Patents

Literature

72results about How to "Accurate automatic detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

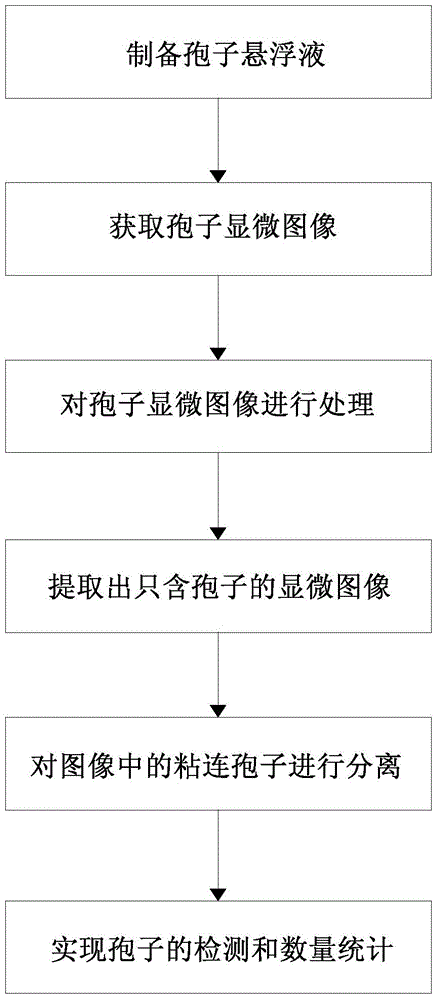

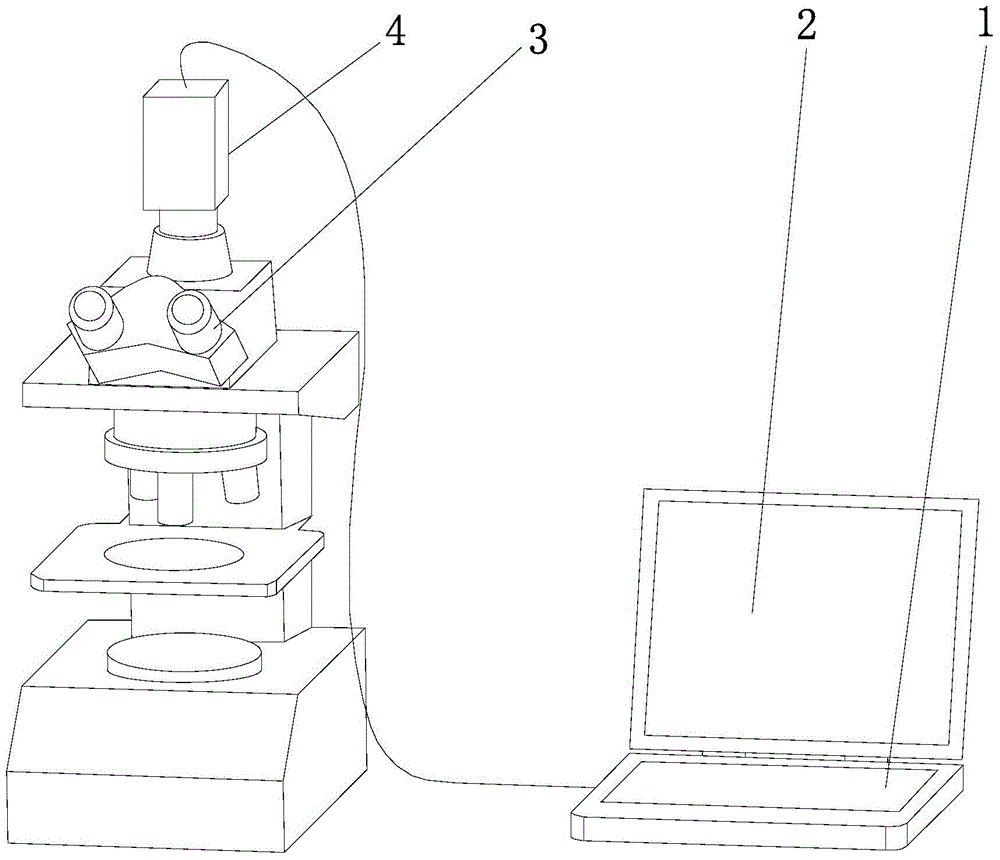

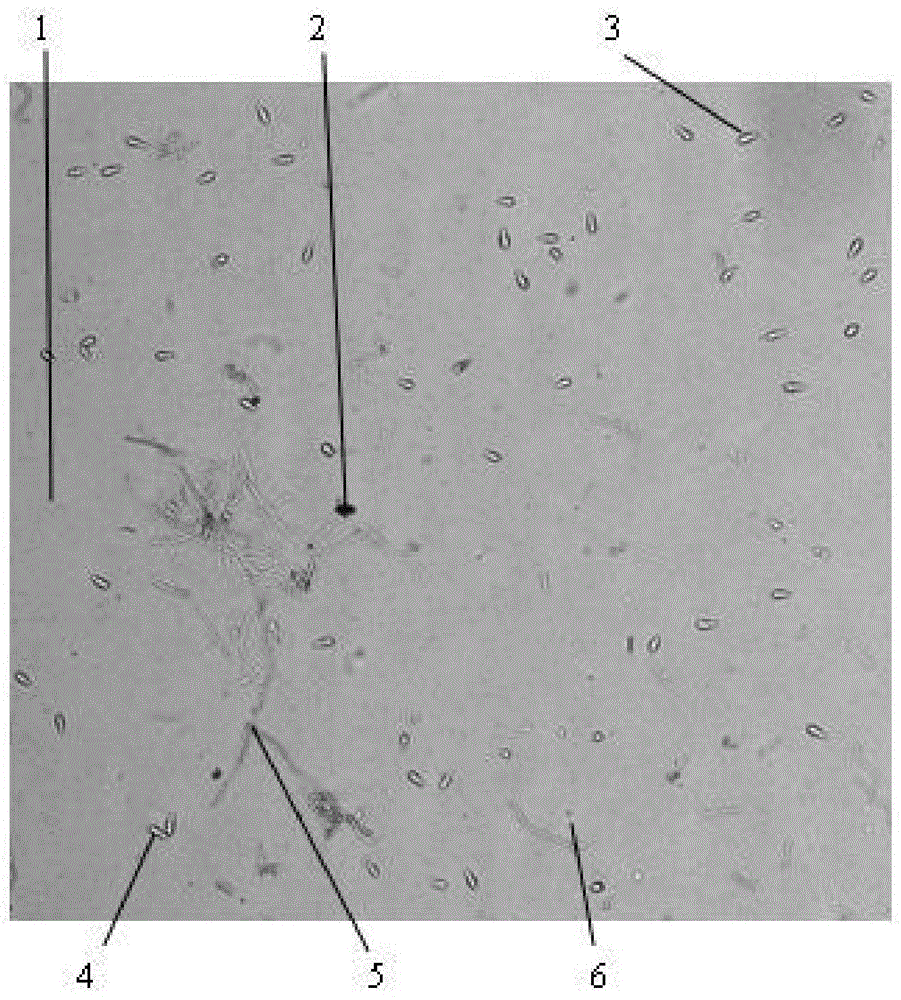

Method for detecting magnaporthe grisea spore based on microscopic image analysis

ActiveCN104651462AEffective segmentationSolve the problem that easily leads to wrong over-segmentationMicrobiological testing/measurementMicroorganism based processesPattern recognitionMicroscopic image

The invention discloses a method for detecting a magnaporthe grisea spore based on microscopic image analysis. The method comprises the following steps: obtaining a spore microscopic image in the spore suspension solution by a magnaporthe grisea spore image detecting system; processing the spore microscopic image by using the image illumination adjustment, the median filtering, the edge detection and the morphological algorithm, and extracting a microscopic image containing the spore by combining with the shape characteristic parameters; separating the adhesion spores by using an improved watershed algorithm to realize the spore detection and quantitative statistics in the microscopic image. By adopting the method for detecting the magnaporthe grisea spore, the number of the magnaporthe grisea spore can be rapidly, accurately and automatically detected, the technical assistance for the indoor resistance identification of the magnaporthe grisea is provided and the technical reference for automatically monitoring the magnaporthe grisea in the fields is also provided.

Owner:SOUTH CHINA AGRI UNIV

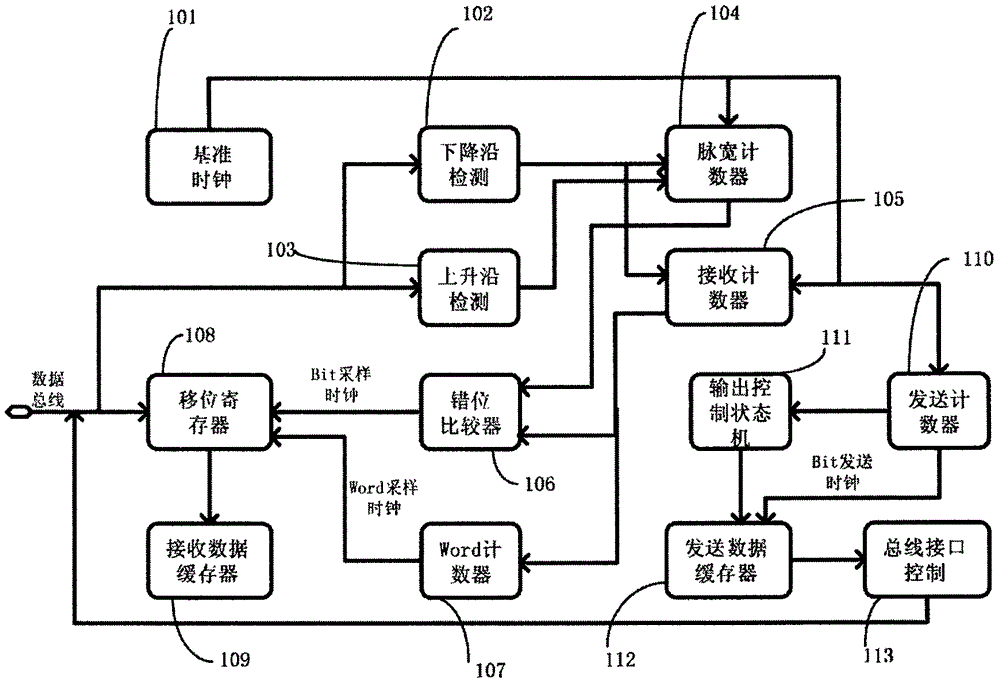

Single-bus asynchronous serial port communication system and communication method thereof

ActiveCN106528478AReduce complexityAccurate automatic detectionElectric digital data processingCommunication interfaceAsynchronous serial communication

The invention discloses a single-bus asynchronous serial port communication system and a communication method thereof. The single-bus asynchronous serial port communication system comprises master equipment and slave equipment, wherein the master equipment is connected with the slave equipment through a data bus; and a serial port communication interface circuit is arranged in the slave equipment, and the slave equipment realizes Baud rate detection and adjustment of the master equipment, receives a control command and data of the master equipment and returns corresponding response data. The single-bus asynchronous serial port communication system transmits data through a single bus, and automatic Baud rate detection is realized by adopting a bit width counting and comparing technology; namely, the slave equipment can transmit data to the master equipment only via one data bus, so that the complexity of a communication interface is greatly reduced; by the adoption of the special bit width counting and comparing technology, the communication Baud rate can be automatically detected quickly and accurately through the automatic Baud rate detection; and the number of adopted integrated circuit transistors is small, and the chip cost is reduced.

Owner:北京中科银河芯科技有限公司

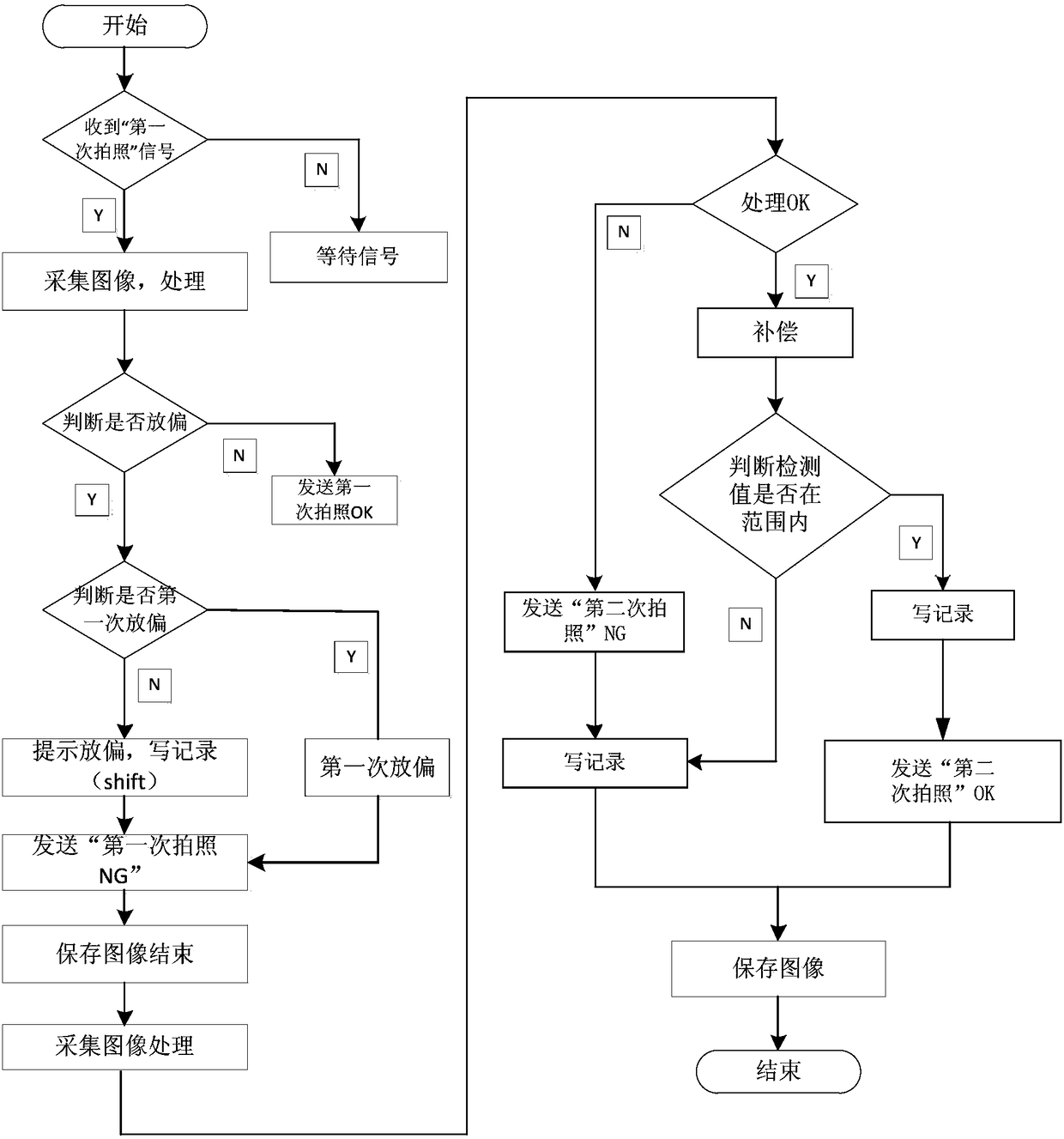

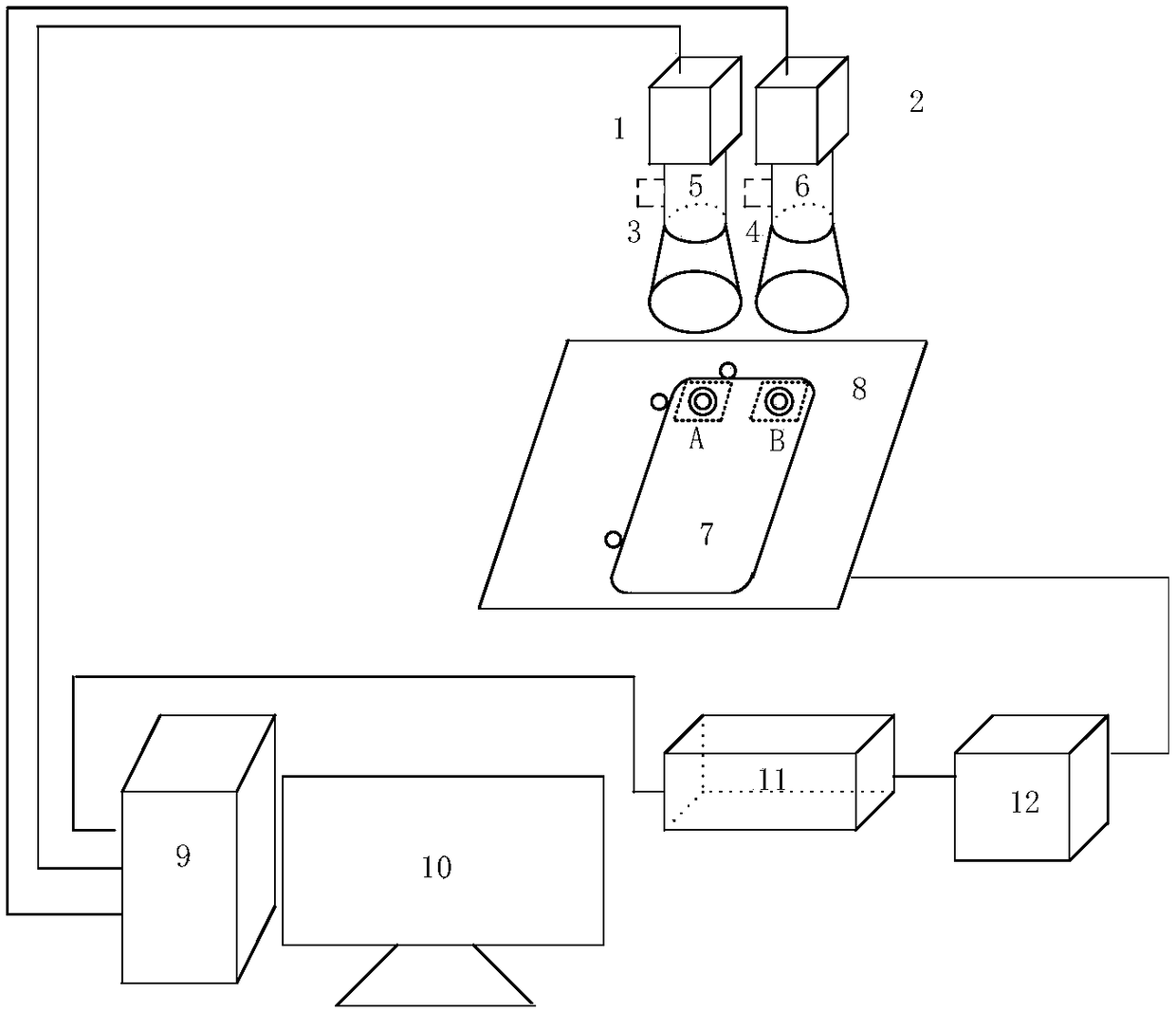

True position detecting method for pin of socket connector of vehicle controller

ActiveCN104913722AImprove reliabilityImprove stabilityUsing optical meansImaging processingDistribution characteristic

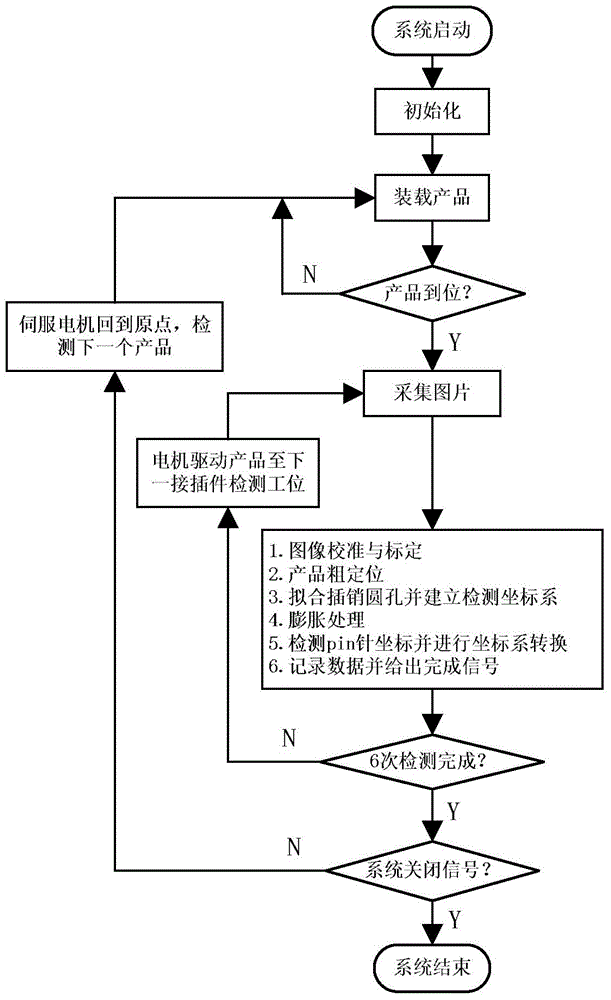

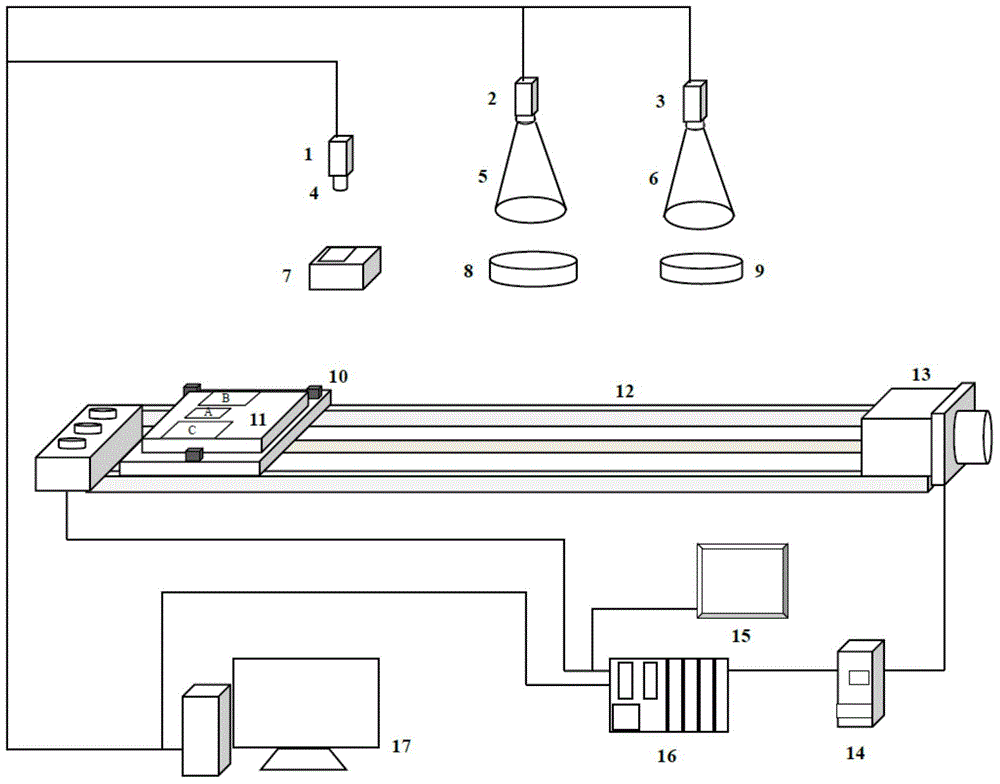

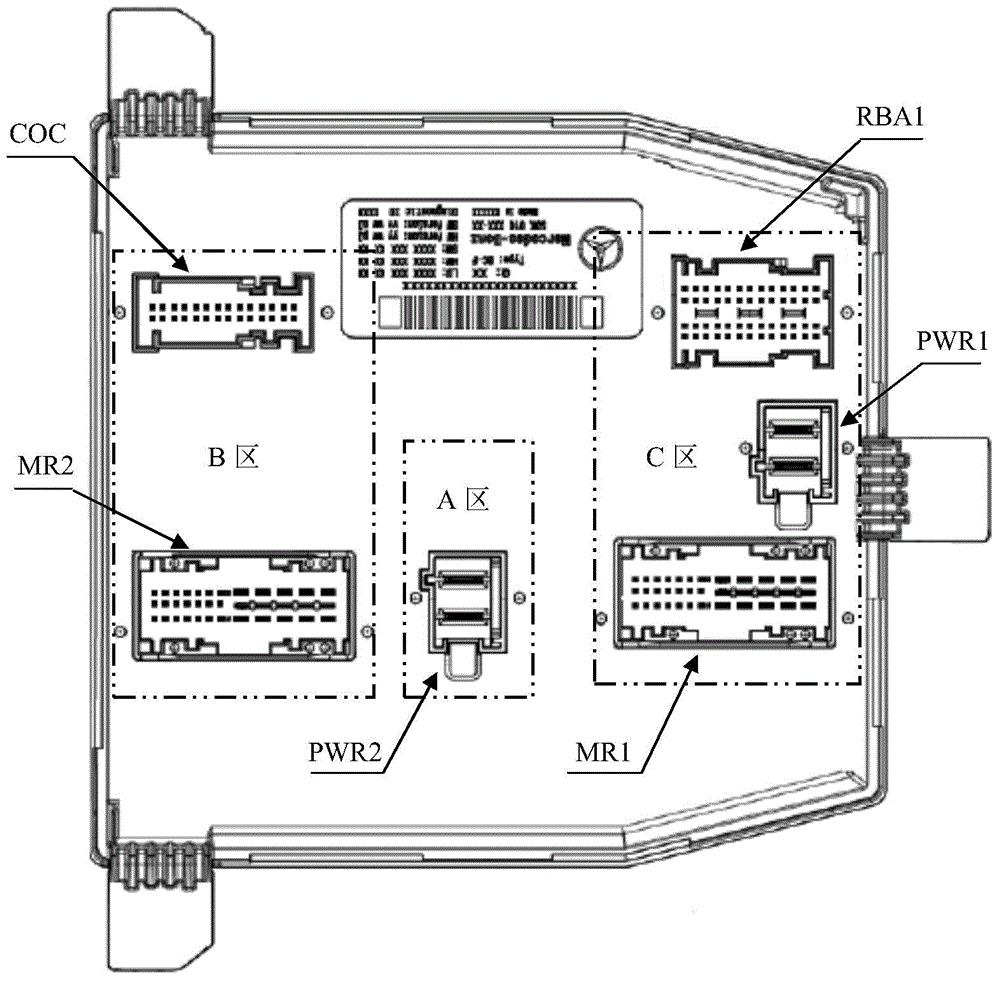

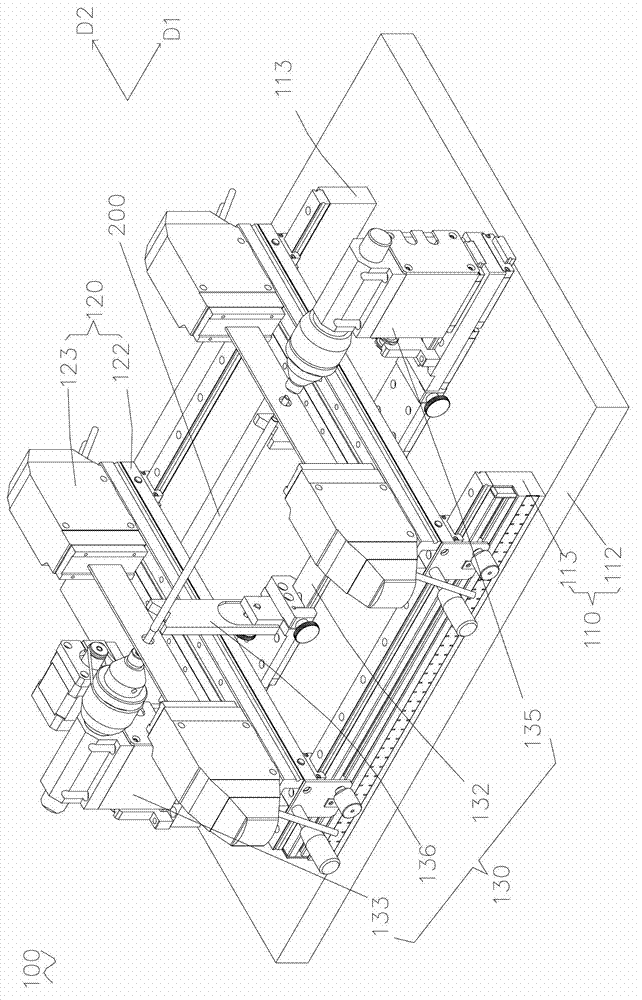

The invention discloses an automatic true position detecting method and specifically relates to a true position detecting method for a pin of a socket connector of a vehicle controller. A detection system includes an image collecting unit, a motion control unit, a servo motor unit, an upper computer processing unit and an auxiliary device. A method of arranging three cameras in three zones including an A zone, a B zone and a C zone for detection is designed according to distribution characteristics of socket connectors. After the system is started, the motion control unit drives a to-be-detected product to a detection station and triggers a photo taking signal. The image collecting unit collects images and sends the images to the upper computer processing unit for processing and the processed data is recorded. An image processing algorithm is used for detecting the true position of the pin of the socket connector and a detection result is displayed and an implementation signal is given out. Later, the motion control unit drives the to-be-detected product to a socket connector station for a next step. By using the method provided by the invention, quick, accurate and automatic detection of true position of the pin of the socket connector of the vehicle controller can be realized.

