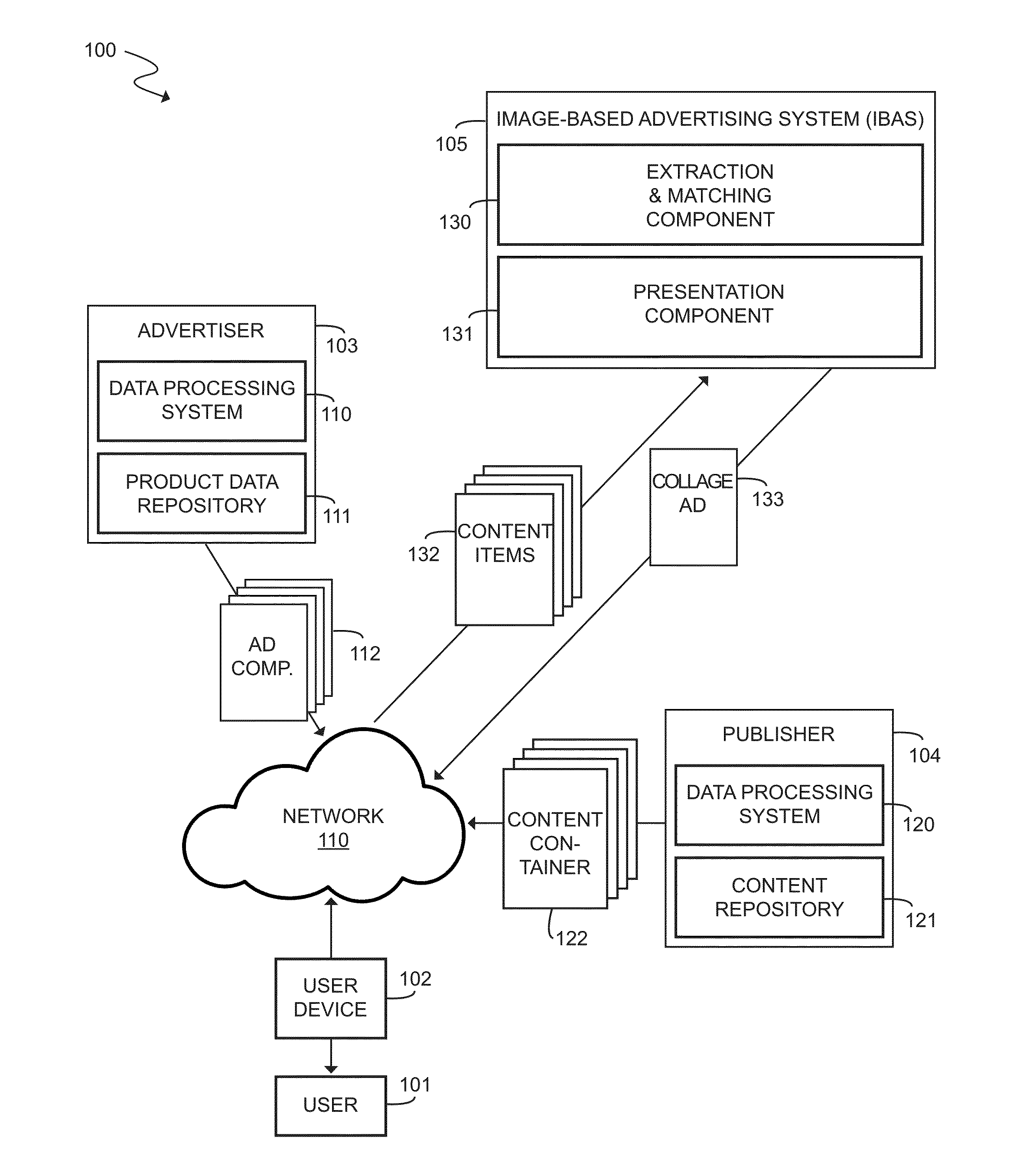

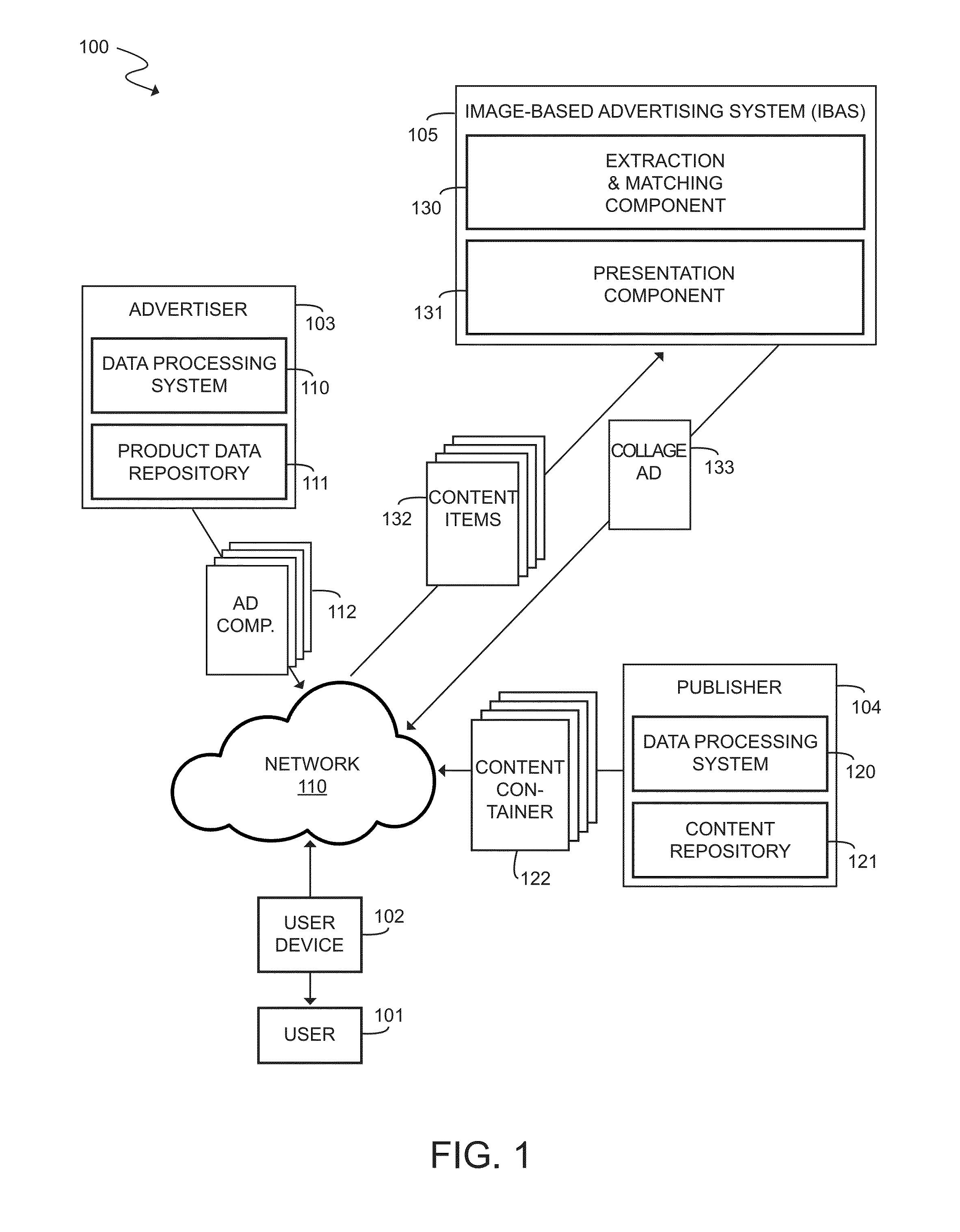

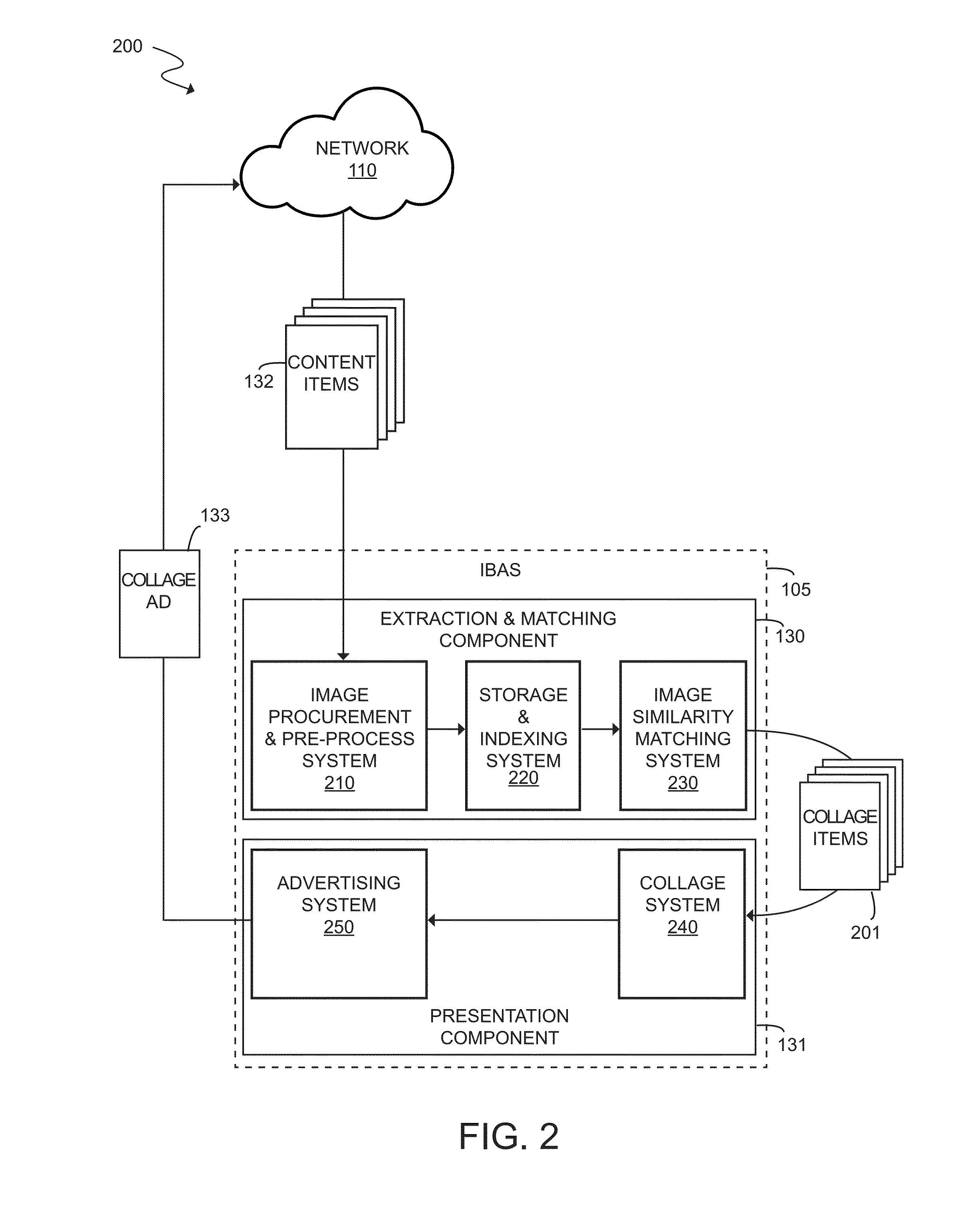

Pictollage: Image-Based Contextual Advertising Through Programmatically Composed Collages

InactiveUS20150178786A1Well formedAdvertisementsOther databases indexingComputer graphics (images)Visual perception

A system and method for creating and serving image-based contextual advertising through programmatically composed image collages, including the procurement, indexing and matching of query images, the procurement, indexing and matching of web images and the transferring of indexed and matched data from those web images to the query images, the procurement, indexing and matching of product images to be used as collage ad components, the matching and selection of one or more decorative template elements and one or more structural templates, the programmatic combining of the product images and the templates and template elements into a collage and the distribution of this collage for display to a user as a collage ad, based at least in part on the visual data extracted and indexed from the query image.

Owner:CLAESSENS CATHARINA A J

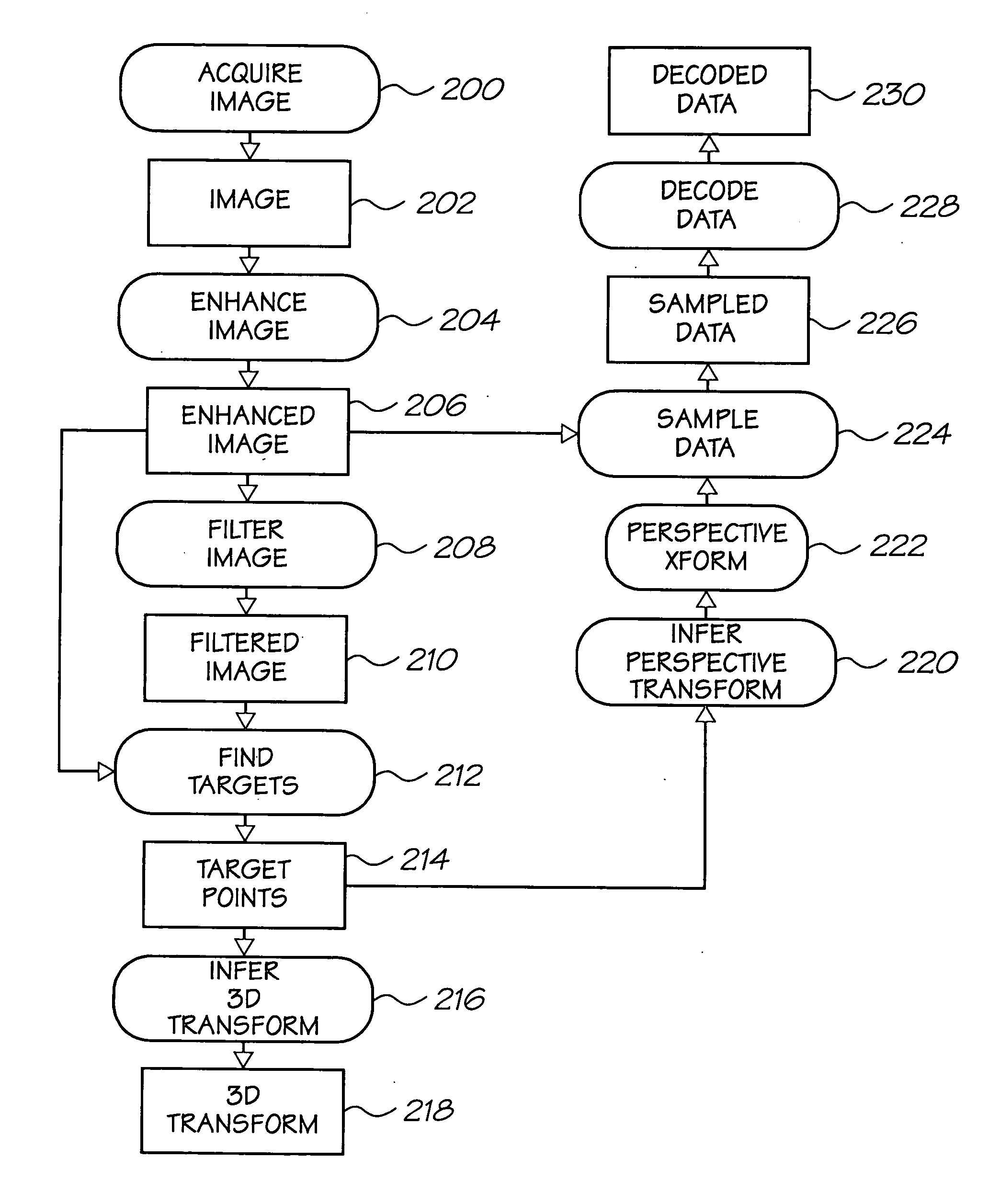

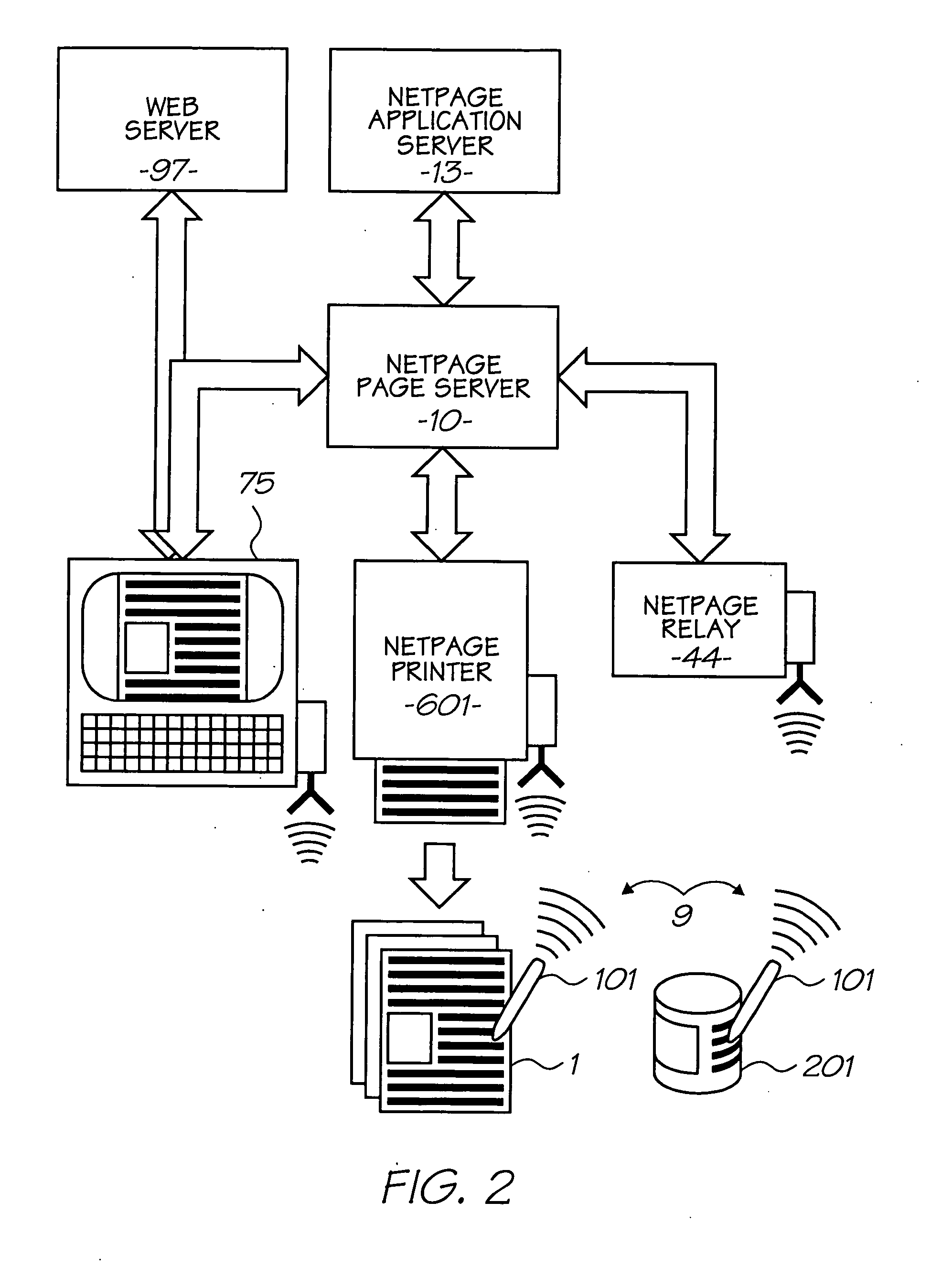

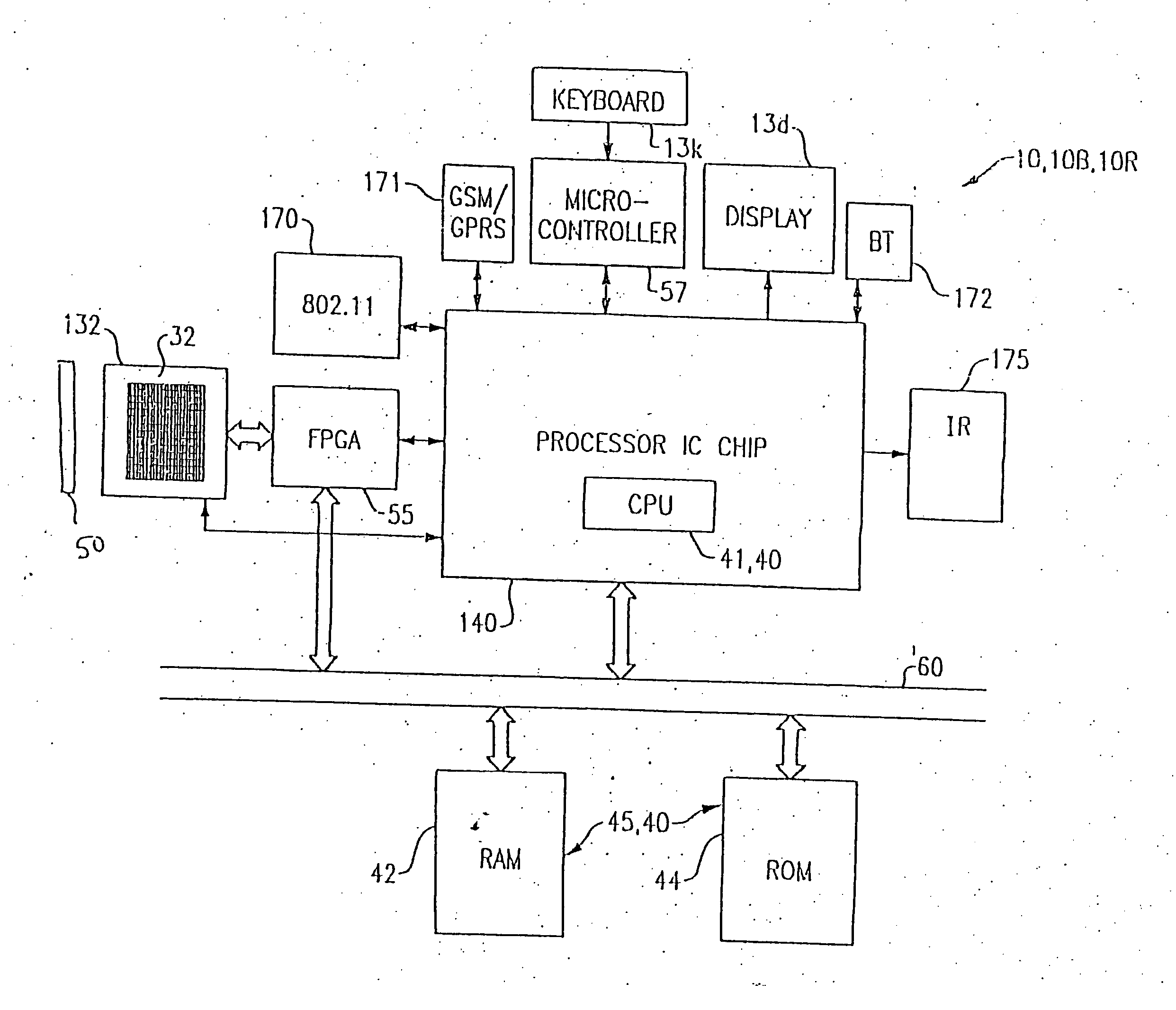

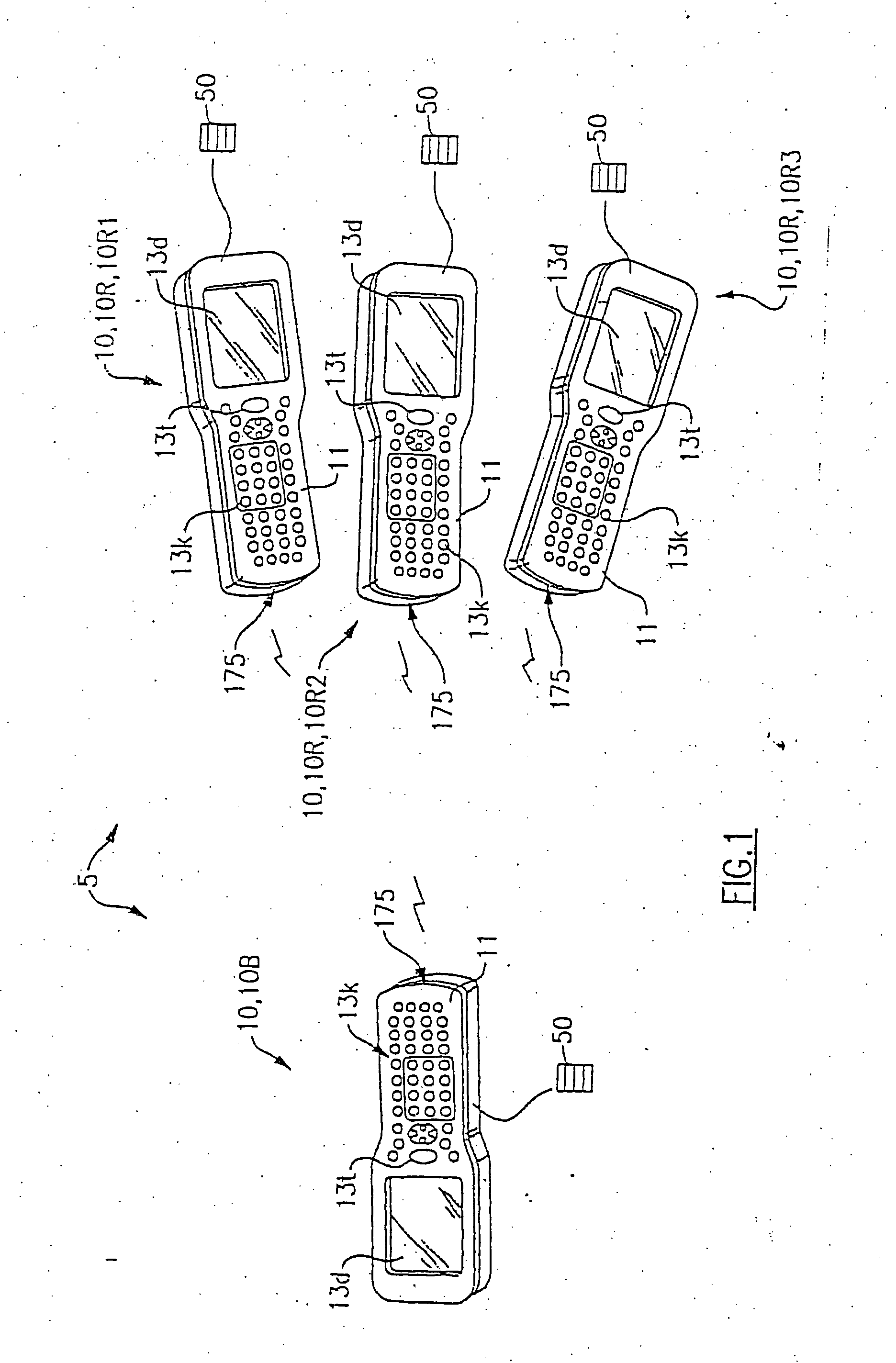

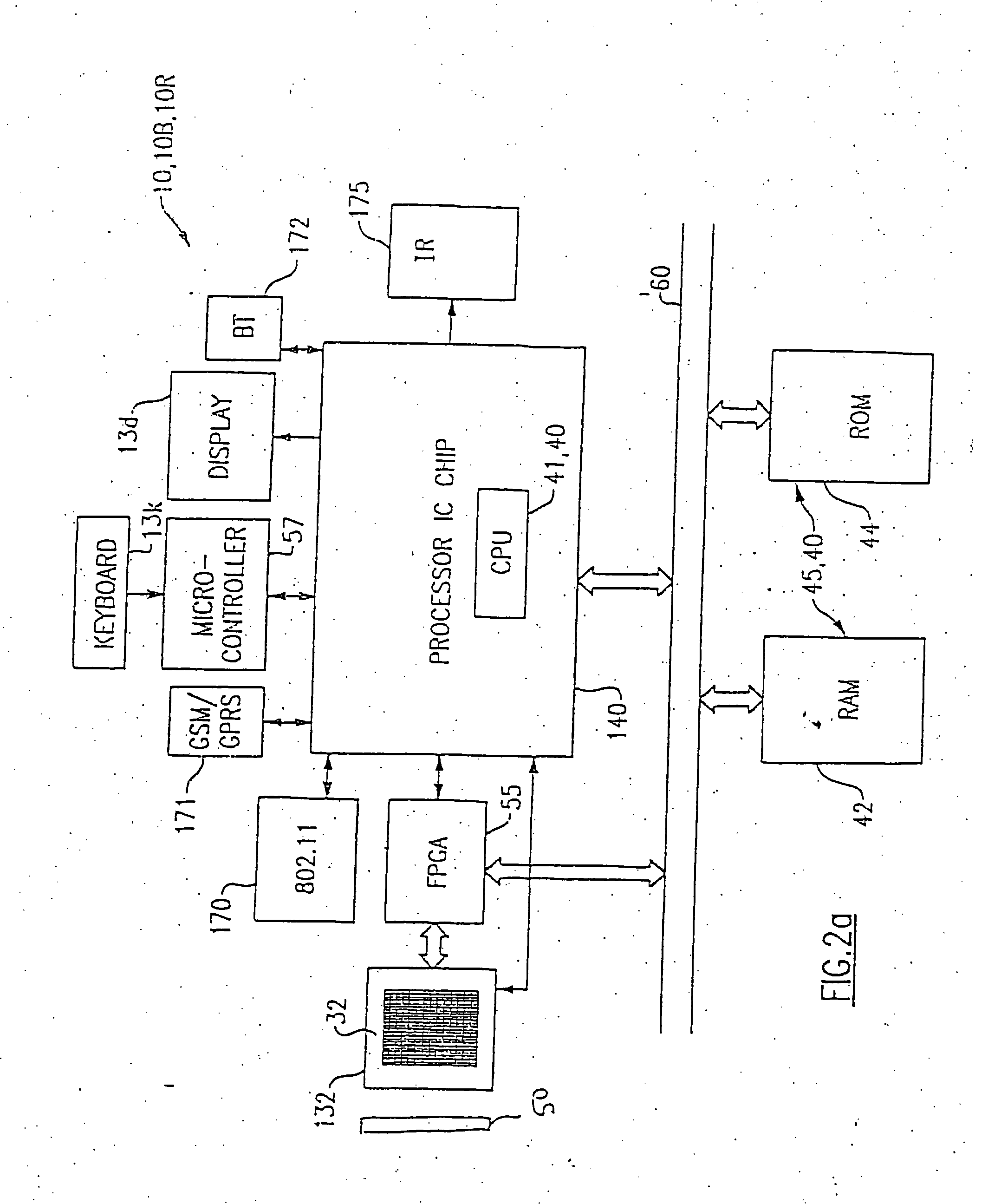

Scanning device for coded data

InactiveUS20050254106A9Input/output for user-computer interactionDigital data processing detailsGratingPhotodetector

A scanning device for: scanning coded data disposed on a surface; and generating interaction data based on the sensed coded data, the interaction data being indicative of interaction of the scanning device with the surface; the coded data including, at a plurality of locations on the interface surface, a corresponding plurality of coded data portions, the scanning device comprising: (a) a laser source and scan optics configured to emit a scanning beam through an aperture in a housing of the scanning device, the scanning beam being directed in first and second orthogonal directions to thereby generate a raster scan pattern over a scanning patch, the scanning patch being positioned to cause the exposure of the at least one coded data portion when the surface and the sensing device are positioned operatively with respect to each other; (b) a photodetector for detecting reflection of the scanning beam from the surface, thereby to capture sample information; (c) at least one analog to digital converter for converting the captured sample information into sample data; (d) a first framestore for storing successive sample data as image data; (e) an image processor for processing the image data to generate processed image data; (e) a host processor for generating the interaction data based at least partially on the processed image data.

