Patents

Literature

92results about How to "Quick Auto Detect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neural network-based method for identifying and classifying visible components in urine

ActiveCN101713776AQuick Auto DetectHigh speedImage analysisNeural learning methodsNerve networkClassification methods

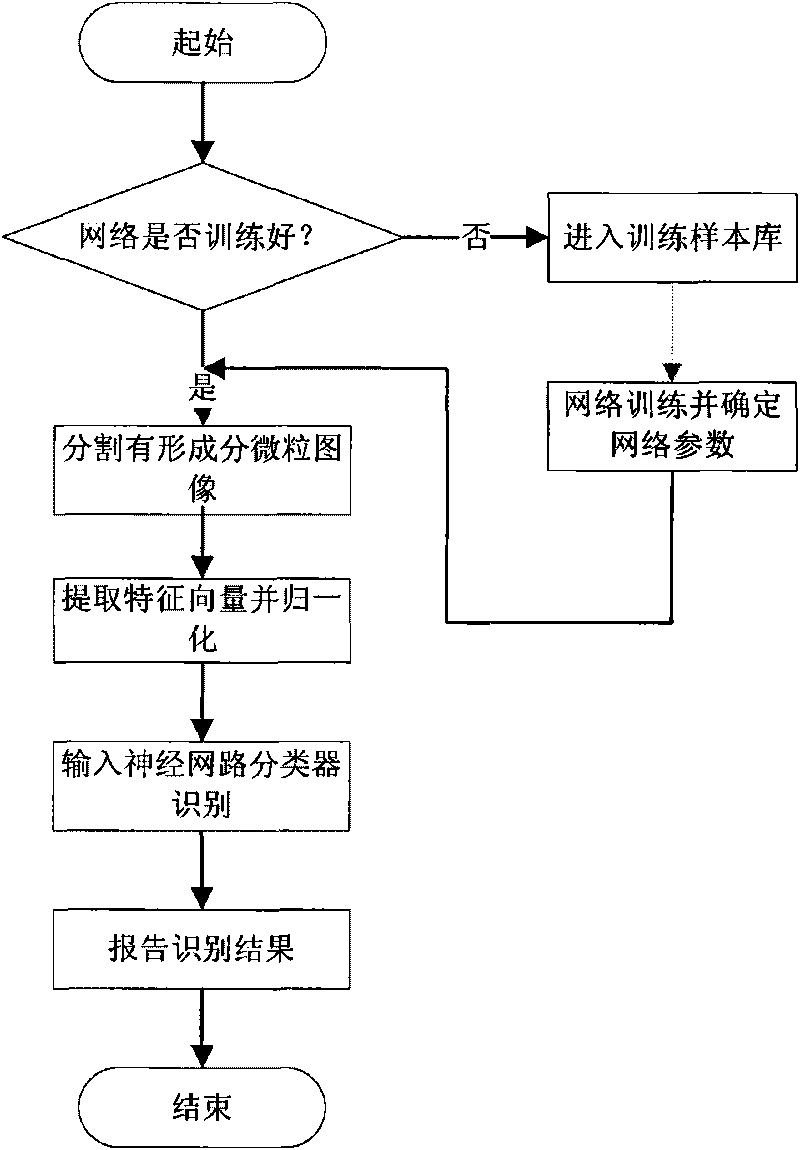

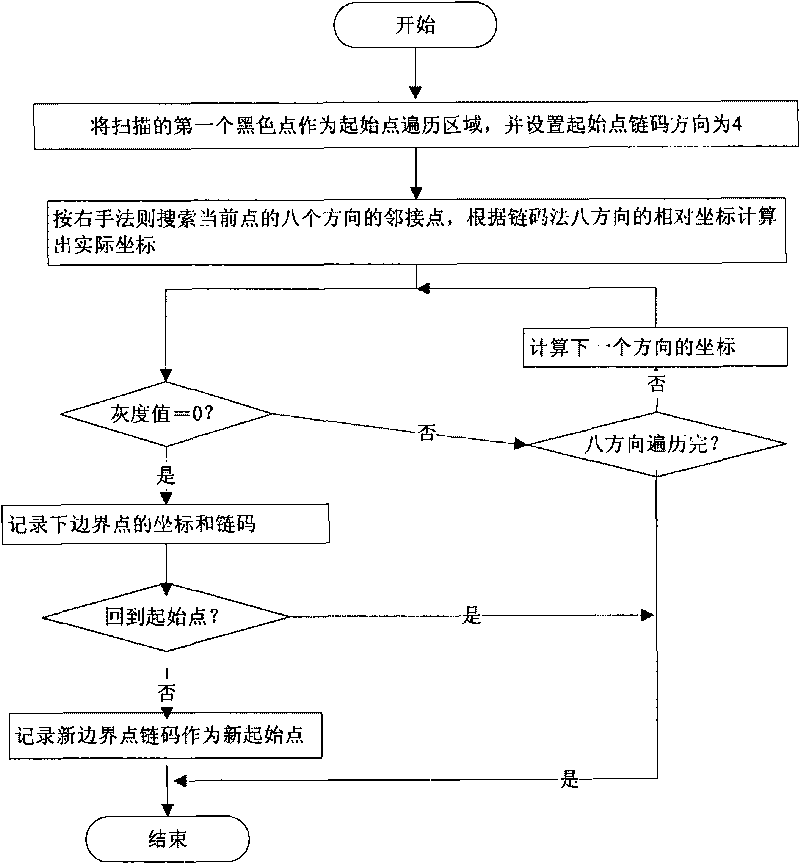

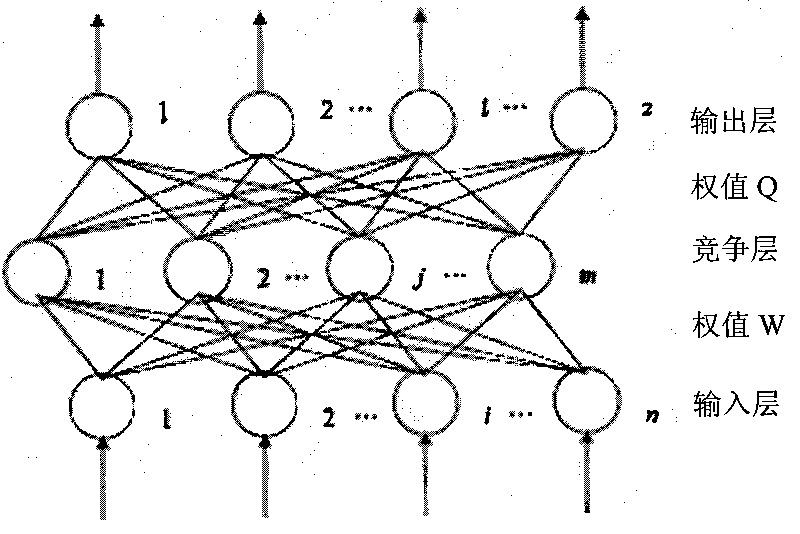

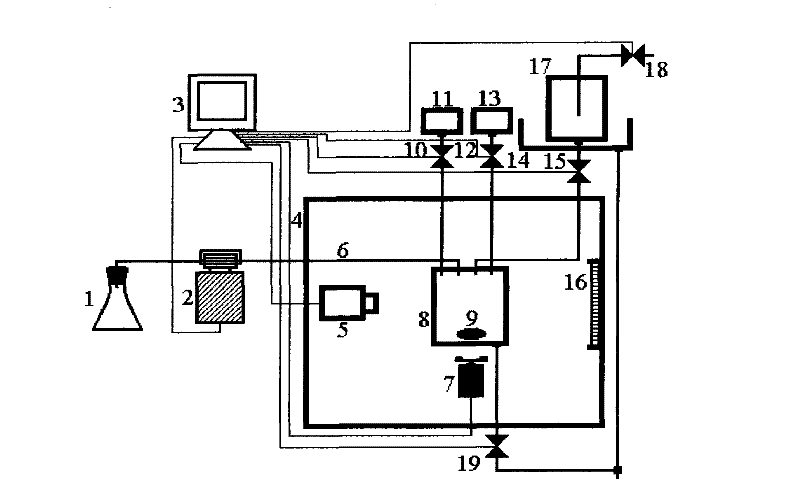

The invention relates to a neural network-based method for identifying and classifying visible components in urine, and belongs to a method for identifying and classifying the visible components in the urine. The method comprises the following steps: shooting an image of a urine sample with a flowing microscope system in urinary sediment detection equipment, and transmitting the image to a memoryof a urinary sediment image workstation; segmenting the shot image in the step 1 to form visible component particle images of the urine, calculating shape and texture feature vectors of the segmentedvisible component particle images in the step 2, and taking the vectors as input of an intelligent neural network; and receiving the feature vectors of the visible component particle images to be identified, normalizing to a range of [0,1], and inputting the trained intelligent neural network for identification. The method has high identification rate and low false positive rate, and greatly improves the accuracy and objectiveness of identifying the visible components in the clinical urine. Meanwhile, the workload of doctors is greatly lightened, and the standardization and automation of detecting the visible components in the urine are realized.

Owner:DIRUI MEDICAL TECH CO LTD

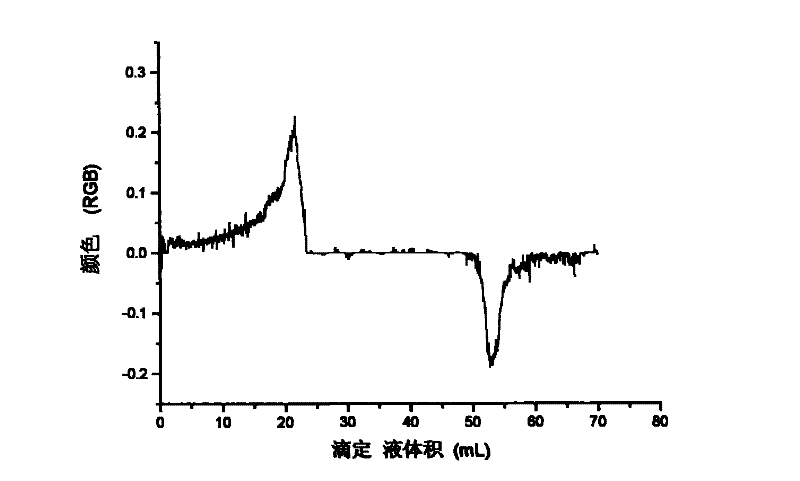

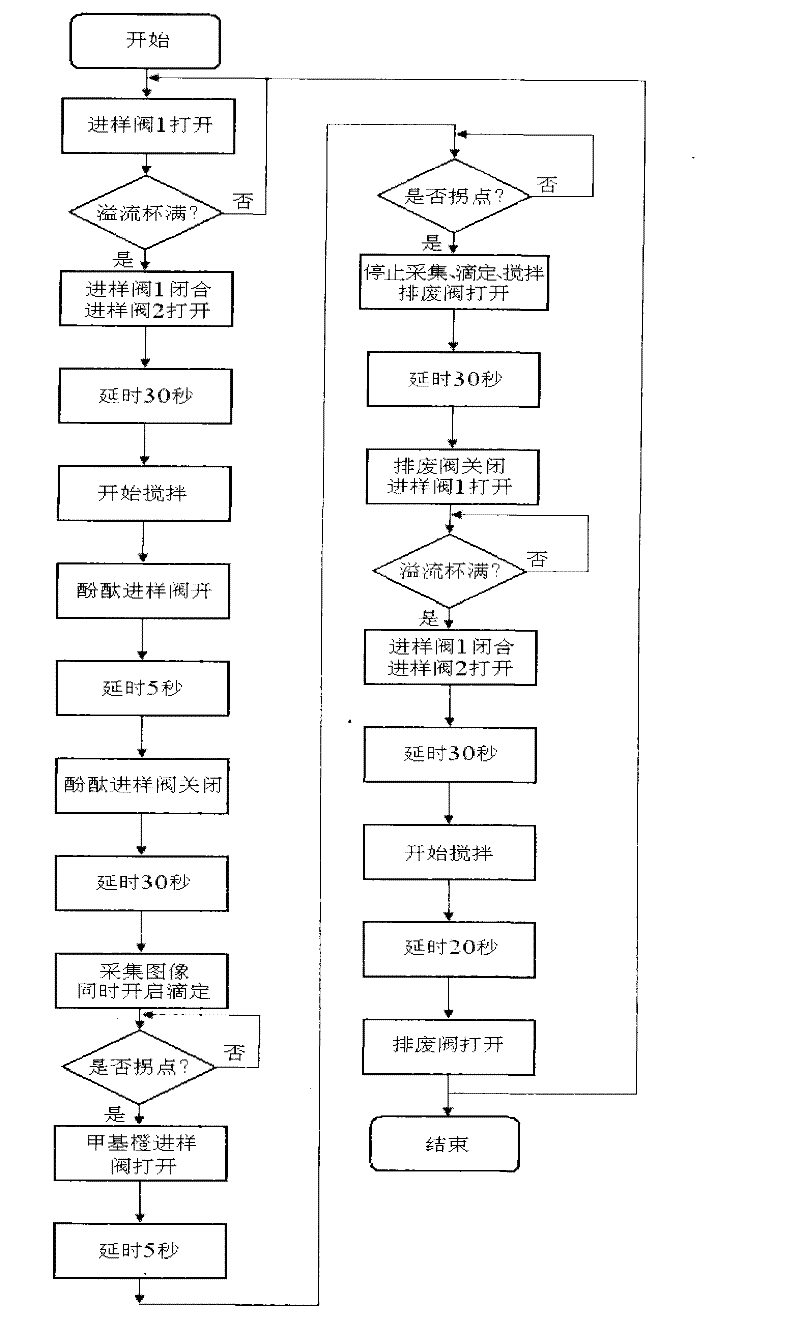

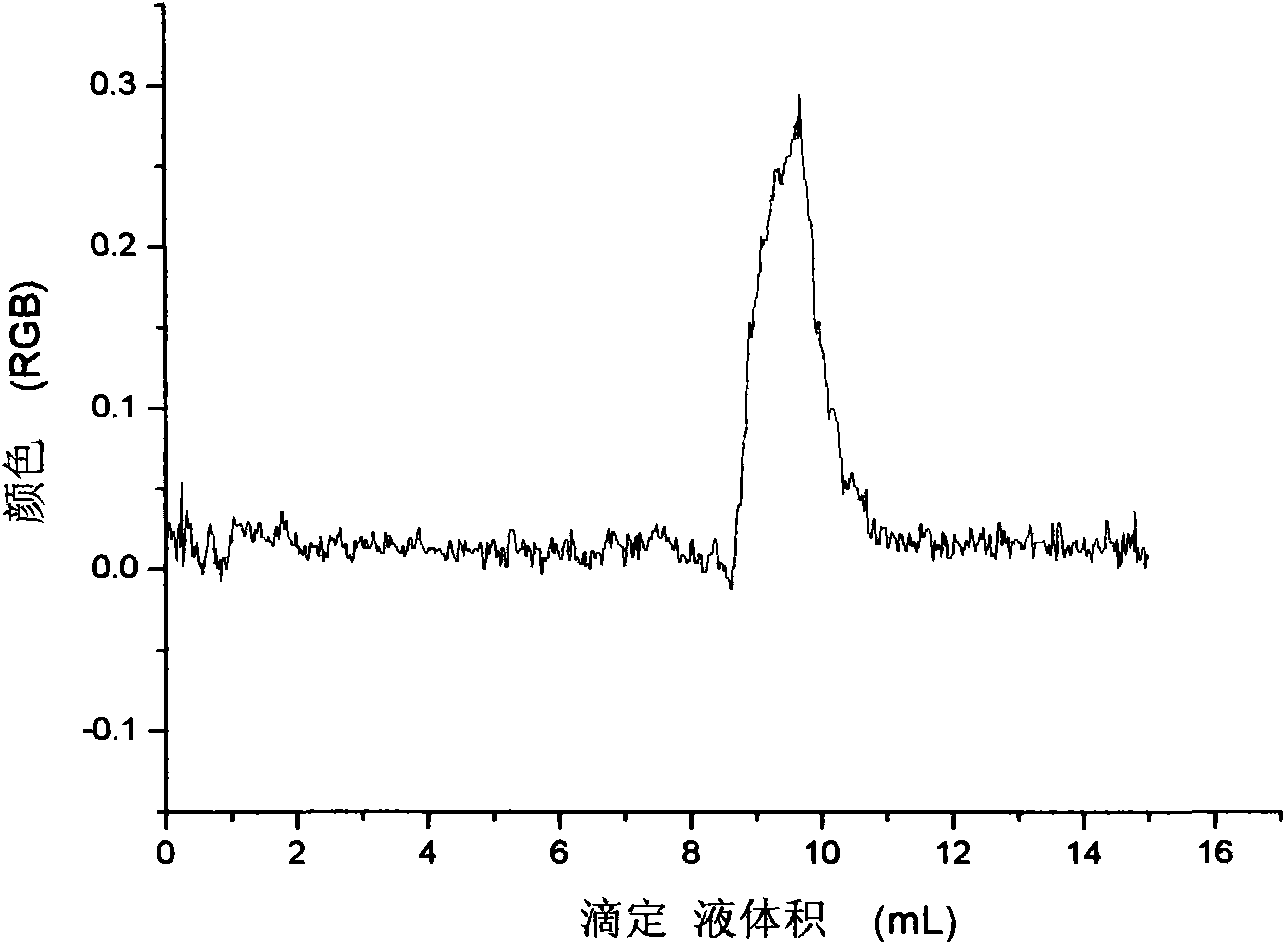

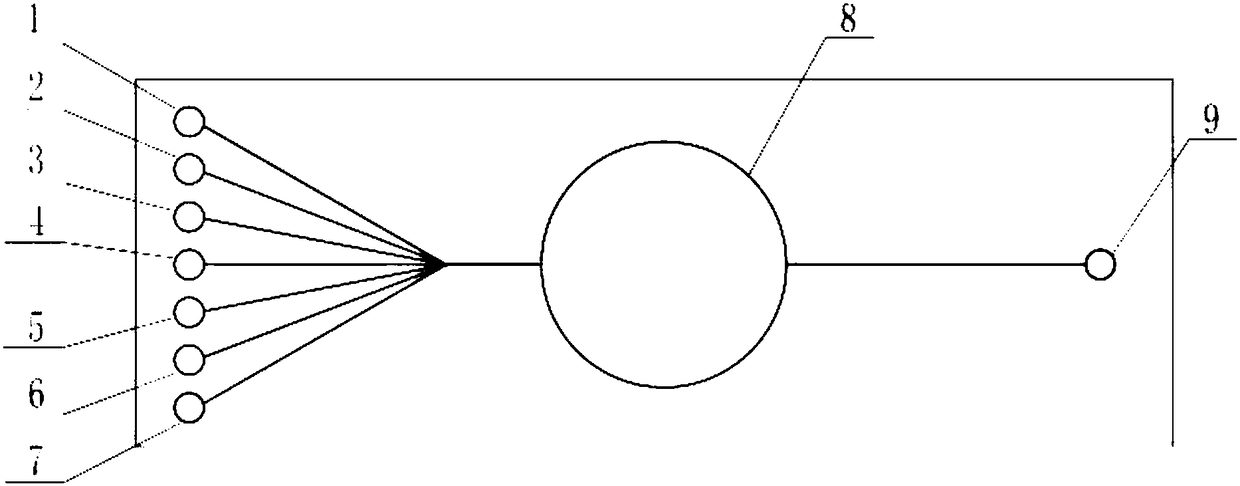

Water alkalinity on-line measuring device based on solution image technology and measuring method thereof

InactiveCN102253164AReduce pollutionReduce consumptionMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationChemical industryMeasurement device

The invention relates to a water alkalinity on-line detection device, a water alkalinity on-line measuring device based on solution image technology and a measuring method thereof, and is characterized in that according to the invention, based on the detection of solution image RGB values during the titration of water to be detected by a HCl solution, an image RGB value-titration solution volume measuring curve is plotted, and the water alkalinity of the solution to be detected is calculated according to the titration solution volume corresponding to an inflection point of the image RGB value measuring curve. With computer image processing technology, the invention establishes a mathematical model of solution RGB values with the change of the titration solution volume during titration, determines the titration end point automatically, establishes a color constancy algorithm model based on a neural network algorithm, and thus increases the precision and reliability of alkalinity measurement. With the device of the invention, on-line measurement of phenolphthalein alkalinity and total alkalinity can be performed optionally, and the operation is convenient. The device is applicable to industry of electric power, petroleum, chemical industry, metallurgy, etc.

Owner:NORTHEAST DIANLI UNIVERSITY

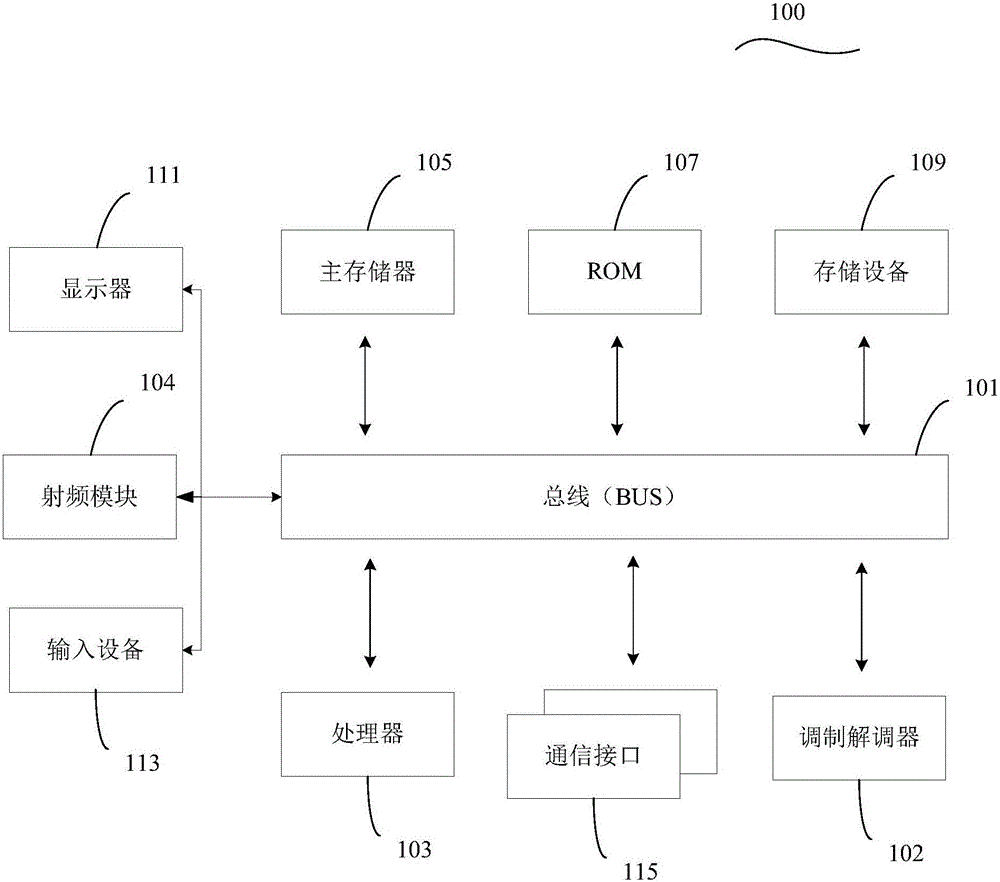

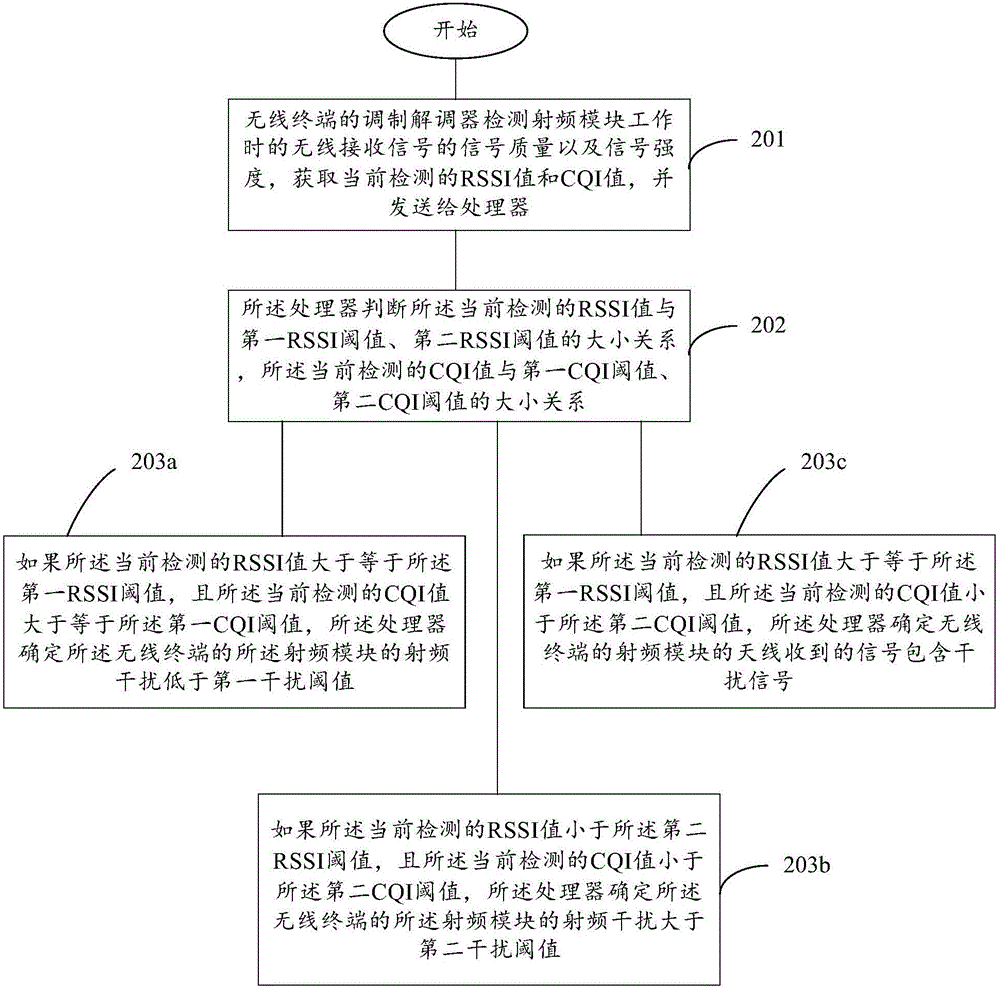

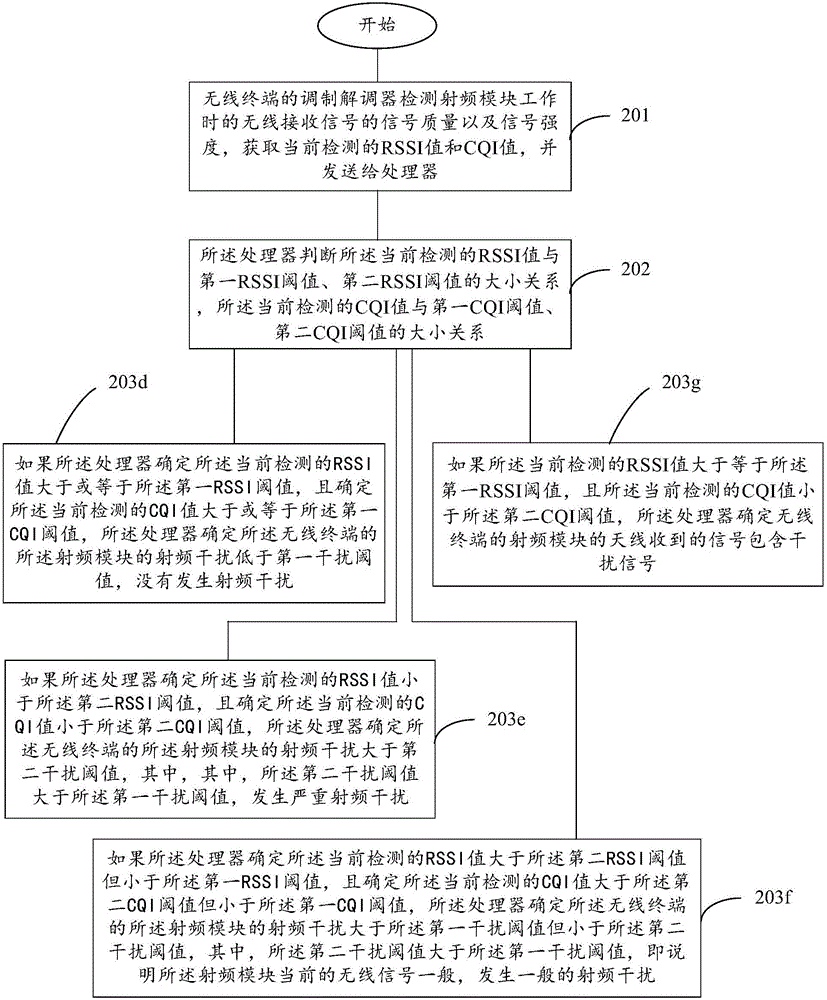

Wireless terminal, radio frequency interference detection method thereof and interference source determination method

The invention provides a wireless terminal, a radio frequency interference detection method thereof and an interference source determination method. According to the radio frequency interference detection method, the received signal strength indicator (RSSI) and received signal quality (CQI) of wireless received signals are detected and compared with threshold values, so that whether radio frequency interference occurs can be detected. With the wireless terminal, the radio frequency interference detection method thereof and the interference source determination method adopted, reduction of additional filter circuit cost can be benefitted, radio frequency interference can be fast detected, baseband signal transmission quality can be improved, and radio frequency performance will not be affected.

