Patents

Literature

57results about How to "Precise automatic positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thunder and lightning locator with sound sensors and locating method thereof

InactiveCN101799560AImprove stabilityQuick responseUsing reradiationData processing systemHyperboloid

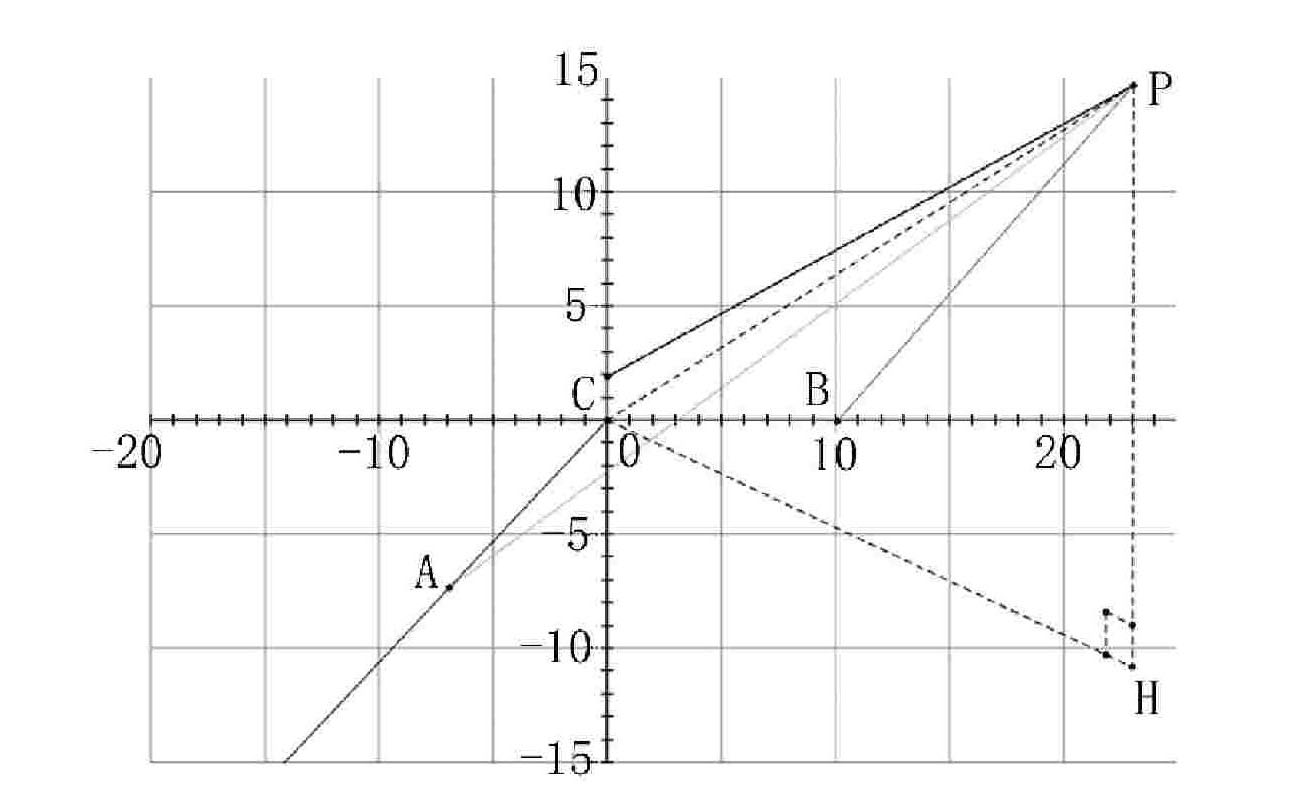

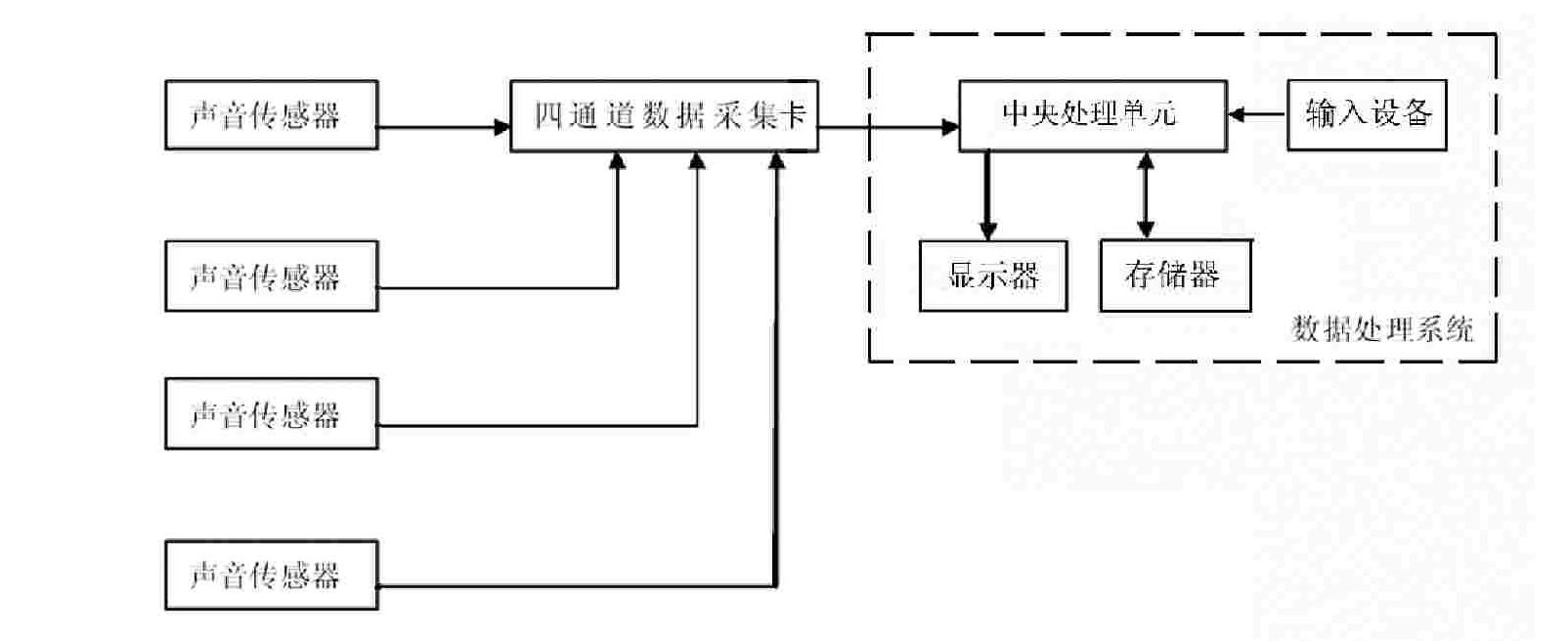

The invention relates to a thunder and lightning locator with sound sensors and a locating method thereof. The thunder and lightning locator comprises four sound sensors, a four-passage data acquisition card and a data processing system, wherein the four sound sensors are distributed on four observing points; when thunder and lightning occur, the sound sensors positioned on the four space observing points respectively record the thunder reaching time of the observing points; four groups of time data are converted from A / D (analog to digital) by the four-passage data acquisition card and then transmitted to the data processing system; the data processing system solves the difference of the thunder reaching time of three space observing points through logical operation and computes the difference of the distances of the three space observing points according to the propagation speed of sound in the air; and a coordinate of a thunder and lightning generation position is determined according to an equation set and a principle that a point can be determined by intersecting three hyperboloids in space. The invention ensures high measurement precision, also simplifies a locating measurement method, reduces the hardware requirements and the equipment cost, realizes the accurate automatic locating of the thunder and lightning and can be widely used in the field of meteorological sounding.