Owner:SILVERBROOK RES PTY LTD

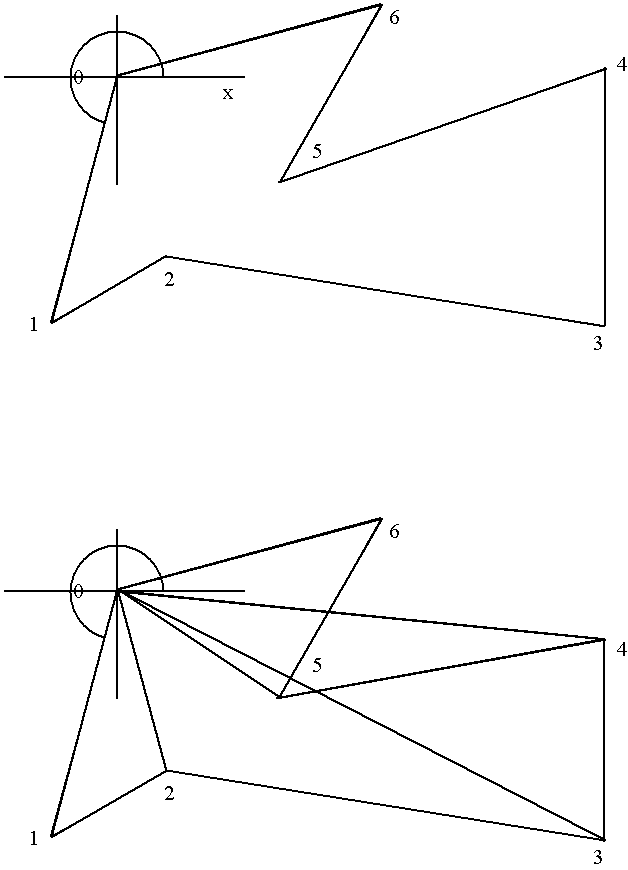

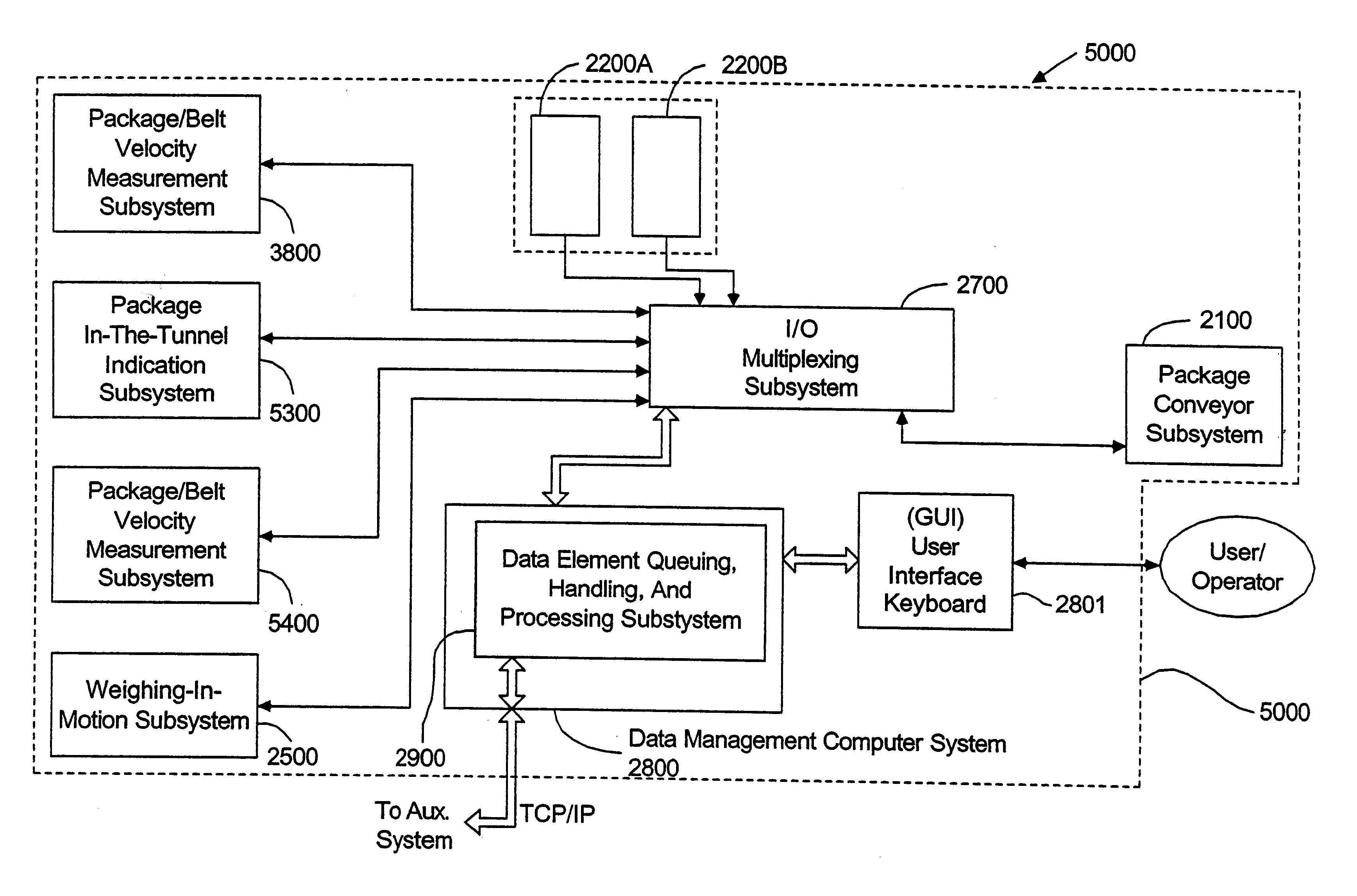

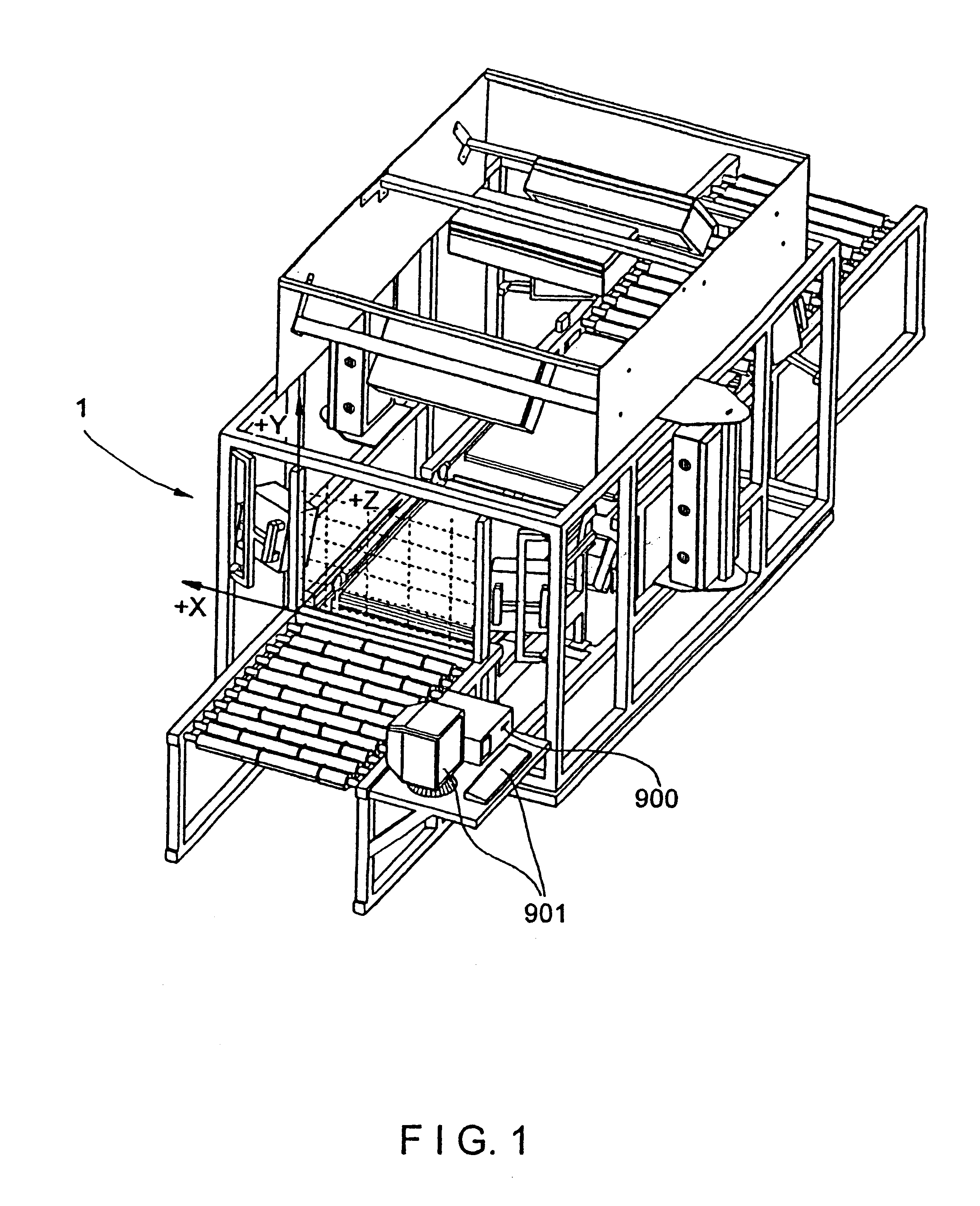

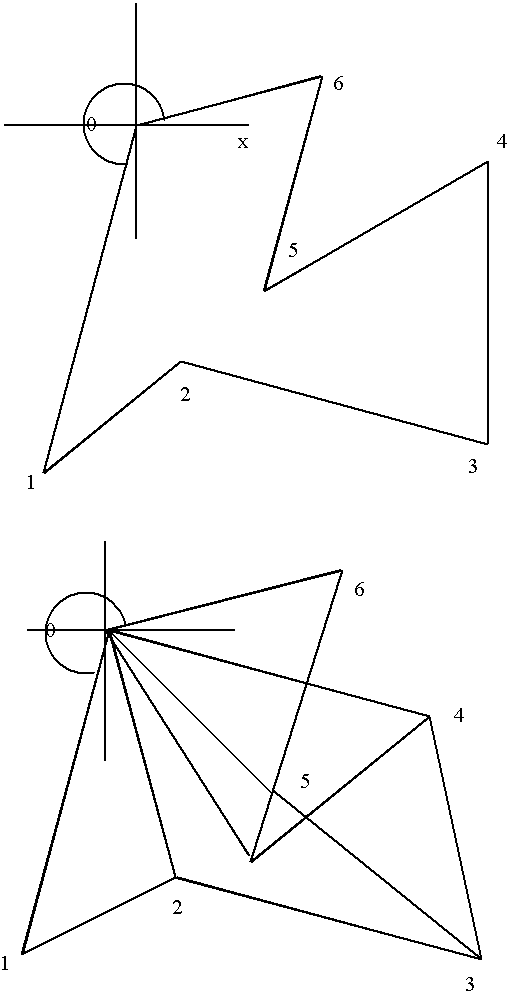

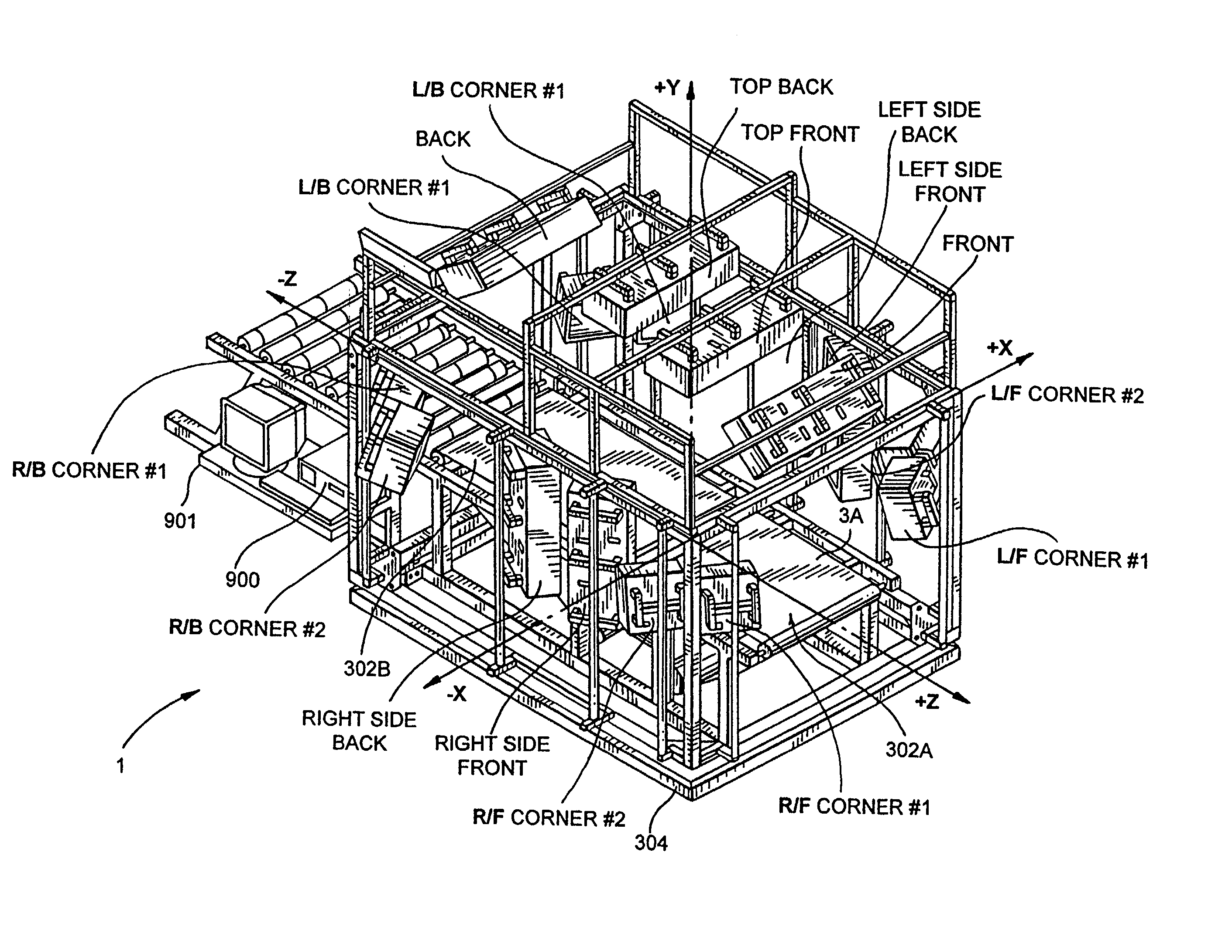

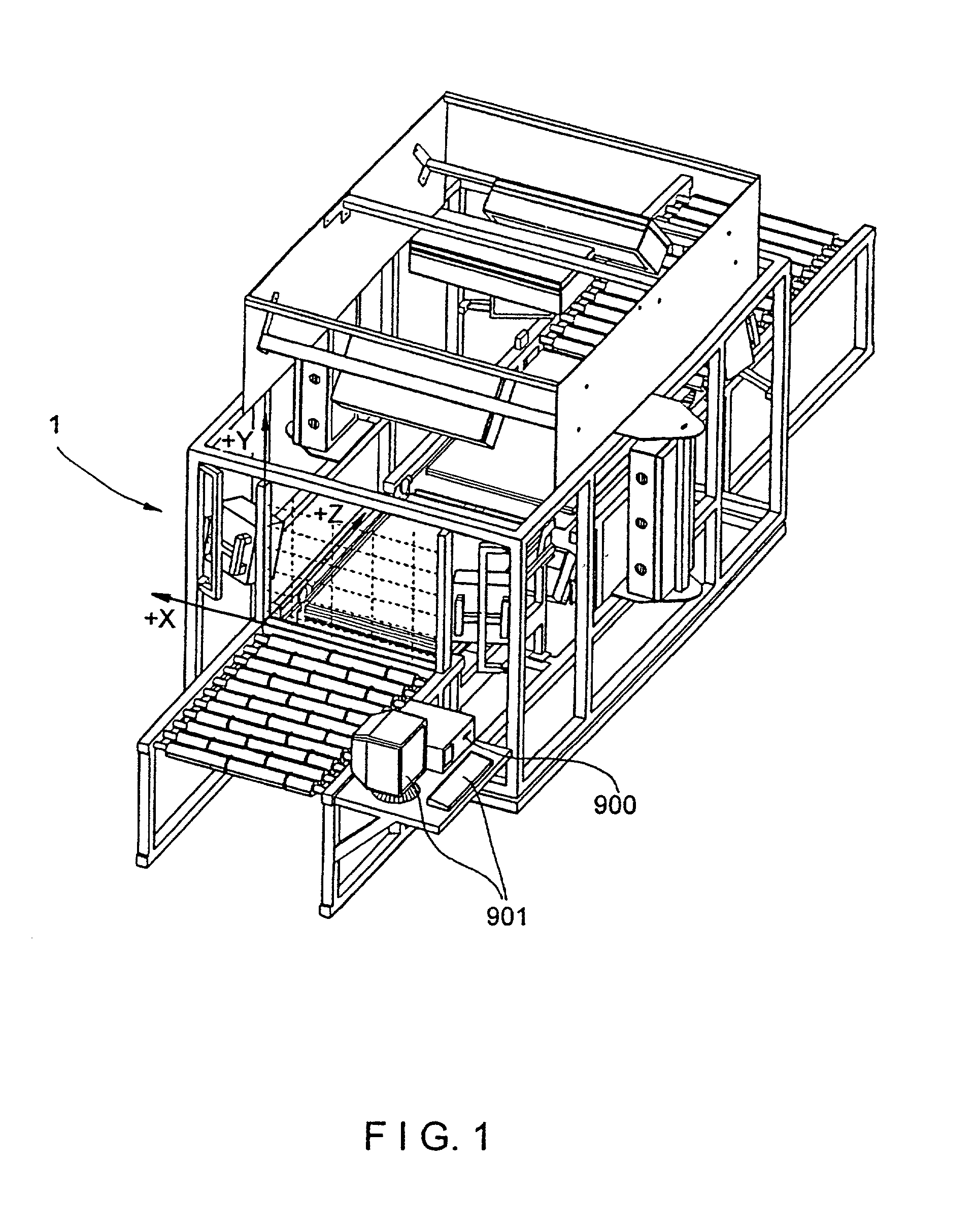

Automated method of and system for dimensioning objects transported through a work environment using contour tracing, vertice detection, corner point detection, and corner point reduction methods on two-dimensional range data maps captured by an amplitude modulated laser scanning beam

InactiveUS6705526B1Guaranteed uptimeSemiconductor/solid-state device manufacturingCo-operative working arrangementsMathematical modelLaser scanning

A fully automated package identification and measuring system, in which an omni-directional holographic scanning tunnel is used to read bar codes on packages entering the tunnel, while a package dimensioning subsystem is used to capture information about the package prior to entry into the tunnel. Mathematical models are created on a real-time basis for the geometry of the package and the position of the laser scanning beam used to read the bar code symbol thereon. The mathematical models are analyzed to determine if collected and queued package identification data is spatially and / or temporally correlated with package measurement data using vector-based ray-tracing methods, homogeneous transformations, and object-oriented decision logic so as to enable simultaneous tracking of multiple packages being transported through the scanning tunnel.

Owner:METROLOGIC INSTR

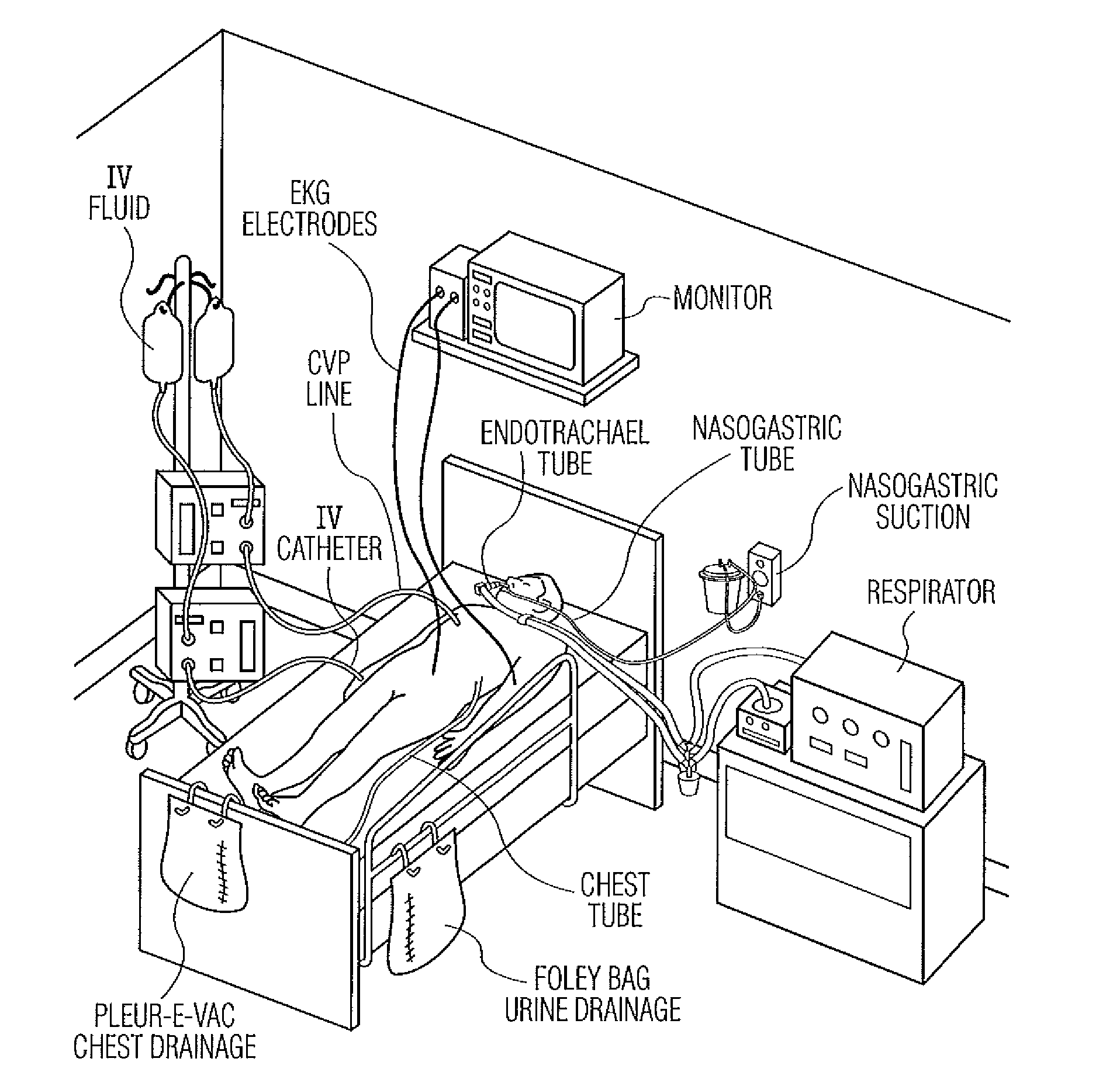

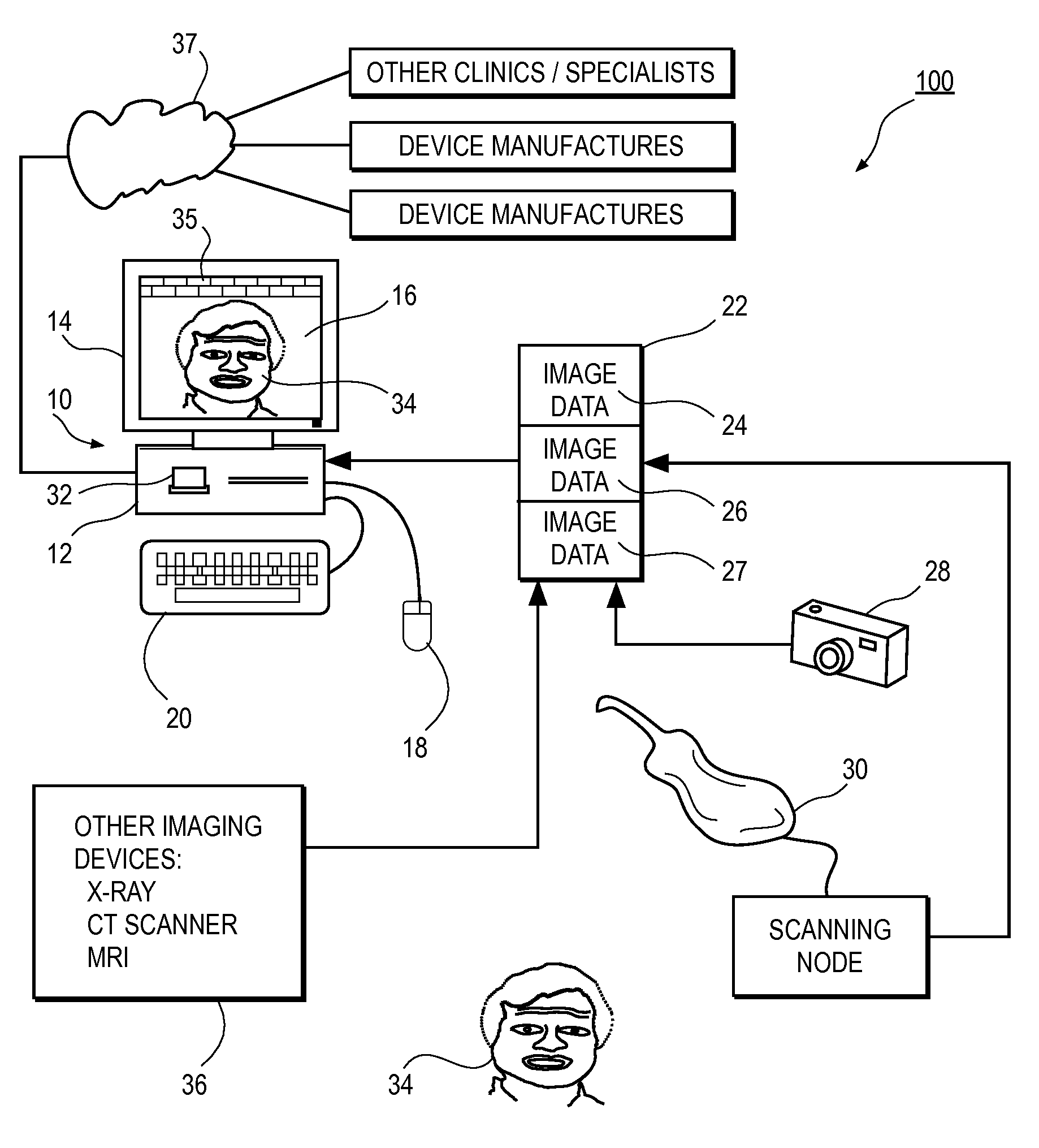

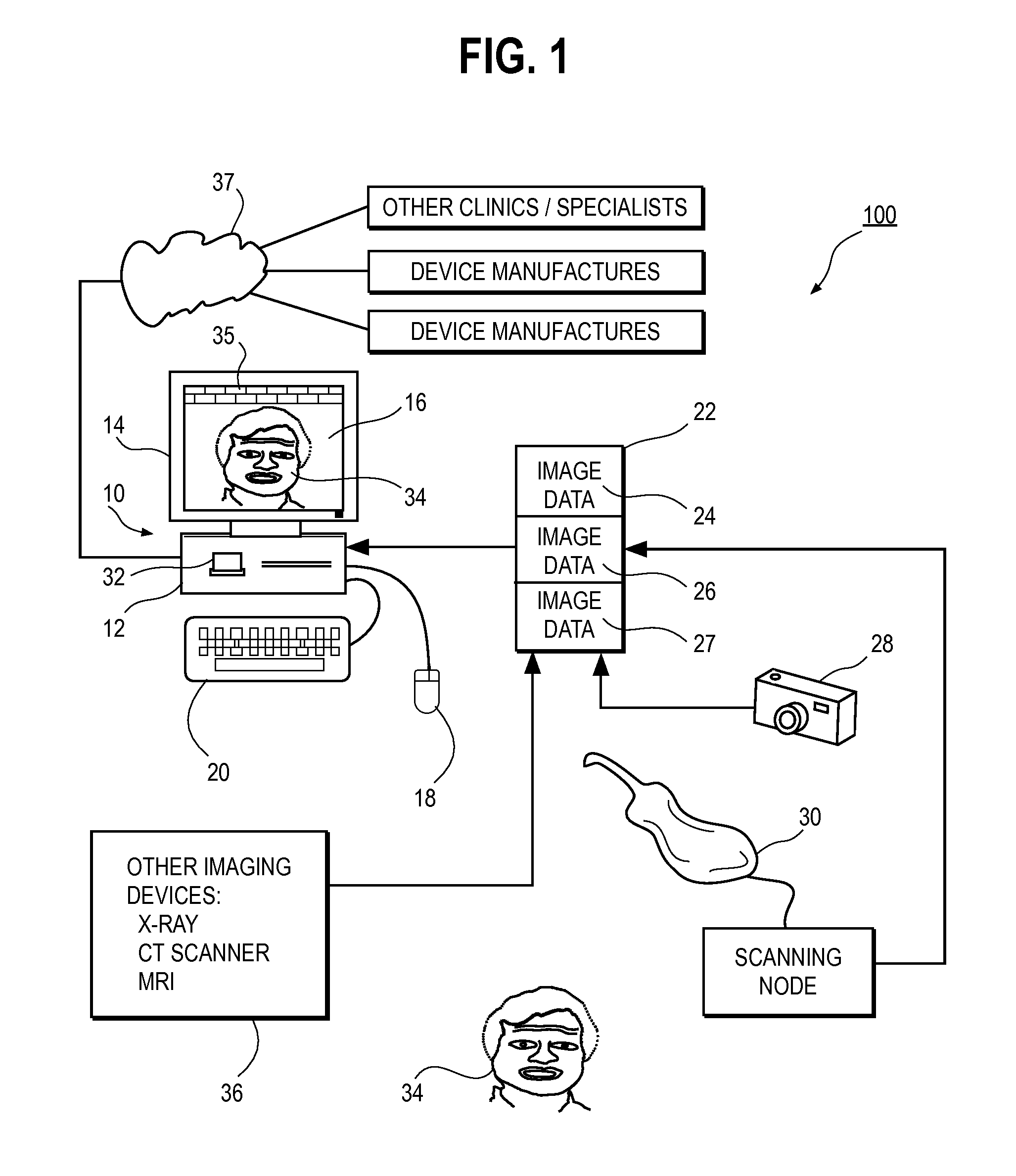

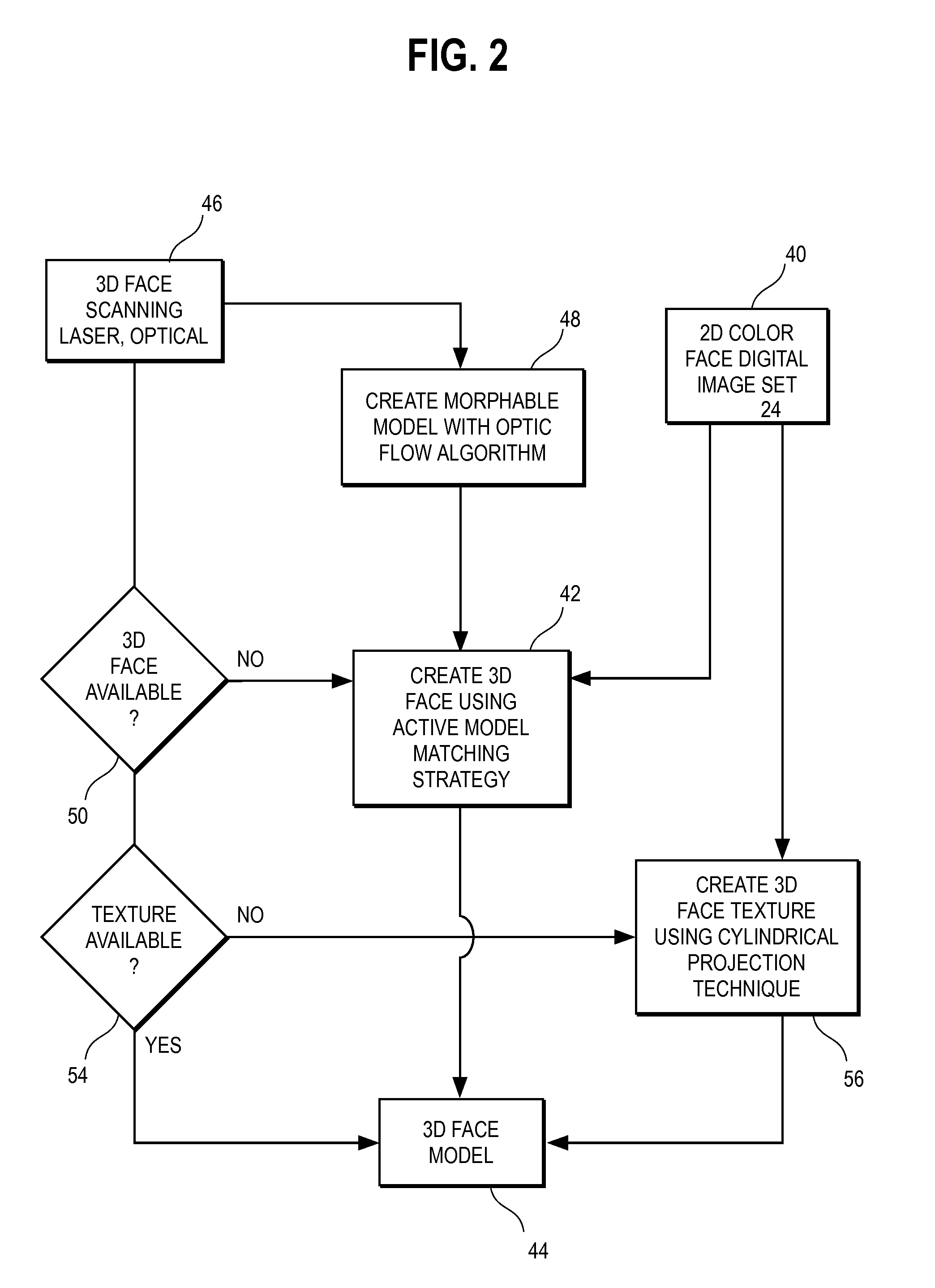

Automatic Patient and Device Recognition and Association System

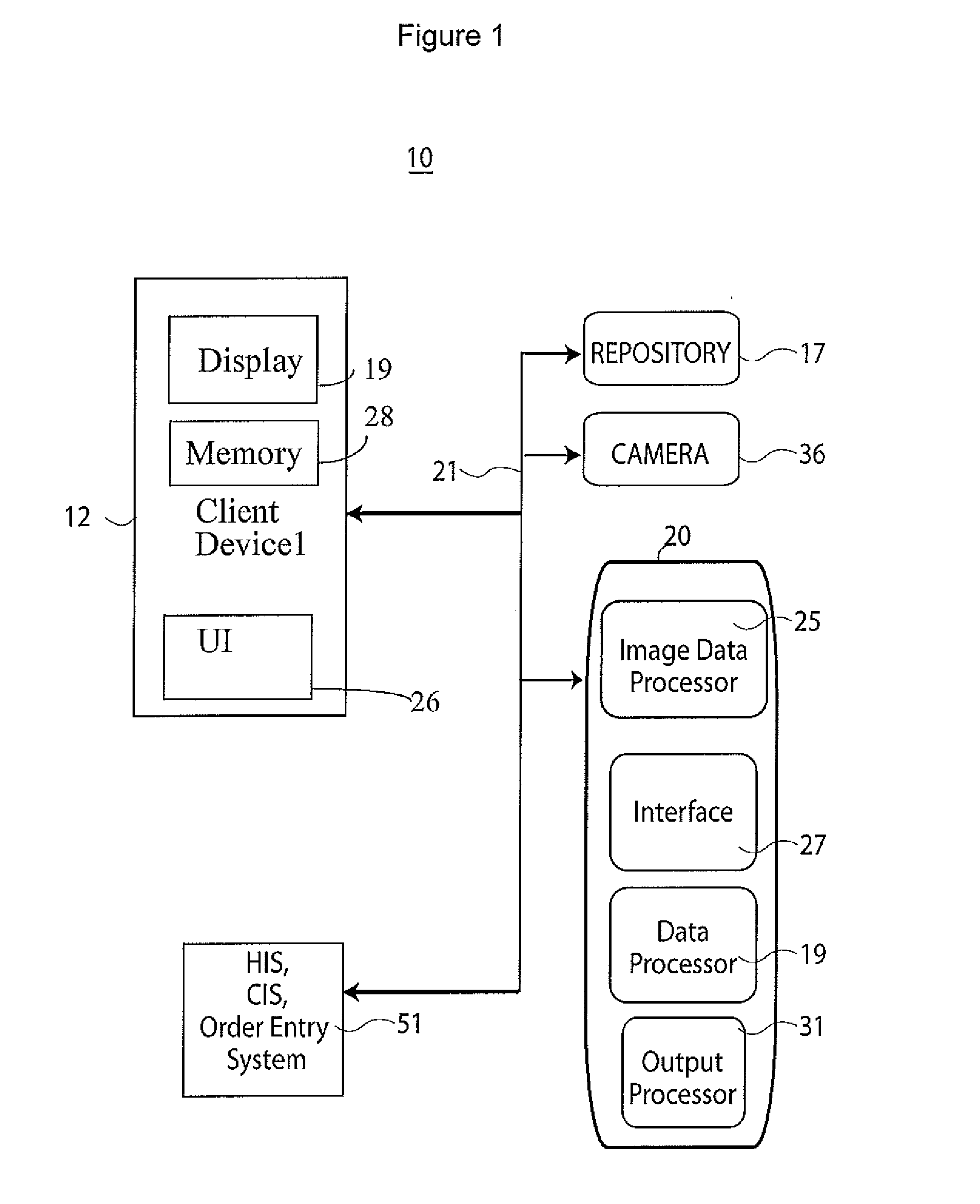

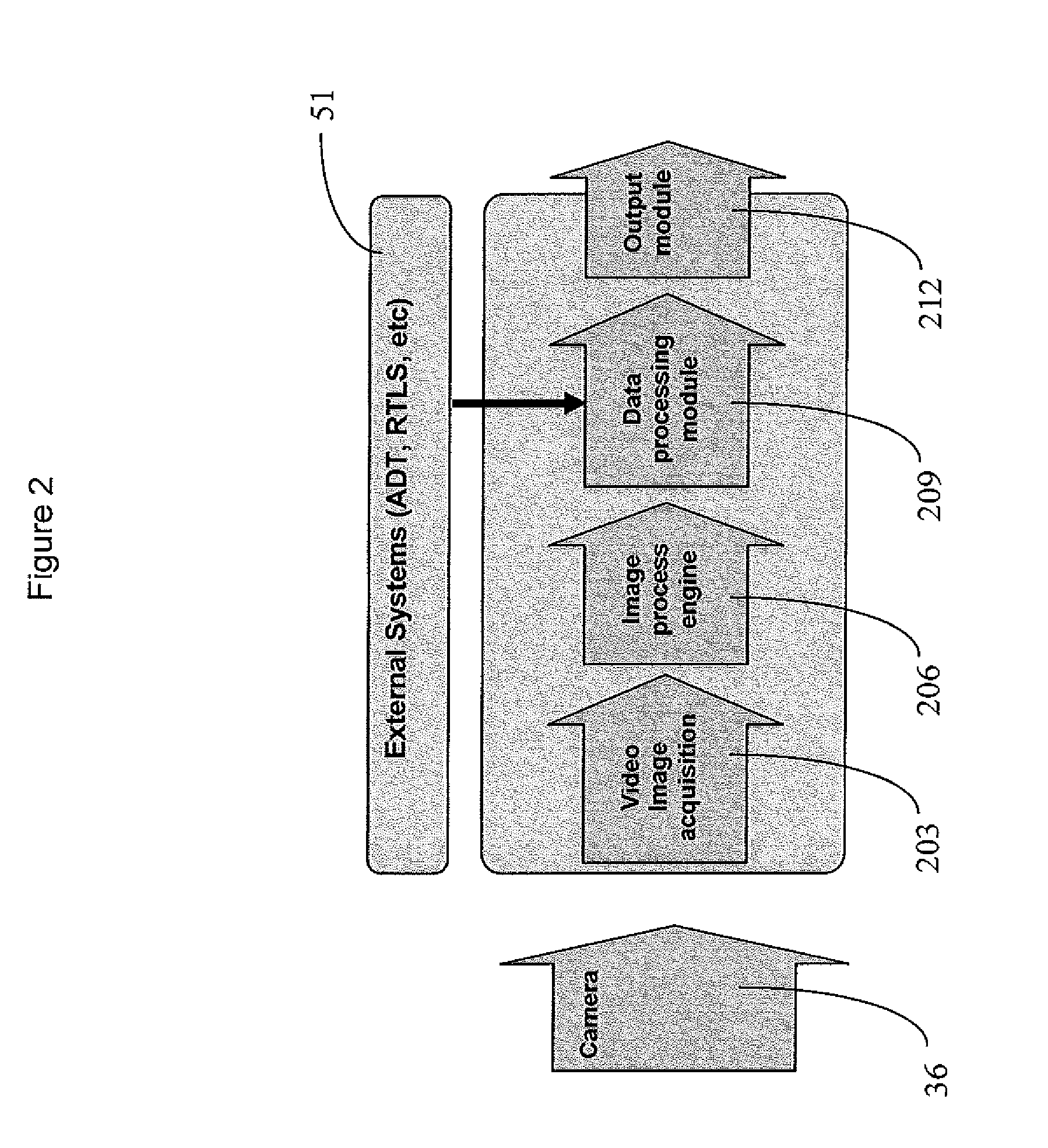

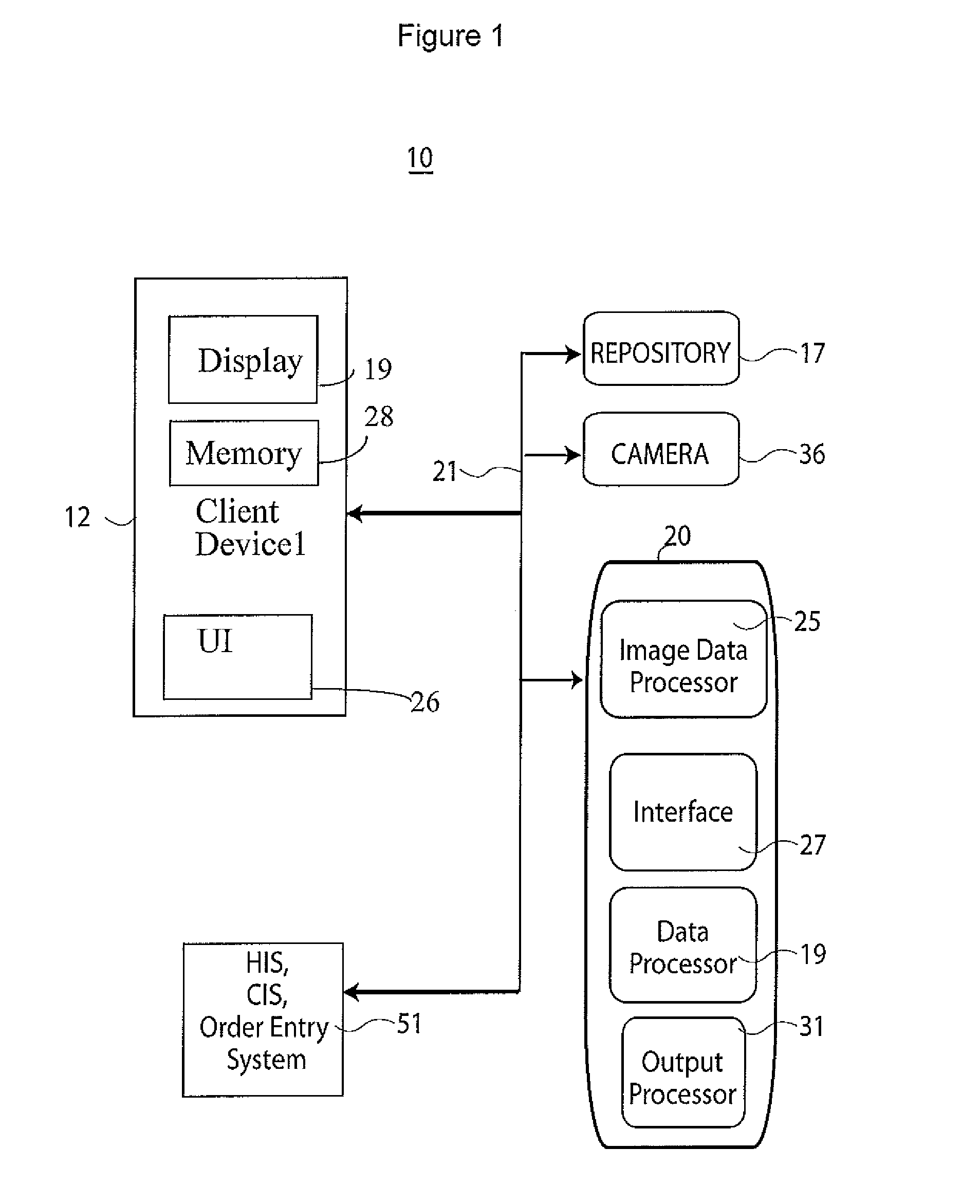

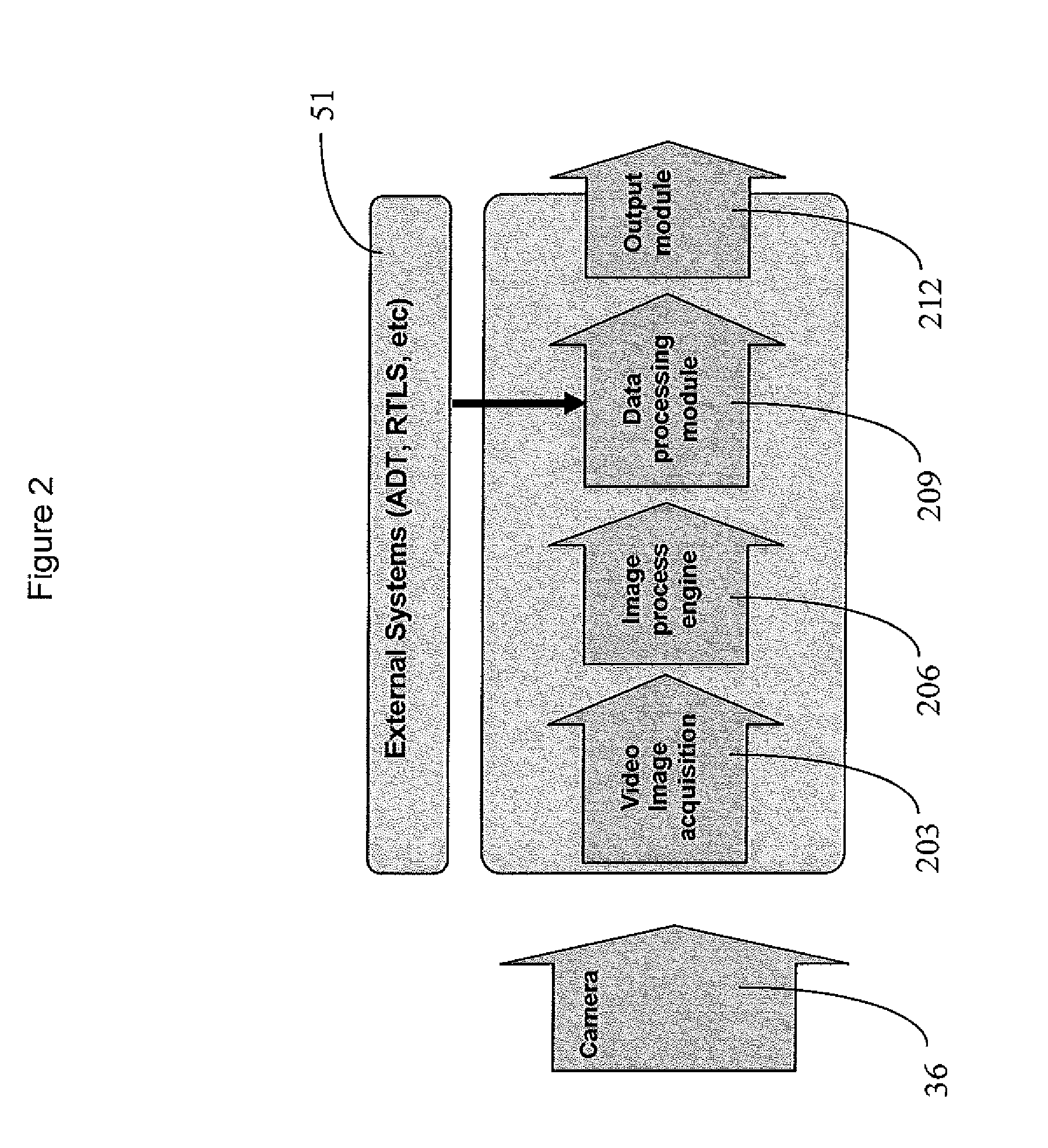

ActiveUS20110305376A1Character and pattern recognitionPatient personal data managementDevice typeCare setting