Owner:LETV HLDG BEIJING CO LTD +1

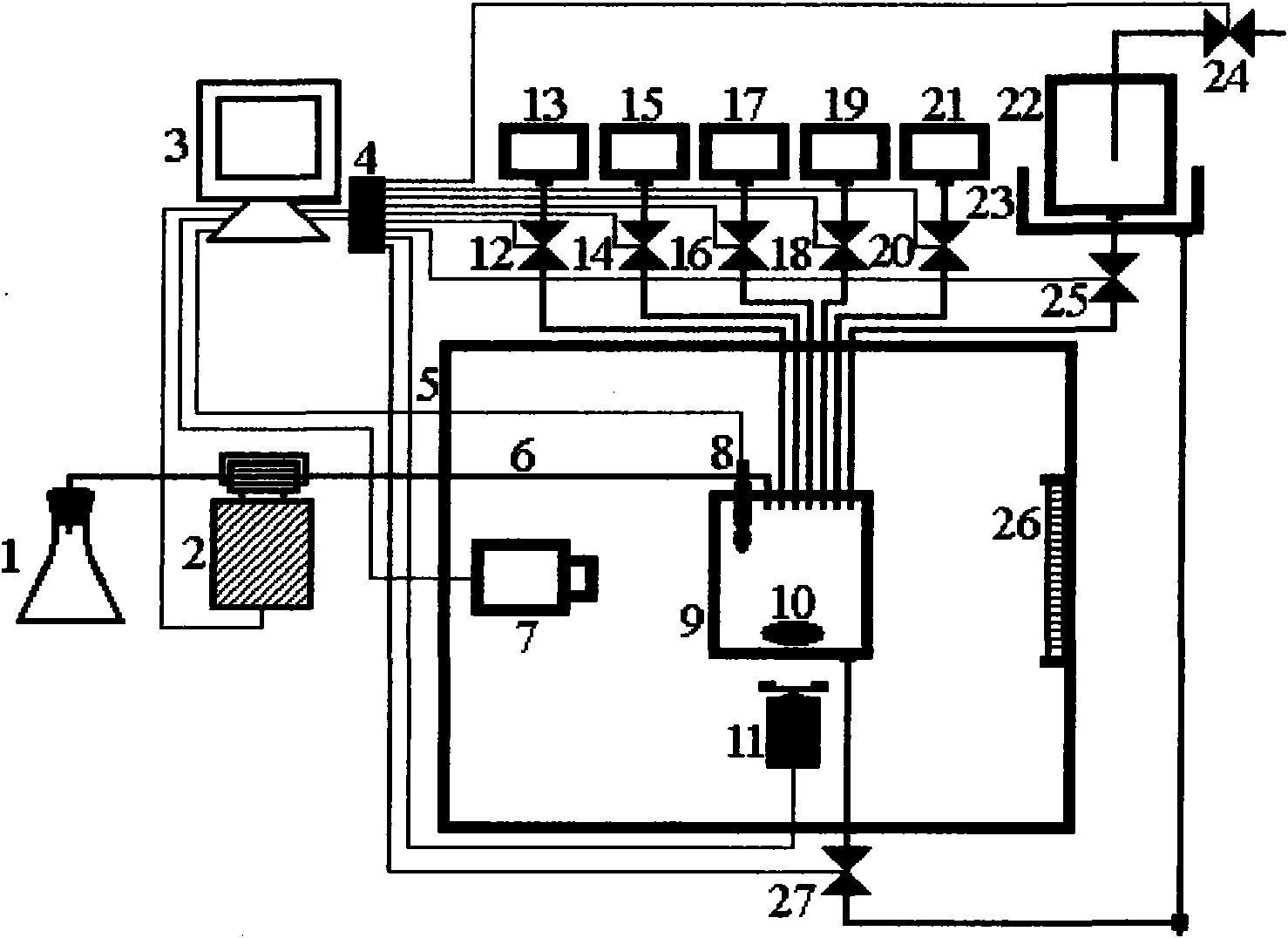

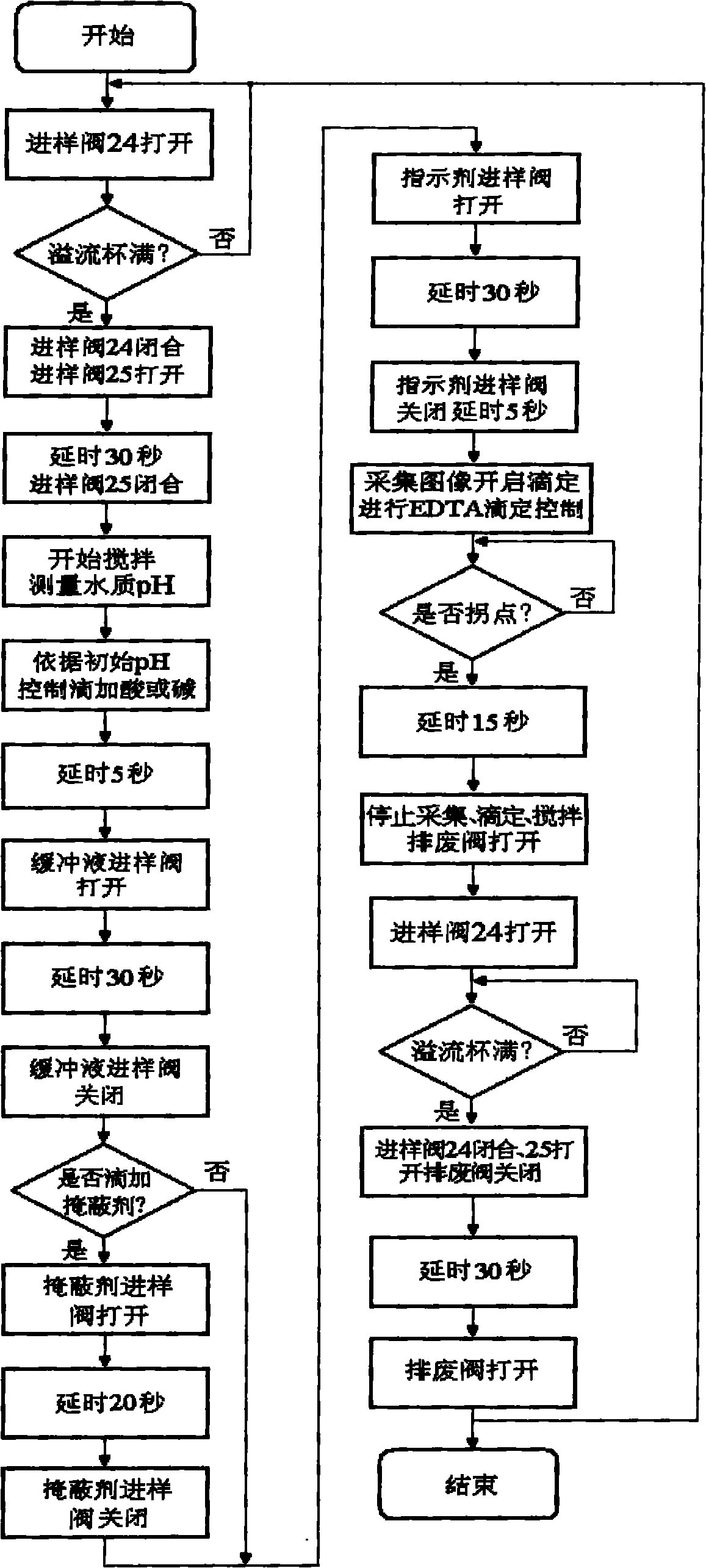

Water hardness on-line measurement device based on solution image technology and measurement method thereof

InactiveCN102183520AReduce pollutionReduce consumptionMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationChemical industryMeasurement device

The invention relates to a water harness on-line measurement device. A measurement method of the water hardness on-line measurement device based on solution image technology is characterized by adding dropwise EDTA into a quantitative water solution with the pH of 10.0 plus or minus 0.1 by using a constant flow adding pump with chrome black T or acid chrome blue K as indicator, L-cysteine hydrochloride and triethanolaminesolution as screening agent and ethylenediaminetetraacetic disodiumsalt solution as titrant, recording the volume of added EDTA (Ethylene Diamine Tetraacetic Acid) solution by a computer, simultaneously collecting water solution image colors by using a CCD (Charged Coupled Device) image sensor, displaying image color RGB (Red, Green and Blue)-titrating solution volume real-time curve on a computer screen, and calculating the water hardness according to the titrating solution volume corresponding to the inflection point of the RGB-titrating solution volume curve, wherein the detection precision is improved by adopting a color constancy algorithm based on a neutral network to reduce the interference of factors such as a light source, sensor noise and the like. The invention have the choices of high hardness and low hardness on-line measurement, is simple and convenient in operation, and can be used in the industries of electric power, petroleum, chemical industry, metallurgy and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

Method for detecting magnaporthe grisea spore based on microscopic image analysis

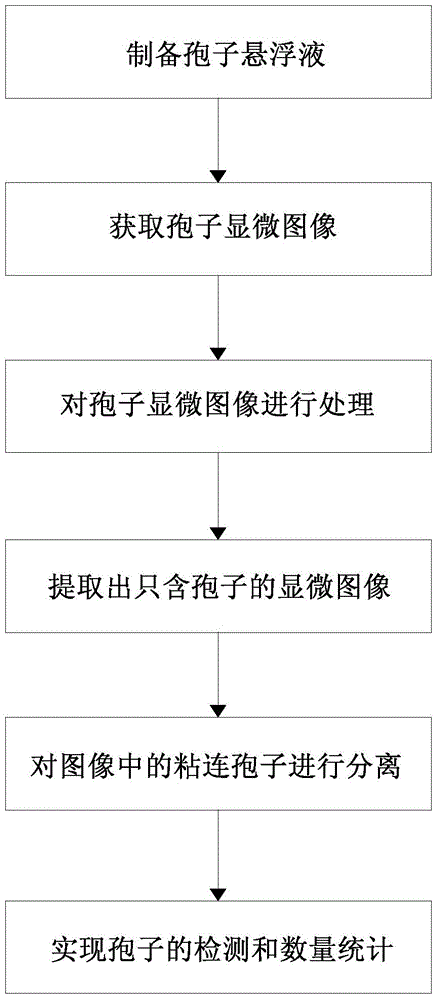

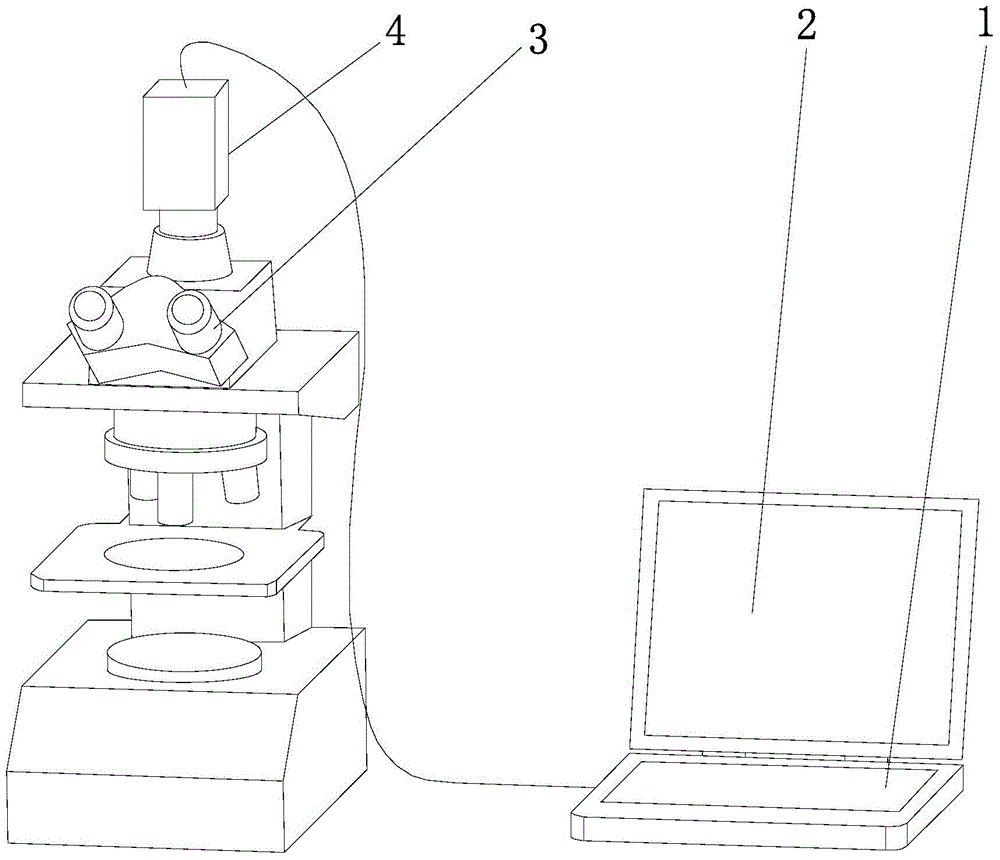

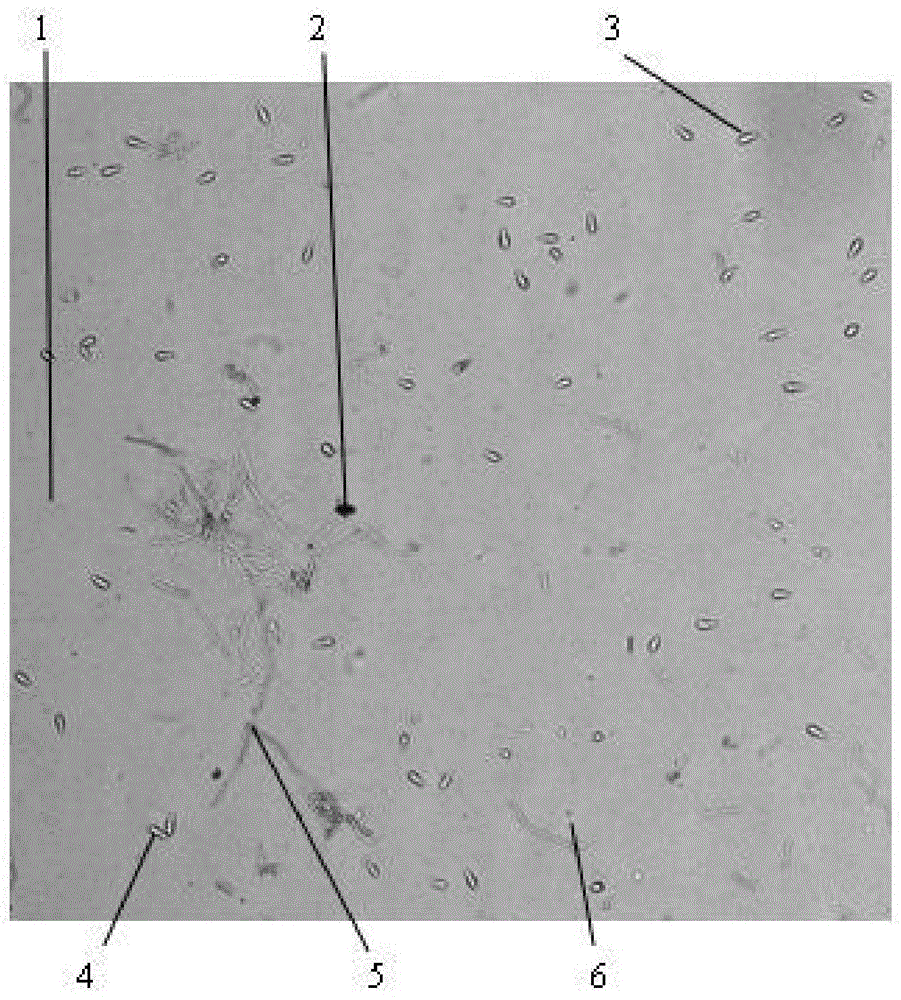

ActiveCN104651462AEffective segmentationSolve the problem that easily leads to wrong over-segmentationMicrobiological testing/measurementMicroorganism based processesPattern recognitionMicroscopic image

The invention discloses a method for detecting a magnaporthe grisea spore based on microscopic image analysis. The method comprises the following steps: obtaining a spore microscopic image in the spore suspension solution by a magnaporthe grisea spore image detecting system; processing the spore microscopic image by using the image illumination adjustment, the median filtering, the edge detection and the morphological algorithm, and extracting a microscopic image containing the spore by combining with the shape characteristic parameters; separating the adhesion spores by using an improved watershed algorithm to realize the spore detection and quantitative statistics in the microscopic image. By adopting the method for detecting the magnaporthe grisea spore, the number of the magnaporthe grisea spore can be rapidly, accurately and automatically detected, the technical assistance for the indoor resistance identification of the magnaporthe grisea is provided and the technical reference for automatically monitoring the magnaporthe grisea in the fields is also provided.

Owner:SOUTH CHINA AGRI UNIV

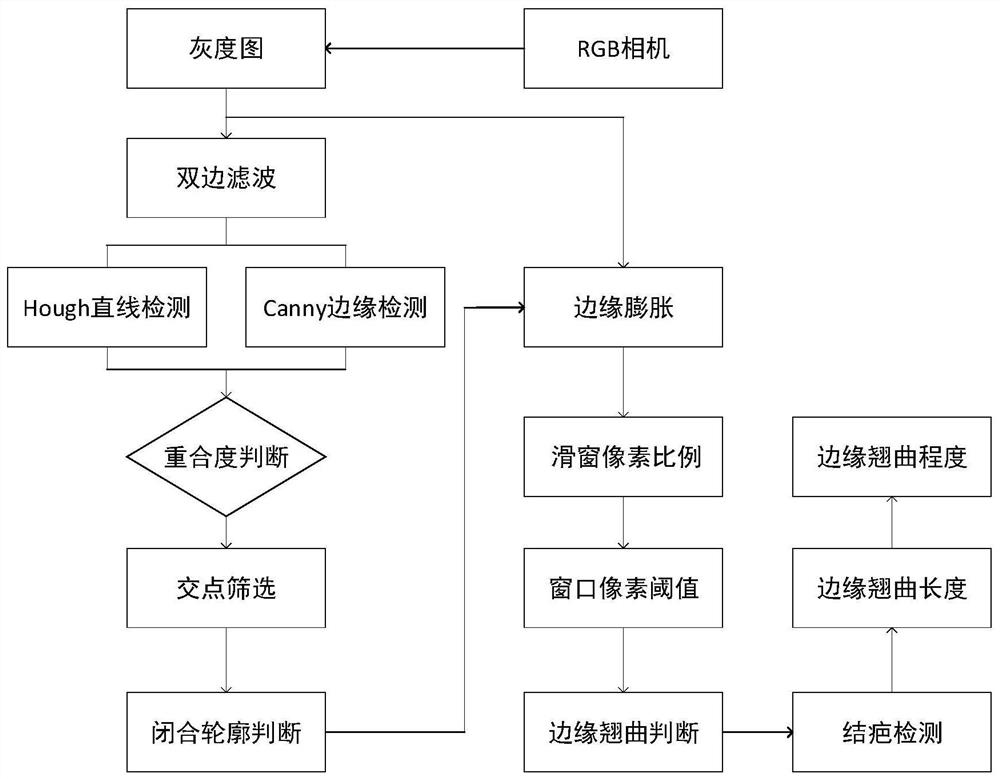

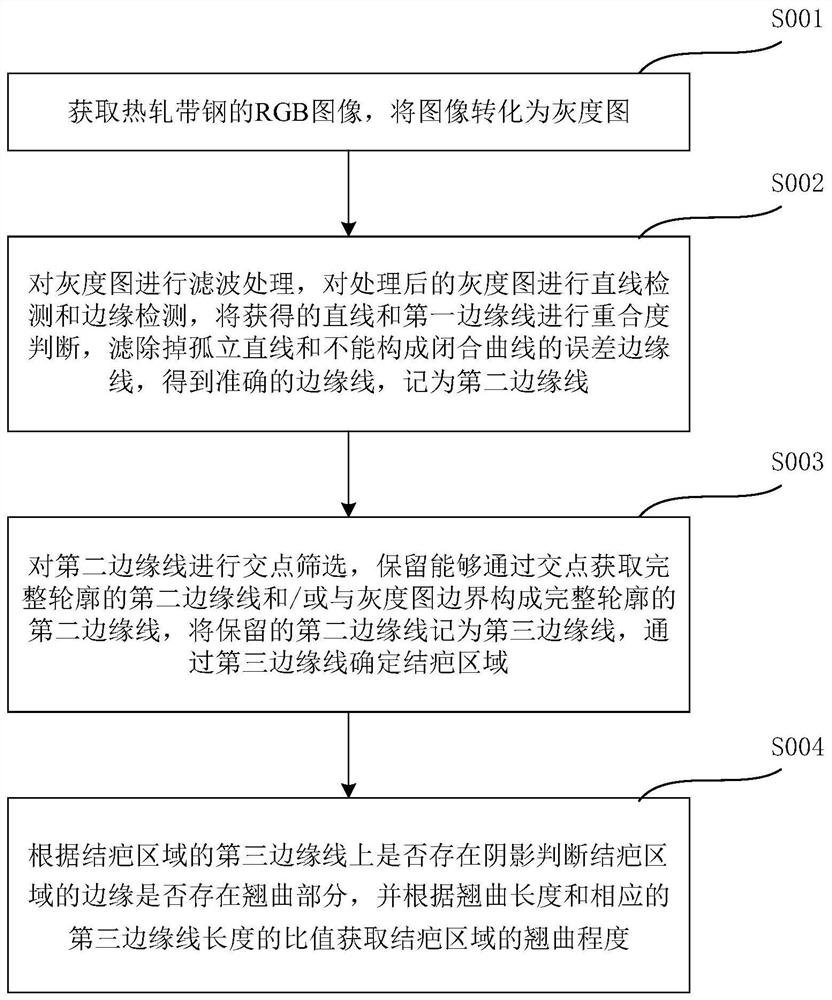

Artificial intelligence-based hot-rolled strip steel scabbing defect detection method and system

InactiveCN112712512ATimely resectionEliminate noise interferenceImage enhancementImage analysisEngineeringEdge detection

The invention relates to the technical field of artificial intelligence, in particular to an artificial intelligence-based hot-rolled strip steel scabbing defect detection method and system. The method comprises the following steps: acquiring an RGB image of hot-rolled strip steel and converting the RGB image into a grey-scale map; filtering the grey-scale map, carrying out straight line detection and edge detection on the processed grey-scale map, carrying out overlap ratio judgment on an obtained straight line and a first edge line, and filtering out an isolated straight line and an error edge line to obtain a second edge line; performing intersection point screening on the second edge lines, so that the second edge lines capable of obtaining the complete contour through intersection points and / or the second edge lines forming the complete contour with the gray-scale map boundary are / is reserved and recorded as third edge lines, and a scabbing area is determined; and judging whether the edge of the scabbing area has a warping part or not according to whether a shadow exists on the third edge line of the scabbing area or not, and obtaining the warping degree of the scabbing area. According to the embodiment of the invention, noise interference can be greatly eliminated, and the scarring defect of the strip steel can be accurately and quickly detected.

