Scanning device for coded data

a scanning device and coded data technology, applied in the field of scanning devices for coded data, can solve the problems of reducing the potential dynamic range of pixel cells, the link between the image sensor and the host processor must support the relatively high read-out data rate of the image sensor,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

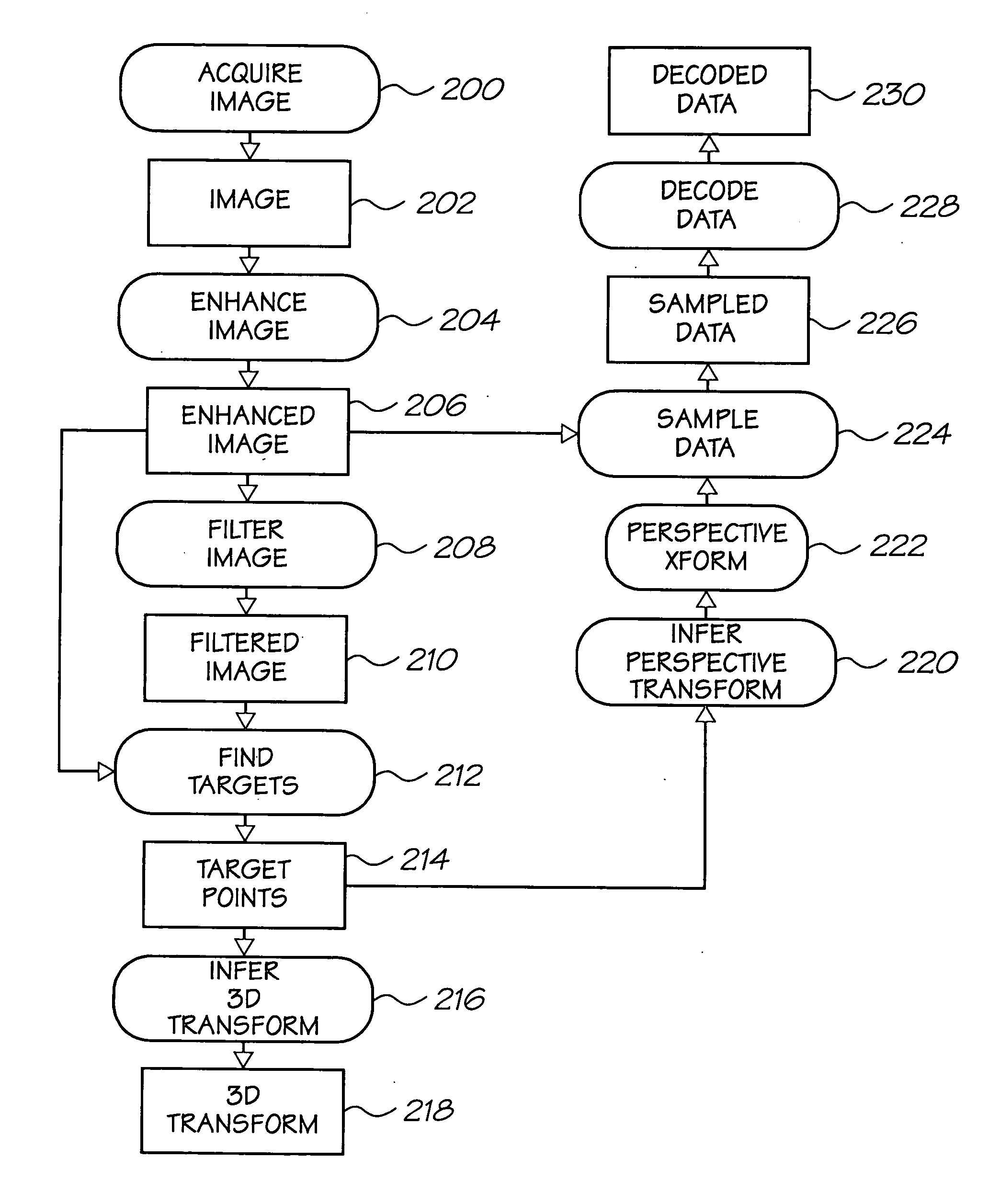

Method used

Image

Examples

first embodiment

[0702]FIG. 58, FIG. 59, FIG. 60 and FIG. 61 show a Hyperlabel scanner 4000. The scanner is designed to image and decode Hyperlabel tags when its tip 4003 is brought into close proximity or contact with a Hyperlabel tagged surface. The scanner can be operated in free mode, in which it continuously and automatically scans tags within its field of view; or in triggered mode, in which it only scans tags when its trigger 4008 is held depressed. Although the scanner is designed with a limited depth of field, thus reducing the likelihood of unintentional scans in free mode, triggered mode can be used to avoid unintentional scans. The trigger may also be configured to be manually operated (as shown), or configured to be automatically activated when the scanner makes contact with the surface. Because an individual product item is tagged with a unique item ID, there is no possibility of duplicate scans.

[0703] During normal operation the scanner returns the item ID encoded in a Hyperlabel tag,...

second embodiment

[0726]FIGS. 72, 73 and 74 show a Hyperlabel scanner 4000. FIGS. 72 and 73 use similar reference numerals to FIGS. 58 and 59 to denote similar elements. In this example, the optical assembly shown in FIG. 59 is replaced with a laser based scanning system, an example of which is shown in FIG. 74.

[0727] As shown in FIG. 74, a scan beam 4540 is produced by a laser 4502. The laser produces a narrowband near-infrared beam matched to the peak wavelength of the near-infrared ink used to print the Hyperlabel tags. An optional amplitude modulator 4503 allows the amplitude of the beam to be modulated, e.g. for ambient light suppression or ranging purposes as discussed below. An optional beam expander 4504 allows the beam to be reduced to produce the desired spot size. The laser is typically a solid-state laser.

[0728] A pair of mirrors 4506 and 4507 injects the scan beam into line with the retroreflective collection system, as described further below.

[0729] An optional focussing lens 4508 foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com