A system associates a patient and patient identifier with a medical device and includes an interface. The interface acquires data representing an image of a patient in a care setting and showing a medical device in the vicinity of the patient and acquires data identifying the patient. An image data processor analyzes the acquired data representing the image to identify the medical device type by, analyzing the acquired data to determine a shape of the medical device, comparing the determined shape of the medical device with predetermined template shapes of known device types and identifying the medical device type in response to the shape comparison indicating a shape match. A data processor associates the identified medical device type with the data identifying the patient. An output processor initiates generation of data indicating an association of the identified medical device type with the data identifying the patient.

Owner:CERNER INNOVATION

Automated method of and system for dimensioning objects over a conveyor belt structure by applying contouring tracing, vertice detection, corner point detection, and corner point reduction methods to two-dimensional range data maps of the space above the conveyor belt captured by an amplitude modulated laser scanning beam

InactiveUS20020179708A1Coin-freed apparatus detailsSemiconductor/solid-state device manufacturingData graphAlgorithm

A fully automated package identification and measuring system, in which an omni-directional holographic scanning tunnel is used to read bar codes on packages entering the tunnel, while a package dimensioning subsystem is used to capture information about the package prior to entry into the tunnel. Mathematical models are created on a real-time basis for the geometry of the package and the position of the laser scanning beam used to read the bar code symbol thereon. The mathematical models are analyzed to determine if collected and queued package identification data is spatially and / or temporally correlated with package measurement data using vector-based ray-tracing methods, homogeneous transformations, and object-oriented decision logic so as to enable simultaneous tracking of multiple packages being transported through the scanning tunnel.

Owner:METROLOGIC INSTR

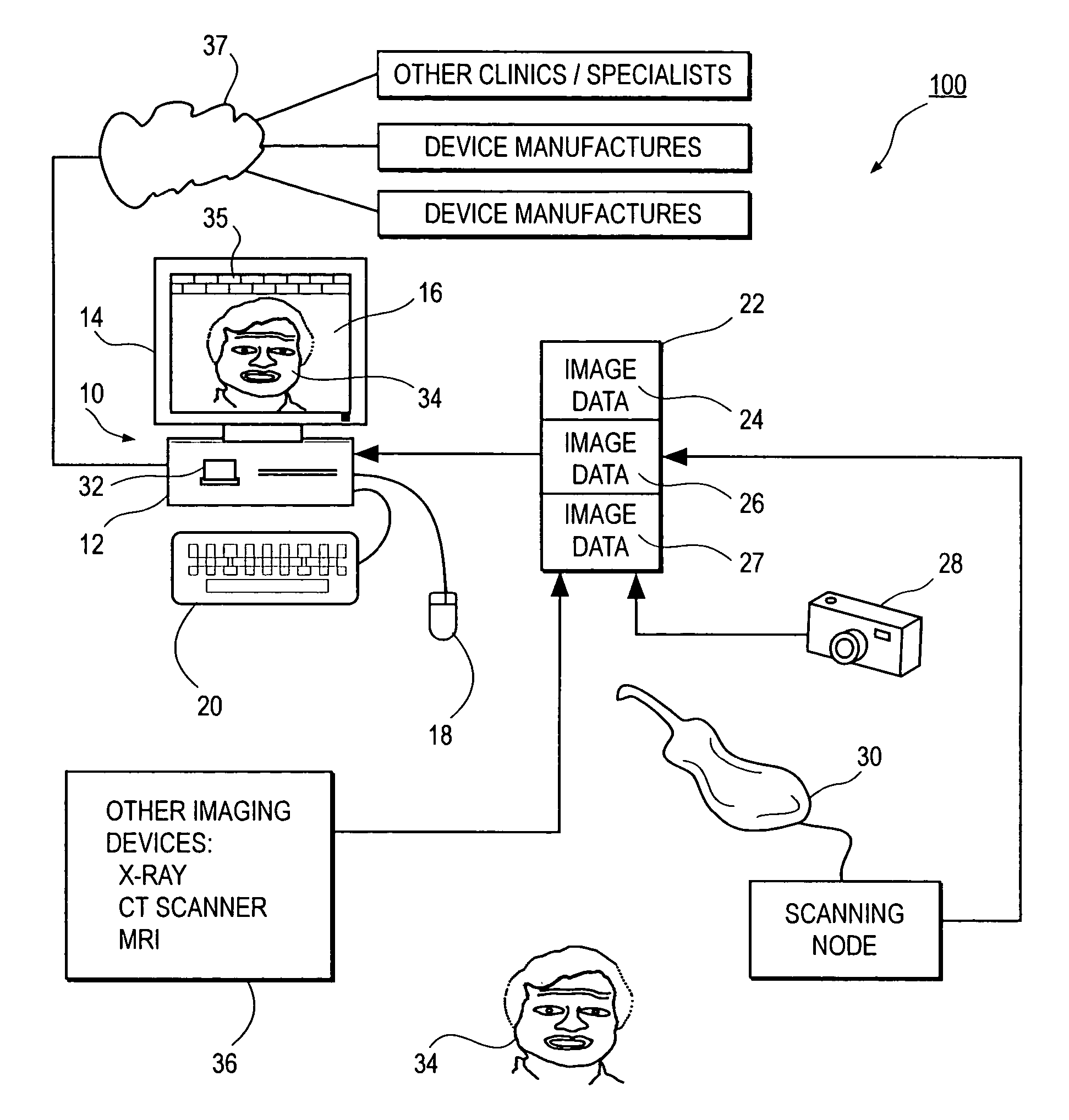

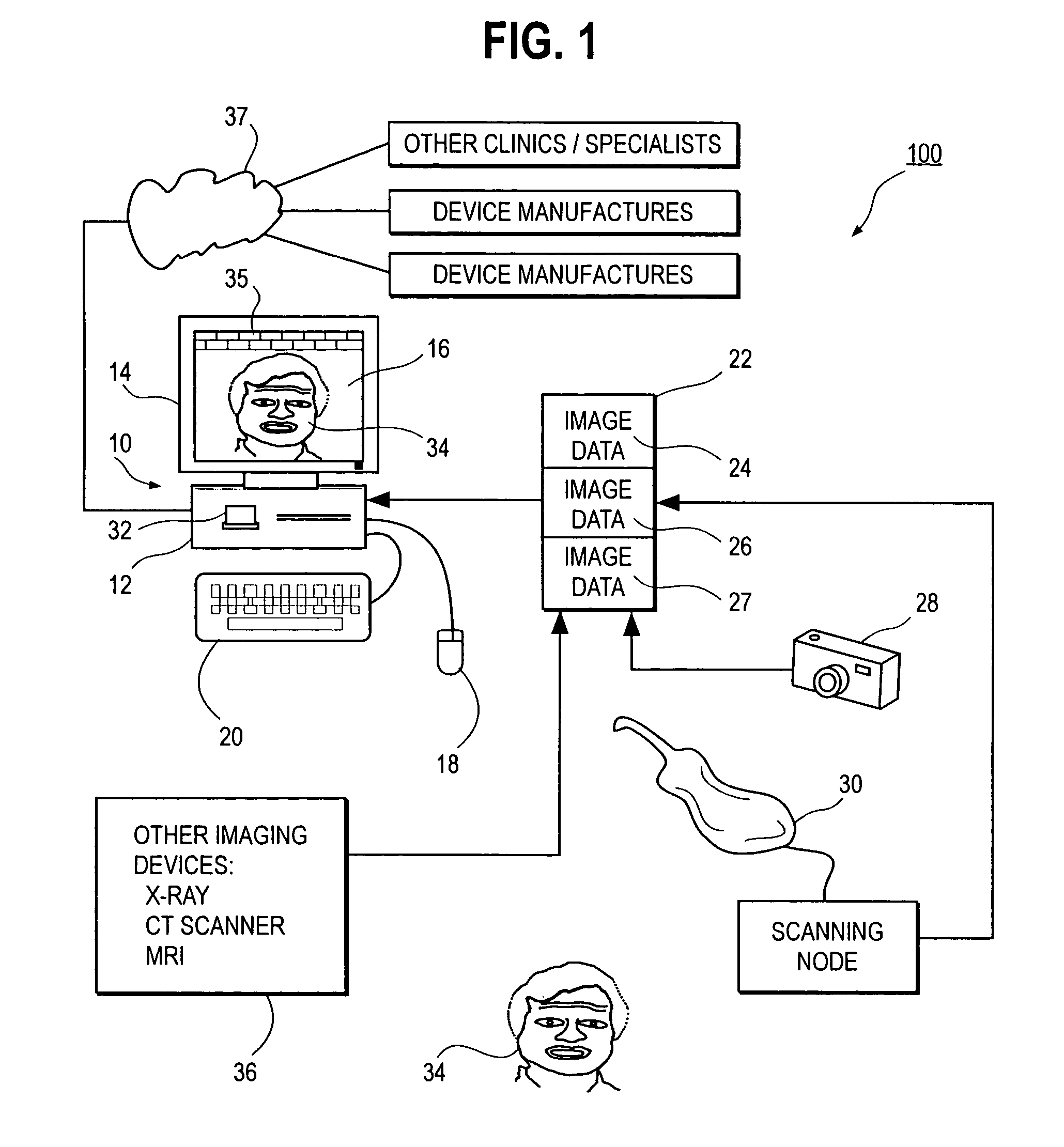

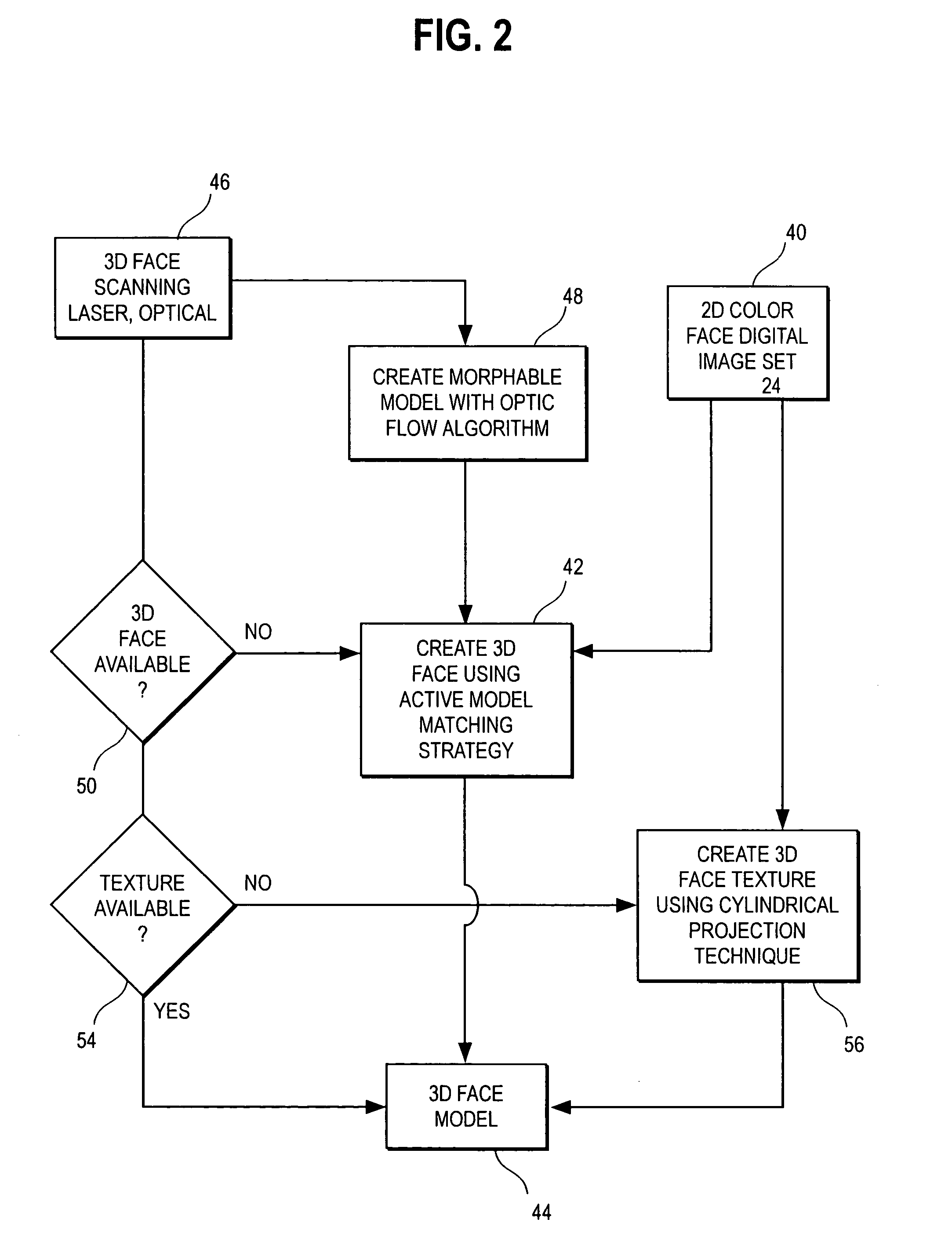

Method and system for integrated orthodontic treatment planning using unified workstation

InactiveUS7717708B2Efficient and cost-effective treatment planHigh simulationMedical simulationImpression capsData graph3d image

A method and workstation for orthodontic treatment planning of a patient. The workstation is based on a computing platform having a graphical user interface, a processor and a computer storage medium containing digitized records pertaining to a patient including image data (3D image data and / or 2D image data). The workstation further includes a set of software instructions providing graphical user interface tools which the user marks a midline and an aesthetic occlusal plane in a two- or three-dimensional virtual model of the patient, marks an occlusal plane in the virtual model; selects a reference tooth in the virtual model; aligns virtual teeth in the virtual model in a proposed arrangement to treat the patient; manages space between the virtual teeth in the proposed arrangement; and repeats one or more of these steps in an iterative fashion to make any further adjustments in the proposed arrangement. When the adjustments are complete, the user selects or identifies a finalized proposed treatment plan for treating the patient.

Owner:ORAMETRIX

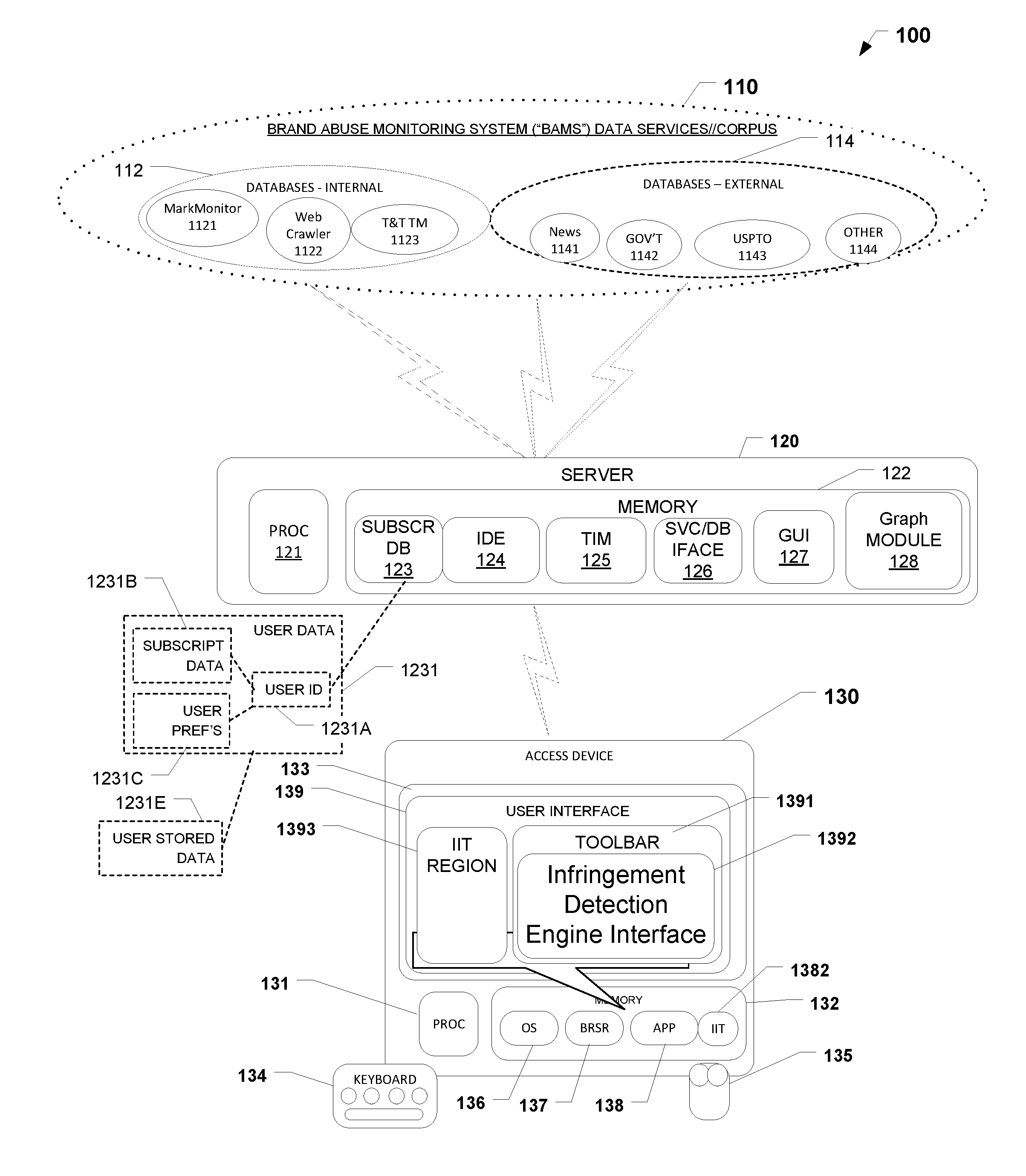

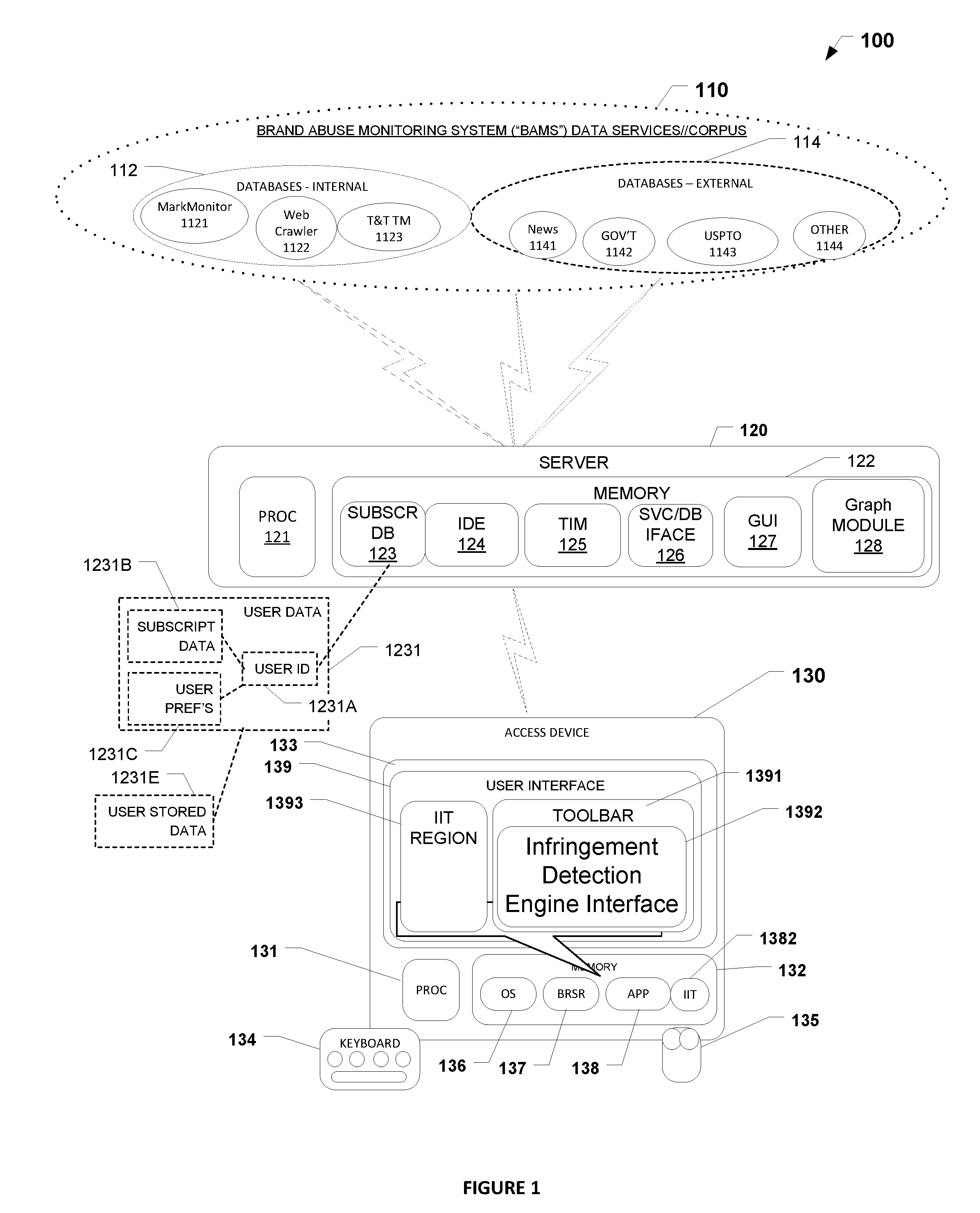

Brand abuse monitoring system with infringement deteciton engine and graphical user interface

A computer-based system connected to a remote user device and a plurality of services. A data collection engine having an input adapted to receive a set of collection data from a set of services, the set of collection data comprising a set of brand data for comparison against a control set of data stored in a database and having a set of fields and via the digital communications network a query. An entity identification module identifies and extracts within the set of collection data a set of entity data, compares the set of entity data against a set of entity control data to resolve entity identification, associates an entity identifier with the identified entity, and determines a set of relationship data between entities; a matching module adapted to receive data derived from the set of collection data and compare the received data against a set of known brand data and generate a set of comparison data and an output indicating a presence of a match; a scoring module adapted to generate a set of score data based on the set of comparison data. A graphic user interface presents a graphic representation of the set of scored data on a display device.

Owner:OPSEC ONLINE LTD

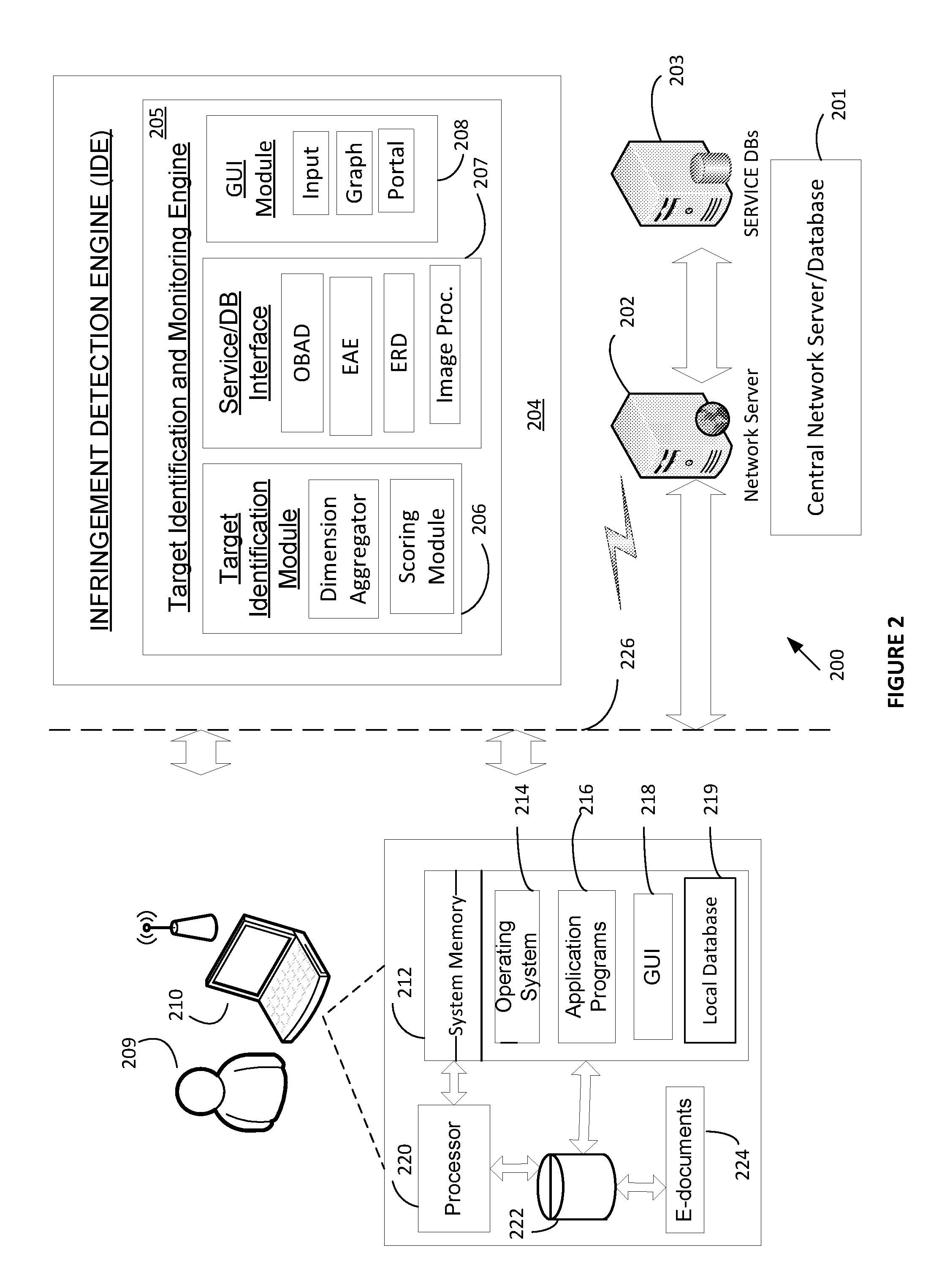

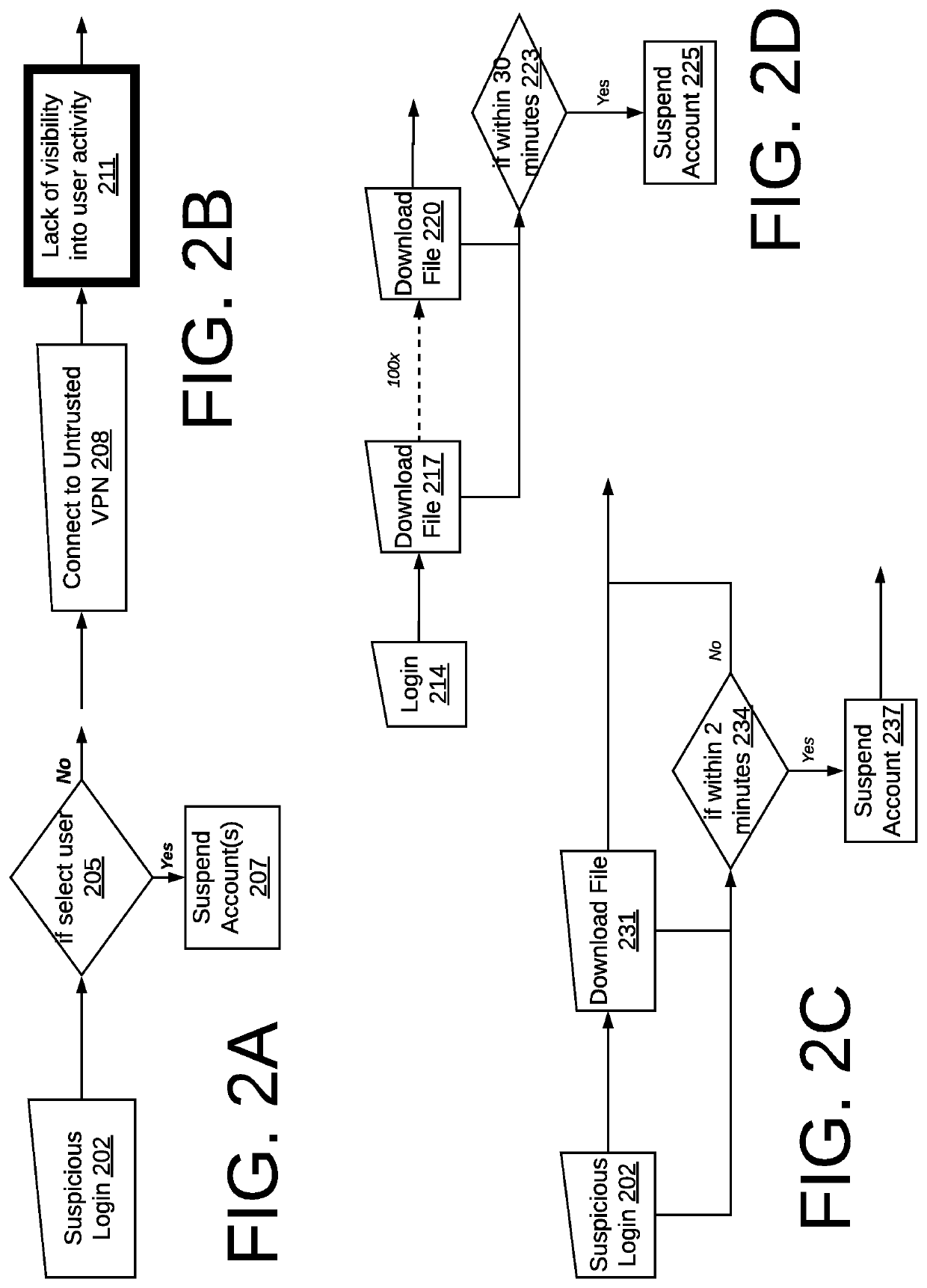

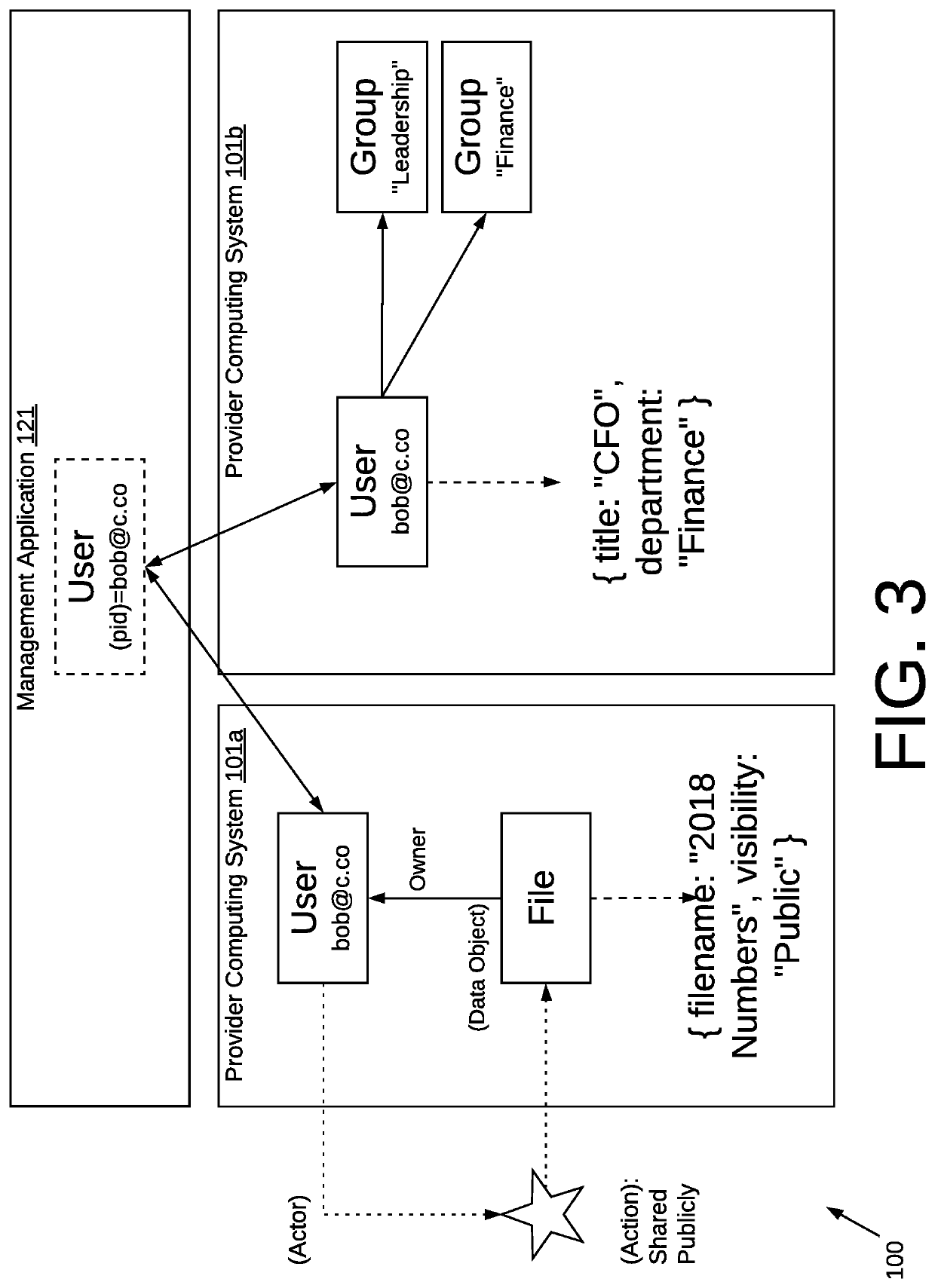

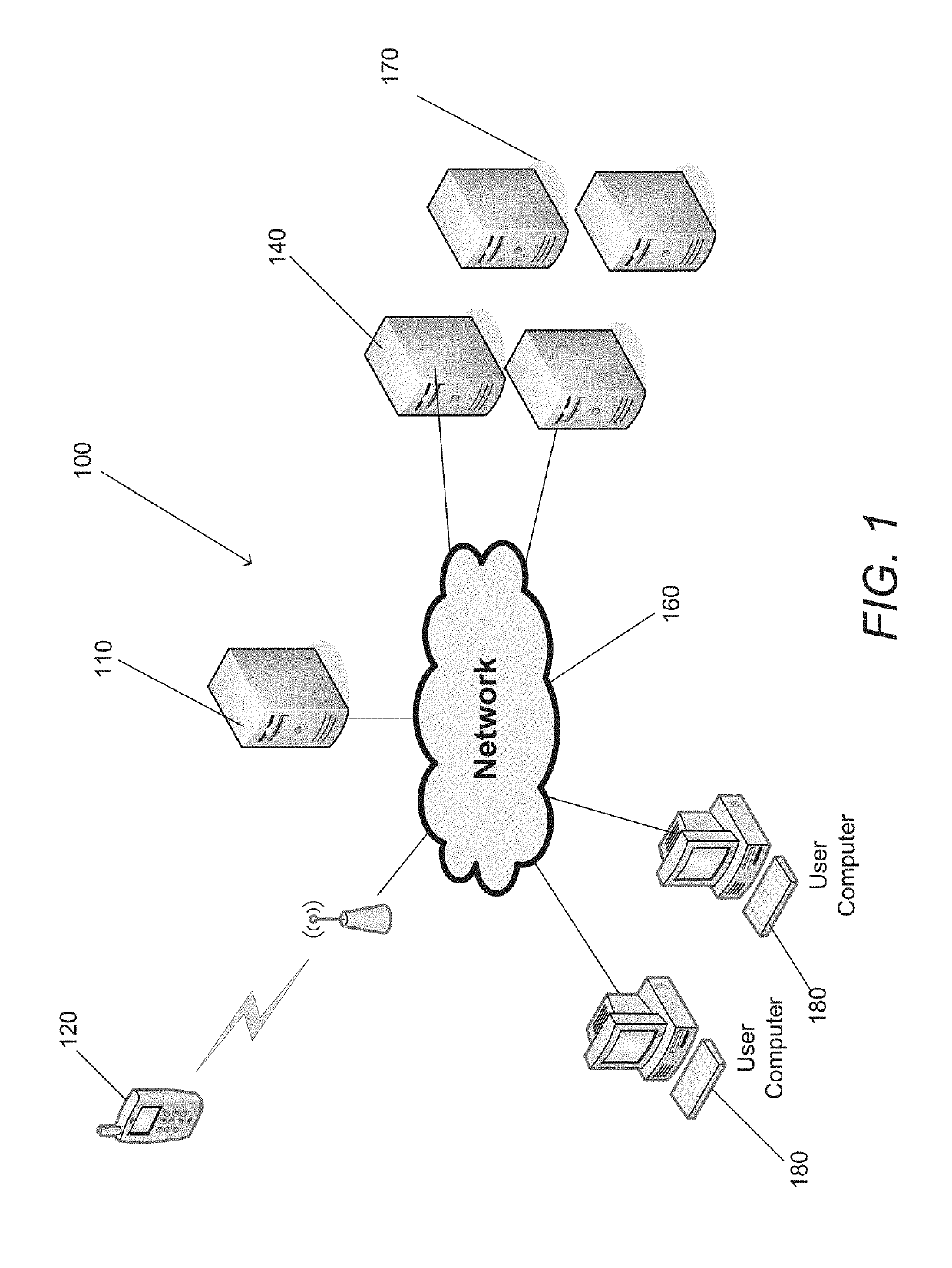

Methods and systems to manage data objects in a cloud computing environment

ActiveUS10965547B1Computer security arrangementsData switching networksData graphPersistent identifier

