True position detecting method for pin of socket connector of vehicle controller

A technology of a body controller and a detection method, which is applied to instruments, measuring devices, and optical devices, etc., can solve the problems of large differences in the flatness and alignment of connector terminals, low precision, and low efficiency, and achieves improved performance. Software reliability and stability, easy configuration, automatic detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

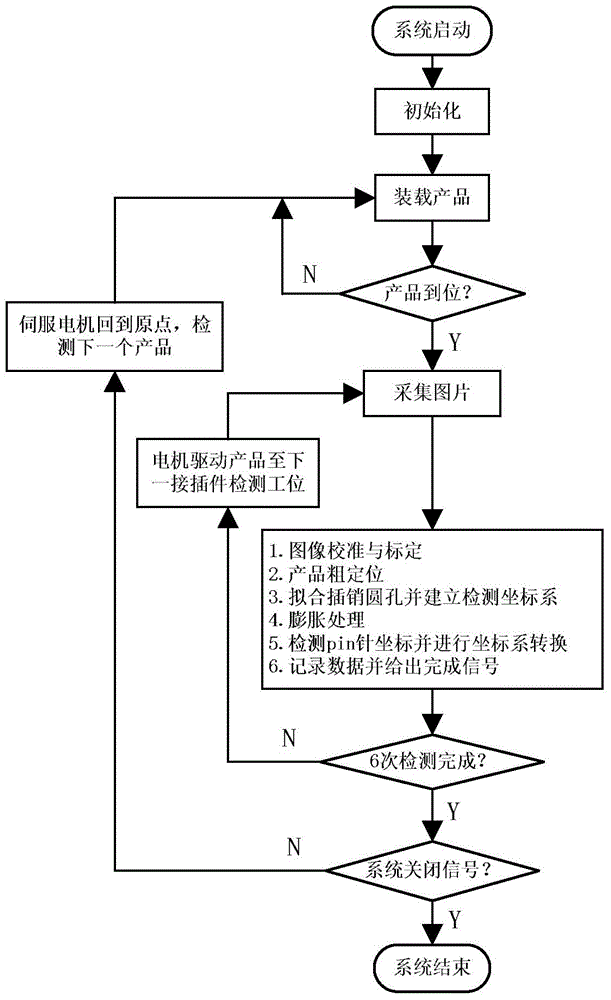

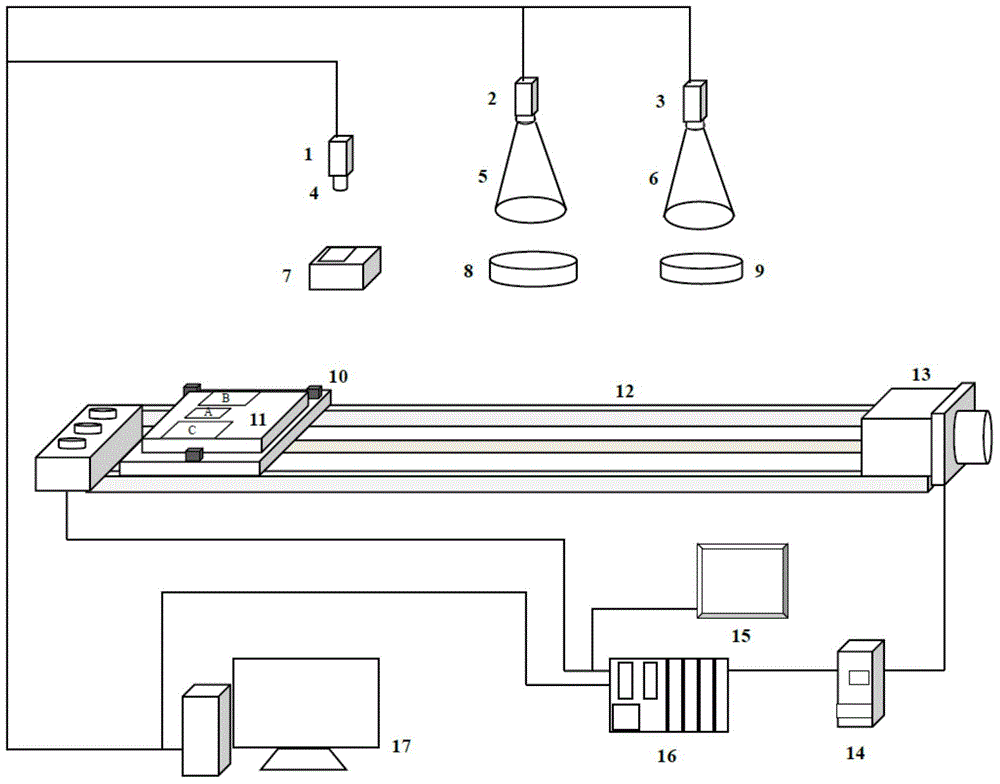

[0026] First set the coordinates of 6 detection stations in the PLC (16), set the process parameters of the current batch of body controllers in the host computer (17), and then start the detection.

