Weld joint pore defect detection method based on image processing

A welding seam porosity and defect detection technology, which is applied in image data processing, image enhancement, image analysis, etc., can solve a lot of labor costs, result impact and other problems, and achieve labor cost saving, good precision and accuracy, The effect of avoiding the influence of subjective label information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

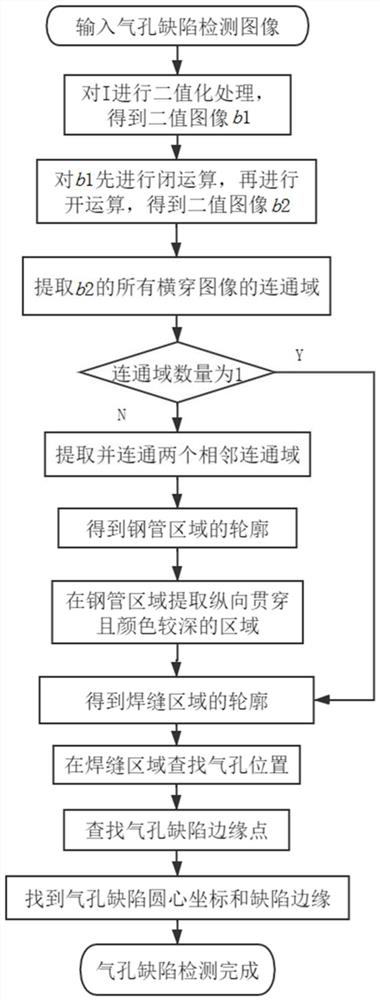

[0082] Such as figure 1 As shown, this embodiment proposes a method for detecting weld porosity defects based on image processing, which includes the following steps:

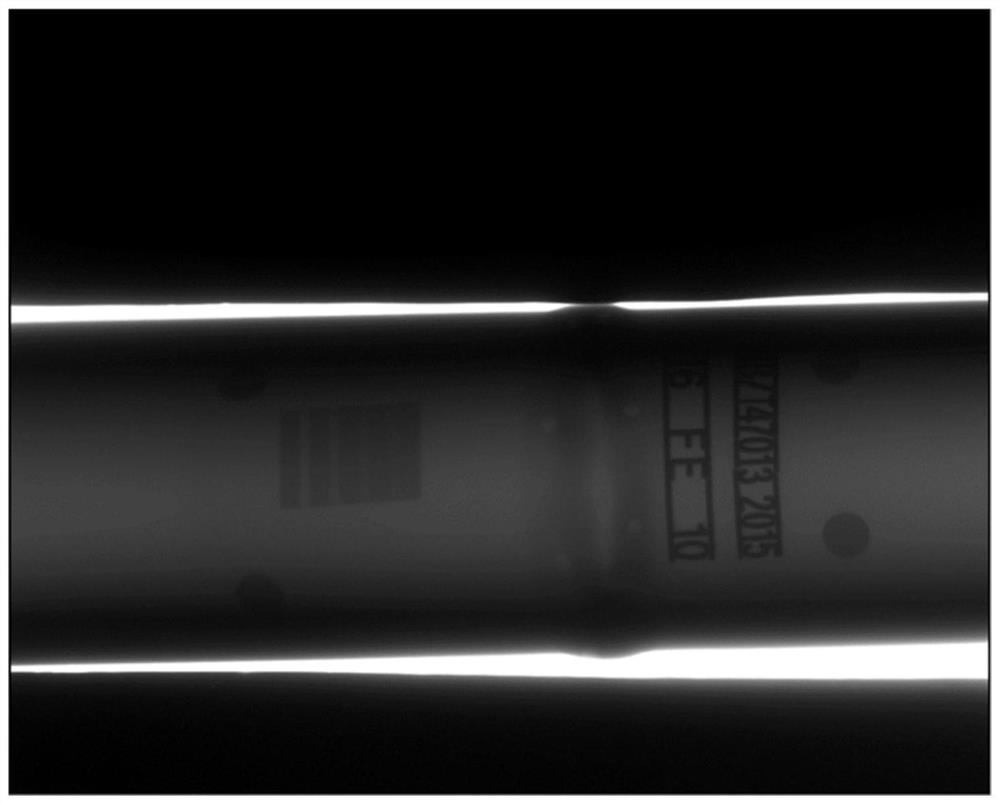

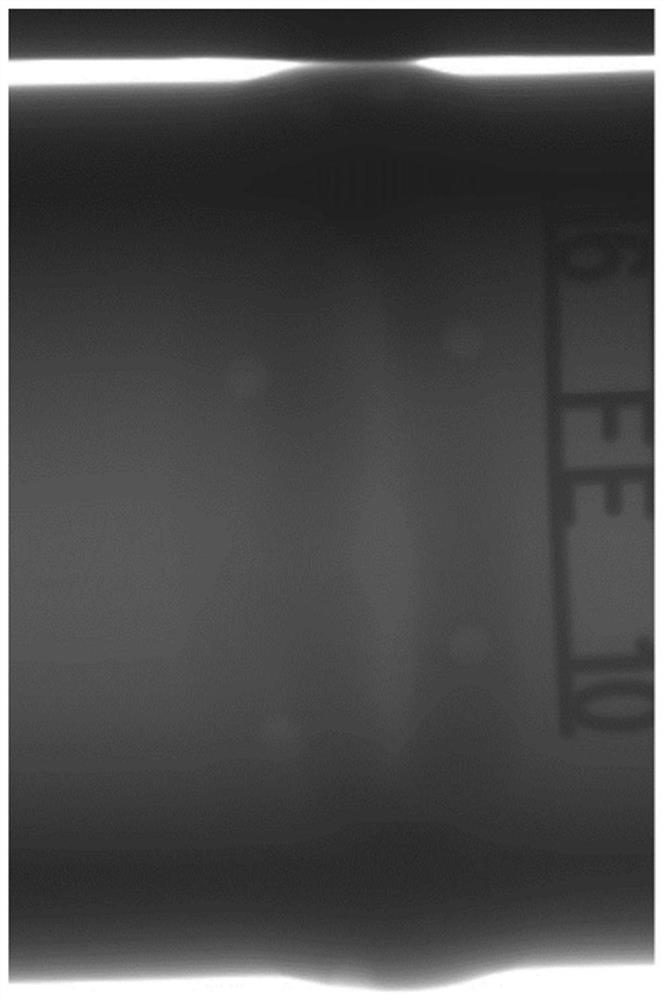

[0083] Step S1: Perform binarization processing on the input image img of pore defects to be detected to obtain a first processed image. In practical application, specific combination figure 2 and image 3 As shown, the input image img to be detected of the air hole defect is specifically the 16-bit original image of the weld seam with the air hole defect, and the first processed image is the binary image imgb1.

[0084] In this embodiment, the first processed image is obtained by performing binarization processing on the input image of the pore defect to be detected, and the specific steps include:

[0085] Step S1-1: performing mean filtering on the image img to be detected for stomatal defects based on a 128×1-dimensional filter check to obtain a first filtered image bimg;

[0086] Step S1-2: Use the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com