The present disclosure relates to managing activity taken with respect to cloud-based software services. A platform manages data objects processed by software services and / or those entities that initiate processing events. The platform uses identifiers such as, for example, a persistent identifier (PID) to track processing events. The platform implements rules and / or permissions related to the managed data objects and / or managed entities to determine whether processing events are in compliance. The platform may update database records, send alerts, send data graphs, or provide a real-time stream related to the managed data objects and / or managed entities. In addition, embodiments involve determining whether a PID-associated managed data object has been modified during processing to generate an additional version of the PID-associated managed data object and, if an object version is present, processing the additional version of the PID-associated managed data object to generate an integrated first PID-associated managed data object.

Owner:BETTERCLOUD INC

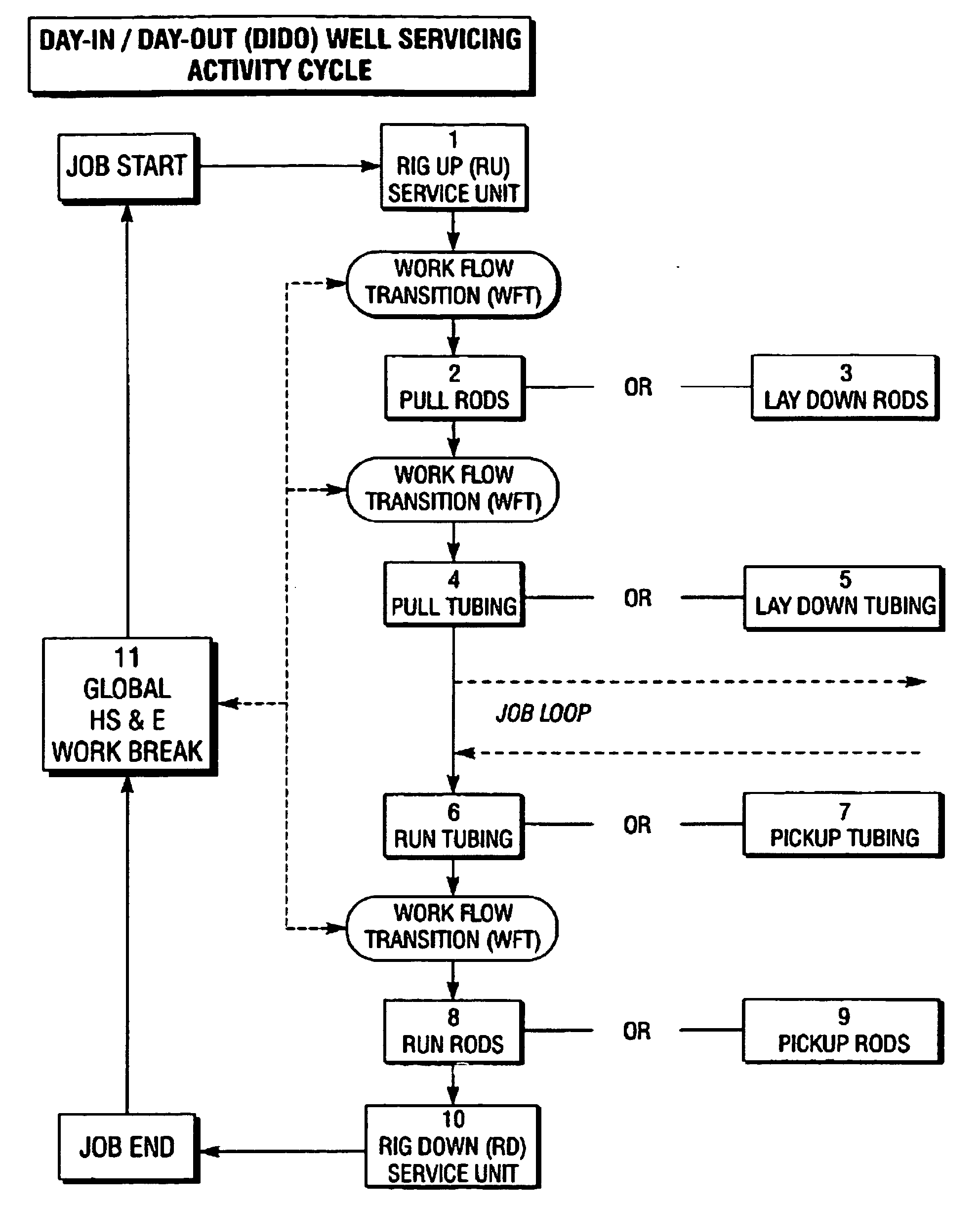

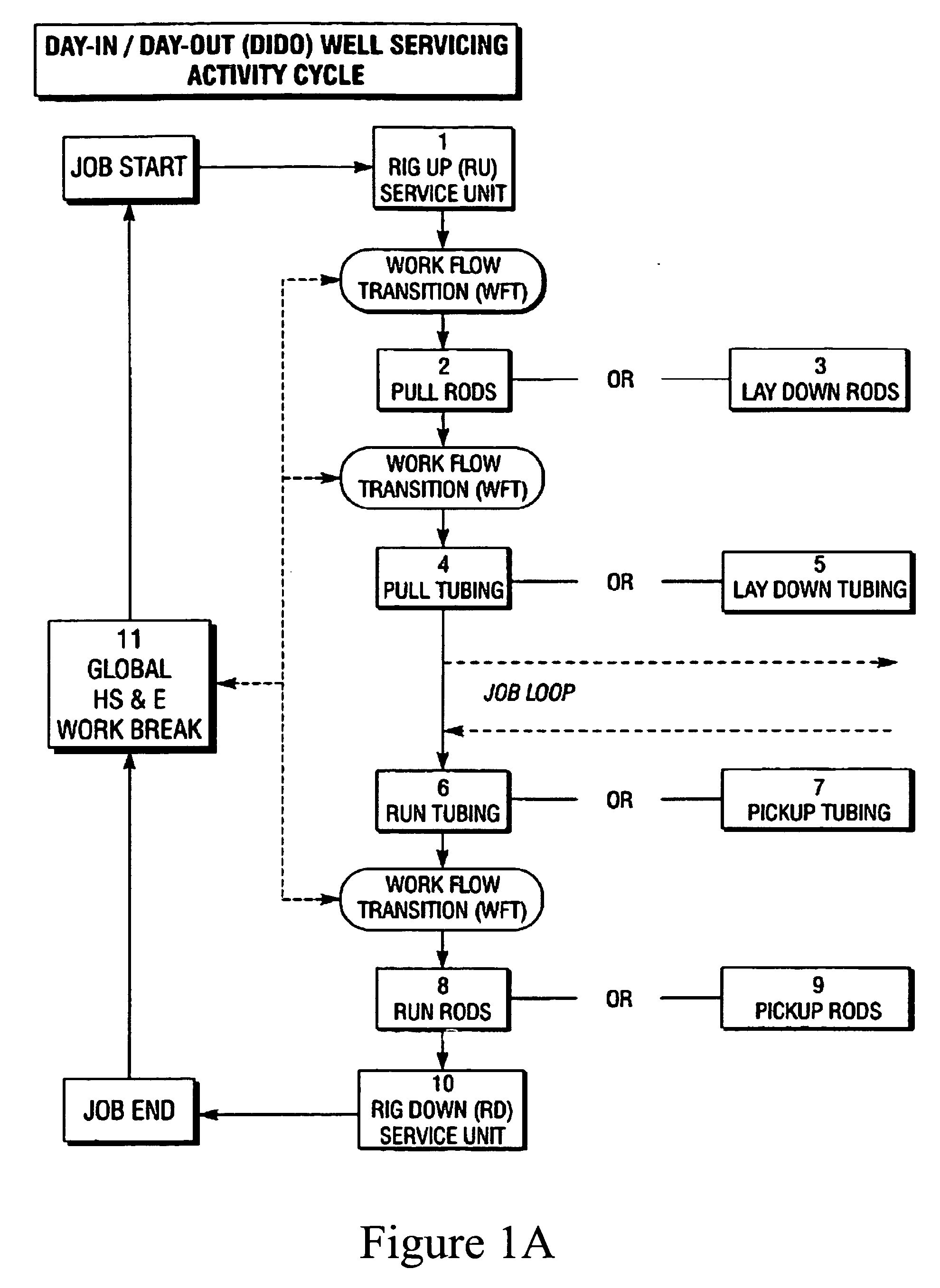

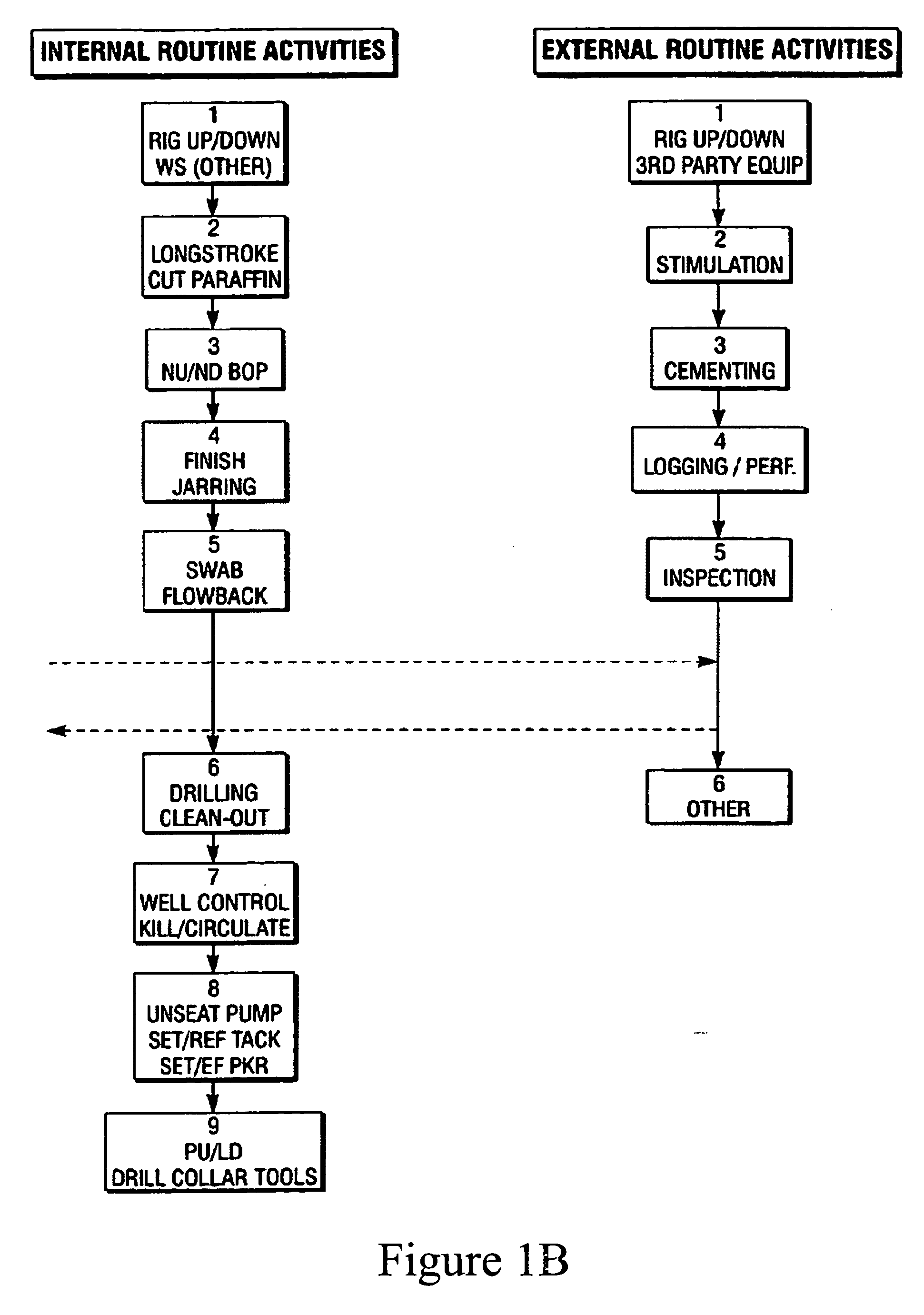

Method and system for evaluating task completion times to data

The present invention is directed to methods of evaluating the operations of a well service rig at a well site by evaluating charts of sensor data obtained from sensors on or associated with the well service rig. An activity listing or Gantt chart can be reviewed and each activity verified by viewing charts of sensor data obtained during that purported activity. In addition service rig downtimes can be determined and evaluated through the evaluation of charts of sensor data. Furthermore, activities and completion times for each activity can be determined by evaluating charts of sensor data obtained from sensors on the service rig or at the well site to verify the operations of the service rig, to improve the efficiency of the operators by identifying long activities and providing additional instruction, and provide improved billing to customers by correcting activities and the time associated therewith.

Owner:KEY ENERGY SERVICES

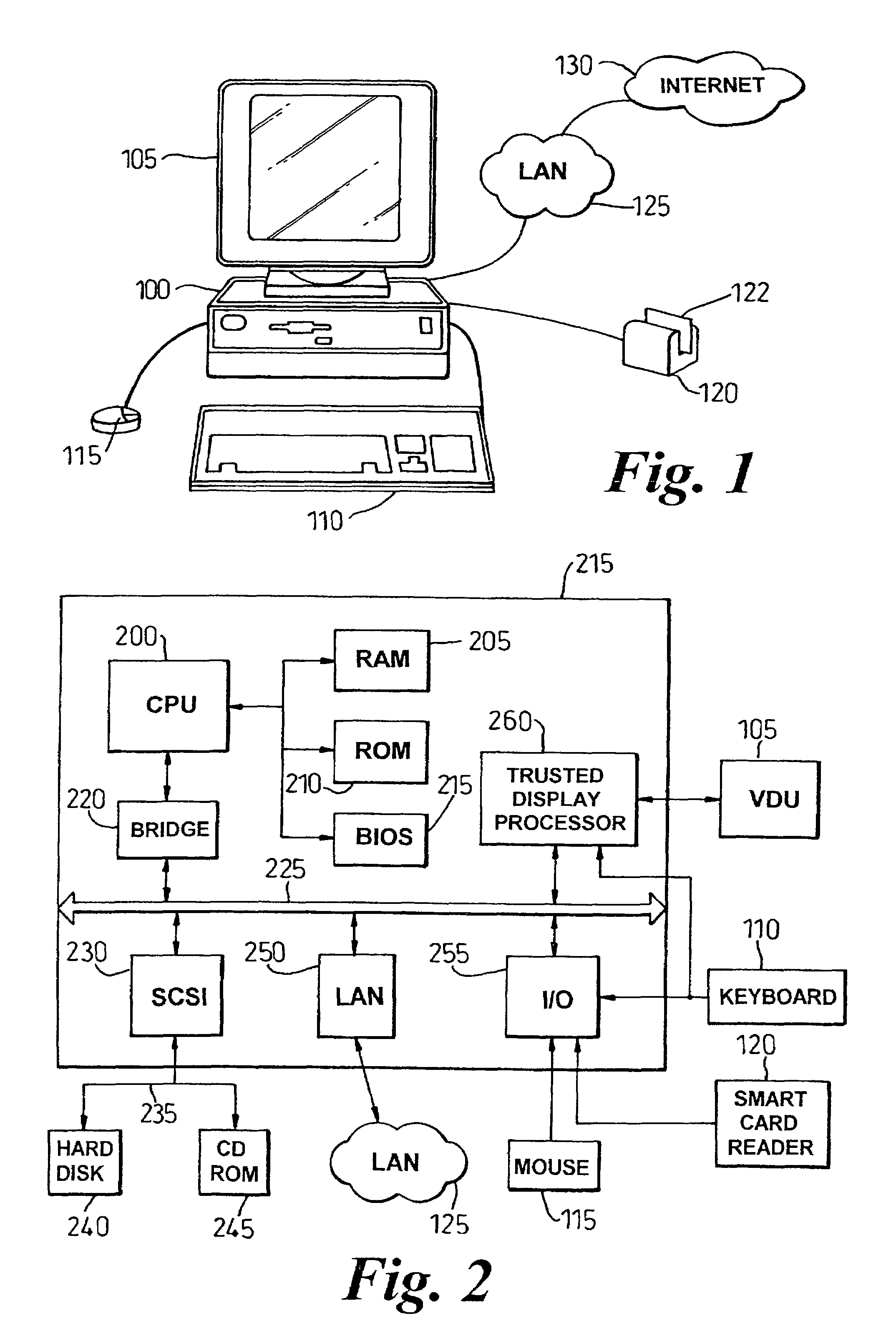

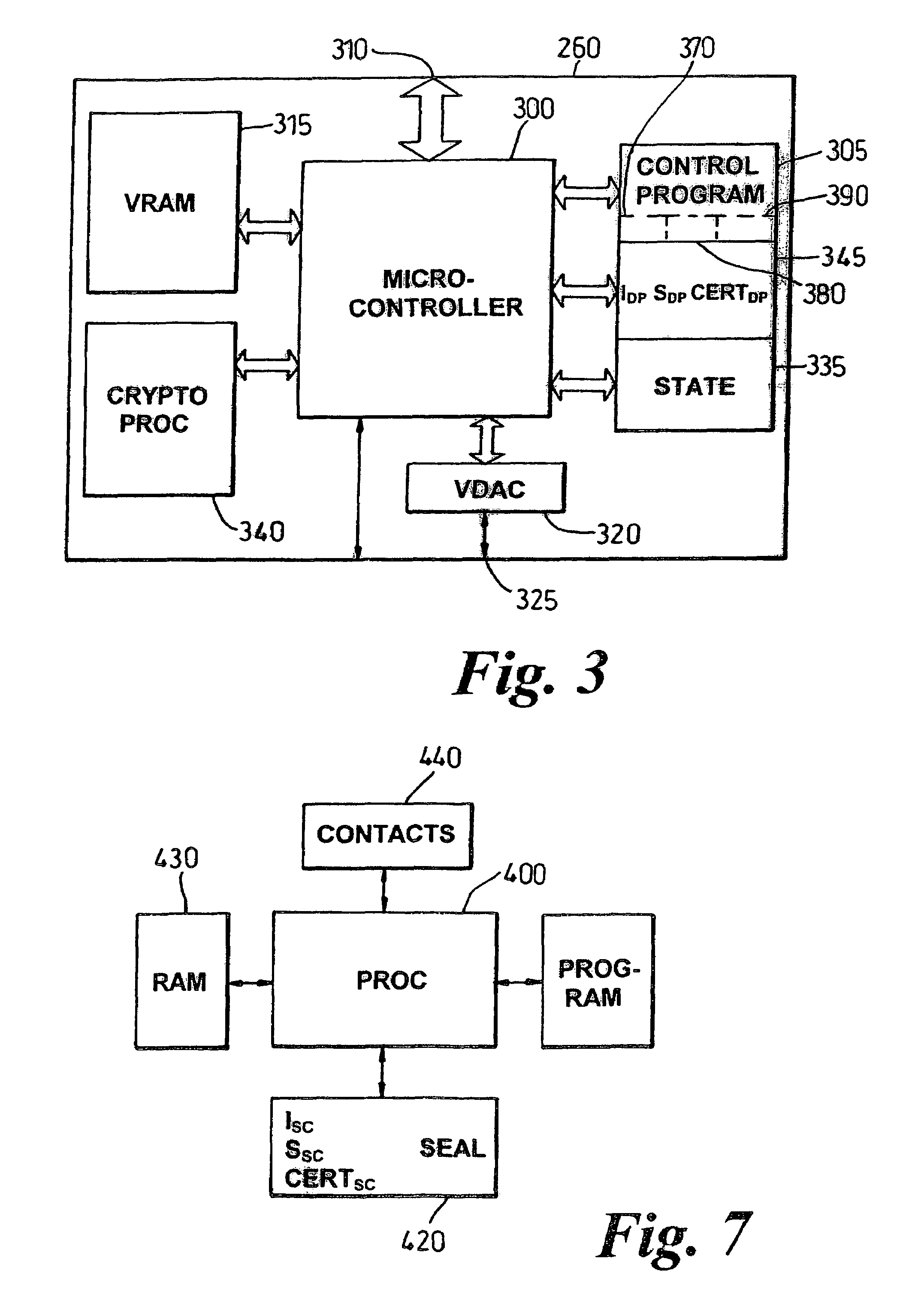

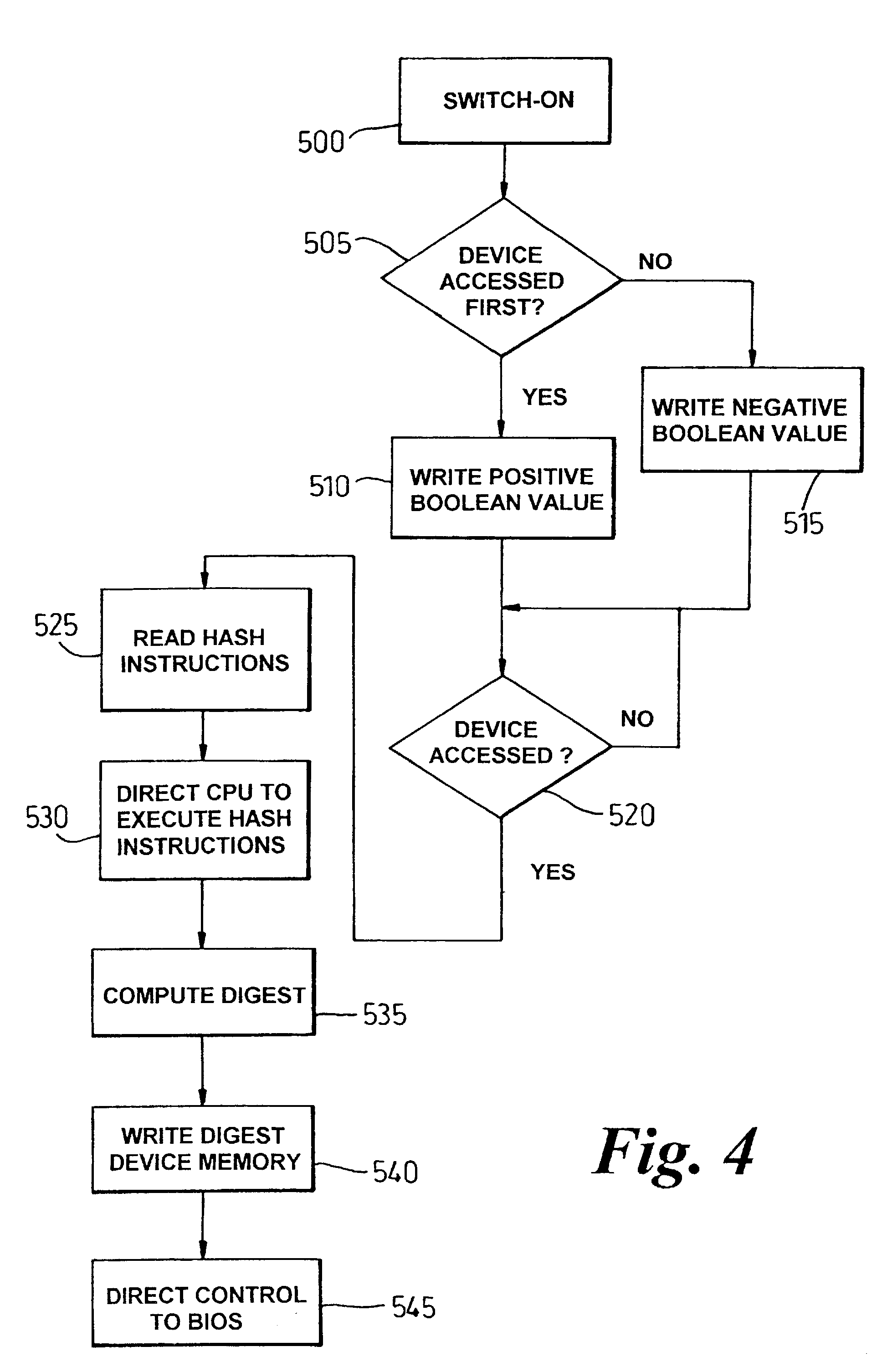

Trusted computing platform for restricting use of data

InactiveUS7526785B1Avoid misuseEffectively protected against attack confidentialityTelevision system detailsData processing applicationsSecure communicationService provision

A client / server system has a client platform adapted to provide restricted use of data provided by a serve. The client platform comprises a display, secure communications means, and a memory containing image receiving code for receiving data from a server by the secure communication means and for display of such data. The client platform is adapted such that the data received from a server is used for display of the data and not for an unauthorised purpose. A server adapted to provide data to a client platform for restricted use by the client platform comprises a memory containing image sending code for providing an image of data executed on the server, and secure communications means for secure communication of images of data to a client platform. The server is adapted to determine that a client platform is adapted to ensure restricted use of the data before it is sent by the image sending code.

Owner:HEWLETT PACKARD DEV CO LP

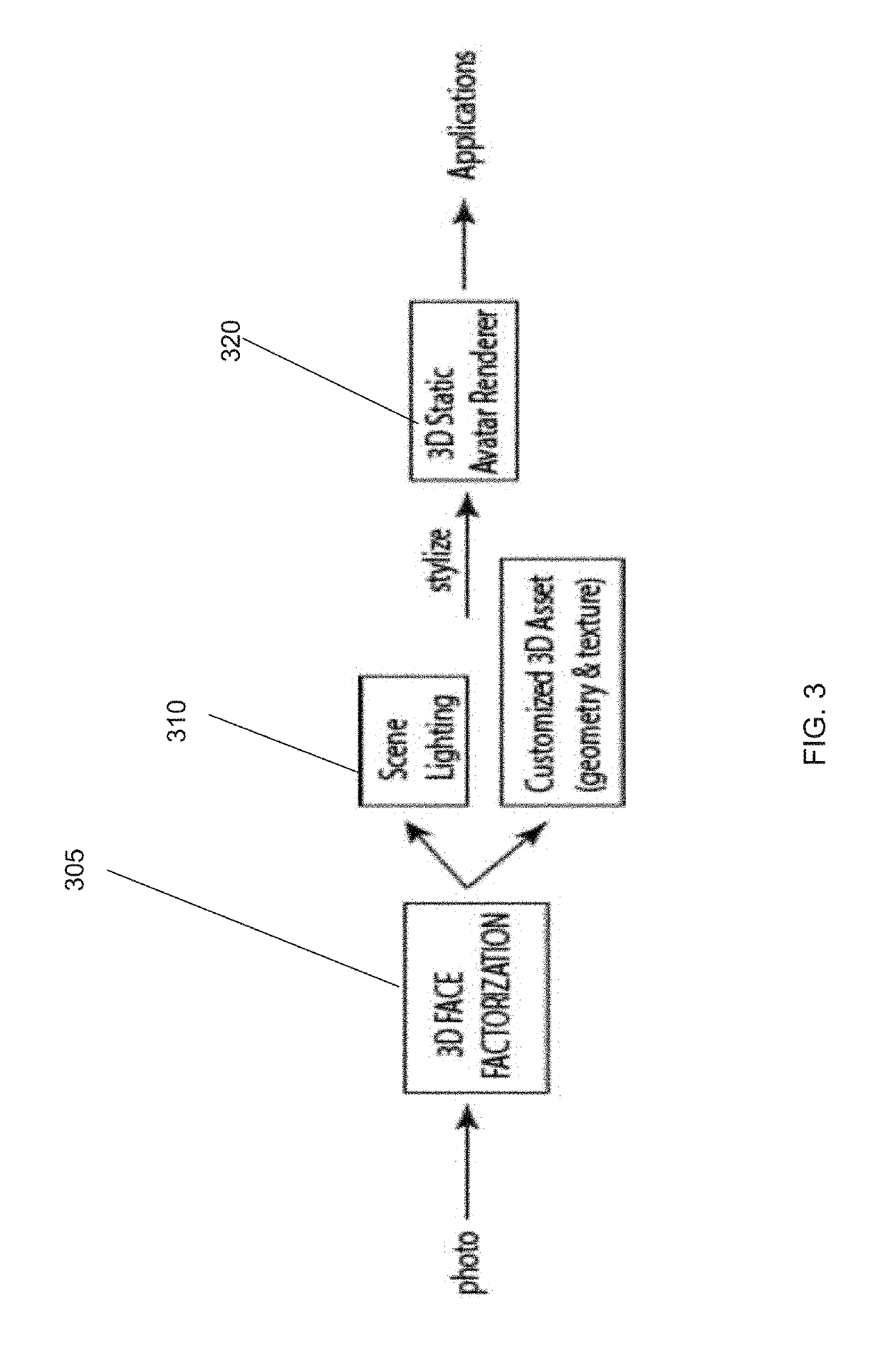

Systems and Methods for Generating Computer Ready Animation Models of a Human Head from Captured Data Images

System and methods for computer animations of 3D models of heads generated from images of faces is disclosed. A 2D captured image that includes an image of a face can be received and used to generate a static 3D model of a head. A rig can be fit to the static 3D model to generate an animation-ready 3D generative model. Sets of rigs can be parameters that each map to particular sounds or particular facial movement observed in a video. These mappings can be used to generate a playlists of sets of rig parameters based upon received audio or video content. The playlist may be played in synchronization with an audio rendition of the audio content. Methods can receive a captured image, identify taxonomy attributes from the captured image, select a template model for the captured image, and perform a shape solve for the selected template model based on the identified taxonomy attributes.