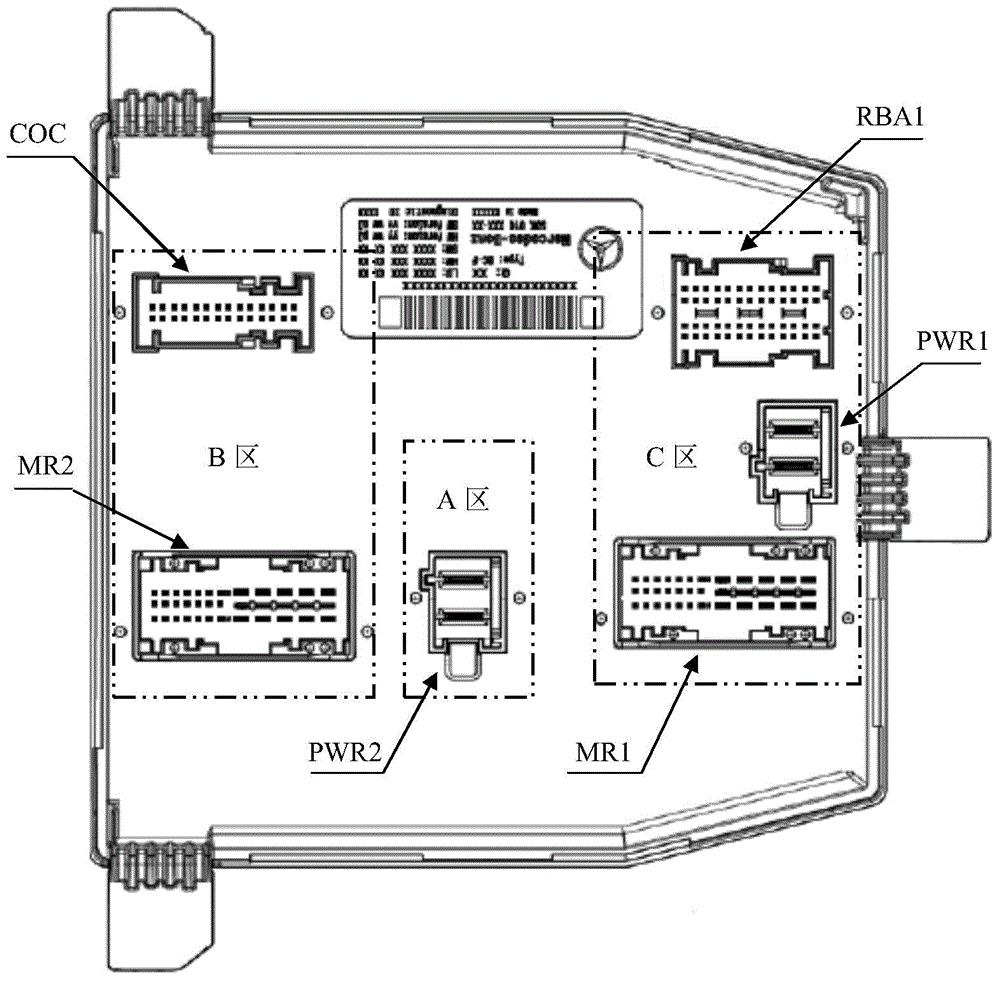

[0027] When the test starts, the product to be tested (11) is manually placed on the tray (10), and the PLC (16) drives the servo motor (13) through the motor controller (14) to carry the product to be tested (11) to the first one in area A. The connector (PWR2) detects the station, and when it is in place, the PLC (16) sends a signal in place through OPC communication, and the host computer (17) triggers the camera (1) to take pictures, and after obtaining the pictures, the image processing is completed by the following 5 steps:

[0028] (1) Calibrate and calibrate the collected images, select a checkerboard calibration plate with a grid size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com