Owner:CMA METEOROLOGICAL OBSERVATION CENT

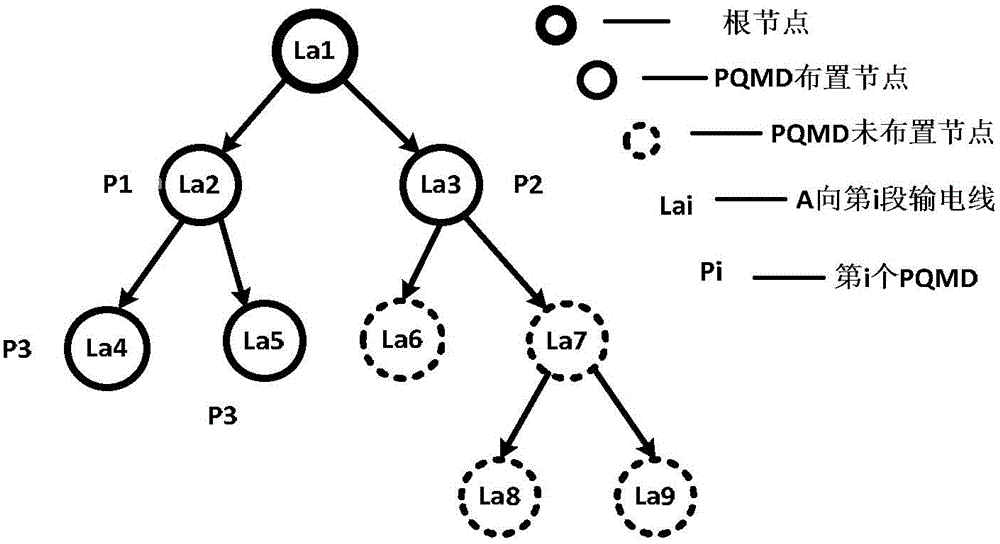

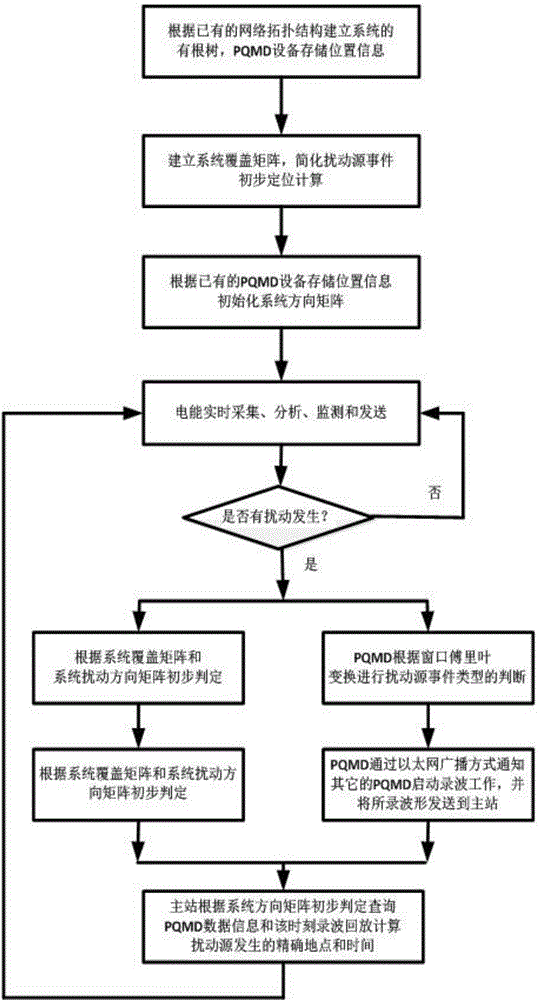

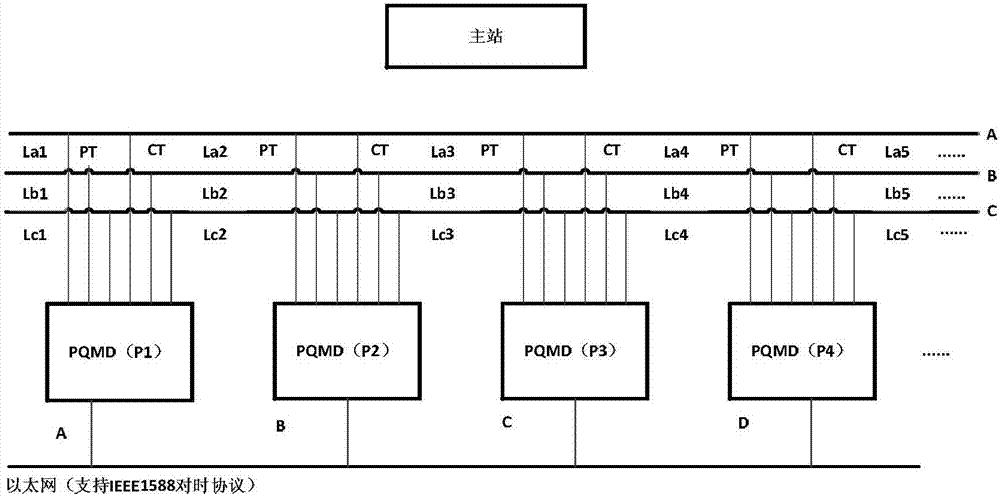

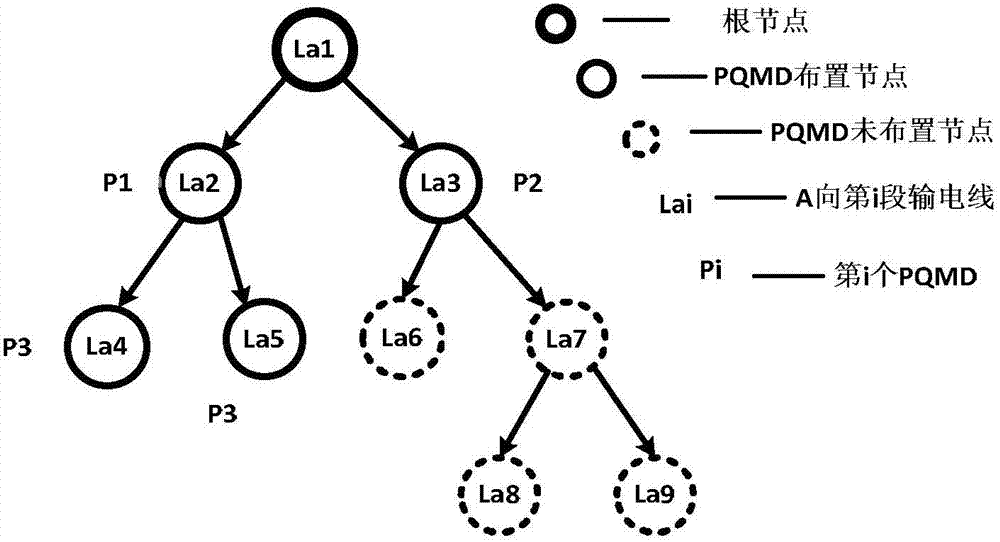

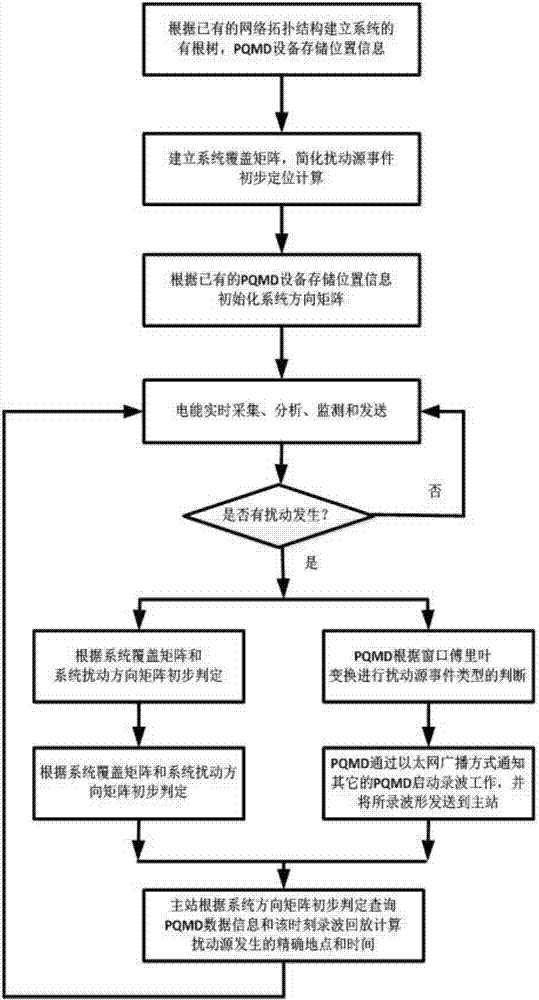

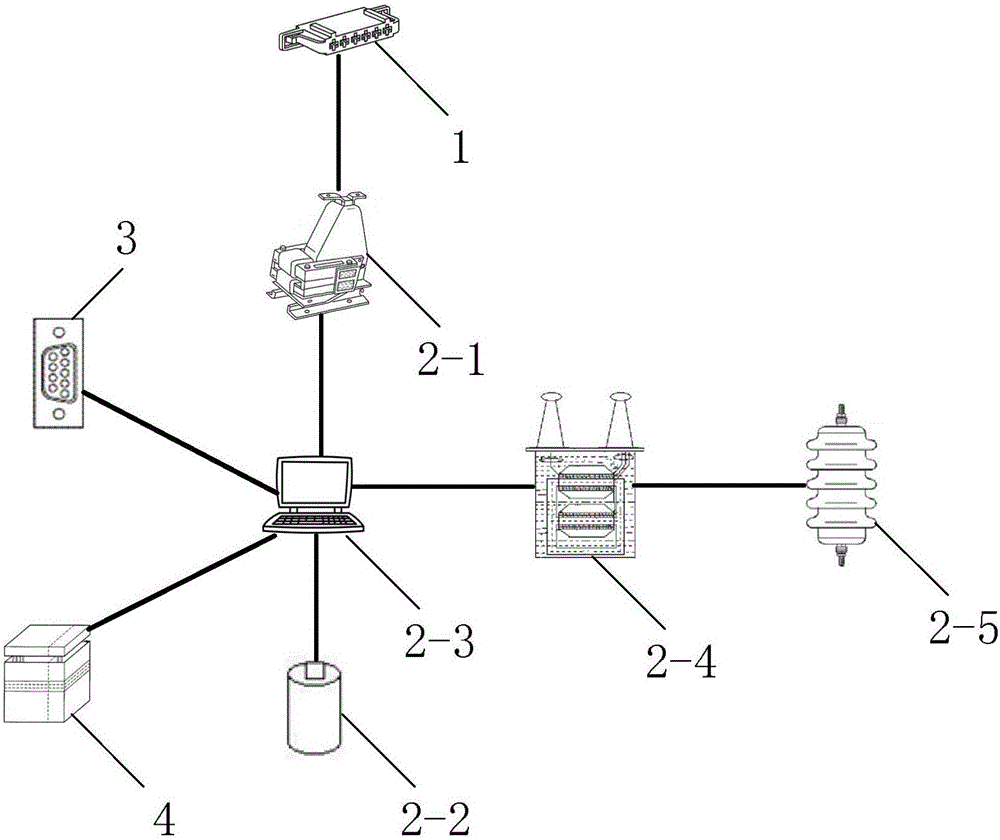

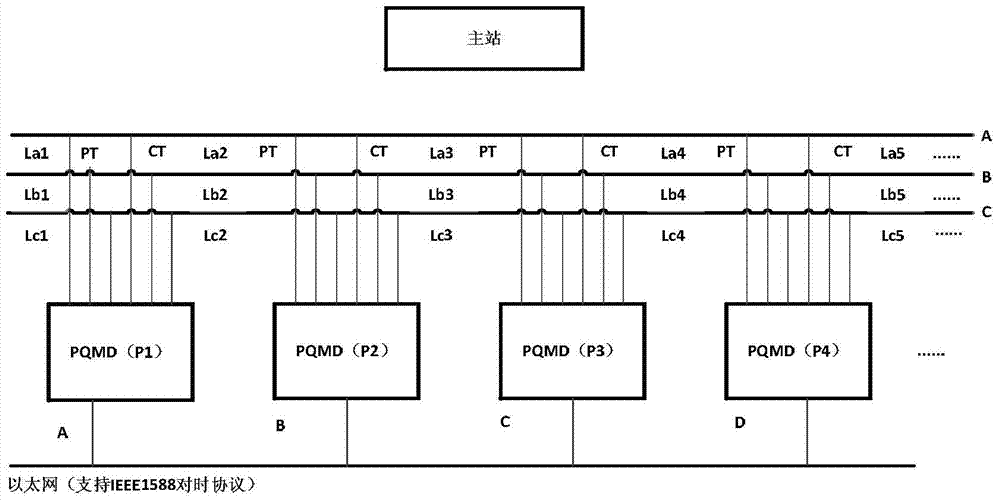

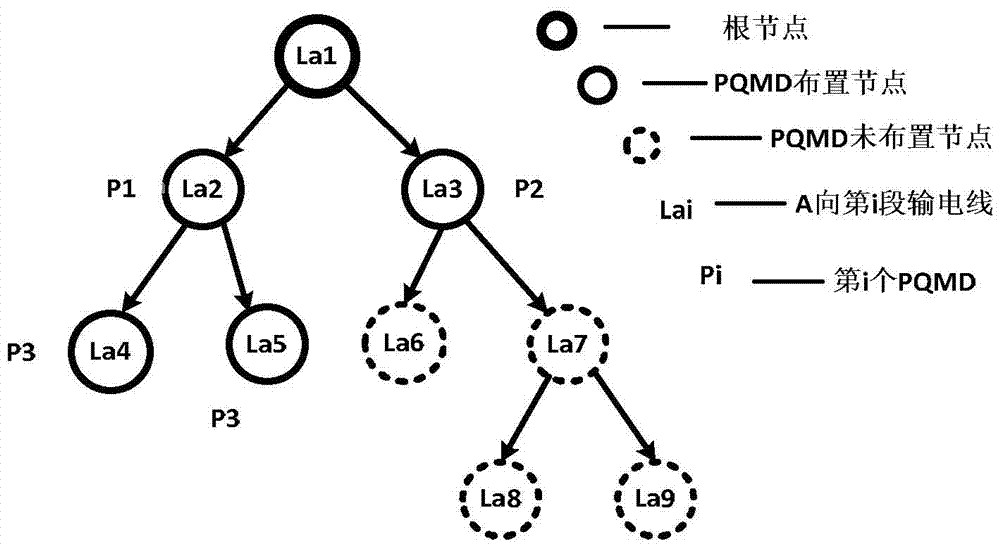

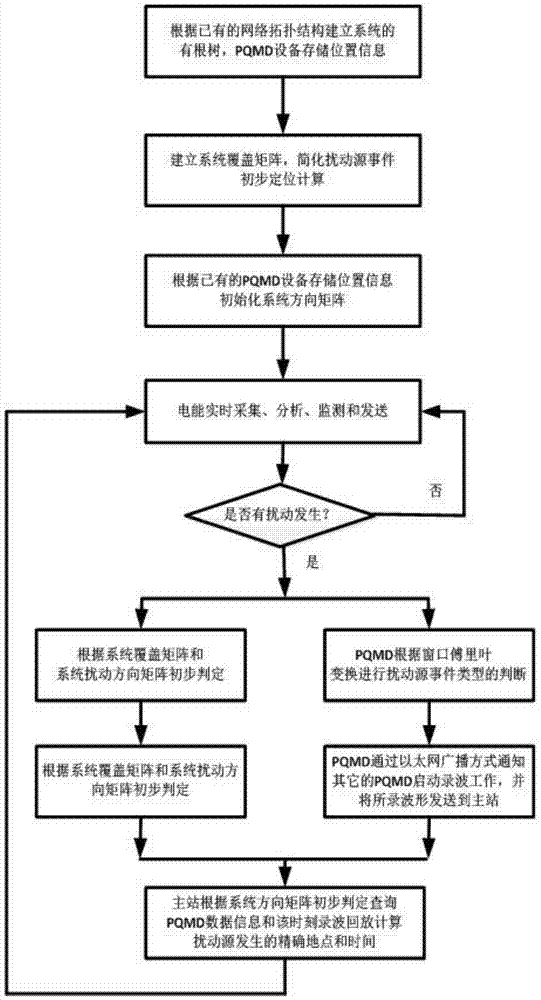

Positioning system and method for electric energy quality disturbance source

ActiveCN104635114ASimple structurePrecise automatic positioningFault locationPower qualityDistribution power system

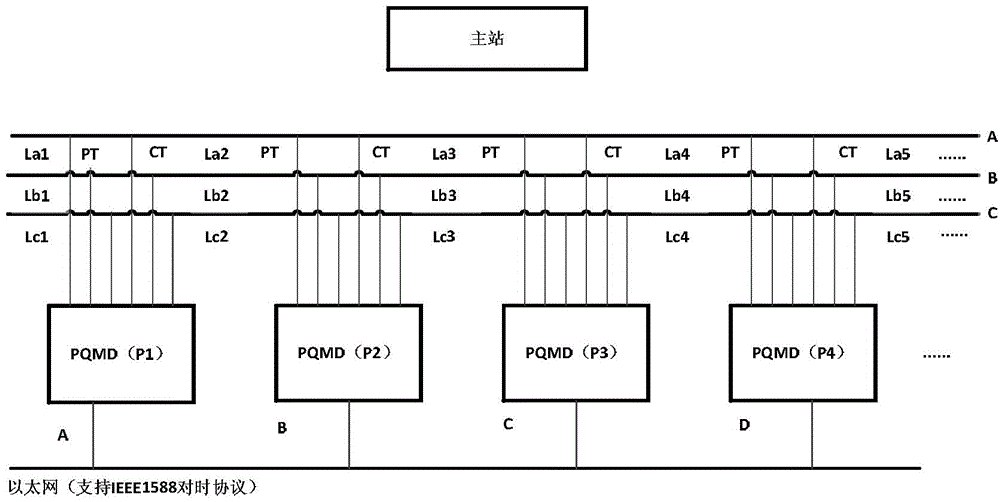

The invention relates to a positioning system and a positioning method for an electric energy quality disturbance source. The positioning system comprises online electric energy quality monitoring devices, wherein each online electric energy quality monitoring device is connected between every two master electric energy quality management stations through the Ethernet. Each online electric energy quality monitoring device is arranged at a monitoring point of a power transmission line of a radiation type power distribution system, and every two online electric energy quality monitoring devices are connected through the Ethernet; when an actual disturbance event occurs in the system, one of the online electric energy quality monitoring devices detects the disturbance event, then records an occurrence moment of the disturbance source, informs the other online electric energy quality monitoring devices in the network through the Ethernet in a broadcasting way to start a disturbance wave recording system on the basis of the moment, records sampling data of N cycles before the moment and N cycles after the moment, and sends the sampling data to the master electric energy quality management stations in real time; through the mutual cooperation of all the online electric energy quality monitoring devices, a system coverage matrix and a system direction matrix are established, and then the disturbance source is positioned.

