Modeling design method of digital screen cabinet for production test and matched test generation method

A technology for production testing and design methods, which is applied in software testing/debugging, electrical digital data processing, design optimization/simulation, etc., and can solve the problem that the automatic detection of relay protection intelligent devices has not achieved generalization and standardization, and increases the difficulty of detection , Failure to achieve automation and digitalization of quality management information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below with reference to the accompanying drawings:

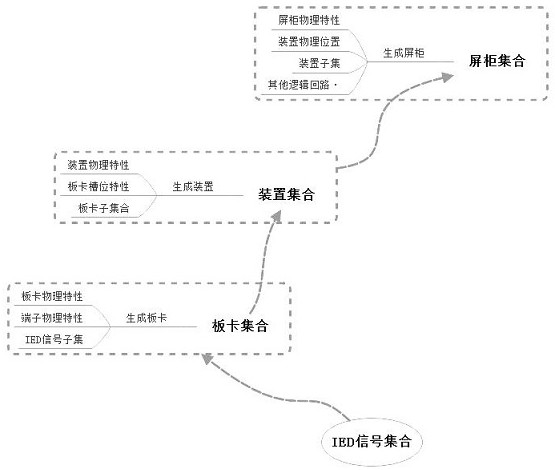

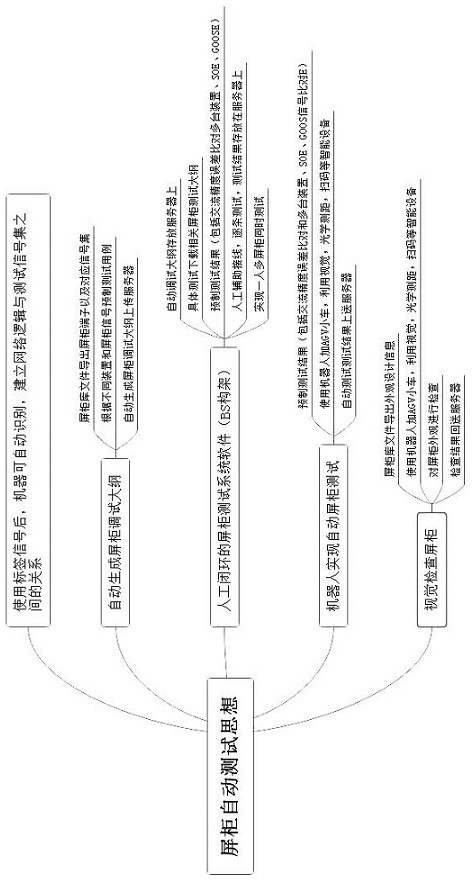

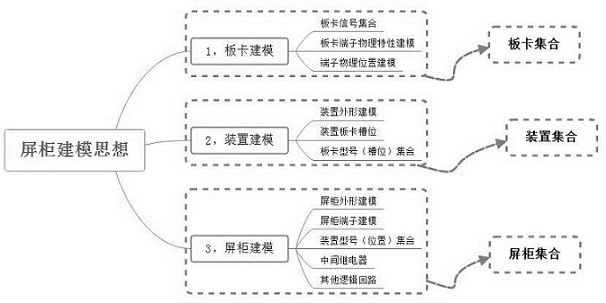

[0060] The present invention provides production test digital screen model modeling design method and supporting test generation method, and designing components, connector terminals, board, devices, and logic in software virtual environments by digitizing test screen cabinet. The circuit is used to model the digital screen cabinet, and the design modeling system has established a digital model board card through the professional signal digital simulation collection of the label, thereby establishing a digital model model, and finally established a digital screen cabinet model. After modeling, generate the machine-identified tag tag signal set, and the topological network structure and logical connection between the screen cabinet terminal model and the device terminal model. This generating screen cabinet debugging outline is used to test the screen cabinet produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com