Owner:余波

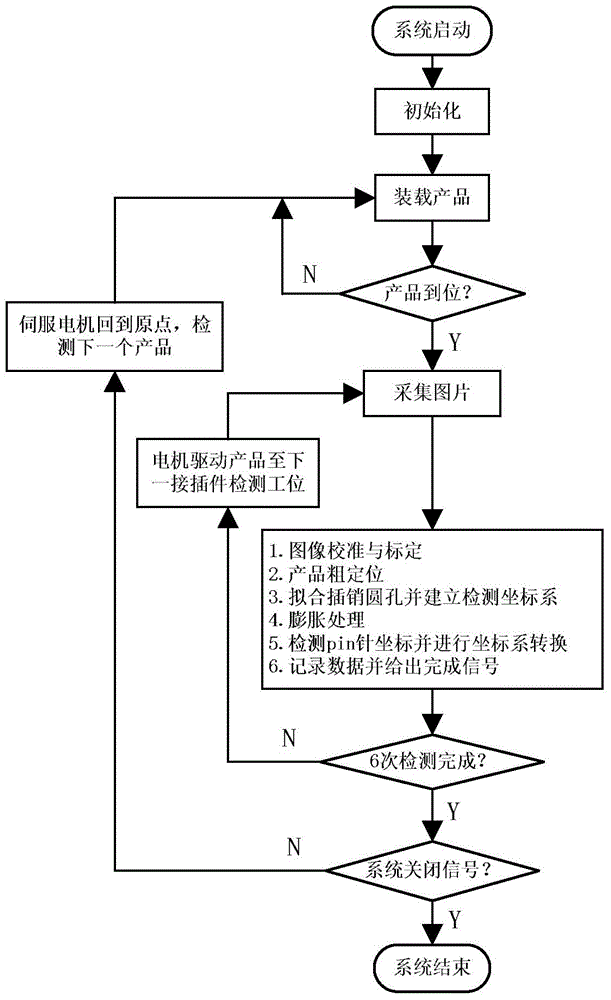

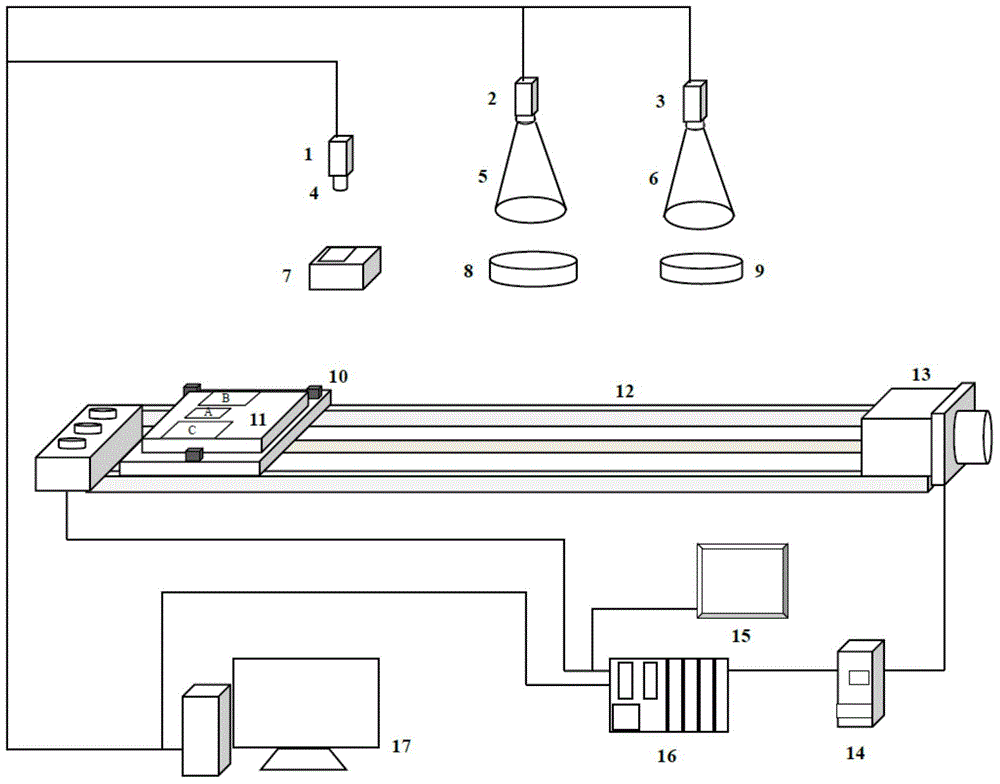

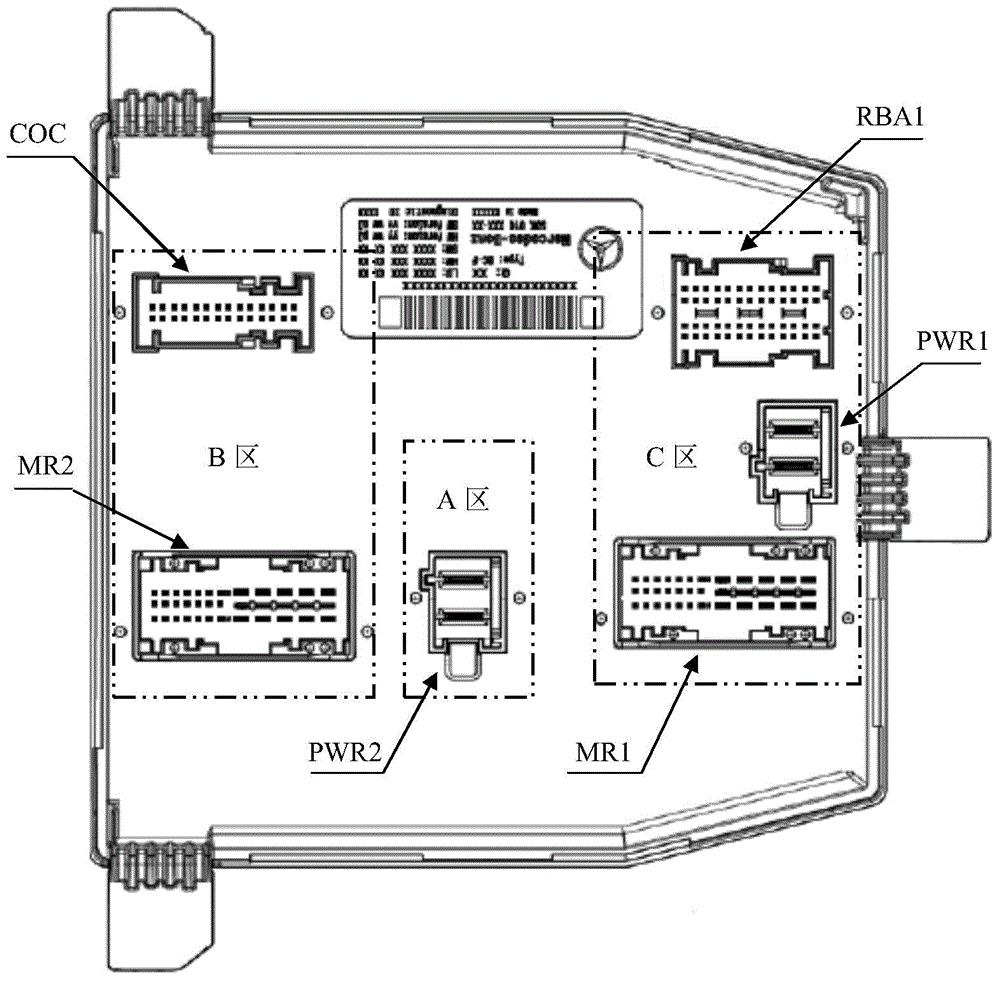

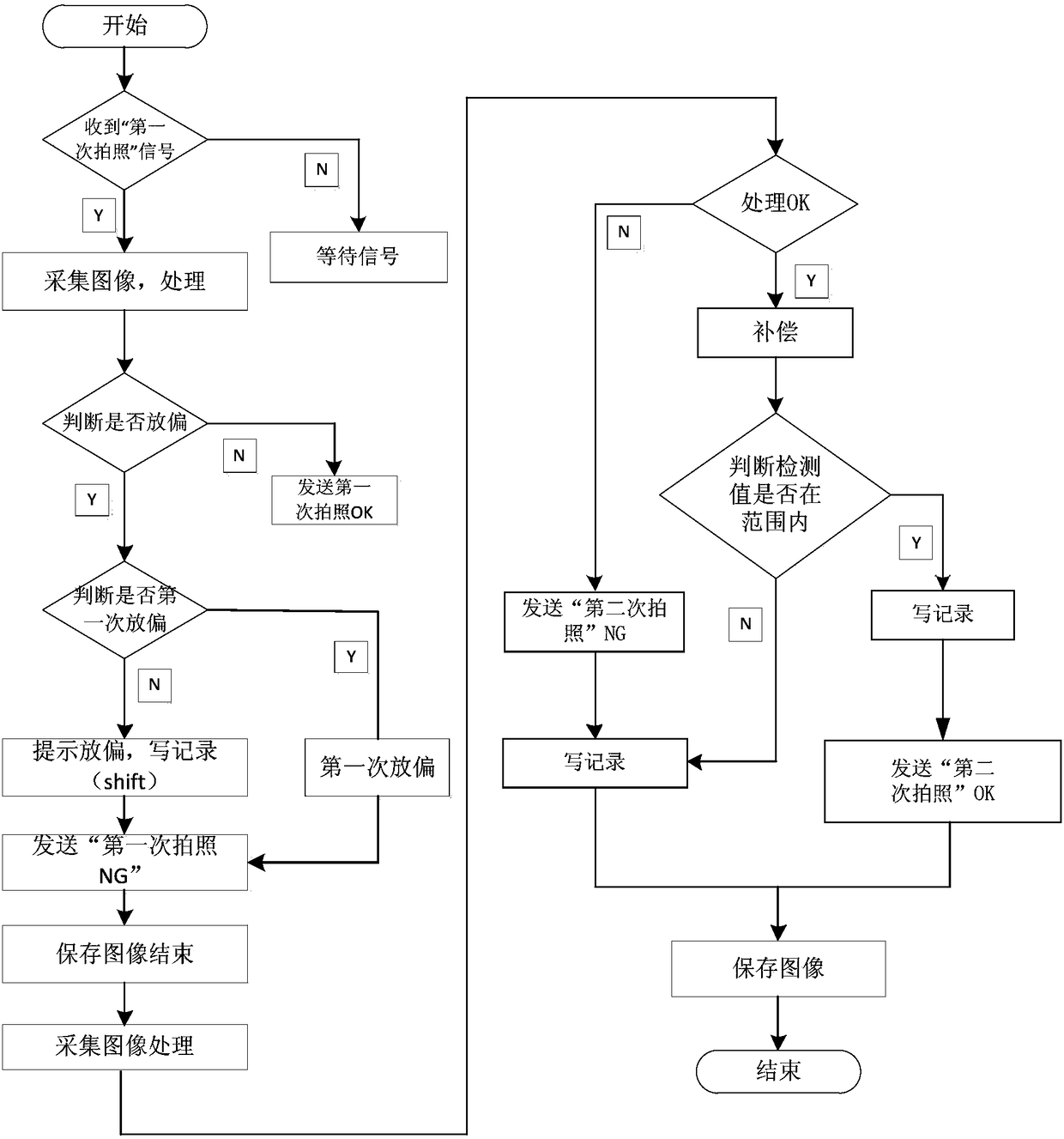

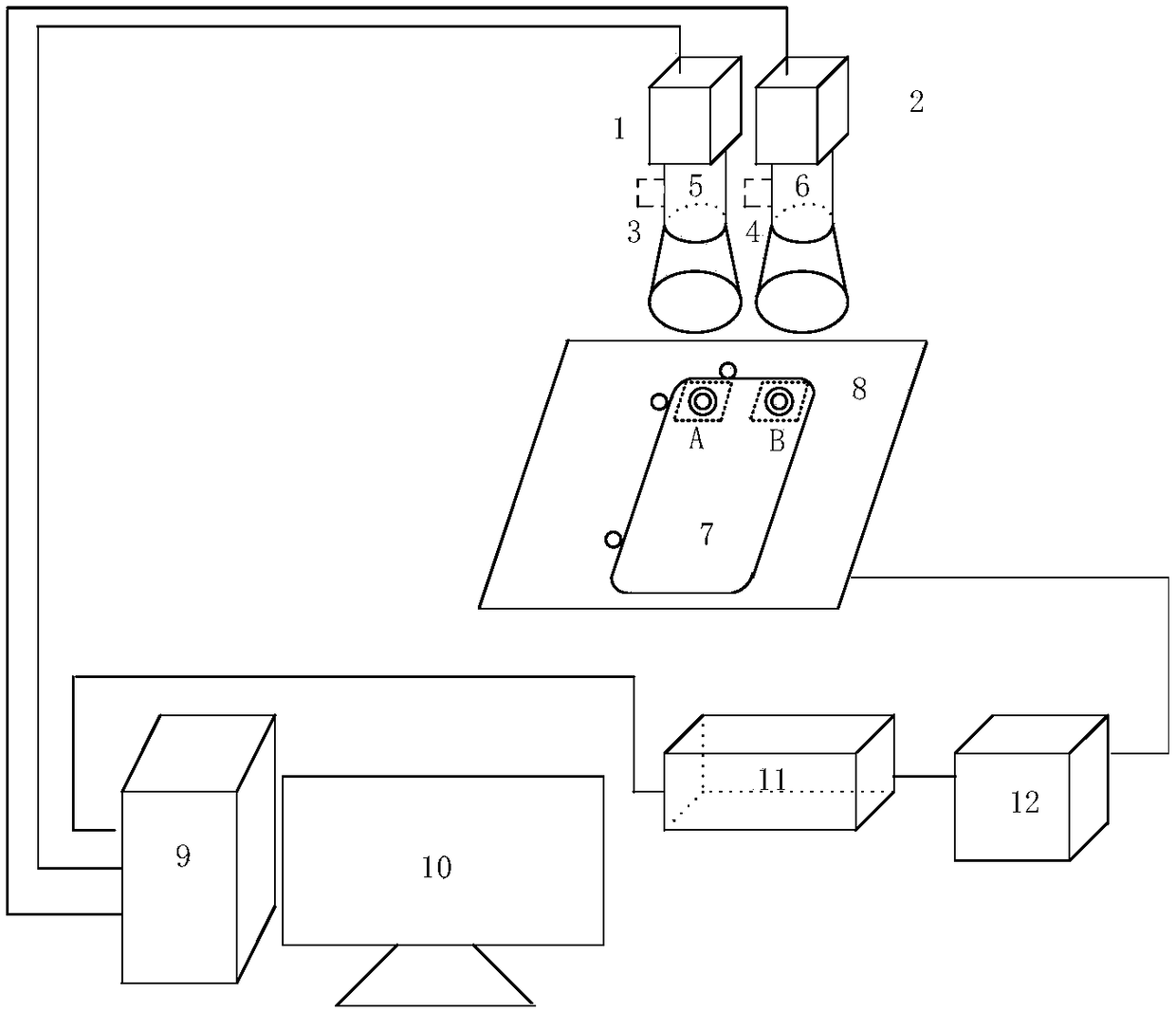

True position detecting method for pin of socket connector of vehicle controller

ActiveCN104913722AImprove reliabilityImprove stabilityUsing optical meansImaging processingDistribution characteristic

The invention discloses an automatic true position detecting method and specifically relates to a true position detecting method for a pin of a socket connector of a vehicle controller. A detection system includes an image collecting unit, a motion control unit, a servo motor unit, an upper computer processing unit and an auxiliary device. A method of arranging three cameras in three zones including an A zone, a B zone and a C zone for detection is designed according to distribution characteristics of socket connectors. After the system is started, the motion control unit drives a to-be-detected product to a detection station and triggers a photo taking signal. The image collecting unit collects images and sends the images to the upper computer processing unit for processing and the processed data is recorded. An image processing algorithm is used for detecting the true position of the pin of the socket connector and a detection result is displayed and an implementation signal is given out. Later, the motion control unit drives the to-be-detected product to a socket connector station for a next step. By using the method provided by the invention, quick, accurate and automatic detection of true position of the pin of the socket connector of the vehicle controller can be realized.

Owner:黑龙江至晟车辆技术服务有限公司

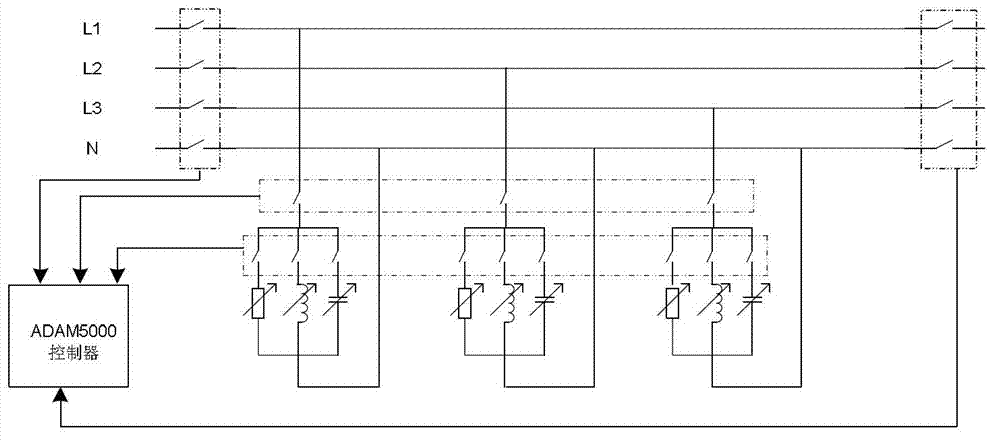

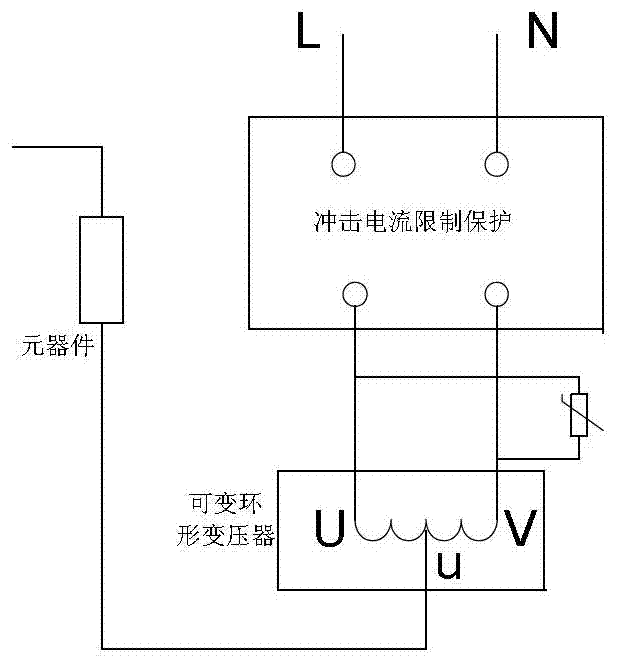

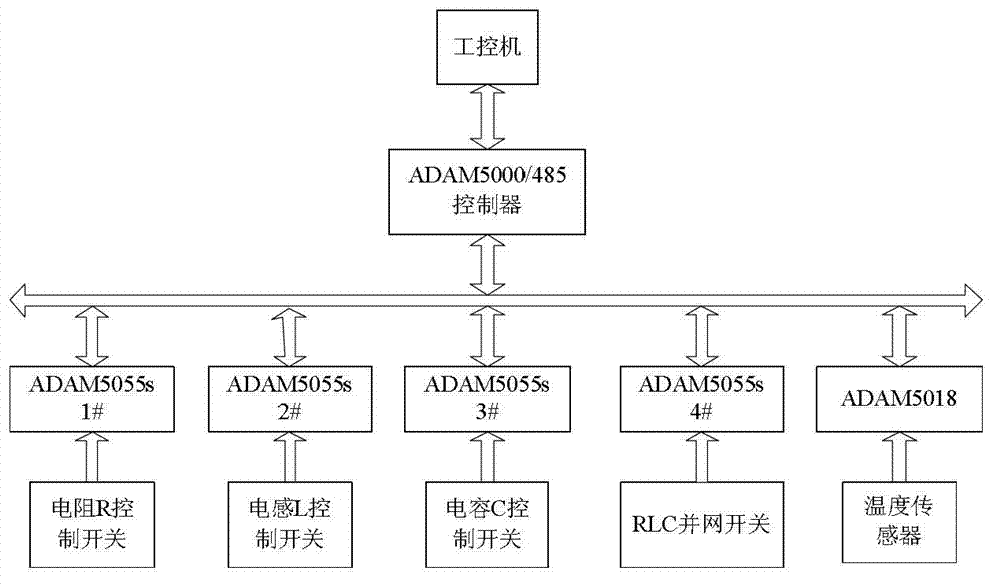

Intelligent RLC (resistance inductance capacitance) load and island-preventing detecting circuit

InactiveCN103117554AQuick Auto DetectContinuous and reliable power outputElectrical testingSingle network parallel feeding arrangementsPower inverterCapacitance

The invention provides an intelligent RLC (resistance inductance capacitance) load and island-preventing detecting unit which comprises a direct current power source, an inverter, switch units, an RLC adjustable load unit, a waveform recorder, a power grid and an ADAM controller. One side of the inverter is connected with the direct current power source, and the other side thereof is connected with the RLC adjustable load unit and the power grid in parallel. The waveform recorder tests current waveforms of the inverter and the power grid respectively. The switch units are arranged on conductive paths of the inverter, the RLC adjustable load unit and the power grid. The ADAM controller controls the switch units. The intelligent RLC load and island-preventing detecting circuit is capable of accurately detecting island-preventing function of a grid power source of a user side and can meet the technical requirements of standard regulations such as VDE-0126 and IEC62116.

Owner:CHINA ELECTRIC POWER RES INST +1

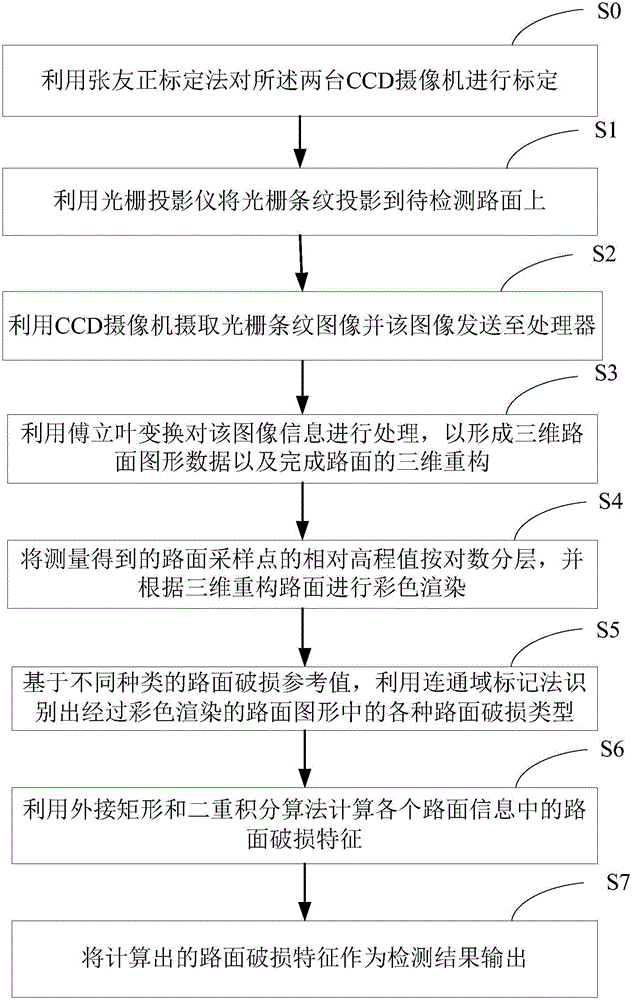

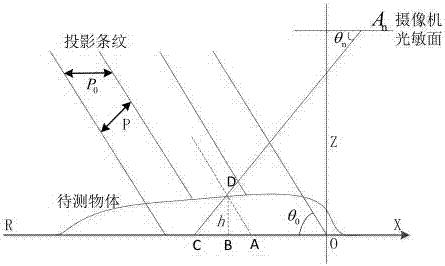

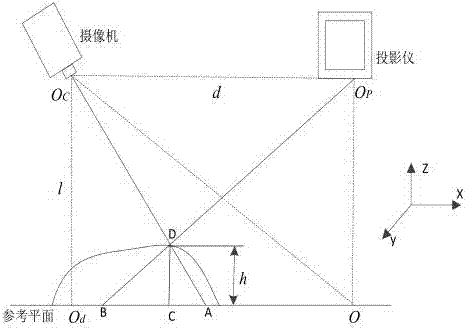

Three-dimensional visual detection method and detection device for road surface damage information

The invention relates to a three-dimensional visual detection method and detection device for road surface damage information. The detection method comprises the following steps that optical grating fringes are projected onto a road surface to be detected; projected optical grating fringe images are photographed correspondingly, and image information is transmitted to a processor; the image information is processed, and three-dimensional road surface image data are formed; three-dimensional reconstruction of the road surface is completed according to the three-dimensional road surface geometric data; color rendering is conducted on the three-dimensional road surface images, and road surface damage types of the road surface images subjected to color rendering are recognized through a connected domain labeling method; road surface damage characteristics of the road surface information are worked out; and finally the worked-out road surface damage characteristics serve as detection results and are output. The detection method is accurate in detection, high in efficiency and capable of detecting various kinds of road surface damage information. The invention further relates to the three-dimensional visual detection device for the road surface damage information. The detection device comprises an optical grating projector, two CCD cameras, an optical-electricity encoder and a detection control computer.