Owner:JIANGSU ELECTRIC POWER CO +2

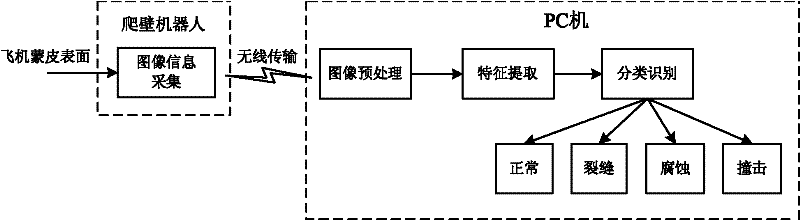

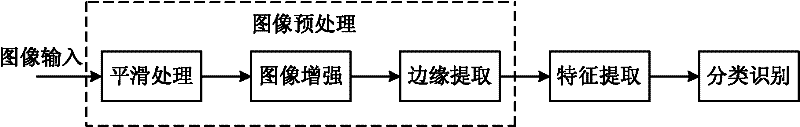

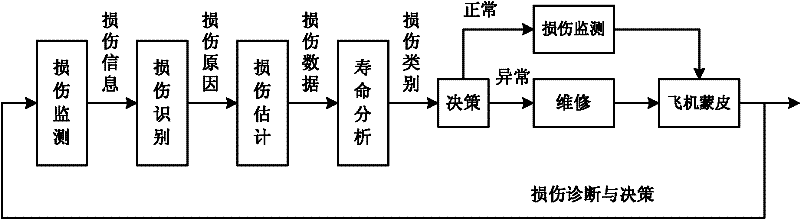

Aircraft skin structure monitoring method based on wireless machine vision

InactiveCN102355569ASimple structureGo cablelessCharacter and pattern recognitionClosed circuit television systemsWorkstationVisual perception

The invention, which belongs to the aircraft skin structure health monitoring field, discloses an aircraft skin structure monitoring method based on wireless machine vision. In the method, a wall-climbing robot, which is equipped with an image acquisition apparatus, is used to move on an aircraft skin surface so as to real-timely collect skin image information; the skin image information is sent to a PC machine in a work station through wireless communication; the PC machine carries out image preprocessing, image feature extraction, classification and identification to the image information and finally gives a skin damage diagnosis and decision according to an identification result. By using the method of the invention, an untethered operation of the aircraft skin structure monitoring can be realized, simultaneously continuity of the monitoring can be guaranteed and accuracy and working efficiency of the monitoring can be raised.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

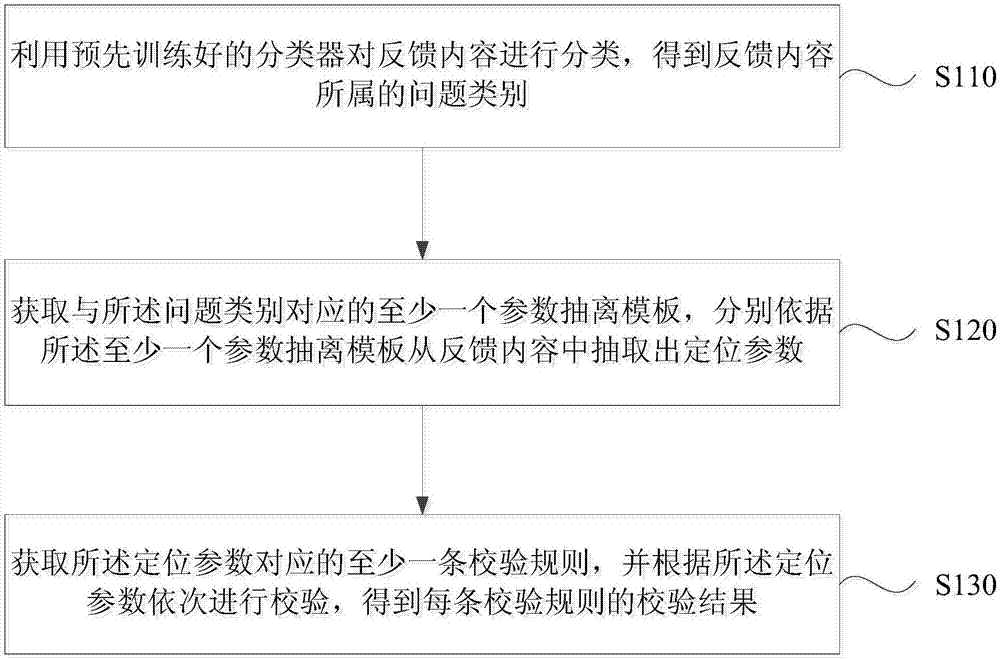

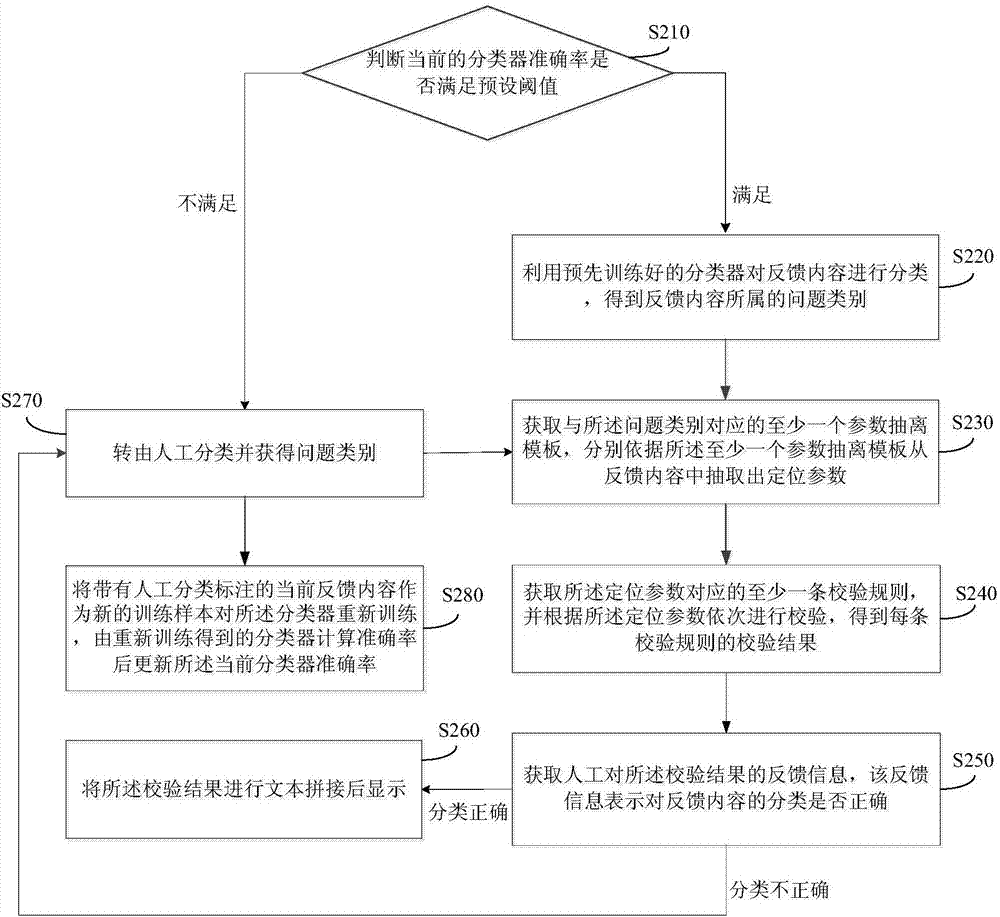

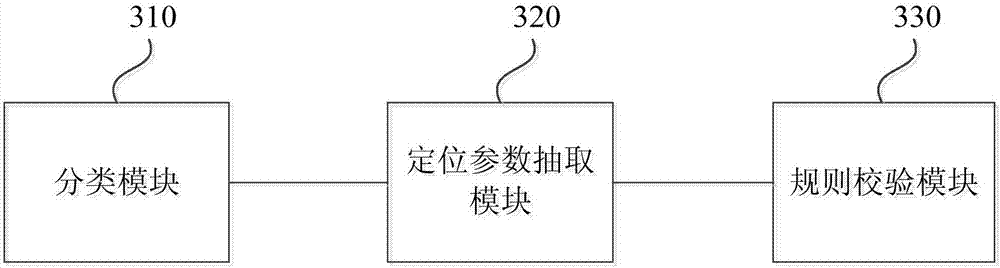

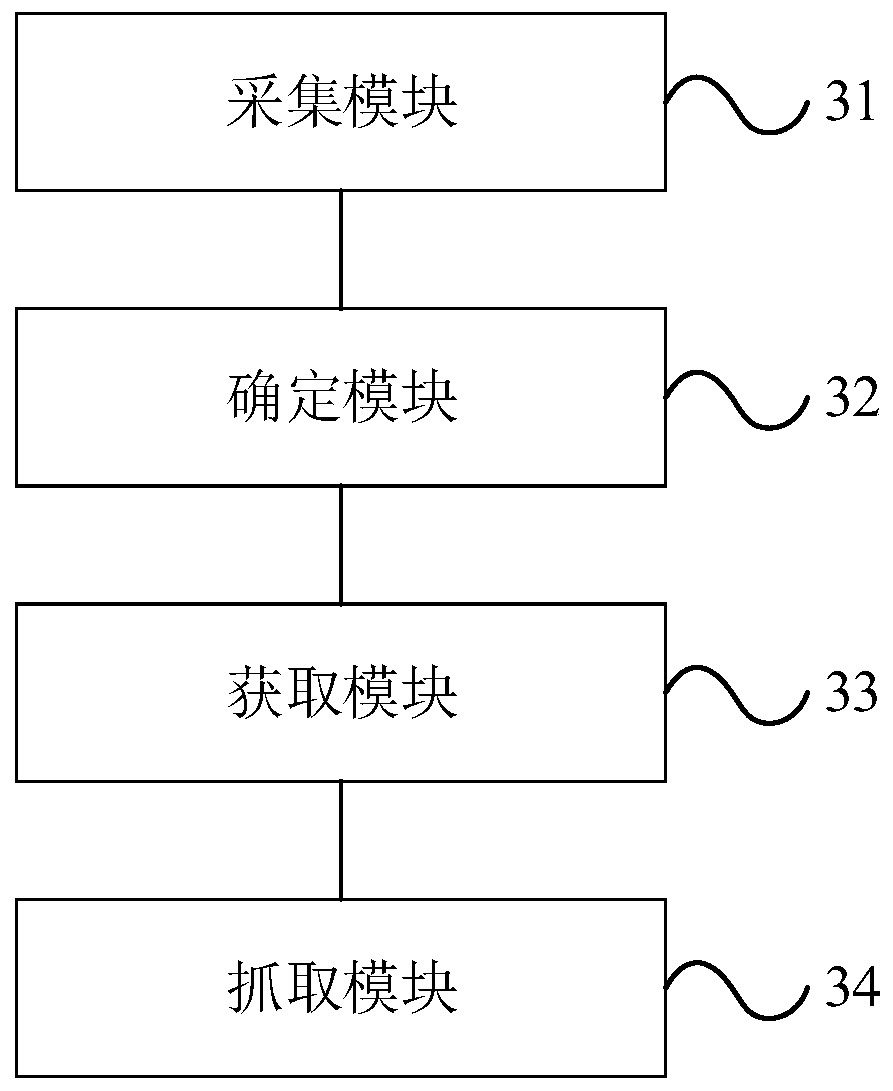

Problem locating method and device of feedback contents, computer equipment and storage medium

ActiveCN107330471APrecise automatic positioningVersatilityCharacter and pattern recognitionData miningData science

Embodiments of the invention disclose a problem locating method and device of feedback contents, computer equipment and a storage medium. The method comprises the following steps: classifying the feedback contents by utilizing a pre-trained classifier to obtain problem categories to which the feedback contents belong; obtaining at least one parameter extraction template corresponding to the problem categories, and extracting locating parameters from the feedback contents respectively according to the at least one parameter extraction templates; and obtaining the at least one verification rule corresponding to the locating parameters, and successively performing verification according to the locating parameters to obtain verification results of the verification rules. A problem is located through classification for the feedback contents, locating parameter extraction and rule verification, so accurate automatic locating for a feedback problem can be achieved and be universal.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