Owner:黑龙江至晟车辆技术服务有限公司

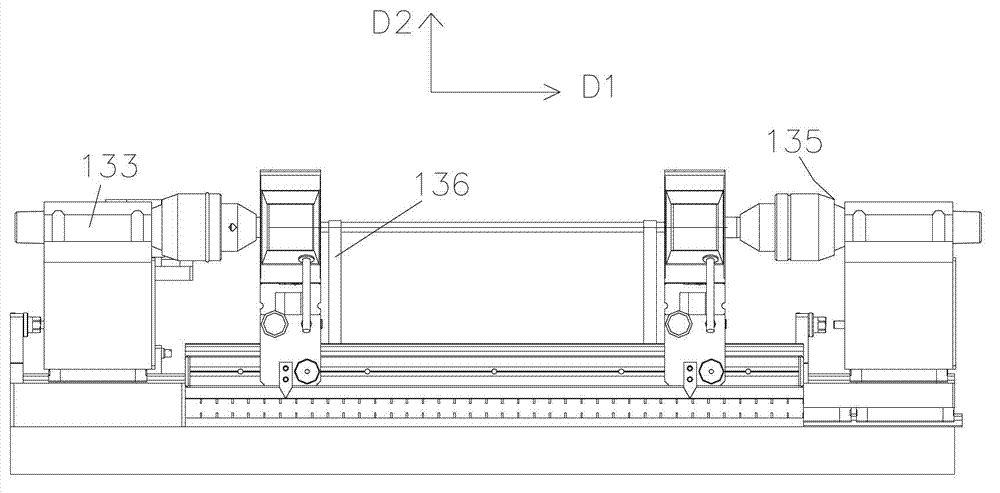

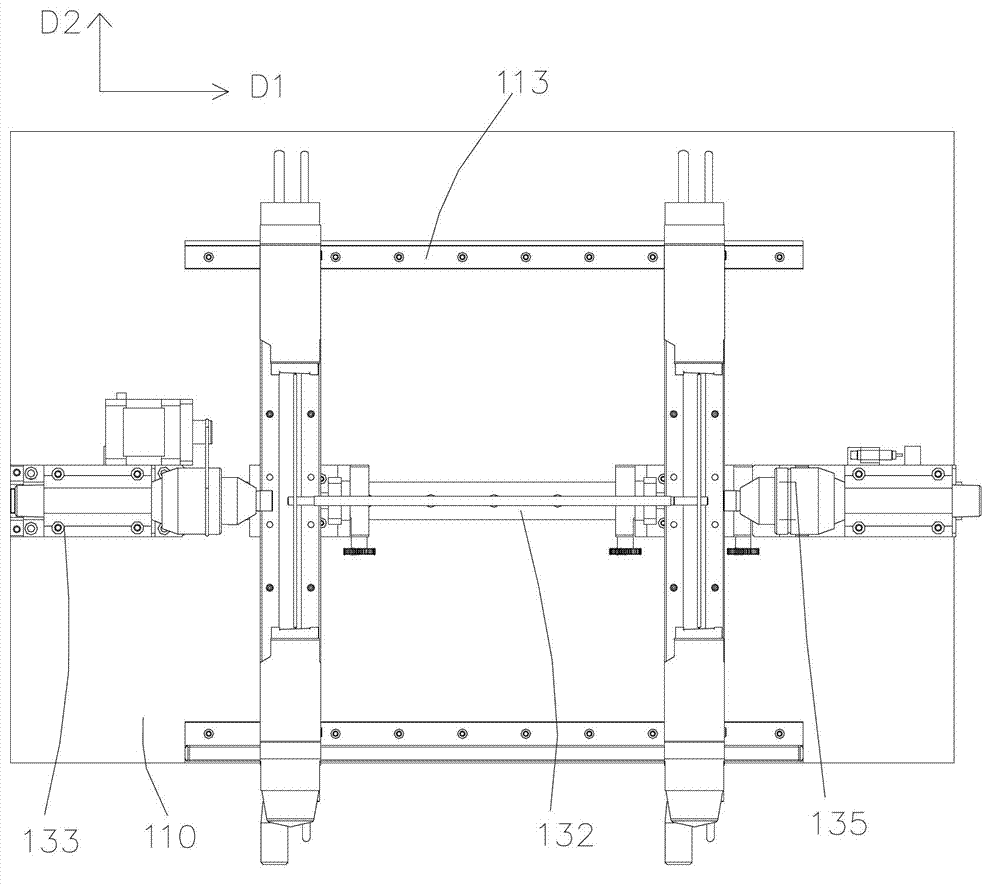

Detection device and method for detecting outer diameter, runout value and roundness of circular shaft

InactiveCN102901456AAccurate automatic detectionFast and accurate titrationUsing optical meansProgrammable logic controllerPersonal computer

The invention relates to a detection device and a method for detecting an outer diameter, a runout value and roundness of a circular shaft. The detection device comprises a base portion, an optical measurement portion, a center portion and a personal computer (PC)-programmable logic controller (PLC) control center, wherein the base portion comprises a base board and two base board guide rails, the optical measurement portion and the center portion are installed on the base portion in a sliding mode, the optical measurement portion comprises an optical measurement instrument guide rail and an optical measurement instrument, the optical measurement instrument guide rail is arranged on the base board guide rails in a sliding mode, the optical measurement instrument is arranged on the optical measurement instrument guide rail in a sliding mode, the center portion comprises a center guide rail, a first center structure and a second center structure, the first center structure and the second center structure are arranged on the center guide rail in a sliding mode, and the PC-PLC control center controls the optical measurement portion and the center portion to move relative to the base portion. The optical measurement instrument is used for measuring a round shaft to be detected, measured data are fed back to the PC-PLC control center, and the PC-PLC control center calculates the outer diameter, the runout value and the roundness of the circular shaft to be detected according to the measured data.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

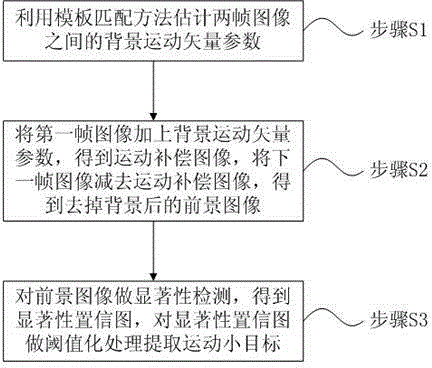

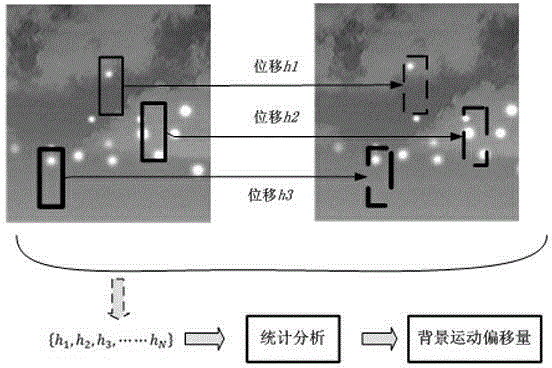

Small infrared moving target detection method based on complicated background estimation

InactiveCN104463911AAccurate automatic detectionImage enhancementImage analysisTemplate matchingMotion vector

The invention discloses a small infrared moving target detection method based on complicated background estimation. The method comprises the steps that a template matching method is utilized for estimating background motion vector parameters between two frames of images, the background motion vector parameters are added to the first frame of image to obtain a motion compensation image, a motion compensation image is removed from the other frame of image to obtain a foreground image with the background removed, saliency detection is carried out on the foreground image to obtain a saliency confidence picture, and thresholding is carried out on the saliency confidence picture to extract a small moving target. According to the small infrared moving target detection method, the small moving target is detected from the complicated infrared scene with no priori knowledge, and the small infrared moving target can be rapidly, accurately and automatically detected.

Owner:SHANGHAI XINYUE METER FACTORY

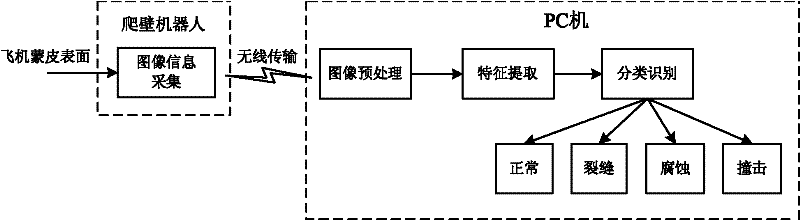

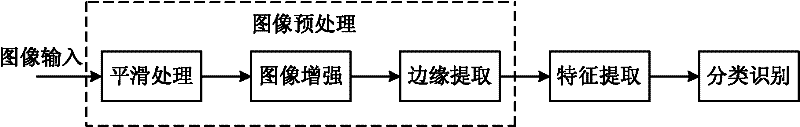

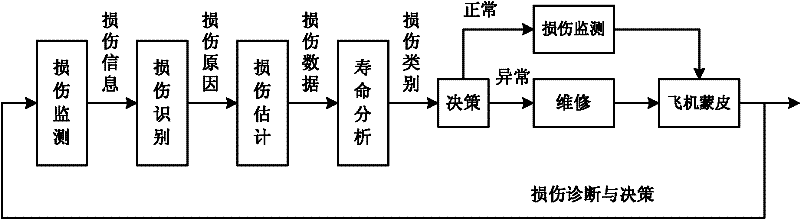

Aircraft skin structure monitoring method based on wireless machine vision

InactiveCN102355569ASimple structureGo cablelessCharacter and pattern recognitionClosed circuit television systemsWorkstationVisual perception

The invention, which belongs to the aircraft skin structure health monitoring field, discloses an aircraft skin structure monitoring method based on wireless machine vision. In the method, a wall-climbing robot, which is equipped with an image acquisition apparatus, is used to move on an aircraft skin surface so as to real-timely collect skin image information; the skin image information is sent to a PC machine in a work station through wireless communication; the PC machine carries out image preprocessing, image feature extraction, classification and identification to the image information and finally gives a skin damage diagnosis and decision according to an identification result. By using the method of the invention, an untethered operation of the aircraft skin structure monitoring can be realized, simultaneously continuity of the monitoring can be guaranteed and accuracy and working efficiency of the monitoring can be raised.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

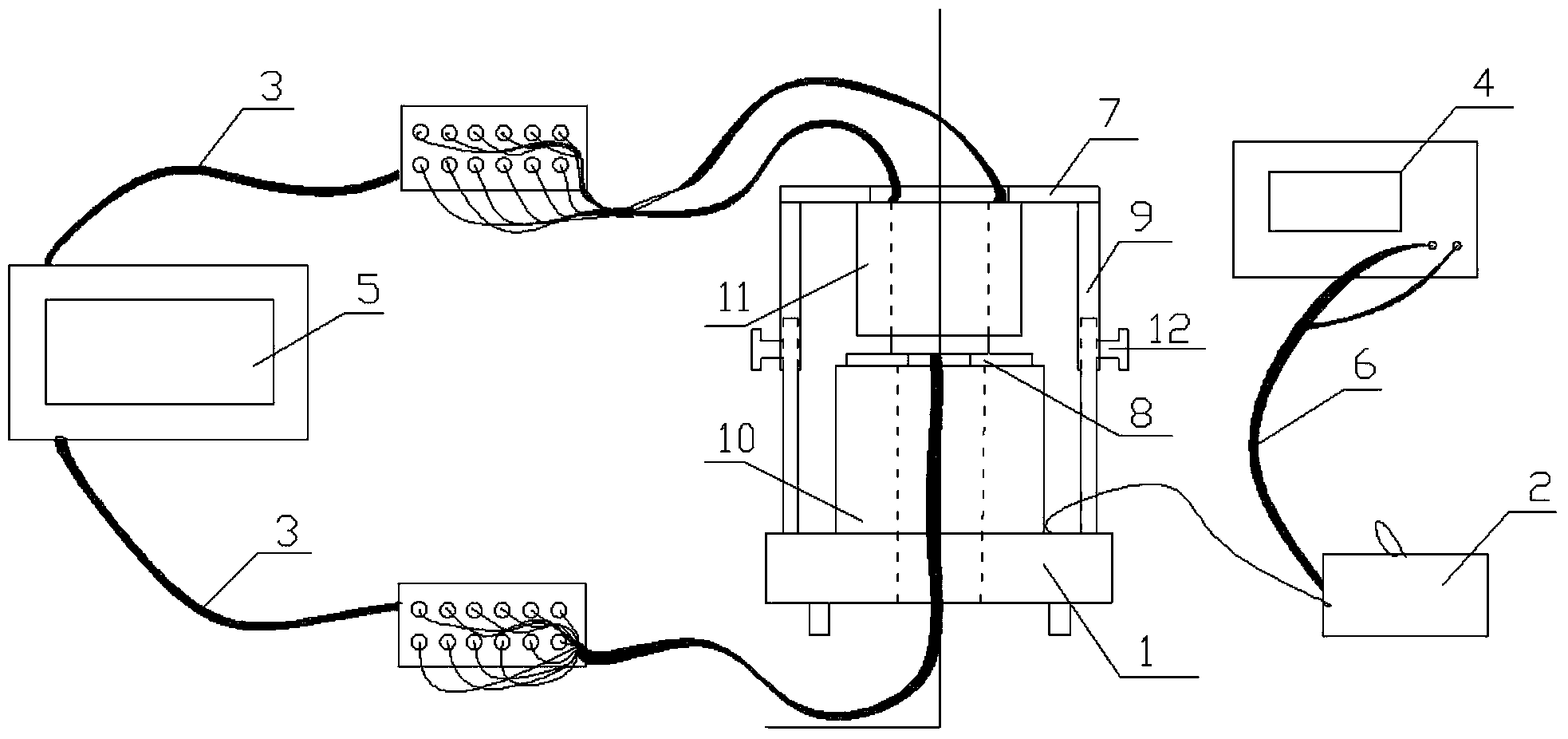

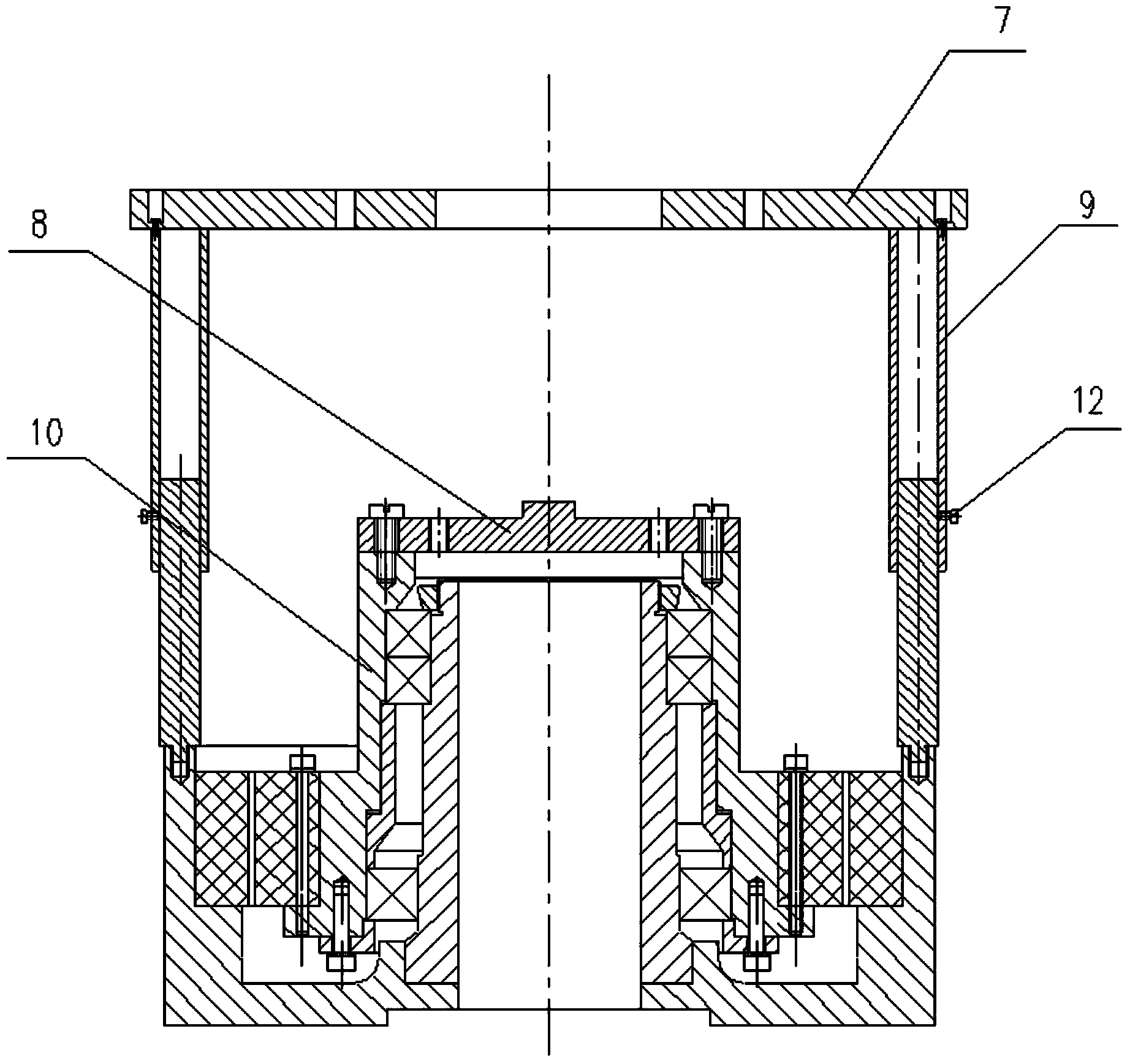

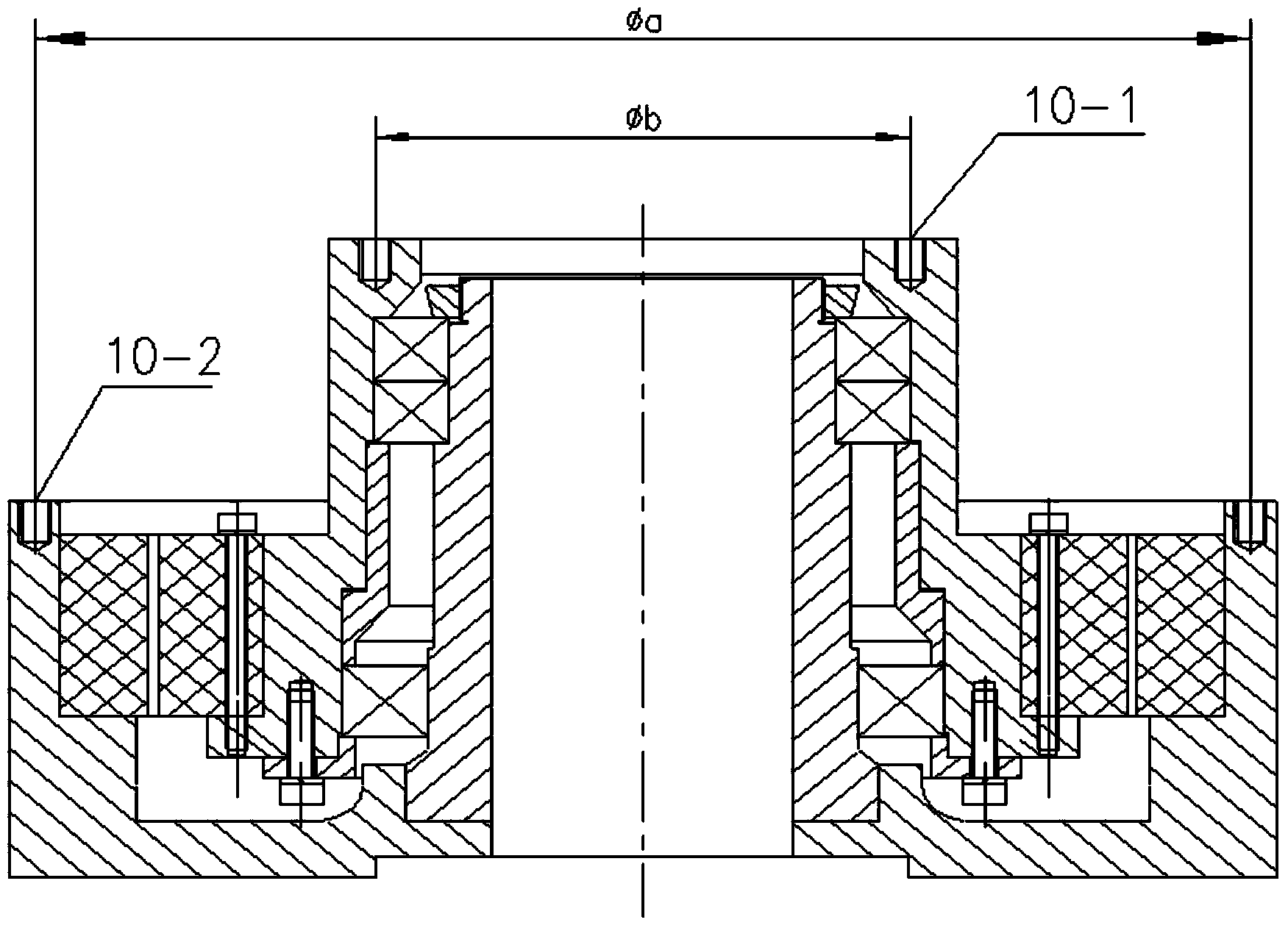

Collector ring rotating state electrical performance detecting device

ActiveCN103954878AImprove detection efficiencyQuick checkElectrical testingEngineeringElectrical performance

The invention provides a collector ring rotating state electrical performance detecting device. The device comprises a dedicated rotating device, a rotating table control device, adaptive cables, a direct-current voltage-stabilized power source and a cable tester. The rotating table control device controls the dedicated rotating device to drive a detected collector ring to rotate, a rotor and a stator of the detected collector ring are respectively connected to the cable tester through the adaptive cables, and the dedicated rotating device comprises a detected collector ring fixing device, a detected collector ring through-connection device, a plurality of sets of lifting rod components controlling the detected collector ring to ascend and descend, and a rotating table. The detected collector ring through-connection device is coaxially fixed to the rotating table, one ends of the lifting rod components are fixed to the rotating table, and the lifting rod components are circumferentially and evenly distributed on the rotating table, the other ends of the lifting rod components are fixedly connected with the detected collector ring fixing device, and the detected collector ring fixing device is coaxial with the detected collector ring through-connection device. The collector ring rotating state electrical performance detecting device is simple in structure, facilitates instrument erecting, and is convenient to operate and high in detection precision.

Owner:西安应用光学研究所

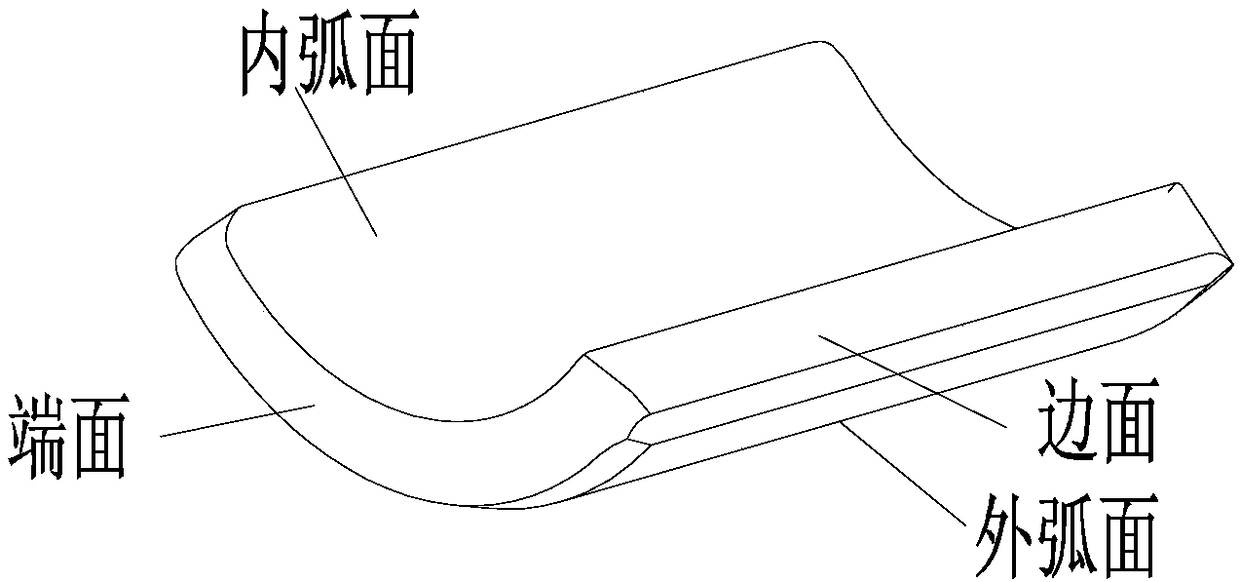

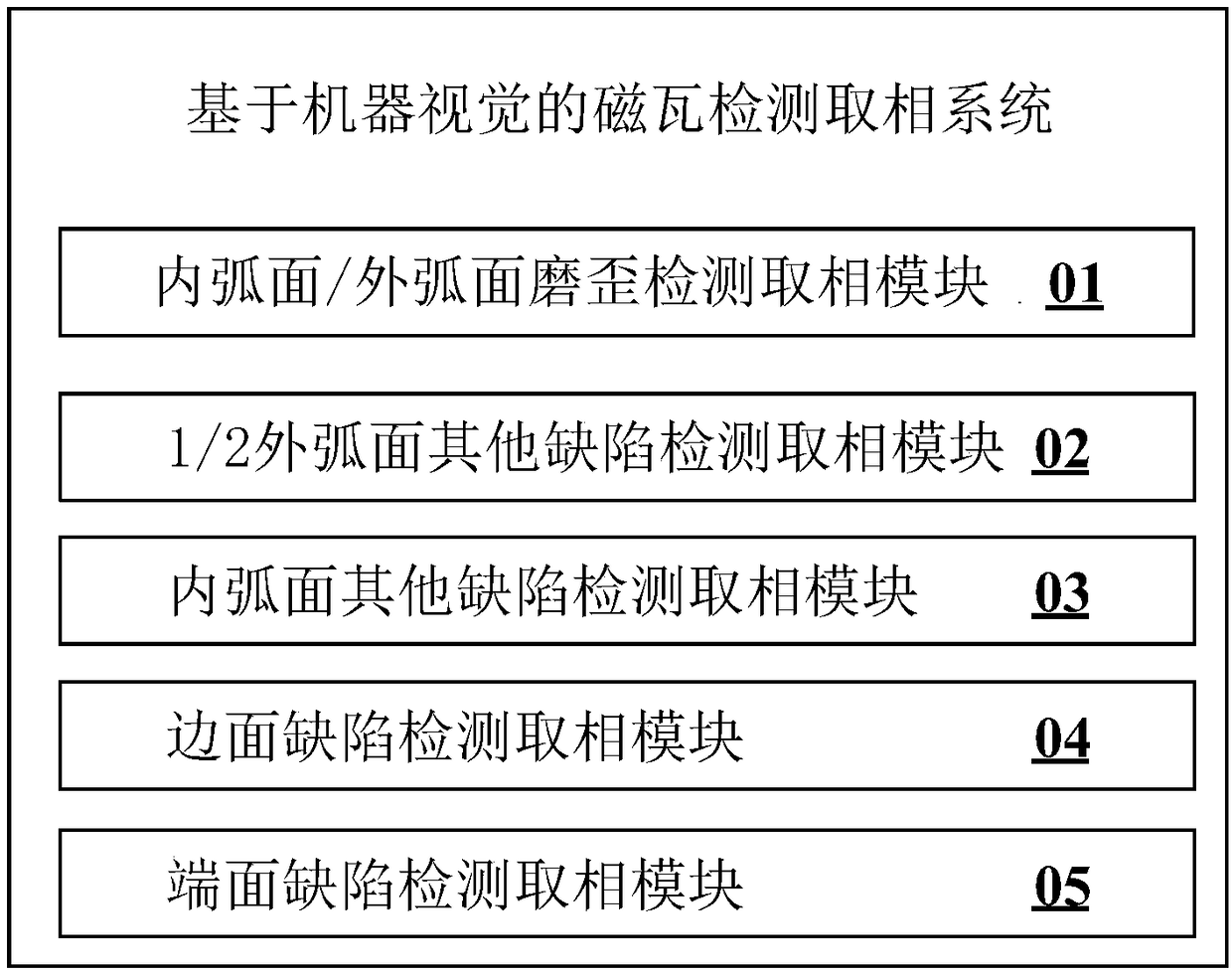

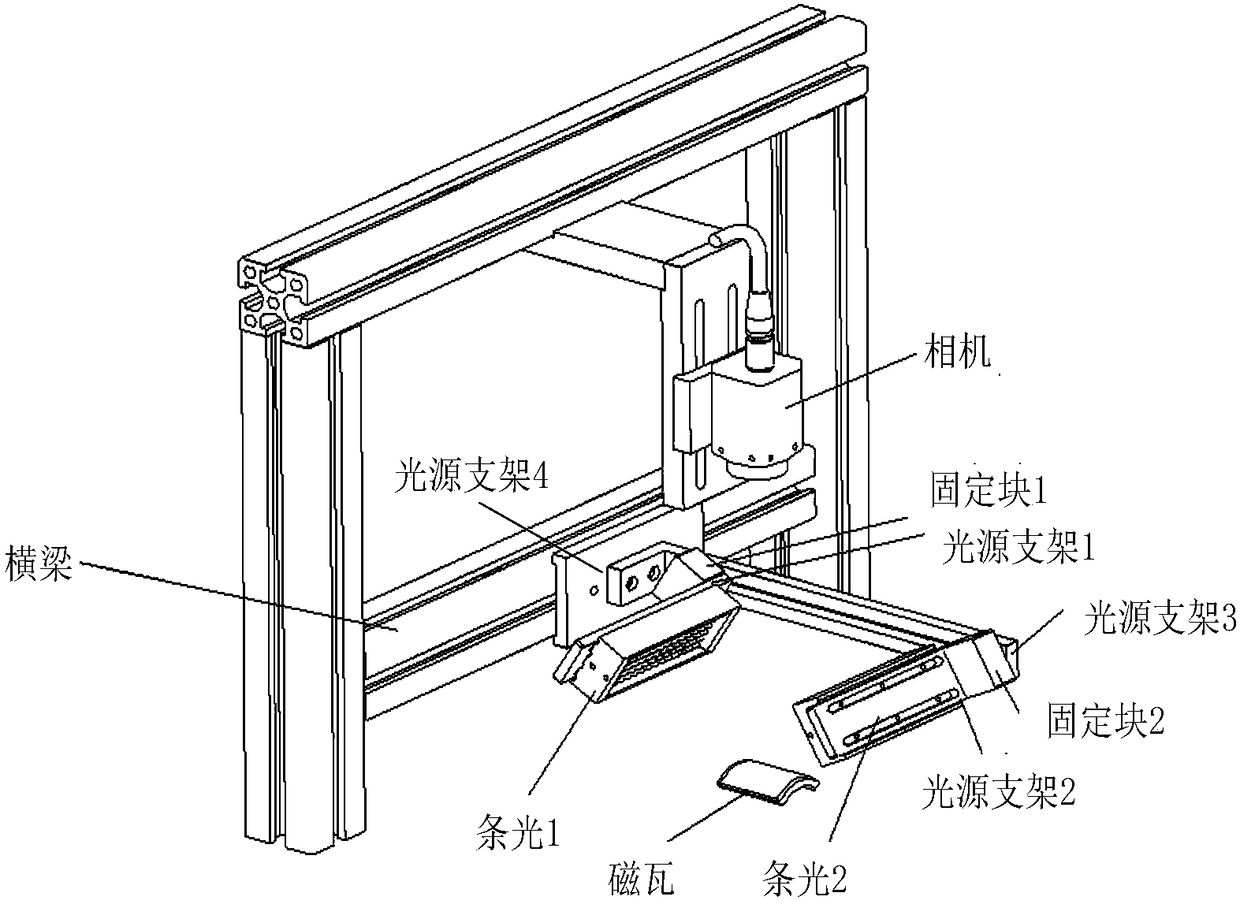

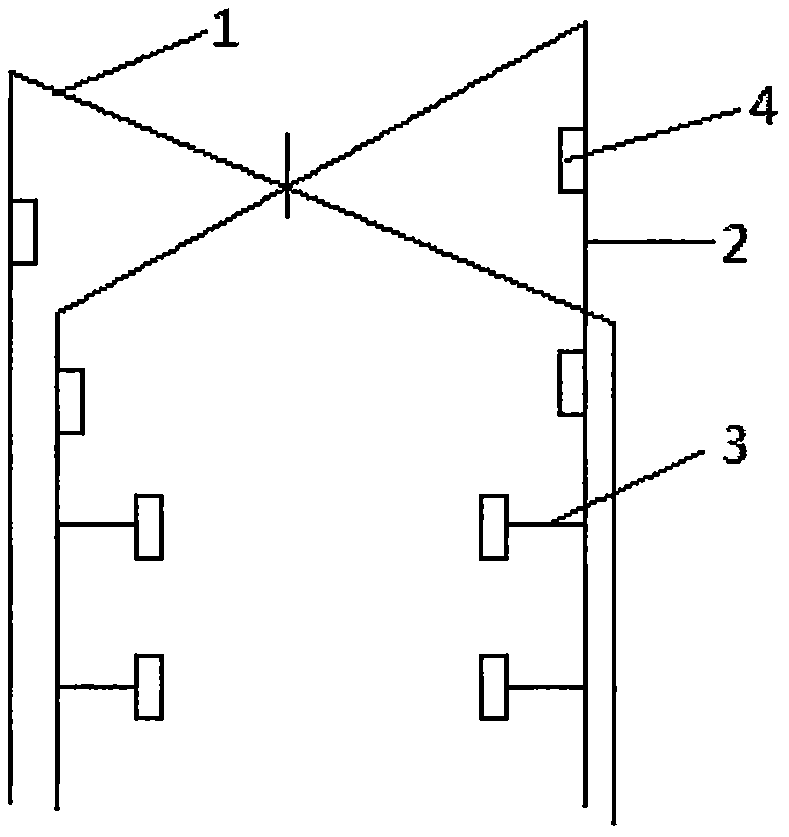

Magnetic tile defect detection and image obtaining system based on machine vision

PendingCN108663369AImplement automatic detectionAccurateOptically investigating flaws/contaminationEdge surfaceVertical plane

The invention provides a magnetic tile defect detection and image obtaining system based on machine vision. The magnetic tile defect detection and image obtaining system comprises an inner / outer arc surface grinding deviation detection and image obtaining module, a 1 / 2 outer arc surface other defect detection and image obtaining module, an inner arc surface other defect detection and image obtaining module, an edge surface defect detection and image obtaining module and an end surface detect detection and image obtaining module, wherein the inner / outer arc surface grinding deviation detectionand image obtaining module comprises a first light source and a first camera, the first light source comprises a first left light source and a first right light source, the first left light source andthe first right light source are symmetrical relative to the vertical plane in which the connection line of the straight edges of the magnetic tile is positioned, and form equal acute angles with thevertical plane, the first camera is used for capturing the inner / outer arc surface of the magnetic tile and is positioned above the geometric center of the inner / outer arc surface, and the magnetic tile is positioned in the center of the light source area of the first light source. According to the present invention, with the magnetic tile defect detection and image obtaining system, the problemsof low manual efficiency and easy error generation of the machine sorting in the magnetic tile sorting can be solved, and the automatic magnetic tile detection based on the machine vision is precise.