Owner:LOOMAI INC

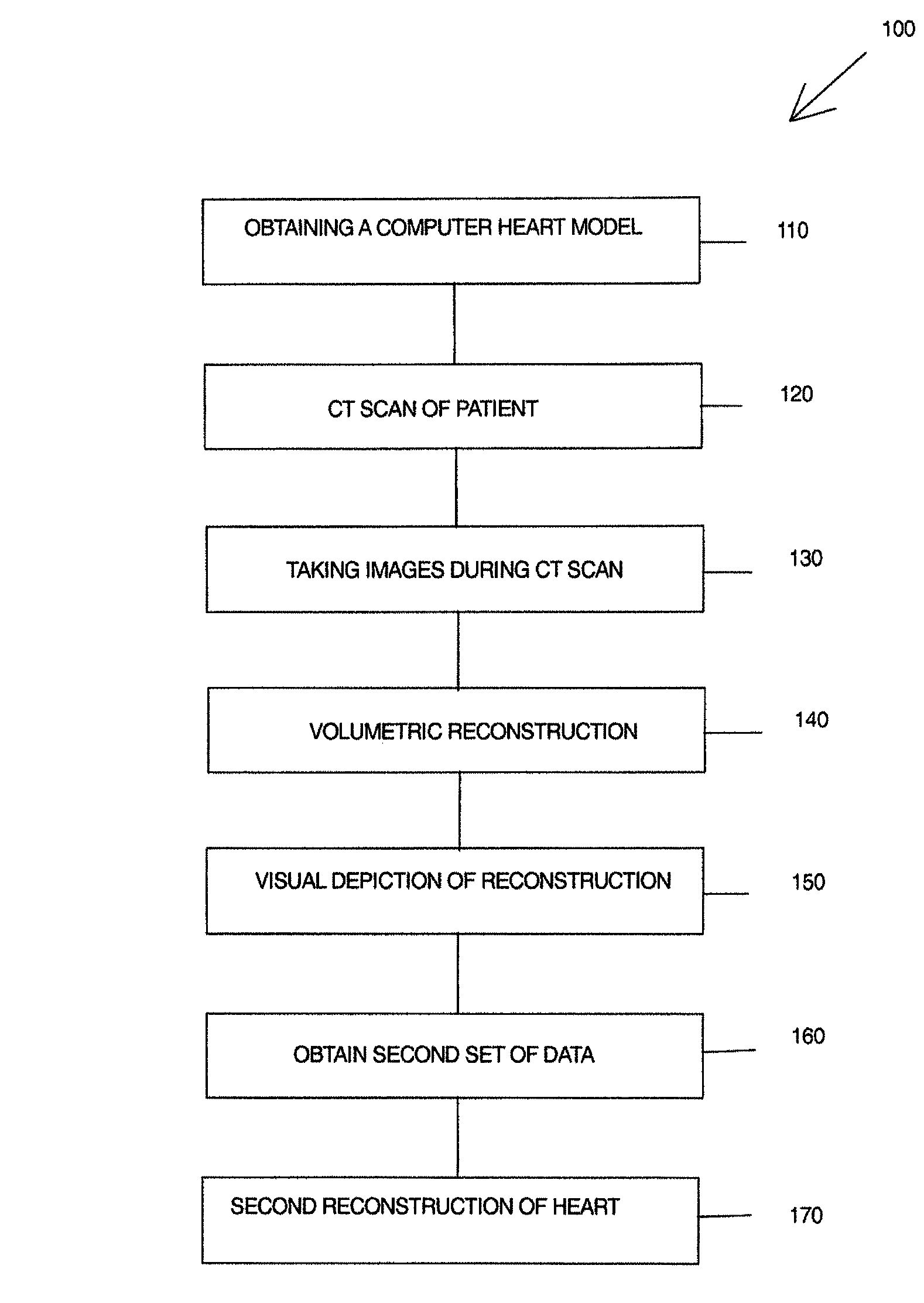

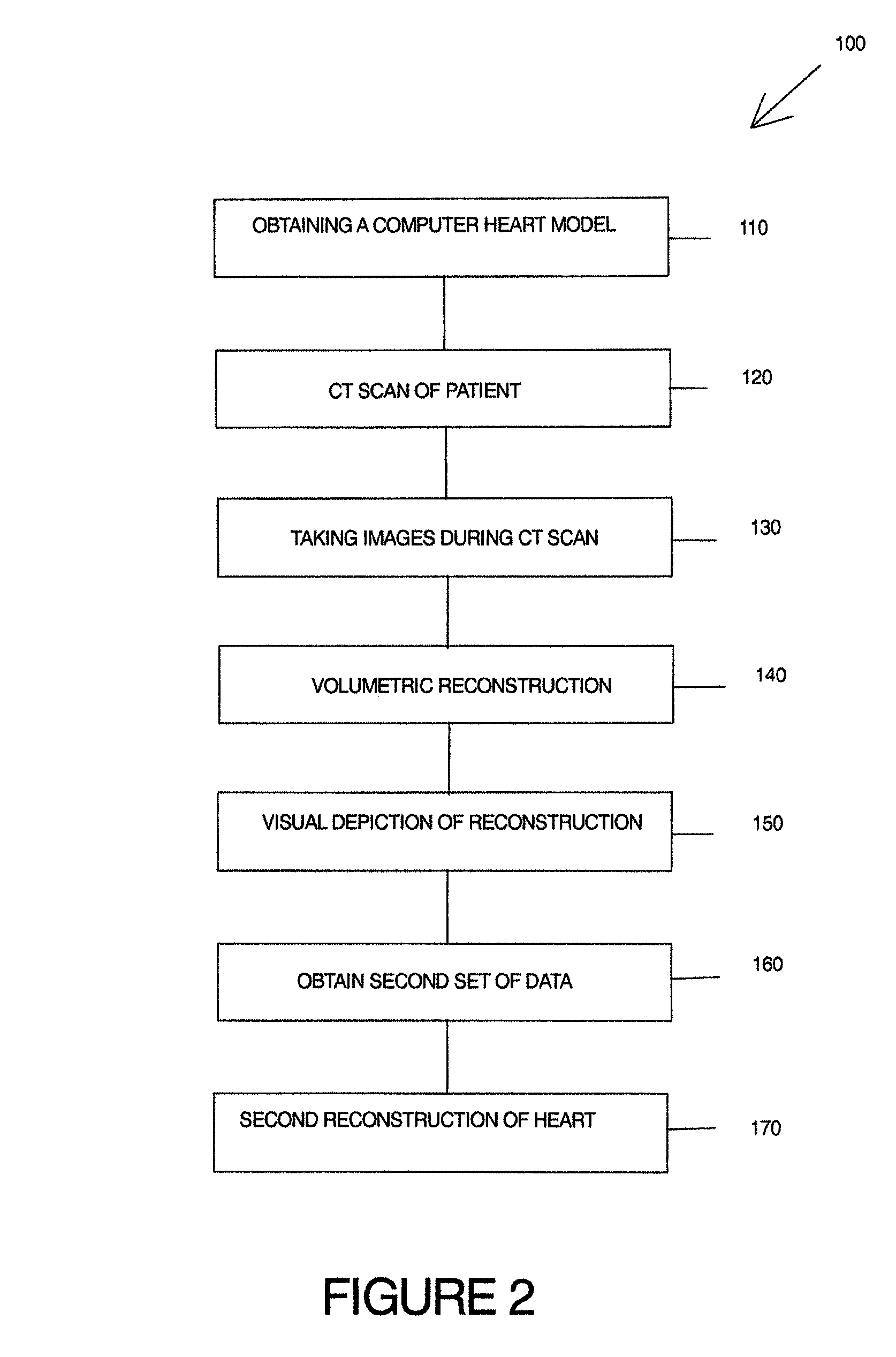

Model-based heart reconstruction and navigation

ActiveUS7773719B2Provide structureMinimize exposureImage enhancementImage analysisBase heartData set

A method to obtain a patient based organ model from patient data, having steps of obtaining a computerized organ model based upon at least one data set of patients, the computerized organ model having a set of classifiers that are used to determine physical parameters of the patients heart, placing the patient in a diagnostic scanner device, taking representative data images of a patients organ while changing position of the image scan, the data images taken with ECG synchronization; and preparing the patient based organ model by evaluating the representative data images of the patients organ with the set of classifiers in the computerized organ model.

Owner:SIEMENS HEALTHCARE GMBH

Memory data copying system for devices

ActiveUS20050005102A1Optimized for speedEasy to controlElectronic circuit testingBootstrappingComputer hardwareOperational system

A portable device is equipped with a broadcasting operating mode in which the broadcasting portable device executes a verbatim memory data image copying to another device or plurality of devices equipped with receiving modes of operation. Single-threaded OS free commands may be utilized to control both the broadcasting and receiving devices during a data copy session. In another aspect, a reprogramming system includes a symbol generator and a reconfigurable device. The symbol generator processes user input data to encode a reprogramming symbol, and the reconfigurable device reads the reprogramming symbol.

Owner:HAND HELD PRODS

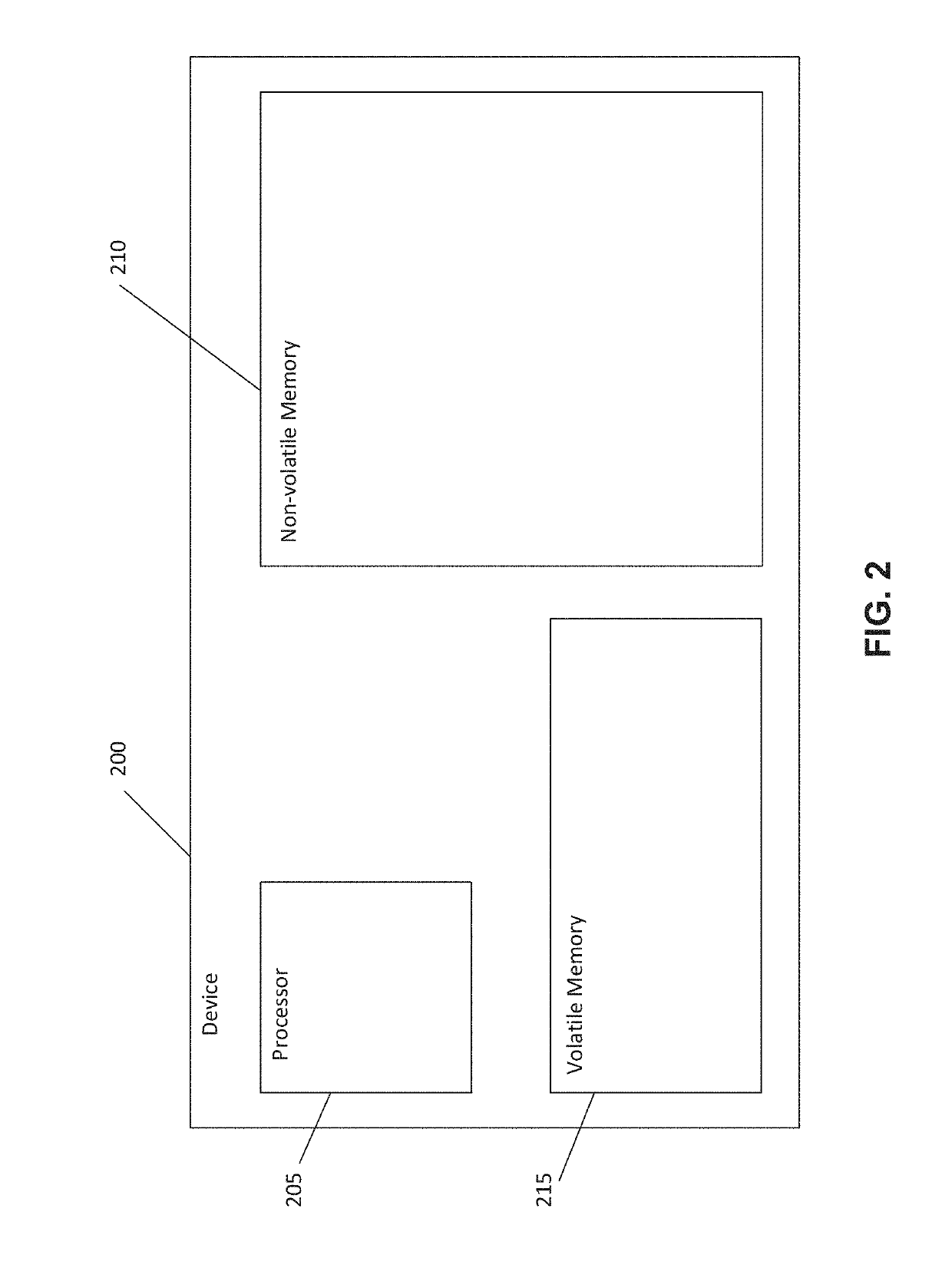

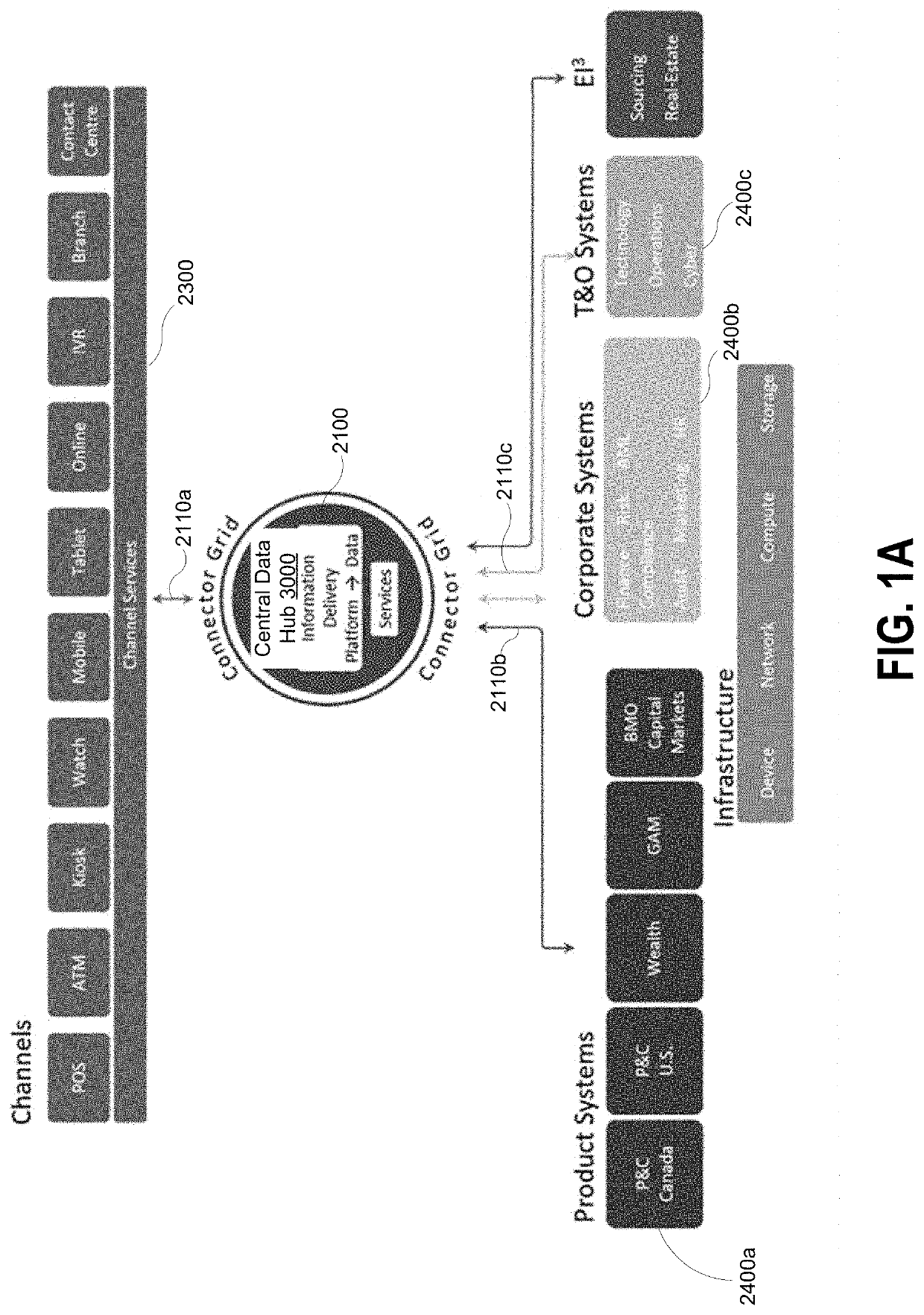

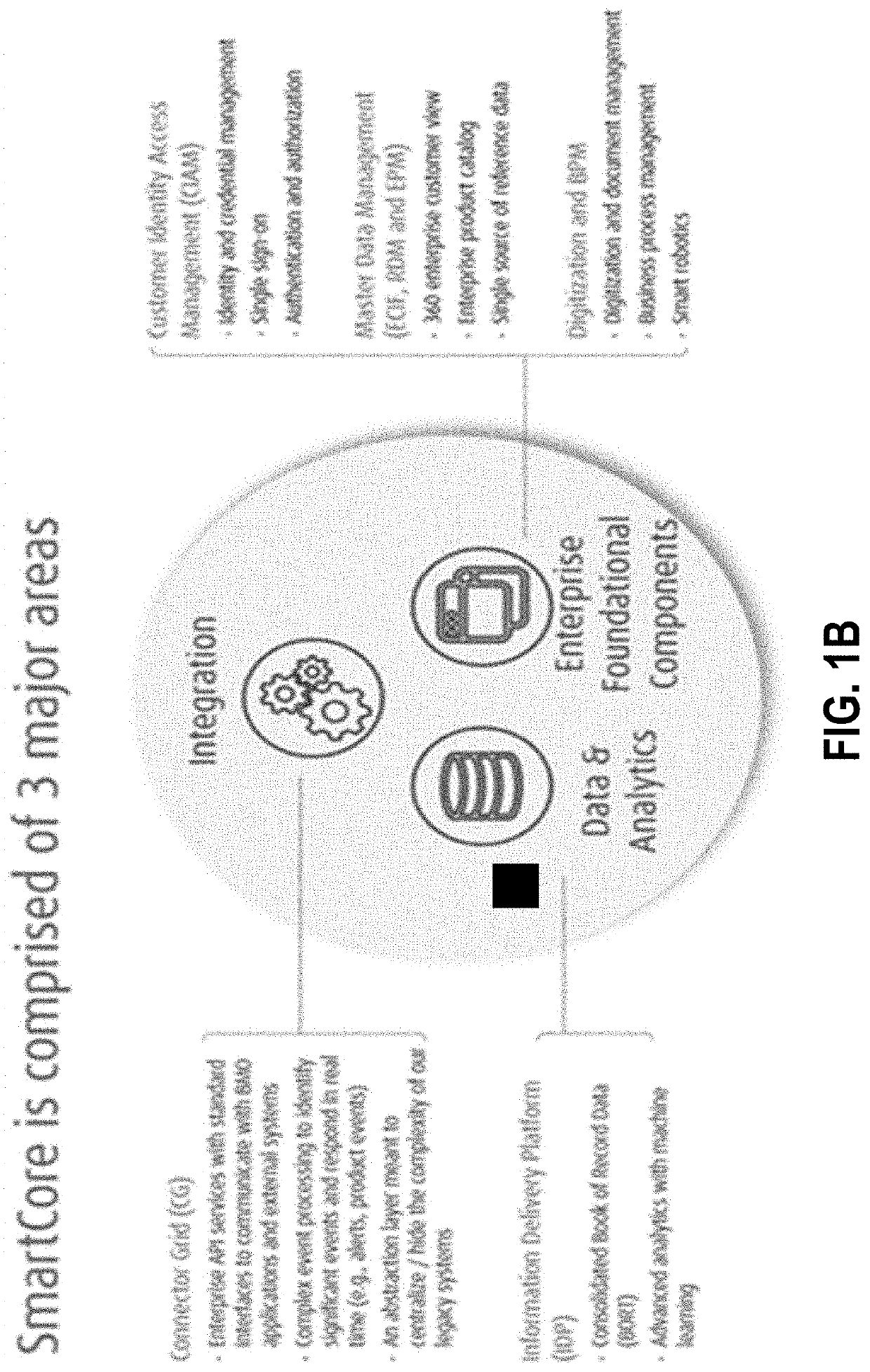

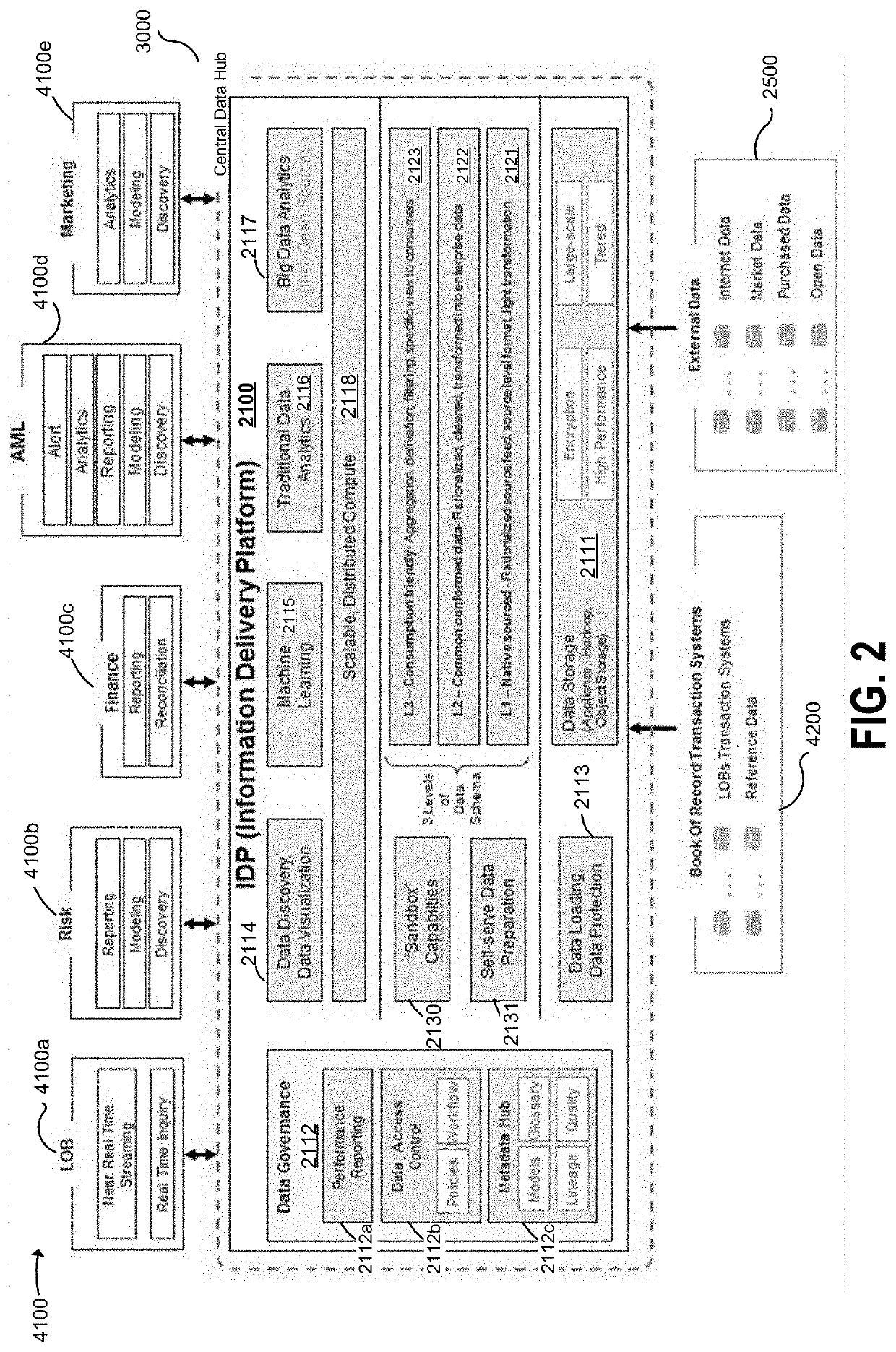

Systems and methods for data storage and processing

ActiveUS20200026710A1Easy to useMaximum efficiencyDatabase management systemsMachine learningData setData graph

Systems and methods for processing data are provided. The system may include at least a processor and a non-transient data memory storage, the data memory storage containing machine-readable instructions for execution by the processor, the machine-readable instructions configured to, when executed by the processor, provide an information delivery platform configured to: extract raw data from a plurality of source systems; load and store the raw data at a non-transient data store; receive a request to generate data for consumption for a specific purpose; in response to the request, select a set of data from the raw data based on a data map; transform the selected set of data into a curated set of data based on the data map; and transmit the curated set of data to a channel for consumption.

Owner:BANK OF MONTREAL

Method and system for integrated orthodontic treatment planning using unified workstation

InactiveUS20080280247A1Efficient and cost-effective treatment planHigh simulationMedical simulationImpression caps3d imageWorkstation

A method and workstation for orthodontic treatment planning of a patient. The workstation is based on a computing platform having a graphical user interface, a processor and a computer storage medium containing digitized records pertaining to a patient including image data (3D image data and / or 2D image data). The workstation further includes a set of software instructions providing graphical user interface tools which the user marks a midline and an aesthetic occlusal plane in a two- or three-dimensional virtual model of the patient, marks an occlusal plane in the virtual model; selects a reference tooth in the virtual model; aligns virtual teeth in the virtual model in a proposed arrangement to treat the patient; manages space between the virtual teeth in the proposed arrangement; and repeats one or more of these steps in an iterative fashion to make any further adjustments in the proposed arrangement. When the adjustments are complete, the user selects or identifies a finalized proposed treatment plan for treating the patient.

Owner:ORAMETRIX

Automatic patient and device recognition and association system

ActiveUS8565500B2Character and pattern recognitionPatient personal data managementMedical equipmentData graph

A system associates a patient and patient identifier with a medical device and includes an interface. The interface acquires data representing an image of a patient in a care setting and showing a medical device in the vicinity of the patient and acquires data identifying the patient. An image data processor analyzes the acquired data representing the image to identify the medical device type by, analyzing the acquired data to determine a shape of the medical device, comparing the determined shape of the medical device with predetermined template shapes of known device types and identifying the medical device type in response to the shape comparison indicating a shape match. A data processor associates the identified medical device type with the data identifying the patient. An output processor initiates generation of data indicating an association of the identified medical device type with the data identifying the patient.

Owner:CERNER INNOVATION

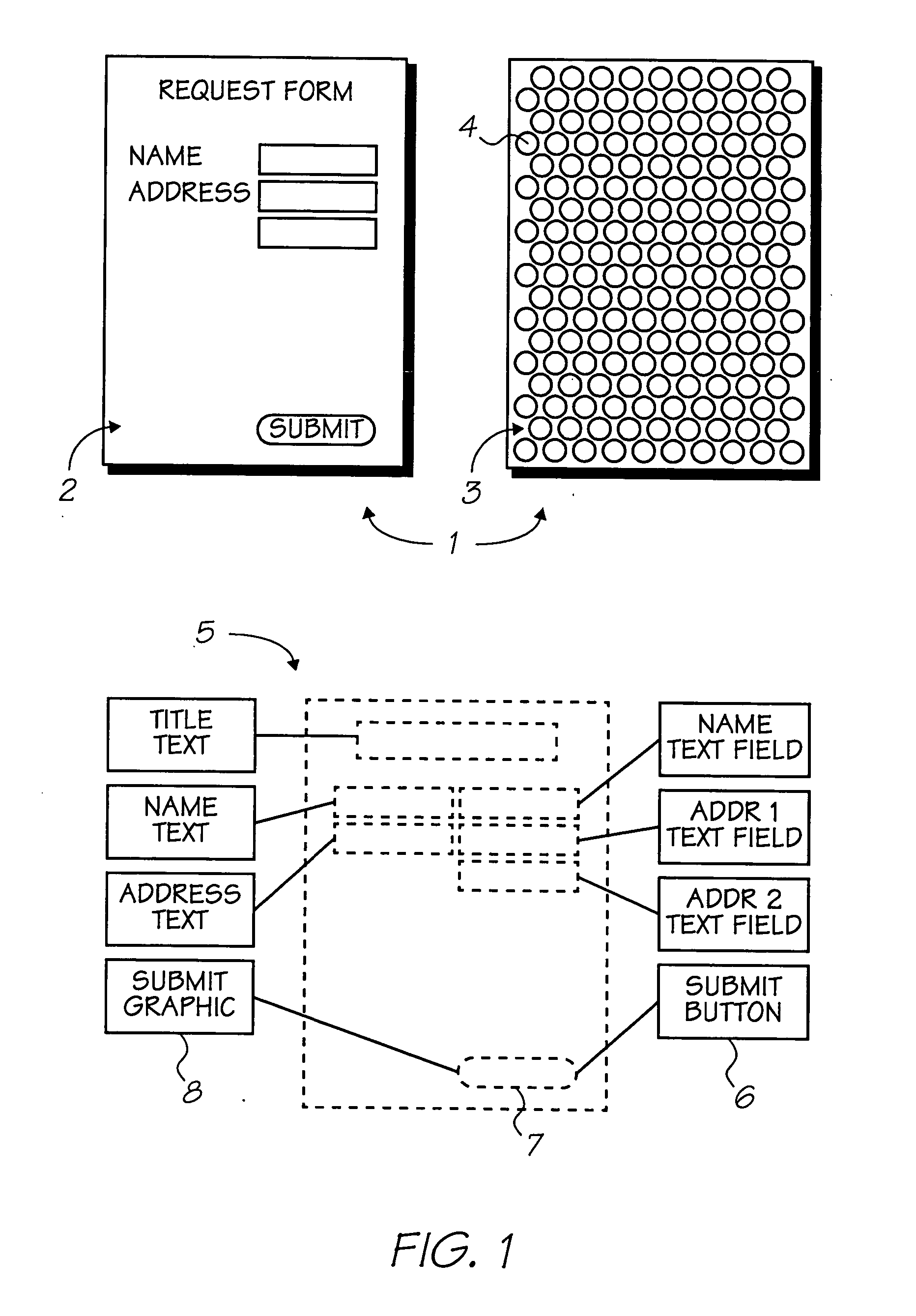

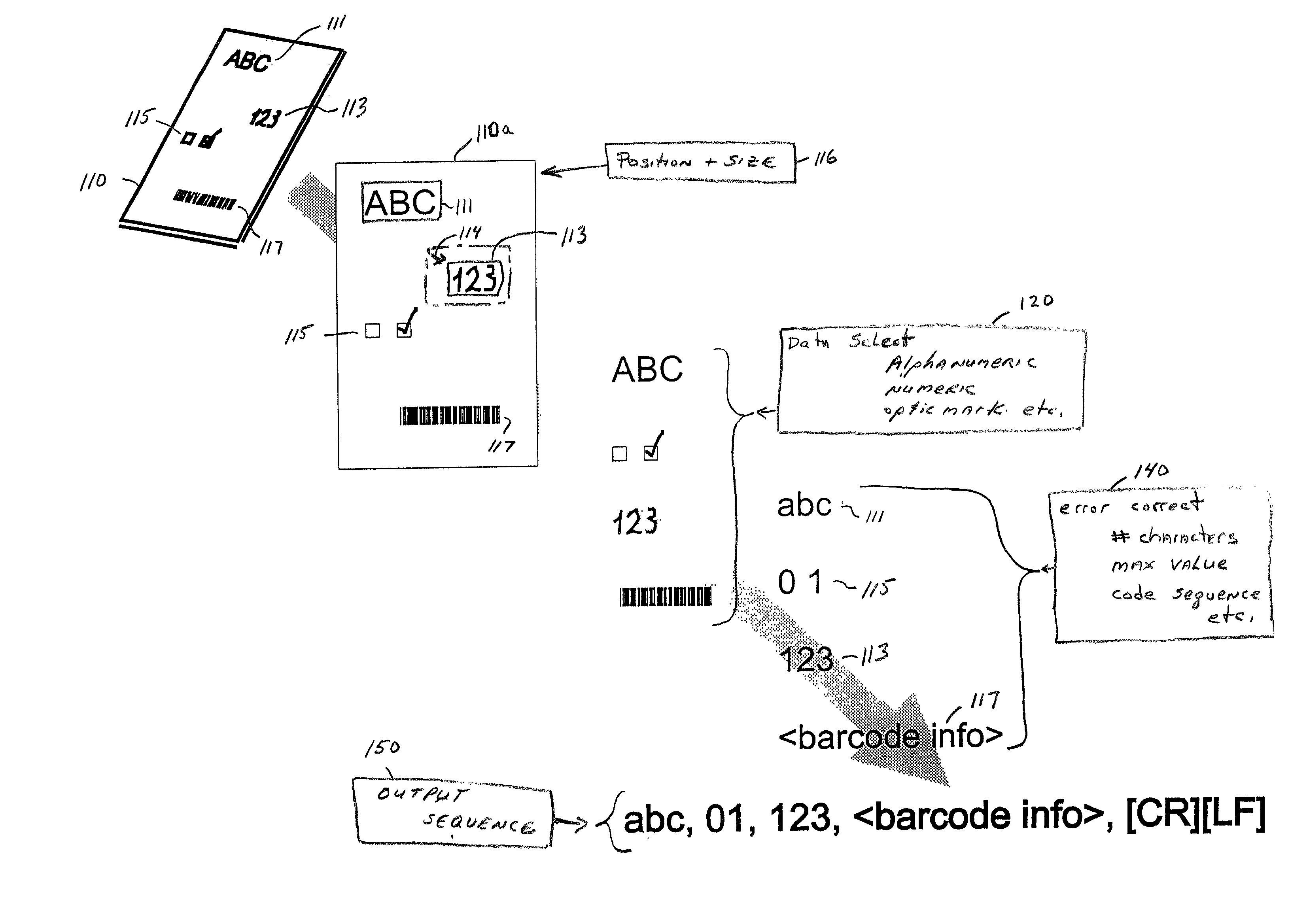

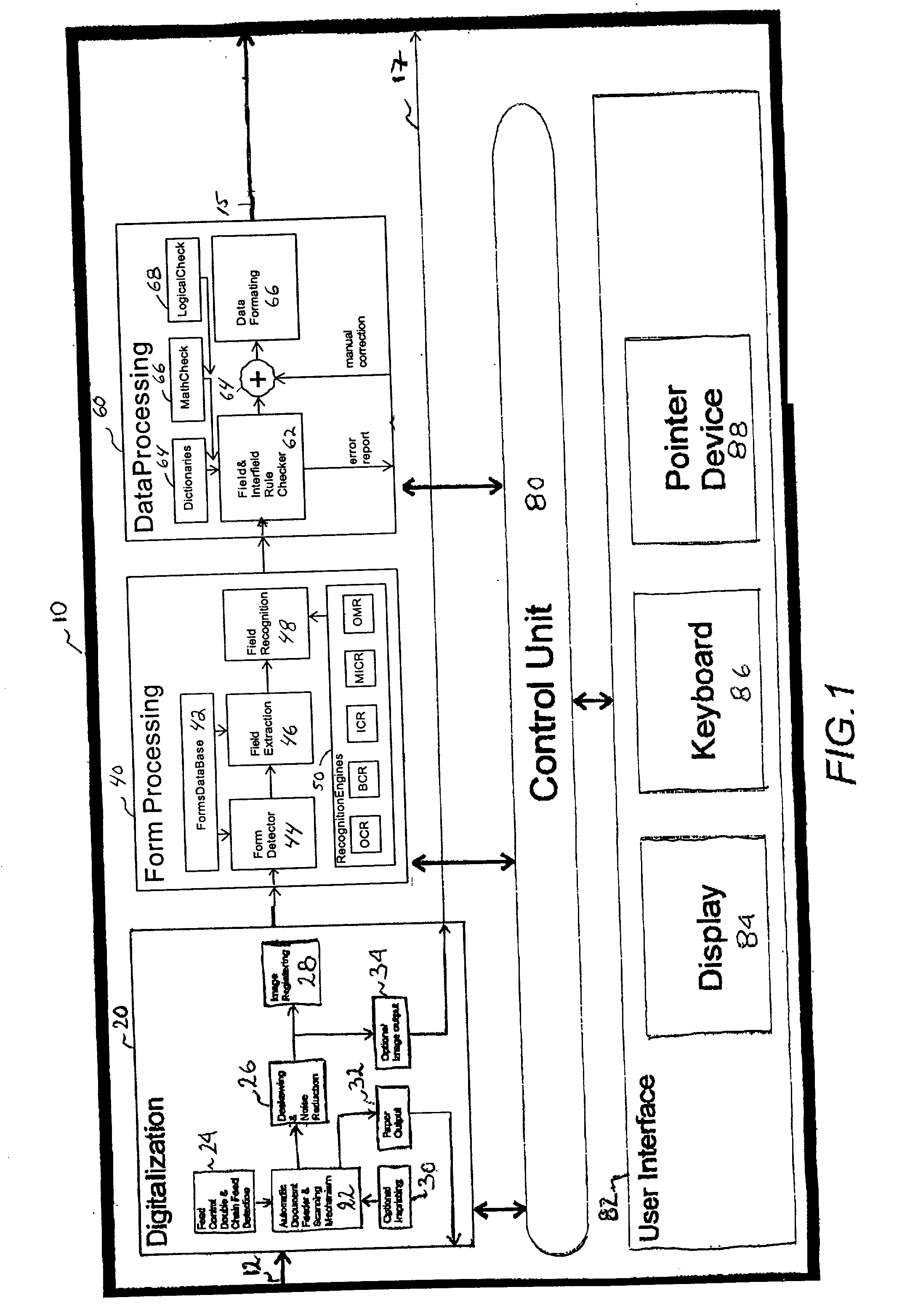

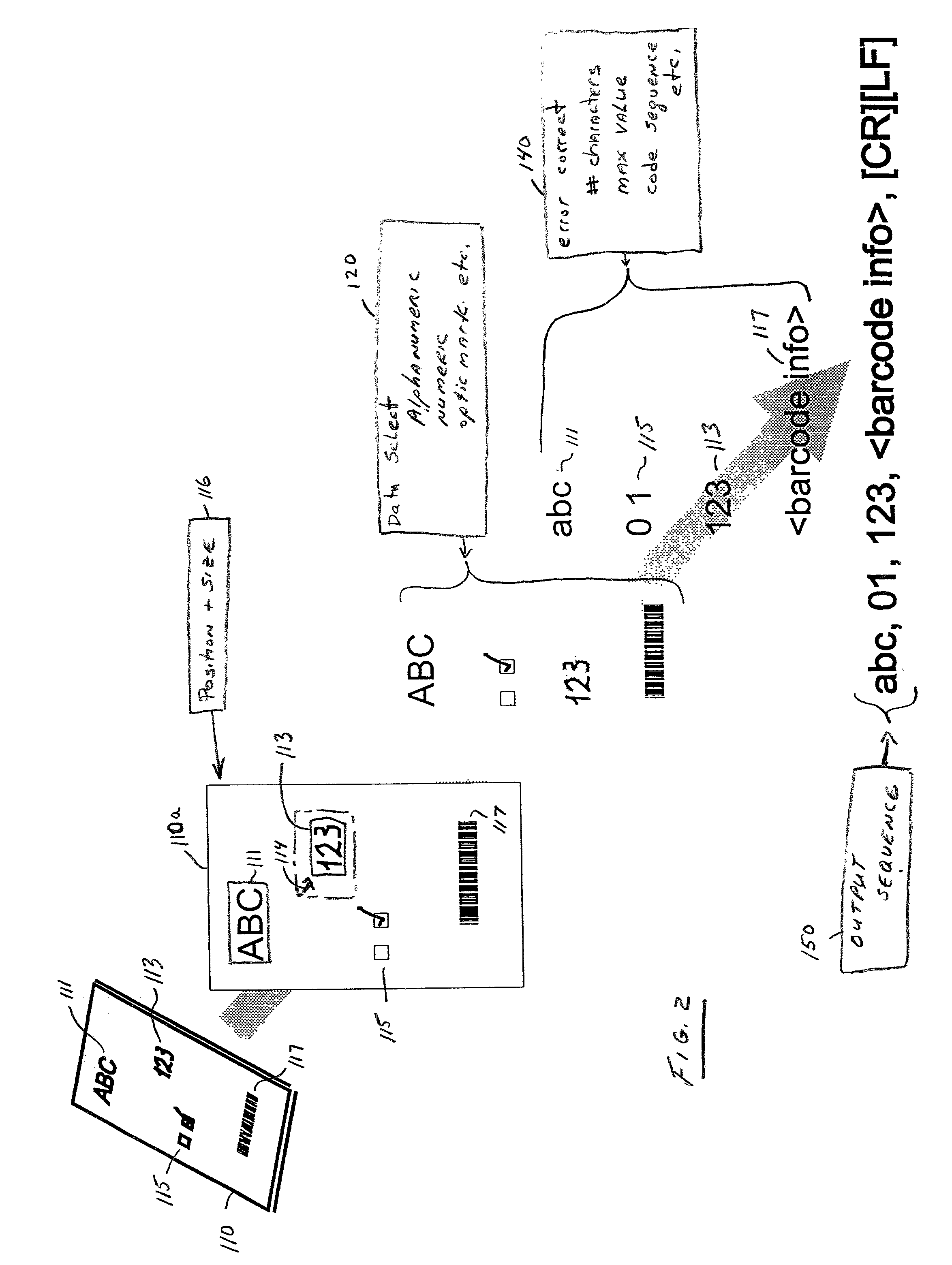

Document scanner, system and method

The document scanner, system and method operates in conjunction with a document imprinted with data and a plurality of form documents adapted to have data imprinted thereon. The documents have at least one and typically many data image fields. Ultimately, the document scanner, system and method outputs a delimited string of decoded characters to another computer system via a common computer communications port. The method includes either scanning a form document to obtain positional information of the data field or fields or inputting a topological description of the field. Typically, the operator identifies descriptors for each data field which include data field size information, data type information, the presence or absence of data validation parameters, the presence or absence of data error reporting and data correction routines or parameters, and data output destination information. The data output destination information locates the decoded data in a certain sequence or location in the delimited string of decoded characters output to the coupled computer system. The document scanner, system and method scans the document imprinted with data and captures an image thereof. The scanned input document image is compared with the stored forms, and particularly the stored data field descriptors utilizing positional, data field size and data type information. The system selects one of the stored forms, extracts the data from each data field, decodes or calculates the data, and validates the data (in the presence of data validation parameters) and stores the decoded / calculated data. A data error reporting and data correction system, activated in the presence of the data error reporting and correction descriptor, enables correction of errors.