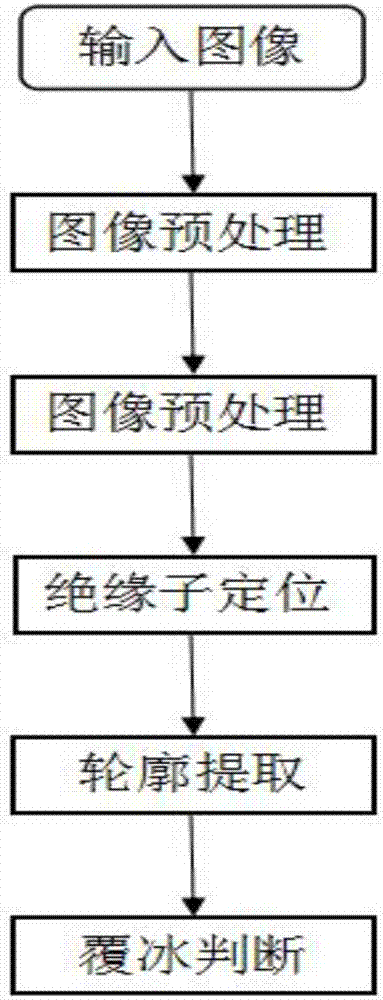

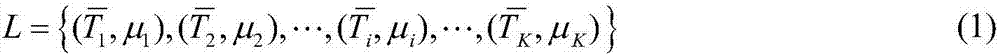

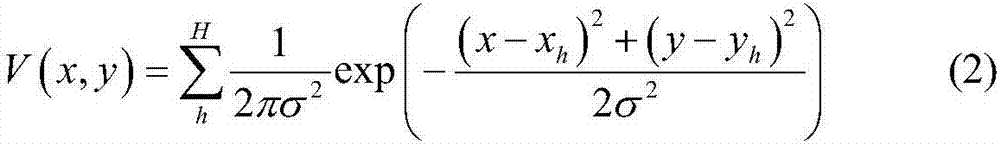

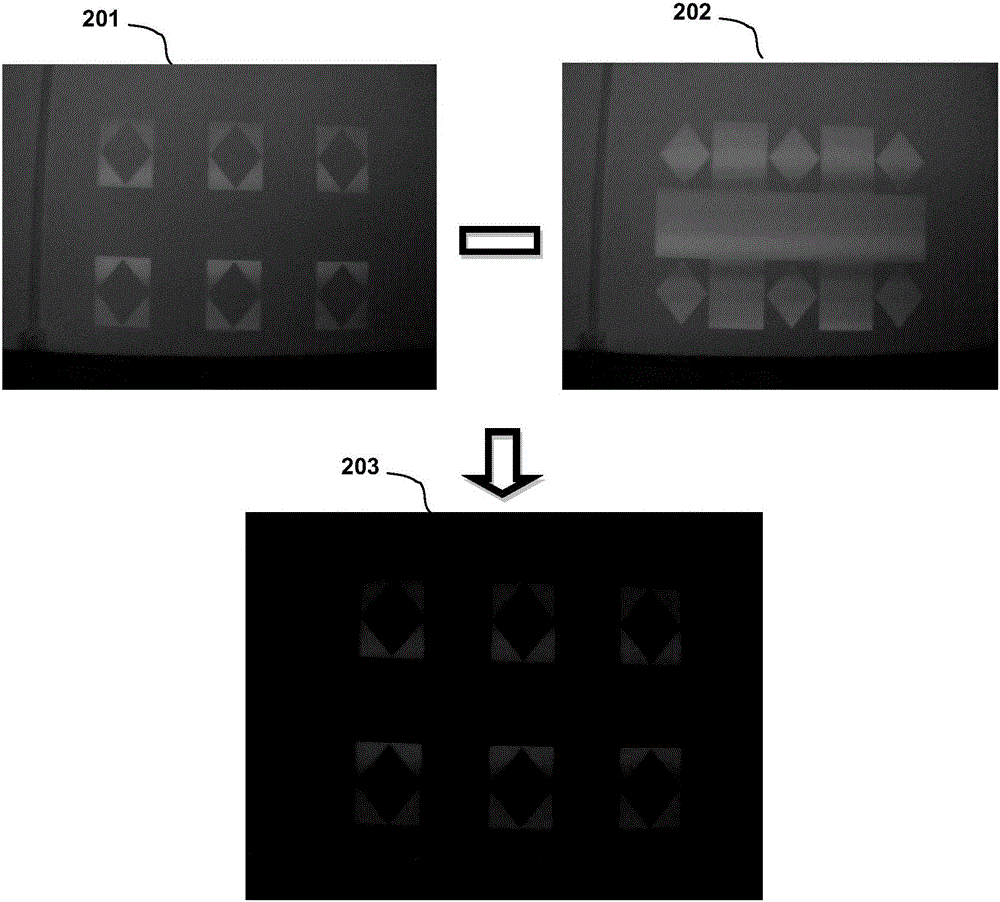

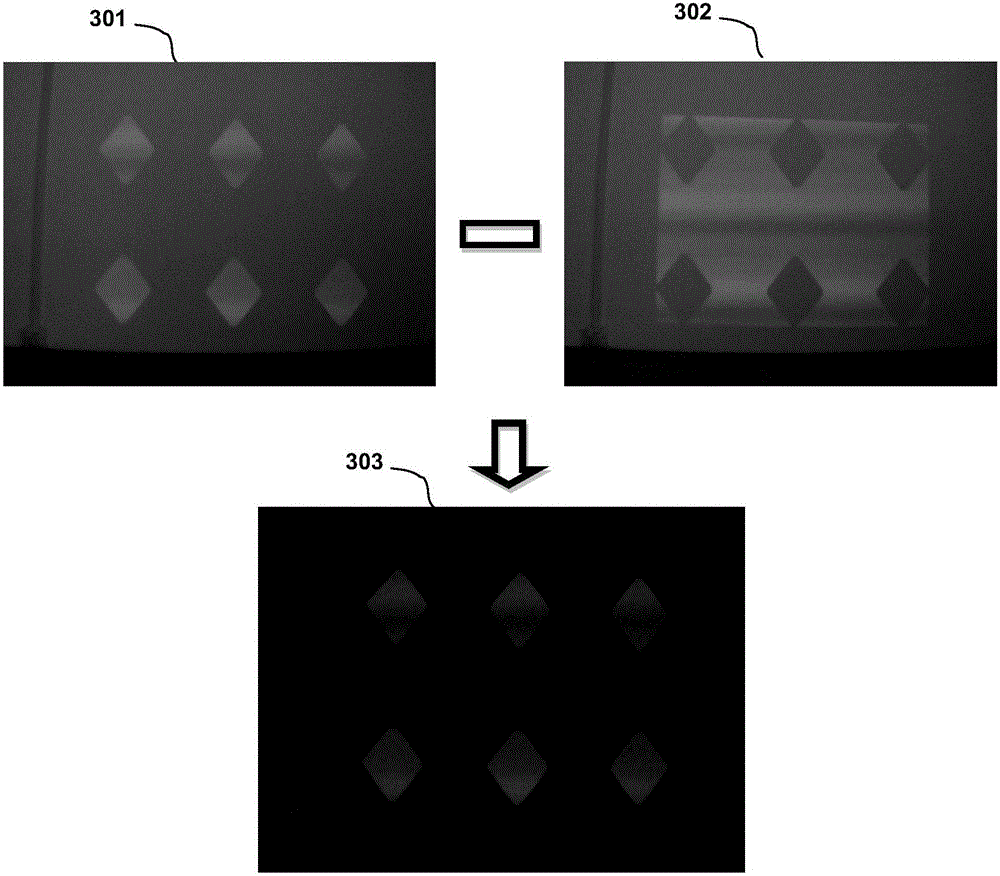

Insulator icing detection method based on GLOH descriptor and GVF-Snake model

ActiveCN107358259APrecise positioningPrecise automatic positioningCharacter and pattern recognitionAlgorithmIcing conditions

The invention discloses an insulator icing detection method based on a GLOH descriptor and a GVF-Snake model. The method comprises steps that 1, an input image is pre-processed; 2, a target area of interest is extracted, and the area contains the insulator information; 3, the GLOH descriptor is utilized to position an insulator; 4, the GVF-Snake model is utilized to precisely detect insulator contour; and 5, the insulator contour is analyzed, whether the insulator is in an icing state is determined through calculating the maximum radial distance, and icing thickness is calculated under the icing condition. The method is advantaged in that a problem of difficulty in distinguishing the insulator from the complex background existing in a traditional method can be solved, and insulator icing condition determination accuracy can be effectively improved.

Owner:STATE GRID CORP OF CHINA +3

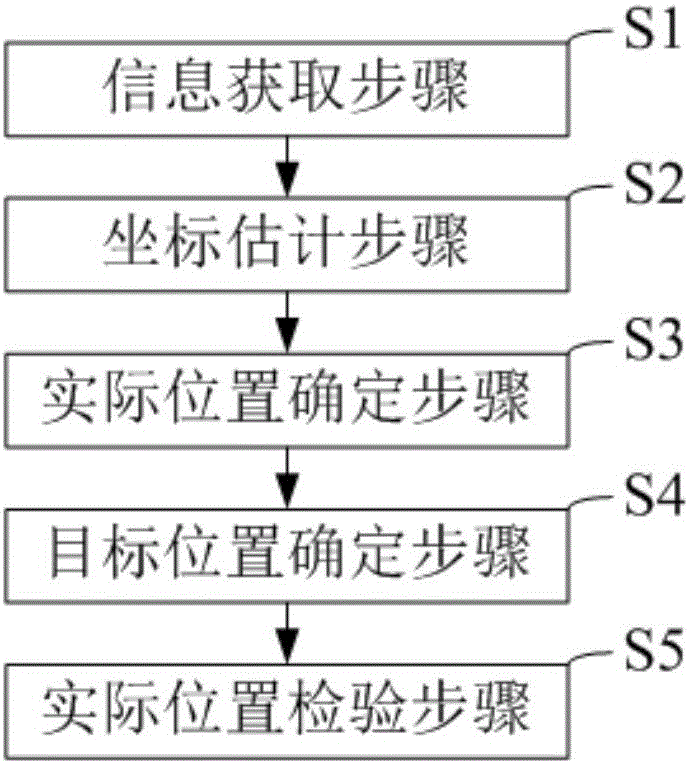

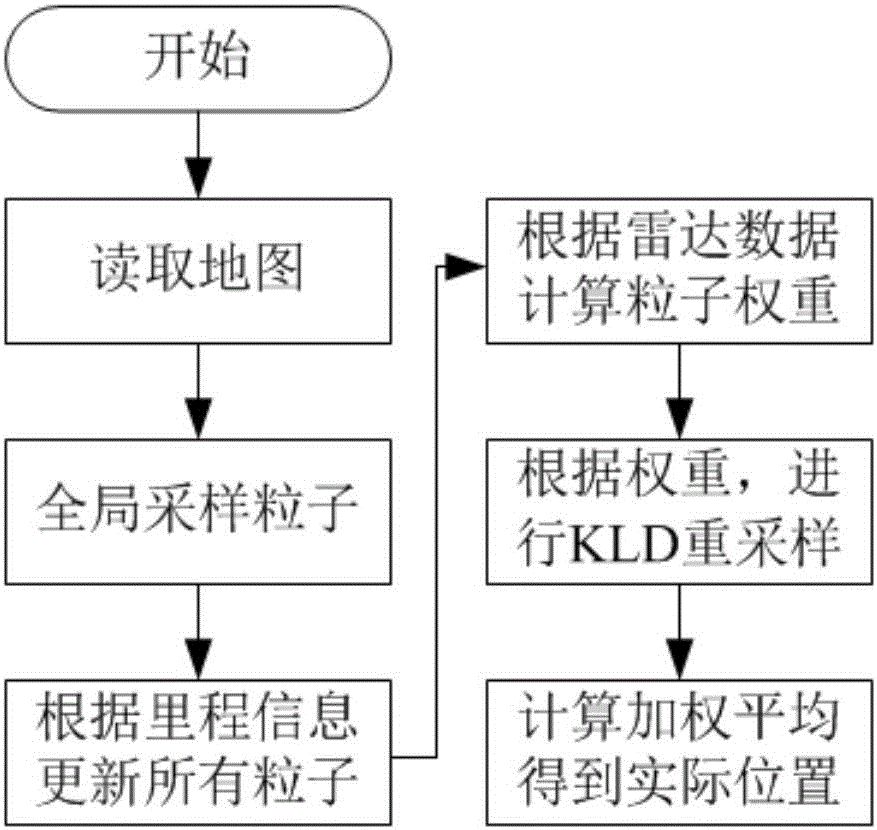

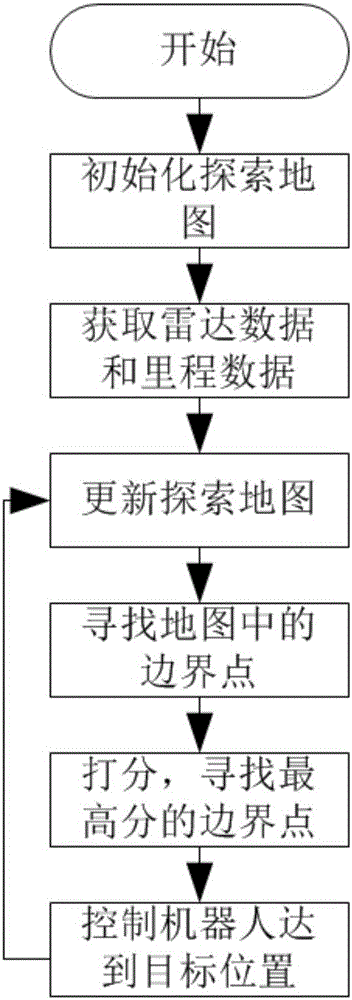

Robot positioning method based on self-positioning and edge searching and system

ActiveCN106441279AQuick and automatic positioningPrecise automatic positioningNavigational calculation instrumentsWeight valueSearch algorithm

The invention belongs to the technical field of robot self-positioning and provides a robot positioning method based on self-positioning and edge searching and a system. The method comprises the following steps: acquiring environmental information around a robot, time information and mileage information; estimating the relative position; acquiring the current position of each particle; confirming a practical position of the robot according to a weighted value and the current position of each particle; scoring a boundary point on the basis of an edge searching algorithm; setting the boundary point with the highest score as a target position of the robot according to a scoring result of the boundary point; moving the robot to the target position; checking if the practical position is correct according to the quantity of the particle and outputting a correct practical position. The robot positioning method based on self-positioning and edge searching and the system, provided by the invention, can increase the robot self-positioning precision and speed, can prevent positioning error, can widen the application scene and can be easily popularized.