Owner:EVOC SMART IOT TECH CO LTD

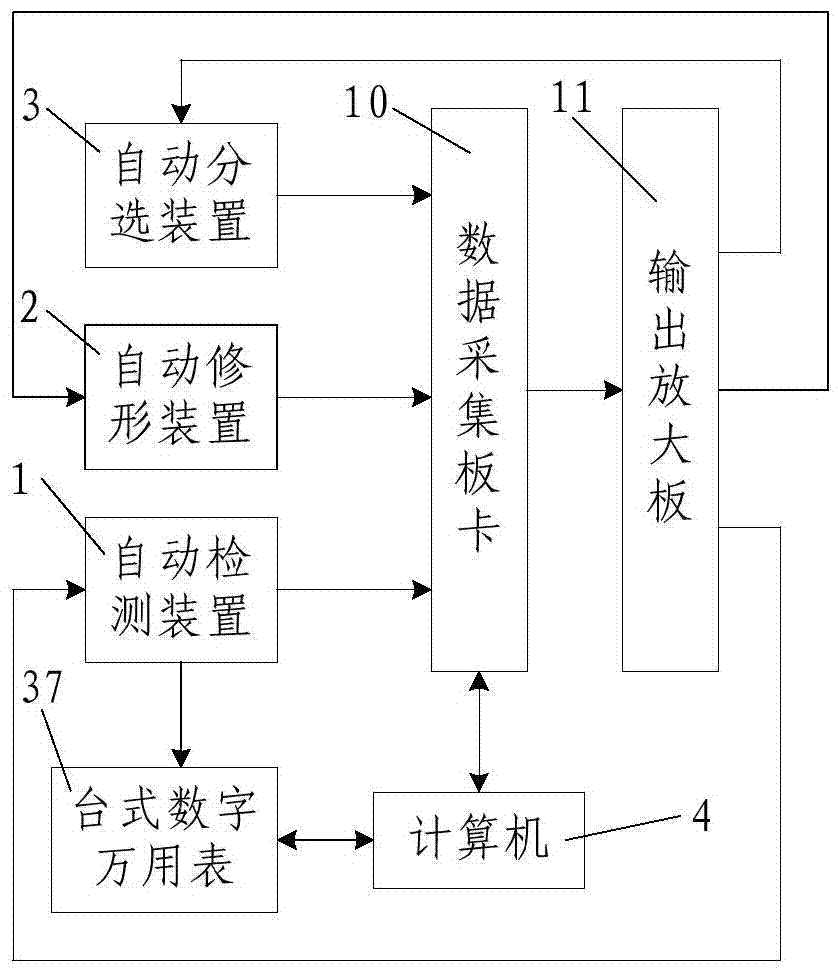

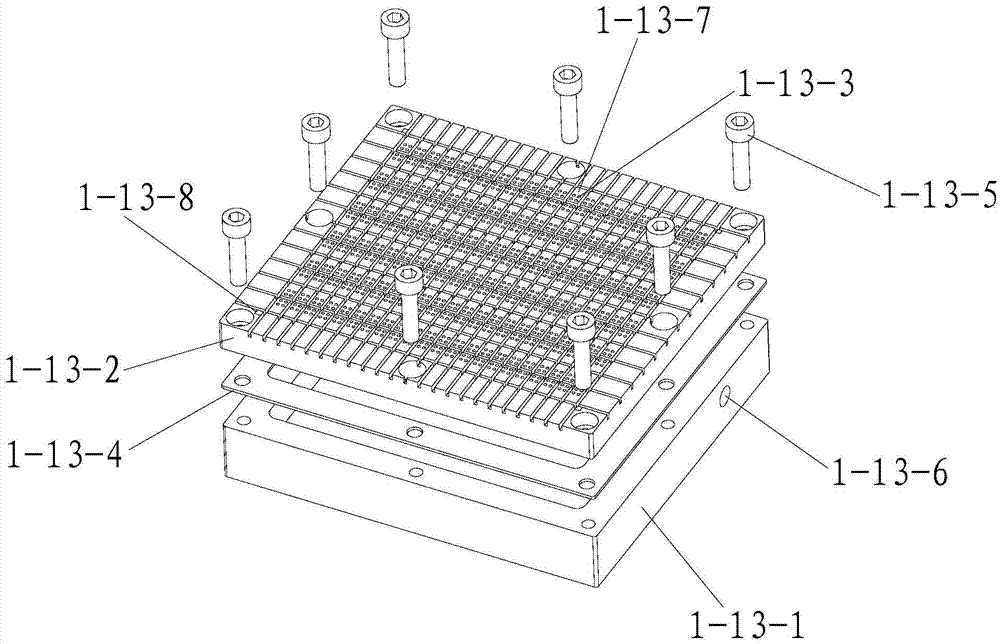

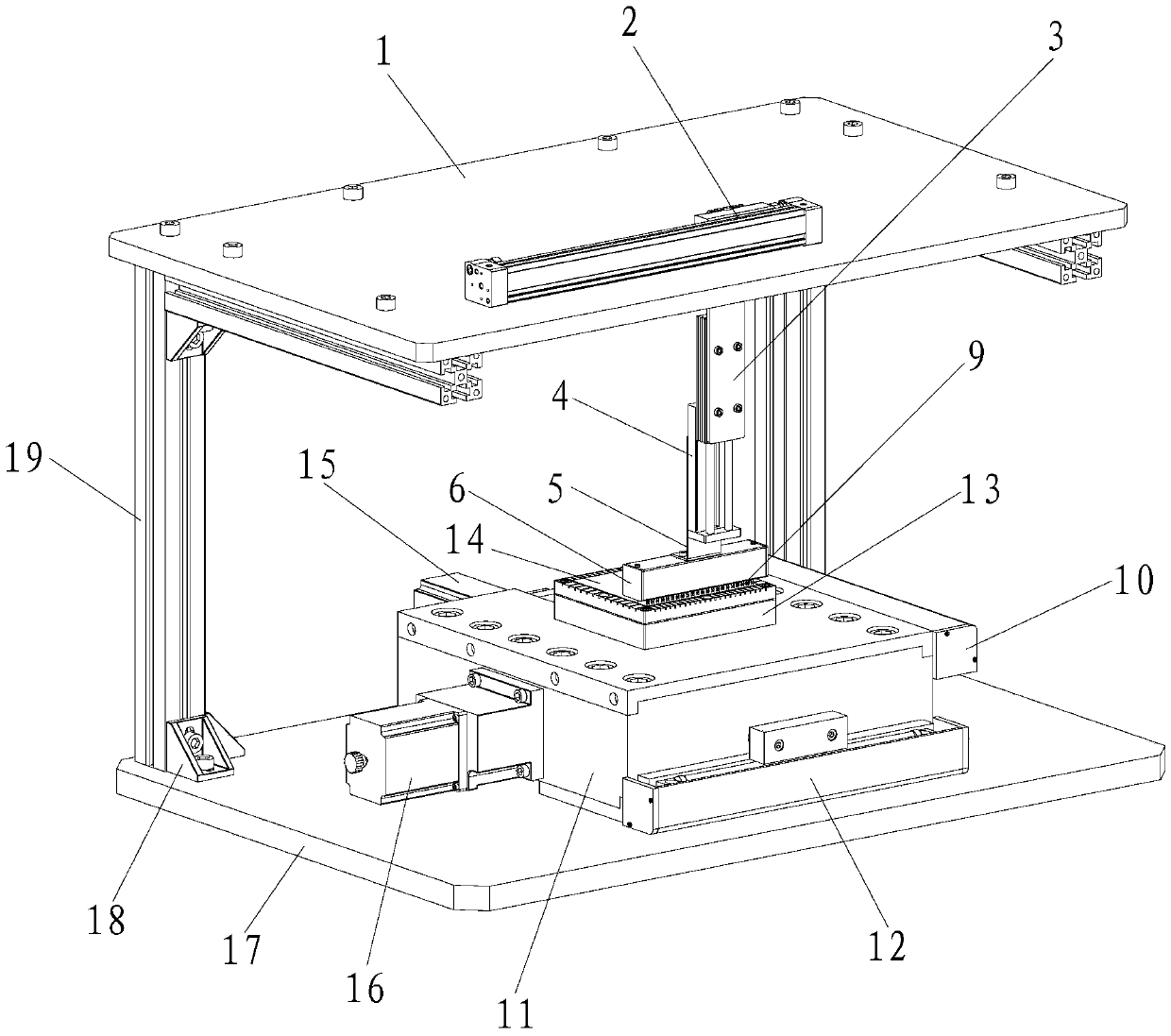

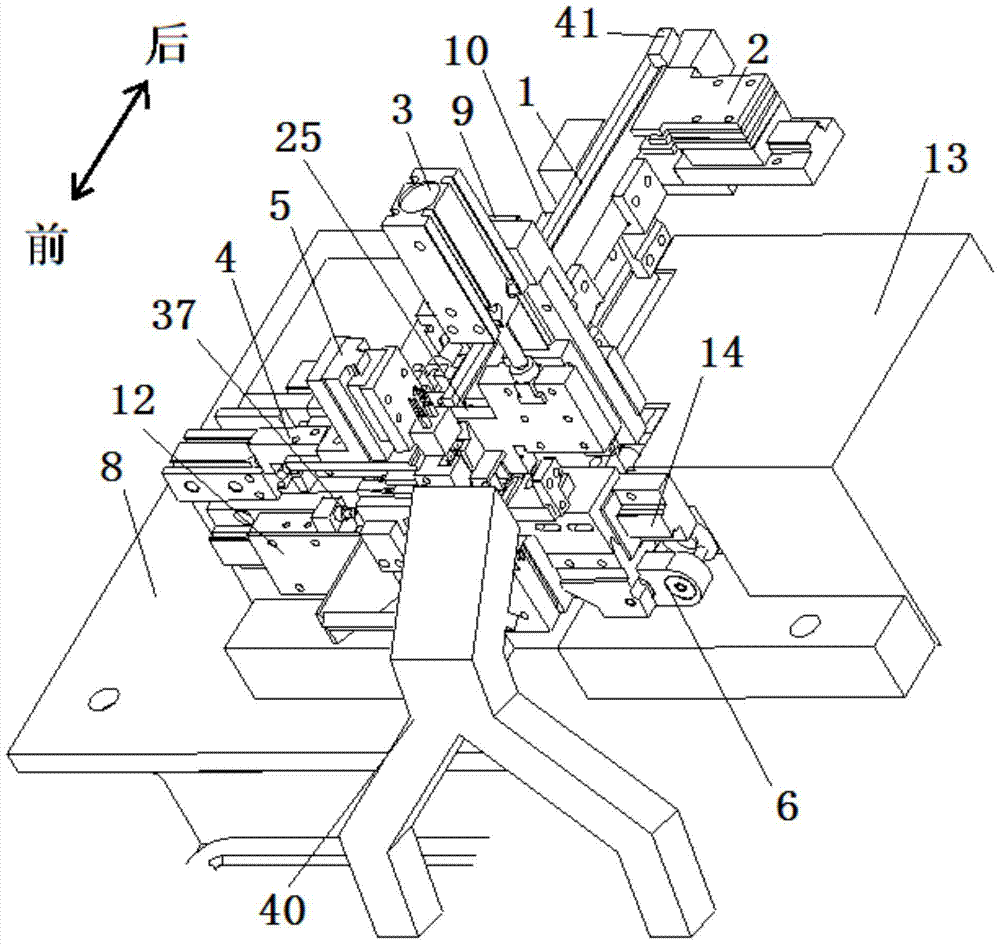

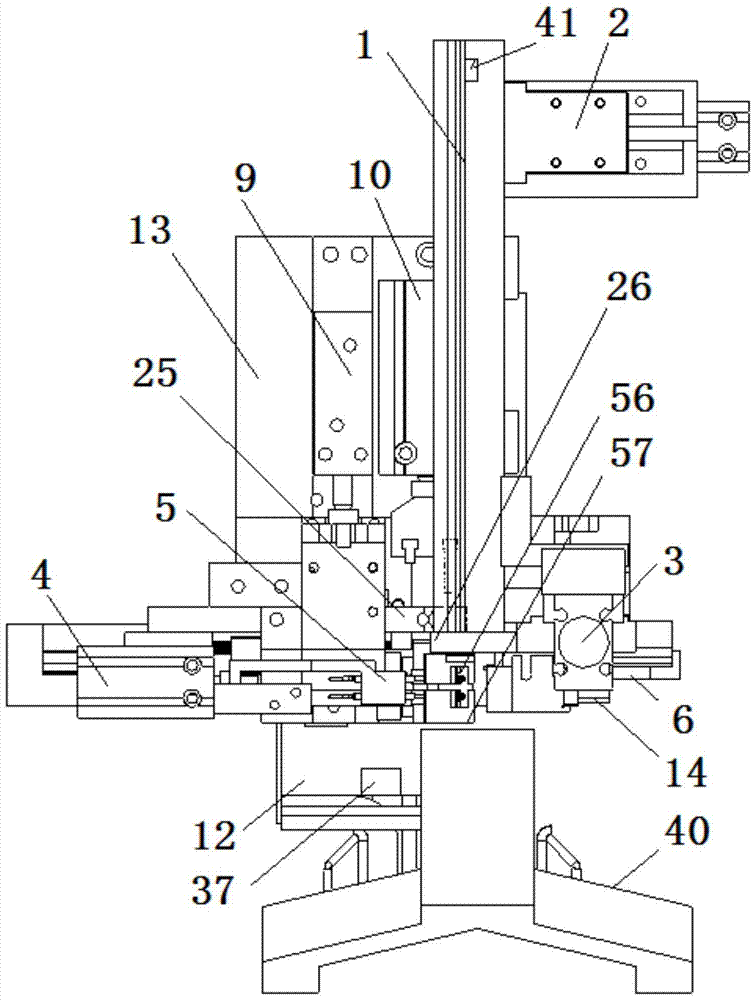

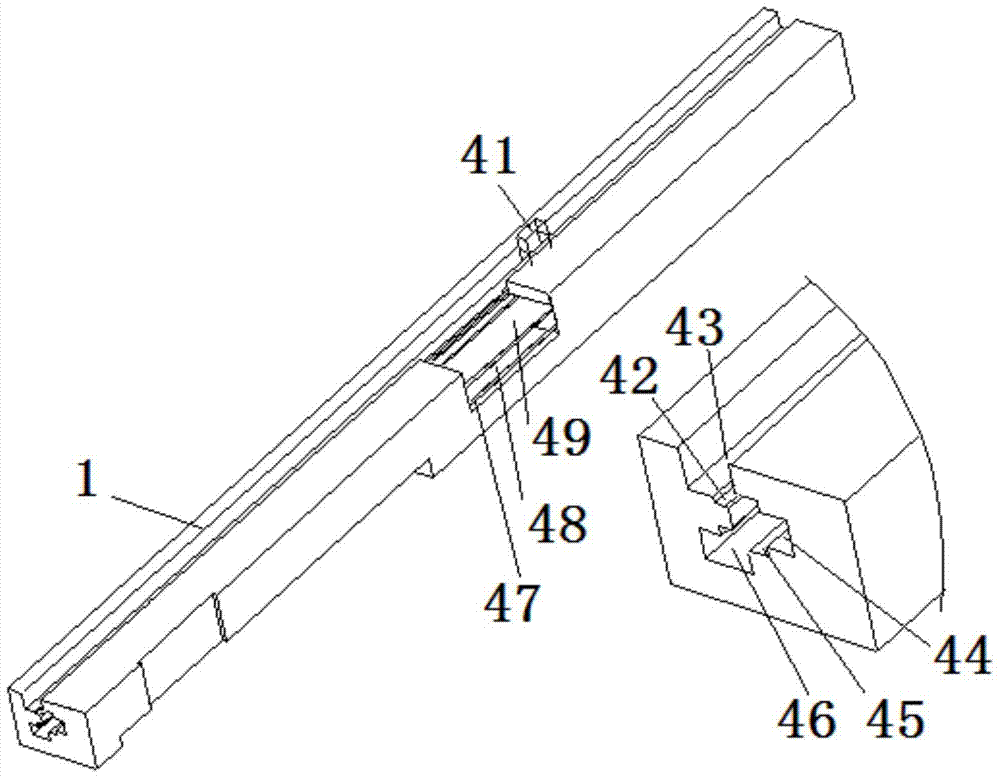

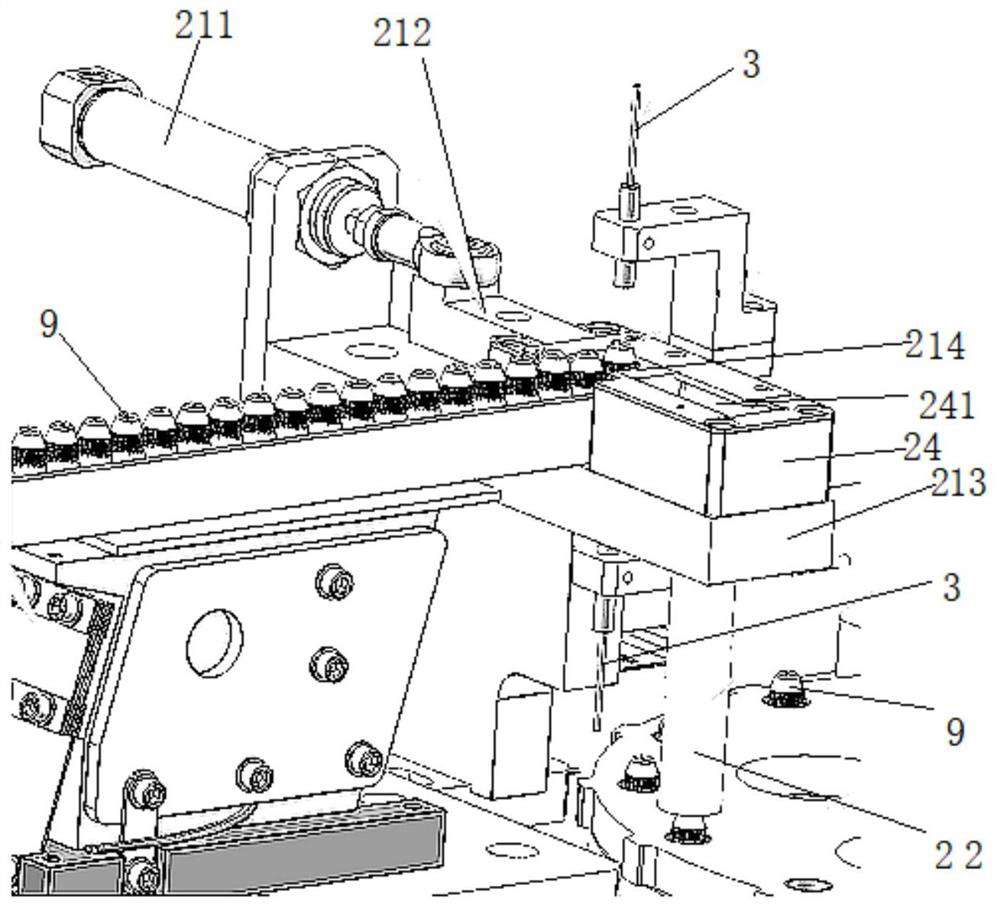

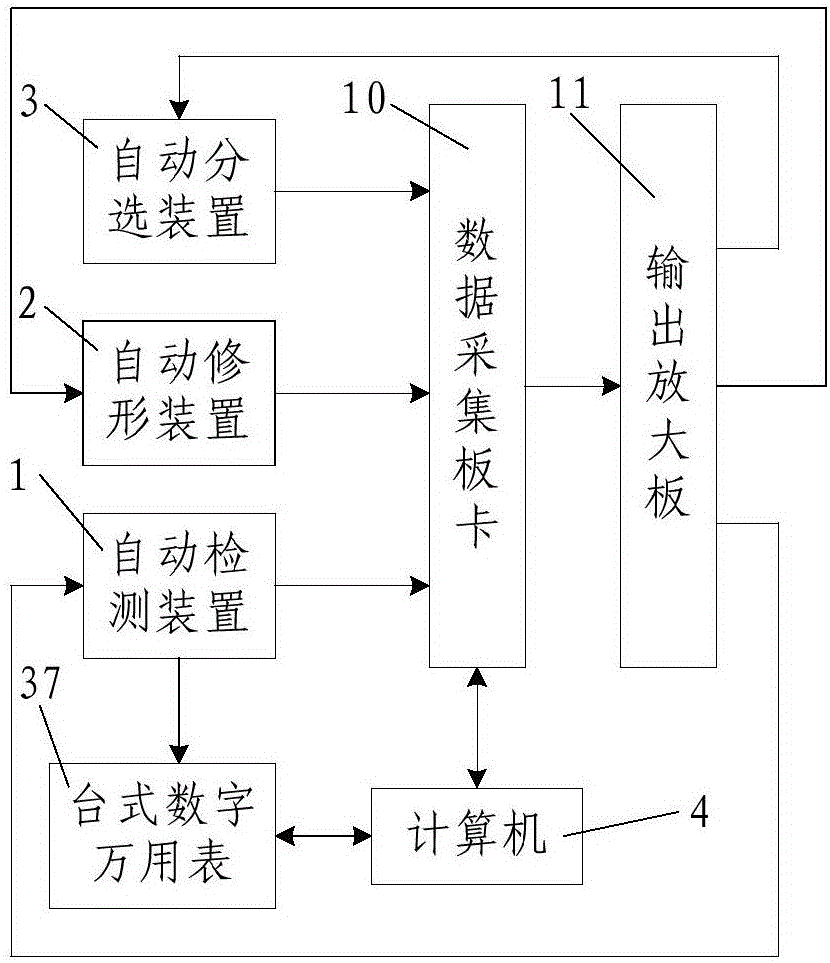

Automatic detection, trimming and sorting device and method for large-array resistance type strain gauges

InactiveCN105436103ACompact structureNovel and reasonable designMeasurement devicesSortingPneumatic circuitData acquisition

The invention discloses an automatic detection, trimming and sorting device for large-array resistance type strain gauges. The automatic detection, trimming and sorting device comprises an automatic detection device, an automatic trimming device, an automatic sorting device, a computer data collection board card, a table type digital multimeter and an output amplification board. The automatic detection device comprises a detection machine frame, a detection positioning and fixing mechanism and a detection mechanism. The automatic trimming device comprises a trimming machine frame, a trimming positioning and fixing mechanism and a trimming mechanism. The automatic sorting device comprises a sorting machine frame, a sorting positioning and fixing mechanism, an adsorption sorting mechanism and a positioning and sorting mechanism. The detection mechanism comprises a first air cylinder sliding platform, a second air cylinder sliding platform and a first pneumatic loop. The trimming mechanism comprises a linear swinging combined air cylinder, a cutter rest and a second pneumatic loop. The adsorption sorting mechanism comprises an adsorption head installation box and a plurality of vacuum adsorption heads. The invention further discloses an automatic detection, trimming and sorting method for the large-array resistance type strain gauges. By means of the automatic detection, trimming and sorting device and method for the large-array resistance type strain gauges, the production efficiency can be improved, labor intensity of workers is relived, and the production cost is reduced.

Owner:SHAANXI UNIV OF TECH

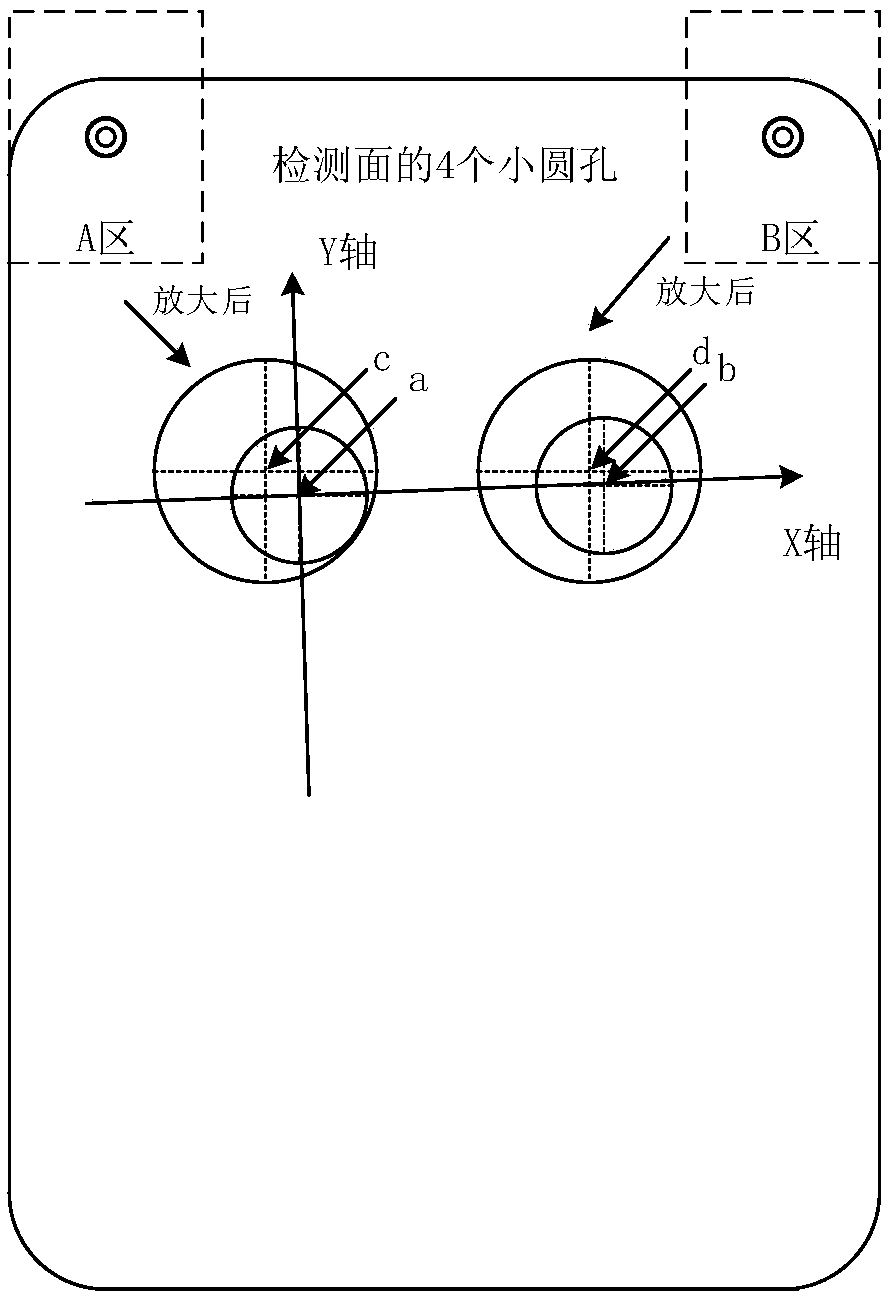

Non-contact visual detection method for Mark positioning of mobile phone touch screen

ActiveCN108363508AQuick Auto DetectAccurate automatic detectionImage enhancementImage analysisImaging processingComputer module

The invention belongs to the technical field of detection of electronic products and discloses a non-contact visual detection method for Mark positioning of a mobile phone touch screen. According to the method, a mobile phone touch screen detection part is divided into two regions of A and B; the region A is photographed by a first black and white industrial camera for detection; the region B is photographed by a second black and white industrial camera for detection; a Mark and a Circle of the region A are photographed by the first black and white industrial camera for detection; and the Markand the Circle of the region B are photographed by the second black and white industrial camera for detection. After photographing, an image is collected by an image collection module and image information is transmitted to an upper computer module; the upper computer module processes data, detects a deviation distance between a Mark central point and a Circle center through an image processing algorithm, displays a detection result and gives out a completion signal; and then a motion control module returns to an initial position to wait for detection of a next workpiece. With the detection method, the rapid, accurate and automatic detection for Mark positioning of the mobile phone touch screen can be realized.