Owner:MULTISCAN

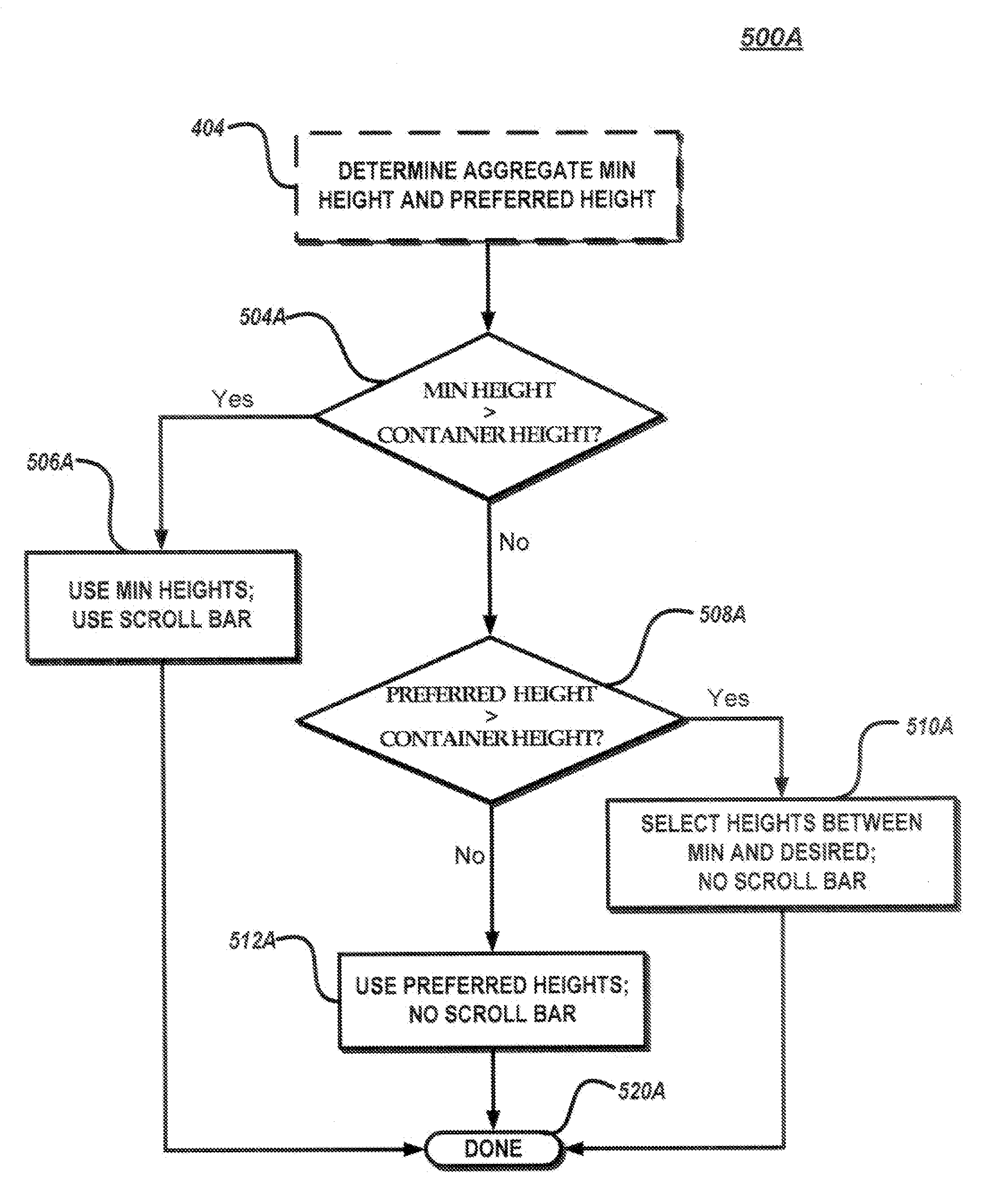

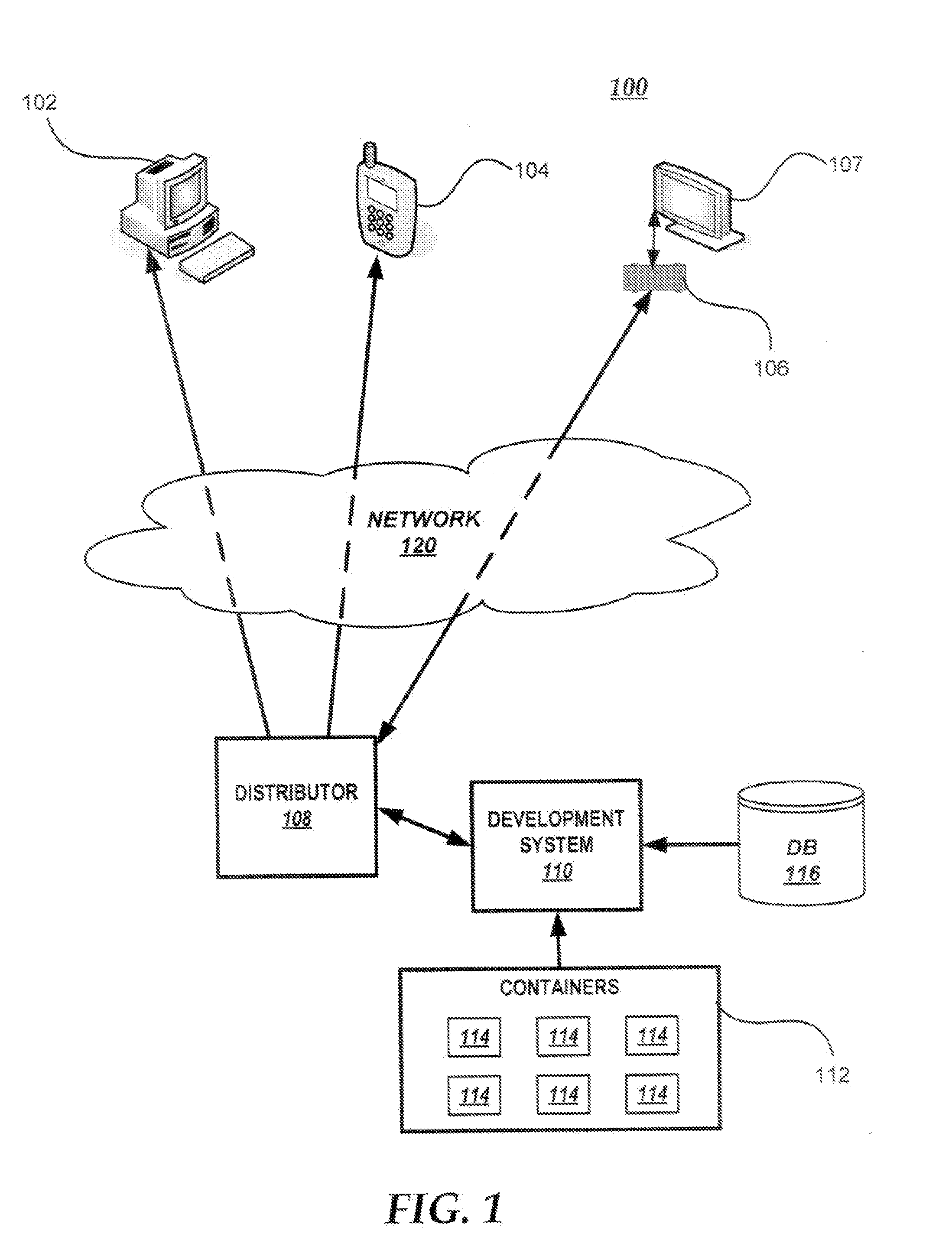

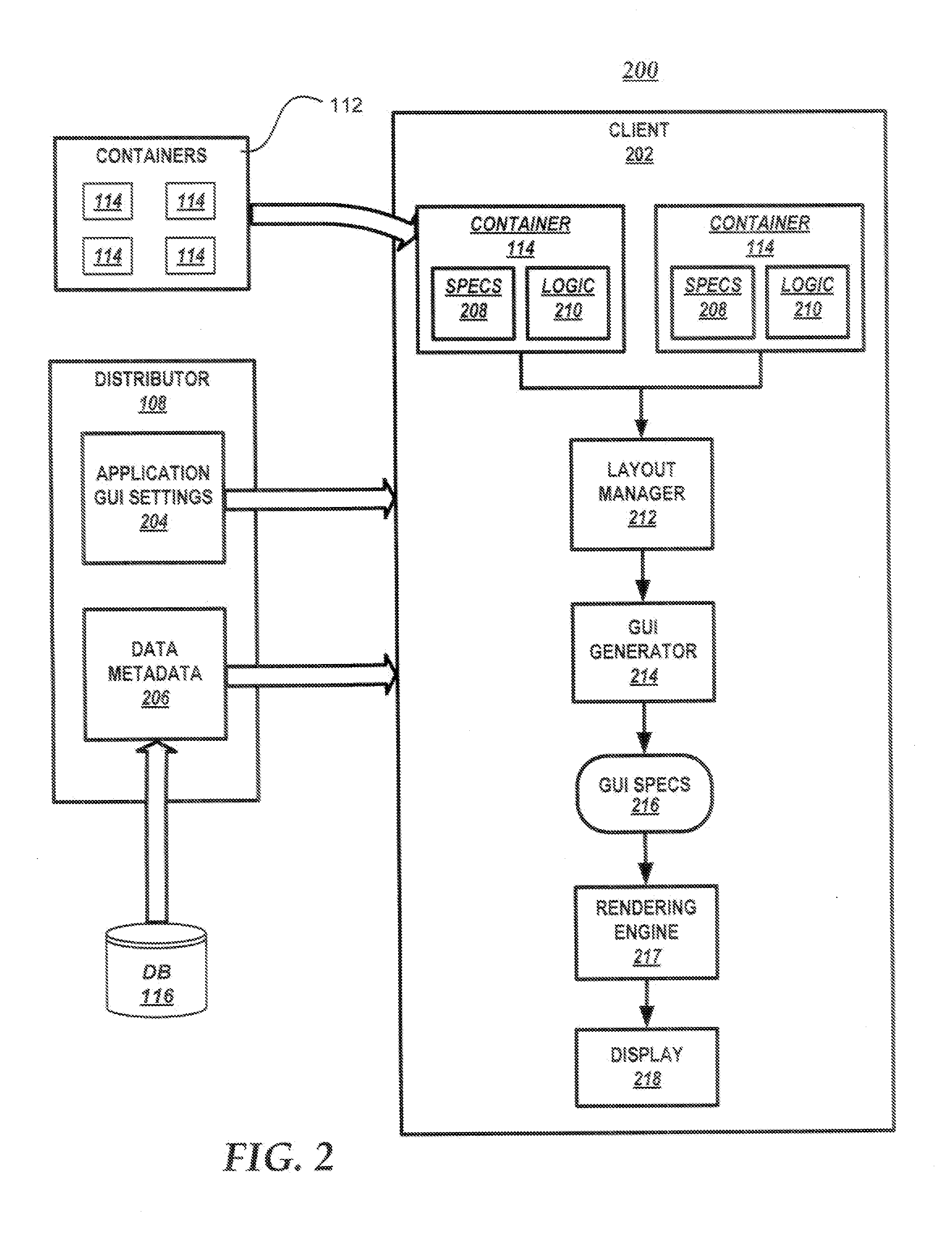

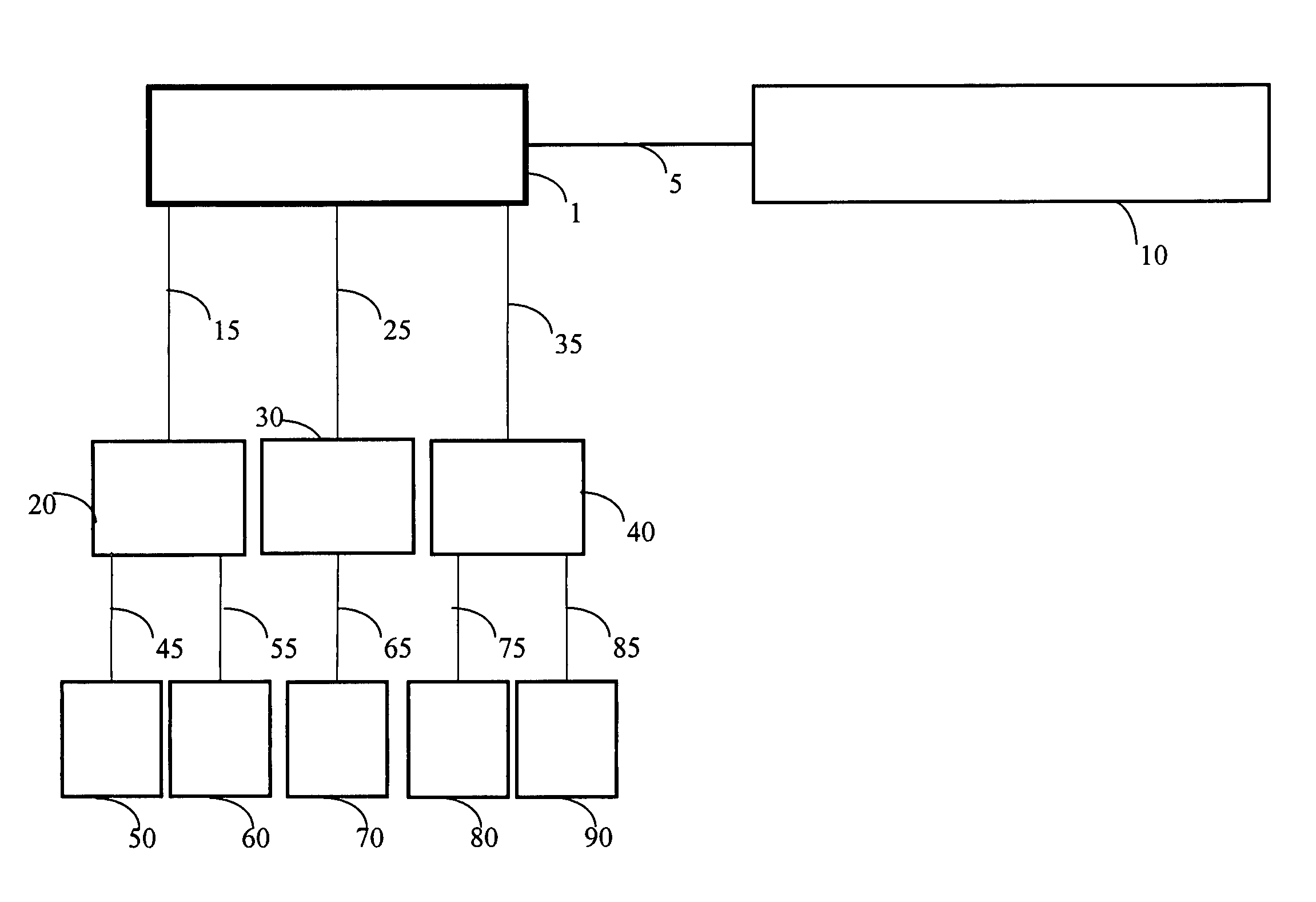

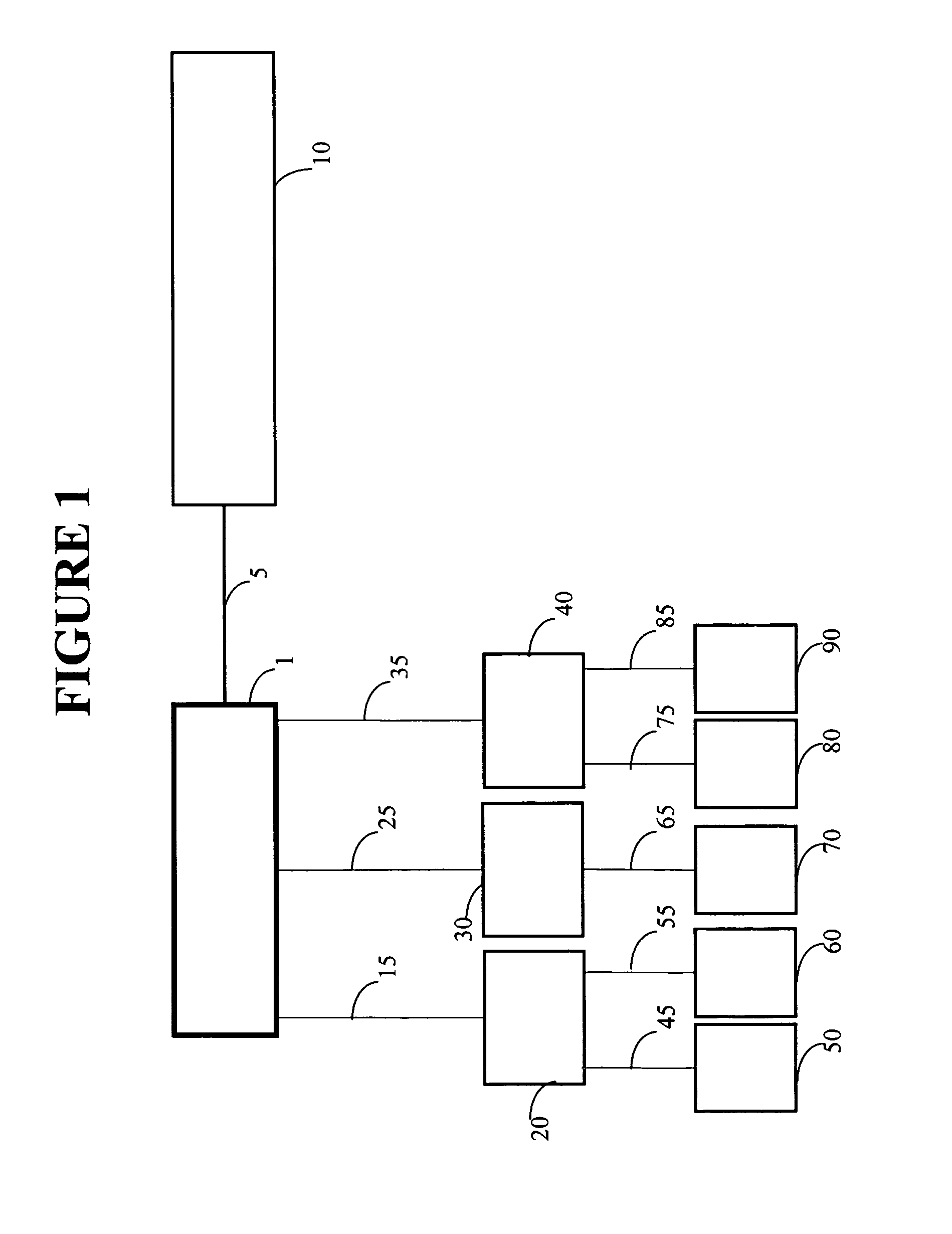

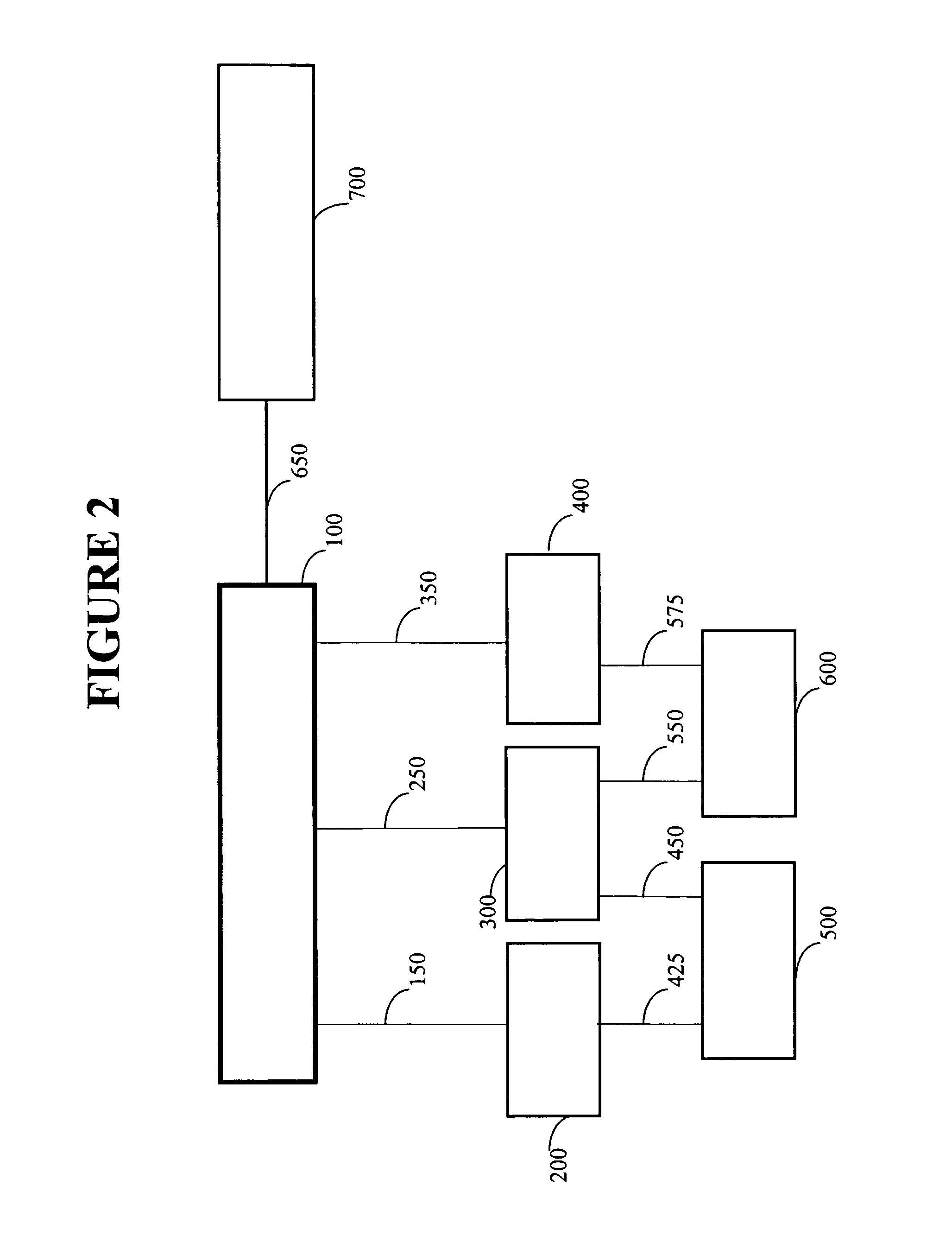

Dynamic graphical user interface layout

InactiveUS20110099494A1Well formed2D-image generationInput/output processes for data processingGraphicsProgram instruction

A system and method for laying out graphical user interface elements at a client device. A client device receives a set of containers, each container including program instructions and specifications. The program instructions of each container are executed to determine a size and position of each graphical user interface element. Each type of container has corresponding logic upon which sizing and positioning of graphical user interface elements is based. The client device may receive data metadata descriptive of the graphical user interface elements and application specifications. Sizing and positioning of the graphical user interface elements may be based on the data metadata and application specifications. A layout process may recursively descend a structure of containers to determine sizes and positions of each GUI element.

Owner:MICROSOFT TECH LICENSING LLC

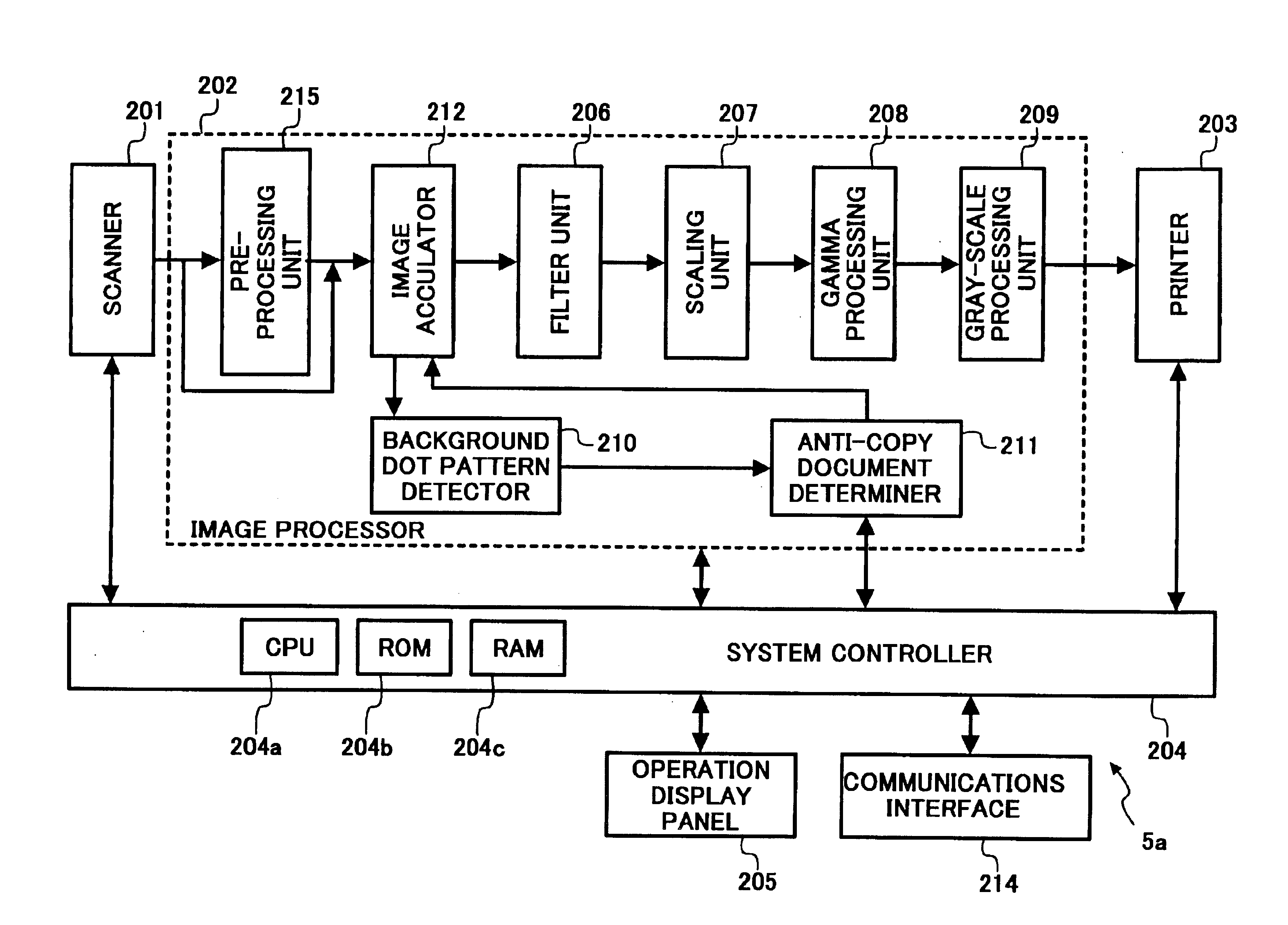

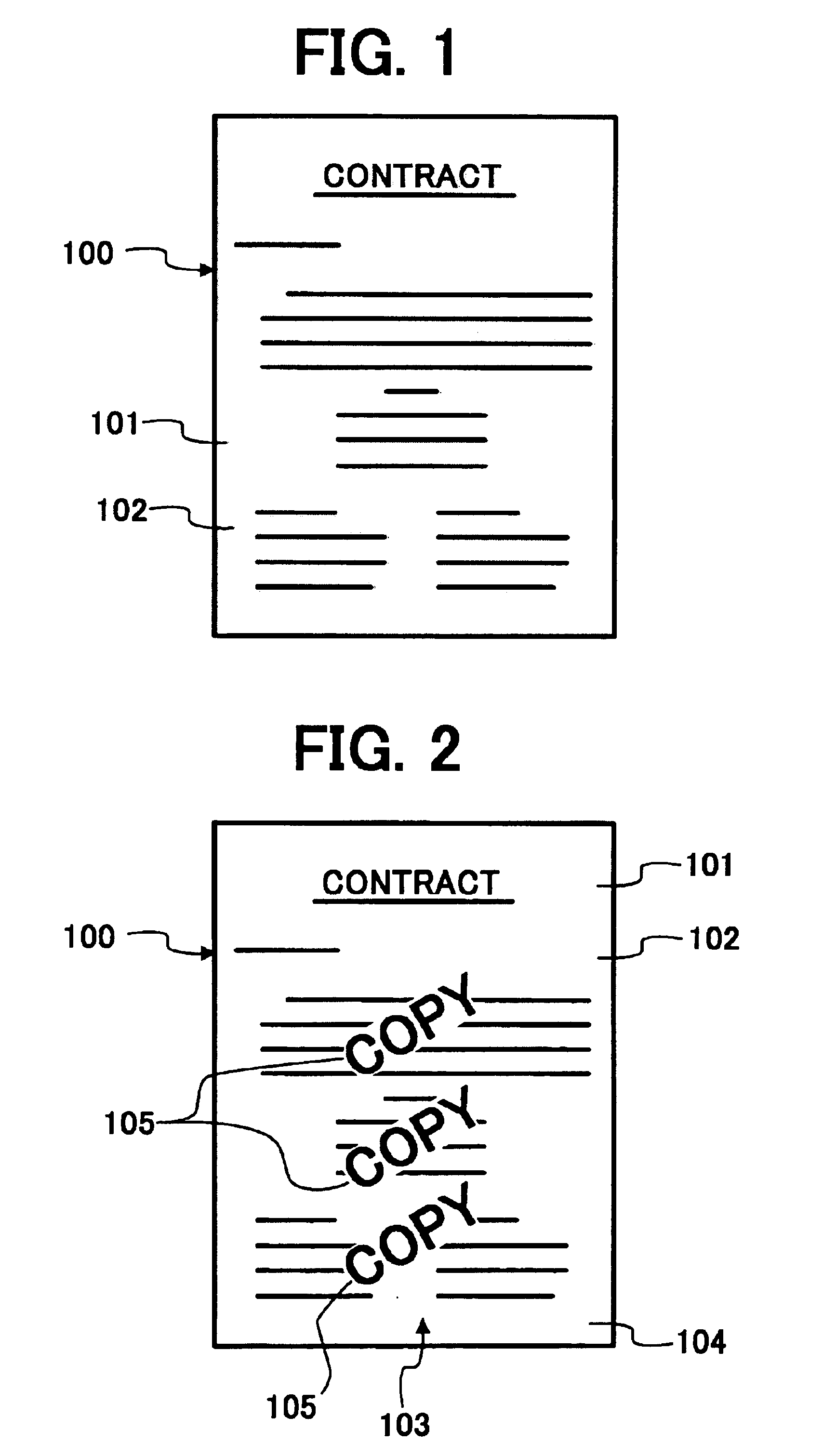

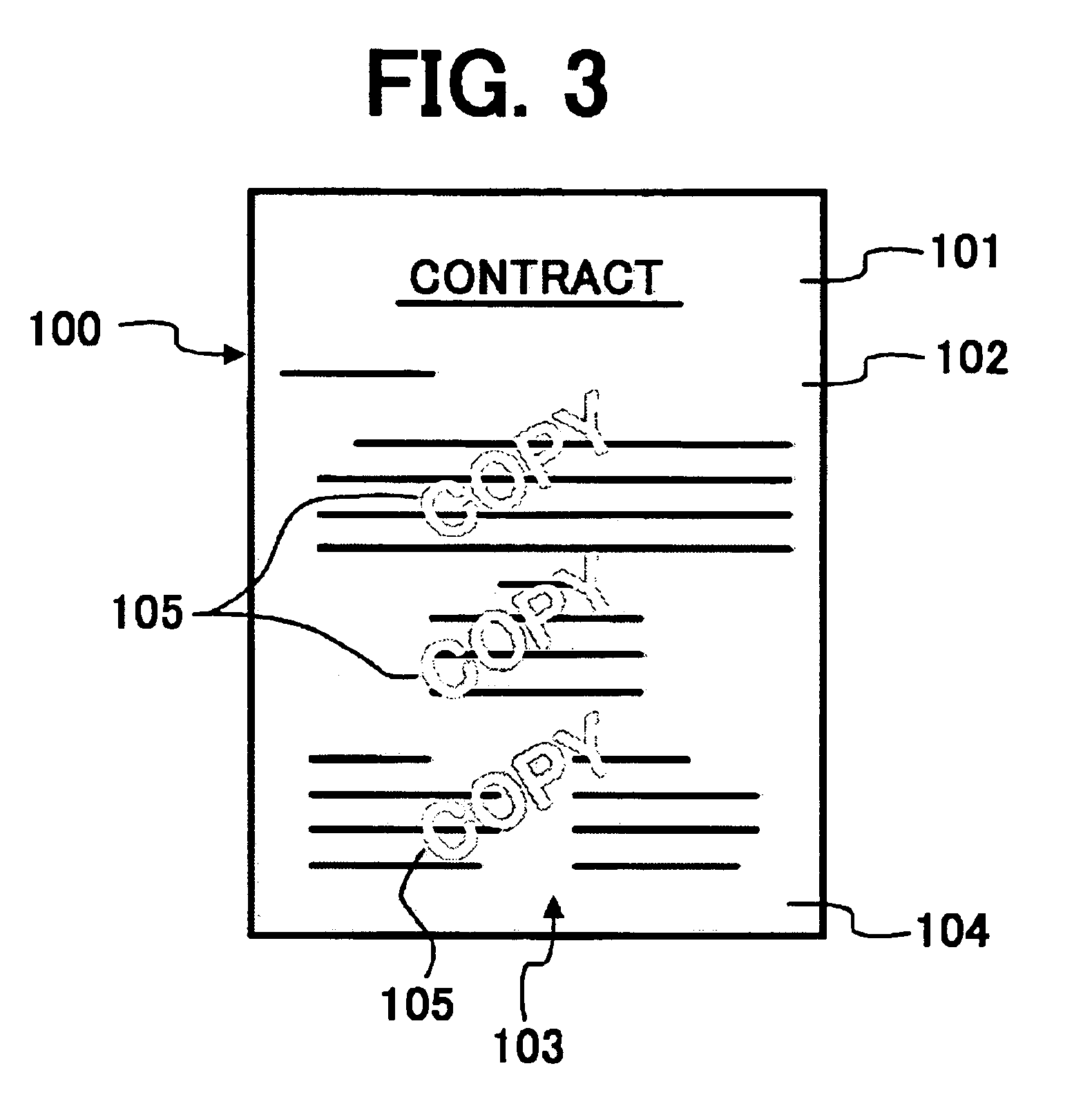

Method, program, and apparatus for preventing a reproduction of an anti-copy document, and a medium storing the program

InactiveUS6901236B2Character and pattern recognitionElectrographic process apparatusPattern recognitionGraphics

An image processing apparatus includes a scanning mechanism, first and second memories, an image accumulating mechanism, a detecting mechanism, a determining mechanism, and a code assigning mechanism. The first memory stores a reference dot pattern indicating an anti-copy background dot pattern. The second memory stores image data. The image accumulating mechanism accumulates image data of an original image into the second memory. The detecting mechanism detects a background dot pattern embedded in a background image included in the image data of the accumulated original image. The determining mechanism compares the detected background dot pattern with the reference dot pattern and determines whether the detected background dot pattern is substantially identical to the reference dot pattern. The code assigning mechanism assigns an identification code to the image data having the detected background dot pattern when the detected background dot pattern is determined as substantially identical to the reference dot pattern.