Owner:CHINA ACAD OF TRANSPORTATION SCI

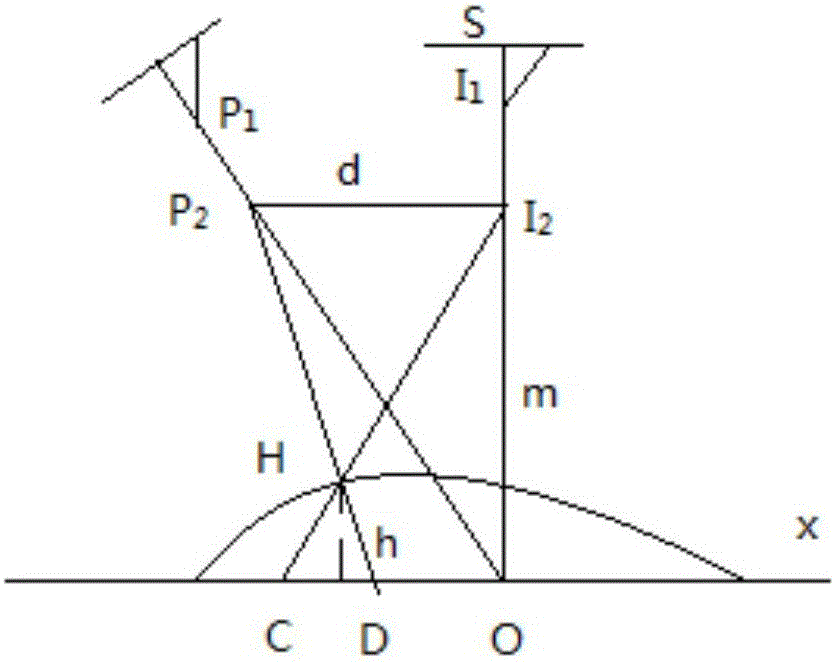

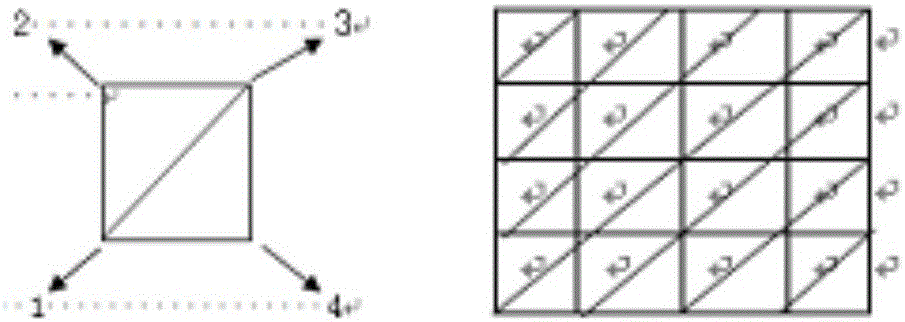

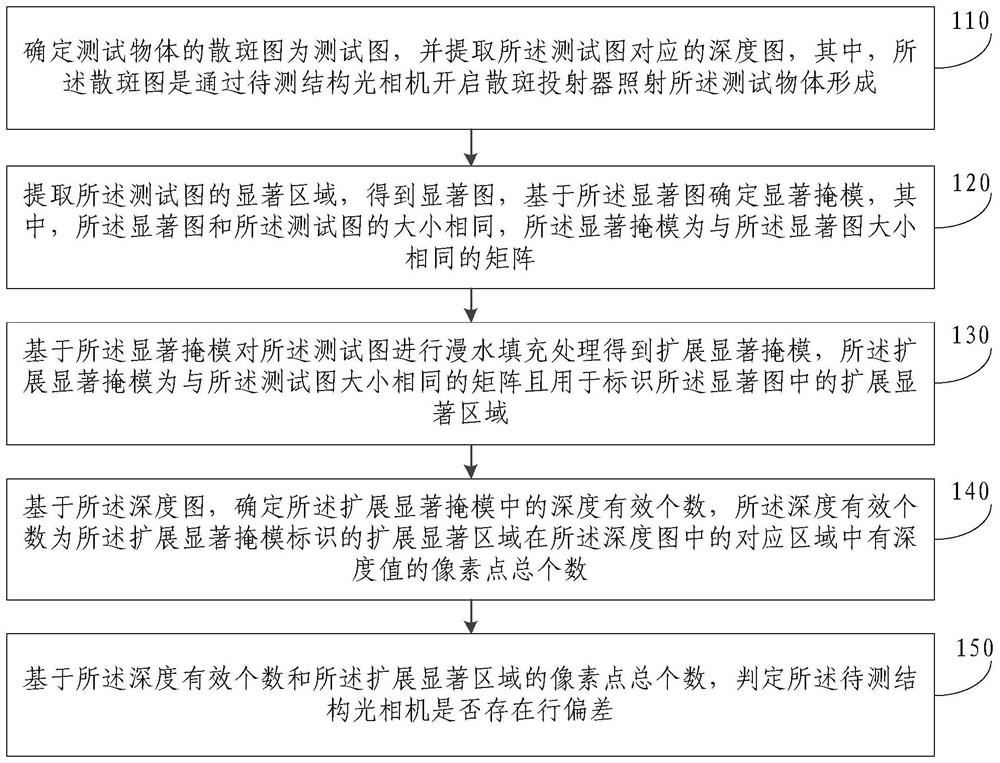

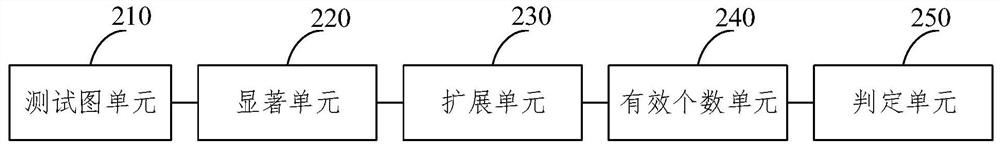

Speckle pattern-based structured light camera row deviation automatic detection method and device

PendingCN111768450AAvoid time delayQuick Auto DetectImage enhancementImage analysisTest objectSaliency map

The embodiment of the invention provides a speckle pattern-based structured light camera row deviation automatic detection method and device. The method comprises the following steps: extracting a speckle pattern of a test object as a test pattern; extracting a depth map and a saliency map corresponding to the test map; further determining a saliency mask corresponding to the saliency map; processing the saliency mask through flooding filling to obtain an extended saliency mask used for identifying an extended salient region in the saliency map; determining that the total number of the pixel points with the depth values in the corresponding region of the depth map in the extended salient region of the extended saliency mask identifier is the effective number of the depths; and finally, judging whether the structured light camera to be detected has row deviation or not based on the effective number of the depths and the total number of the pixel points in the extended salient region. According to the method and the device provided by the embodiment of the invention, whether a test speckle pattern shot by a to-be-tested structured light camera has the row deviation or not can be quickly and automatically detected, and time delay caused by re-calibration when the camera is used each time is avoided.

Owner:合肥的卢深视科技有限公司

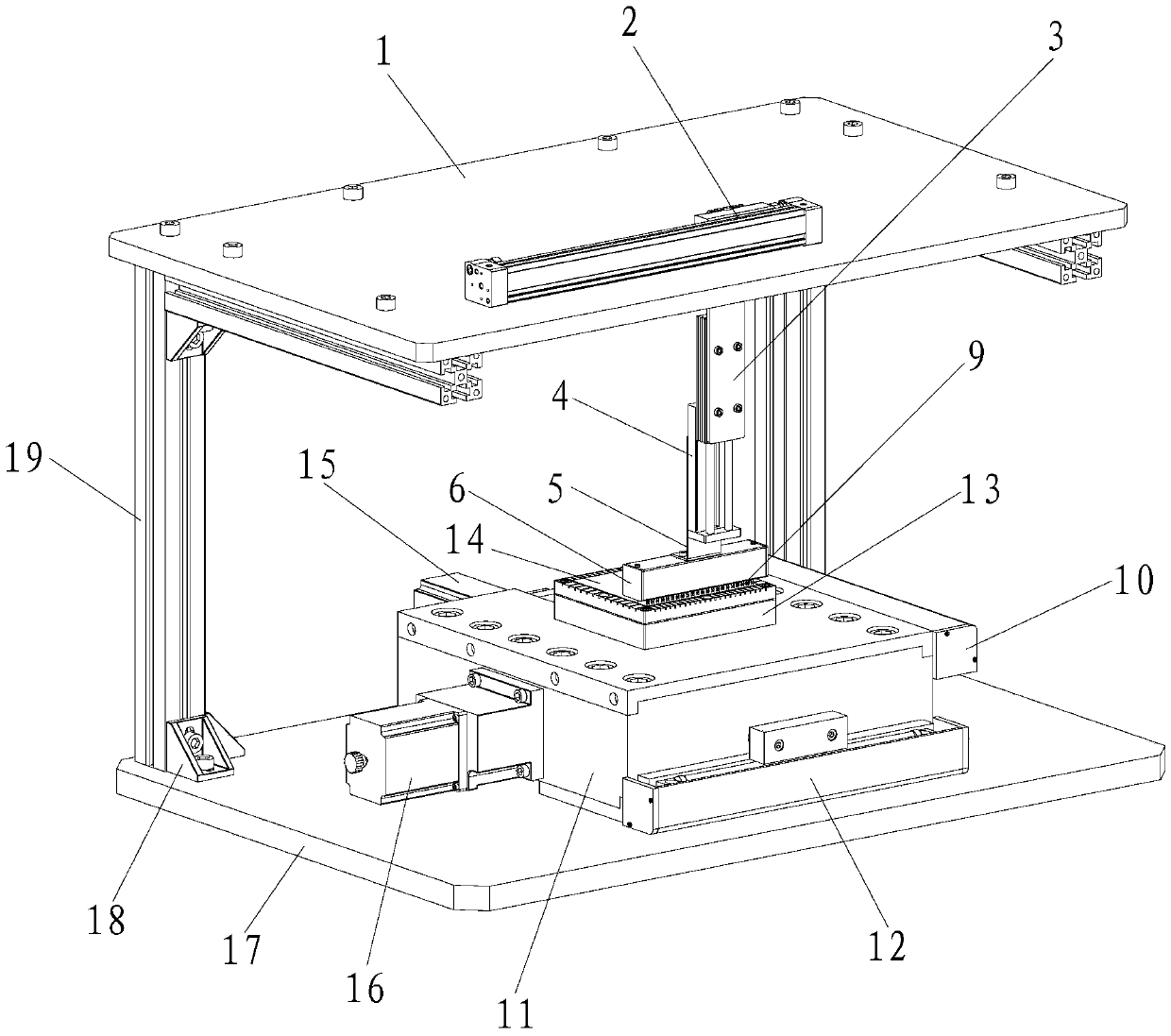

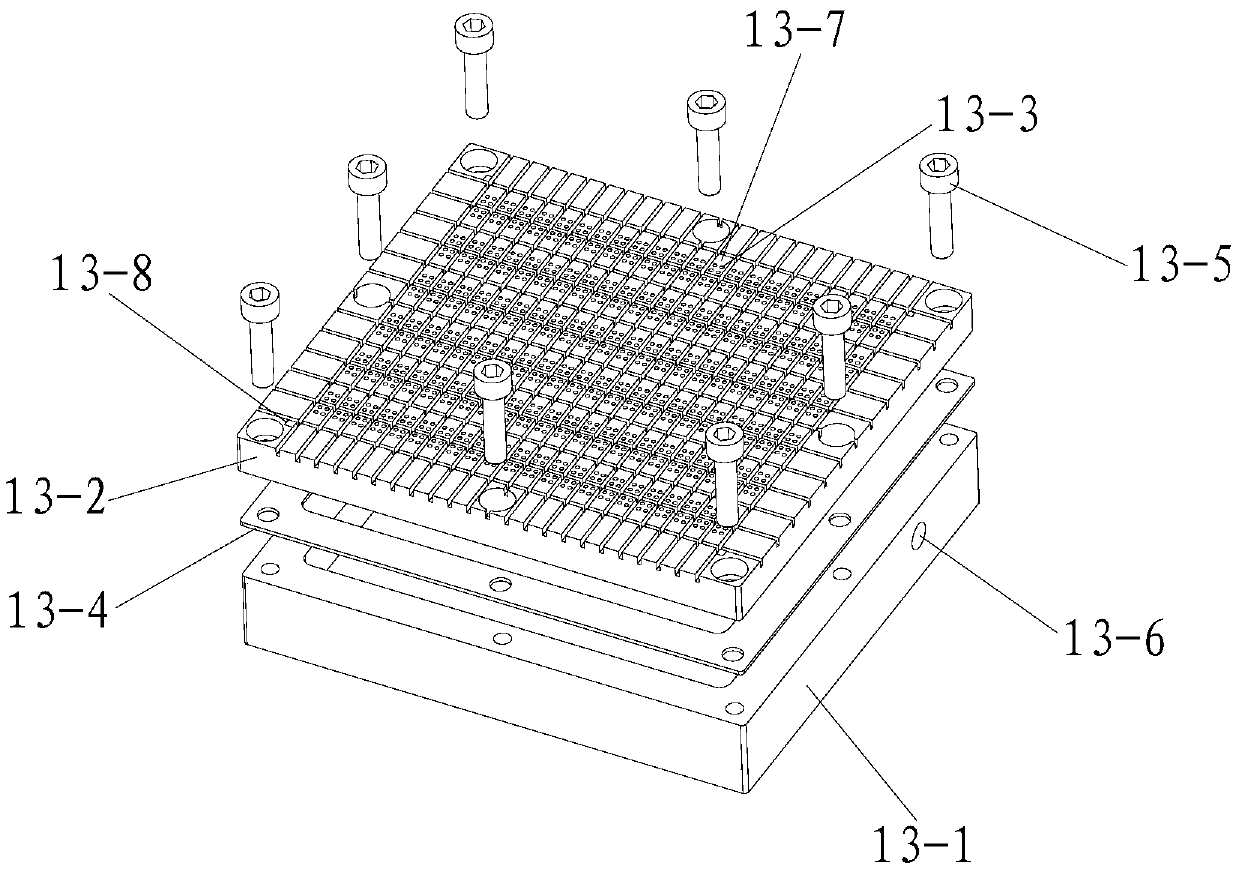

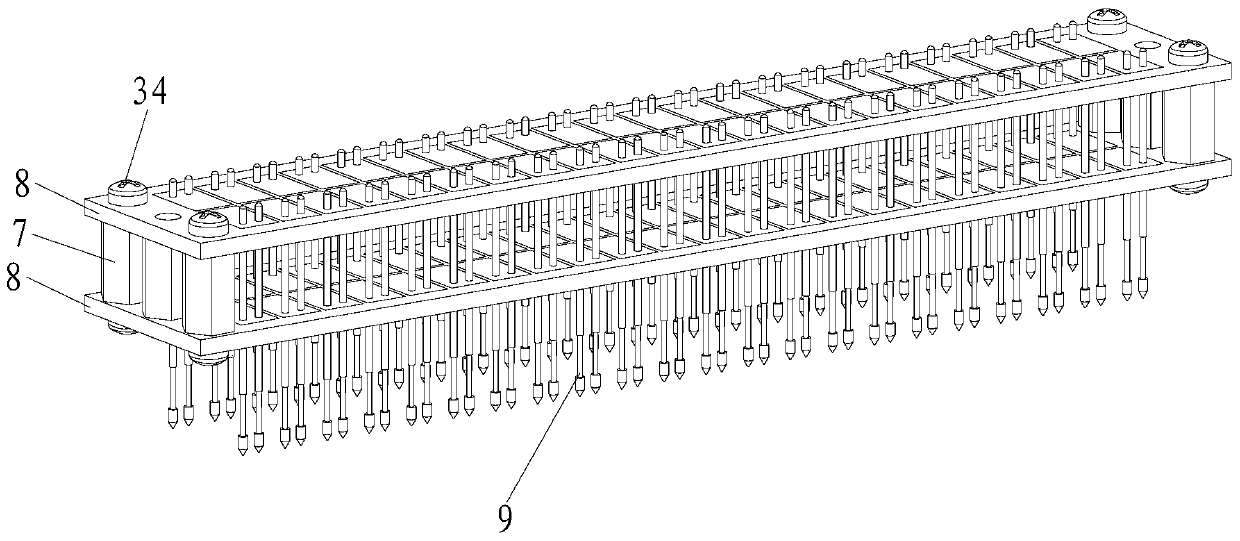

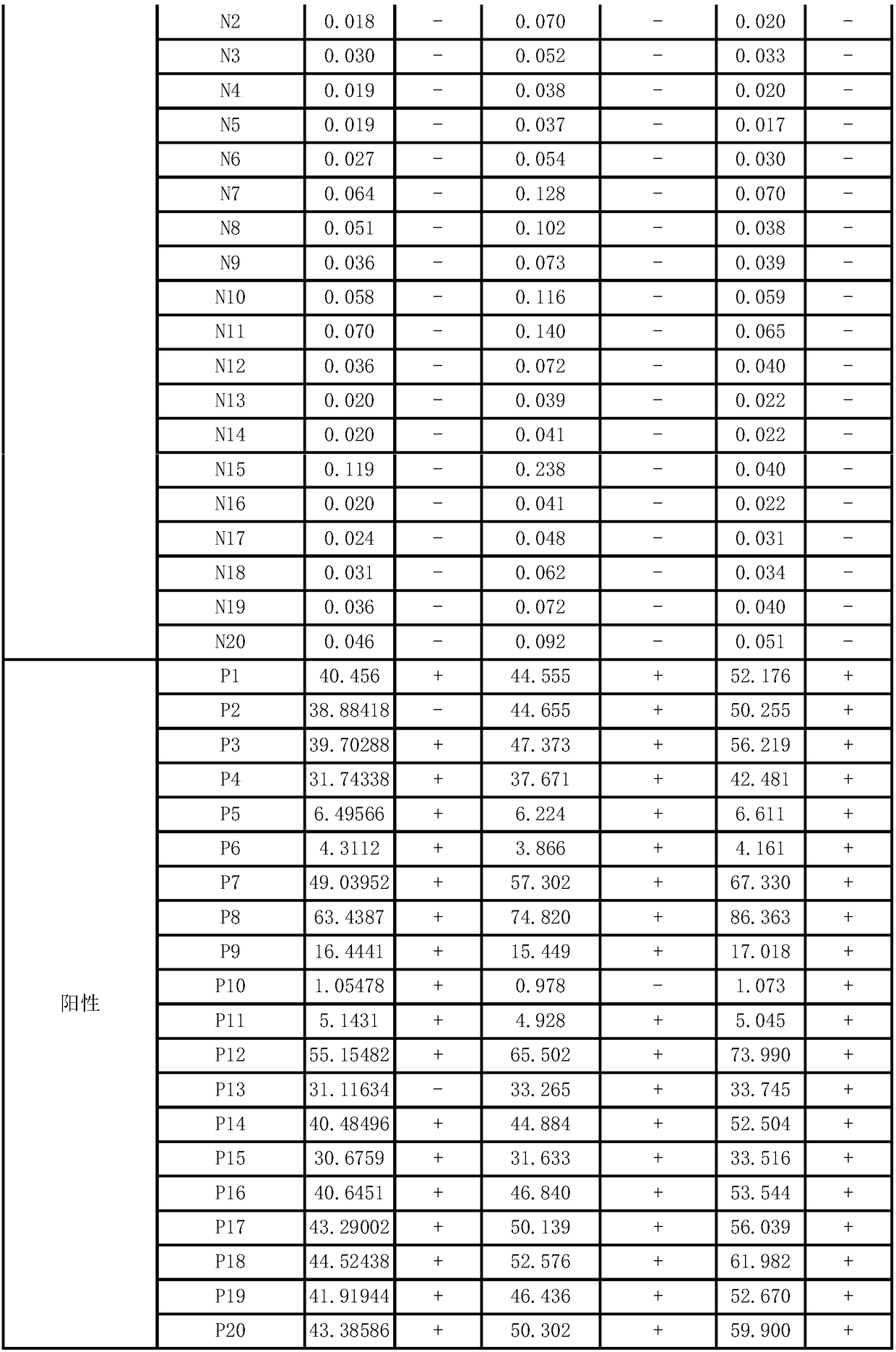

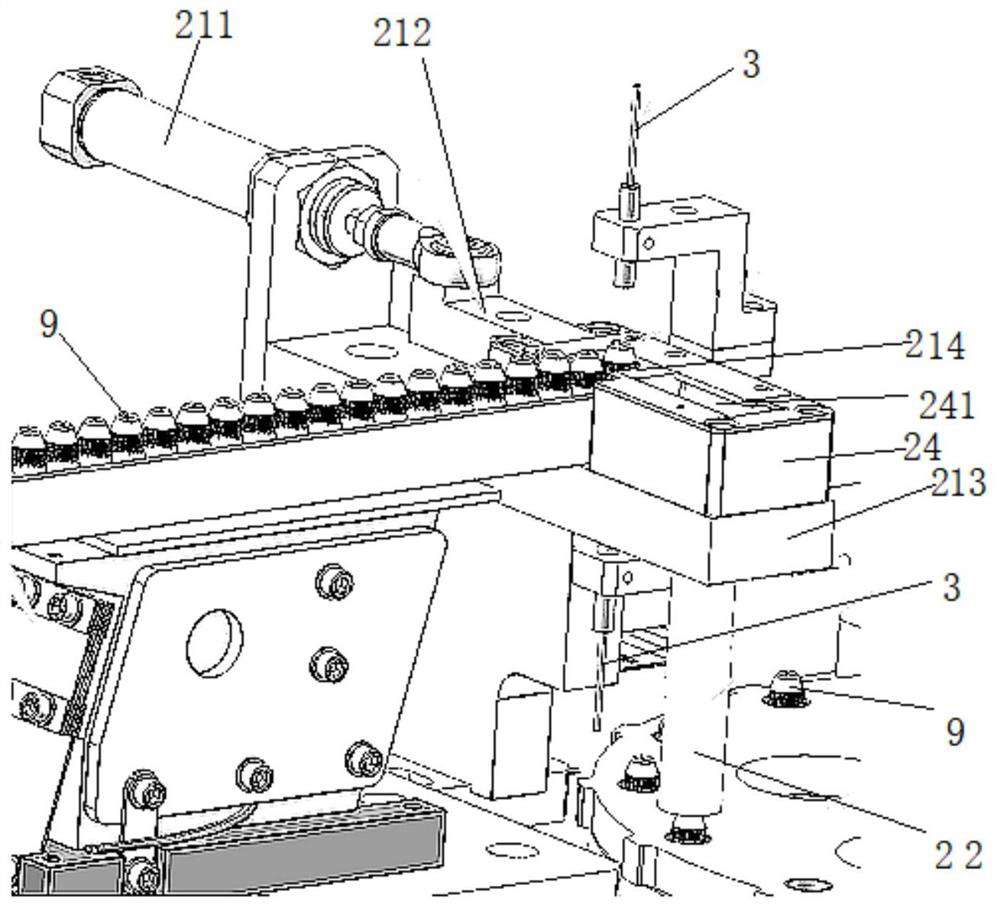

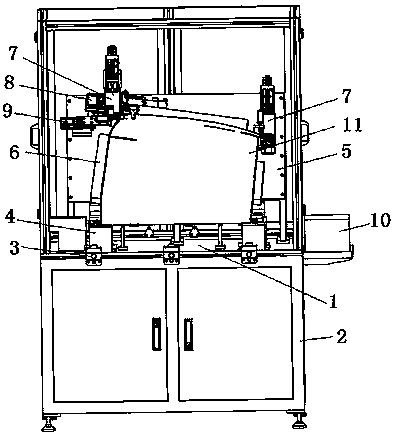

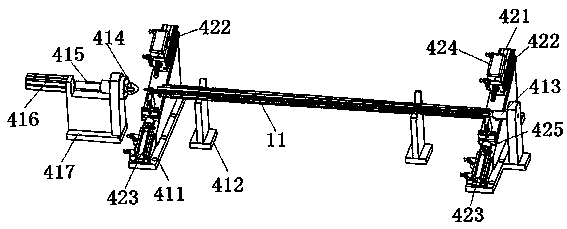

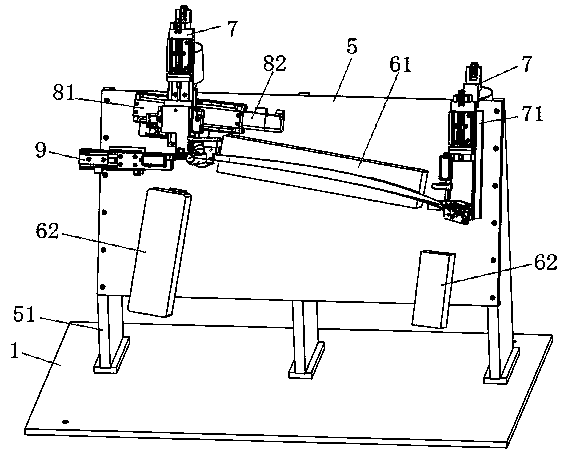

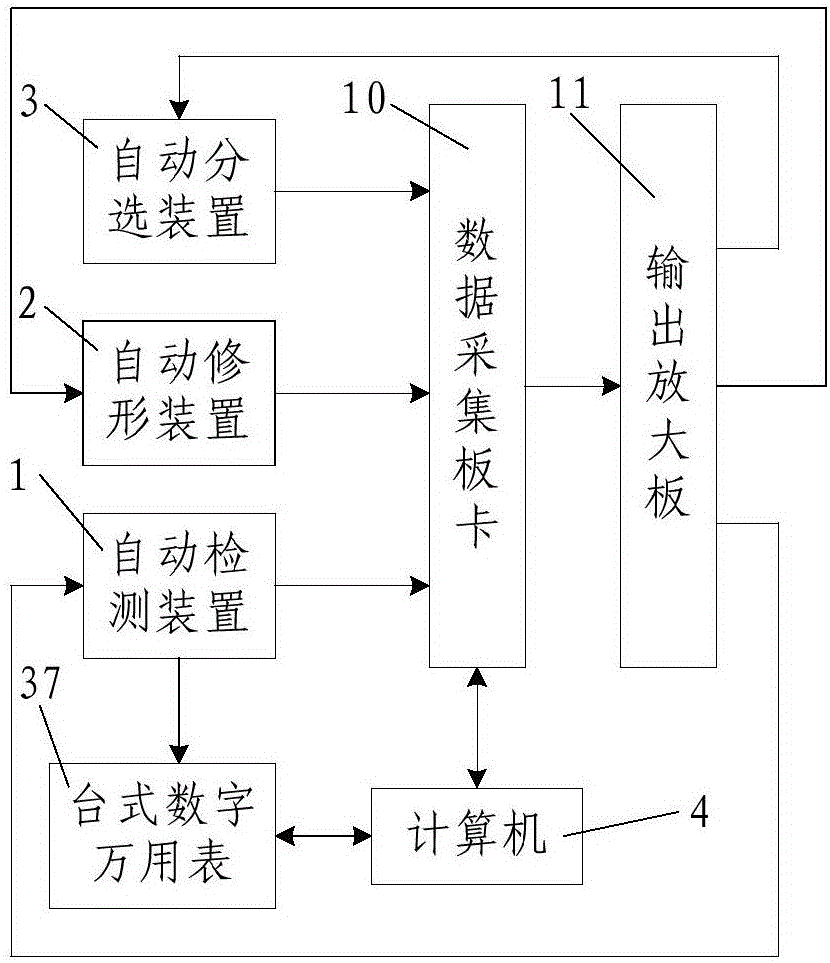

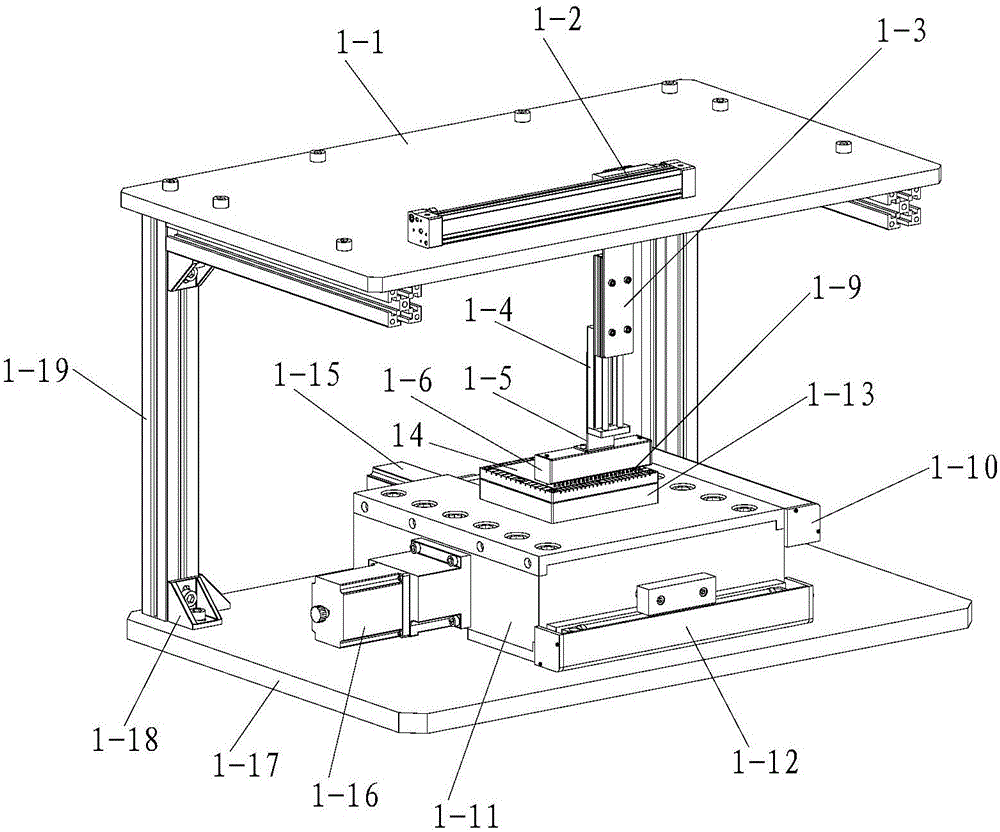

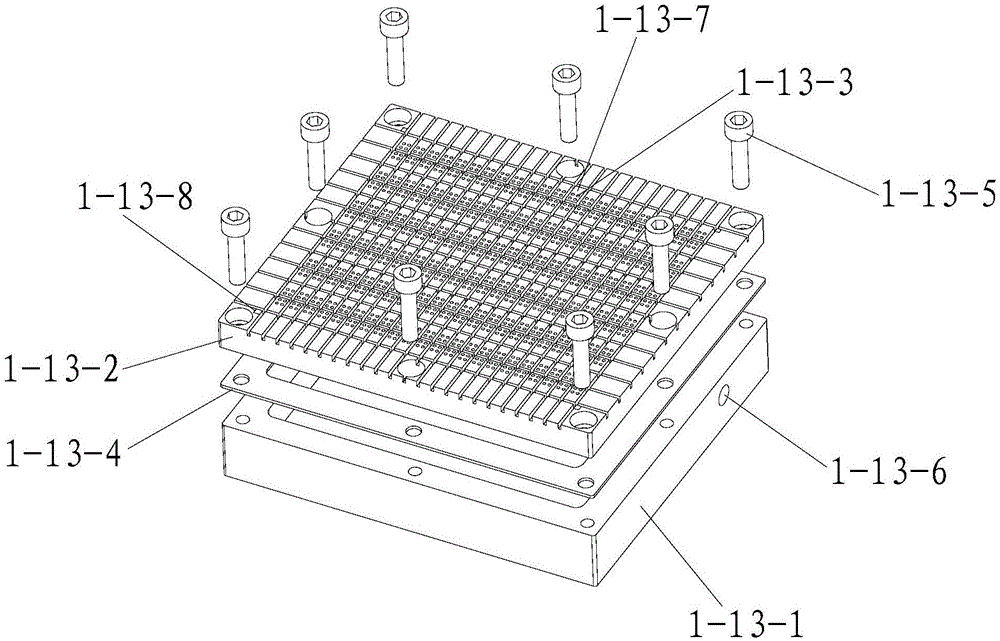

Automatic detection, trimming and sorting device and method for large-array resistance type strain gauges