Owner:JIANGNAN UNIV

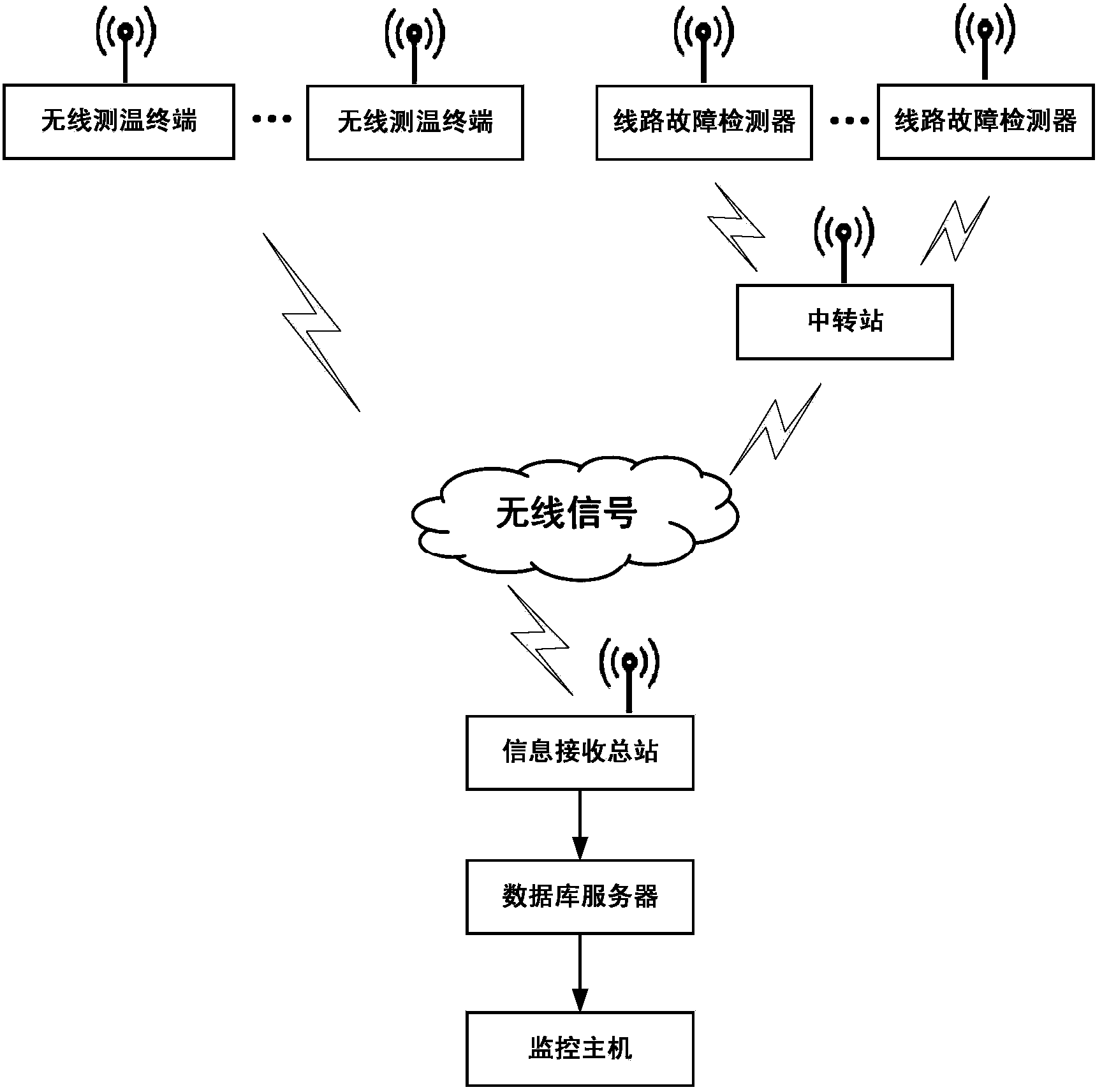

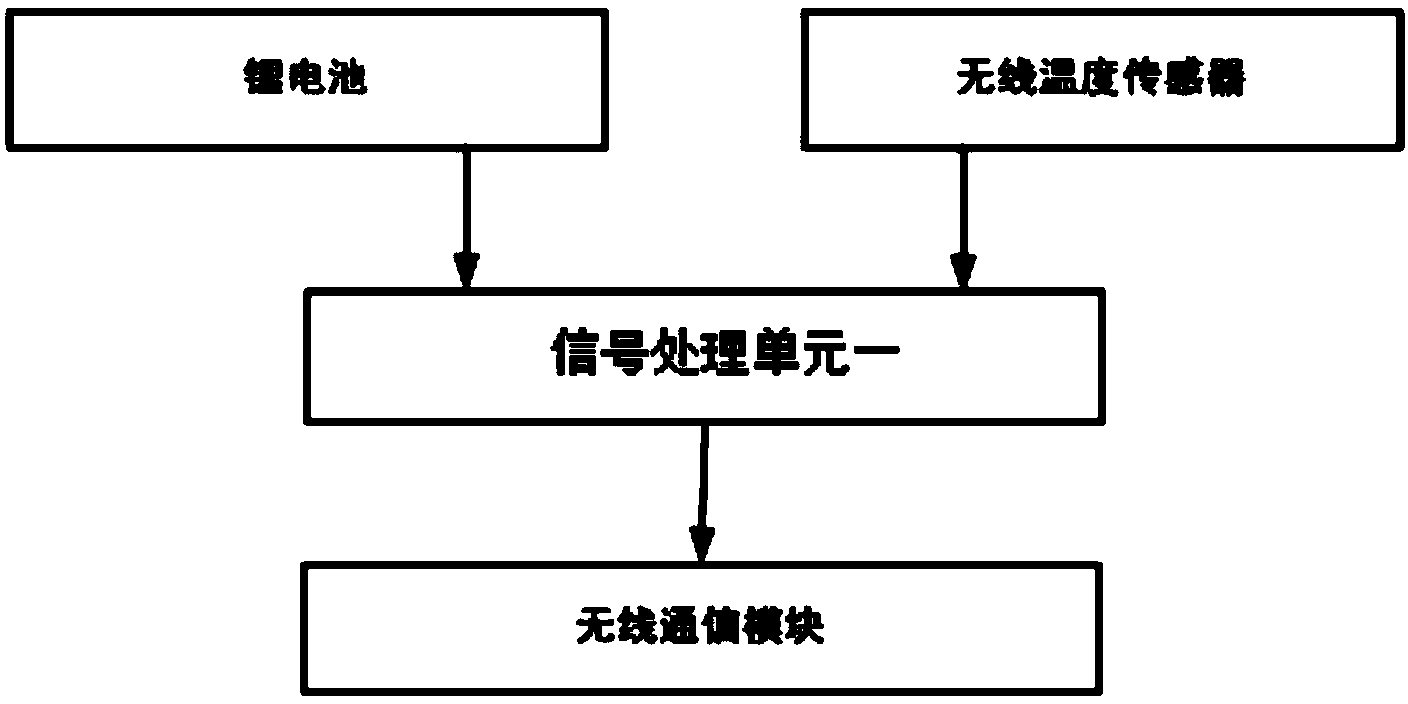

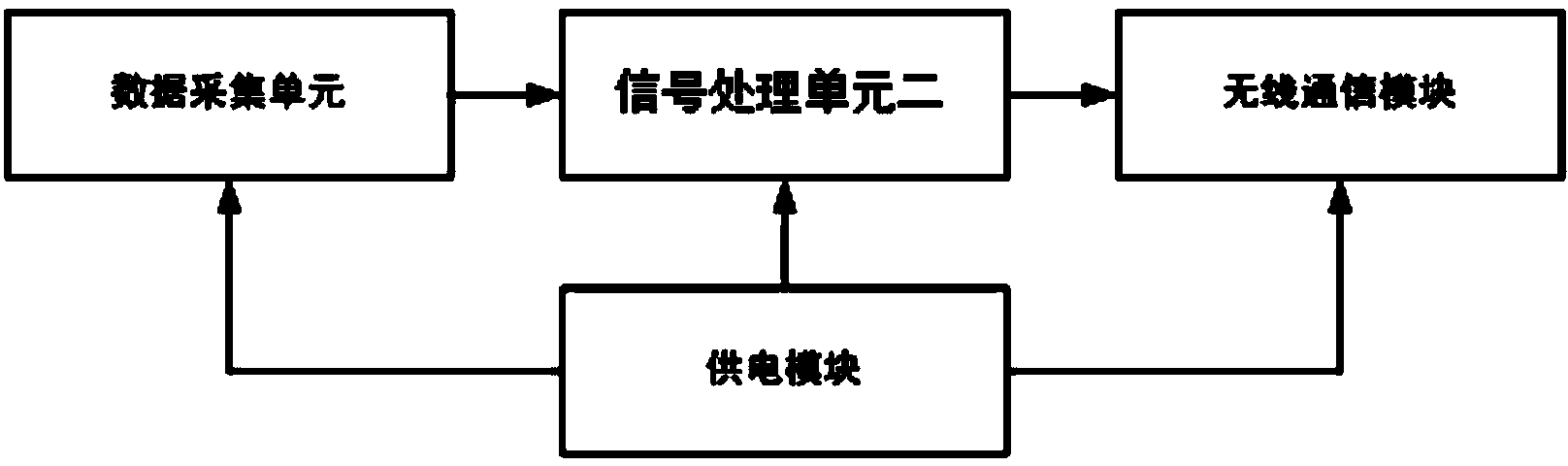

Power equipment and transmission line malfunction comprehensive online monitoring system

InactiveCN104316839AImprove signal anti-interference abilityTo achieve temperature compensationFault locationInformation technology support systemDatabase serverMonitoring system

The invention discloses a power equipment and transmission line malfunction comprehensive online monitoring system which comprises a wireless temperature measuring terminal, a line malfunction detector, a transfer station, an information receiving main station, a database server and a monitoring host. The wireless temperature measuring terminal is wirelessly connected with the information receiving main station through a built-in wireless communication module, the line malfunction detector is wirelessly connected with the information receiving main station through a built-in wireless communication module and the transfer station, and the information receiving main station is connected with the database server which is connected with the monitoring host. The system can monitor and upload power equipment temperature rise standard exceeding and transmission line ground fault information in real time, quickly locate line fault sections and fault branches, shorten fault clearing time and improve safety and reliability of power equipment and transmission lines.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

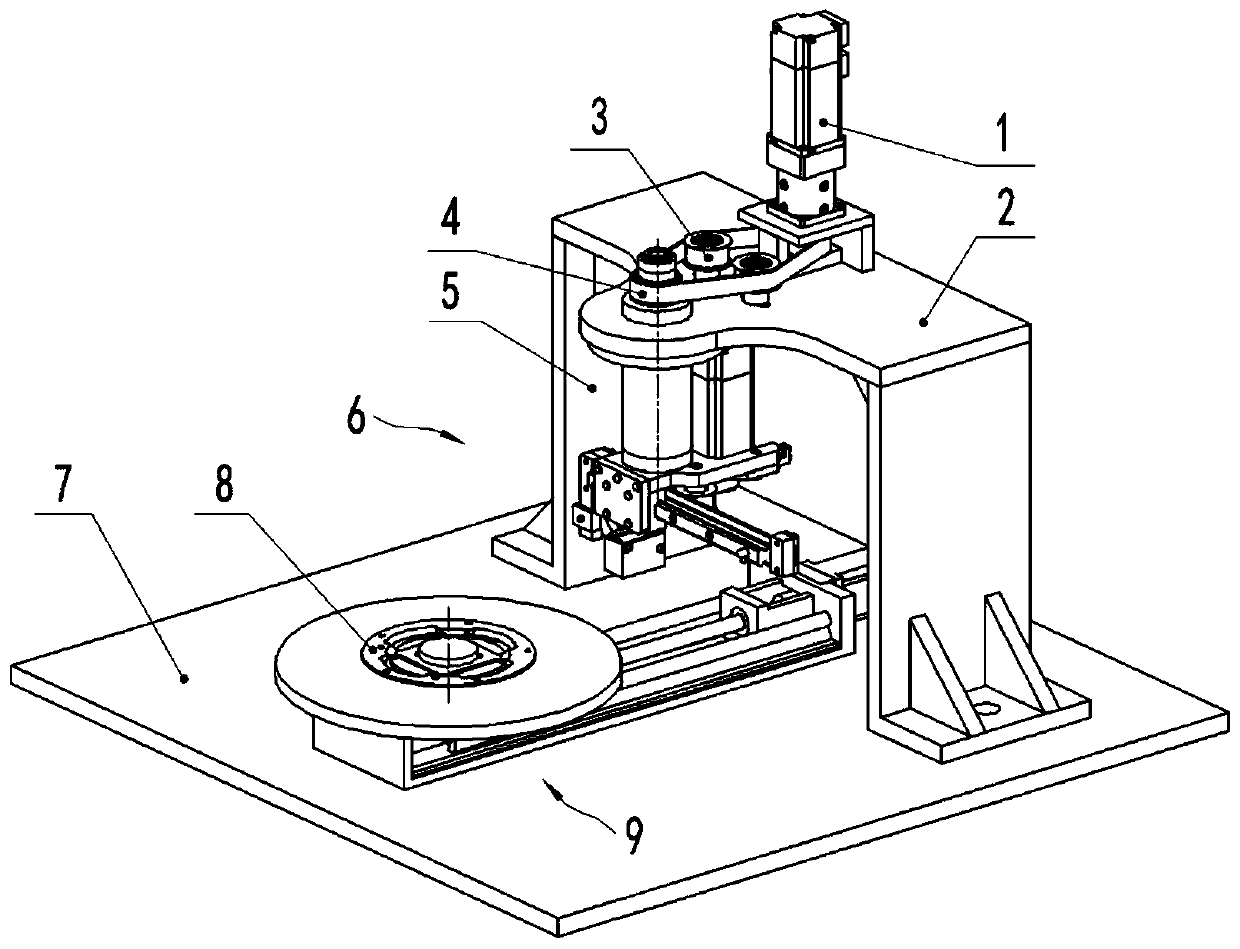

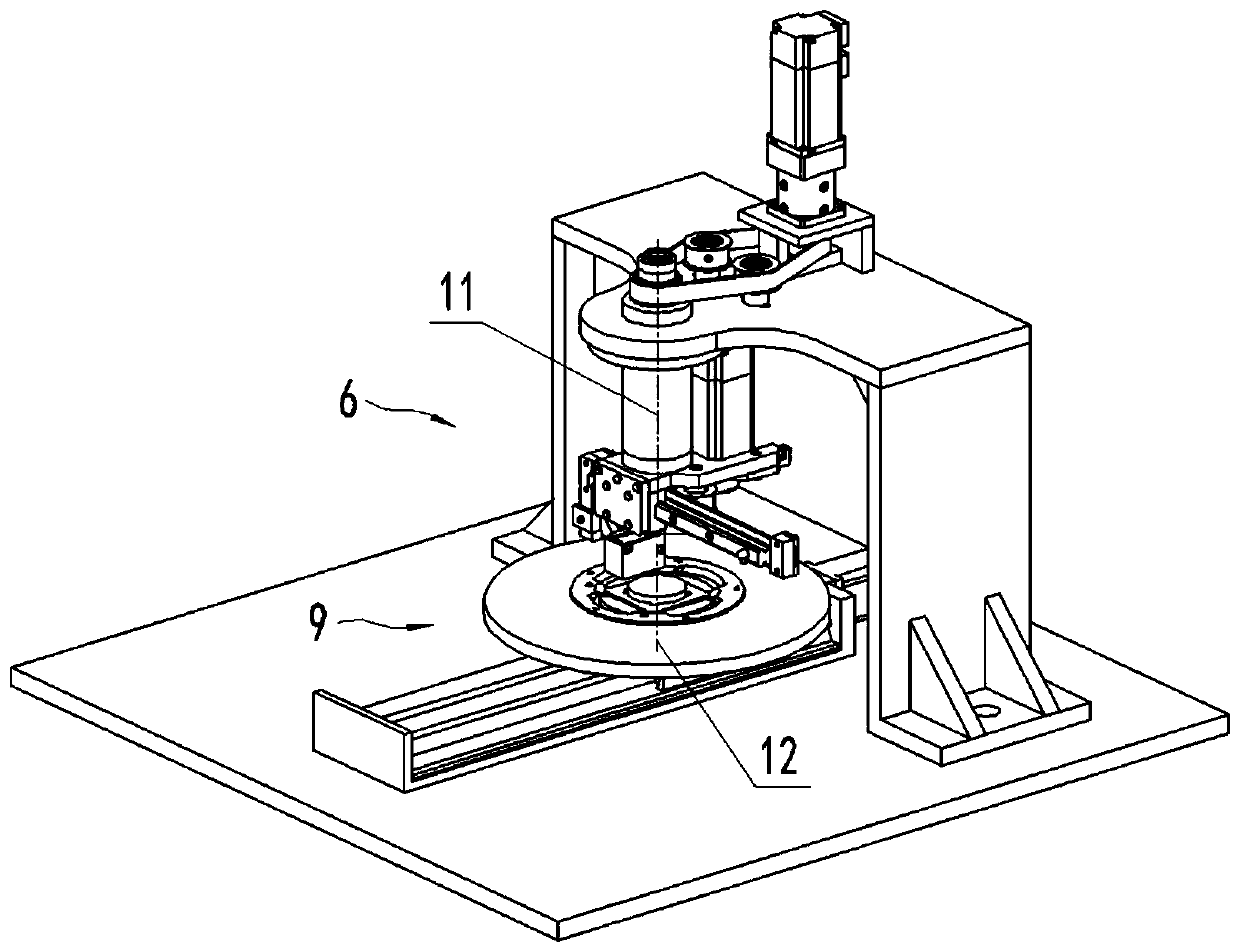

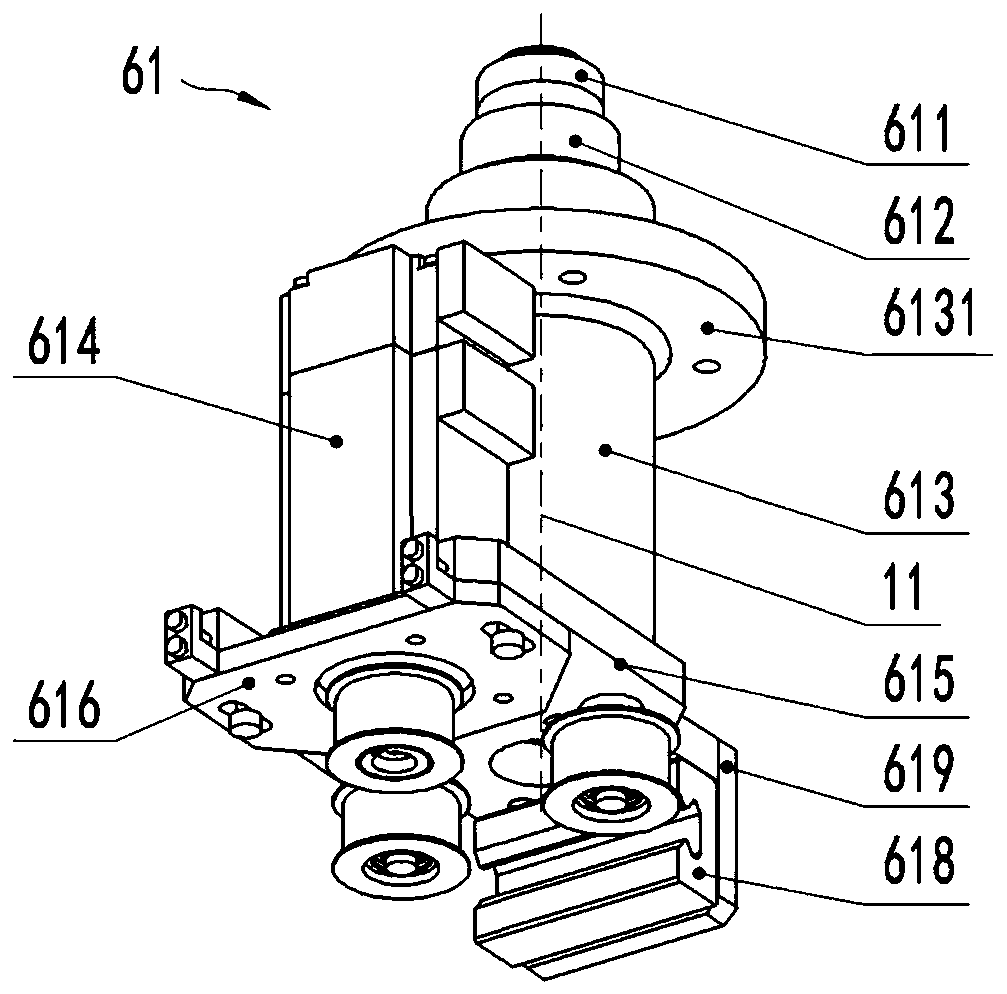

Disc-shaped part flatness detecting device, automatic detecting table and detecting method thereof

InactiveCN109916364AEasy accessFast detection operationMeasurement devicesEngineeringSurface flatness

The invention discloses a disc-shaped part flatness detecting device, an automatic detecting table and a detecting method thereof. The device comprises a bottom plate; a bracket, a detecting mechanism, a displacement sensor and a slip assembly, wherein the bracket is fixedly disposed on the bottom plate; the detecting mechanism is fixedly disposed on the bracket and comprises a rotary assembly anda guide rail assembly which are vertically connected in sequence, the rotary assembly is fixedly disposed on a support and the output end rotates around a Z axis, and the guide rail assembly is horizontally fixed to the output end of the rotary assembly to provide linear movement in a horizontal direction; the displacement sensor is fixedly disposed at one end of the guide rail assembly; and theslip assembly is fixed on the bottom plate and located below the detecting mechanism for mounting and transporting a to-be-detected part. The cost is moderate, the occupied space is small, a disc-shaped part can be taken and placed conveniently, the detecting operation is quick, an executing mechanism is accurately controlled, the automation degree is high, manual product surface flatness measurement can be replaced, the detecting efficiency and the accuracy can be effectively improved, and the requirements of the daily detection quantity can be met.

Owner:SOUTH CHINA UNIV OF TECH

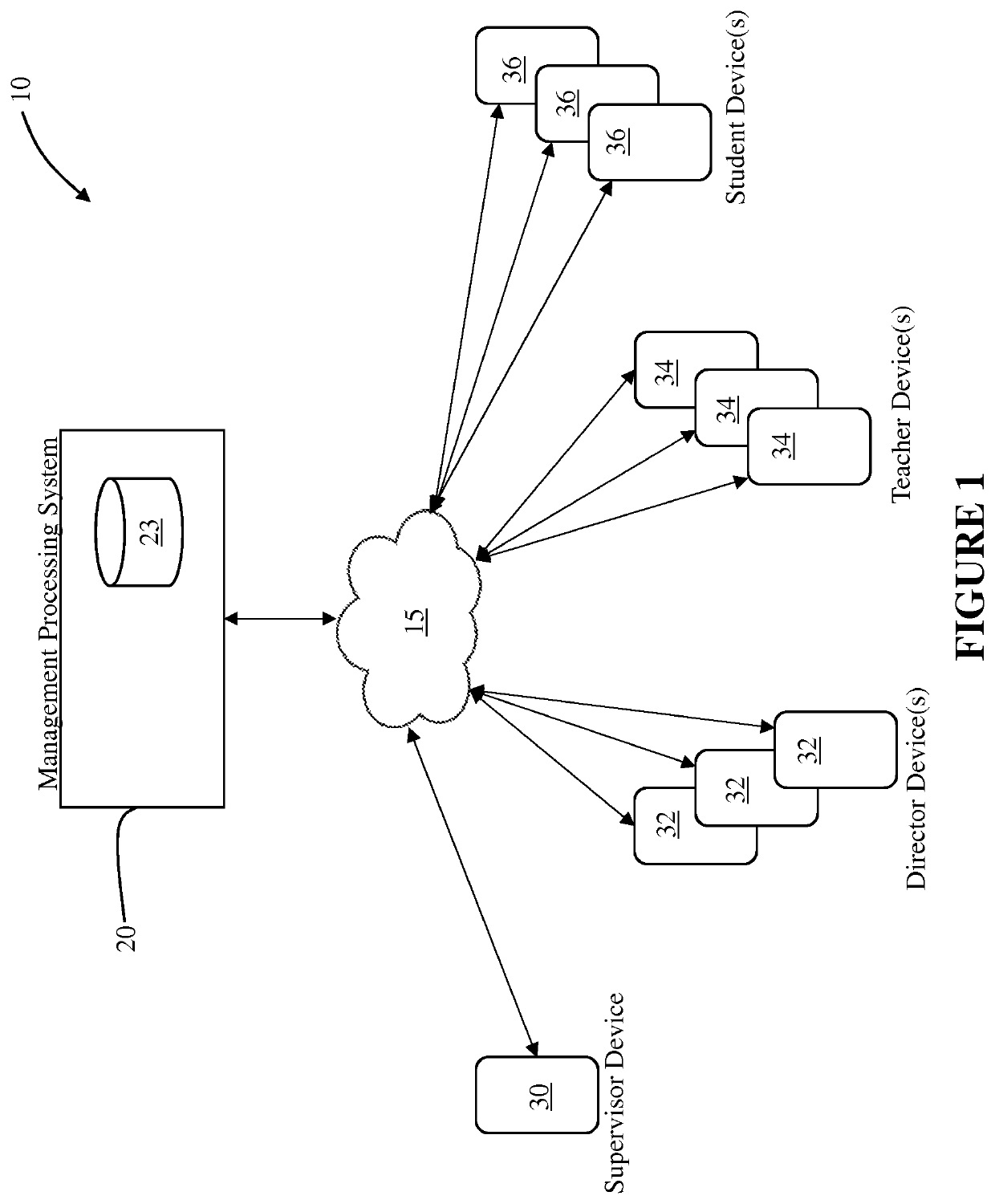

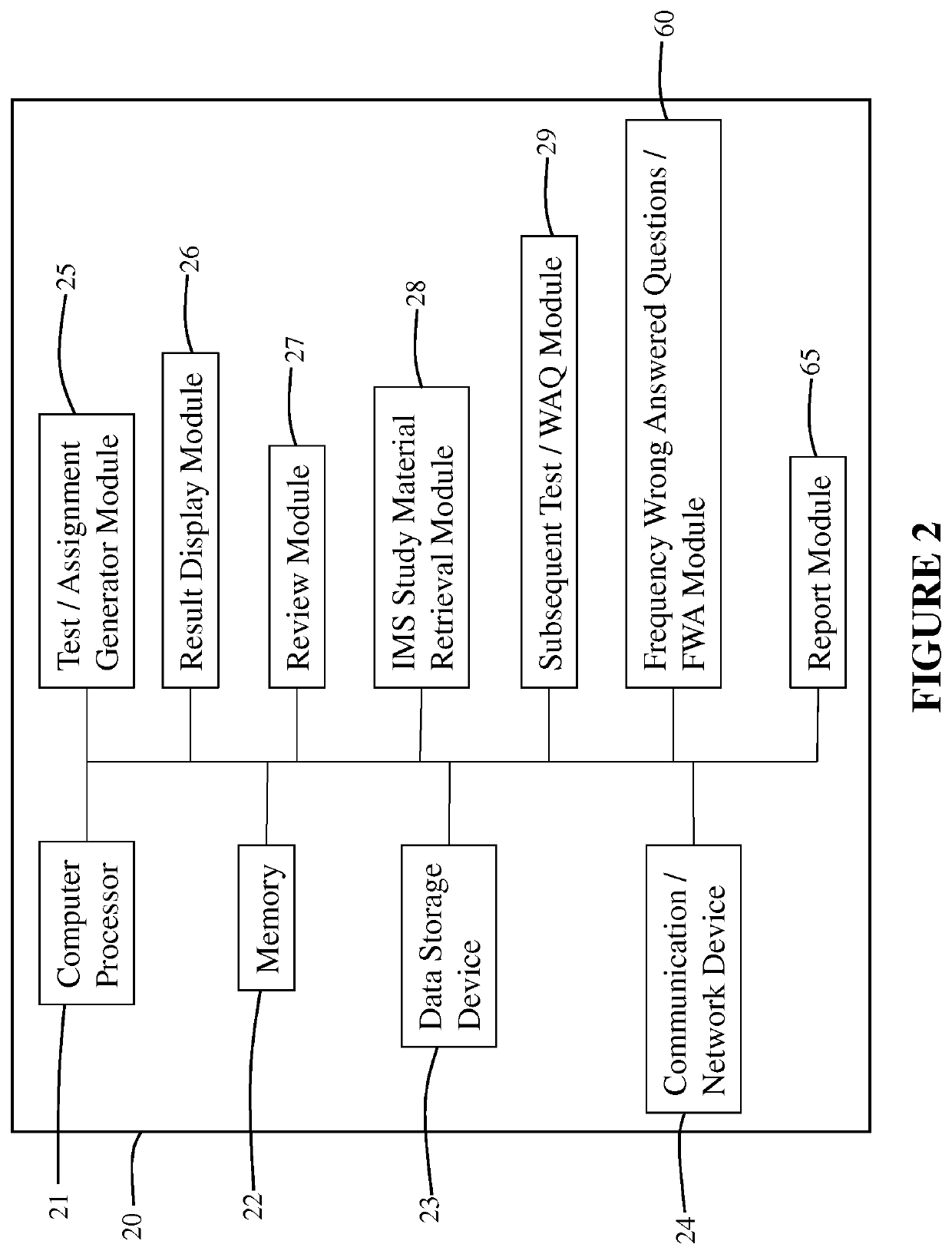

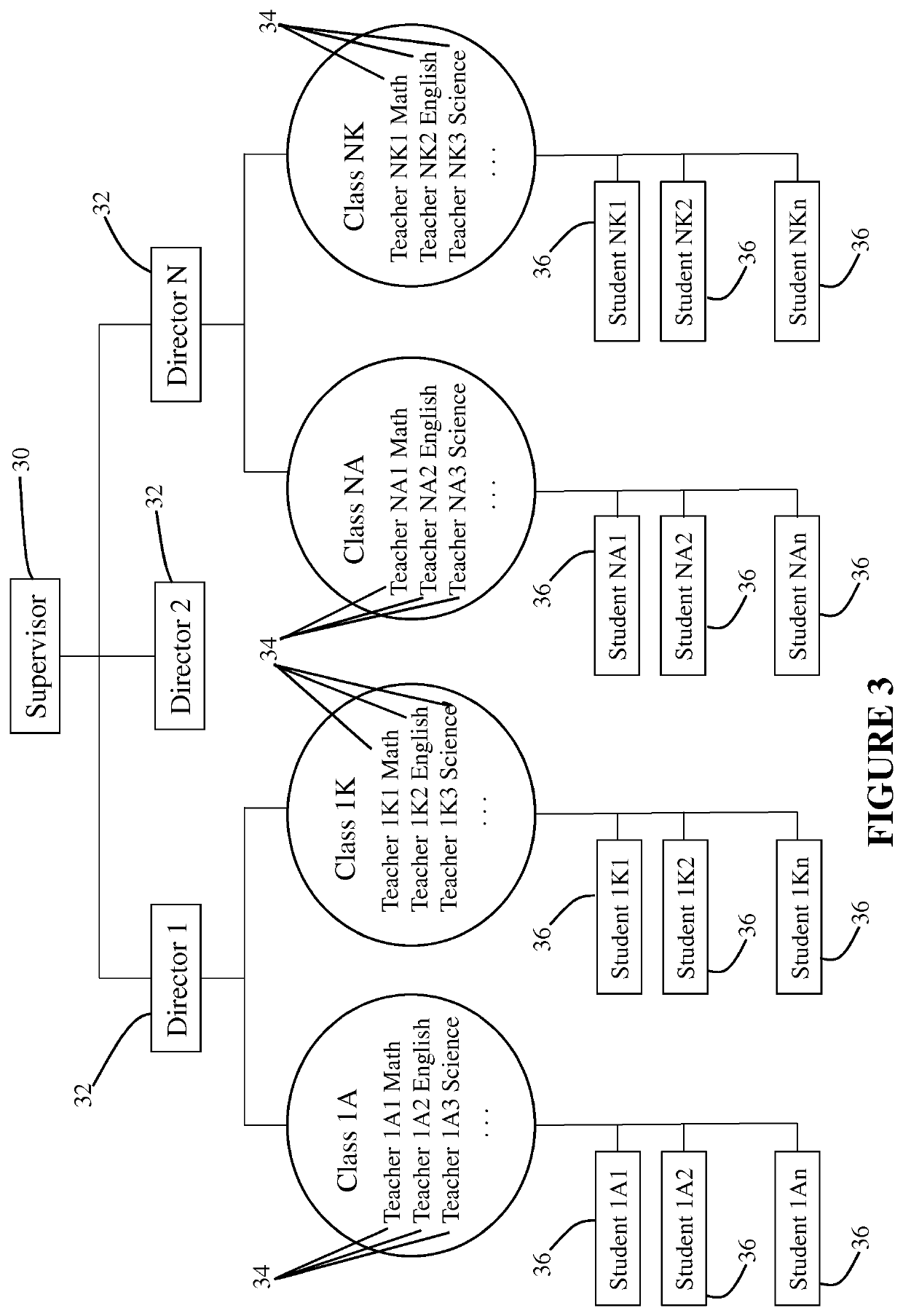

Online test taking and study guide system and method

ActiveUS10679512B1Reduces and eliminates needRemoval costElectrical appliancesOnline testEngineering