Owner:RICOH KK

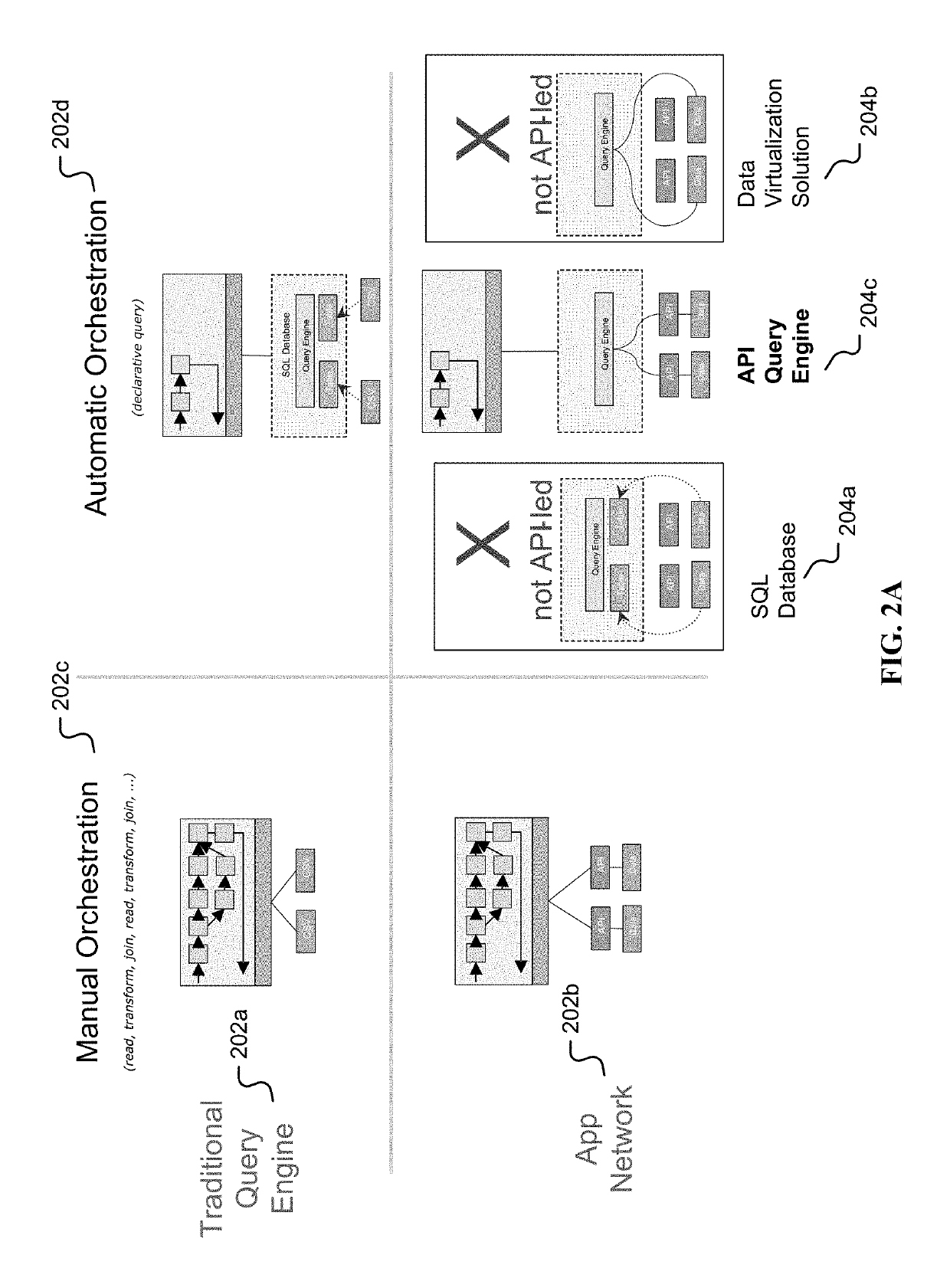

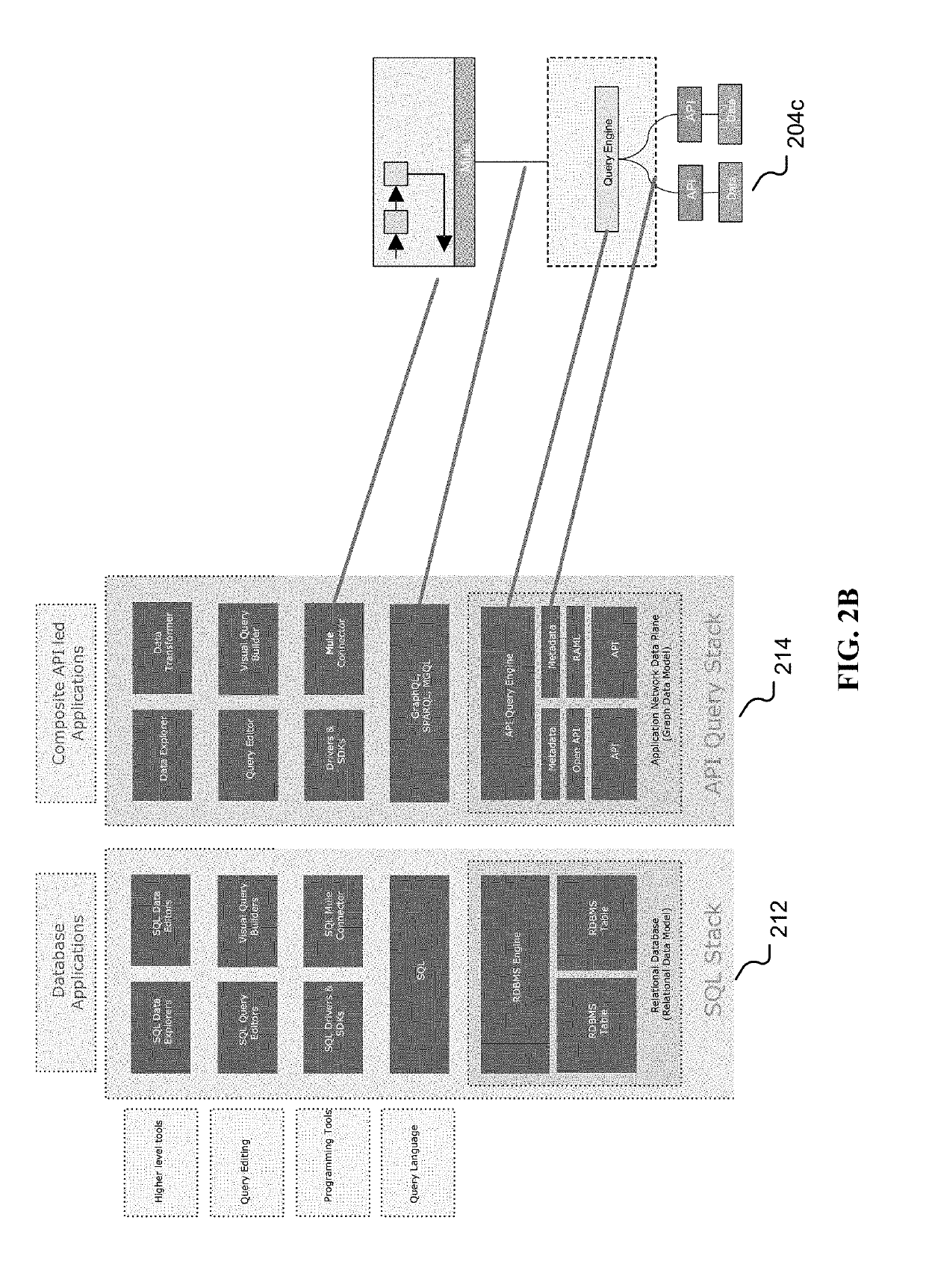

Api query

ActiveUS20190196890A1Web data indexingInterprogram communicationData graphDistributed Computing Environment

A plurality of network APIs are received. The plurality of network APIs are transformed then mapped into a unified data graph. A query in a distributed computing environment is performed using the unified data graph or performing discovery for at least one of the plurality of network APIs using the unified data graph.

Owner:MULESOFT LLC

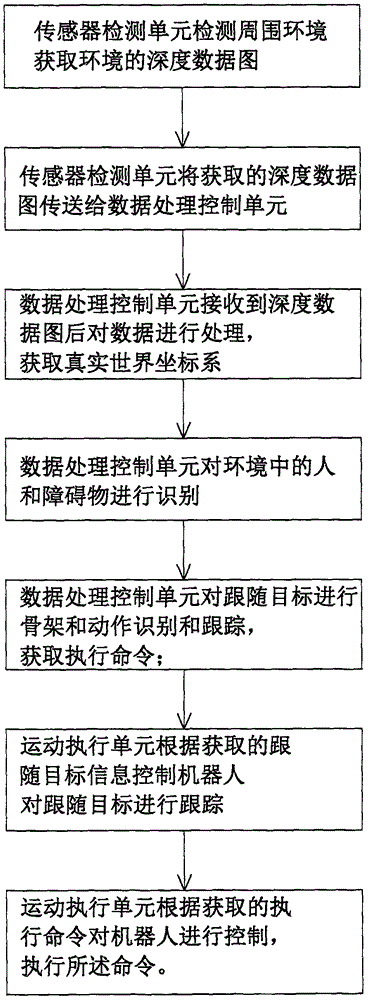

Vision following control method of robot and robot

InactiveCN105955251ARealize follow-up interactionPosition/course control in two dimensionsVehiclesExecution unitVisual perception

The present invention relates to a vision following control method of a robot and a robot. A sensor detection unit is configured to detect the surrounding environment, obtain the depth datagram of the environment, and send the obtained depth datagram to a data processing control unit; the data processing control unit is configured to process the received date after receiving the depth datagram, obtain the real world coordinate system, identify the human and barriers in the environment, and perform skeleton and motion identification and tracking of a following object to obtain an execution command; and a motion execution unit is configured to control the robot to track the following object according to the obtained following object information, and controlling the robot according to the obtained execution command to execute the command. The vision following control method of the robot and the robot are able to rapidly identify the following object, complete the effective identification of the following object in the environment having many people and rapidly make out reaction for the position changing of the following object, and are applicable to the vast majority of the commercial application scenes.

Owner:北京克路德人工智能科技有限公司

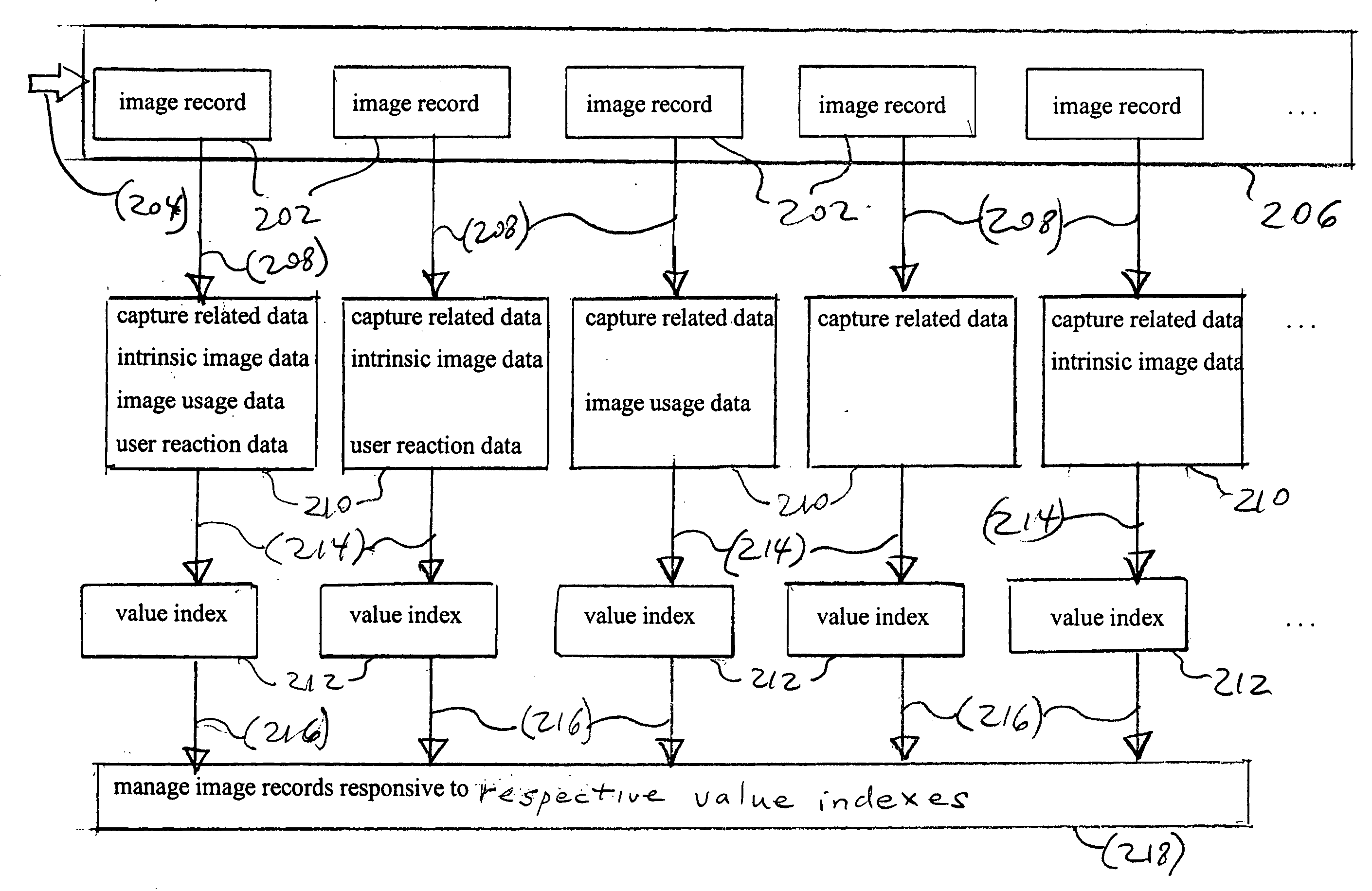

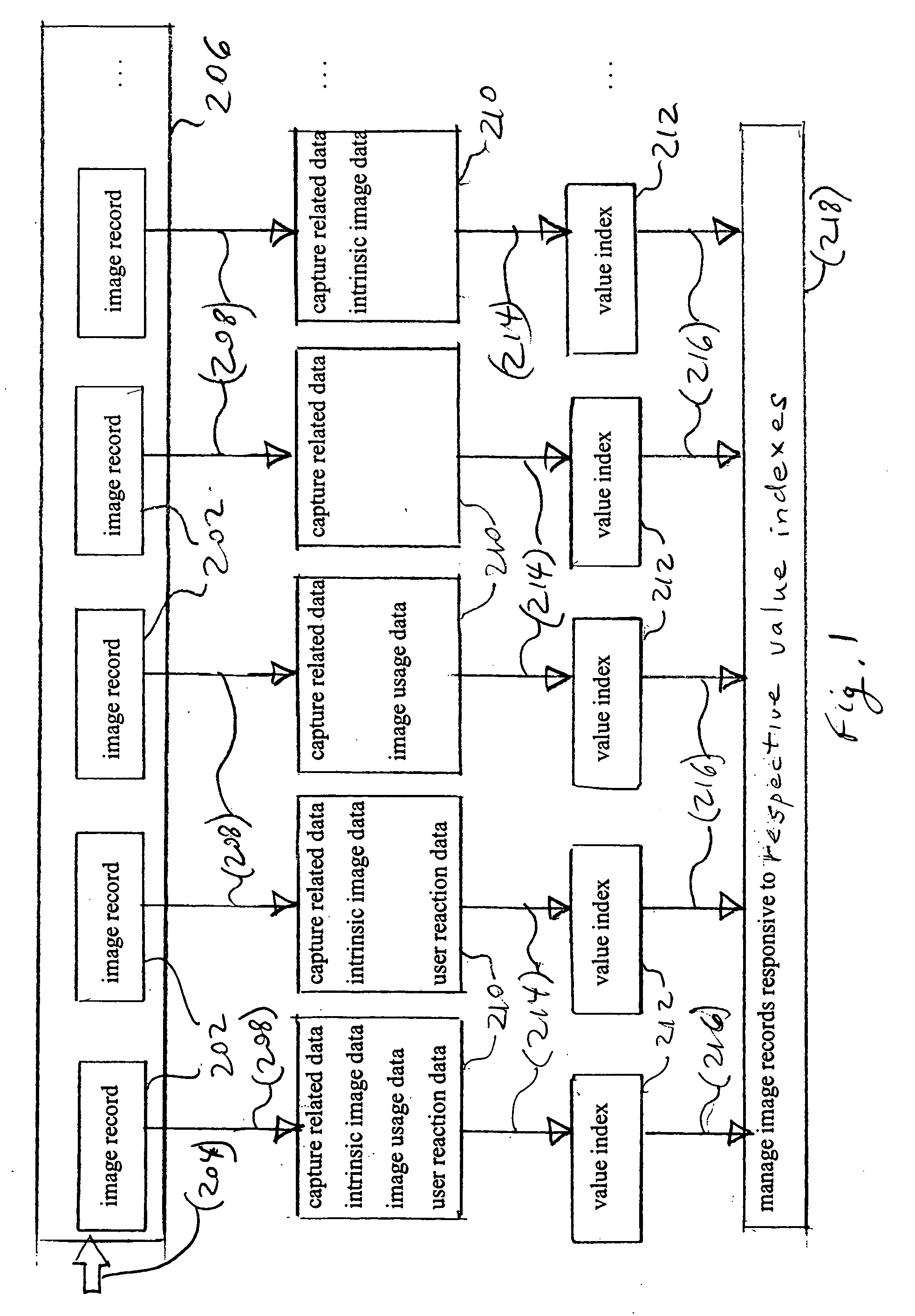

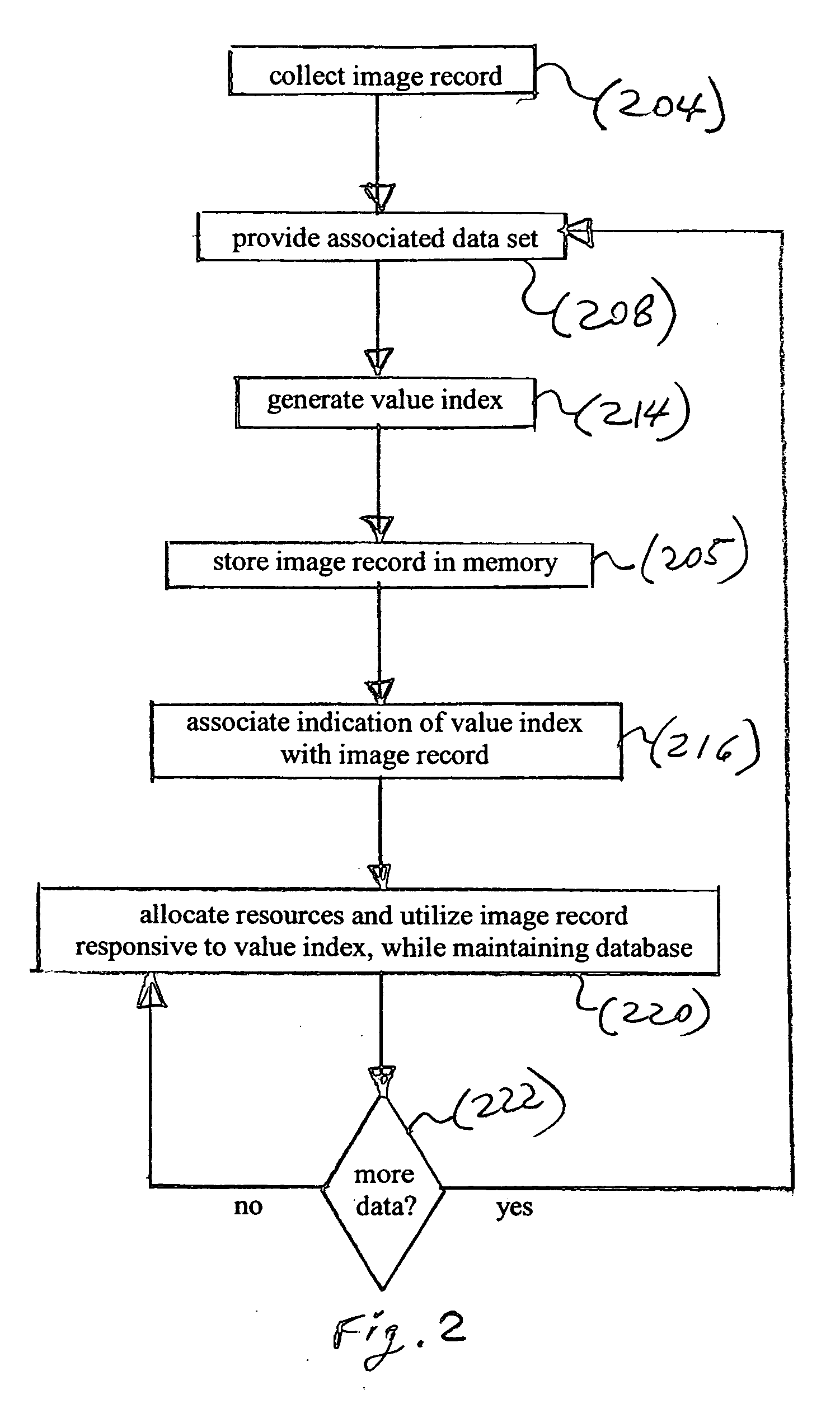

Value index from incomplete data

In a digital image administration method and system, a database of image records is maintained. Data sets are provided. The data sets are each associated with a respective image record. The data sets each include data in a plurality of the categories: capture related data, intrinsic image data, image usage data, and user reaction data. A plurality of the data sets have missing data in different combinations of the categories. A value index of each of the image records is generated from the respective data set. The image records are managed responsive to respective value indexes.

Owner:APPLE INC

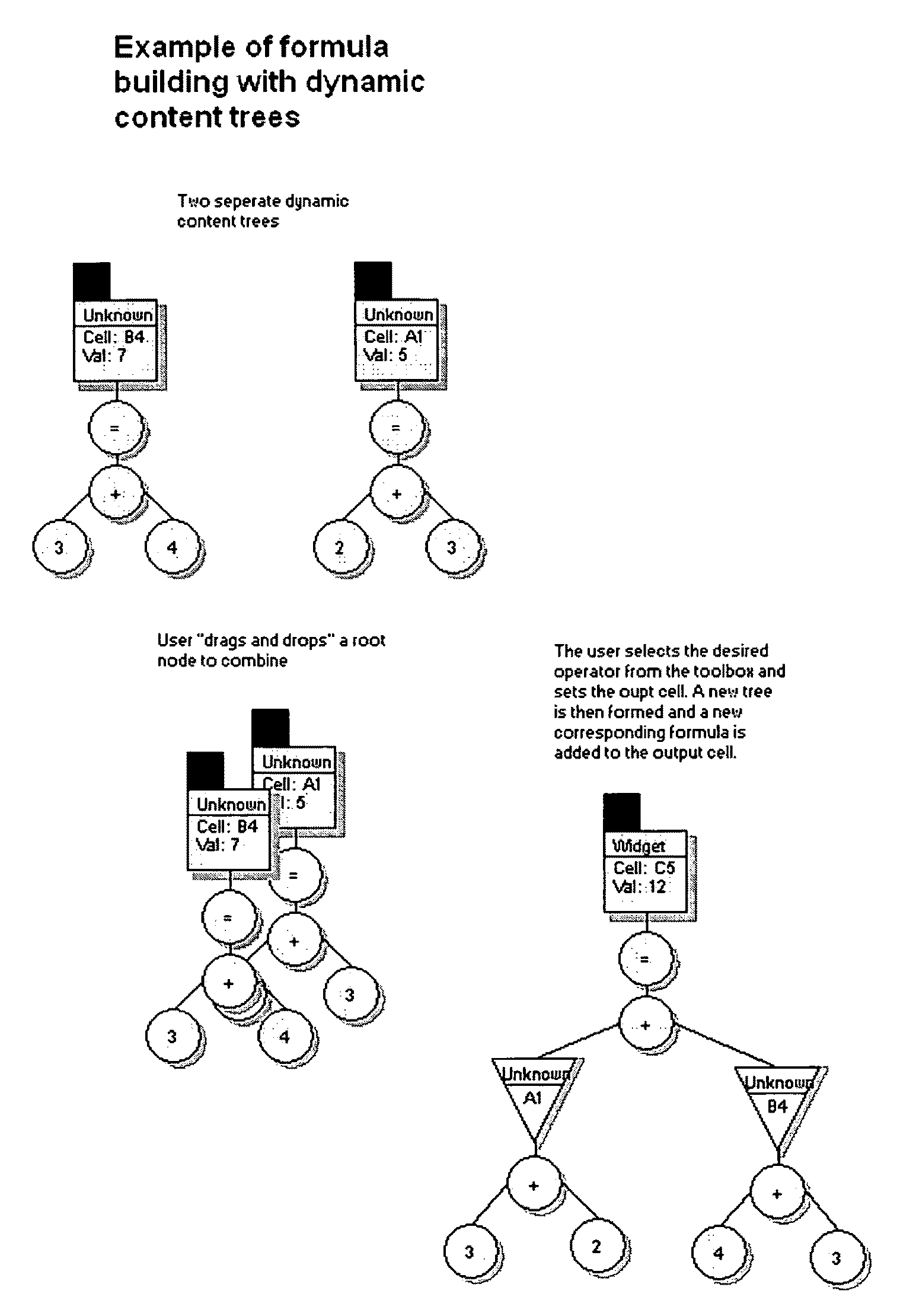

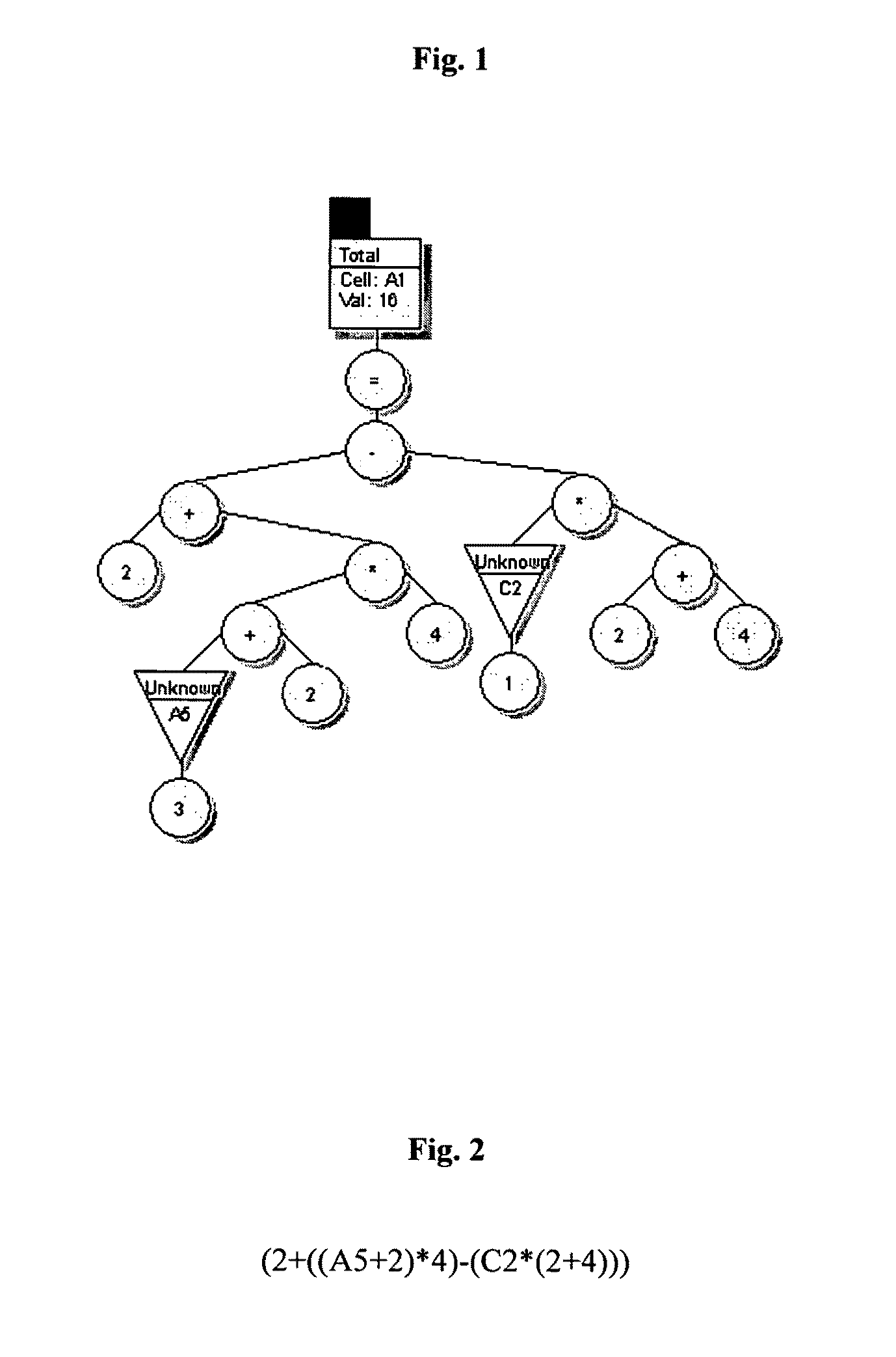

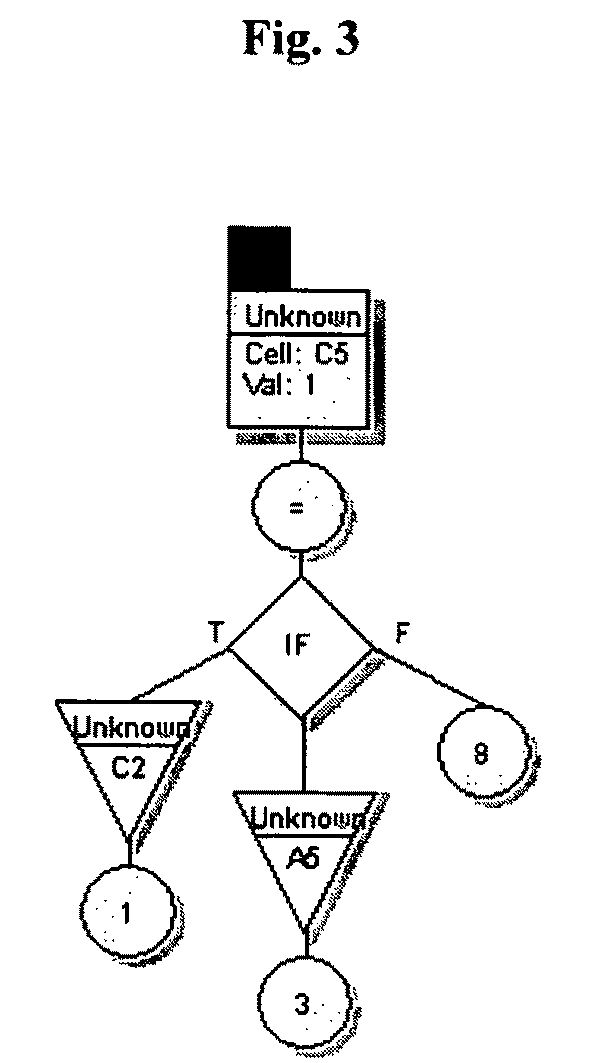

Method and system for the graphical modeling of data and calculations of a spreadsheet

InactiveUS7984371B2Reduce in quantityEfficient interfaceDigital data processing detailsText processingGraphicsTheoretical computer science

A method and system for the graphical modeling of calculations in a spreadsheet that provides a graphical representation of formulas and data contained in a spreadsheet. The graphical representation consists of nodes and edges connected in a tree or graph structure. The nodes represent operators and operands of a formula and are arranged in an expression hierarchy based on operational precedence. Formulas containing cell references are represented through a compound expression hierarchy consisting of an expression hierarchy that includes a descendant expression hierarchy representing the contents of each referenced cell. Expression hierarchies that share similar nodes can be represented through a shared graphical representation to reduce the number of items displayed concurrently within a view and to simplify multiple formula edits. The expression hierarchies and the formulas they represent are kept consistent so that changes made to either can be reflected in both the spreadsheet and graphical representation.

Owner:ZDENEK ANDREW JOSEPH

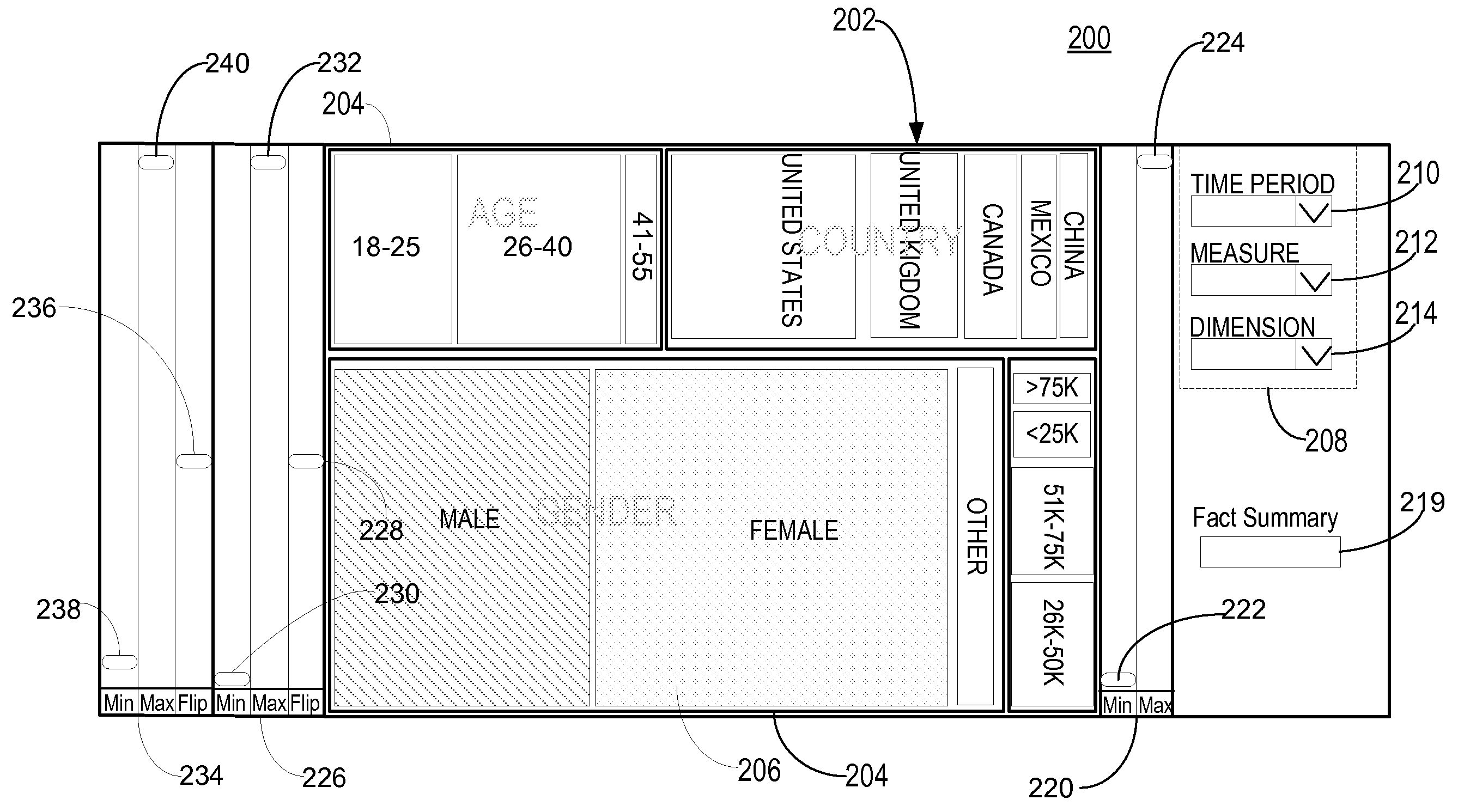

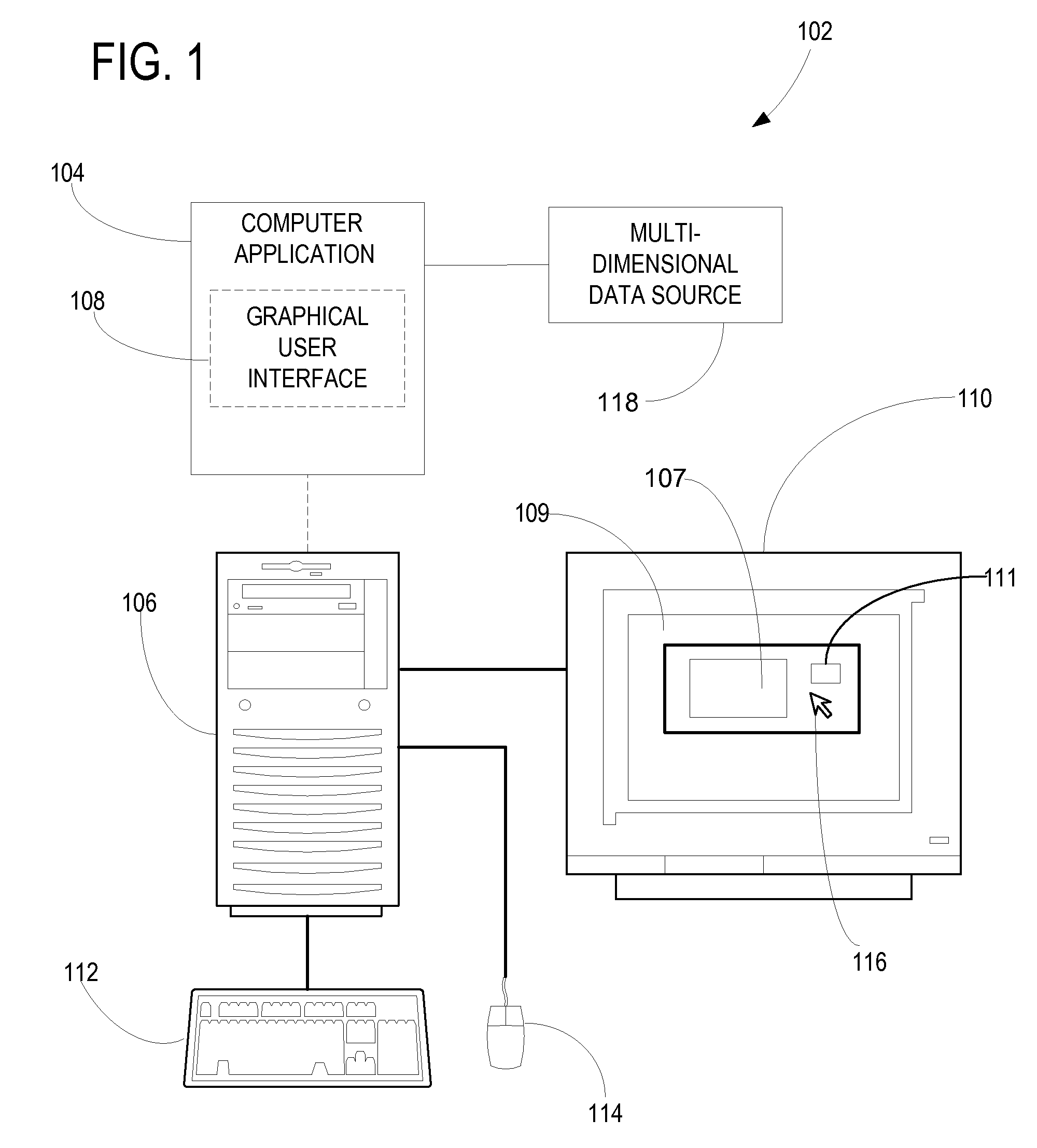

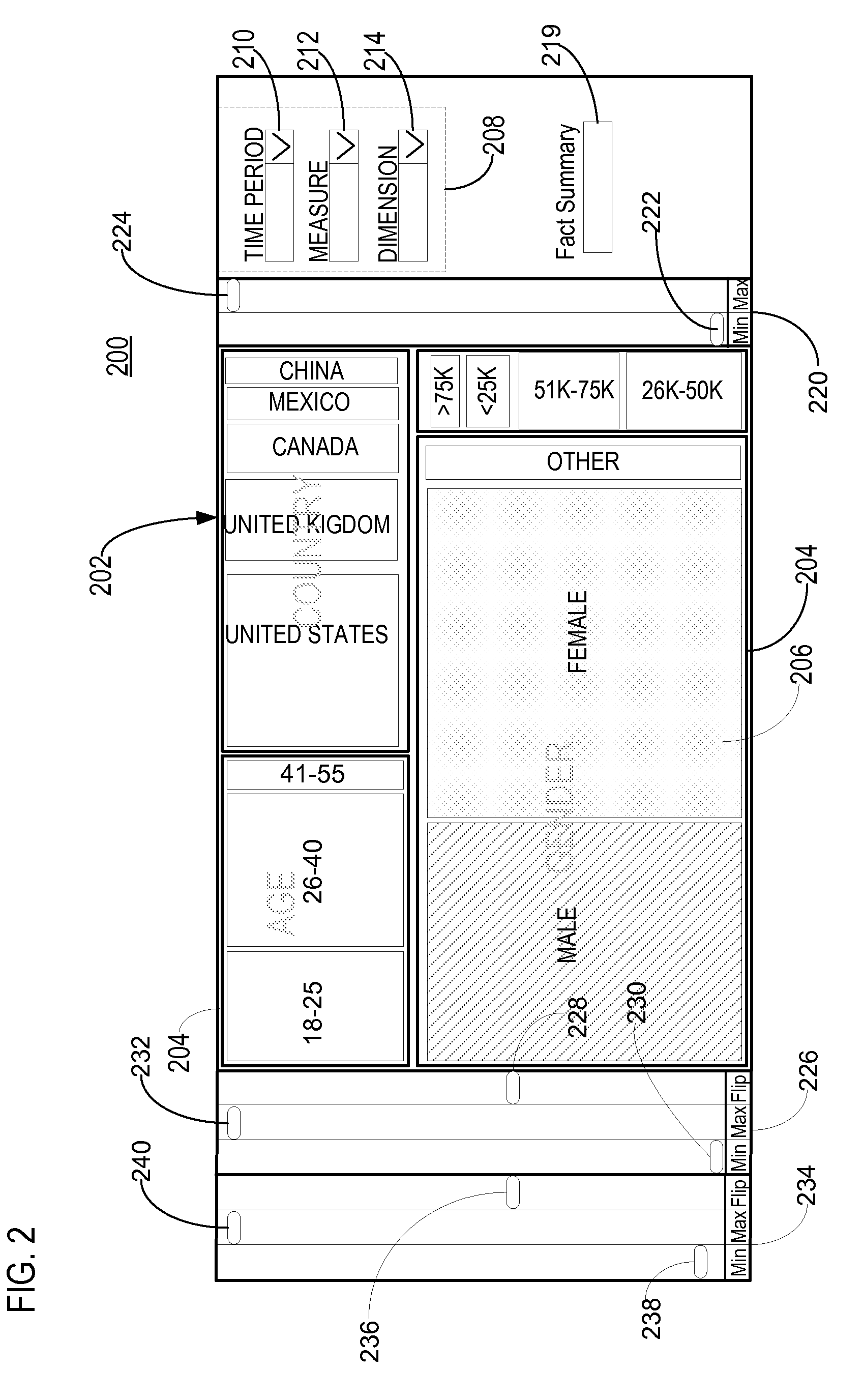

System and method for interactively displaying multi-dimensional data

InactiveUS7506274B2Overcome deficienciesEasy to identifyDrawing from basic elementsCathode-ray tube indicatorsGraphicsGraphical user interface

Methods and systems for displaying data retrieved from a multi-dimensional data source via an interactive data diagram. A graphical user interface is responsive to input from a user to retrieve multi-dimensional data for display via an interactive data diagram. The interactive data diagram displays multi-dimensional data in a hierarchical structure that includes a plurality of dimension levels and one or more member levels within each dimension level. A user specifies a change to the display structure by selecting a displayed member level in the hierarchical structure. The interactive data diagram is responsive to the user specified change to generate a drilled down data diagram displaying detailed dimension and member levels related to the selected member level.