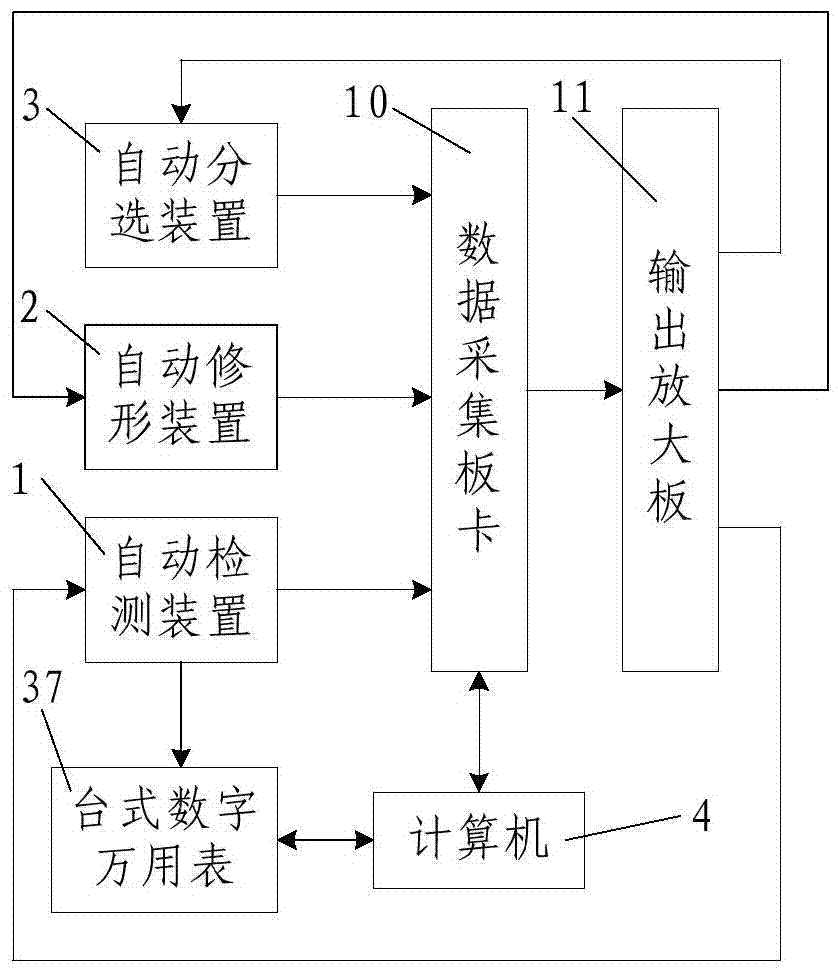

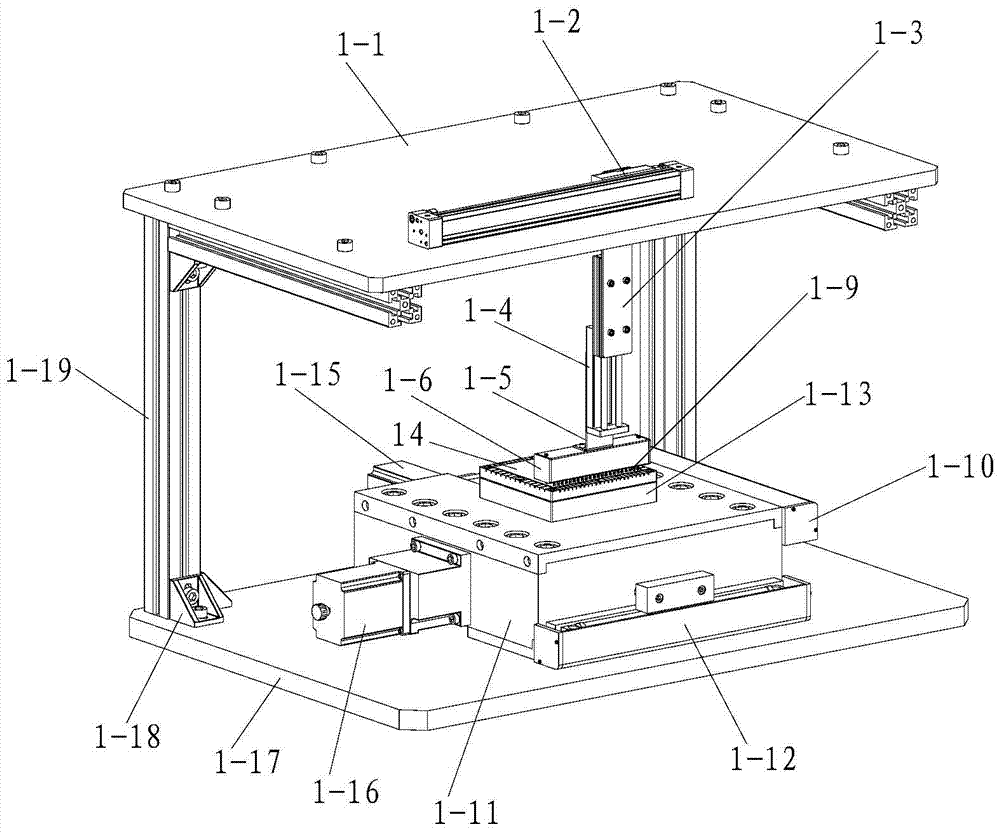

InactiveCN105436103ACompact structureNovel and reasonable designMeasurement devicesSortingPneumatic circuitData acquisition

The invention discloses an automatic detection, trimming and sorting device for large-array resistance type strain gauges. The automatic detection, trimming and sorting device comprises an automatic detection device, an automatic trimming device, an automatic sorting device, a computer data collection board card, a table type digital multimeter and an output amplification board. The automatic detection device comprises a detection machine frame, a detection positioning and fixing mechanism and a detection mechanism. The automatic trimming device comprises a trimming machine frame, a trimming positioning and fixing mechanism and a trimming mechanism. The automatic sorting device comprises a sorting machine frame, a sorting positioning and fixing mechanism, an adsorption sorting mechanism and a positioning and sorting mechanism. The detection mechanism comprises a first air cylinder sliding platform, a second air cylinder sliding platform and a first pneumatic loop. The trimming mechanism comprises a linear swinging combined air cylinder, a cutter rest and a second pneumatic loop. The adsorption sorting mechanism comprises an adsorption head installation box and a plurality of vacuum adsorption heads. The invention further discloses an automatic detection, trimming and sorting method for the large-array resistance type strain gauges. By means of the automatic detection, trimming and sorting device and method for the large-array resistance type strain gauges, the production efficiency can be improved, labor intensity of workers is relived, and the production cost is reduced.

Owner:SHAANXI UNIV OF TECH

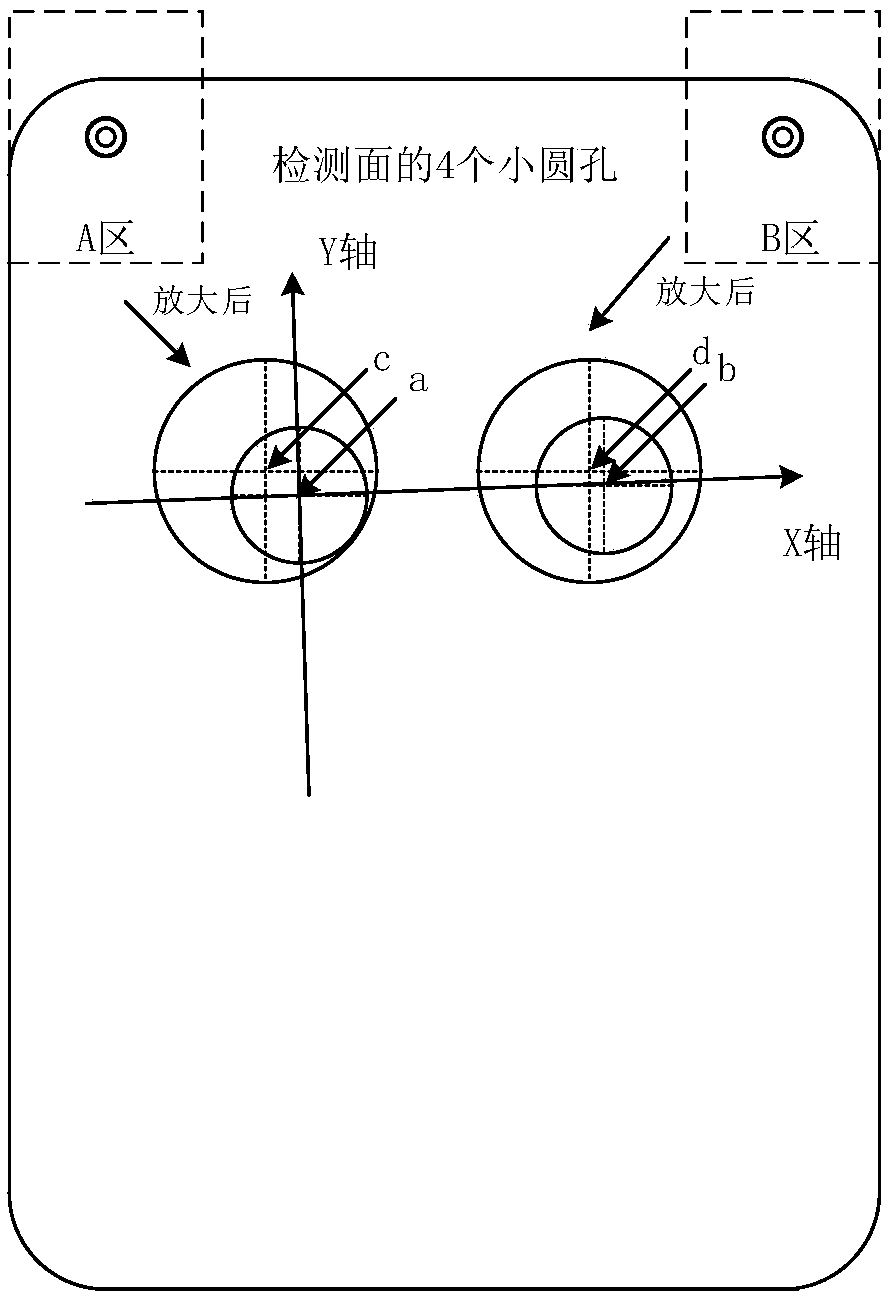

Non-contact visual detection method for Mark positioning of mobile phone touch screen

ActiveCN108363508AQuick Auto DetectAccurate automatic detectionImage enhancementImage analysisImaging processingComputer module

The invention belongs to the technical field of detection of electronic products and discloses a non-contact visual detection method for Mark positioning of a mobile phone touch screen. According to the method, a mobile phone touch screen detection part is divided into two regions of A and B; the region A is photographed by a first black and white industrial camera for detection; the region B is photographed by a second black and white industrial camera for detection; a Mark and a Circle of the region A are photographed by the first black and white industrial camera for detection; and the Markand the Circle of the region B are photographed by the second black and white industrial camera for detection. After photographing, an image is collected by an image collection module and image information is transmitted to an upper computer module; the upper computer module processes data, detects a deviation distance between a Mark central point and a Circle center through an image processing algorithm, displays a detection result and gives out a completion signal; and then a motion control module returns to an initial position to wait for detection of a next workpiece. With the detection method, the rapid, accurate and automatic detection for Mark positioning of the mobile phone touch screen can be realized.

Owner:JIANGNAN UNIV

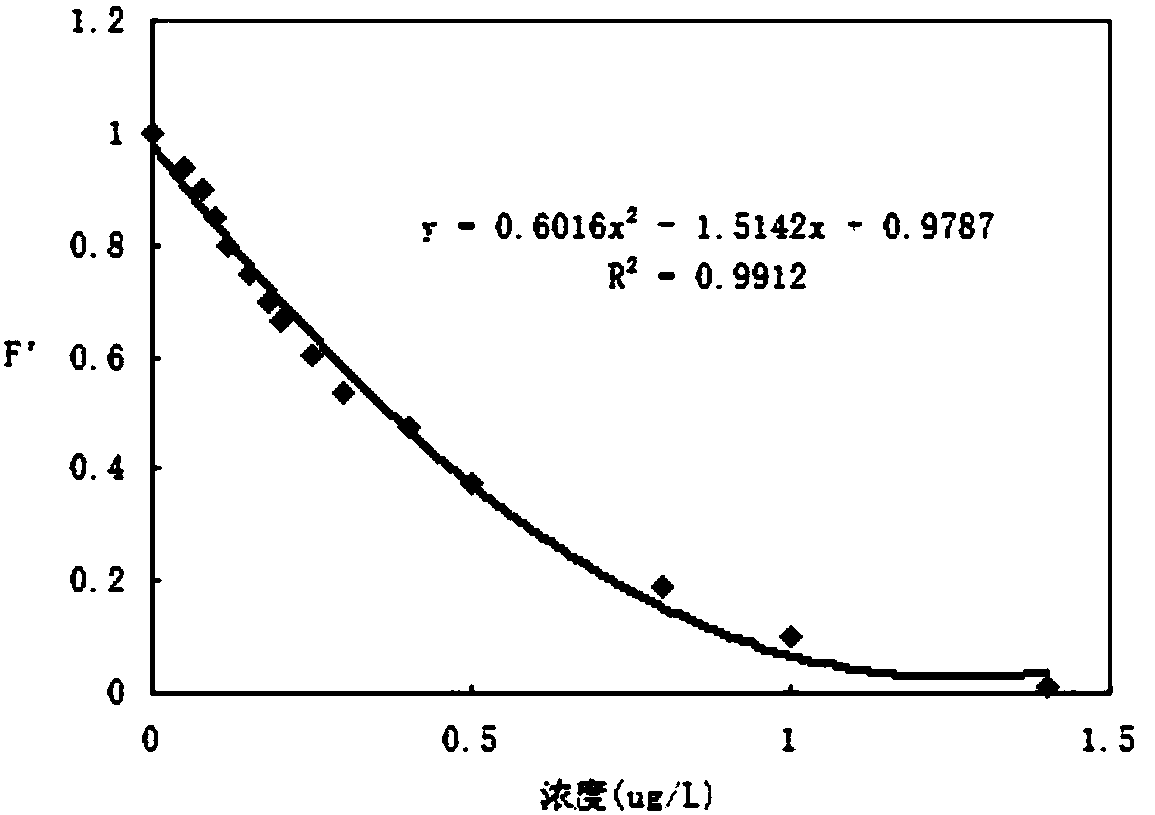

Microfluidic chip for detecting microcystins in water and detection method

The invention discloses a microfluidic chip for detecting microcystins in water. The microfluidic chip comprises a substrate made of organic glass and a cover sheet, wherein the cover sheet is thermally bonded on the substrate; the substrate is carved with a micro flow path; the micro flow path comprises a reagent channel, a circular detection pool and a waste liquid draining channel in sequence;the reagent channel comprises an immunomagnetic bead channel, a PBST (Phosphate Buffered Saline Tween-20) buffer solution channel, a microcystins antibody channel, a fluorescein-marked second antibodychannel, a blank sample channel, a water sample channel and an antigen antibody dissociating agent channel; immunomagnetic beads are fixed in the detection pool through a micro circuit and magnets; the surfaces of the immunomagnetic heads are coupled with the microcystins. The invention further discloses a detection method for detecting the microcystins in the water by the microfluidic chip. Theanalyzing method has the advantages of high detection speed, high sensitivity, low reagent consumption, high system concentration degree, high automation degree, easiness in operation, low cost and the like.

Owner:杭州绿洁科技股份有限公司

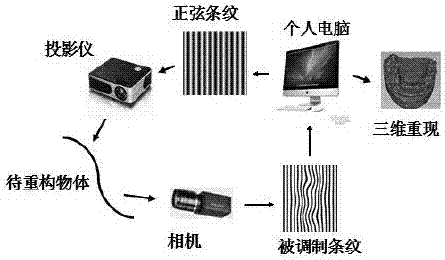

Work piece automatic welding method based on grating projection three-dimensional reconstruction

InactiveCN107063130AFully automatedRealize intelligenceWelding/cutting auxillary devicesUsing optical meansGratingAutomatic control

The invention discloses a work piece automatic welding method based on grating projection three-dimensional reconstruction. Welding industrial automation is a main development direction of future welding, and most of conventional welding robots adopt a teaching and playback working mode, and operators are required to approach processing stations to complete teaching, and in addition, large teaching difficulties are presented in large-scale work pieces with complicated structures, and therefore welding effect is hard to guarantee. The work piece automatic welding method based on the grating projection three-dimensional reconstruction adopts the grating projection technology for three-dimensional reconstruction of detected work pieces, and the contour three-dimensional information of the welding work pieces is acquired by combining with two-dimensional contour extraction, and is used for the automatic control of the welding robots. The work piece automatic welding method is advantageous in that the three-dimensional information of the work pieces is detected quickly, and a measuring range is wide, and measuring precision is high; the work piece automatic welding method is directly used for the operation trajectory control of the welding robots, and the full automation of the work piece detection and welding is realized.

Owner:SOUTHWEST PETROLEUM UNIV

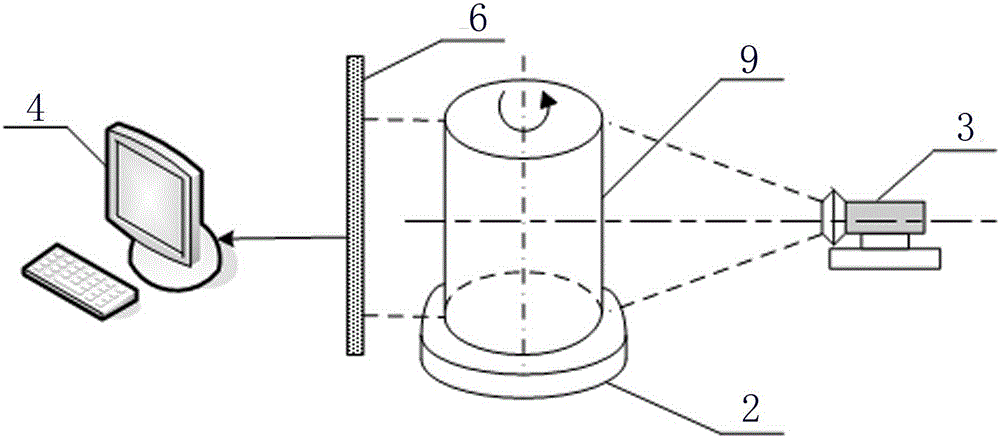

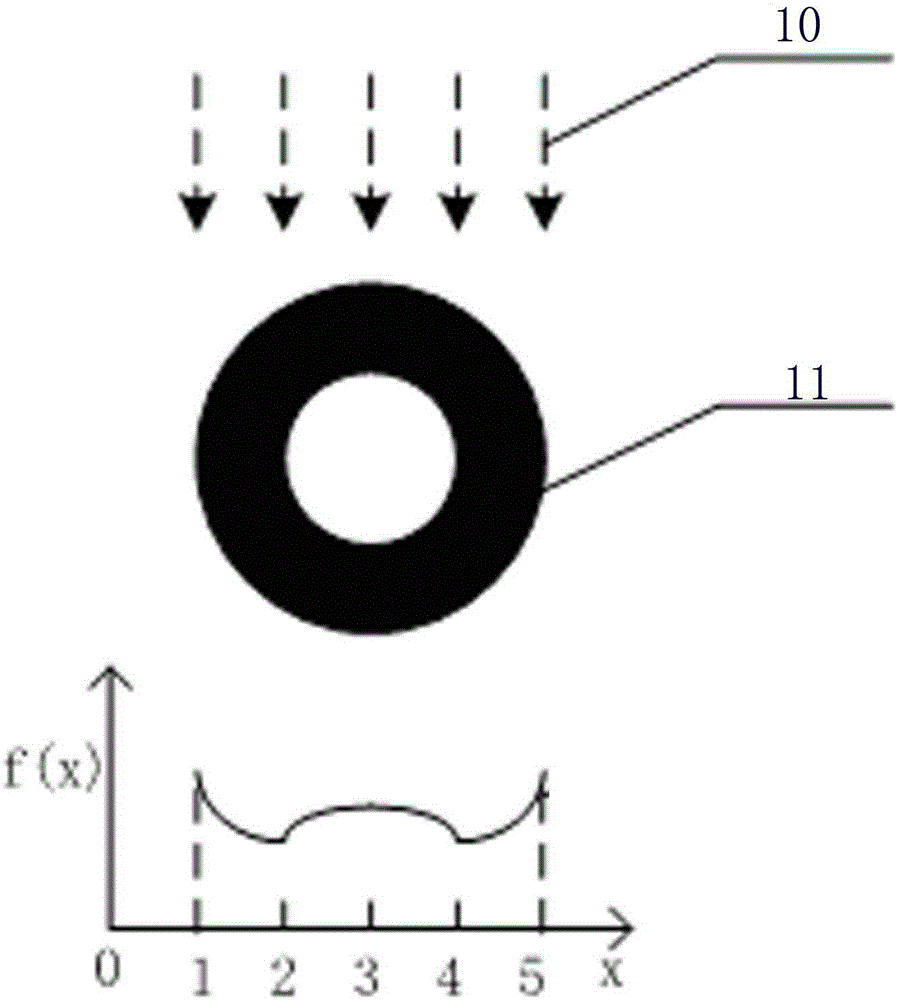

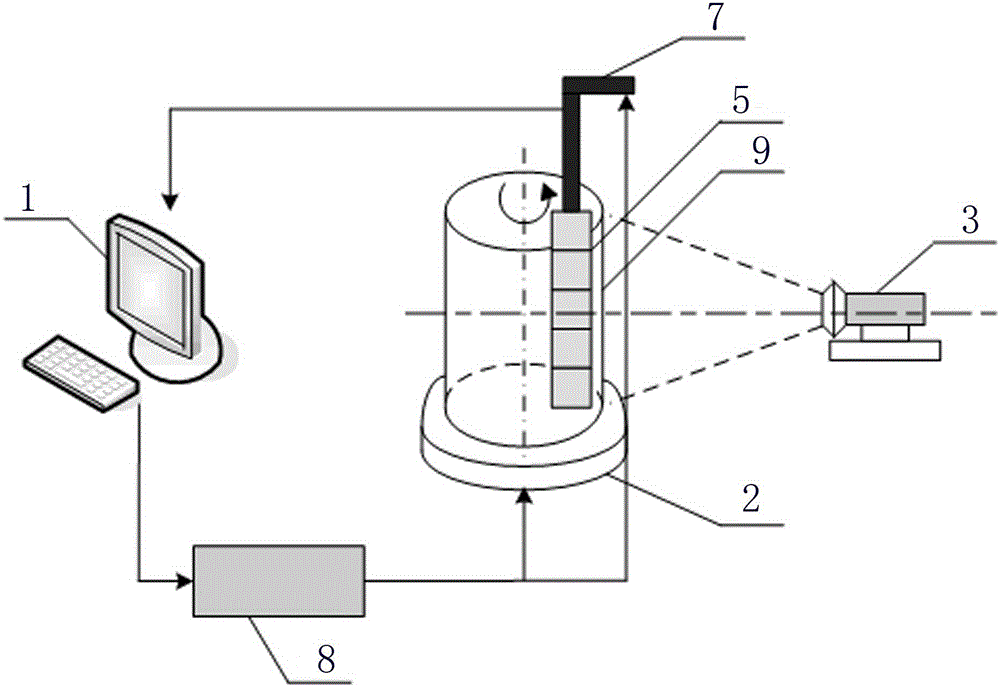

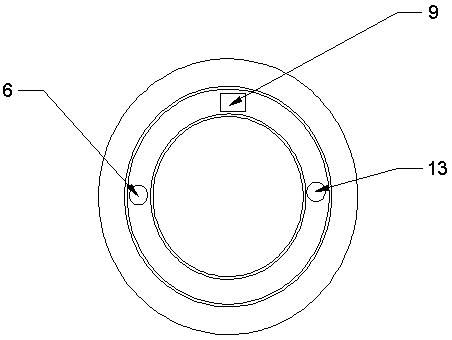

Device and method for automatically detecting defects of cylinder liners by aid of X-rays

InactiveCN105203570AAvoid inaccurate test resultsEasy accessMaterial analysis by transmitting radiationSoft x rayImage resolution

The invention relates to X-ray nondestructive detection technologies, in particular to a device and a method for automatically detecting defects of cylinder liners by the aid of X-rays. The device and the method have the advantages that the technical problem of inaccurate detection results due to the fact that defects of products cannot be accurately reflected by images acquired when components such as cylinder liners with tubular structures are detected by the aid of rays at present can be solved by the aid of the device and the method; an imaging process is a single-wall imaging process implemented by the aid of linear-array type detectors arranged inside the cylinder liners, images of single walls, which are positioned between ray sources and the detectors and are close to imaging surfaces of the detectors, of the cylinder liners are vertically formed by the aid of image data of the cylinder liners, accordingly, the imaging process is essentially equivalent to a mode in which the cylinder liners are spread to form rectangular panels and then the rectangular panels are scanned by the linear-array type detectors columns by columns to form the images, and the shortcoming of sine effects due to arc lengths can be overcome; the resolution of the images can be obviously improved by the single-wall imaging process as compared with double-layer wall imaging, and irregular cross imaging interference of threads of front and rear walls during double-layer wall imaging can be effectively prevented under the condition that the cylinder liners are provided with external threads.