A system and method for presenting an online study guide and testing program is presented herein. In particular, the system and method includes a plurality of test questions stored within a database or question bank and a plurality of testing materials corresponding to subject areas, topics, and specific categories. Each of the test questions are coded or otherwise include a study code associated therewith, the study code representing a particular subject area, category or sub-category. Similarly, the study materials are also coded to represent a subject area, category, or sub-category. Accordingly, once a student has completed a test or assignment, the system and method will automatically detect the student's weak areas via wrong answered questions and provide the study code. The student can then obtain study materials relating to that study code in order to advance his or her knowledge in those weak areas.

Owner:YANG TERRY

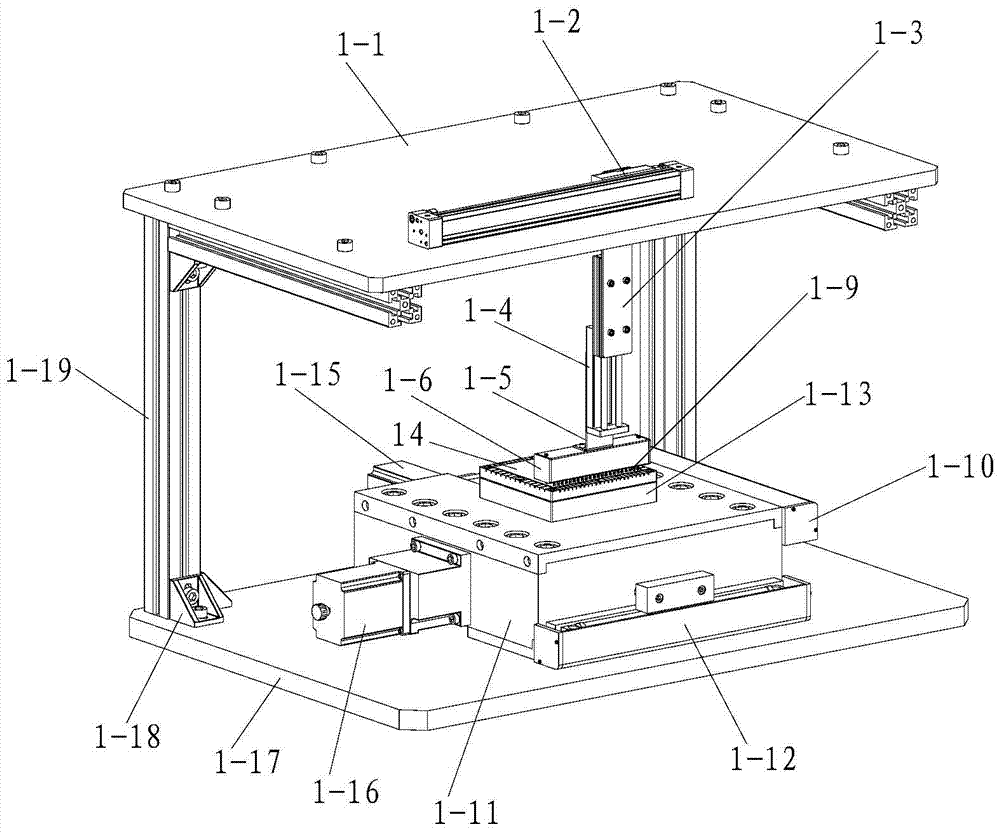

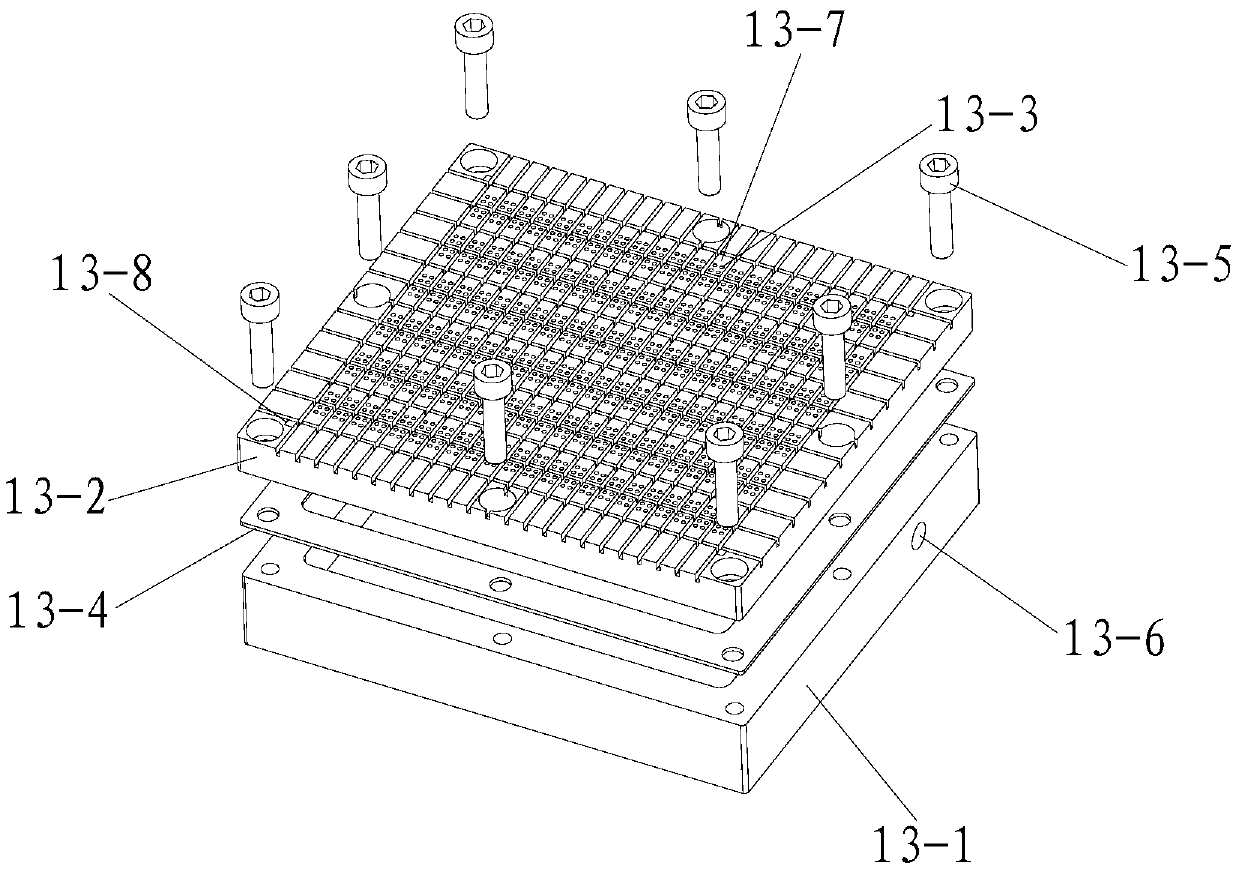

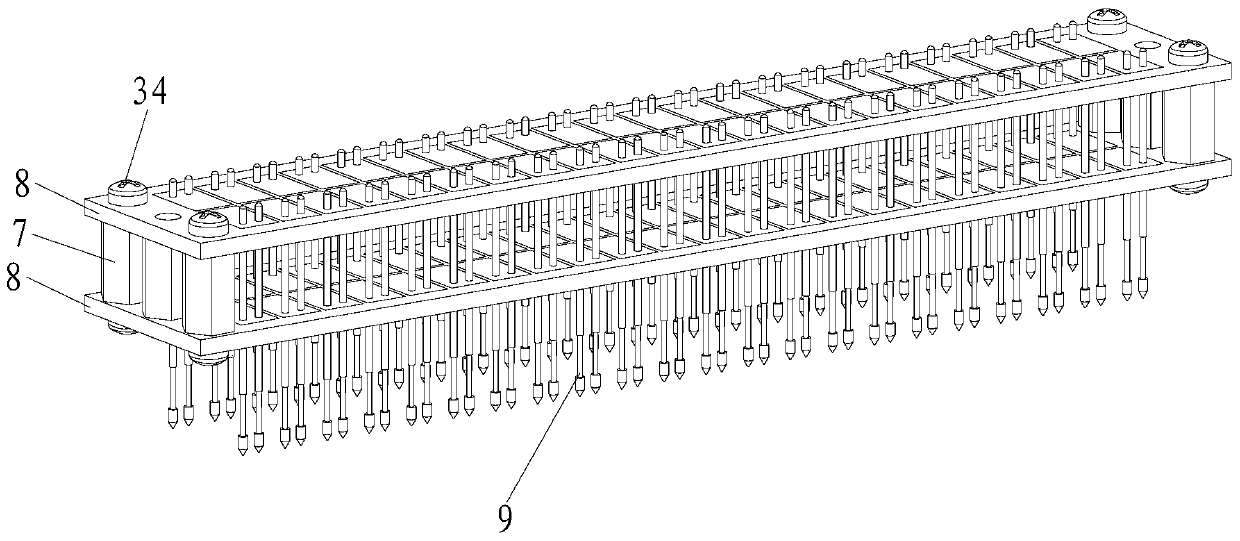

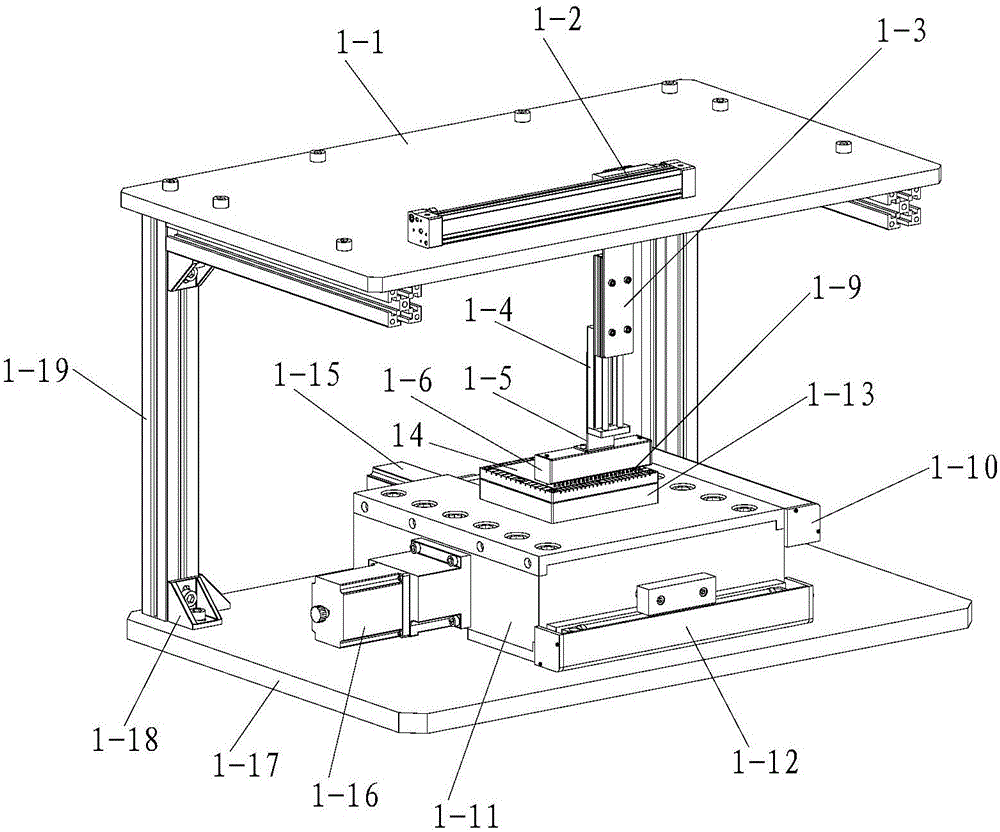

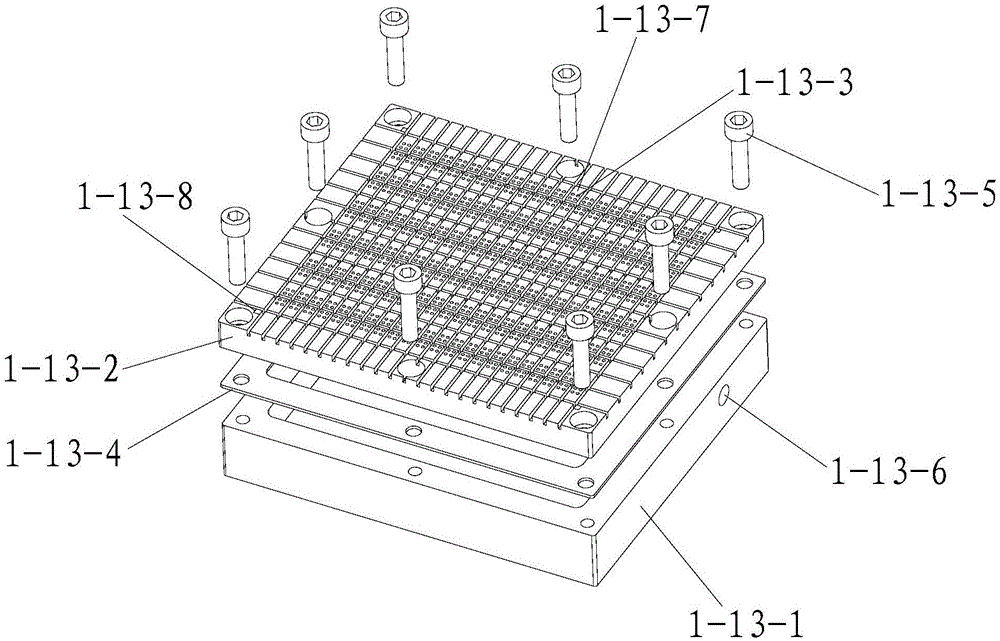

Automatic detecting device and method for large-array resistance strain gauge

InactiveCN105509961ACompact structureNovel and reasonable designResistance/reactance/impedenceElectrical/magnetic solid deformation measurementStrain gaugeLarge array

The invention discloses an automatic detecting device for a large-array resistance strain gauge. The automatic detecting device comprises a frame, a positioning and fixing mechanism, a detecting mechanism, a computer, a data acquisition board, a table digital multimeter, and an output amplification board. The positioning and fixing mechanism comprises a two-dimension mobile platform, a vacuum adsorption table, and a vacuum adsorption loop. The vacuum adsorption table comprises an adsorption table lower cover and an adsorption table upper cover. The vacuum adsorption loop comprises a vacuum pump, a vacuum filter, a vacuum degree regulating valve and a vacuum solenoid valve. The detecting mechanism comprises a first cylinder sliding table, a cylinder sliding table installation plate, a second cylinder sliding table, a pneumatic loop, a probe box, a detecting circuit board, and a spring probe array. The pneumatic loop comprises an air pump, an air filter, a reducing valve, and a pressure gauge. The invention further discloses an automatic detecting method for the large-array resistance strain gauge. The automatic detecting device is novel and reasonable in design, low in production cost, high in operation reliability, reduces worker labor intensity and product production cost, and achieves high popularization and application value.

Owner:SHAANXI UNIV OF TECH

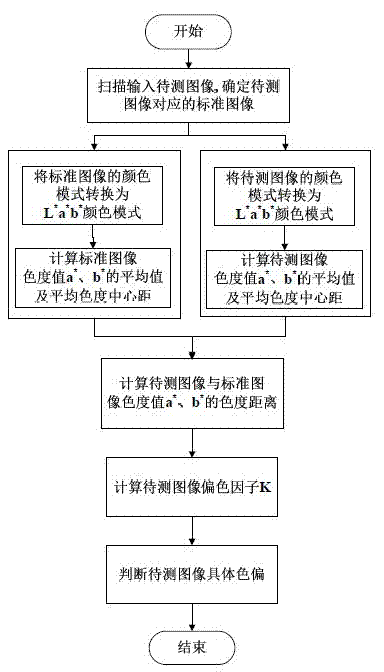

Scanned image color cast automatic detection method

InactiveCN103200349AAccurate automatic detectionImprove accuracyPictoral communicationMethod selectionColor space

The invention provides a scanned image color cast automatic detection method. When being scanned by a scanner, an image is easily affected by an ambient light source, reflecting characteristics of the image, photosensitive coefficients of collecting equipment and the like as to ensure that color cast exists in an obtained image through scanning. Even CIEL*a*b* color space having nothing to do with the equipment is selected through the method, then statistics are conducted on chrominance information, an average chrominance value, average chrominance center distance and color cast factors of the scanned image, and last, the chrominance information, the average chrominance value, the average chrominance center distance and the color cast factors are compared with a standard average chrominance value obtained by a typical standard non-color-cast image so as to judge whether color cast exists in the scanned image and specific color cast conditions. The scanned image color cast automatic detection method can accurately and automatically detect the color cast of the scanned image, is high in accuracy and reliability, and meanwhile can make certain evaluation to color cast degrees of the scanned image.