Owner:SUGAN TECH BEIJING

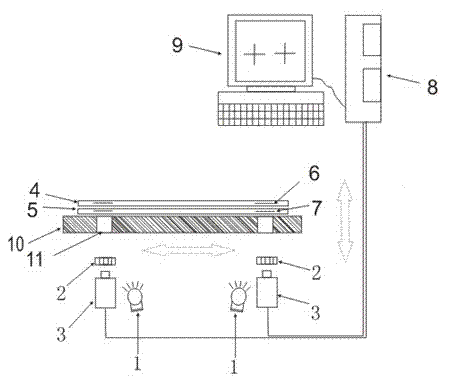

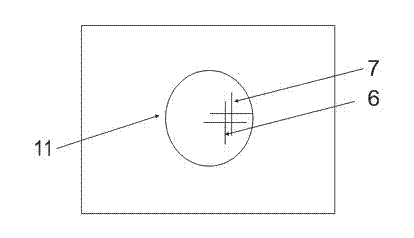

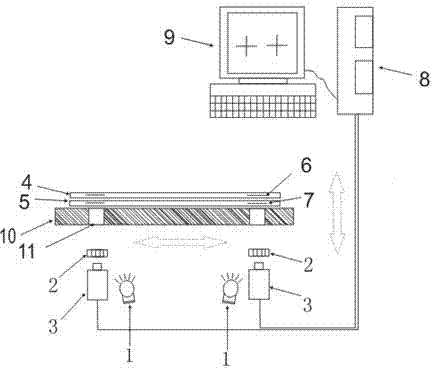

ITO (indium tin oxide) membrane photoetching automatic recognition positioning method

InactiveCN102338995AReduce transmittanceEasy to catchPhotomechanical exposure apparatusMicrolithography exposure apparatusUltraviolet lightsIndium tin oxide

The invention discloses an ITO (indium tin oxide) membrane photoetching automatic recognition positioning method. The method is characterized in that two ultraviolet light sources, two sets of CCD (charge coupled device) imaging devices and two sets of imaging optical systems are arranged under a mask plate and a membrane; two sets of CCD imaging devices shot the left and right alignment marks at the bottoms of the mask plate and the membrane through two sets of imaging optical systems, an image acquiring card acquires image data and inputs the image data to a computer to process, position and real-time display the alignment mark images, and a position of the membrane is regulated through a relative position error of the left and right alignment mark images of the mask plate and the membrane displayed on the screen of the computer, thereby automatically and accurately aligning the membrane and the mask plate. The ITO membrane photoetching automatic recognition positioning method has simple structure, convenience for operation, high automatic imaging clear accuracy of 3-5 microns and high photoetching processing quality.

Owner:DONGGUAN RUNHUA OPTOELECTRONICS

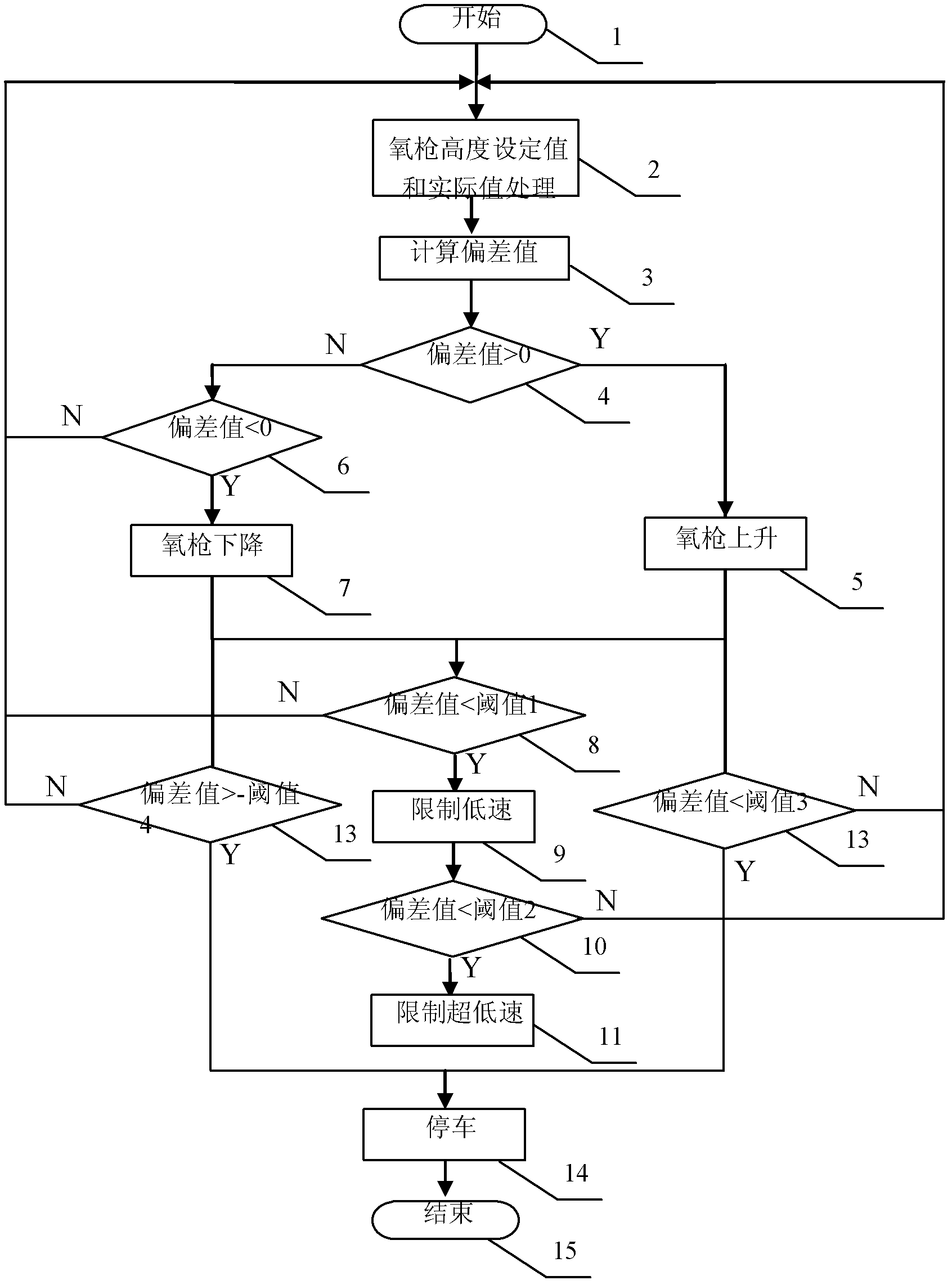

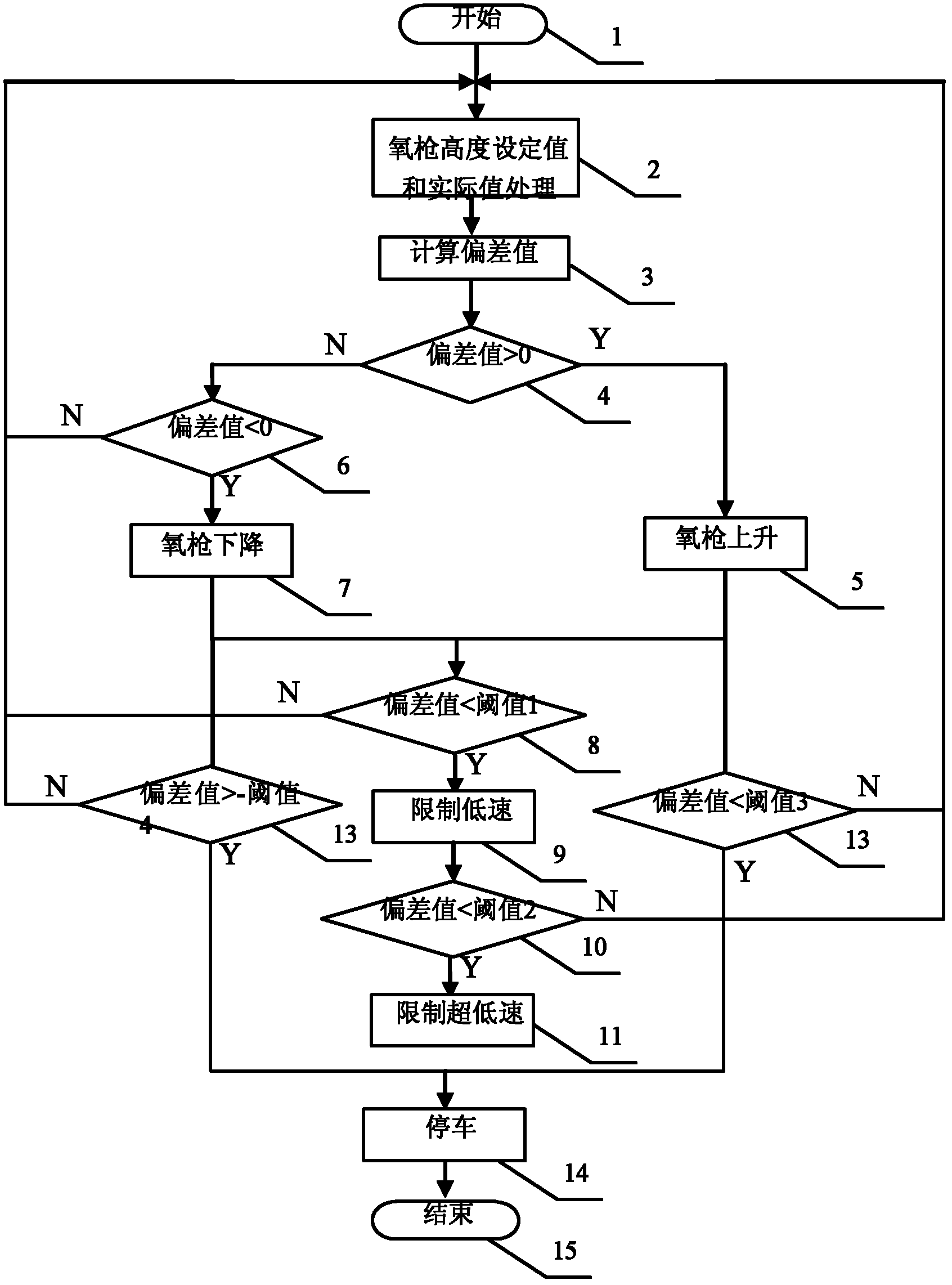

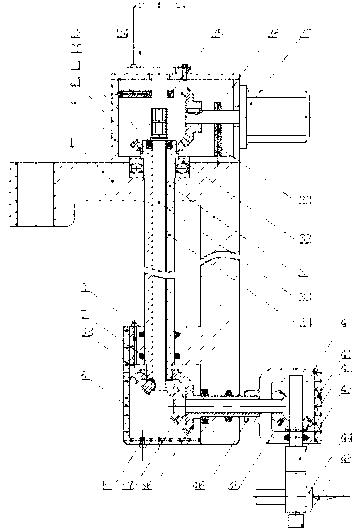

Automatic positioning and controlling method for oxygen lance of converter

InactiveCN102220450APrecise automatic positioningQuick and automatic positioningManufacturing convertersLow speedOxygen

The invention relates to an automatic positioning and controlling method for an oxygen lance of a converter. The method comprises the following steps of: setting the relative height set value of the oxygen lance and acquiring the relative height actual value of the oxygen lance by an absolute value encoder detecting calculation method; calculating a deviation value, wherein the deviation value is acquired by subtracting the relative height actual value from the relative height set value; lifting the oxygen lance at a high speed when the deviation value is greater than 0; descending the oxygen lance at a high speed when the deviation value is less than 0; limiting the rising or falling speed of the oxygen lance at a low speed when the deviation value is less than a first threshold value and greater than a second threshold value; limiting the rising or falling speed of the oxygen lance at an ultralow speed when the deviation value is less than the second threshold value; stopping lifting the oxygen lance when the deviation value is less than a third threshold value; and stopping descending the oxygen lance when the deviation value is greater than a negative fourth threshold value. The automatic positioning and controlling method provided by the invention can quickly and accurately position the oxygen lance at the specified relative height, completely avoiding the overshoot and oscillation.