Owner:MICROSOFT TECH LICENSING LLC

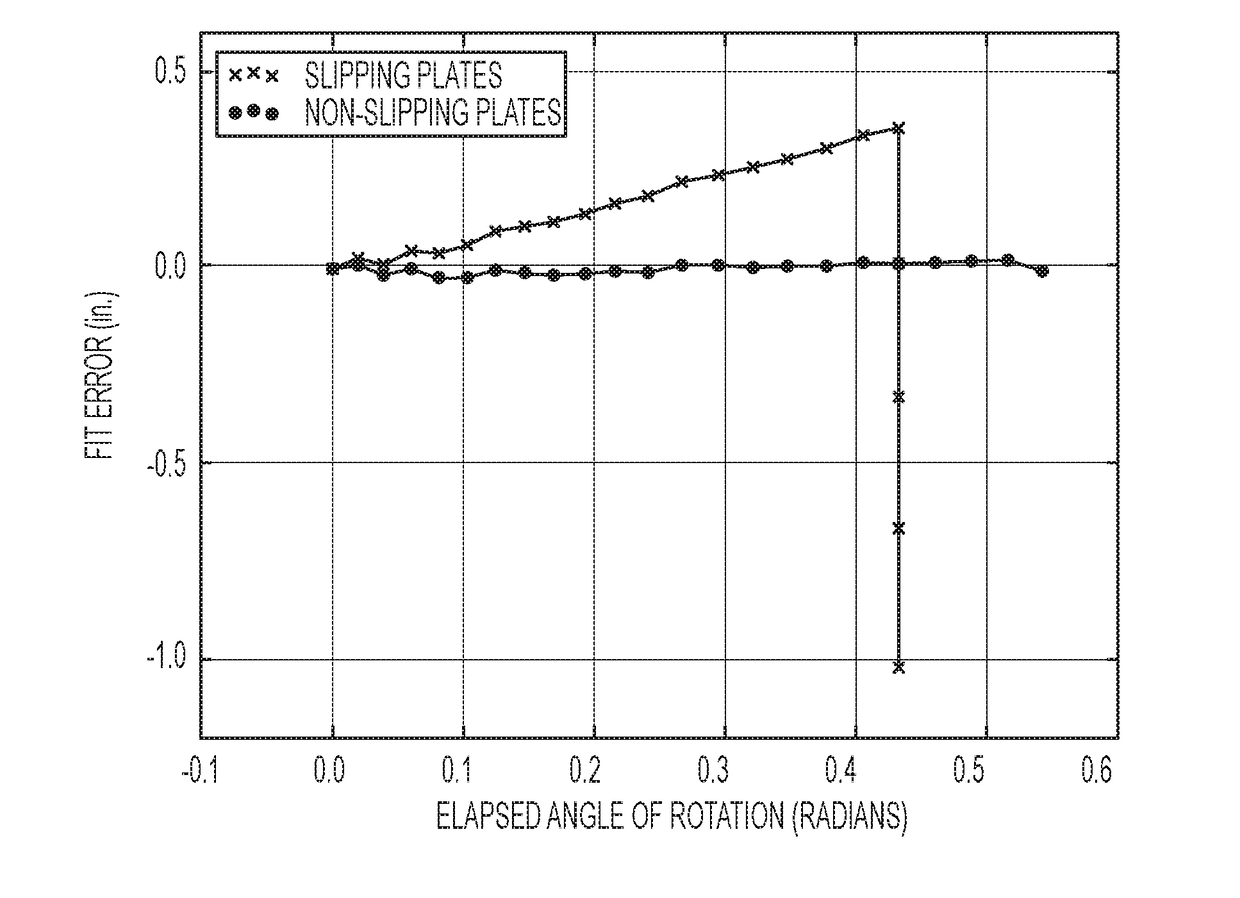

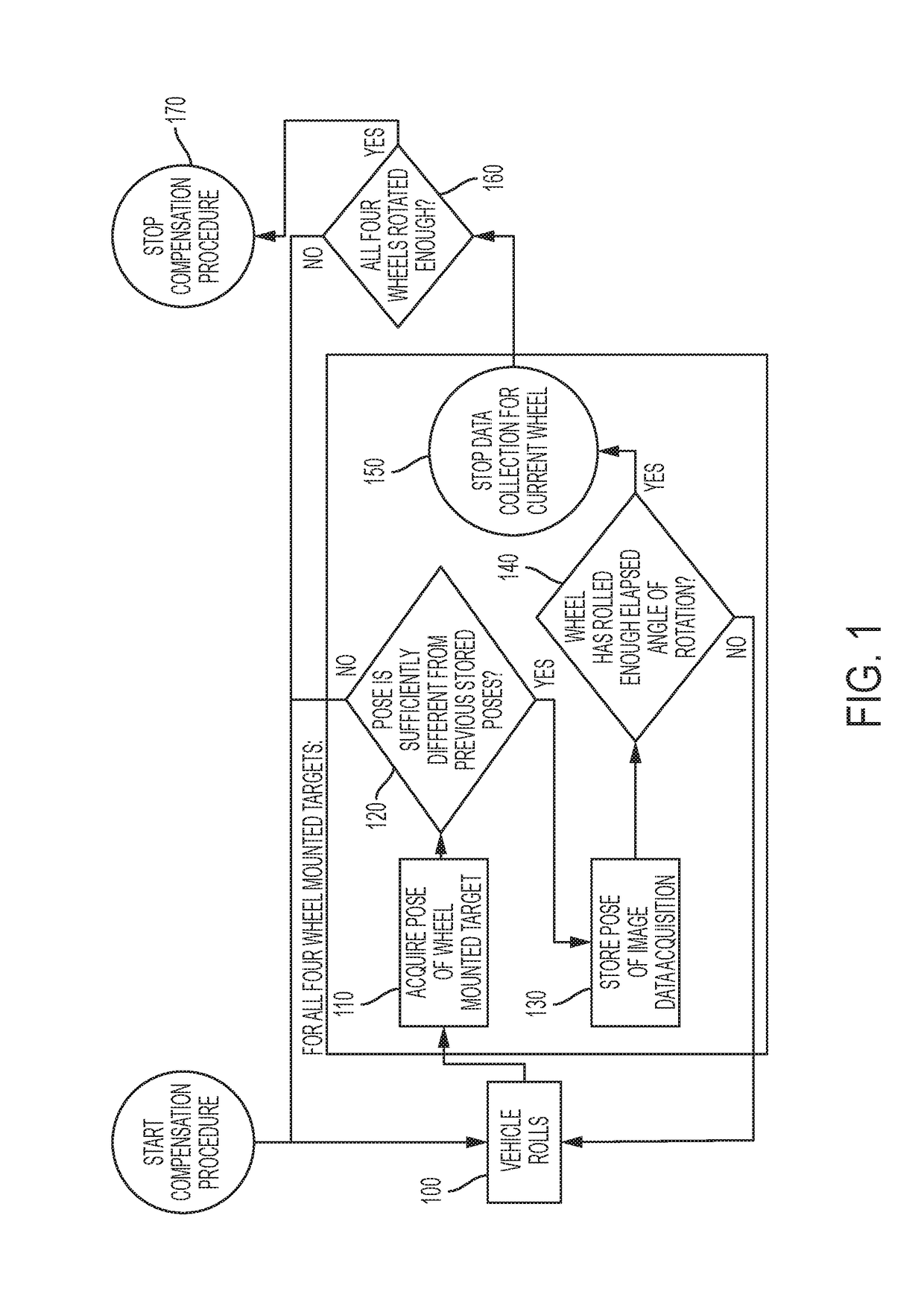

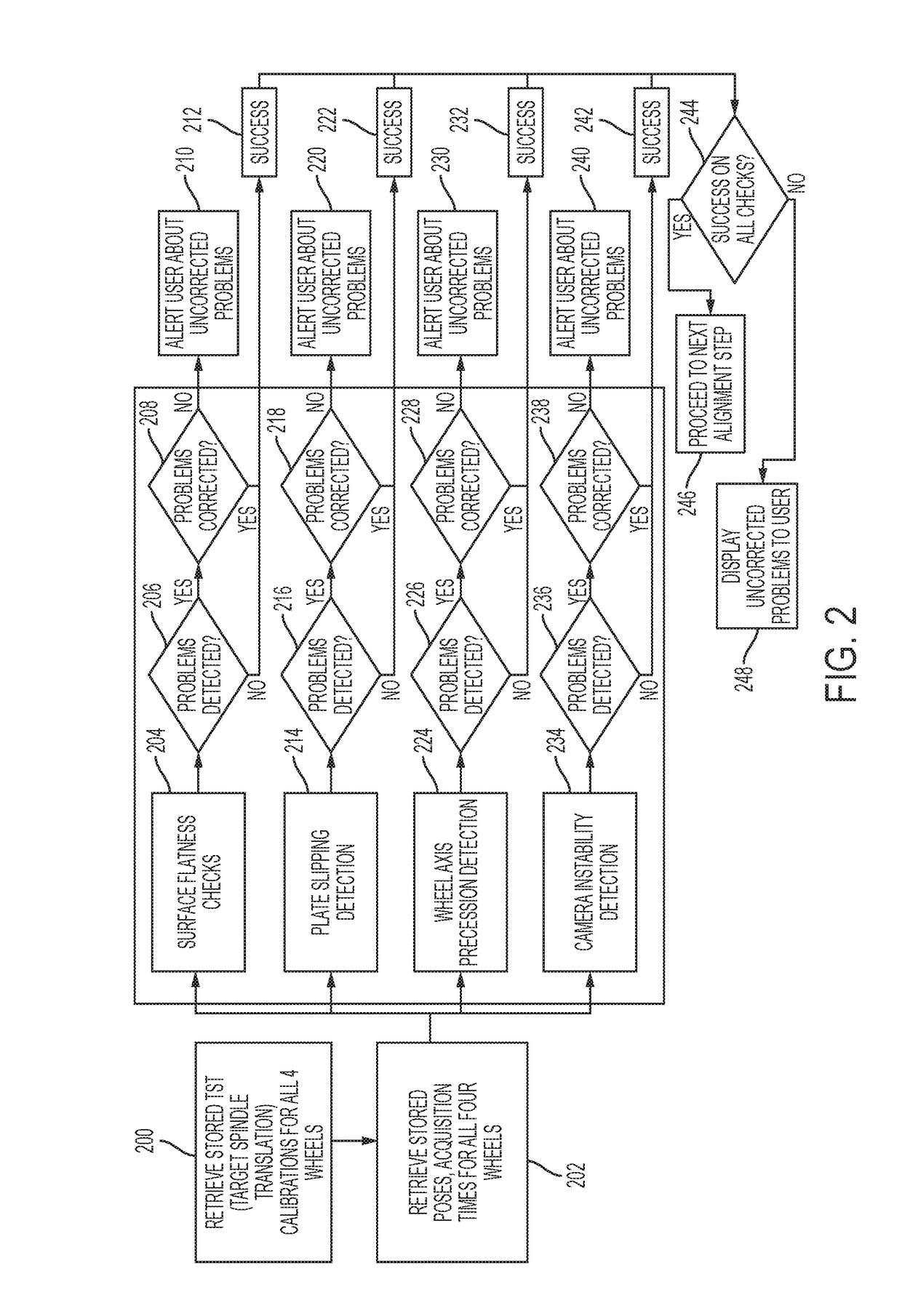

Wheel aligner with advanced diagnostics and no-stop positioning

InactiveUS20170097229A1Reduce weightLow costTelevision system detailsImage enhancementEngineeringImaging data

A vehicle wheel alignment system has a plurality of cameras, each camera for viewing a respective target disposed at a respective wheel of the vehicle and capturing image data of the target as the wheel and target are continuously rotated a number of degrees of rotation without a pause. The image data is used to calculate a minimum number of poses of the target of at least one pose for every five degrees of rotation as the wheel and target are continuously rotated the number of degrees of rotation without a pause. At least one of the cameras comprises a data processor for performing the steps of preprocessing the image data, and calculating an alignment parameter for the vehicle based on the preprocessed image data.

Owner:SNAP ON INC

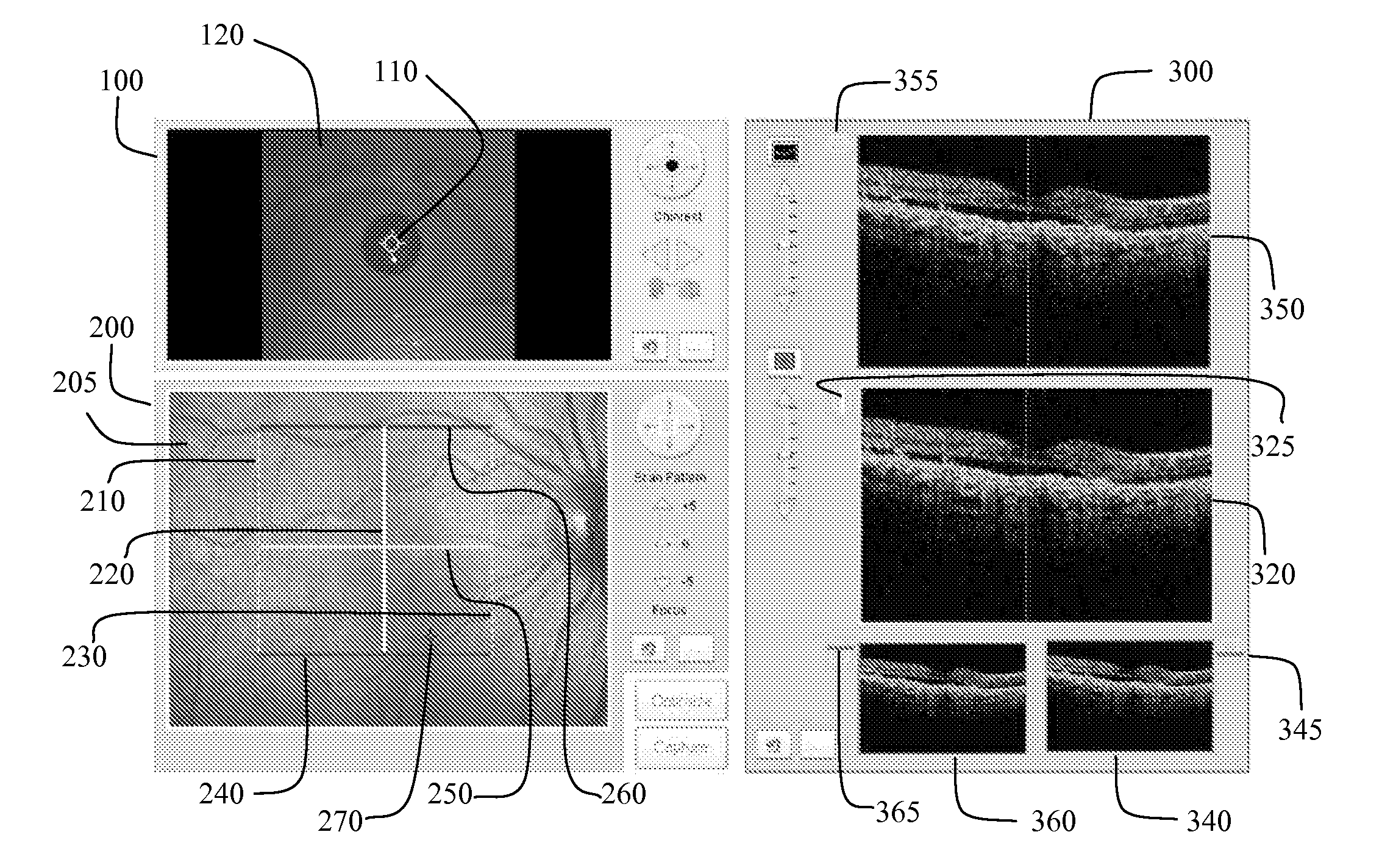

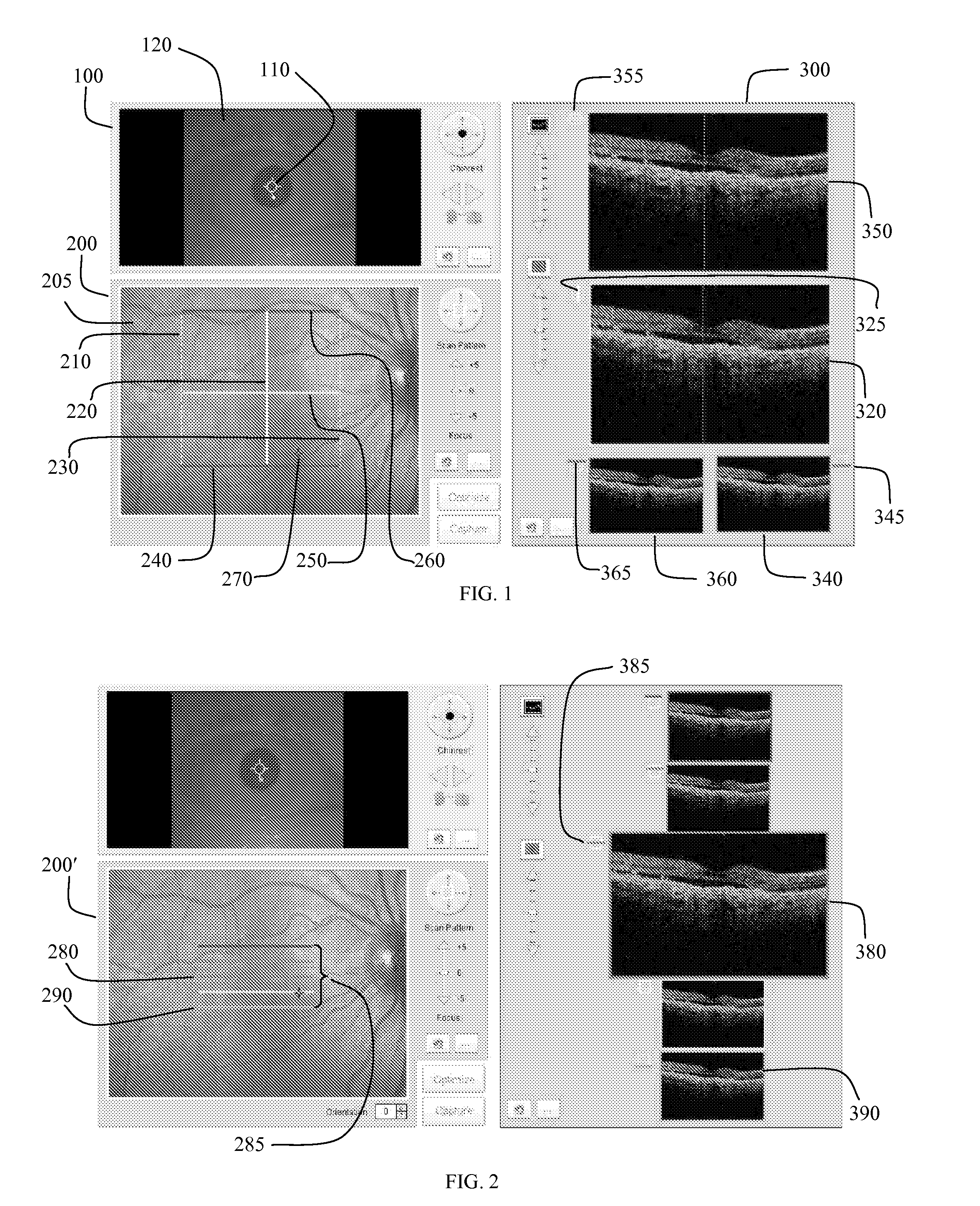

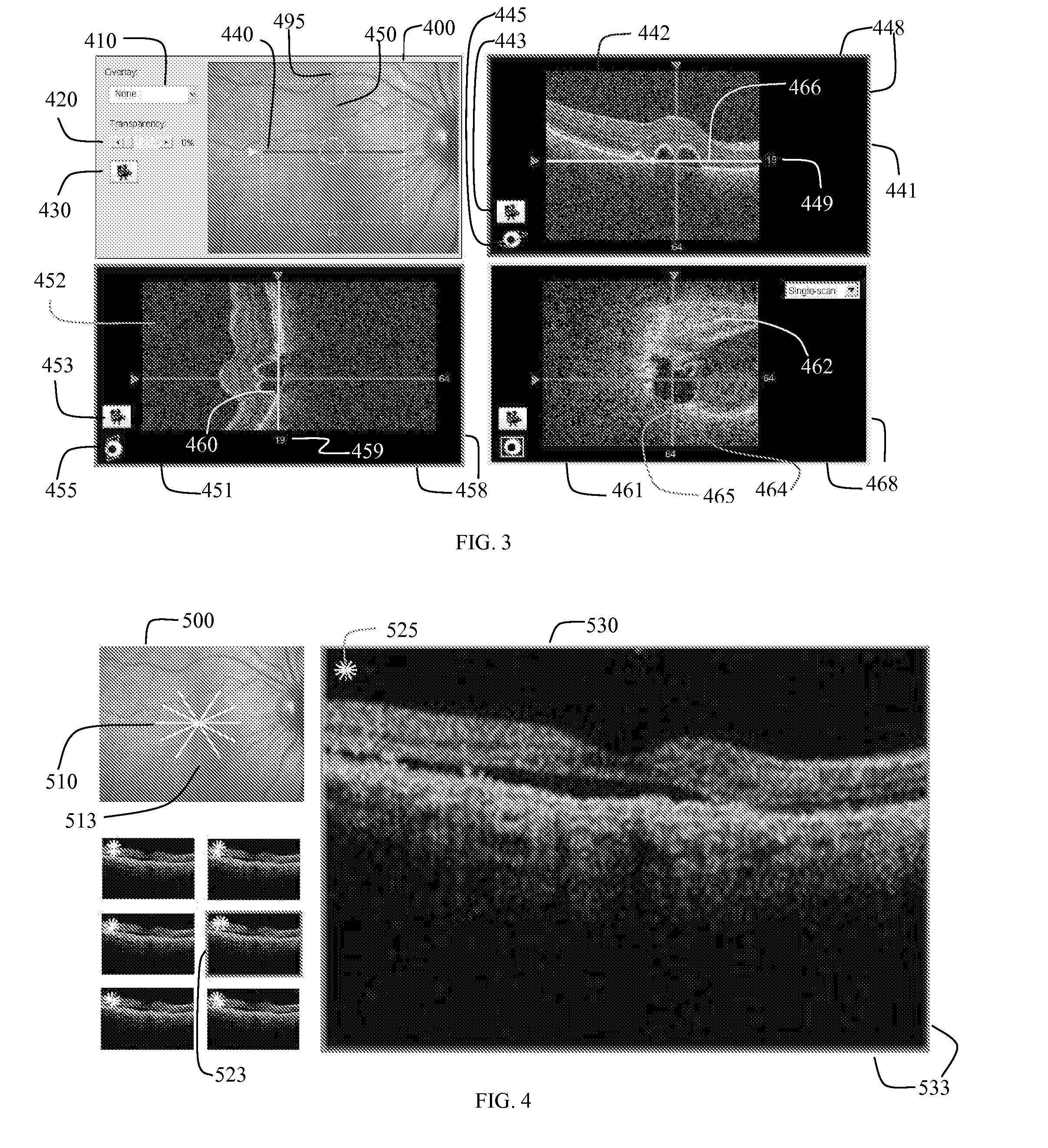

User interface for efficiently displaying relevant oct imaging data

InactiveUS20130181976A1Effective displayDiagnostic recording/measuringEye diagnosticsData graphImaging quality

The present invention is an OCT imaging system user interface for efficiently providing relevant image displays to the user. These displays are used during image acquisition to align patients and verify acquisition image quality. During image analysis, these displays indicate positional relationships between displayed data images, automatically display suspicious analysis, automatically display diagnostic data, simultaneously display similar data from multiple visits, improve access to archived data, and provide other improvements for efficient data presentation of relevant information.

Owner:CARL ZEISS MEDITEC INC

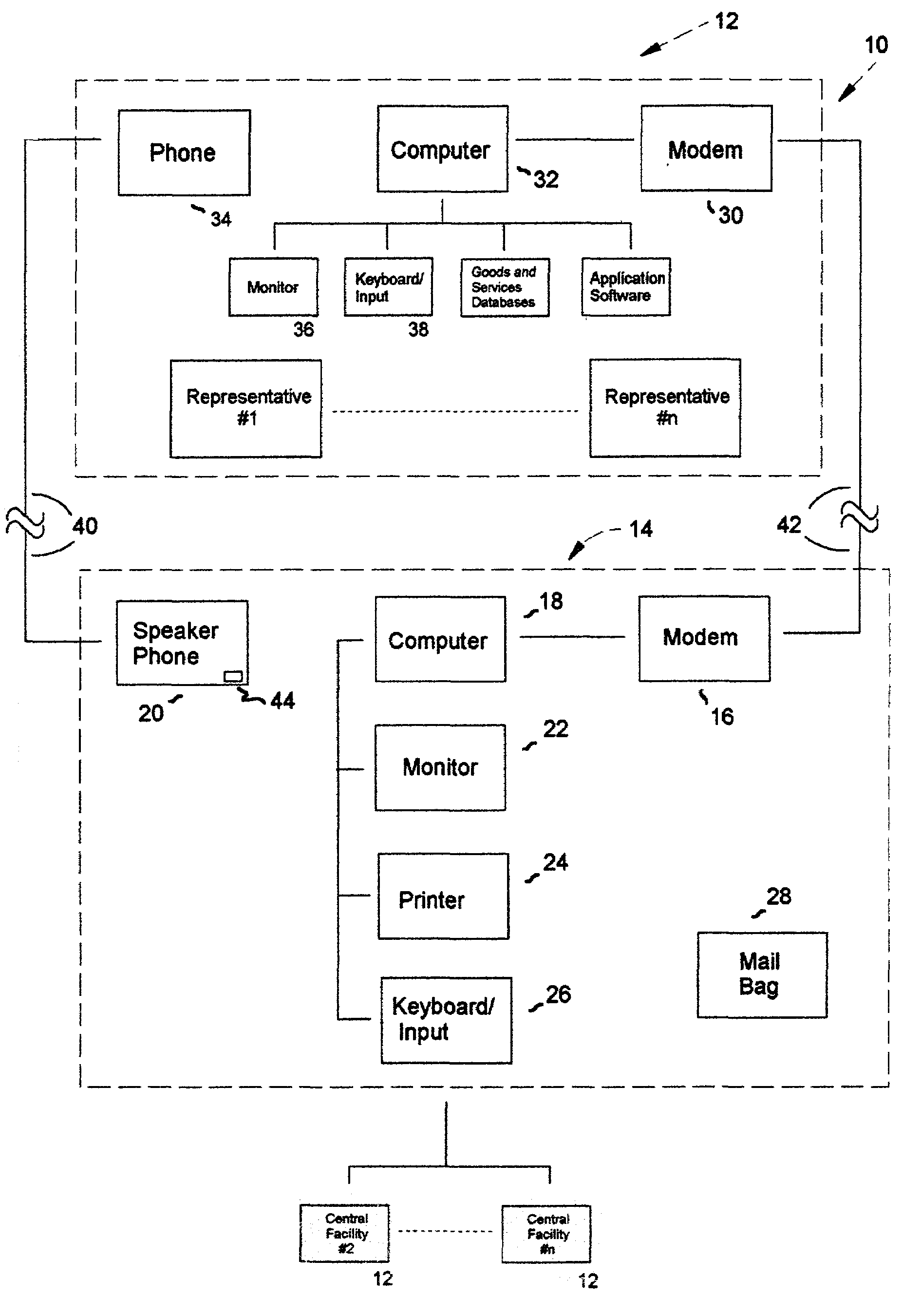

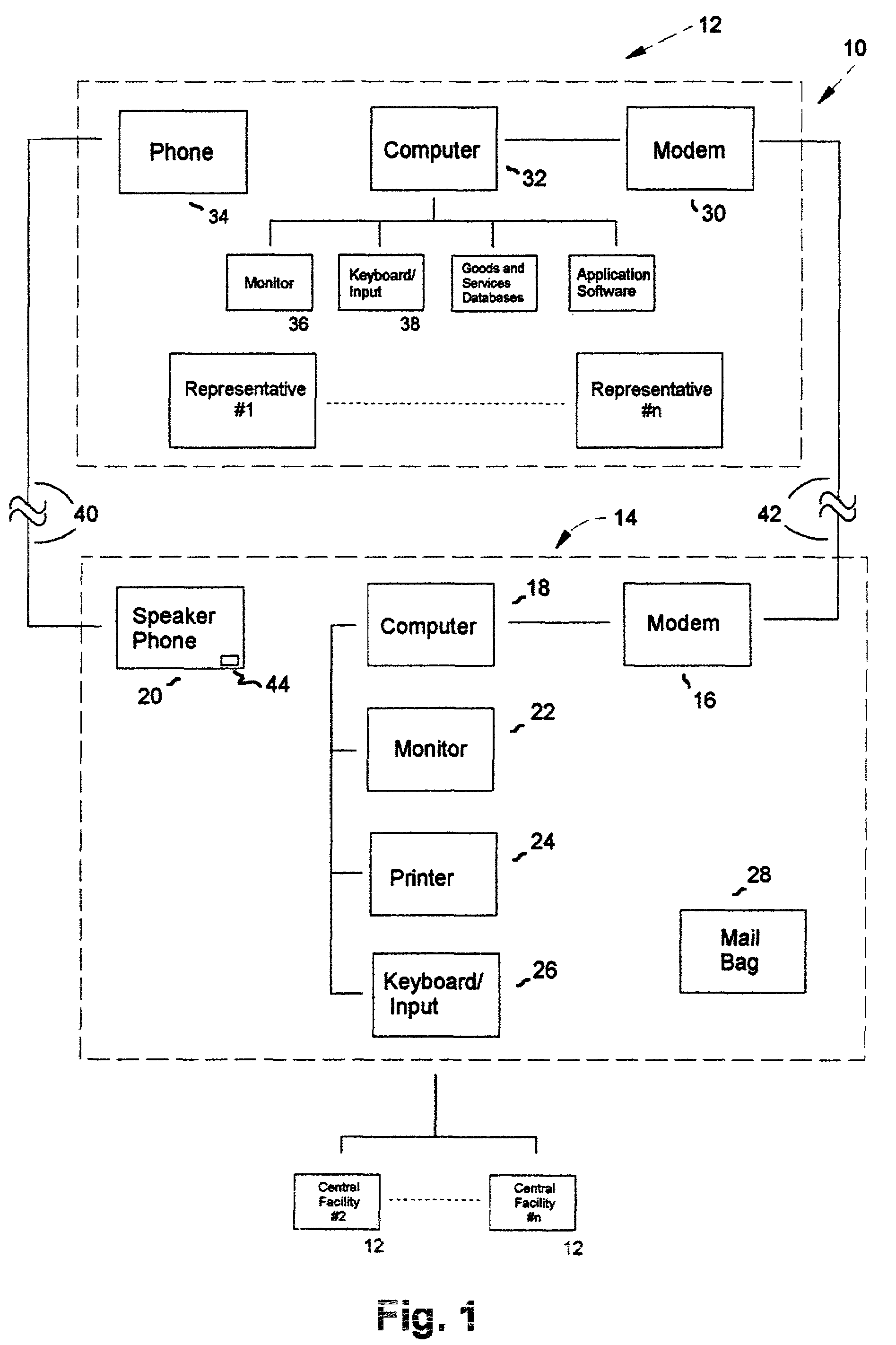

System for marketing goods and services utilizing computerized central and remote facilities

InactiveUS7624044B2Heightened sense of realismSimplify the update processFinanceTelephonic communicationData graphTelecommunications

A system and means for facilitating transactions between central and remote facilities utilizes electronic communications devices, and computing equipment for concurrently or nonconcurrently transmitting voice, music, audio, data, images, video, optic information, and / or signals. Such systems are used to market, sell, finance, and insure goods and / or services. A study of these systems shows that they fall short because none of them take all types of customer personalities into consideration. A system is needed which provides the customers with more latitude and fewer limitations in shopping for goods and services, or for engaging in business transactions. Such a system and means are provided herein, which meet the needs and desires of independent customers, more dependent customers, and a third, or passive, group of customers. All customer types can at anytime request help from a centrally staffed live attendant.

Owner:VARIANT HLDG

Session bean implementation of a system, method and software for creating or maintaining distributed transparent persistence of complex data objects and their data relationships

InactiveUS7167862B2Data processing applicationsSpecial data processing applicationsData graphTheoretical computer science

The invention provides systems, methods and software for creating or maintaining distributed transparent persistence of complex data objects and associated data stores. In one aspect, the invention also relates to an application programming object capable of creating or maintaining distributed transparent persistence of data objects or data object graphs without the necessity of inserting any byte codes or modification of the object graph. Virtually any java object or object graph can be transparently persisted. Further, copies of a data graph or of a portion of the data graph can be automatically reconciled and changes persisted without any persistence coding in the object model.

Owner:THOUGHT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com