Visual inspection equipment for elastic sheets

A technology of visual inspection and visual inspection devices, which is applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc., which can solve problems such as inconvenient operation, low production efficiency, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

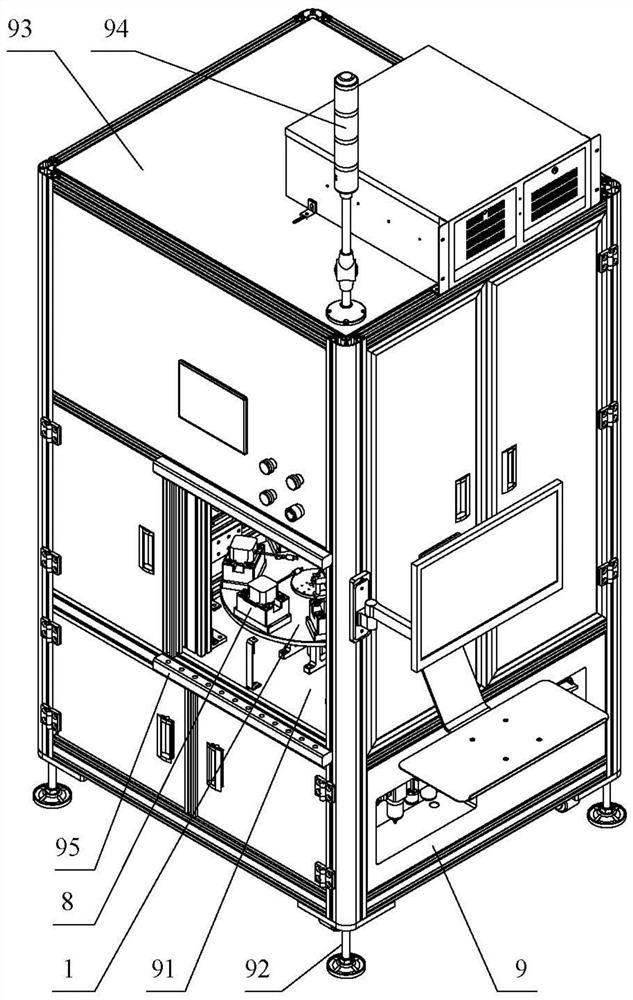

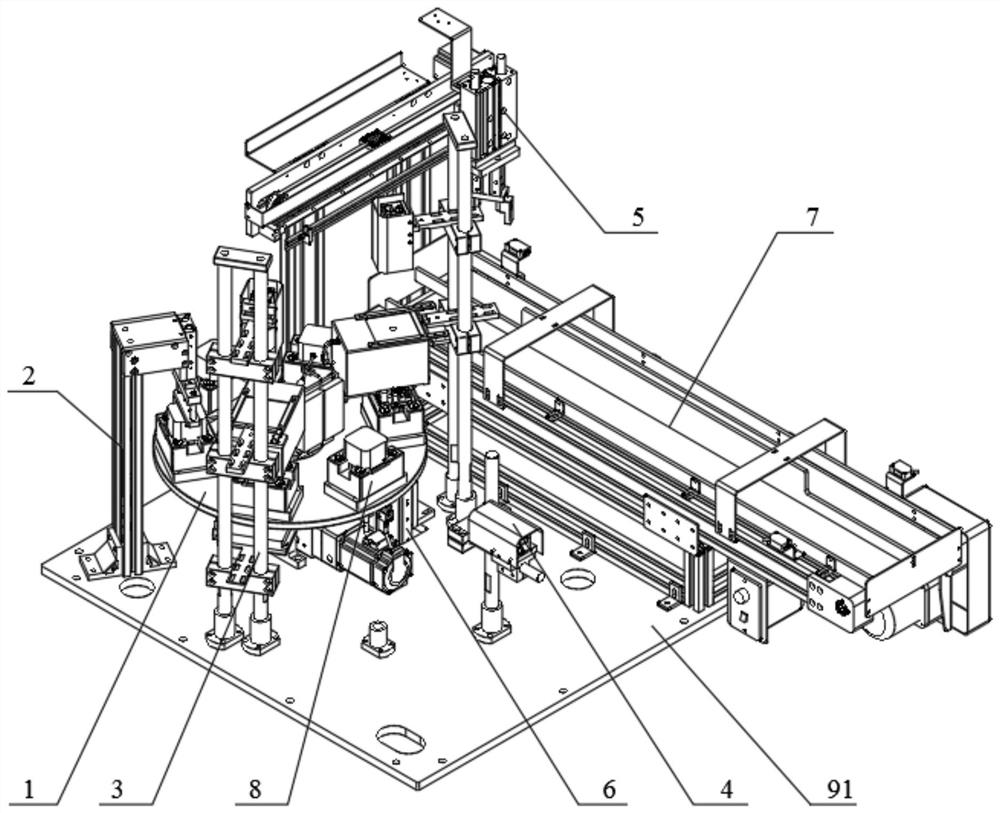

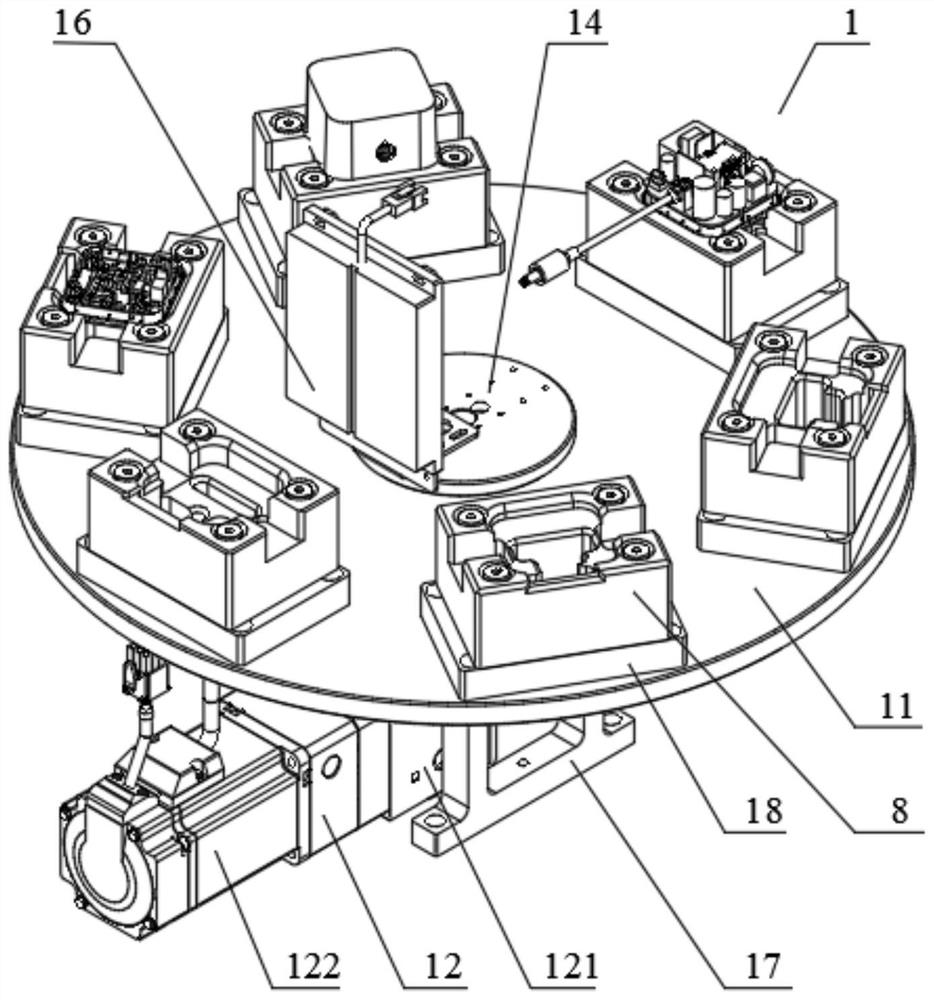

[0035] Such as Figure 1-12 As shown, a visual inspection device for shrapnel is mainly used in the production process of power adapters for electronic products such as mobile phones, notebook computers, tablet computers, and Bluetooth headsets. After shrapnel is riveted on the housing of the power adapter, the shrapnel is detected. Whether the horizontal direction is deformed, whether the vertical direction is deformed, whether the state of the riveting point is OK, whether it is assembled in place, etc. The visual detection equipment usually includes a frame 9, and the working base 91 of the frame 9 at least includes a rotary table 1, a conveying device 7, a correction device 2 corresponding to the rotary table 1, at least one upper visual detection device 3, Horizontal visual inspection device 4, material retrieving manipulator 5 and jacking mechanism 6, a number of positioning fixtures 8 for placing products are arranged on the rotary table 1, and a first conveying section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com