Owner:ZHONGBEI UNIV

Automatic detecting device and method for large-array resistance strain gauge

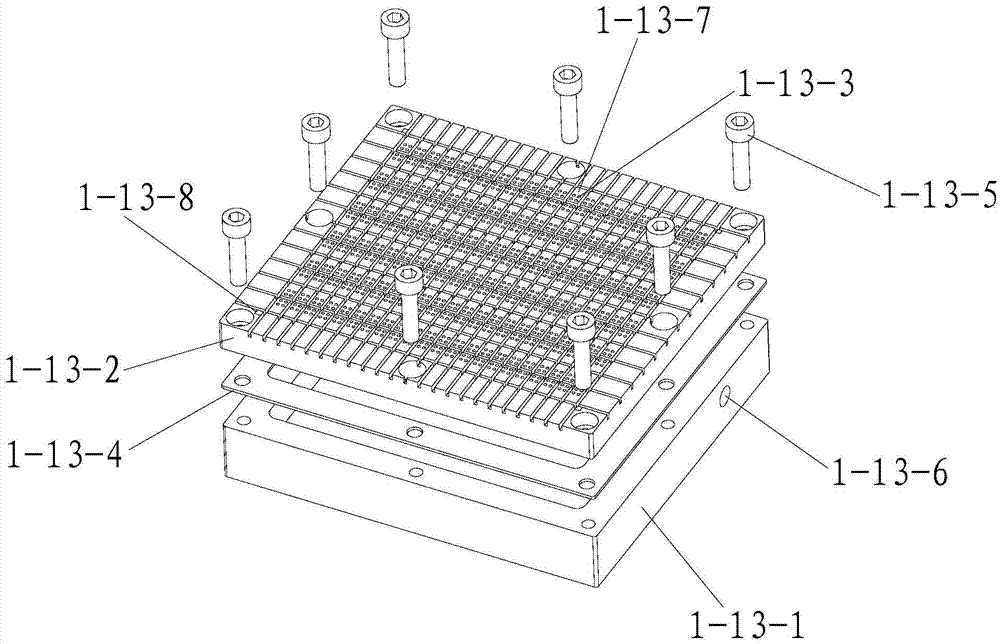

InactiveCN105509961ACompact structureNovel and reasonable designResistance/reactance/impedenceElectrical/magnetic solid deformation measurementStrain gaugeLarge array

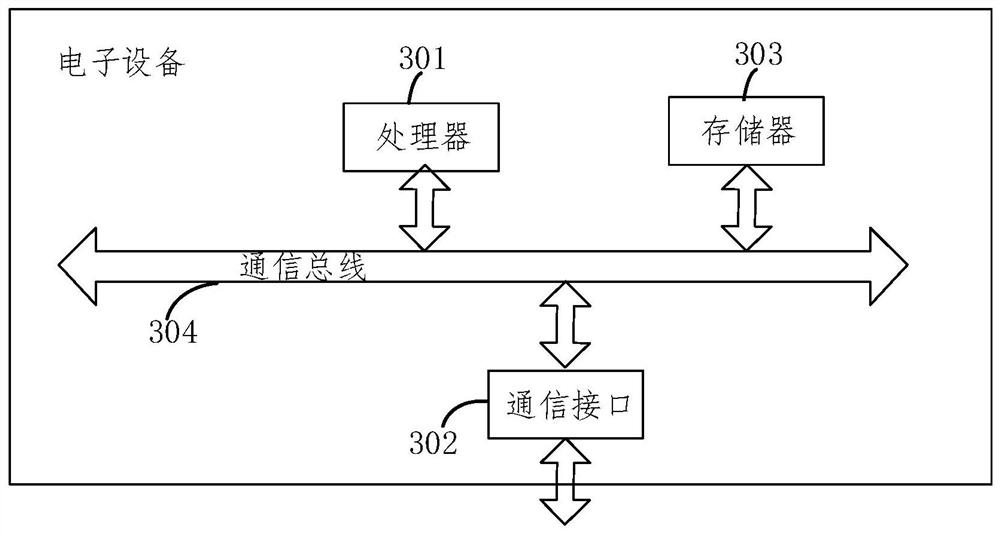

The invention discloses an automatic detecting device for a large-array resistance strain gauge. The automatic detecting device comprises a frame, a positioning and fixing mechanism, a detecting mechanism, a computer, a data acquisition board, a table digital multimeter, and an output amplification board. The positioning and fixing mechanism comprises a two-dimension mobile platform, a vacuum adsorption table, and a vacuum adsorption loop. The vacuum adsorption table comprises an adsorption table lower cover and an adsorption table upper cover. The vacuum adsorption loop comprises a vacuum pump, a vacuum filter, a vacuum degree regulating valve and a vacuum solenoid valve. The detecting mechanism comprises a first cylinder sliding table, a cylinder sliding table installation plate, a second cylinder sliding table, a pneumatic loop, a probe box, a detecting circuit board, and a spring probe array. The pneumatic loop comprises an air pump, an air filter, a reducing valve, and a pressure gauge. The invention further discloses an automatic detecting method for the large-array resistance strain gauge. The automatic detecting device is novel and reasonable in design, low in production cost, high in operation reliability, reduces worker labor intensity and product production cost, and achieves high popularization and application value.

Owner:SHAANXI UNIV OF TECH

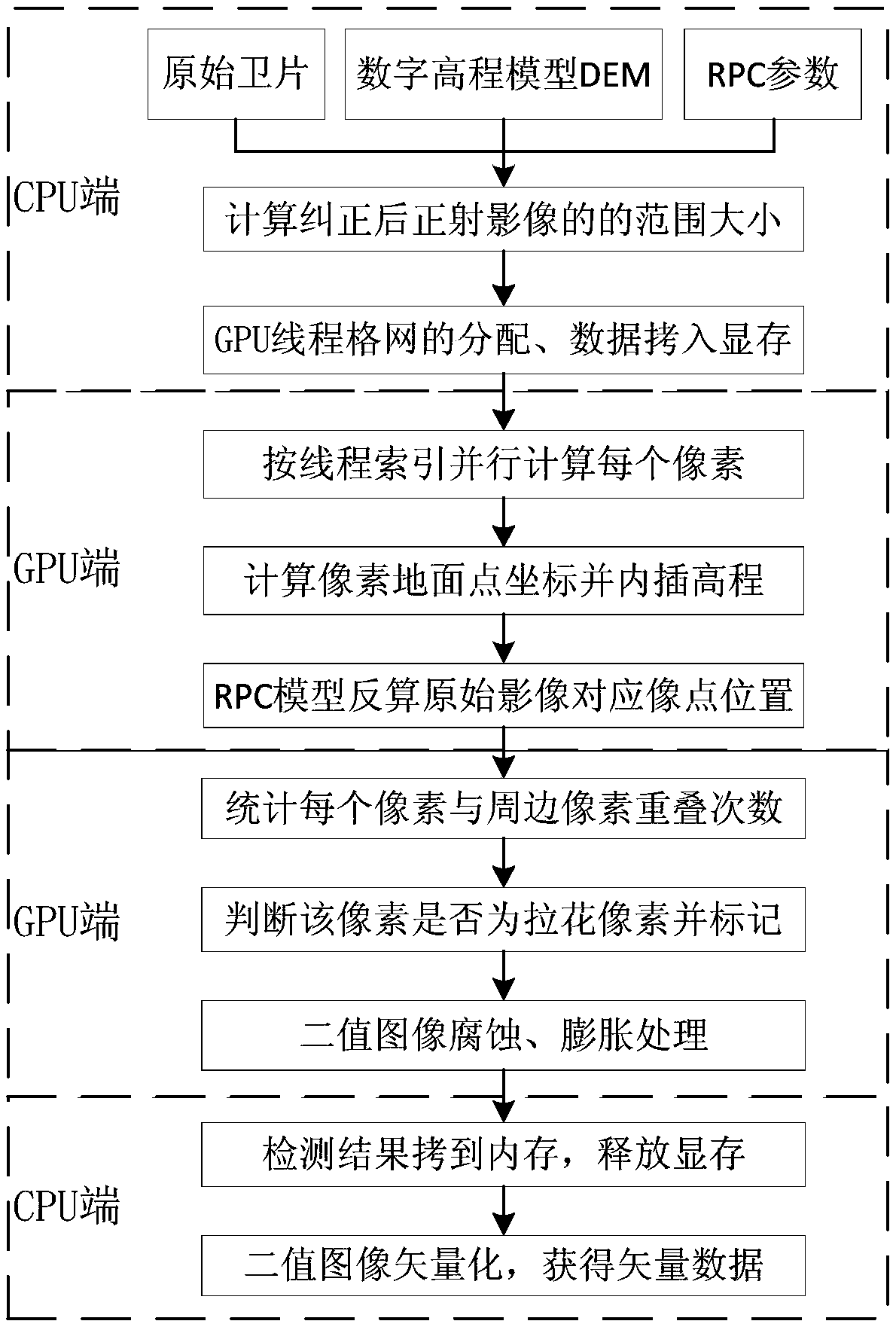

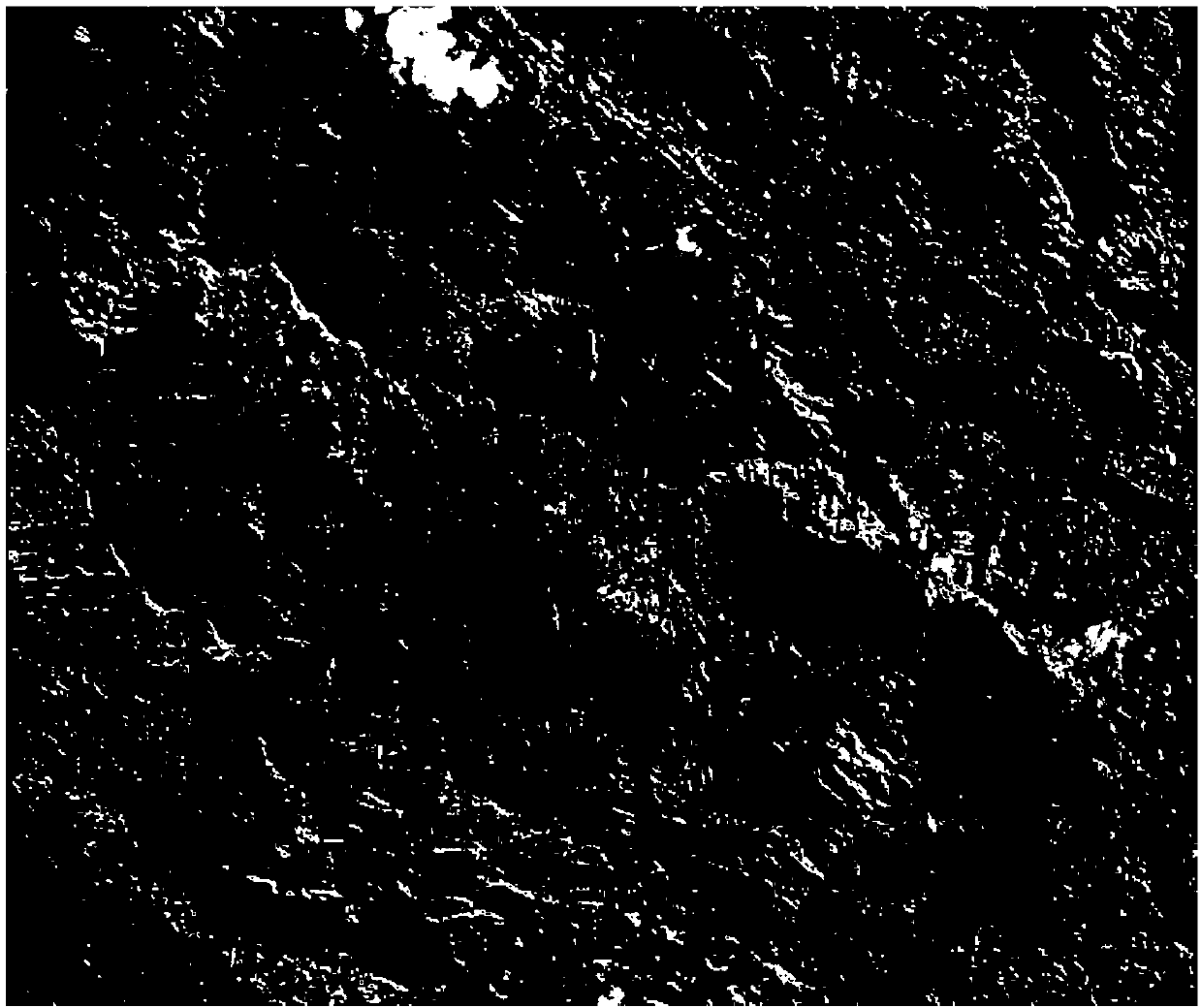

Rapid satellite image stretching deformation detection method based on GPU-CPU (graphics processing unit-central processing unit) collaboration

ActiveCN108230326AImprove search efficiencyImprove quality inspection efficiencyImage enhancementImage analysisVideo memoryInternal memory

The invention discloses a rapid satellite image stretching deformation detection method based on GPU-CPU (graphics processing unit-central processing unit) collaboration. The method comprises steps asfollows: a CPU terminal loads an original satellite image, RPC (rational polynomial coefficient) parameters and DEM (digital elevation model) and solves the size and range of a corrected orthoimage through iteration; the CPU terminal designs allocation of a GPU thread grid and copies corresponding data to a corresponding video memory from an internal memory; a GPU terminal performs parallel computing on pixel coordinates, corresponding to the original satellite image, of each pixel according to the thread grid; the GPU terminal counts the overlapping times of current pixels and surrounding pixels and performs stretching pixel judgment; the GPU terminal performs corrosion processing and expansion processing on a binary image according to the thread grid; the CPU terminal copies a binary image result to the internal memory from a global memory and vectorizes the binary image result to obtain vector data of a stretching deformation area. The method has the remarkable effects that rapid automatic detection of the stretching deformation area in a satellite image is realized, and the lookup and quality control efficiency of stretching deformation in the optical remote sensing satelliteorthoimage is greatly improved.

Owner:CHONGQING GEOMATICS & REMOTE SENSING CENT

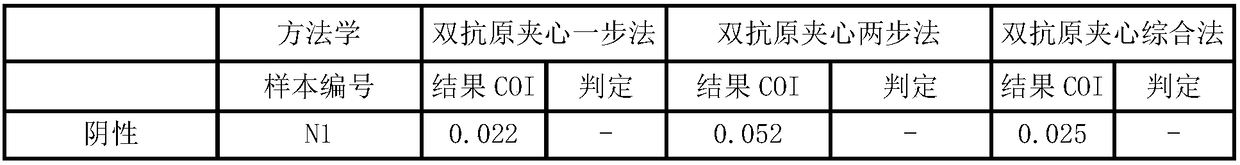

Double-antigen sandwich antibody detection method

ActiveCN109444434AImproving Sensitivity of Chemiluminescent ImmunoassaysHigh chemiluminescent immunoassay sensitivityBiological material analysisBiological testingBinding siteHook effect

The invention relates to a double-antigen sandwich antibody detection method. According to the method, detection is finished in a manner of forming a solid-phase support-a first antigen Ag1-a to-be-detected antibody-a second antigen Ag2, wherein the Ag2 is coupled with a marker for displaying signal strength; the method comprises the following steps: 1), enabling the Ag1 and the Ag2 to be in contact with a to-be-detected object under the condition that antigen / antibody reaction can occur with enough Ag1, Ag2 and the to-be-detected object, so as to form an immune compound, wherein the content of the Ag1 is greater than that of the Ag2 based on mol number; 2) washing the unbound to-be-detected antibody; 3) adding the Ag2 to bind the Ag2 with residual antigen binding sites in the immune compound; 4) detecting the markers to indicate the existence and / or content of the to-be-detected antibody. Compared with the prior art, the method provided by the invention ensures the low-value sensitivity of detection, also can solve a hook effect and reduce the miss rate.

Owner:GUANGDONG FAPON BIOTECH CO LTD

Rapid and automatic detection method and controller for shaft sleeve crack of mechanical sealing element

InactiveCN105910773AHigh degree of automationImprove detection efficiencyMeasurement of fluid loss/gain rateMaterial analysisPhotoswitchElectric machinery

The invention relates to the mechanical field, especially to a rapid and automatic detection method and controller for a shaft sleeve crack of a mechanical sealing element. The method comprises the steps of equipment preparation, feeding, testing, sorting, and framing and warehousing. In addition, the controller consists of a programmable controller, a proximity switch, a photoelectric switch, an electromagnetic valve, and a stepping motor driver. According to the invention, two end surfaces of a shaft sleeve are sealed by choke plugs and then inflation is carried out in an inner cavity of the shaft sleeve to form a high pressure; an electronic barometer detects the pressure; and an objective of rapid detection is achieved according to a principle of different pressures of to-be-detected workpieces with or without cracks. With a vibrating screen and a synchronous belt, automatic feeding is realized; and a sorting assembly carried out sorting. The automation degree and the detection efficiency are high. The apparatus with a simple structure has low costs.

Owner:宁波精科机械密封件制造有限公司 +1

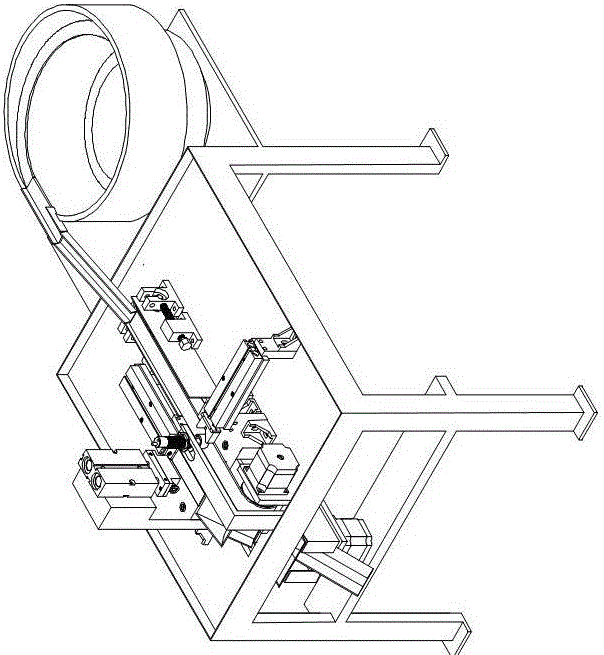

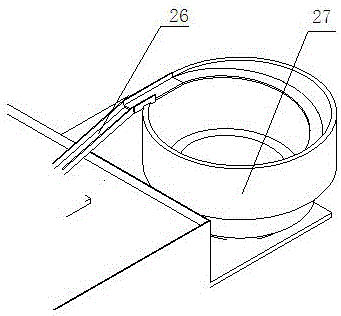

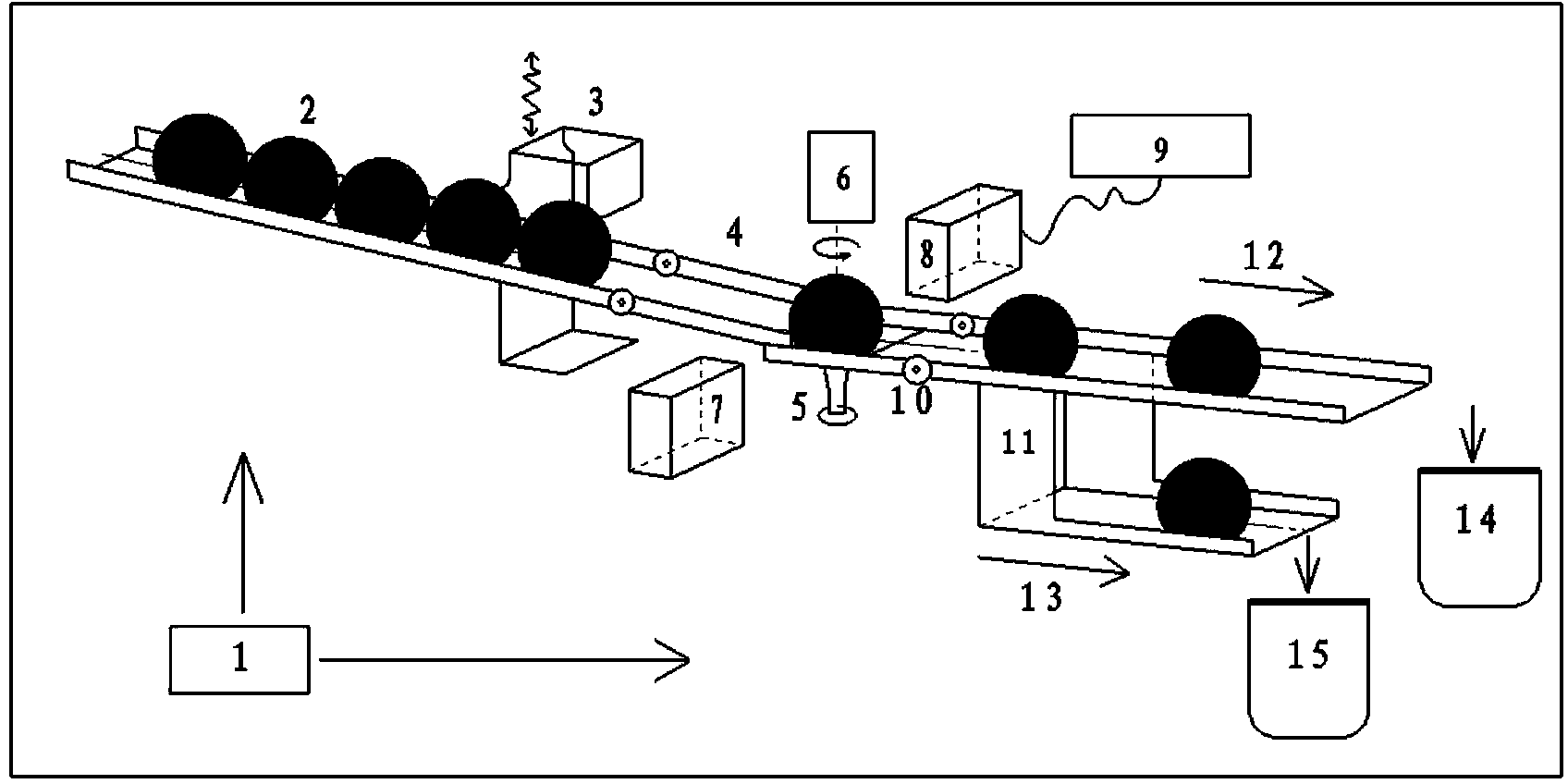

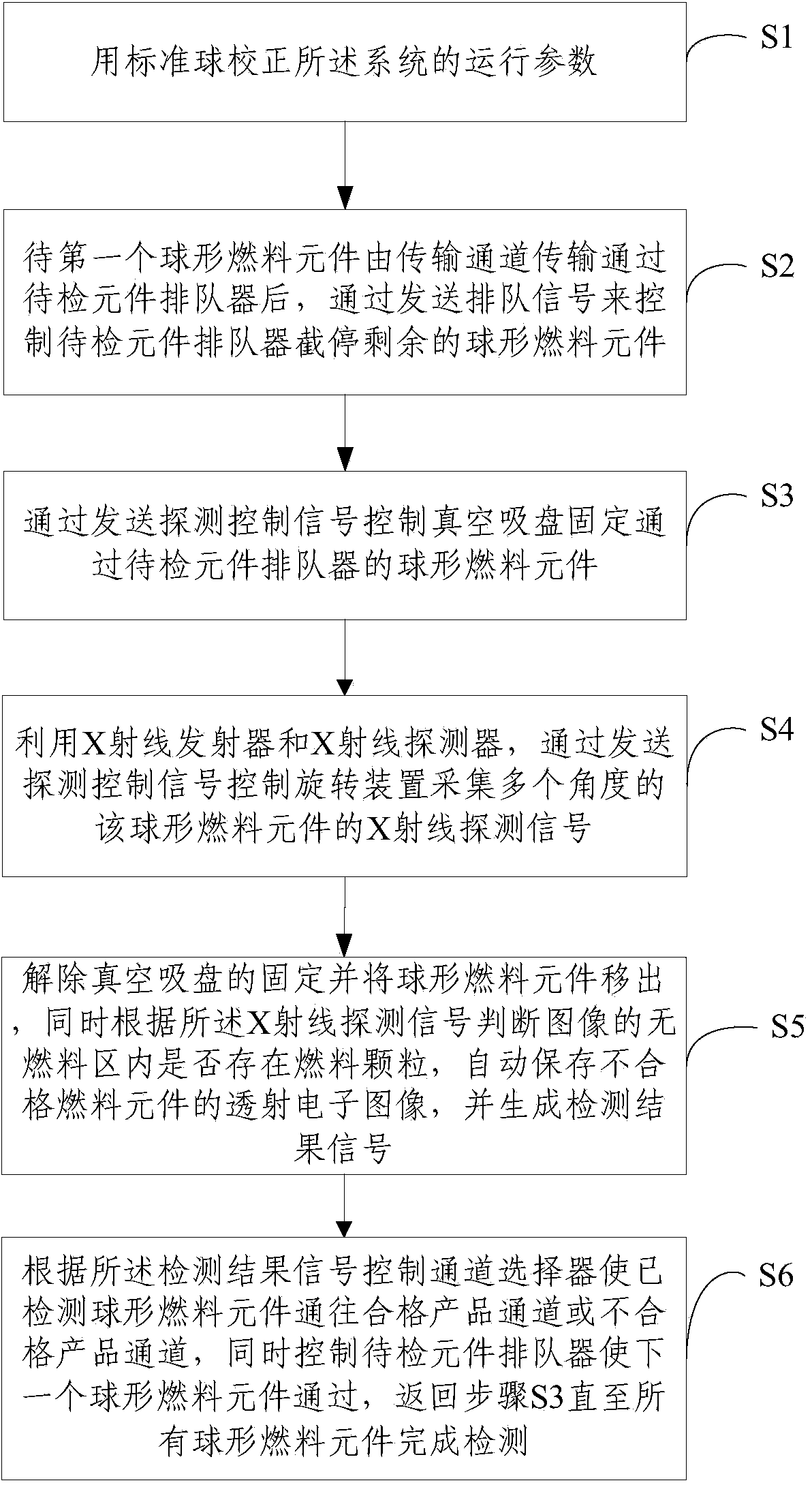

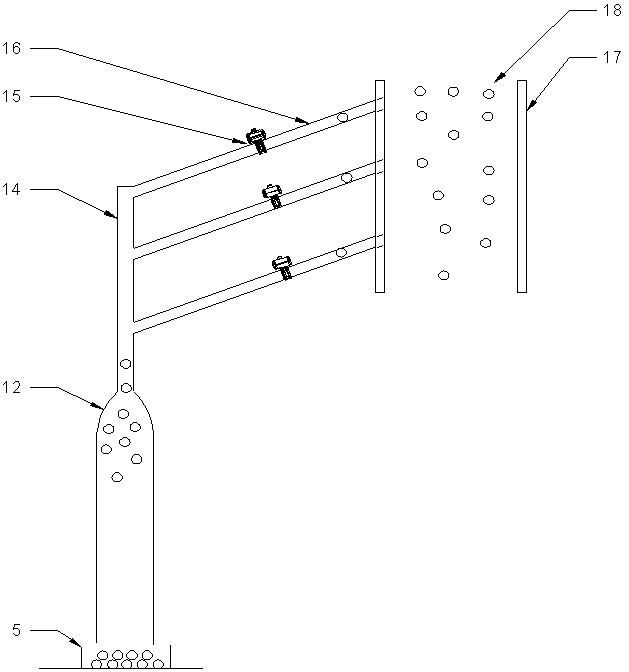

Automatic detection system and method for spherical fuel element fuel-free section

ActiveCN103817089AEasy accessQuick and automatic acquisitionSortingMaterial analysis by transmitting radiationX-rayEngineering

The invention relates to the field of nondestructive testing, provides an automatic detection system and method for a spherical fuel element fuel-free section, and aims to solve the problem that spherical fuel element fuel-free sections in the prior art are insufficient in detection precision, detection speed, detection reliability. The automatic detection method comprise the following steps: the transmitted electron images of spherical fuel elements are acquired through an X-ray nondestructive detection real-time imaging technique, the distribution situation of more than ten thousand fuel particles with diameters of greater than 400 micrometers in fuel elements with diameters of greater than 600 millimeters can be acquired through processing the images, whether fuel particles exist in specific areas or not is examined, and finally qualified and unqualified spherical fuel elements are separated to finish the automatic detection process according to automatic detection results. According to the invention, the automatic detection system and the automatic detection method can realize the fast and automatic detection of the spherical fuel elements fuel-free section, meet the detection efficiency design objective of at least two fuel elements every minute, and reach the detection result that the omission ratio of the unqualified products is 0% in a series of verified experiments.