Owner:桂林澳群彩印有限公司

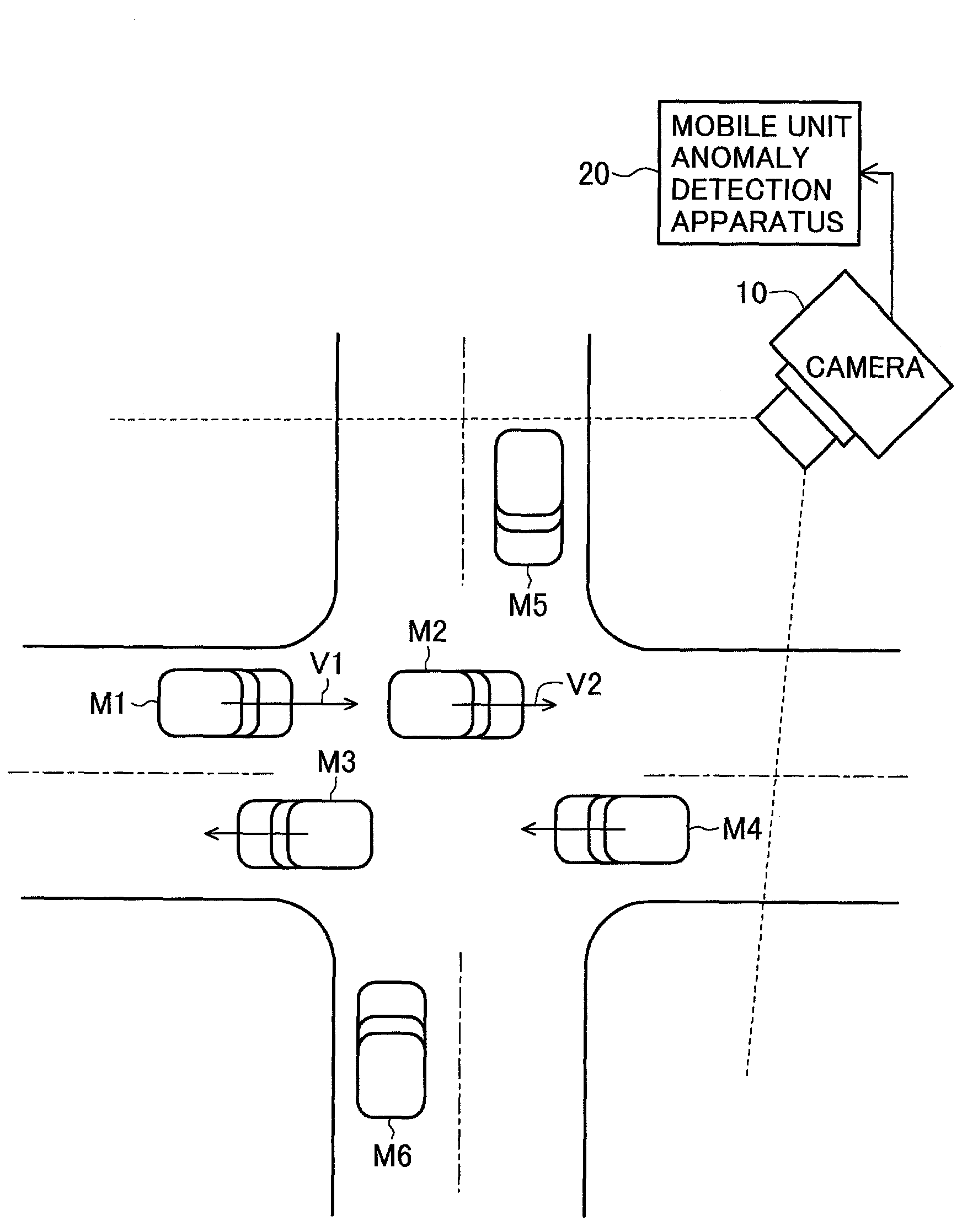

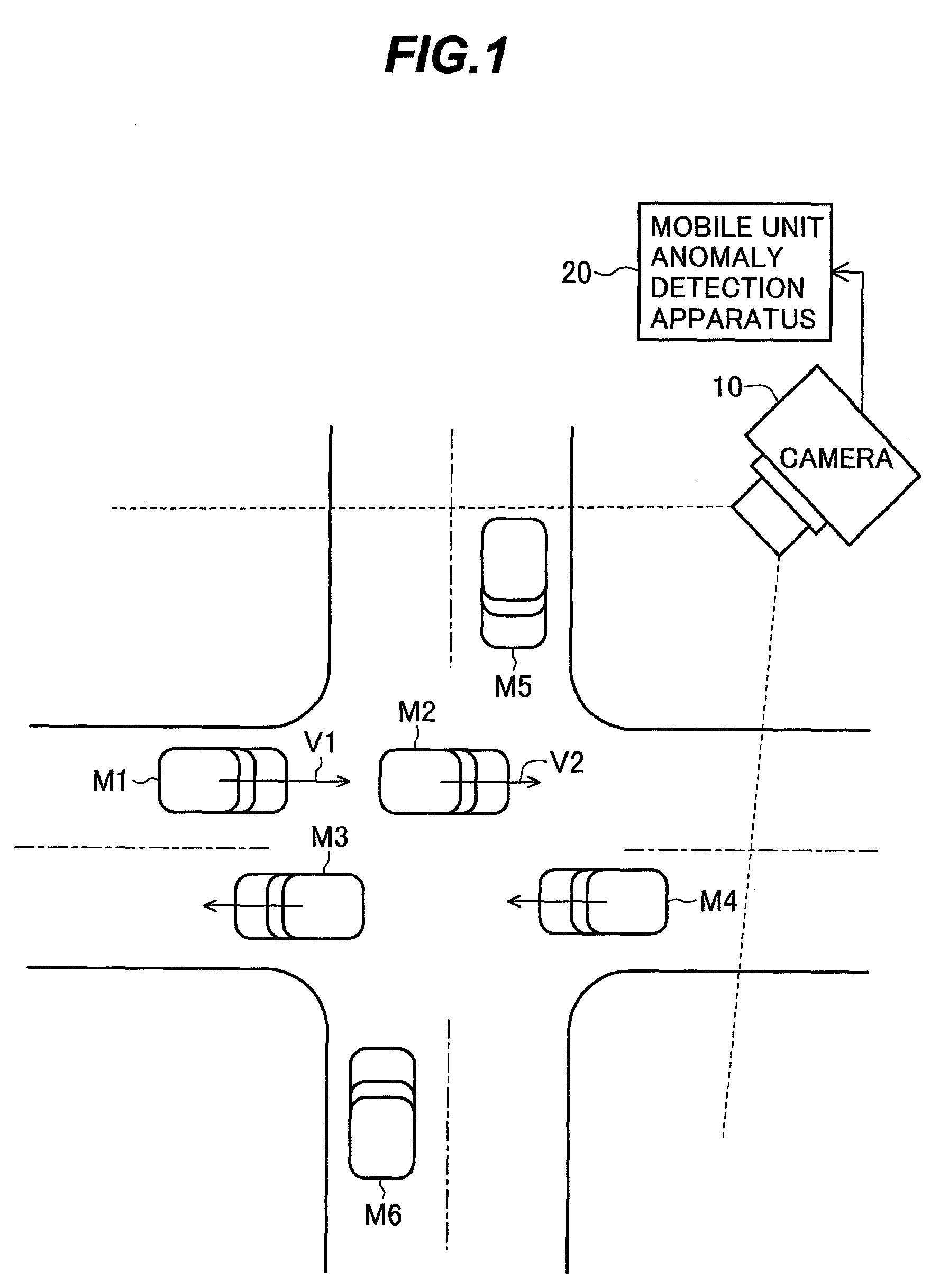

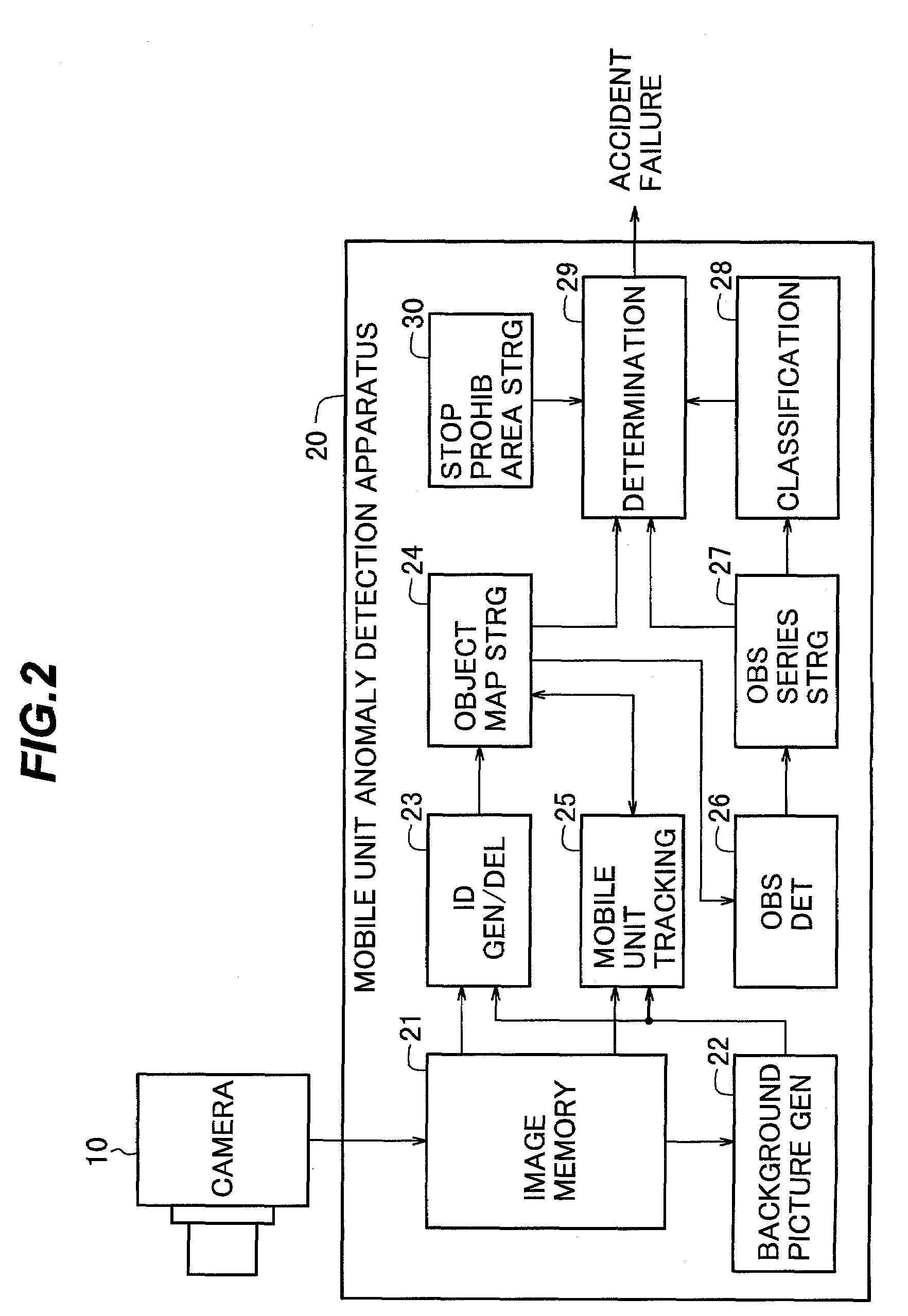

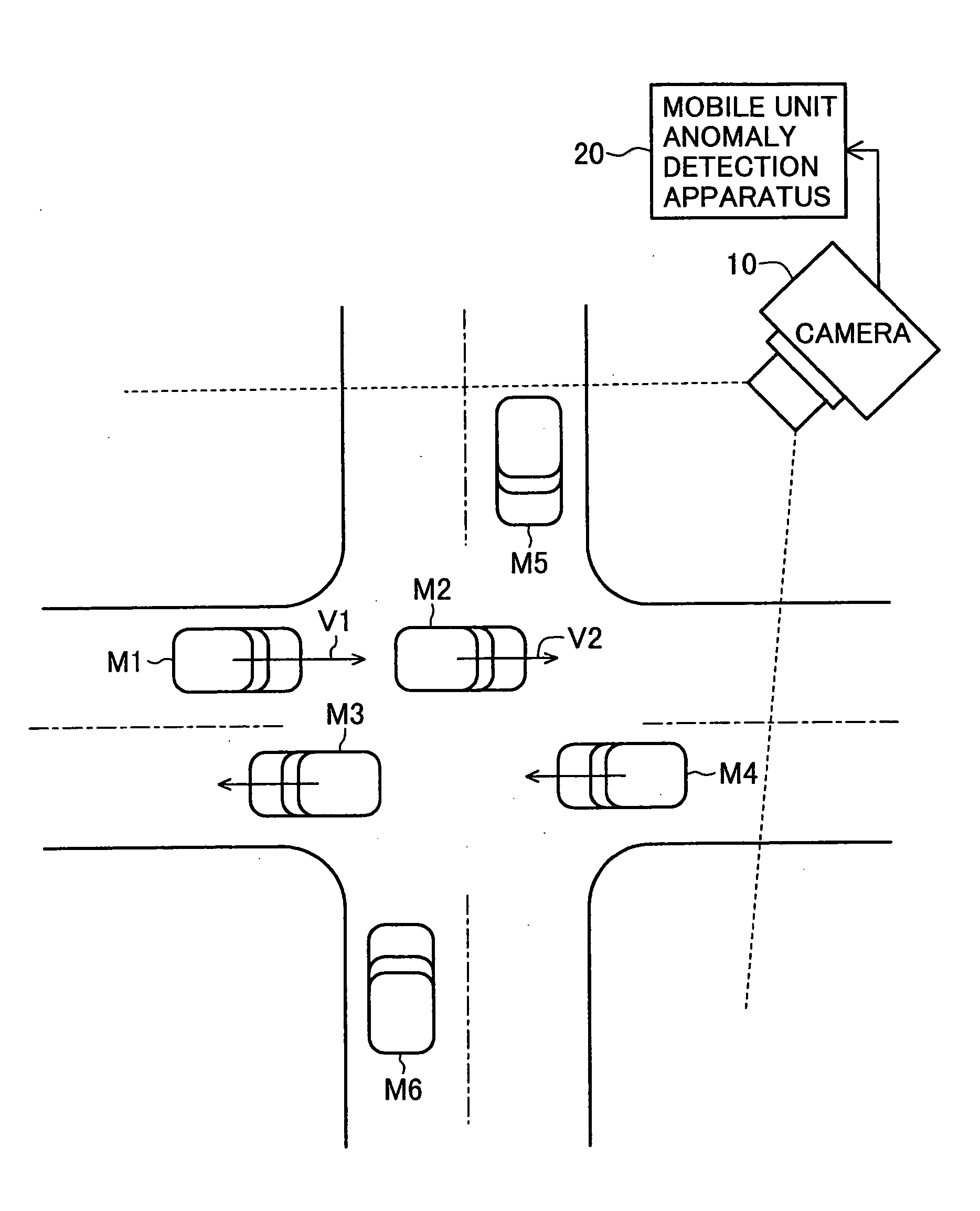

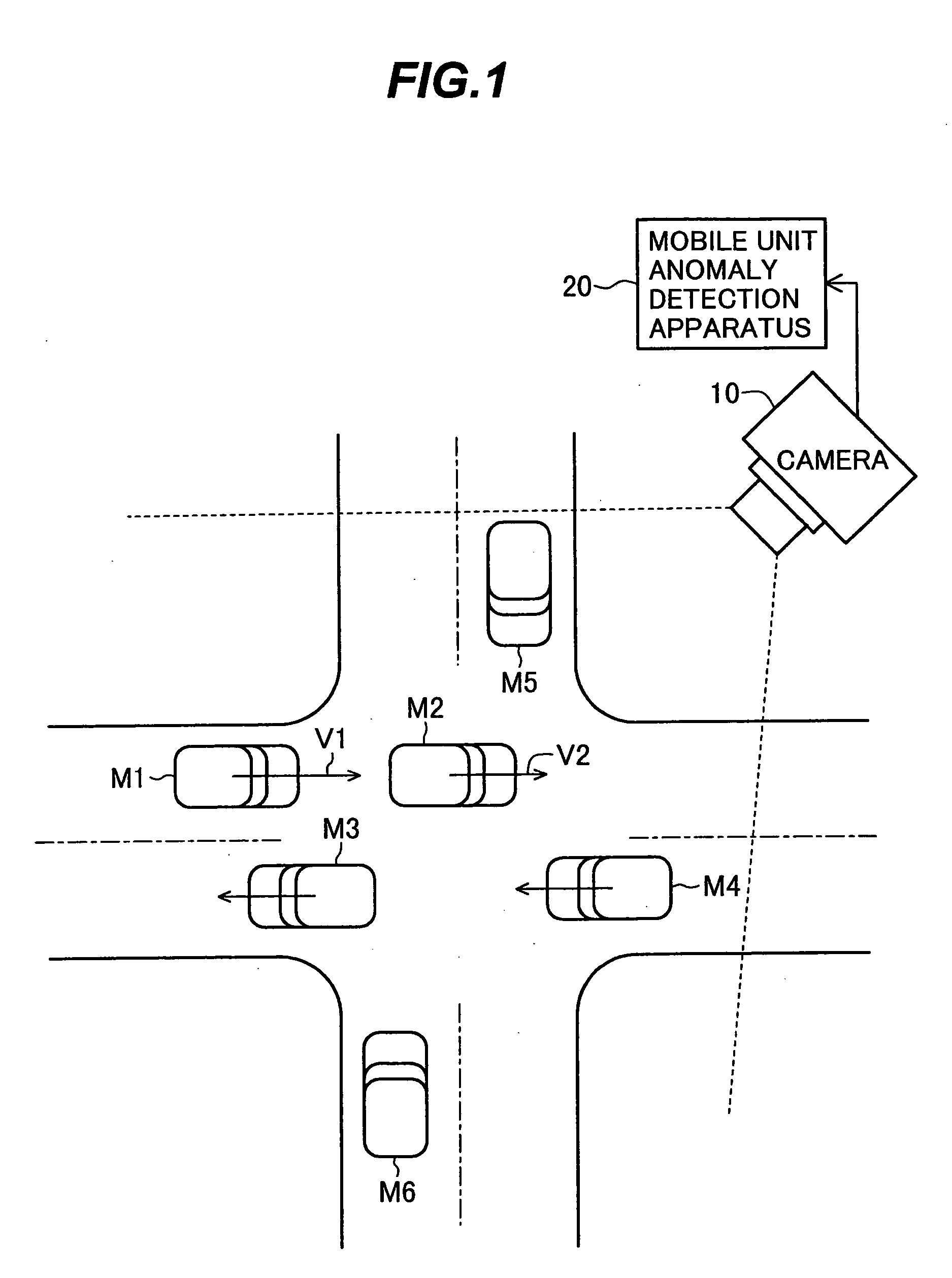

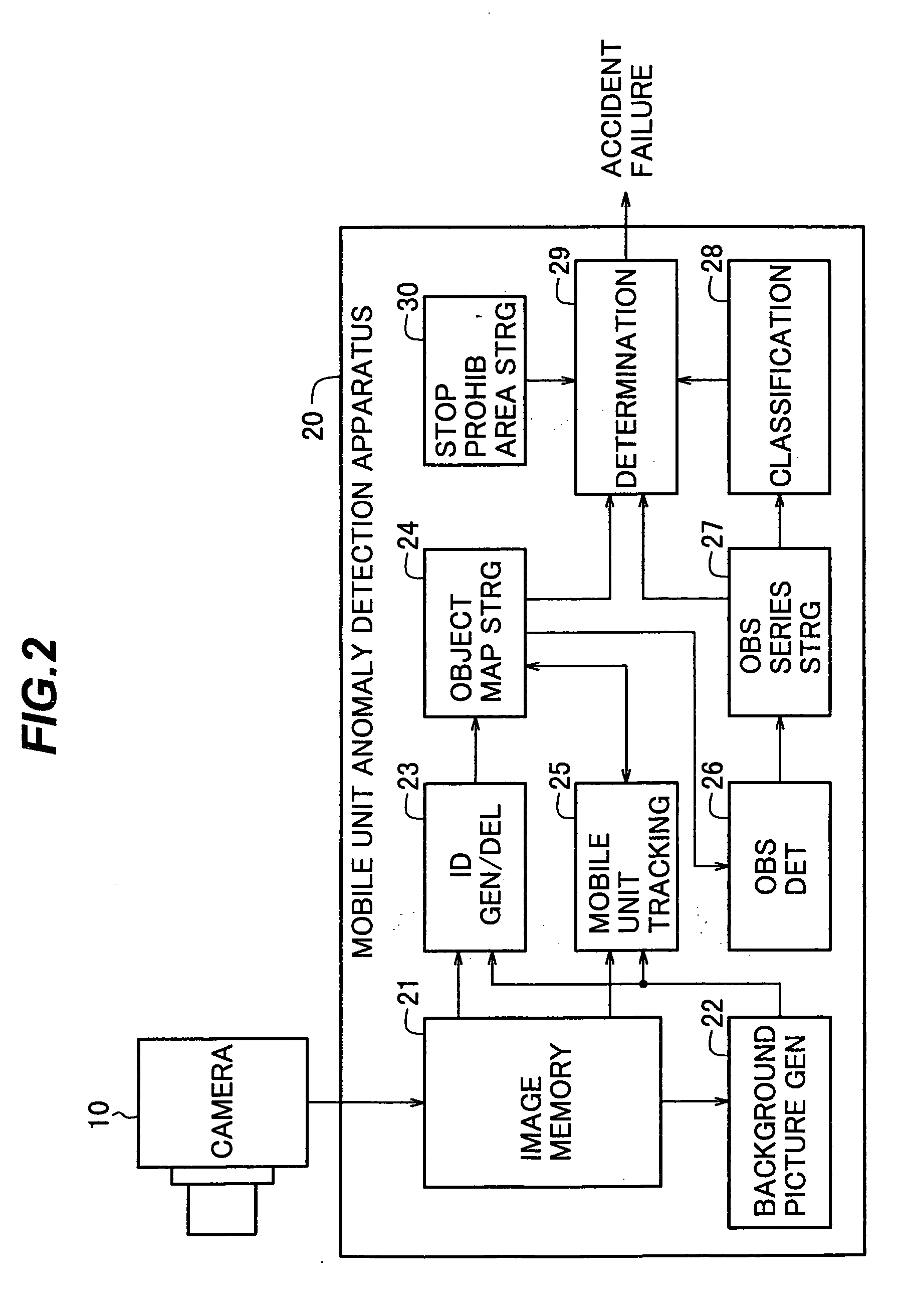

Method and apparatus for processing pictures of mobile object

ActiveUS7298394B2Automatic detectionAccurate automatic detectionImage enhancementTelevision system detailsComputer graphics (images)Relative velocity

A feature amount of an inter-mobile unit relative movement are detected as an observation amount by an observation amount detecting section 26, time series of the observation amounts are stored as an observation series into a storage section 27 to calculate a similarity of the observation series to a predetermined collision observation series by a classification section 28. A determination section 29 determines to be a collision accident if, in a case where the similarity is larger than a predetermined value, a mobile unit associated with the similarity is at rest in a stoppage prohibition area set in a storage section 30 and another mobile unit is moving, and to be a mobile unit failure if collision determination conditions except for the similarity are met. By consisting of not only a first scalar obtained by quantizing a relative velocity vector between mobile units but also a second scalar obtained by quantizing a relative position vector between mobile units as the observation amount, a relative movement between mobile units is classified in more detail. A mobile unit is tracked in units of block by a mobile unit tracking section 25 to discriminate overlapped mobile units in pictures.

Owner:SOCIONEXT INC +1

Rice quality detection method

InactiveCN105954284AEasy access to quality statusExcellent self-learning abilityImage enhancementImage analysisImpurityMulti parameter

The invention discloses a rice quality detection method, which comprises the steps of: S1, taking 400-500g of to-be-detected rice and placing the rice in a rice storage box, removing impurities from the to-be-detected rice, then taking the rice out of the rice storage box by a rice fetcher, and arranging the rice regularly on a detection box; S2, weighing the rice on the detection box by a weighing device, and transmitting the weighing data to an intelligent terminal; S3, acquiring a rice appearance image through an image acquisition device, transmitting the rice appearance image to the intelligent terminal, conducting denoising on the rice appearance image, then analyzing and contrasting the rice tissue characteristics of the rice appearance image to obtain rice acquired data, and displaying the rice acquired data on a display screen of the intelligent terminal; S4, converting the rice appearance image by an analog digital conversion module; and S5, carrying out grading according to the rice quality. The method provided by the invention is simple, can realize accurate and automatic detection of various appearance quality indexes of rice, and can perform multi-parameter and batched automatic analysis, and is suitable for various rice.

Owner:ANHUI PERTON INTELLIGENCE TECH CO LTD

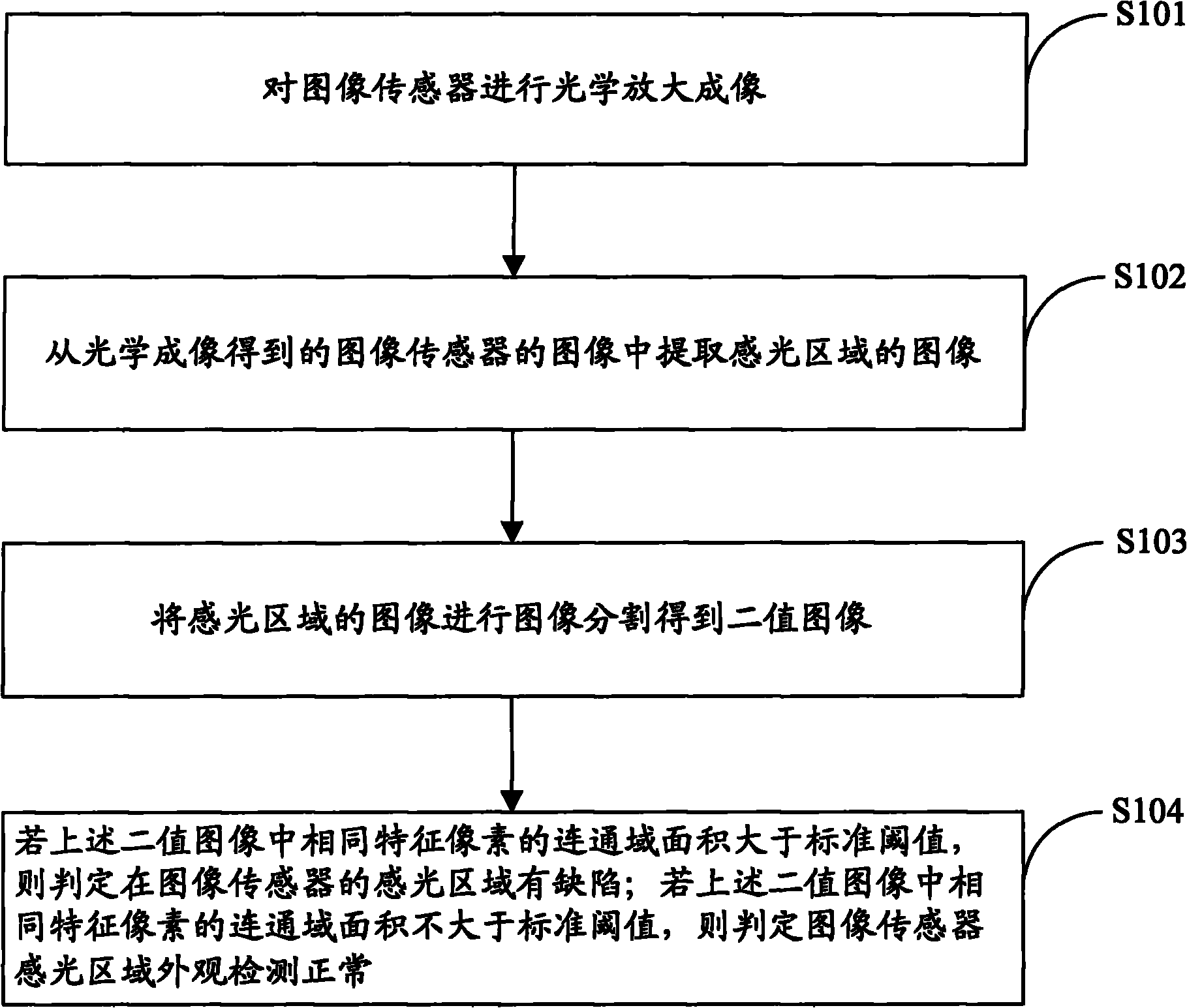

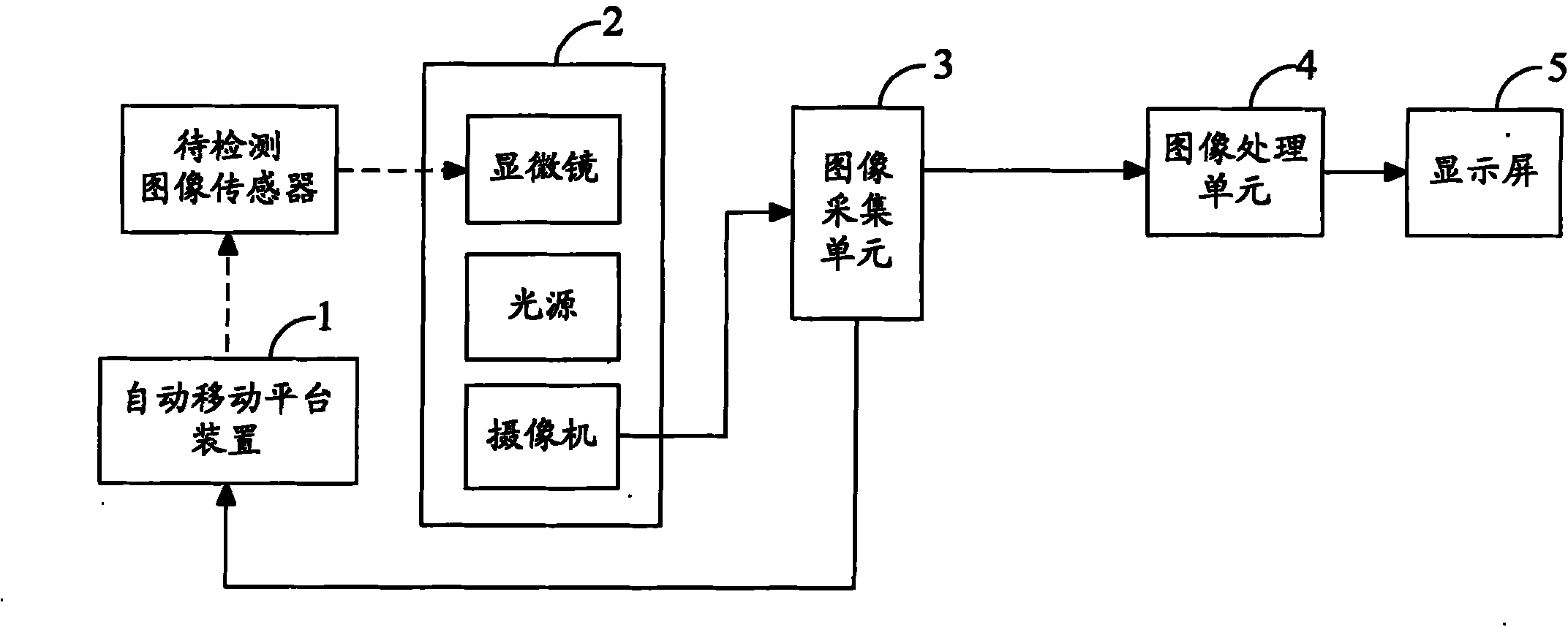

Appearance detection method and system of image sensor

InactiveCN101995325AEfficient automatic detectionAccurate automatic detectionOptical apparatus testingLight sensingAutomation

The invention provides appearance detection method and system of an image sensor, which is applicable to the technical field of chip manufacture procedures. The method comprises the following steps of: carrying out optical amplification imaging on the image sensor; extracting images of light sensing regions of the image sensor from images obtained through optical application imaging, and further obtaining binary images; judging that the light sensing region of the image sensor has defects if the value of the communication region area of the identical character pixels in the binary images is greater than a standard threshold value; and judging that the appearance of the light sensing region of the image sensor is normal if the value of the communication region area is not greater than the standard threshold value, wherein the pixels corresponding to the standard threshold values have the same color characteristics as the pixels in the communication region. The invention can efficiently and accurately carry out automatic detection on the light sensing region defects on the image sensor, the whole process can be conveniently integrated into the existing automation manufacture procedures, the manual participation is not needed in judgment, and the consistency of the detection standard can be ensured, so the detection quality is improved.

Owner:BYD CO LTD

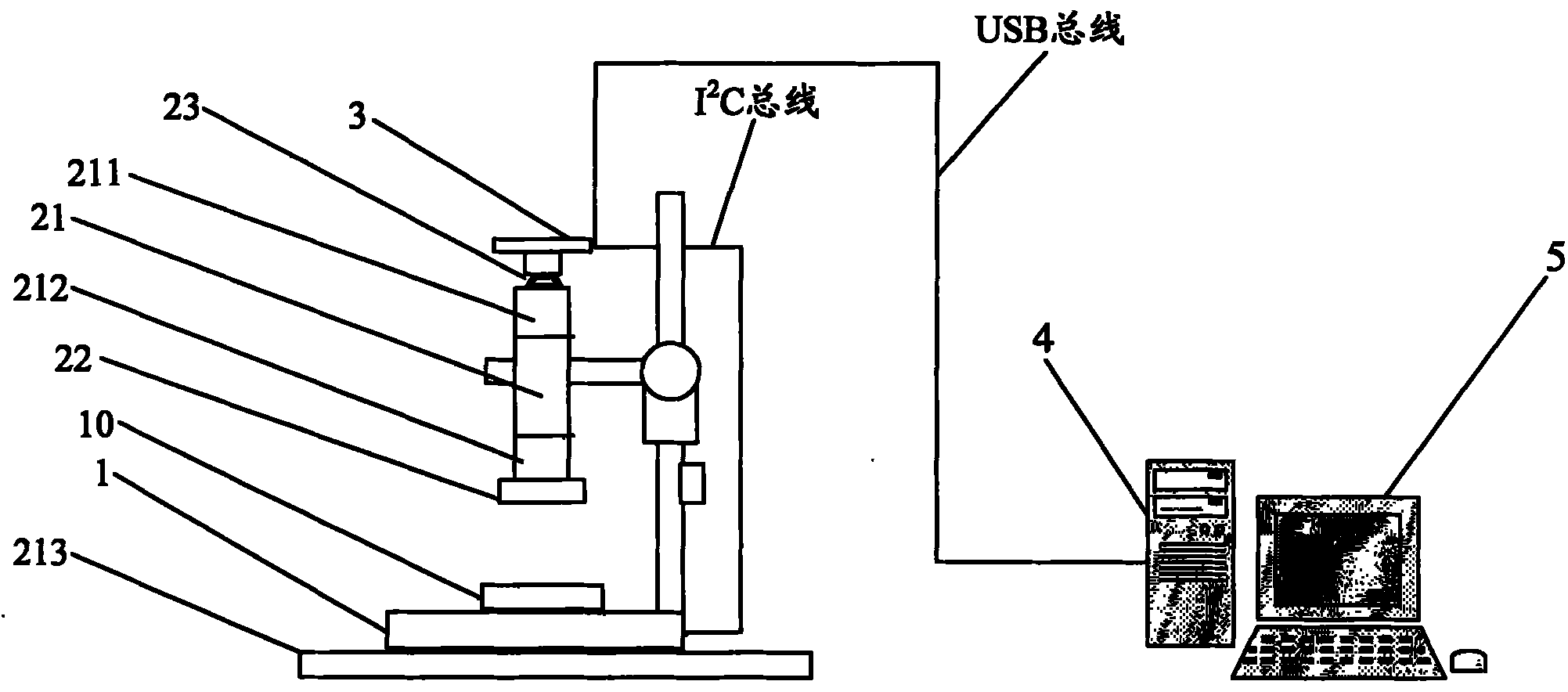

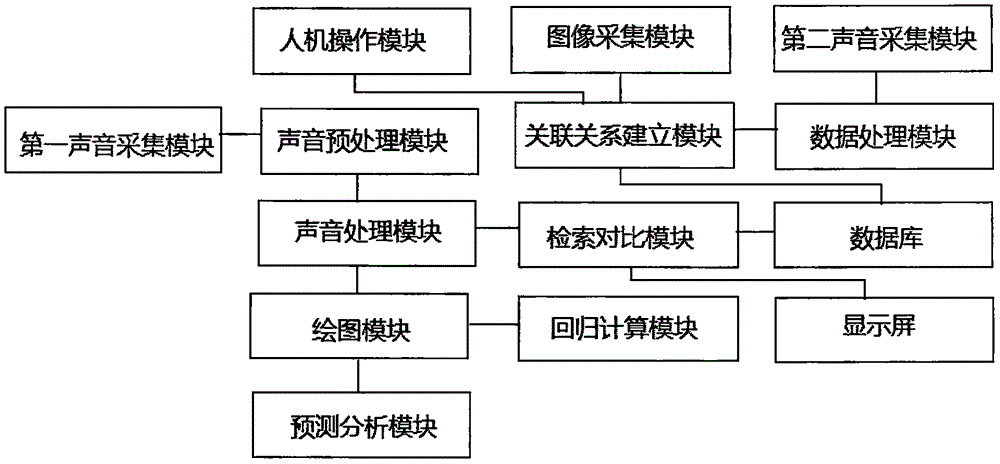

Stored-grain pest sound detection identification system

InactiveCN106094008AReal-time automatic detectionAccurate automatic detectionAcoustic presence detectionSound detectionMan machine

The invention discloses a stored-grain pest sound detection identification system, including a first sound collection module, a sound pretreatment module, a sound processing module, a retrieval contrast module, a drawing module, a regression calculating module, a prediction analysis module and a database. The database is connected with a second sound collection module, an image collection module, a man-machine operation module, a data processing module and a correlation establishing module. The invention completes pest detection through identifying insect sounds, achieves real-time, accurate and lossless automatic detection of pests in stored grain, and can predict the multiplying condition of pests, thereby facilitating pest treatment measure making and reducing economic loss caused by delayed discovery and delayed treatment.

Owner:WEINAN NORMAL UNIV

A fully automatic detection device for a light touch switch

ActiveCN105044593BHigh repeatabilityFacilitates automatic detectionCircuit interrupters testingExecution unitTouch switch

The invention discloses a fully automatic detection device for a light touch switch. A conveying slide rail is fixedly installed on the upper surface of the workbench along the longitudinal direction, and a horizontal main sliderail is fixedly installed on the front end of the workbench. Light touch switch discharge sorting screw sorting vibrating plate docking; the rear end of the conveying slide rail is provided with a shaping component; the front end of the conveying slide rail is respectively provided with a material cavity adjustment The front end of the machine is equipped with a lifting material selection mechanism and a material blocking mechanism; a universal detection mechanism is arranged before the material blocking mechanism; a sorting mechanism is arranged before the universal detection mechanism; The various execution components are connected to each other. The device of the invention has the advantages of simple structure, high working efficiency and convenient implementation.

