Method for size detection and post-treatment of sheeted molded polymer material and detection and post-treatment machine for implementing method

A dimensional detection and polymer technology, which is applied to the bearing/suspension of the movable parts of the measuring device, can solve the problems of the lack of automatic technical content of the dimensional detection of sheet-like moldings, and achieve the effect of fast and efficient automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

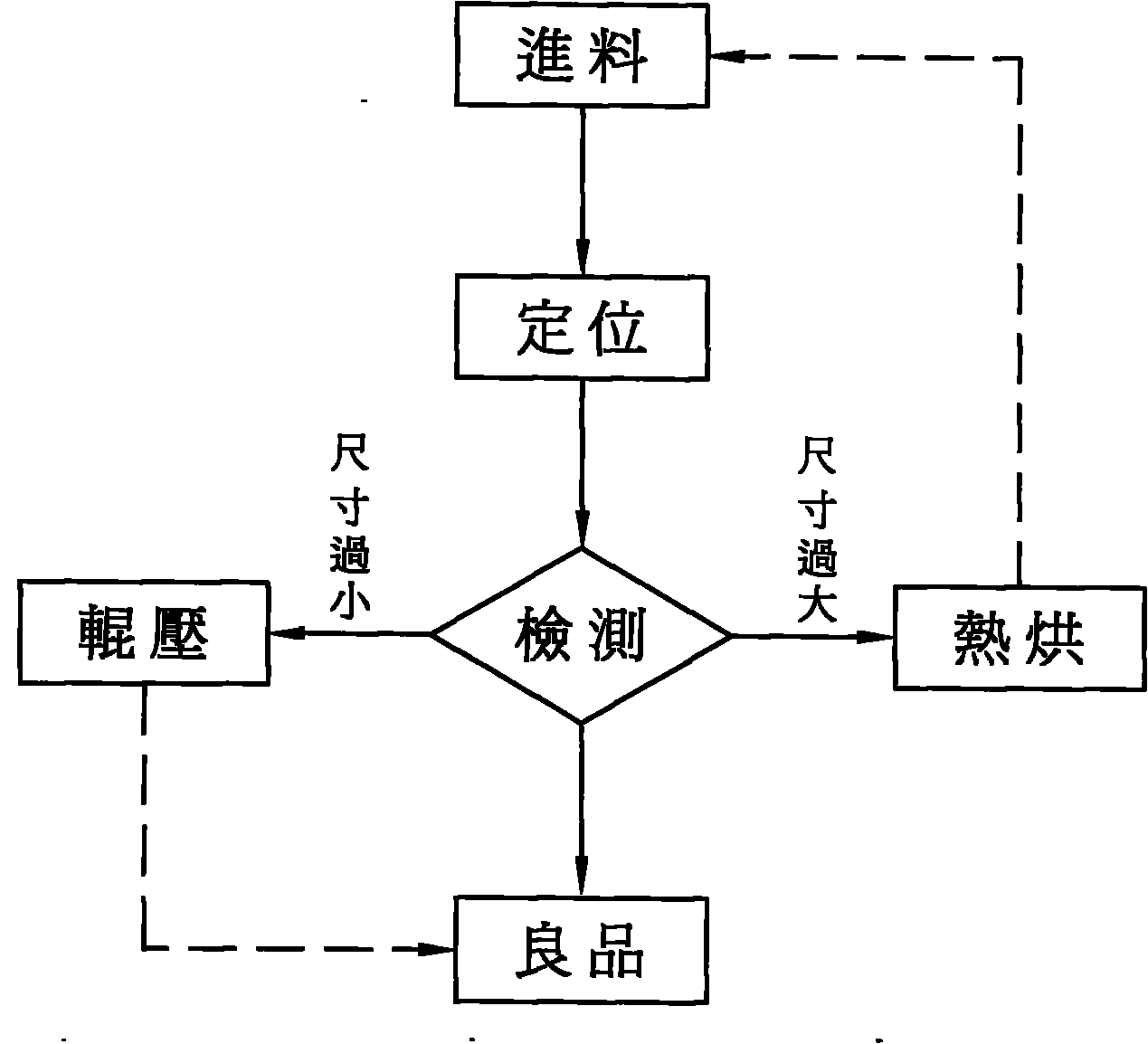