Owner:TSINGHUA UNIV +1

Automatic pipeline-corrosion detecting device using concave phased array probe with adjustable curvature

PendingCN107271570ACompact designSolve the defect that it cannot be used universally for pipes of different diametersMaterial analysis using sonic/ultrasonic/infrasonic wavesStructural engineeringWater jacket

The invention discloses an automatic pipeline-corrosion detecting device using a concave phased array probe with adjustable curvature. The automatic pipeline-corrosion detecting device comprises a probe mechanism, which is composed of the probe and a water sleeve, wherein the water sleeve sleeves the probe; a probe fixing clamp, which is composed of a pedestal and magnetic sucking wheels, wherein the pedestal is connected with the probe and the magnetic sucking wheels are arranged on the pedestal; and a crawl device, which is composed of a crawl device body, a driving mechanism and driving magnetic wheels, wherein the crawl device body is connected with the probe fixing clamp, the driving mechanism and the driving magnetic wheels are arranged on the crawl device body, and the driving mechanism drives the driving magnetic wheels to move. The automatic pipeline-corrosion detecting device provided by the invention is light in design, applicable to detection of oil-conveying pipes of different pipe diameters, reduced in detection cost and improved in detection efficiency.

Owner:广州多浦乐电子科技股份有限公司

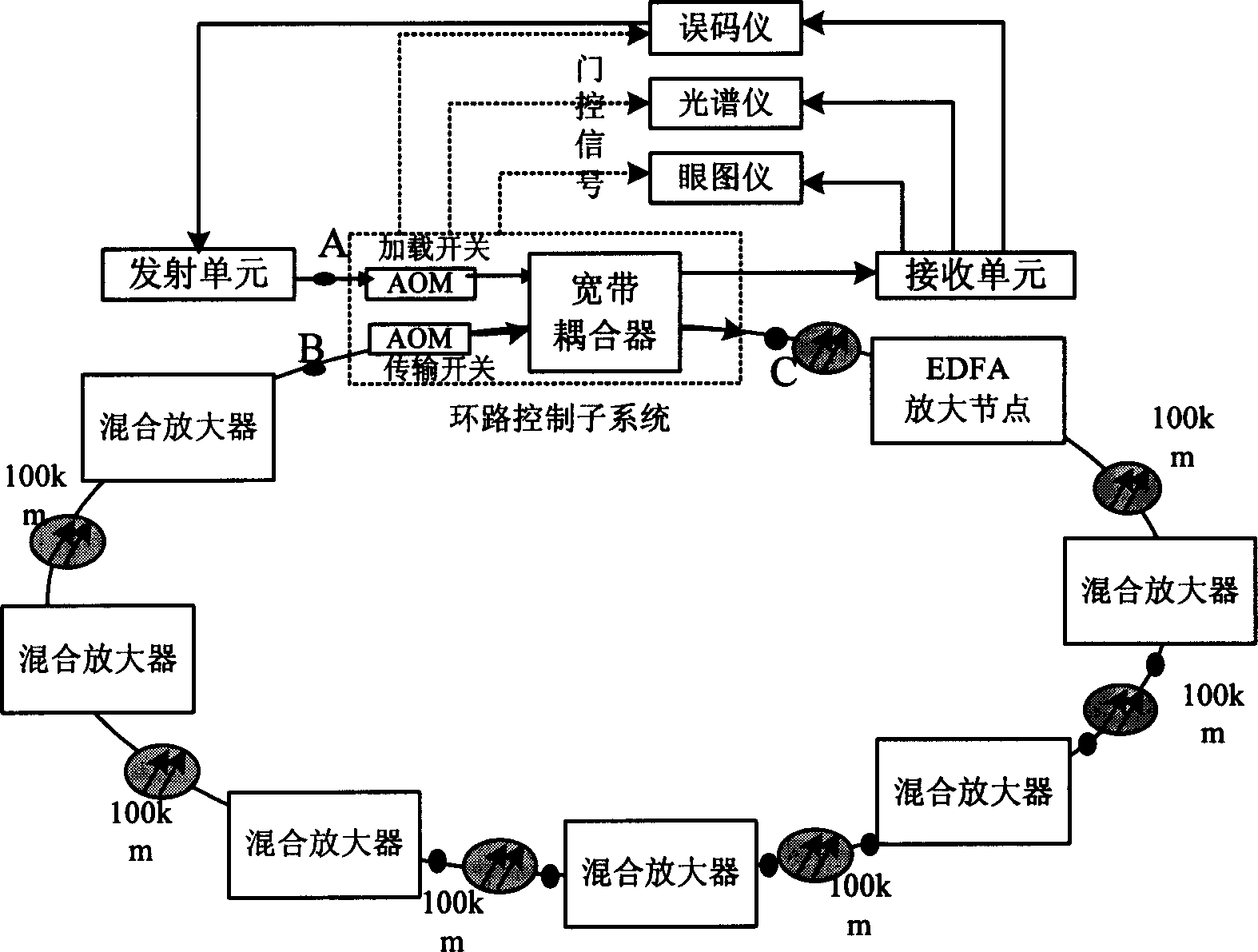

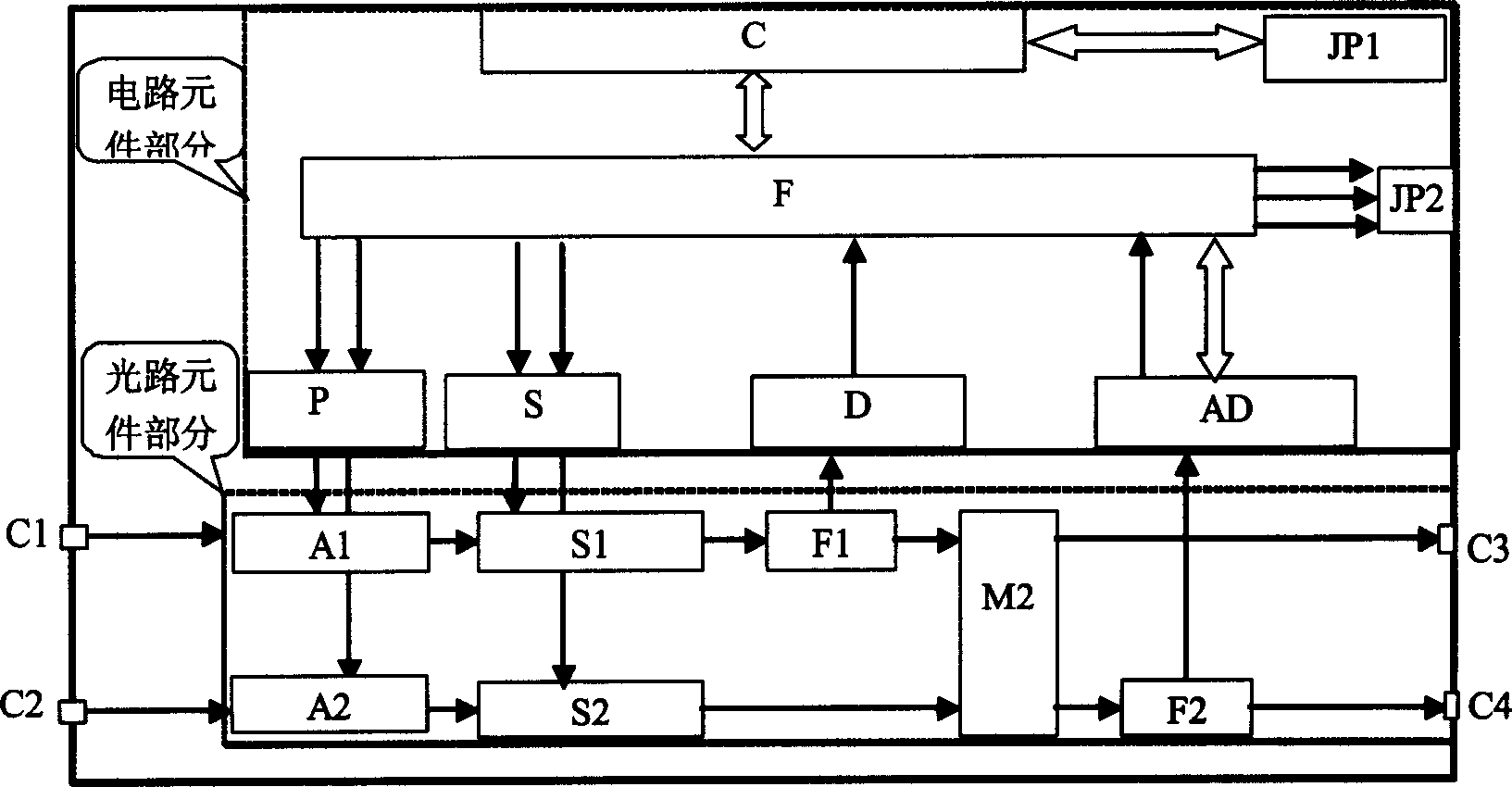

Automatic control apparatus and control method for WDM loop transmitting system

InactiveCN1863027ASolve automatic control technology problemsQuick Auto DetectWavelength-division multiplex systemsAutomatic controlTransfer system

The invention relates to a wavelength division multiplexing ring loop transferring system automatically controlling device and the controlling method. The device includes light path component section and circuit control section. The light path component section includes the first and the second adjustable attenuator, the first and the second rapid light switch, the first and the second optical splitter and a coupler. The first adjustable attenuator locates at sending end to adjust the light power coming into the ring loop. The second adjustable attenuator adjusts the power of ring loop out end. The first and the second adjustable attenuator connect to the first and the second rapid light switch to adjust the light power. The device and the controlling method solve the automatic control technology problem of ring loop transferring system and ensure the efficiency of the whole test.

Owner:ZTE CORP

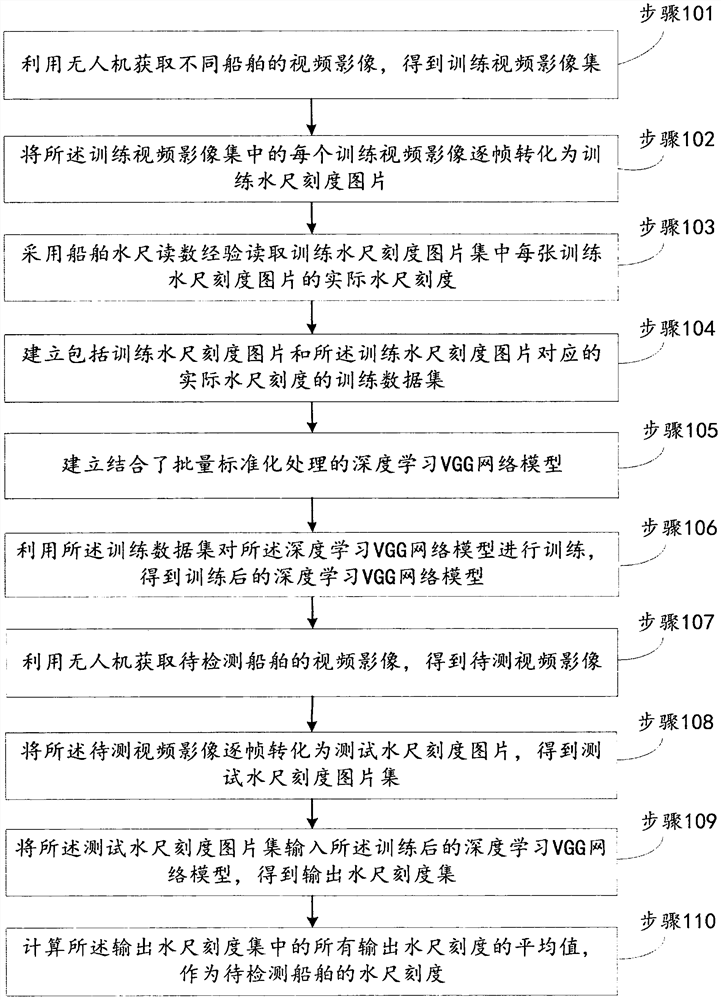

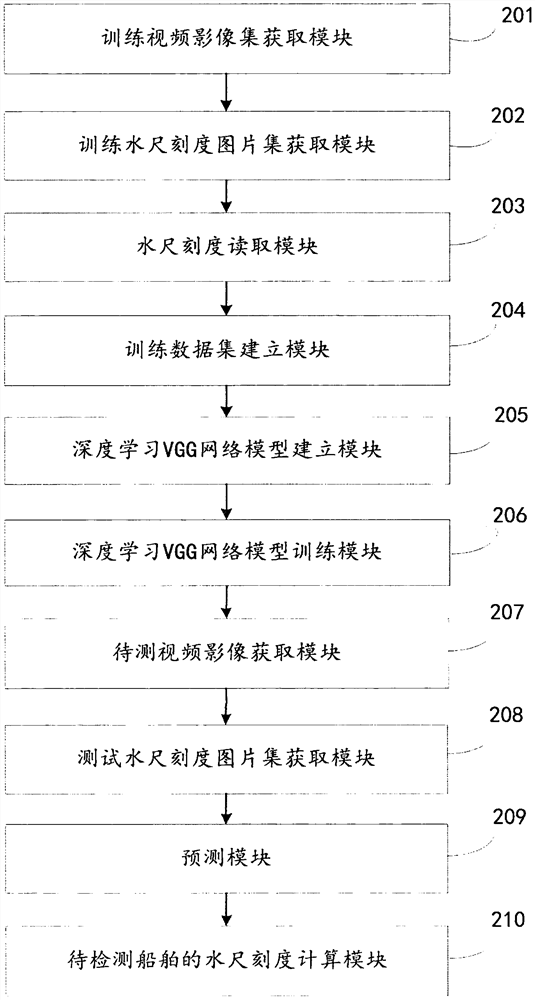

Ship water gauge automatic detection method and system

PendingCN112347827AImplement automatic detectionHigh speedCharacter and pattern recognitionVessel stability improvementData setNetwork model

The invention provides a ship water gauge automatic detection method and system. Video images of different ships are acquired by using unmanned aerial vehicle equipment and are converted into trainingwater gauge scale pictures, actual water gauge scales of the training water gauge scale pictures are read by using ship water gauge reading experience, and a training data set is established; the deep learning VGG network model is trained by using the training data set to obtain a trained deep learning VGG network model; finally, a video image of a ship to be detected is acquired by the unmannedaerial vehicle, the video image is converted into a test water gauge scale picture, and the test water gauge scale picture is input into the trained deep learning VGG network model to obtain a prediction result, thereby achieving the purpose of ship water gauge identification automatic detection. Calculation speed is improved. According to the invention, high-precision automatic detection of the ship waterline scale can be realized rapidly and accurately under various extreme environment conditions.

Owner:东北大学秦皇岛分校 +1

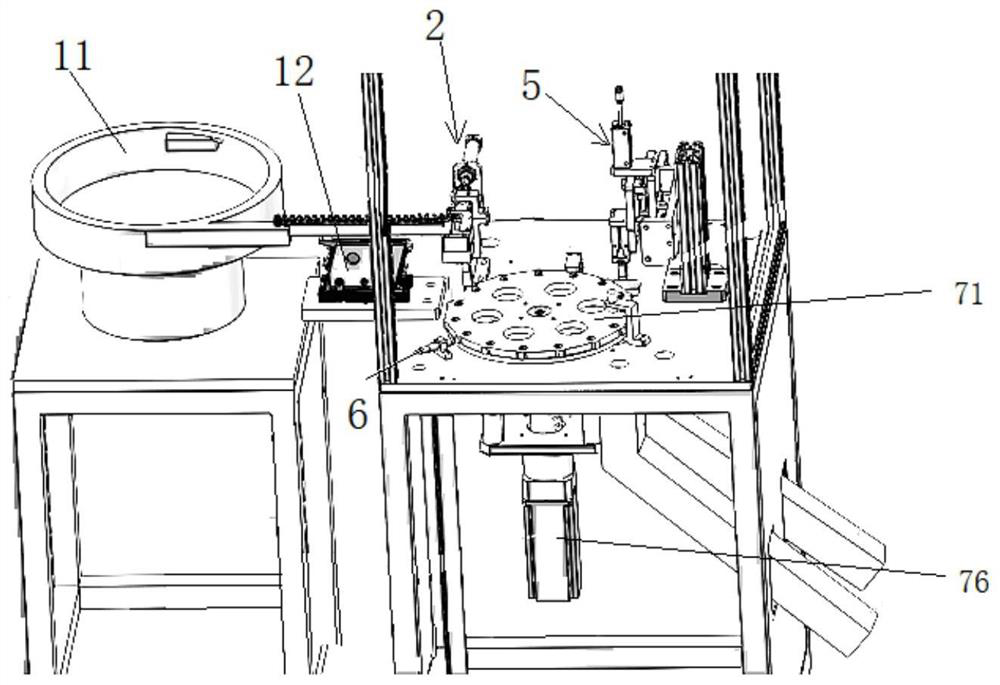

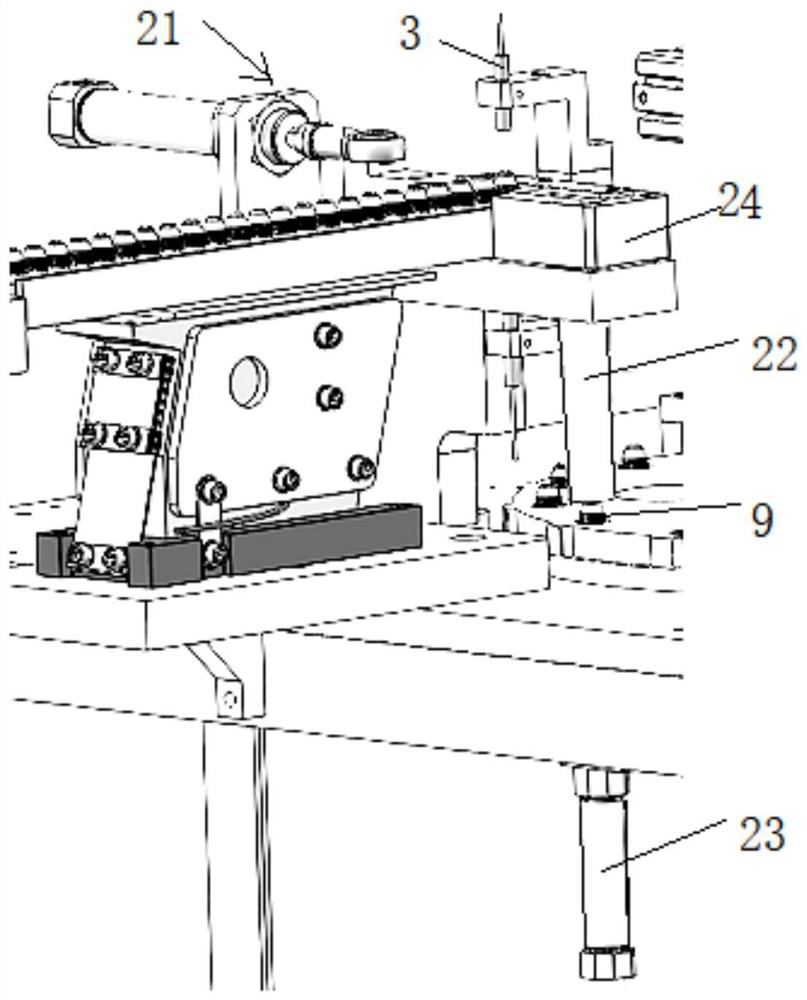

Automatic electrode detection device

PendingCN111958238ARealize automatic feeding processQuick Auto DetectAssembly machinesTransmissivity measurementsEngineeringManipulator

The invention discloses an automatic electrode detection device. The automatic electrode detection device comprises an automatic feeding component, an automatic mounting component, a hafnium wire detection component, a brass core detection component and a knurling detection manipulator. The automatic feeding component is used for conveying an electrode to be mounted to the automatic mounting component; the automatic mounting component is used for mounting the electrode in a station hole of a multi-station turntable; the hafnium wire detection component is used for detecting whether a hafnium wire is mounted on the electrode; the brass core detection component is used for detecting whether a brass core is mounted on the electrode; and the knurling detection manipulator is used for detectingwhether the surface of the electrode is knurled. According to the device, automatic feeding can be achieved, and a PLC system is combined with a mechanical structure, so that rapid, efficient and accurate automatic detection is achieved; and the installation condition or qualified condition of knurls, brass cores and hafnium wires can be detected at a time, and qualified products and unqualifiedproducts can be automatically classified.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

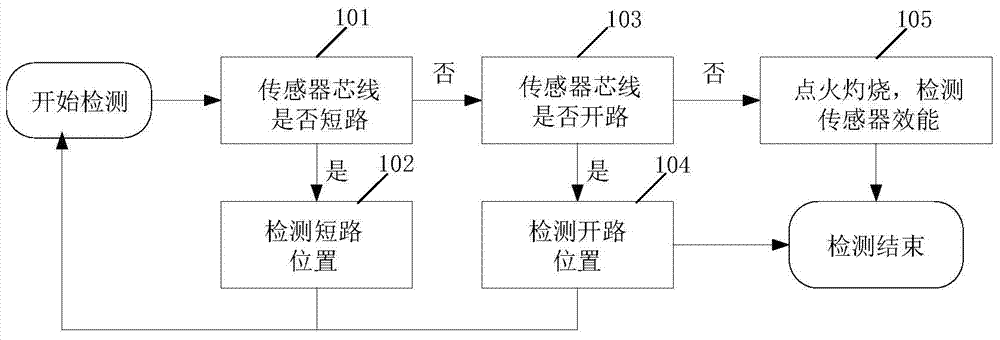

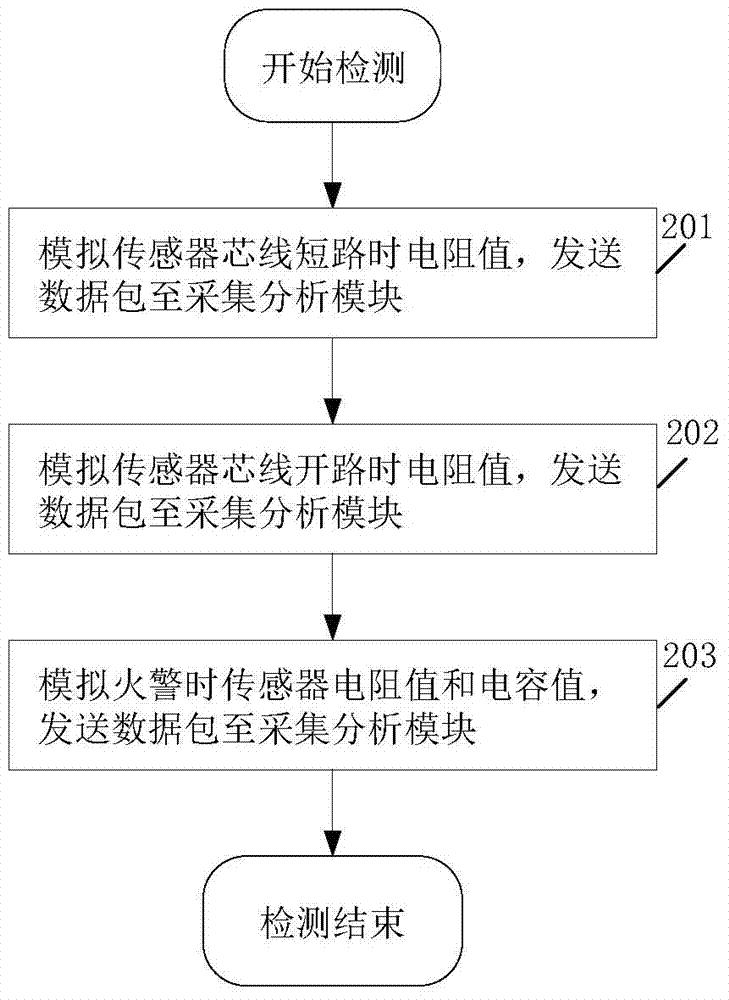

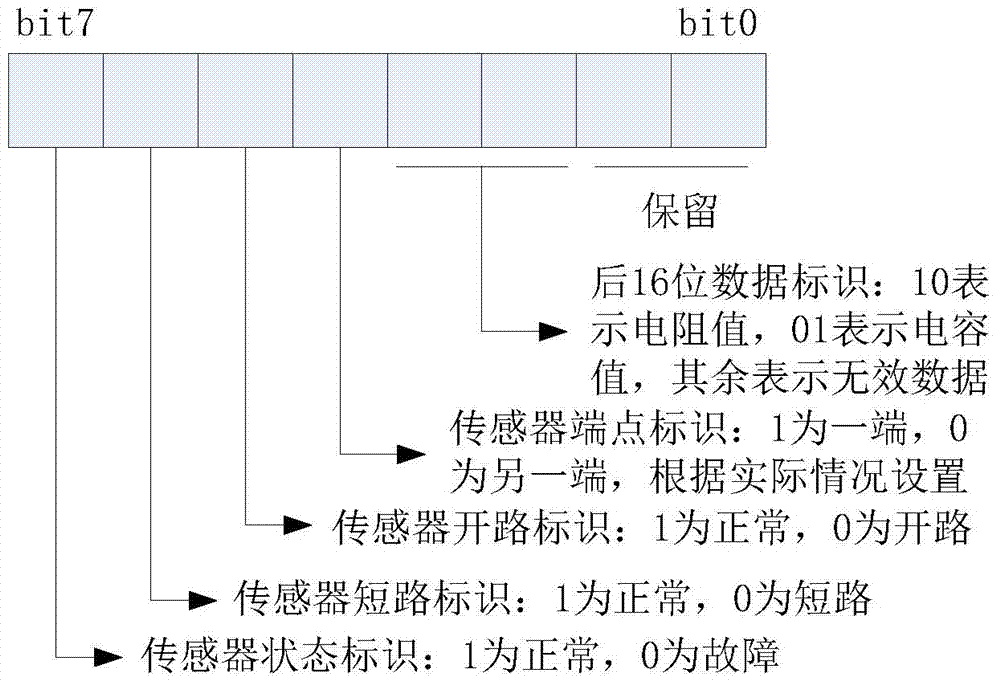

Method and device for detecting fire alarm system based on linear flame sensor

The invention relates to a method and device for detecting a fire alarm system based on a linear flame sensor. The method for detecting the fire alarm system based on the linear flame sensor comprises the steps that the short circuit state and the open circuit state of the linear flame sensor are detected; if the short circuit state and / or the open circuit state exist / exists, the working performance parameter of the linear flame sensor is detected after the corresponding fault position is determined and a fault is removed; a data packet is sent to an acquisition and analysis module through simulation, and whether the short circuit state and the open circuit state of the linear flame sensor can be accurately judged by the acquisition and analysis module and whether the alarm function is normal or not are judged according to the analysis result on the data packet by the acquisition and analysis module. According to the method and device for detecting the fire alarm system based on the linear flame sensor, the fault and the performance of the fire alarm system can be detected rapidly and automatically.