Owner:武钢集团有限公司

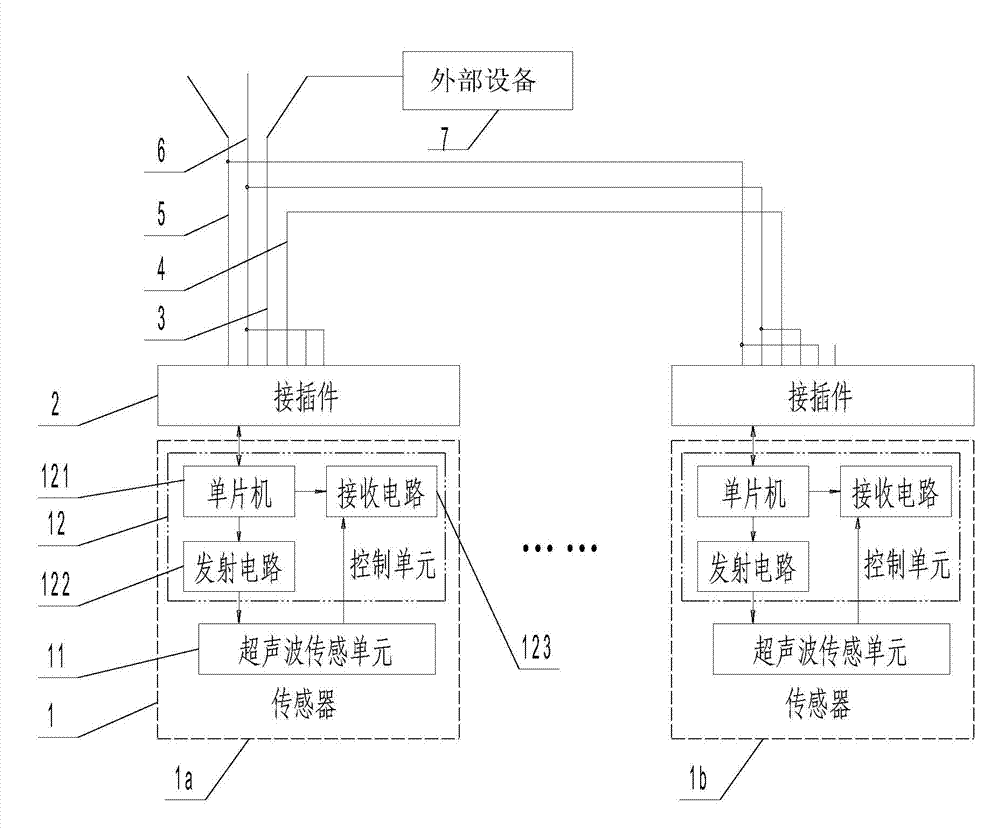

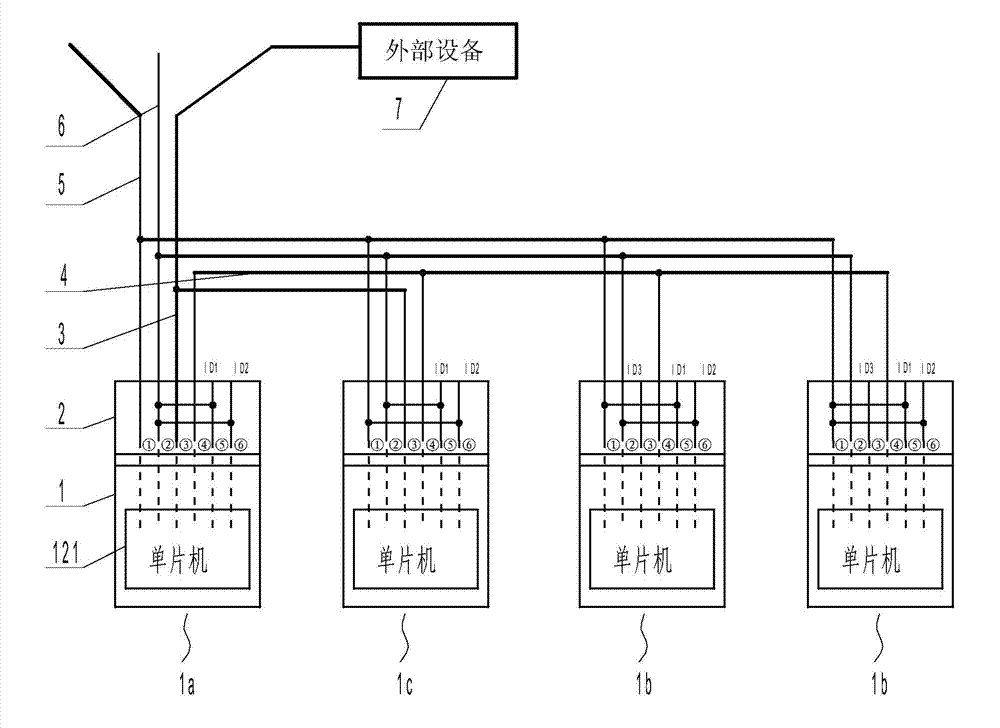

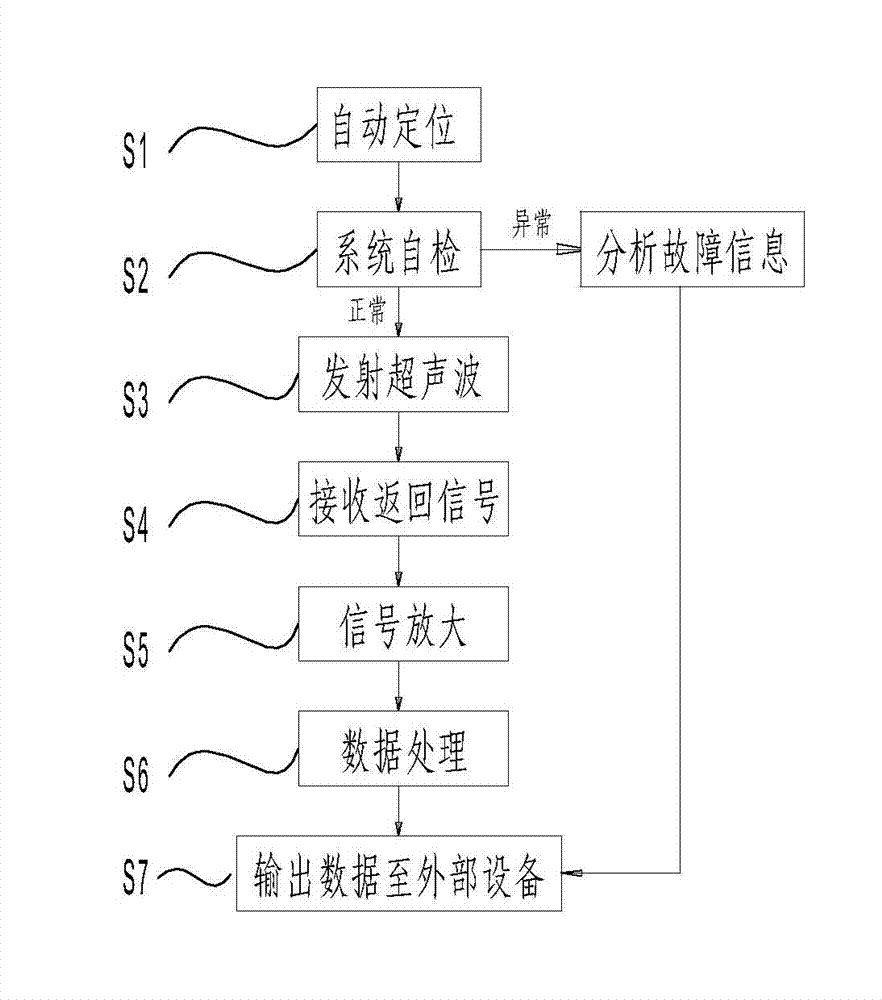

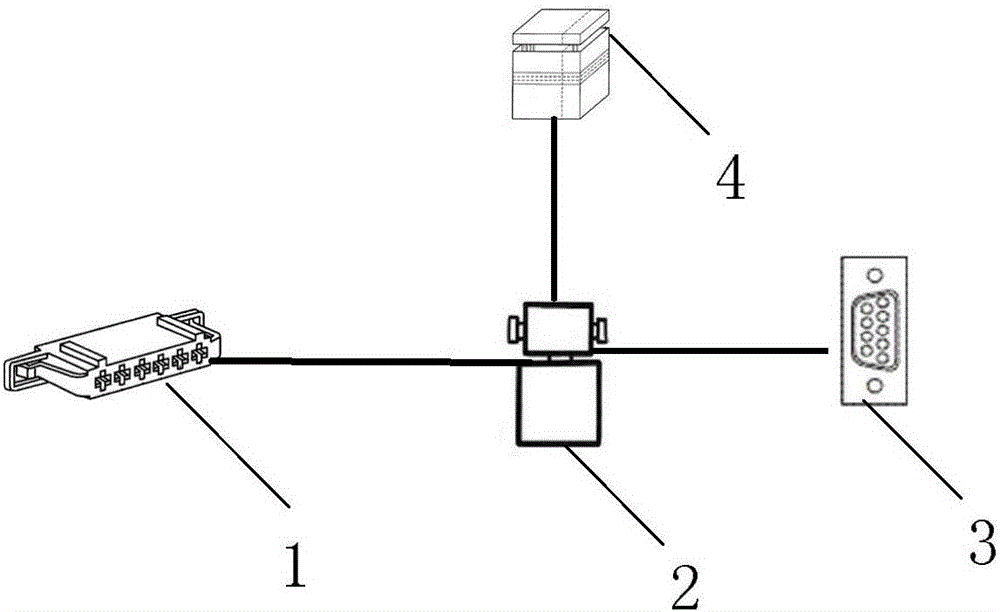

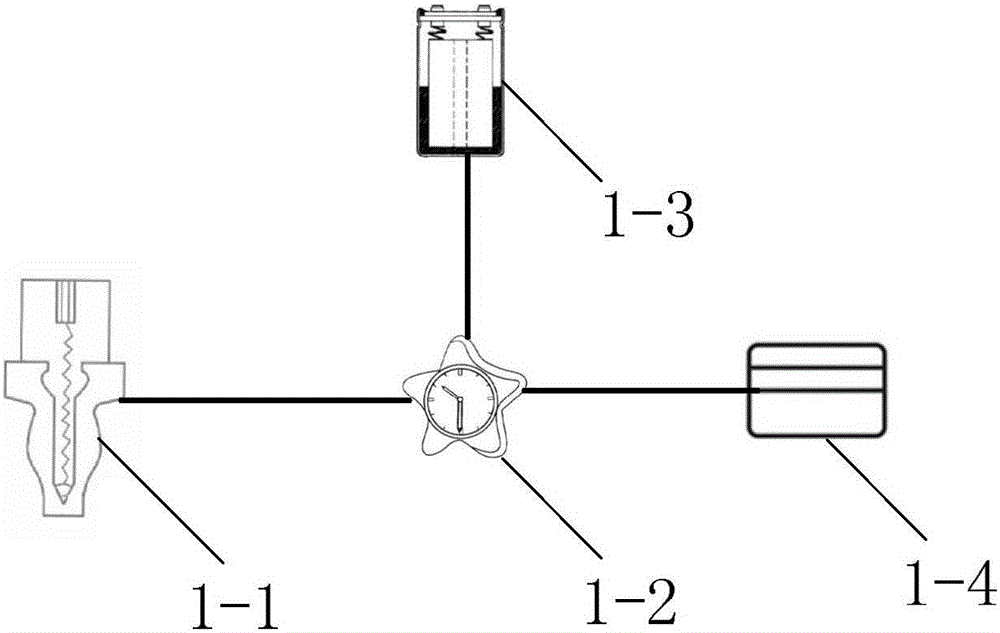

Intelligent reversing radar system and automatic control method thereof

InactiveCN103499817ASimple hardware circuitAvoid multiple wiring harnessesVehicle componentsAcoustic wave reradiationRadar systemsAutomatic control

An intelligent reversing radar system and an automatic control method thereof relate to a radar system and a control method thereof. The system comprises at least two sensors; each sensor comprises an ultrasonic sensing unit and a control unit; each control unit comprises a single-chip microcomputer, an emitting circuit and a receiving circuit, which are connected in sequence; the single-chip microcomputer of each sensor is connected with a connector; the single-chip microcomputer of the main control sensor is connected with external equipment by an external data line; all single-chip microcomputers are connected by an internal communication line and are respectively connected with a reversing lamp signal line and a grounding line. The method comprises the steps that the system is subjected to self-inspection after all sensors realize automatic positioning; the system emits an ultrasonic wave and receives a returning signal; the signal is subjected to data processing after being amplified and is finally output to the external equipment by the main control sensor. According to the intelligent radar reversing radar system and the automatic control method thereof, a hardware circuit can be simplified, the performances are stable and reliable, the positions of the sensors can be fast and accurately identified, and the radar system can be simply and reliably controlled and is suitable for the configuration of different vehicle models.