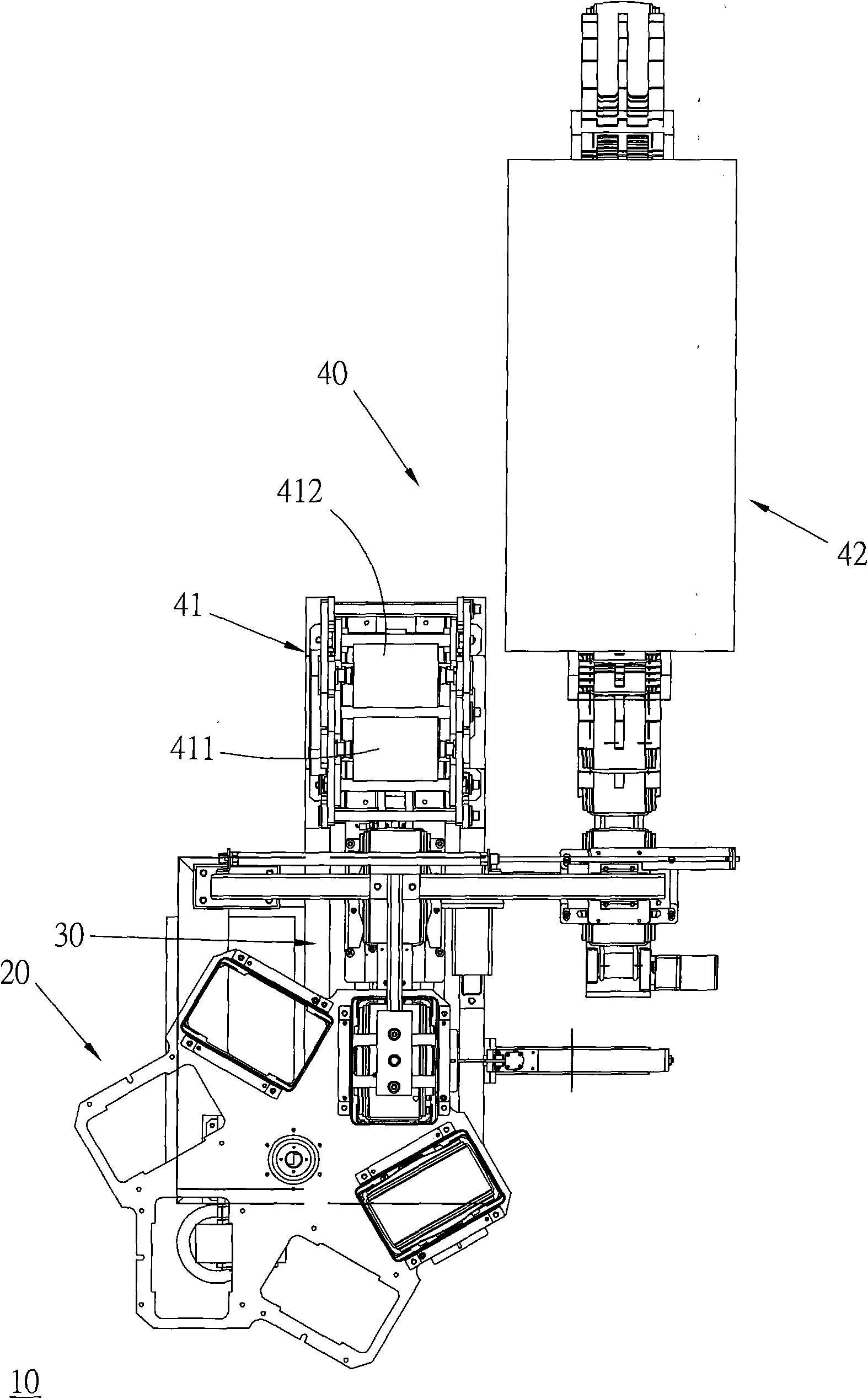

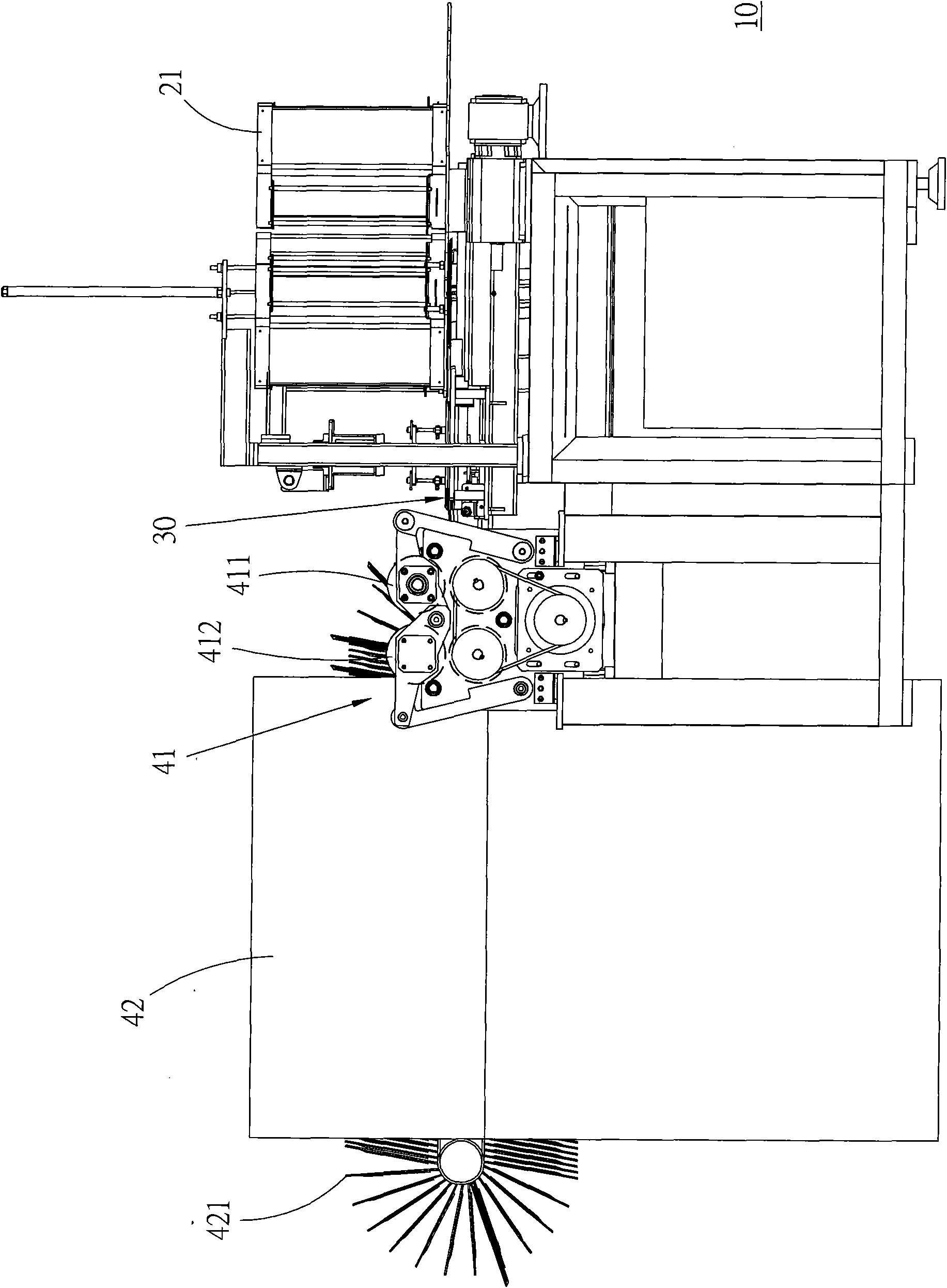

[0058] First, see figure 1 As shown, in a preferred embodiment of the present invention, the method for dimension detection and post-processing of sheet-like polymer moldings is provided, and its steps mainly include the following:

[0059] a. Make the sheet-like polymer moldings to be detected that have been processed by post-stabilization procedures, which are roughly rectangular sheets, on a horizontal plane; wherein, the post-stabilization procedures refer to making the sheet-like polymer moldings in the prior art as described above. In a temperature-controlled environment, there is an existing method to stabilize the dimensions over a period of time, but the implementation of the stabilization procedure has not yet completely cooled the shape of the sheet-like polymer.

[0060] b. Place the sheet-like polymer molding to be detected on the horizontal plane, and make the sheet-like polymer molding to be detected along the rectangular shape under the condition that the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com