Owner:陕西中达鑫盛信息科技有限公司

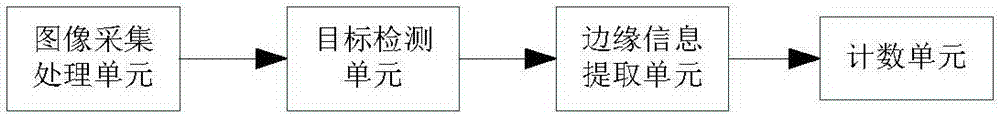

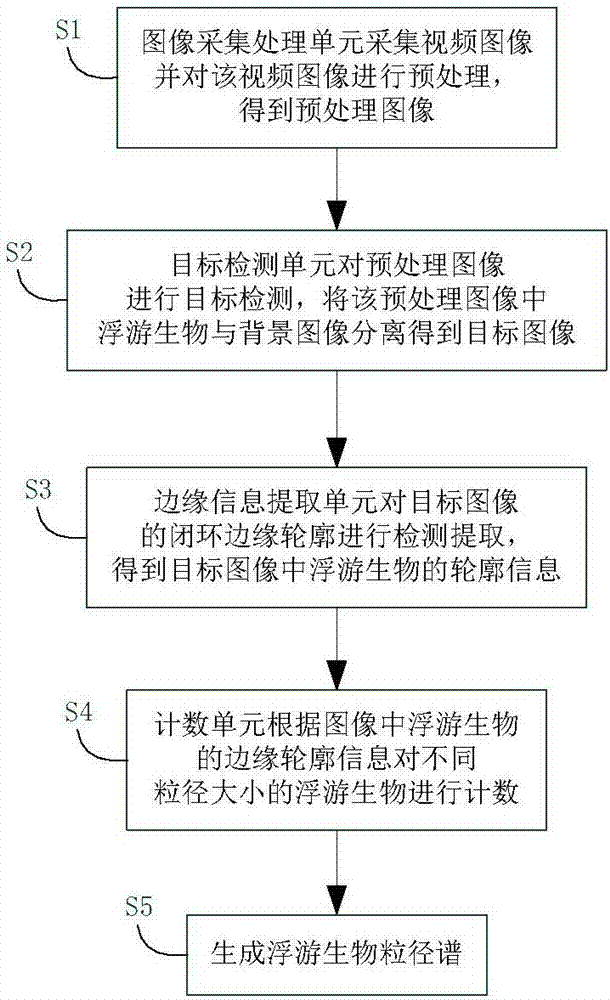

Plankton particle size spectrum detection system and method thereof

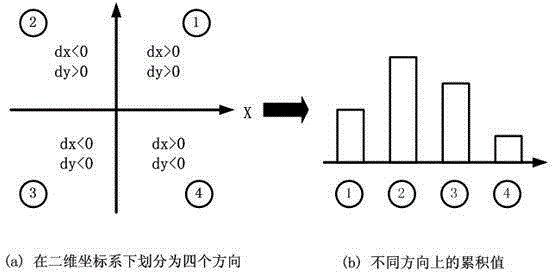

InactiveCN107194403AReal-time automatic detectionAccurate automatic detectionCharacter and pattern recognitionCounting objects with random distributionOcean bottomPlankton

The present invention provides a plankton particle size spectrum detection system and a method thereof. The system comprises an image acquisition processing unit, a target detection unit, an edge information extraction unit, and a counting unit that are sequentially connected. The image acquisition processing unit preprocesses a collected video image IO to obtain a preprocessed image I1; the target detection unit separates the plankton in the preprocessed image I1 from the background image to obtain a target image I2; the edge information extraction unit carries out detection and extraction on the closed-loop edge contour of the target image I2 to obtain contour information of each plankton in the target image I2; and the counting unit detects the amount of plankton in different particle sizes to generate the plankton particle size spectrum of the correspondence between the different particle sizes of the plankton and the amount of plankton. According to the system and method provided by the present invention, the amount of plankton particle size spectrum detection can be effectively simplified, automatic detection of the plankton particle size spectrum in the seabed can be accurately carried out in situ in time, and the red tide can be effectively detected and forecasted.

Owner:OCEAN UNIV OF CHINA

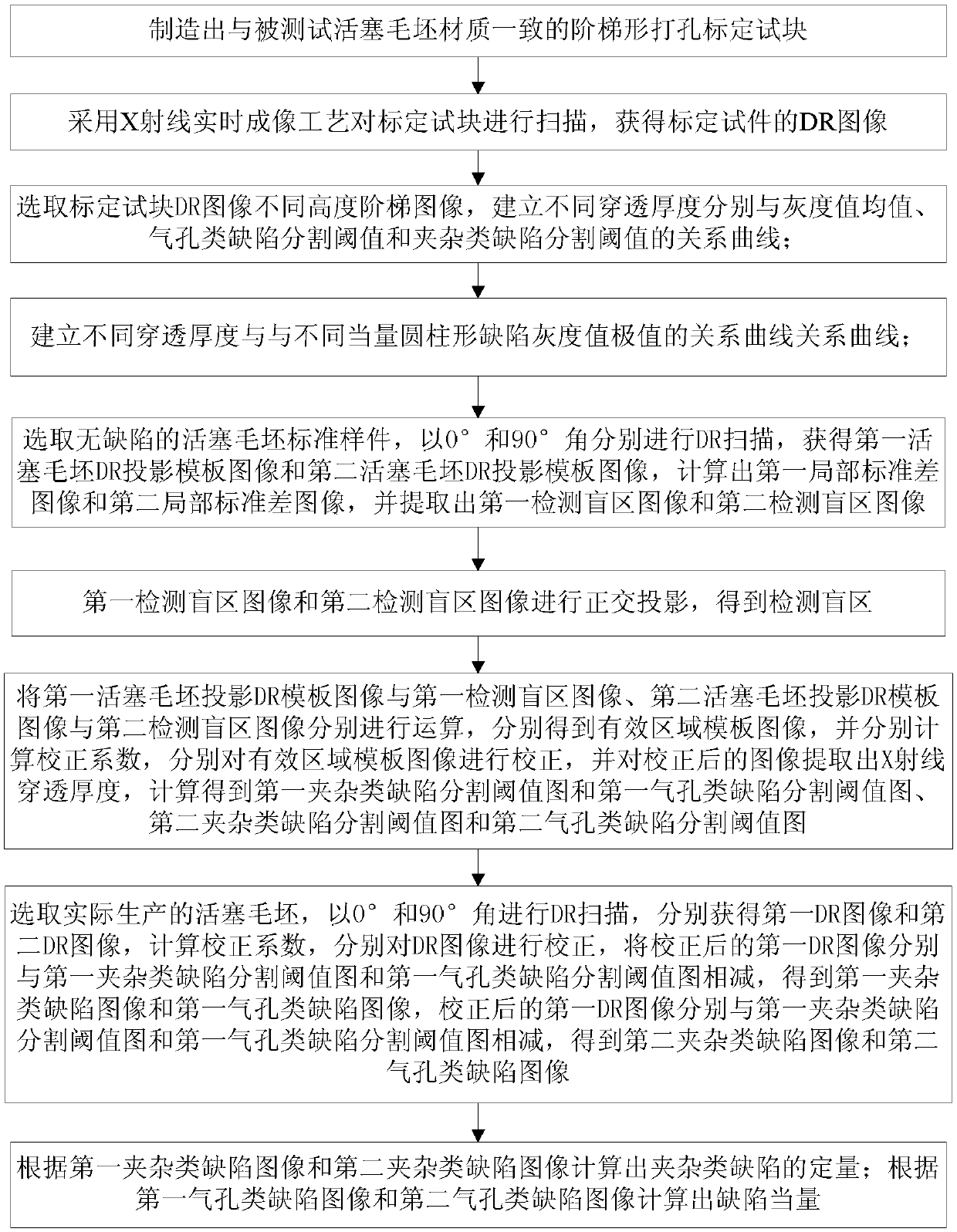

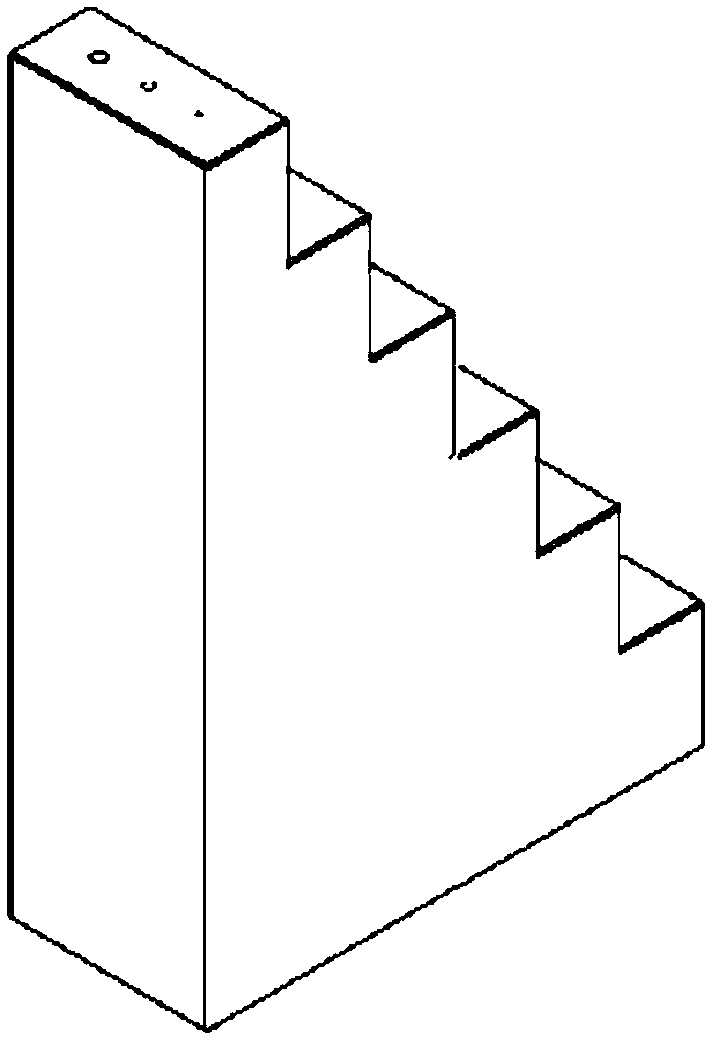

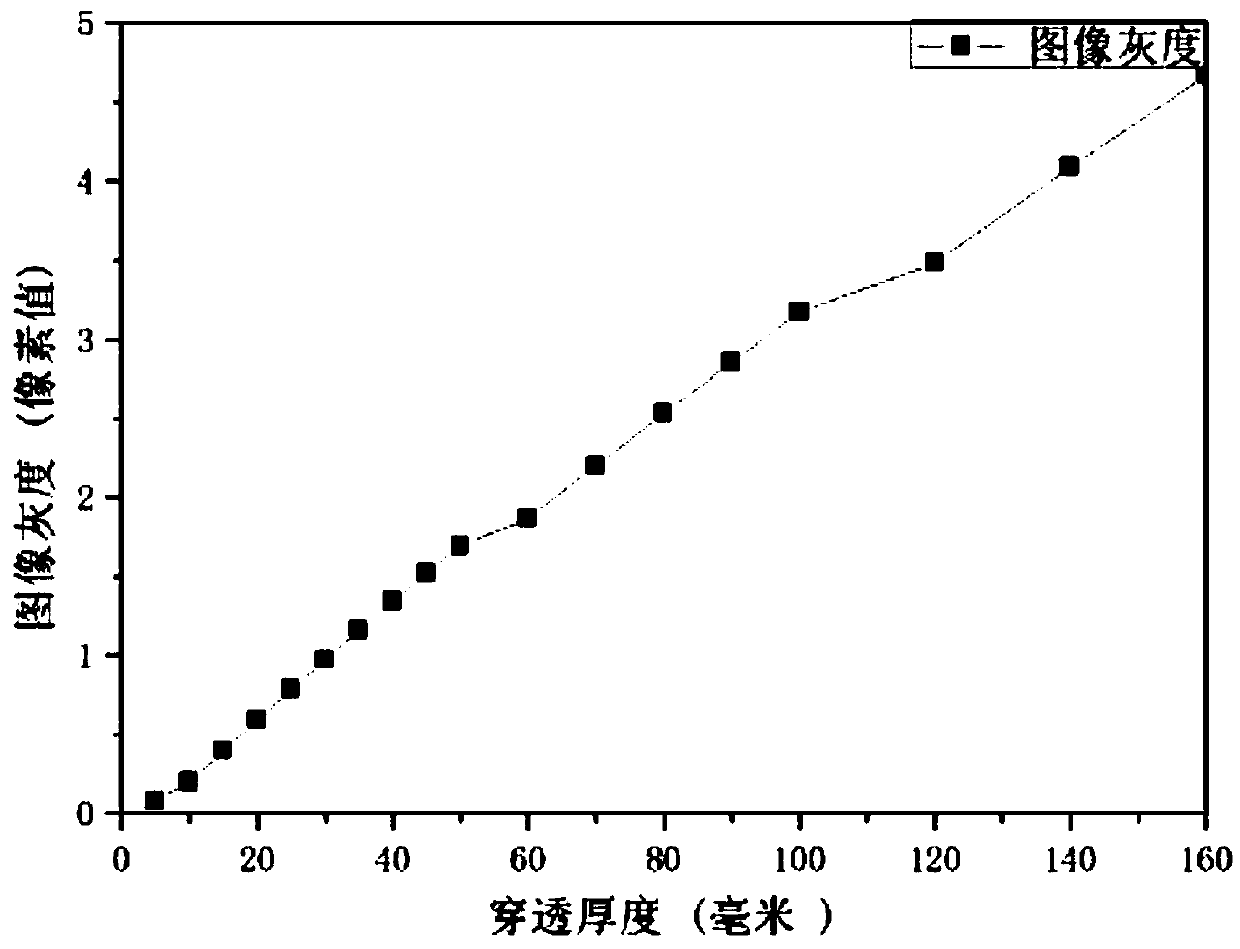

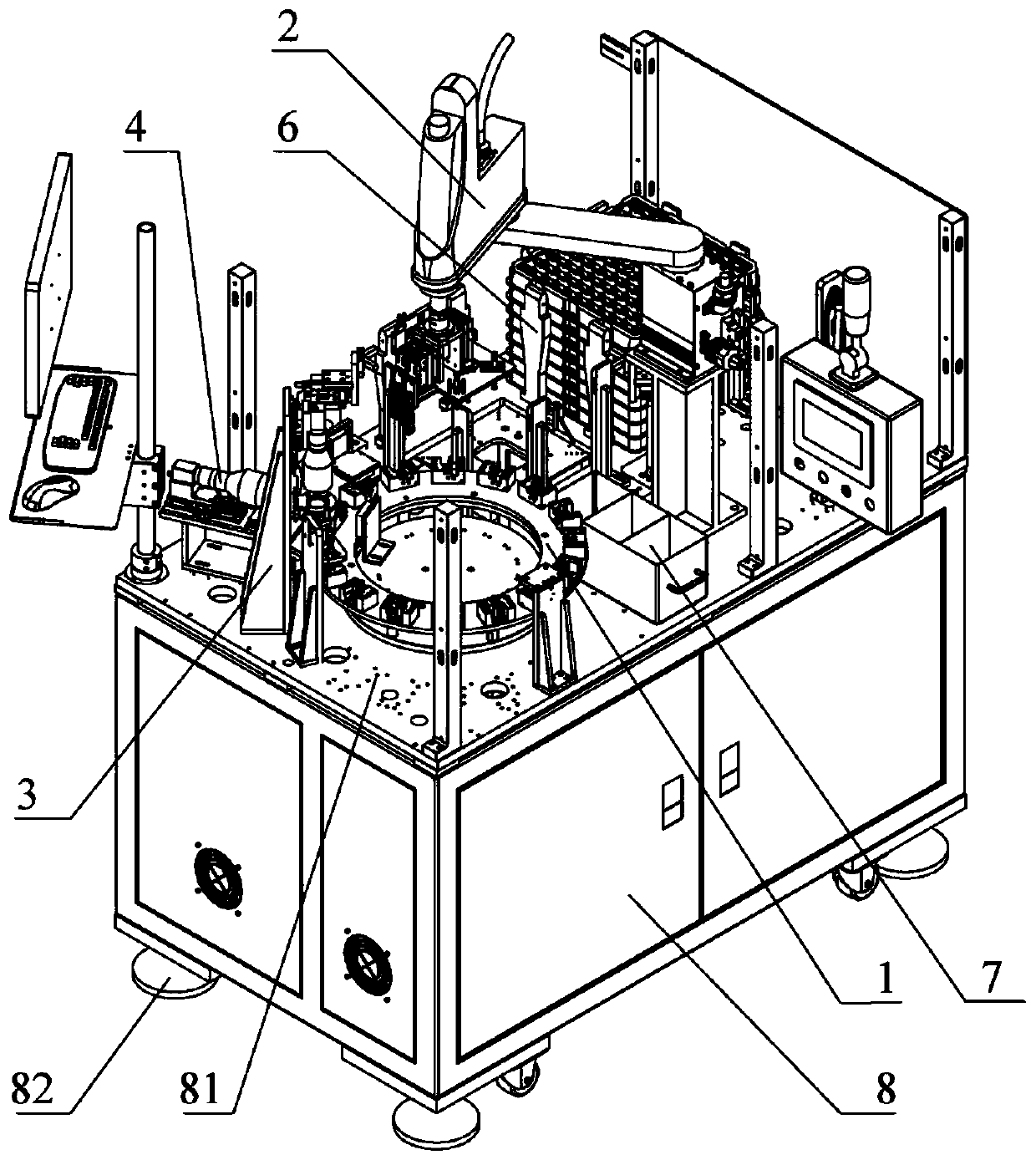

A method for detecting defects of a piston blank with a complex inner structure

ActiveCN109584231AAccurate automatic detectionReliable automatic detectionImage enhancementImage analysisThreshold graphPunching

The invention relates to a method for detecting defects of a piston blank with a complex inner structure. The method comprises the following steps of: forming a stepped punching calibration test blockwhich is consistent with the tested piston blank; Obtaining a DR image of the calibration test piece; Establishing a relation curve between different penetration thicknesses and the gray value mean value, the pore defect segmentation threshold value and the inclusion defect segmentation threshold value respectively; Establishing relation curves of different penetration thicknesses and different equivalents of cylindrical defect gray value extreme values; Detecting the defect-free standard sample piece of the tested piston blank from 0 degree to 90 degrees to obtain a first detection blind area image and a second detection blind area image; Calculating an inclusion type and pore type defect segmentation threshold map according to the defect-free piston blank; Calculating an inclusion defect image and an air hole defect image of the actually produced piston blank through the defect segmentation threshold graph; And calculating defect equivalents and quantification. According to the defect segmentation statistical distribution principle, the defect equivalents and quantification can be accurately and reliably detected.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

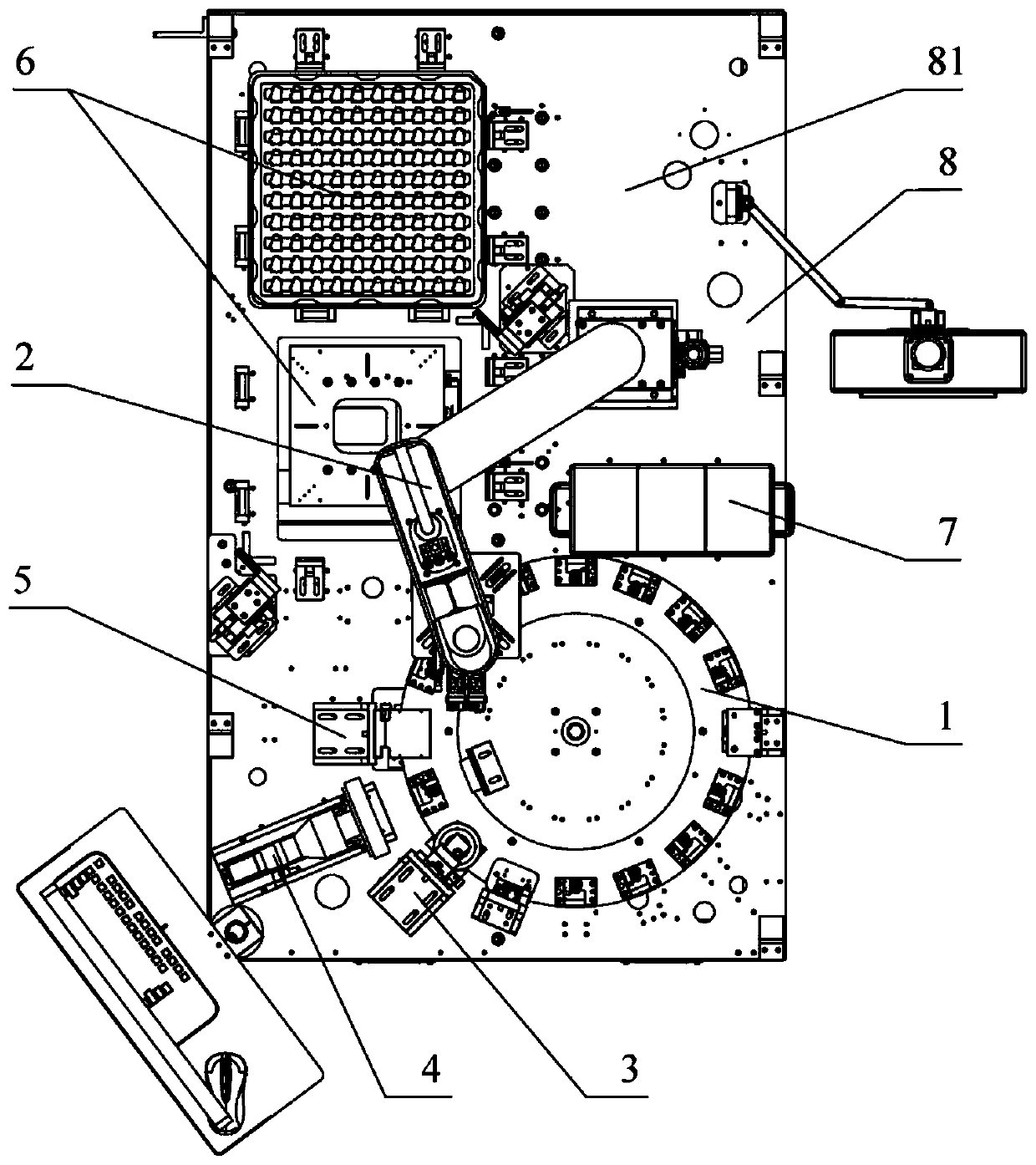

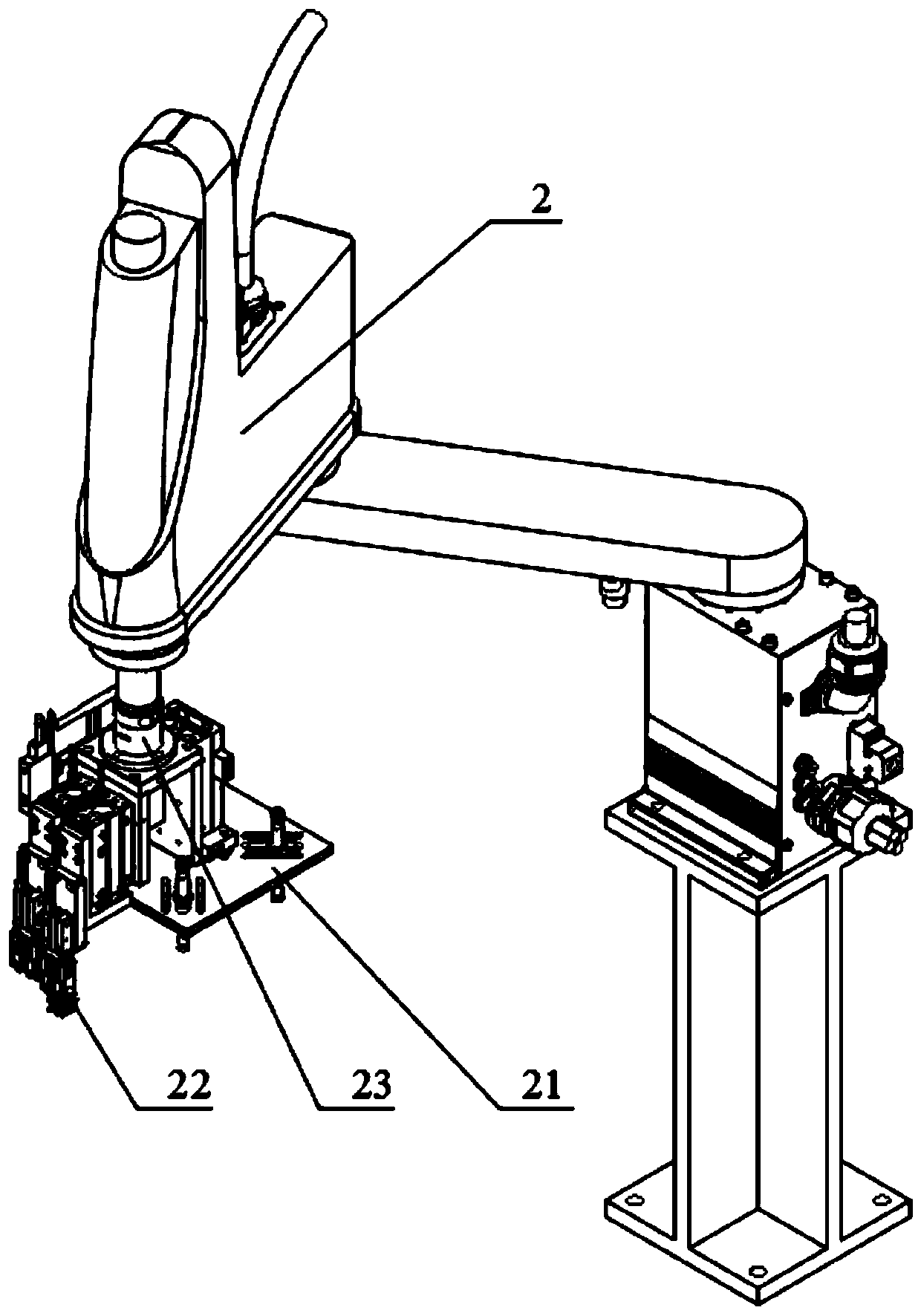

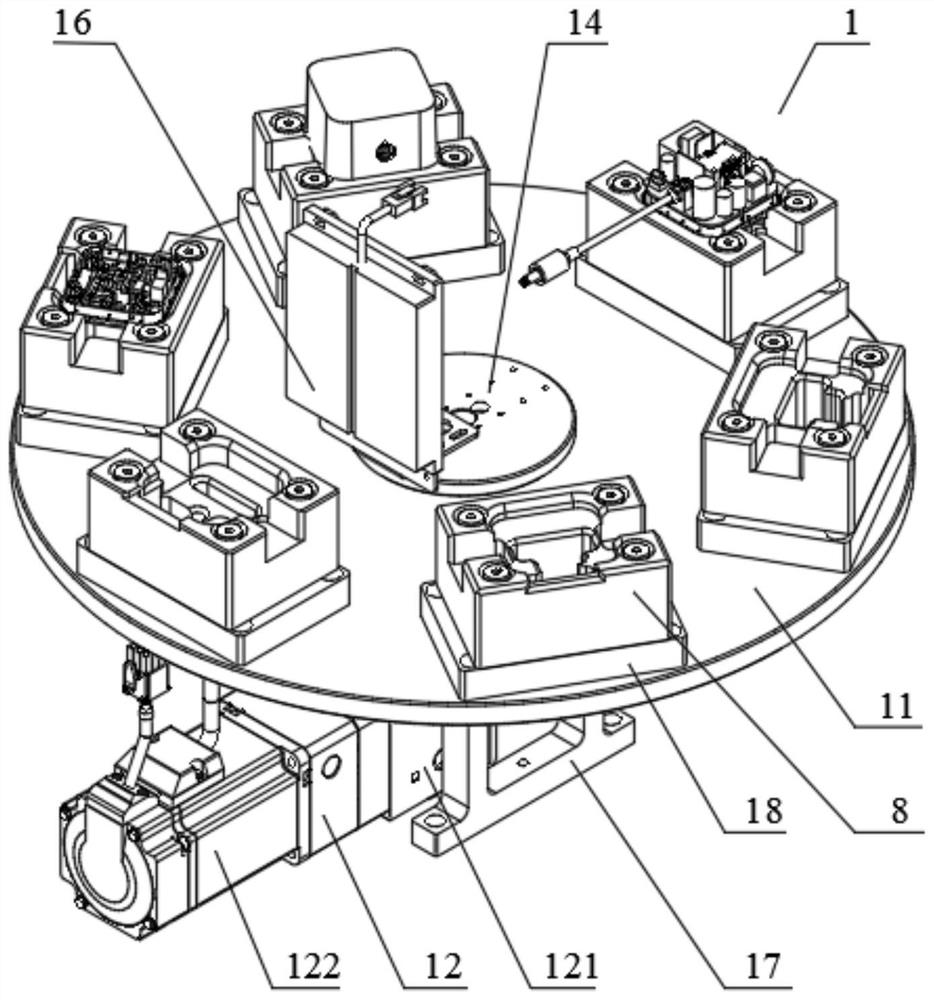

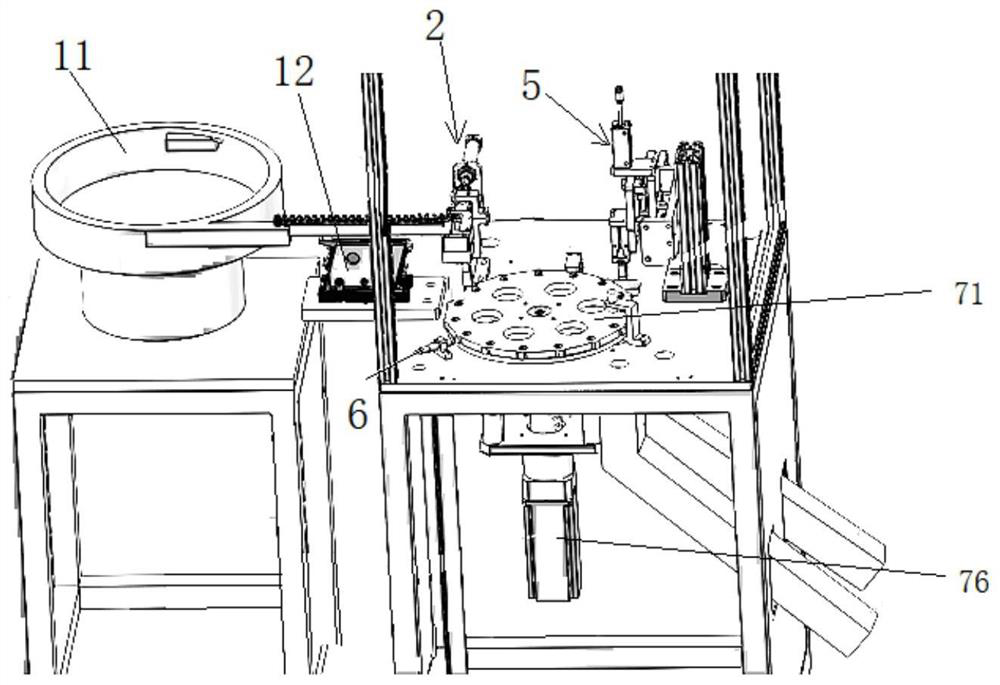

Multi-station detecting and packaging device

PendingCN111532487AFully automatic detectionFully automatic inspection of packagingPackaging automatic controlSortingRobot handProcess engineering