Owner:柳州市华航电器有限公司

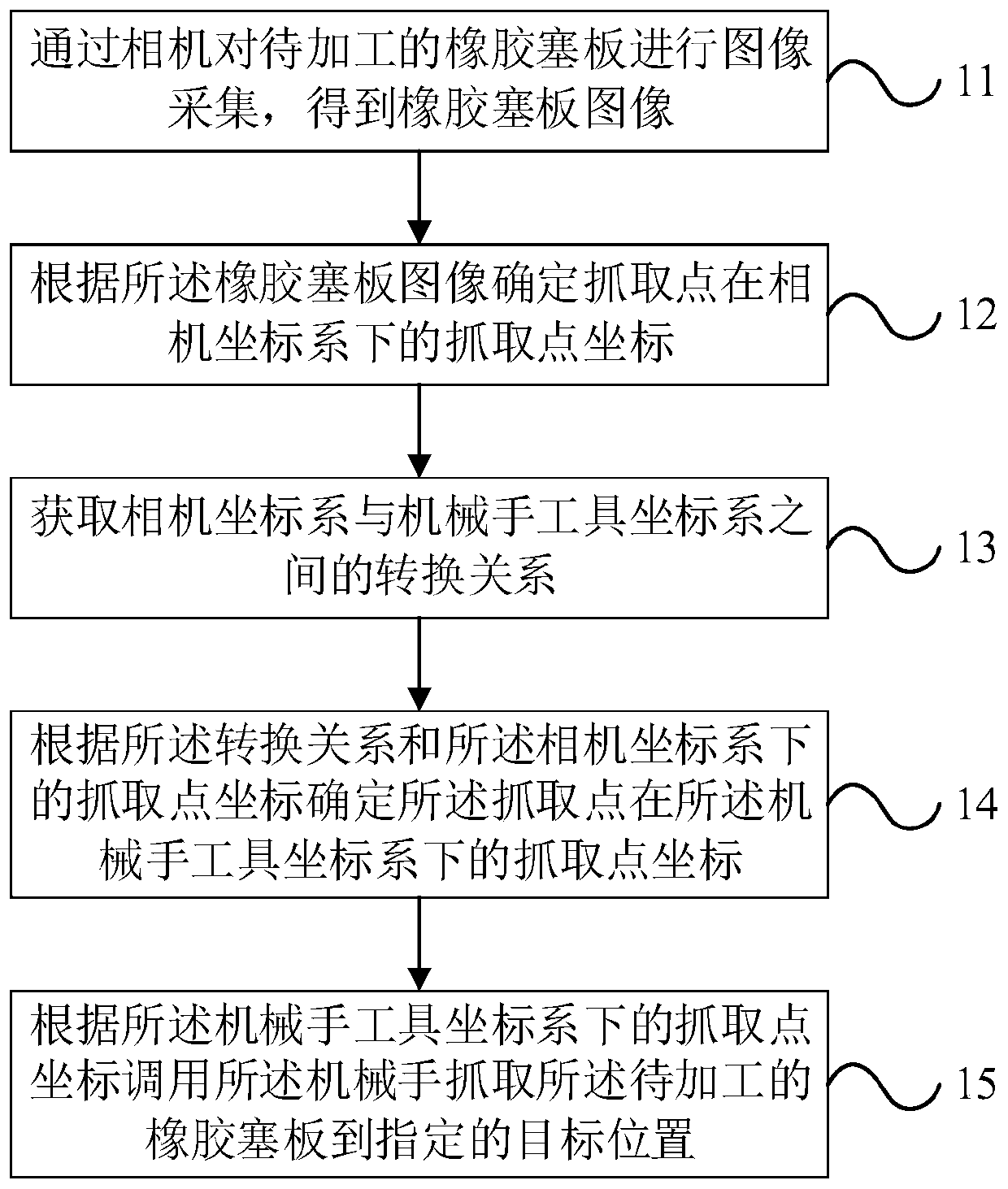

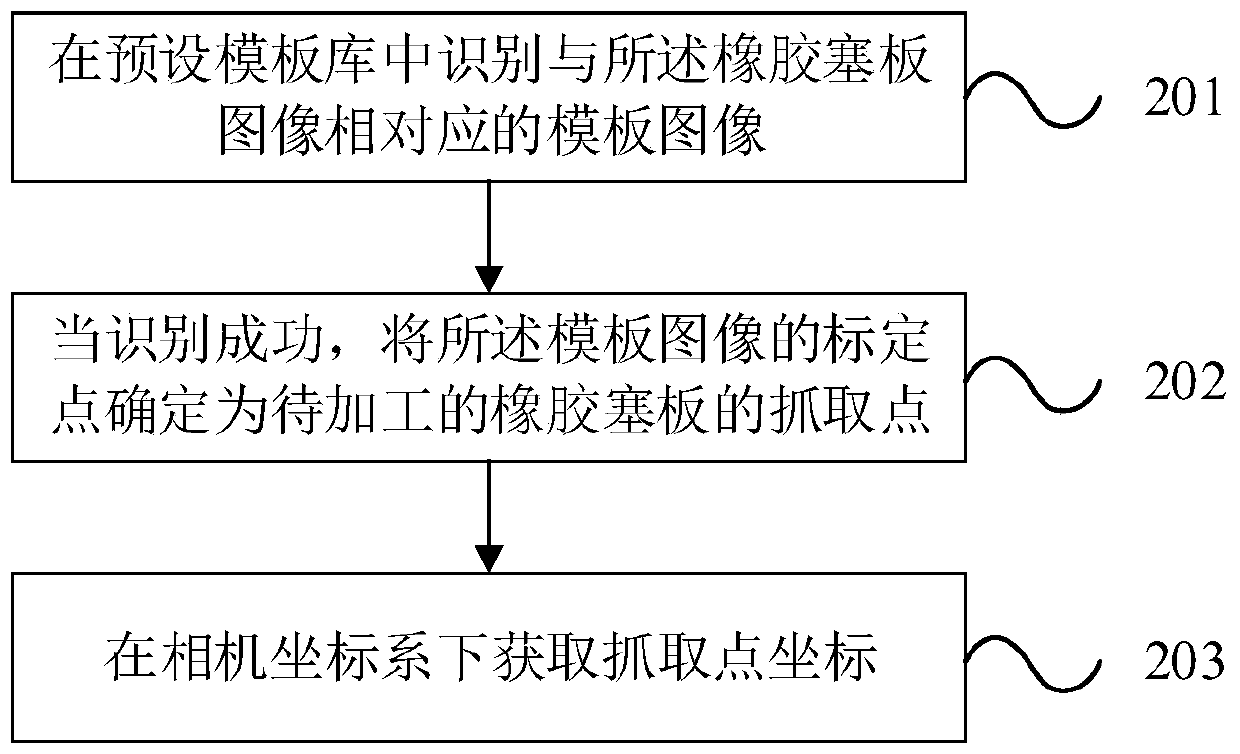

Method, device and system for processing rubber plug

InactiveCN110142765AImprove pass rateImprove work efficiencyProgramme-controlled manipulatorManipulatorEngineering

The invention provides a method, device and system for processing a rubber plug. The method comprises the following steps that image acquisition on a to-be-processed rubber plug board is conducted through a camera to obtain rubber plug board images, grabbing point coordinates of grabbing points under a camera coordinate system are determined according to the rubber plug board images, the conversion relation between the camera coordinate system and a mechanical arm tool coordinate system is obtained, grabbing point coordinates of the grabbing points under the mechanical arm tool coordinate system are determined according to the conversion relation and the grabbing point coordinates under the camera coordinate system, and a mechanical arm is called for grabbing the to-be-processed rubber plug board to a designated target position according to the grabbing point coordinates under the mechanical arm tool coordinate system. The mechanical arm is automatically positioned and grabs the rubberplug board to the designated target position on a conveying device, and then the rubber plug board is conveyed to an edge removal machine for edge removal, so that the rubber plug is separated from the rubber plug board, manual operation of an operator is not needed in the whole process, the working efficiency is improved, automatic positioning of the mechanical arm is more accurate relative to manual positioning, and the percent of pass of rubber plug finished products is improved.

Owner:深圳市皕像科技有限公司

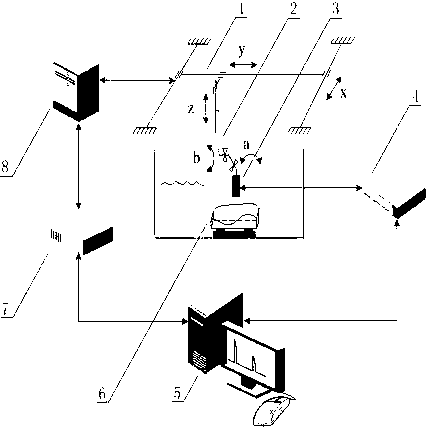

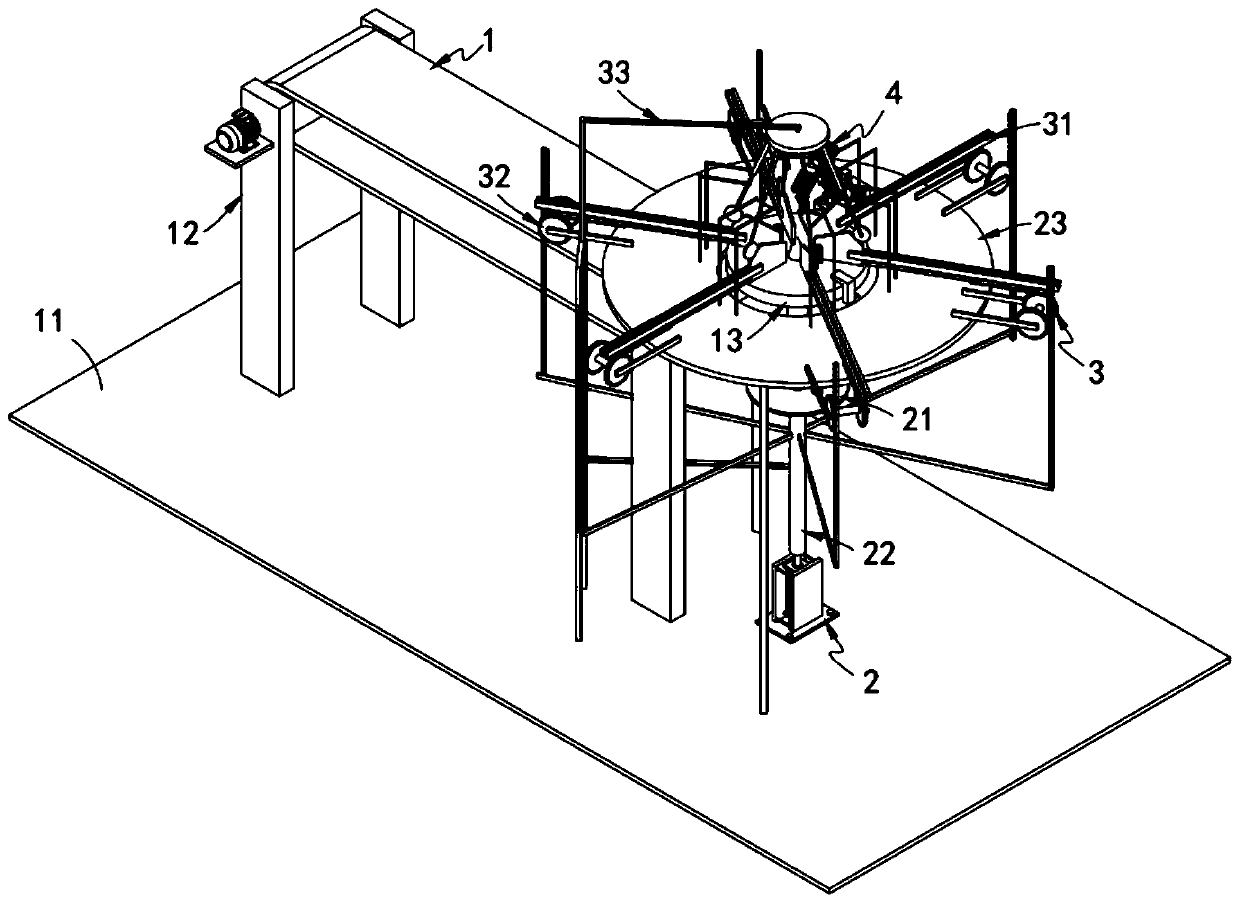

Probe frame used for automatic water immersion ultrasonic testing of components with complicated surfaces

ActiveCN103344707AGood sealingImprove rust resistanceMaterial analysis using sonic/ultrasonic/infrasonic wavesWatering troughBiomedical engineering

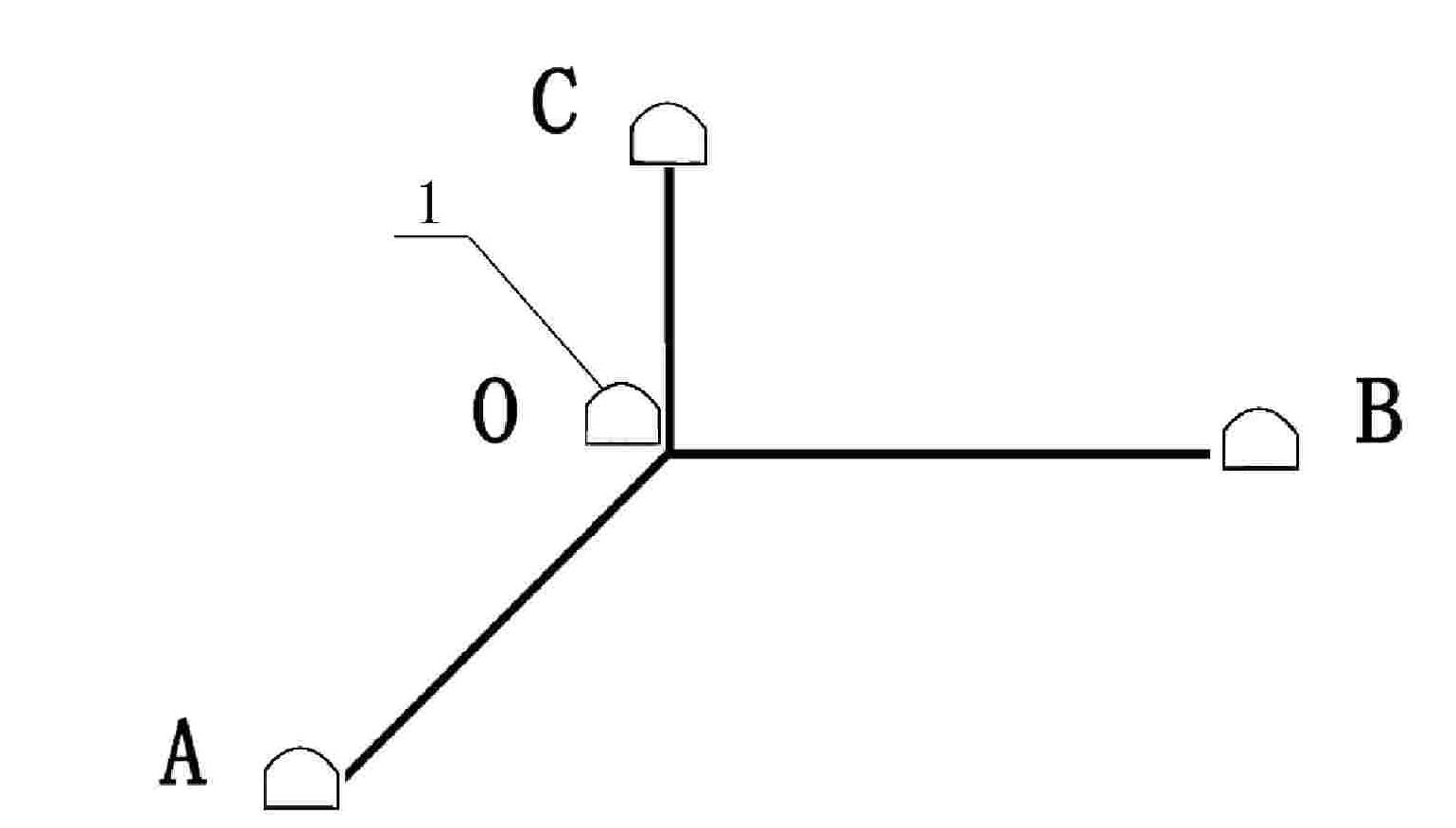

The invention discloses a probe frame used for automatic water immersion ultrasonic testing of components with complicated surfaces. The probe can be applied to the automatic water immersion ultrasonic testing of the components with complicated surface characteristics. A probe can realize the arbitrary-angle rotation along a shaft A and a shaft B so as to realize the arbitrary adjustment for the posture. Meanwhile, the probe frame has good airtightness and can be adapted to the long-term water immersion testing. By combining the probe frame with an X / Y / Z three-axis motion mechanism assembled on a water trough, the precise control of the pose of the probe in the automatic water immersion ultrasonic testing of the components with complicated surfaces can be realized.