Owner:CHINA SOUTH IND GRP SHANGHAI ELECTRIC CONTROL RES INST

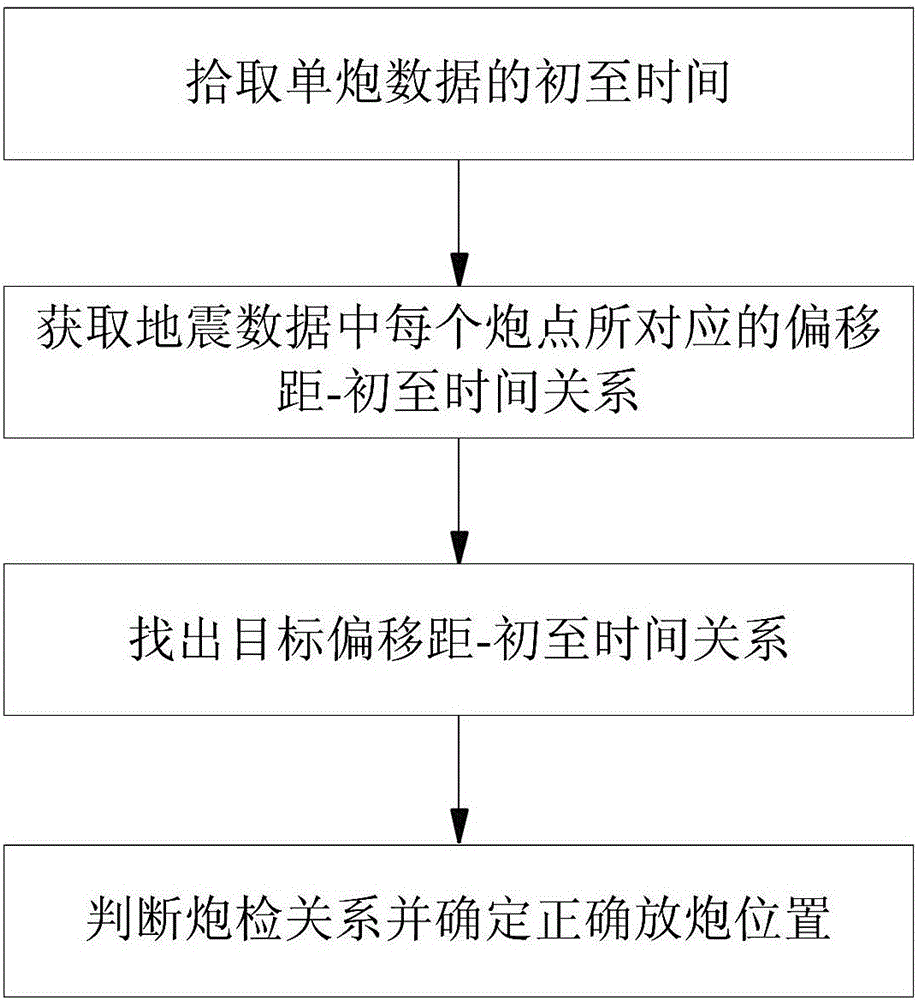

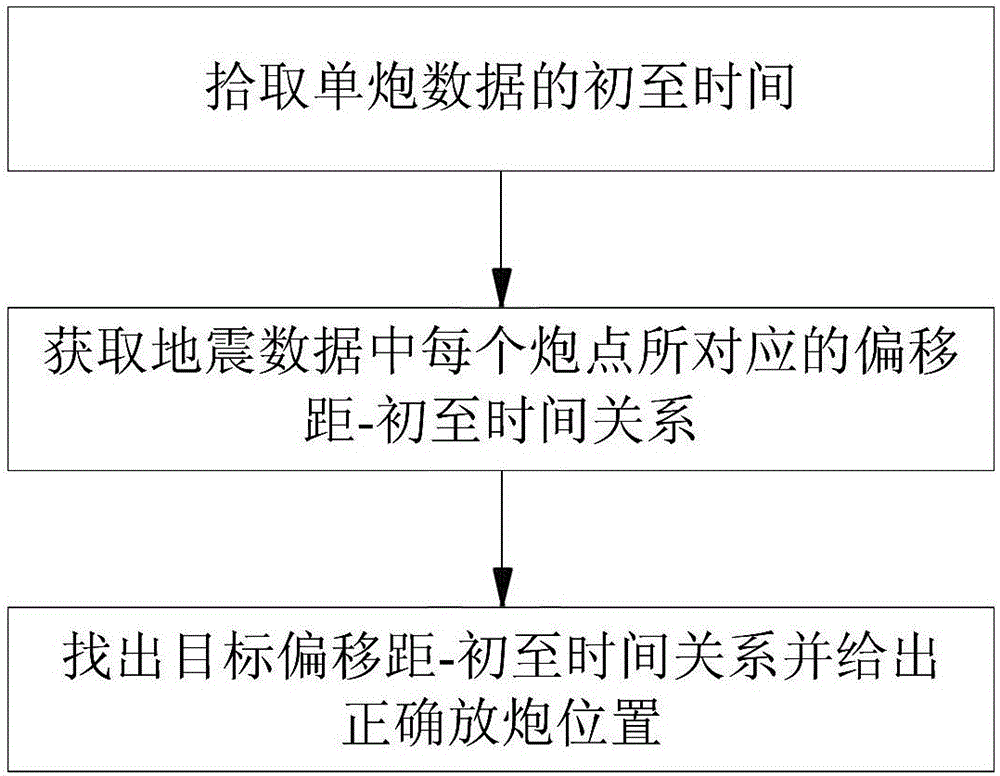

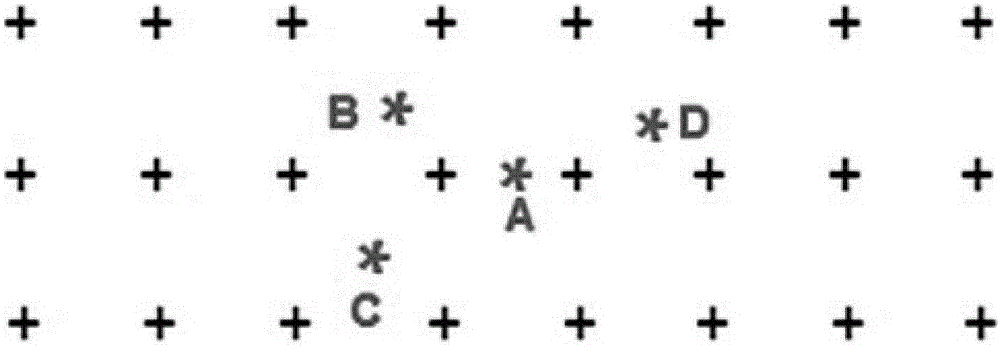

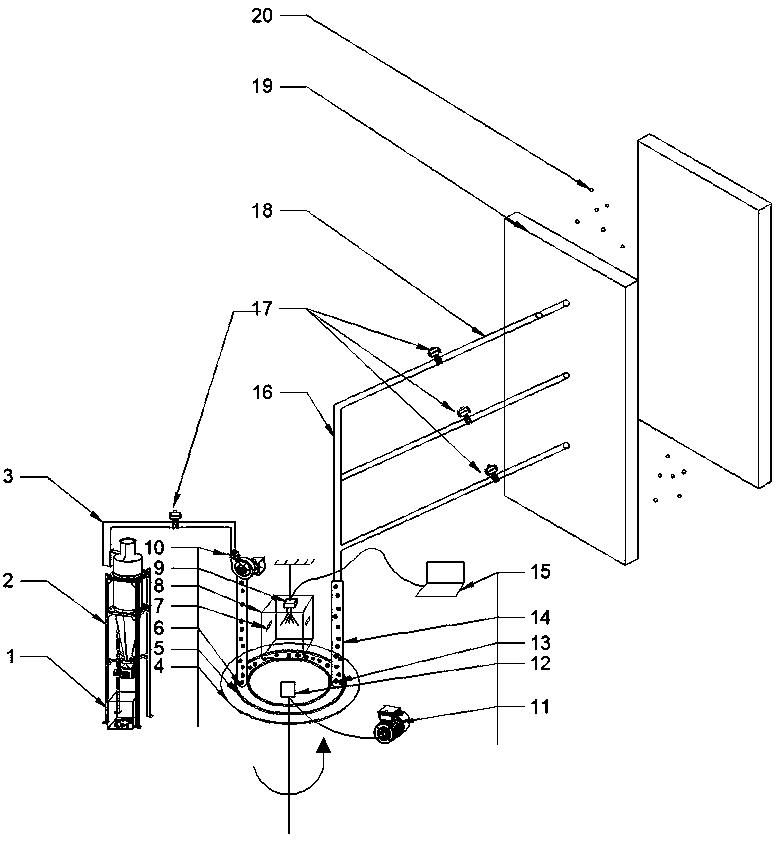

Method for shot deviation in seismic prospecting and method for positioning correct shot position

ActiveCN106291699ABroad application prospectsQuick Auto DetectSeismic signal processingOffset distanceShot point

The invention provides a method for shot deviation in seismic prospecting and method for the positioning correct shot position. The method for shot deviation includes picking up the first-arrival time of the single-shot data; constructing the corresponding offset distance-first arrival time relation for each shot point in the serial shot point including the shot point and the receiver point position relation data; finding out the optimal target offset distance-first arrival time relation for the condition that the first-arrival time is gradually increased along the increasing of the offset distance; comparing the shot point corresponding to the target offset distance-first arrival time relation with the shot pint recorded in the trace header of the single-shot data, if the coordinate positions of the shot points are not consistent, determining that the shot detection relation of the shot is incorrect (namely, deviated), and meanwhile, taking the shot point corresponding to the target offset distance-first arrival time relation as a correct shooting position. According to the invention, the shot deviation of the single-shot record can be rapidly and accurately detected; and meanwhile, the correct shooting position can be pointed out, and the need of field single-shot onsite quality control can be met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Intelligent fine particle recognition device and method for friction electric separation

ActiveCN109490174AQuick Auto DetectAvoid wastingIndividual particle analysisExternal electric electrostatic seperatorEngineeringHigh voltage electrode

The invention relates to an intelligent fine particle recognition device and method for friction electric separation. The device mainly comprises a pipeline sampling system, a sampling round table, animage acquisition and recognition system and a sample recovery system, dust particles moving in a multi-stage high-voltage electrode plate in friction electric separation equipment are automaticallyacquired, images are recognized and detected, and the dust particles are automatically recovered to solve the problems that parameters of dust particles moving in an existing friction electric separator are difficultly detected, detection period is long, and the dust particles are difficultly recycled after detection and the like. The device has the advantages of short detection period, simplicityin operation, easiness in control and low manufacturing cost.

Owner:CHINA UNIV OF MINING & TECH

Automatic detection equipment for automobile curtain

PendingCN109187169AHigh precisionReduce manual misjudgmentMaterial strength using tensile/compressive forcesElectrical controlEngineering

The invention discloses automatic detection equipment for an automobile curtain. The equipment comprises a workbench, and an electrical control cabinet fixed at the bottom of the workbench; a PLC controller is installed in the electrical control cabinet, a control button connected with the PLC controller via a wire is fixedly connected with the workbench; a principle shaft diameter detection mechanism is fixedly connected with the workbench; a support plate inclined to the workbench is fixedly connected with one side of the principle shaft diameter detection mechanism; a size detection plate is fixedly connected with the support plate; deformation-resistant curtain cloth detection devices are fixedly connected with the support plate and positioned on two sides of the size detection plate,and a tensile-resistant side shaft detection device is fixedly connected with the edge of the deformation-resistant curtain cloth detection device on one side. According to the equipment provided by the invention, all projects needing to be detected can be completed at a time before the automobile curtain leaves a factory, the detection processes are reduced, and the labor cost is also saved whilethe detection efficiency during production is improved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

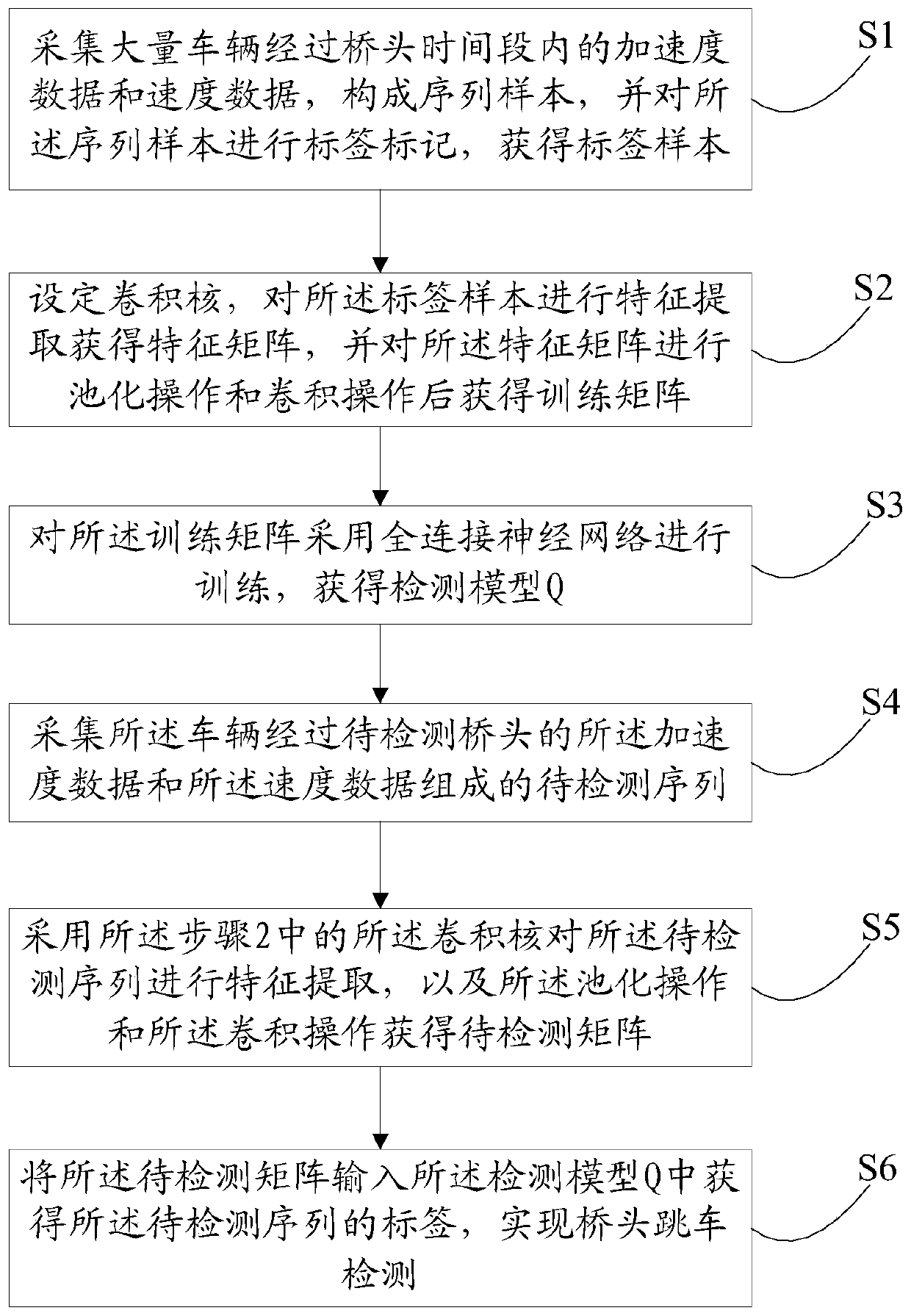

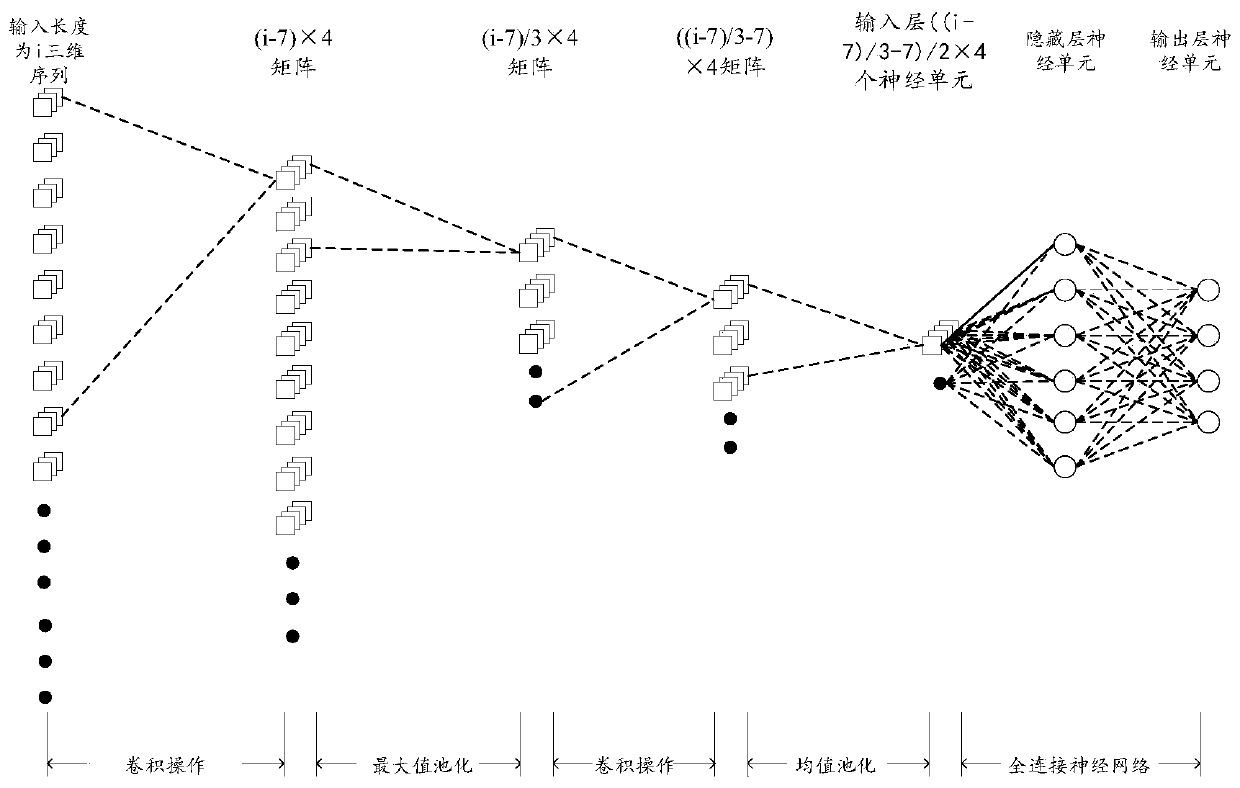

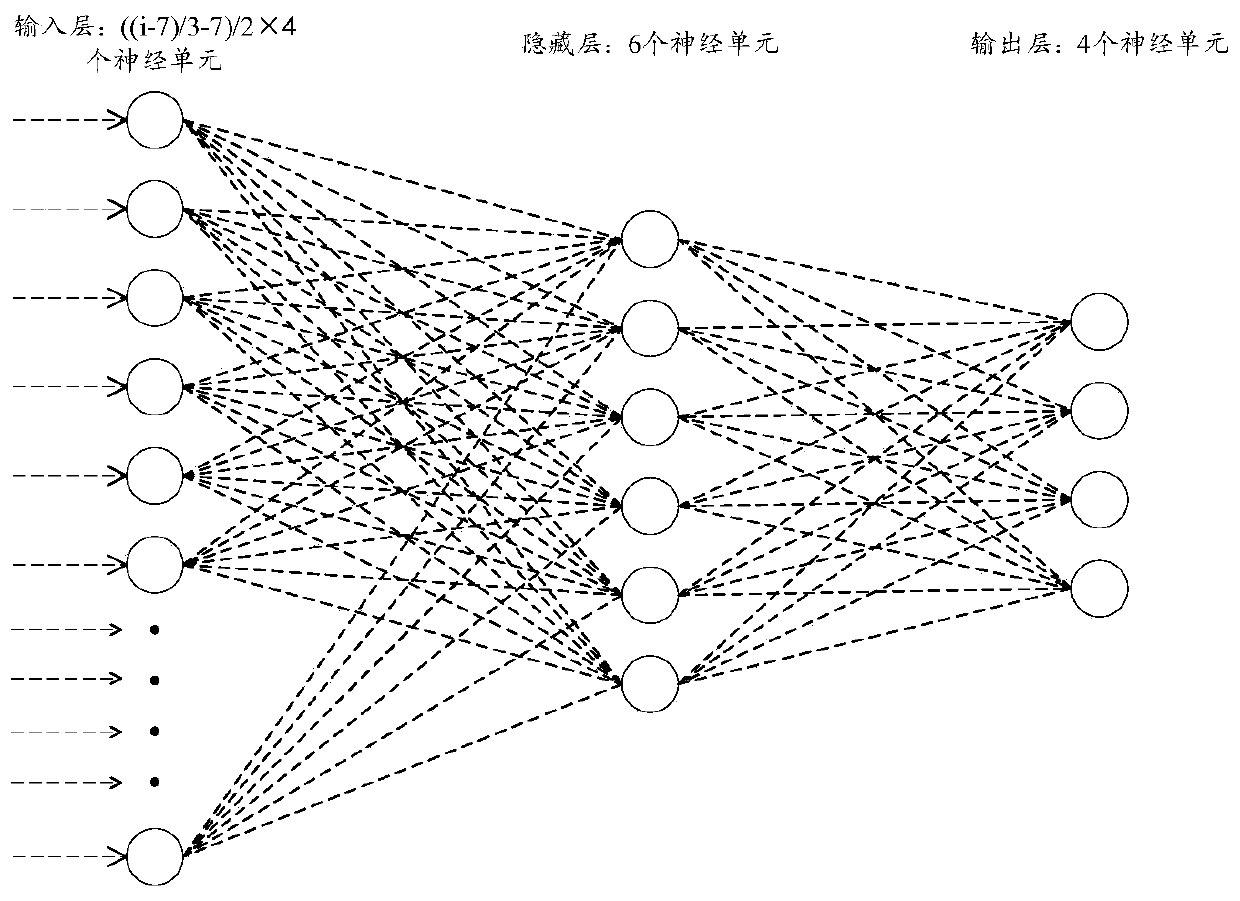

Bridgehead bumping rapid detection method based on one-dimensional convolution kernel feature extraction

ActiveCN111368916AQuick checkQuick Auto DetectAcceleration measurement using interia forcesCharacter and pattern recognitionFeature vectorFeature extraction

The invention discloses a bridgehead bumping rapid detection method based on one-dimensional convolution kernel feature extraction. The method comprises the following steps: acquiring vehicle motion state data by using a vehicle-mounted attitude sensor, extracting a feature vector from the acquired vehicle motion state data through one-dimensional convolution, and training the feature vector by using a full-connection neural network to obtain a one-dimensional convolutional neural network model; and based on the neural network model, inputting the motion state data of the vehicle passing through the to-be-detected road section into the model, and detecting whether the road section has a bridgehead bump condition and the severity of bridgehead bump.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP +1

Automatic detection, profiling and sorting method for macroarray resistance strain gages

InactiveCN106345709ACompact structureNovel and reasonable designMeasurement devicesSortingData acquisitionUltimate tensile strength

The invention discloses an automatic detection, profiling and sorting method for macroarray resistance strain gages; devices used in the method include an automatic detection device, an automatic profiling device, an automatic sorting device, a computer data collection card, a bench type digital multimeter, and an output amplifying board; the automatic detection device comprises a detection frame, a detection positioning and fixing mechanism and a detection mechanism; the automatic profiling device comprises a profiling frame, a profiling positioning and fixing mechanism, and a profiling mechanism; the automatic sorting device comprises a sorting frame, a sorting positioning and fixing mechanism, a suction sorting mechanism and a positioning sorting mechanism; the method includes the steps of first, automatically detecting macroarray resistance strain gages; second, automatically profiling the macroarray resistance strain gages; third, automatically sorting the macroarray resistance strain gages. The method enables production efficiency to be improved, and labor intensity of workers and production cost to be reduced.

Owner:SHAANXI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com