The invention discloses a multi-station detecting and packaging device at least comprising a multi-station rotary plate device, a material taking and placing mechanical hand, an upper detection device, a horizontal detection device, a lower detection device, a material bin device and a waste material collection box. The material taking and placing mechanical hand, the upper detection device, the horizontal detection device and the lower detection device correspondingly cooperate with the multi-station rotary plate device. The material bin device and the waste material collection box correspondingly cooperate with the material taking and placing mechanical hand. Multiple positioning jigs used for containing products are arranged on the multi-station rotary plate device. The material takingand placing mechanical hand can place to-be-detected products on the positioning jigs and place the detected products in material plates or the waste material collection box. By means of the multi-station detecting and packaging device, the products are automatically detected and packaged in a precise and comprehensive manner, the material plates do not need to be manually replaced or stacked, operation is easy and convenient, precision is high, the speed is high, time and labor are effectively saved, and therefore the production efficiency and the overall quality and yield of the products areimproved, the production cost is reduced, and competiveness of the products is enhanced.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

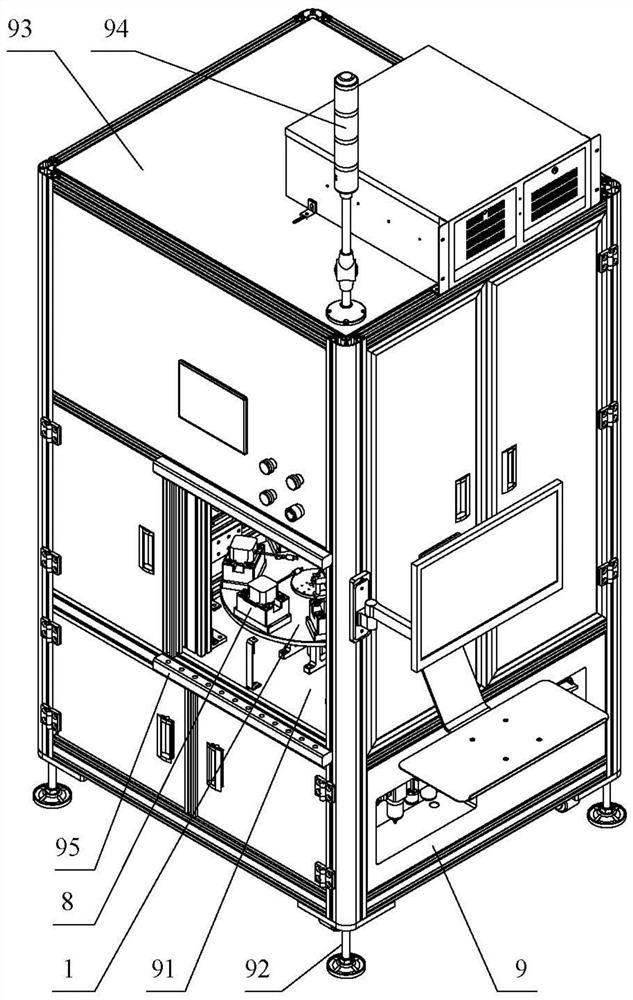

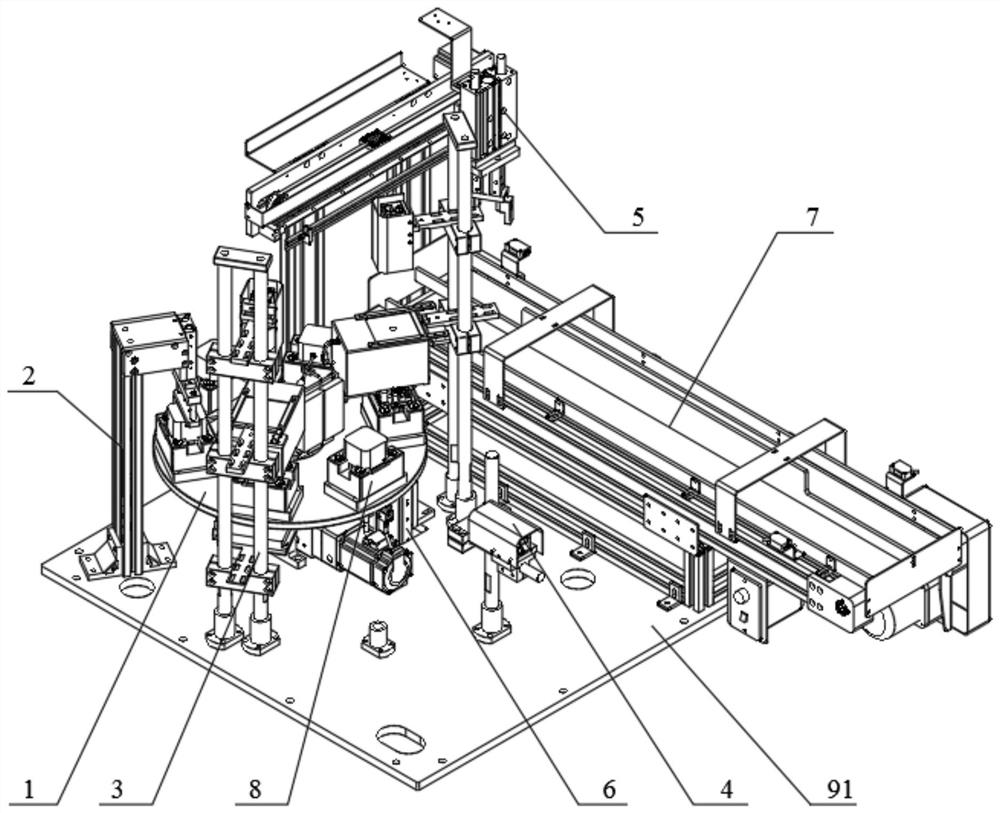

Visual inspection equipment for elastic sheets

PendingCN111774329AAccurate automatic detectionFully automatic detectionOptically investigating flaws/contaminationUsing optical meansVisual inspectionReclaimer

The invention provides visual inspection equipment for elastic sheets. The visual inspection equipment at least includes a rotating worktable, a conveying device and a correction device correspondingly matched to the rotating worktable, at least one upper visual inspection device, a horizontal visual inspection device, a material taking manipulator, and a jacking mechanism, a plurality of positioning jigs for placing products are arranged on the rotating worktable, and a first conveying interval for conveying qualified products and a second conveying interval for conveying unqualified productsare arranged on the conveying device. The comprehensive and accurate automatic detection of the elastic sheets on the products can be realized, the operation is simple and convenient, the labor intensity is low, manpower and time are effectively saved, the detection accuracy is high, misjudgment, missed detection and the like are not prone to causing, so that the overall quality and yield of theproducts are improved, the production efficiency is high, the output is high, and the production cost is reduced.

Owner:赛尔康(贵港)有限公司

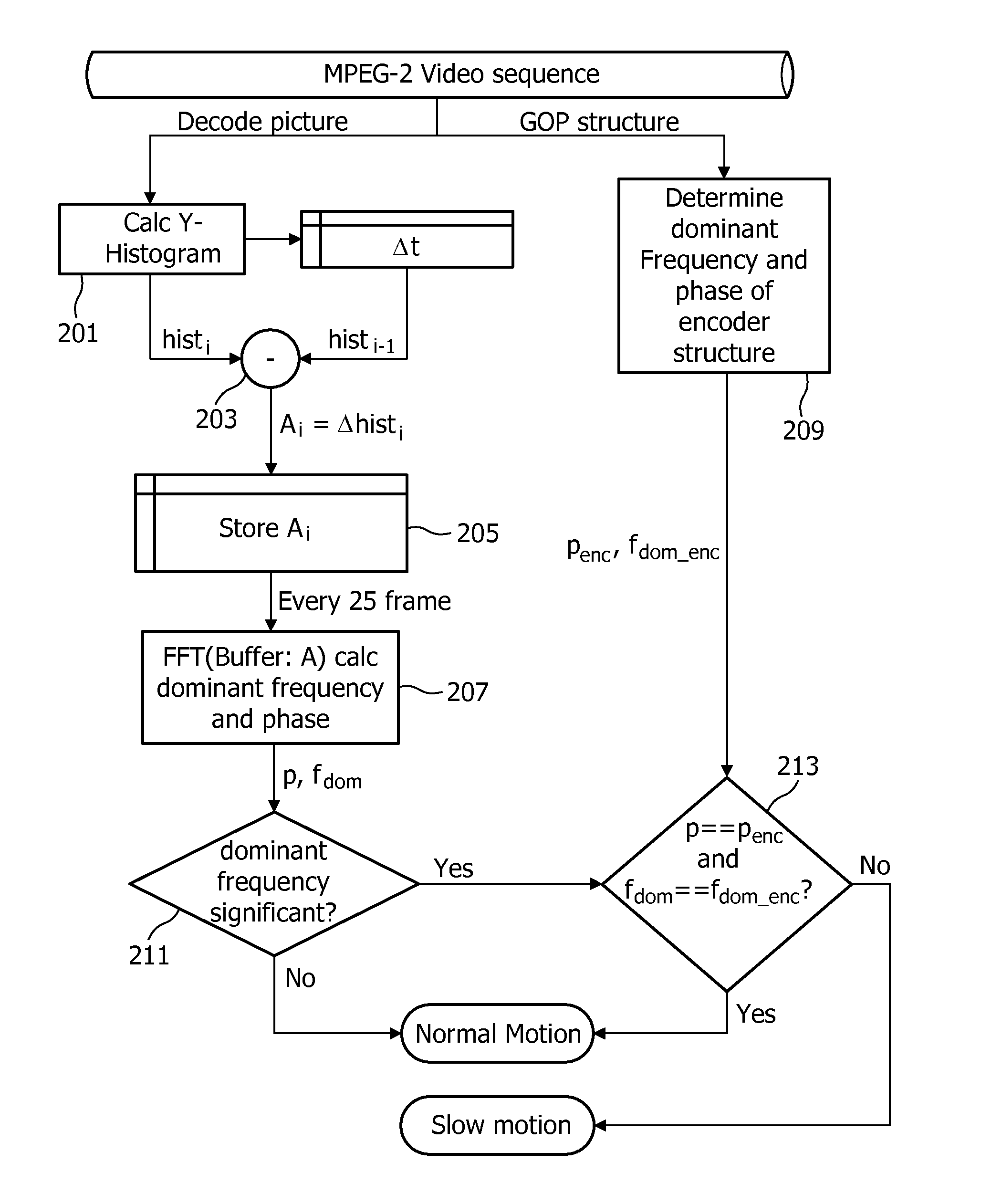

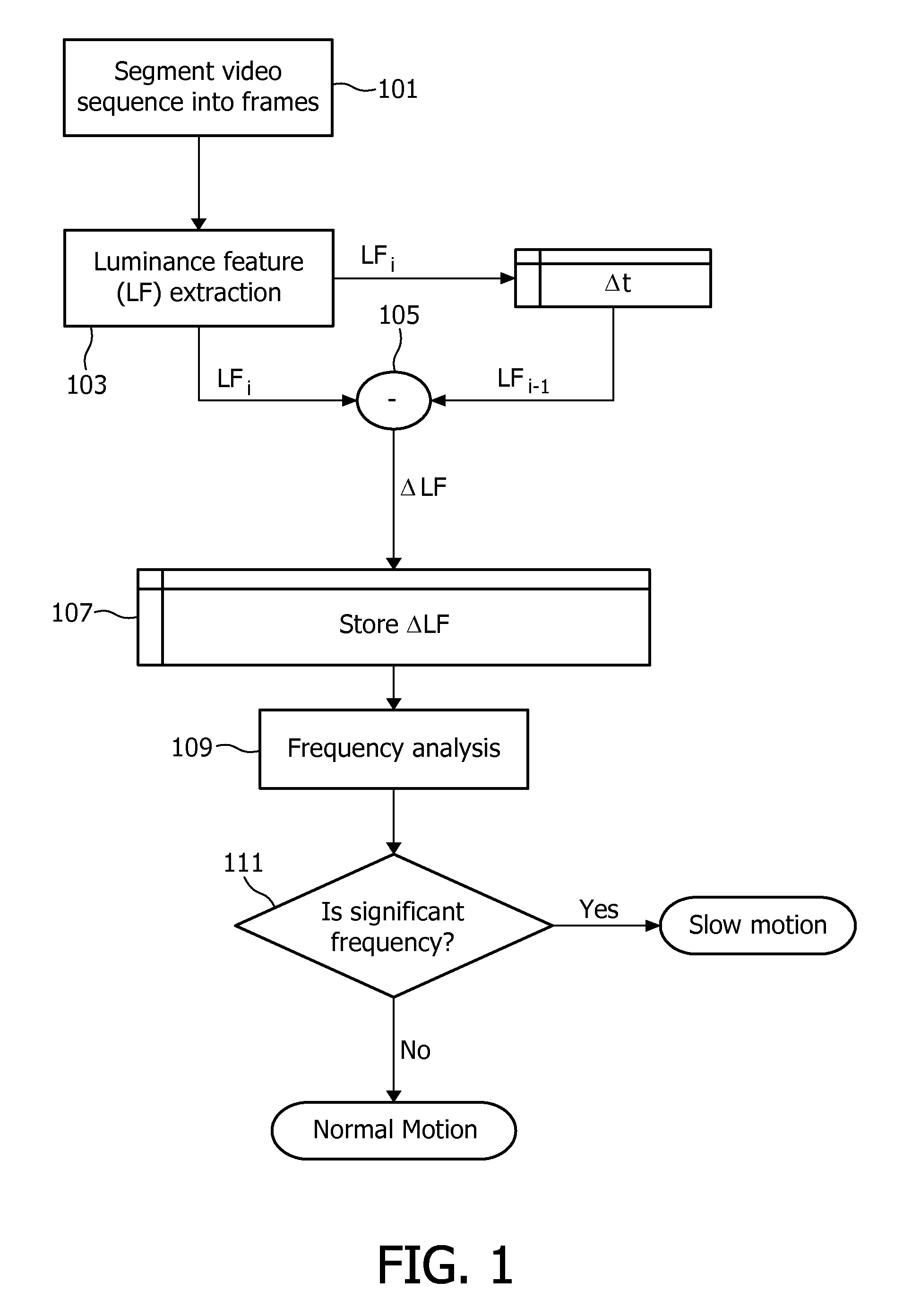

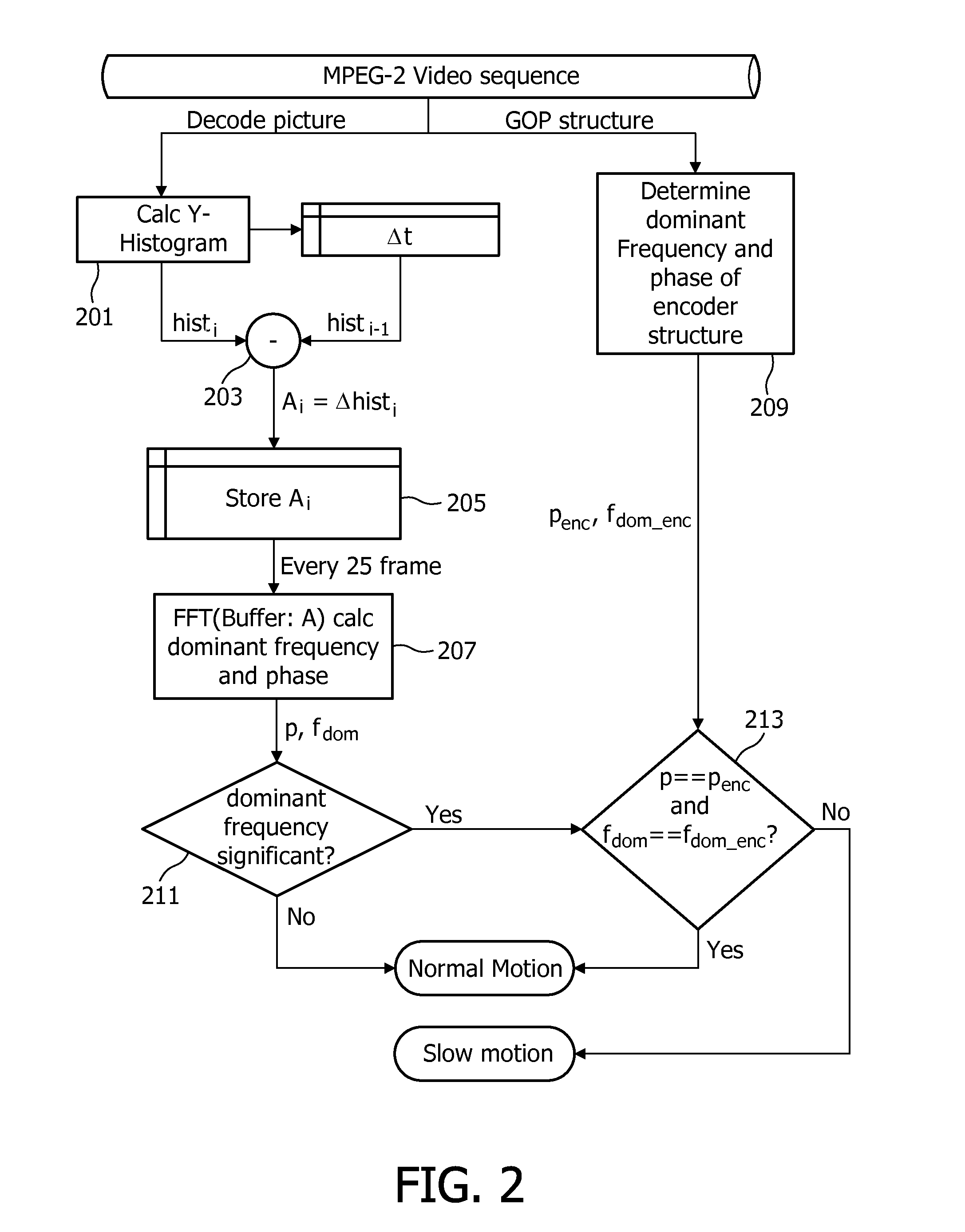

Method and apparatus for detecting slow motion

InactiveUS20100002149A1Accurate and simple techniqueHigh-precision detectionTelevision system detailsImage analysisPattern recognitionLuminosity

The occurrence of slow motion in a video sequence is detected by: extracting a feature of luminosity for each of a plurality of frames of a video sequence, step 103; determining differences between the extracted features of luminosity, step 105; performing frequency analysis on the determined differences, step 109; and detecting the occurrence of slow motion in said video sequence when a frequency variation between the differences exceeds a predetermined threshold.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Gust front automatic recognition method based on Doppler weather radar data

InactiveCN106526558AAccurate automatic detectionFull automatic detectionRadio wave reradiation/reflectionICT adaptationExperimental validationWeather radar

The invention discloses a gust front automatic recognition method based on Doppler weather radar data, and the method comprises the following steps: 1), extracting a weak narrow band echo suspected area according to the radar performance characteristics of gust front through employing a local binaryzation algorithm; 2), carrying out the segmentation, connection and screening of the weak narrow band echo suspected area, and obtaining a skeleton image corresponding to a weak ridge-shaped belt; 3), obtaining an optical flow field through two low-pitching-angle radar images at a current moment and a former moment, supposing the matched skeletons at the former and latter moments in the skeleton images corresponding to the weak ridge-shaped belt obtained at step 2) as the suspected gust front, and recognizing the gust front according to the relation between the position and speed of the suspected gust front and the position and speed of a windstorm cell and the relation between the direction and speed of the suspected gust front. The method achieves the automatic detection of the gust front, achieves the timely early warning of disasters, and reduces the economic loss and casualty. Moreover, the validity of the method is verified.

Owner:TIANJIN UNIV

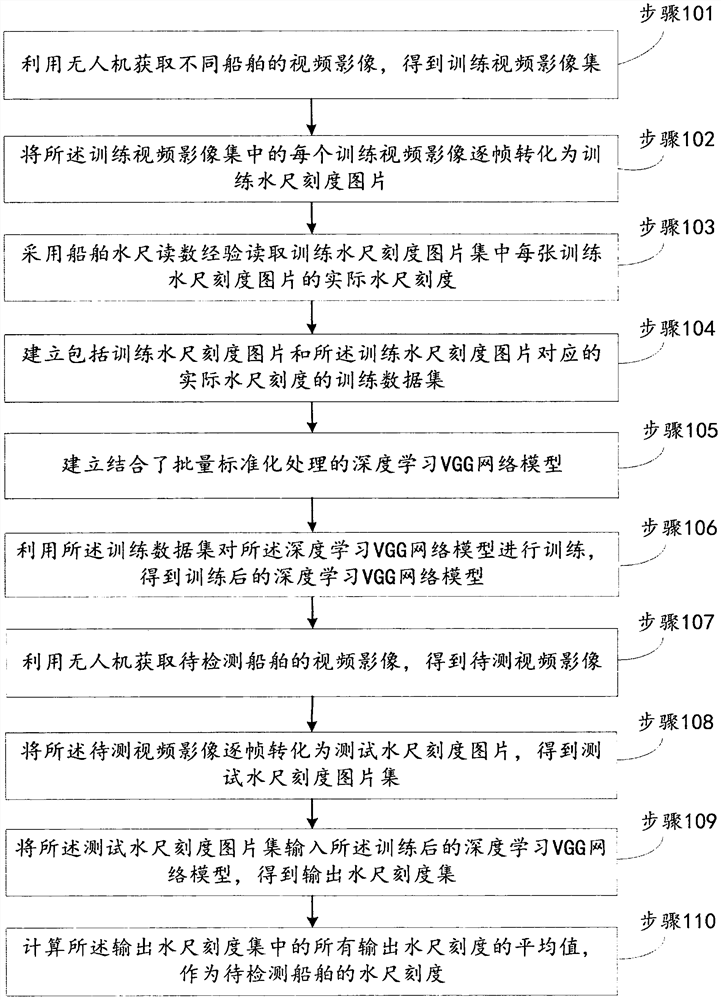

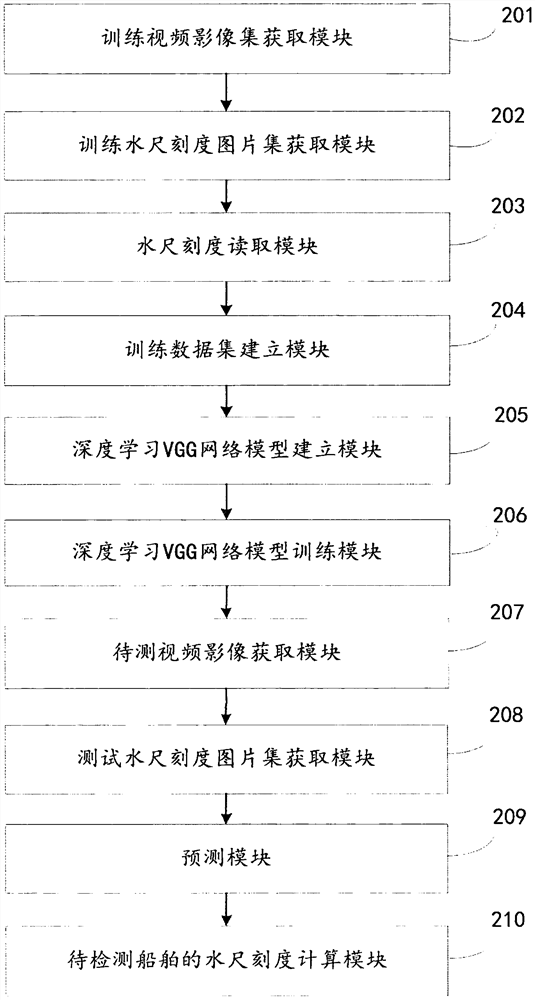

Ship water gauge automatic detection method and system

PendingCN112347827AImplement automatic detectionHigh speedCharacter and pattern recognitionVessel stability improvementData setNetwork model

The invention provides a ship water gauge automatic detection method and system. Video images of different ships are acquired by using unmanned aerial vehicle equipment and are converted into trainingwater gauge scale pictures, actual water gauge scales of the training water gauge scale pictures are read by using ship water gauge reading experience, and a training data set is established; the deep learning VGG network model is trained by using the training data set to obtain a trained deep learning VGG network model; finally, a video image of a ship to be detected is acquired by the unmannedaerial vehicle, the video image is converted into a test water gauge scale picture, and the test water gauge scale picture is input into the trained deep learning VGG network model to obtain a prediction result, thereby achieving the purpose of ship water gauge identification automatic detection. Calculation speed is improved. According to the invention, high-precision automatic detection of the ship waterline scale can be realized rapidly and accurately under various extreme environment conditions.

Owner:东北大学秦皇岛分校 +1

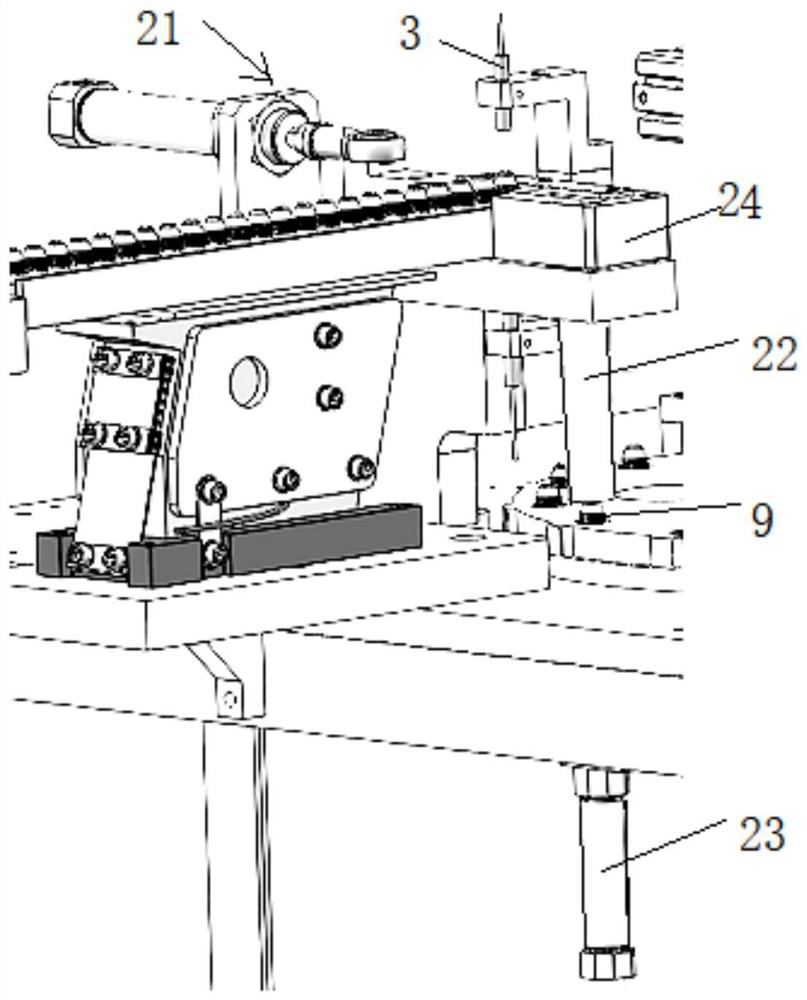

Automatic electrode detection device

PendingCN111958238ARealize automatic feeding processQuick Auto DetectAssembly machinesTransmissivity measurementsEngineeringManipulator

The invention discloses an automatic electrode detection device. The automatic electrode detection device comprises an automatic feeding component, an automatic mounting component, a hafnium wire detection component, a brass core detection component and a knurling detection manipulator. The automatic feeding component is used for conveying an electrode to be mounted to the automatic mounting component; the automatic mounting component is used for mounting the electrode in a station hole of a multi-station turntable; the hafnium wire detection component is used for detecting whether a hafnium wire is mounted on the electrode; the brass core detection component is used for detecting whether a brass core is mounted on the electrode; and the knurling detection manipulator is used for detectingwhether the surface of the electrode is knurled. According to the device, automatic feeding can be achieved, and a PLC system is combined with a mechanical structure, so that rapid, efficient and accurate automatic detection is achieved; and the installation condition or qualified condition of knurls, brass cores and hafnium wires can be detected at a time, and qualified products and unqualifiedproducts can be automatically classified.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Method and apparatus for processing pictures of mobile object

ActiveUS20050285939A1Automatic detectionAccurate automatic detectionImage enhancementTelevision system detailsRelative velocityTime series

A feature amount of an inter-mobile unit relative movement are detected as an observation amount by an observation amount detecting section 26, time series of the observation amounts are stored as an observation series into a storage section 27 to calculate a similarity of the observation series to a predetermined collision observation series by a classification section 28. A determination section 29 determines to be a collision accident if, in a case where the similarity is larger than a predetermined value, a mobile unit associated with the similarity is at rest in a stoppage prohibition area set in a storage section 30 and another mobile unit is moving, and to be a mobile unit failure if collision determination conditions except for the similarity are met. By consisting of not only a first scalar obtained by quantizing a relative velocity vector between mobile units but also a second scalar obtained by quantizing a relative position vector between mobile units as the observation amount, a relative movement between mobile units is classified in more detail. A mobile unit is tracked in units of block by a mobile unit tracking section 25 to discriminate overlapped mobile units in pictures.

Owner:SOCIONEXT INC +1

Automatic detection, profiling and sorting method for macroarray resistance strain gages

InactiveCN106345709ACompact structureNovel and reasonable designMeasurement devicesSortingData acquisitionUltimate tensile strength

The invention discloses an automatic detection, profiling and sorting method for macroarray resistance strain gages; devices used in the method include an automatic detection device, an automatic profiling device, an automatic sorting device, a computer data collection card, a bench type digital multimeter, and an output amplifying board; the automatic detection device comprises a detection frame, a detection positioning and fixing mechanism and a detection mechanism; the automatic profiling device comprises a profiling frame, a profiling positioning and fixing mechanism, and a profiling mechanism; the automatic sorting device comprises a sorting frame, a sorting positioning and fixing mechanism, a suction sorting mechanism and a positioning sorting mechanism; the method includes the steps of first, automatically detecting macroarray resistance strain gages; second, automatically profiling the macroarray resistance strain gages; third, automatically sorting the macroarray resistance strain gages. The method enables production efficiency to be improved, and labor intensity of workers and production cost to be reduced.

Owner:SHAANXI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com