Owner:贤亿(厦门)智能科技有限公司

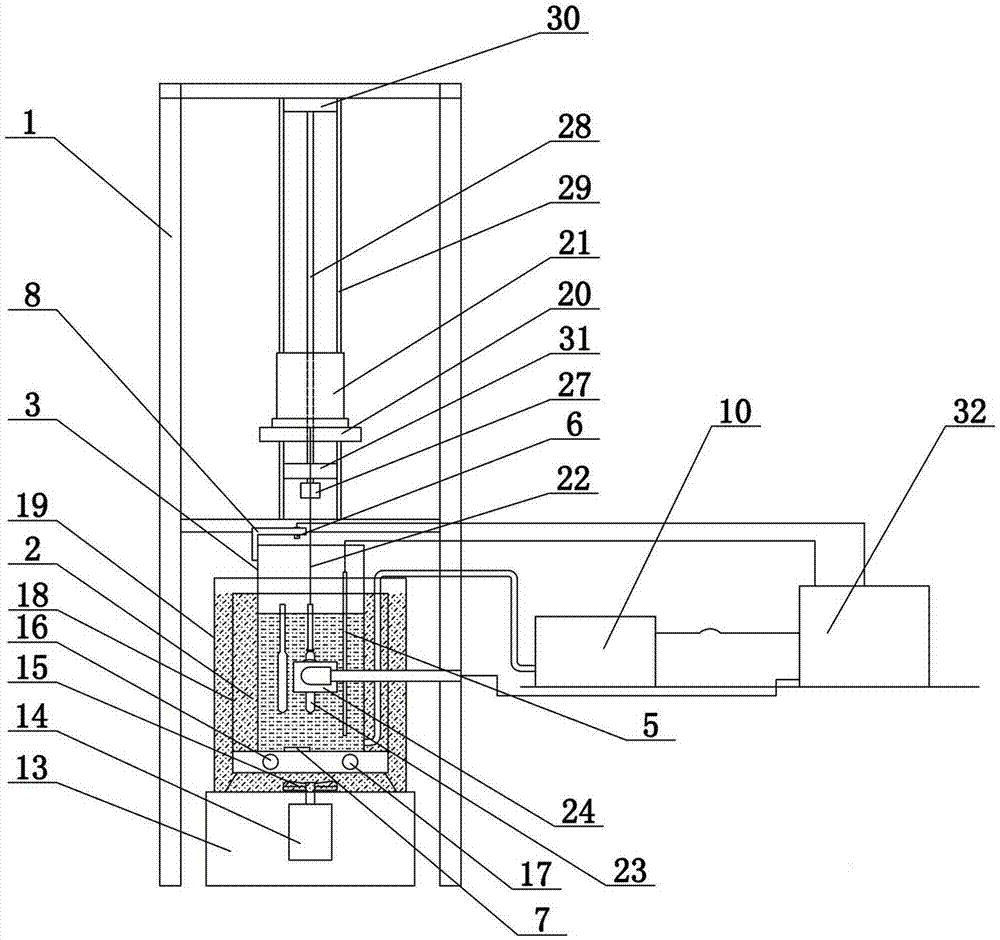

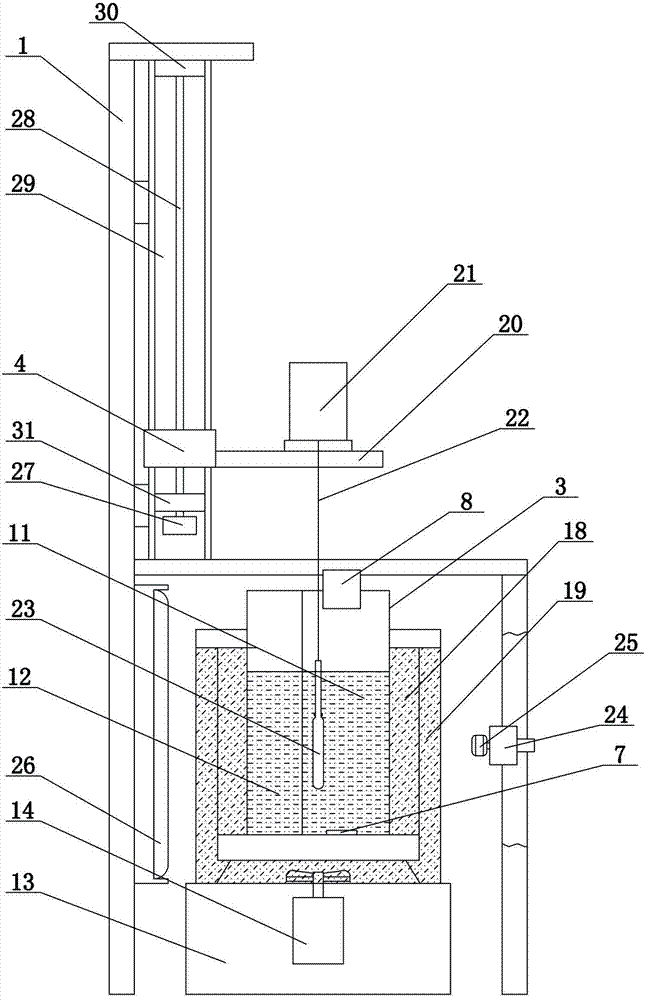

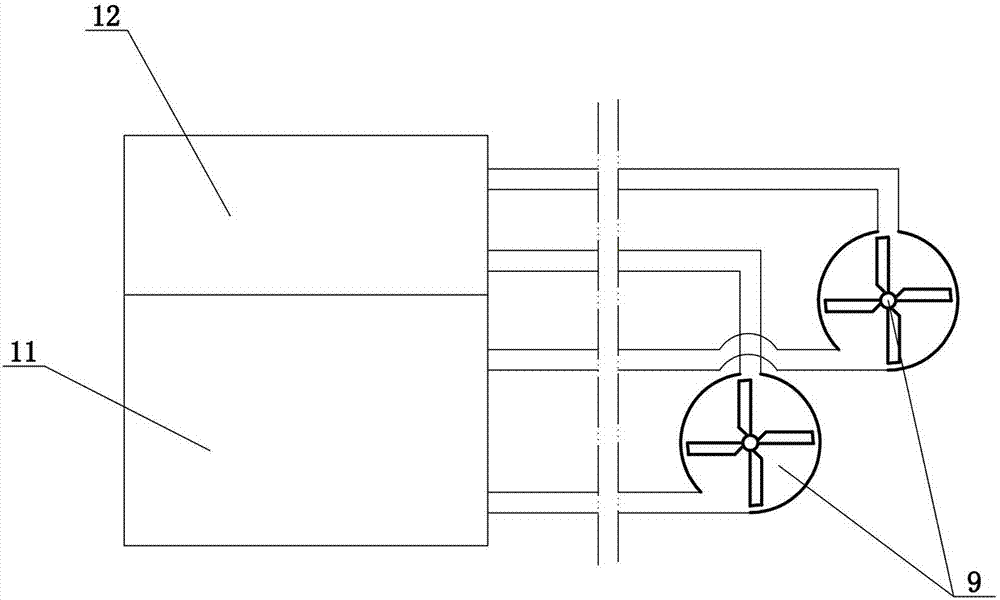

Glass hydrometer detecting/calibrating device

ActiveCN104237067AAchieve calibrationHigh degree of automationSpecific gravity measurementHydrometerGraduated cylinder

Owner:HENAN PROVINCE INST OF METROLOGY

Automatic positioning method of positioning system for electric energy quality disturbance source

ActiveCN107576887ASimple structurePrecise automatic positioningFault locationPower qualityDistribution power system

The invention relates to an automatic positioning method of a positioning system for an electric energy quality disturbance source. The positioning system comprises an electric energy quality management master station and electric energy quality online monitoring devices connected with the master station through the Ethernet. One electric energy quality online monitoring device is arranged at eachmonitoring point of an electric transmission line of a radiation type power distribution system, and the electric energy quality online monitoring devices are connected through the Ethernet; when anactual disturbance event occurs in the system, after the electric energy quality online monitoring devices detect the disturbance event, the moment when the disturbance source occurs can be recorded,and other electric energy quality online monitoring devices in the internet are informed in a broadcasting mode through the Ethernet to start a disturbance wave recording system by adopting the momentas the reference, sampling data of previous N cyclic waves and later N cyclic waves before the moment is recorded and sent to the electric energy quality management master station in real time, a system coverage matrix and a system direction matrix are built through cooperation among the electric energy quality online monitoring devices, and then the disturbance source is positioned.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD +2

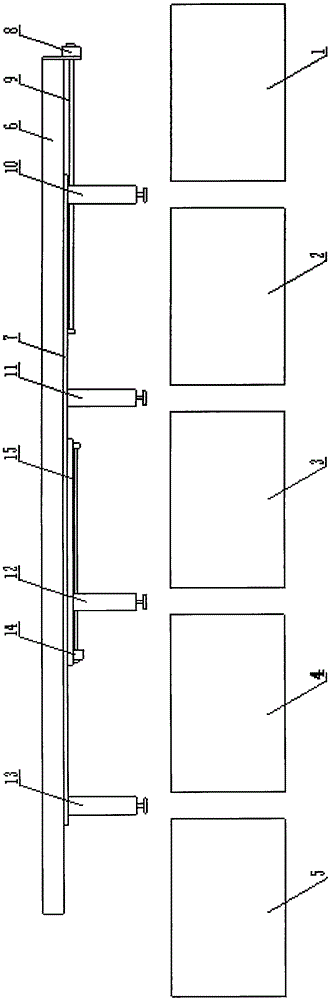

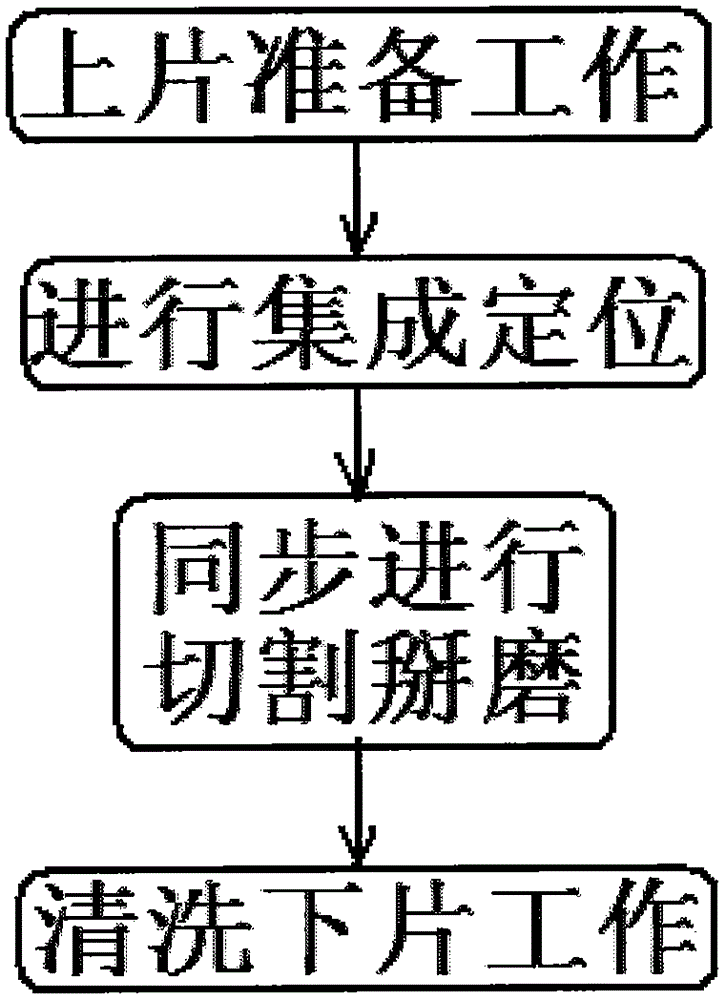

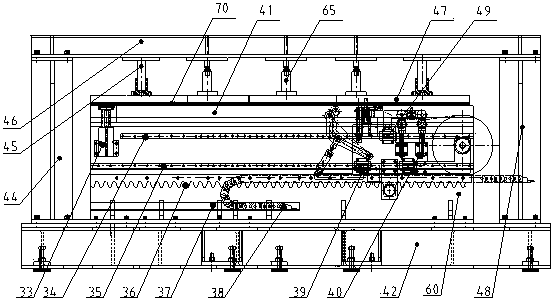

Special-shaped glass remote control cutting, breaking and grinding integrated processing production line and operation method thereof

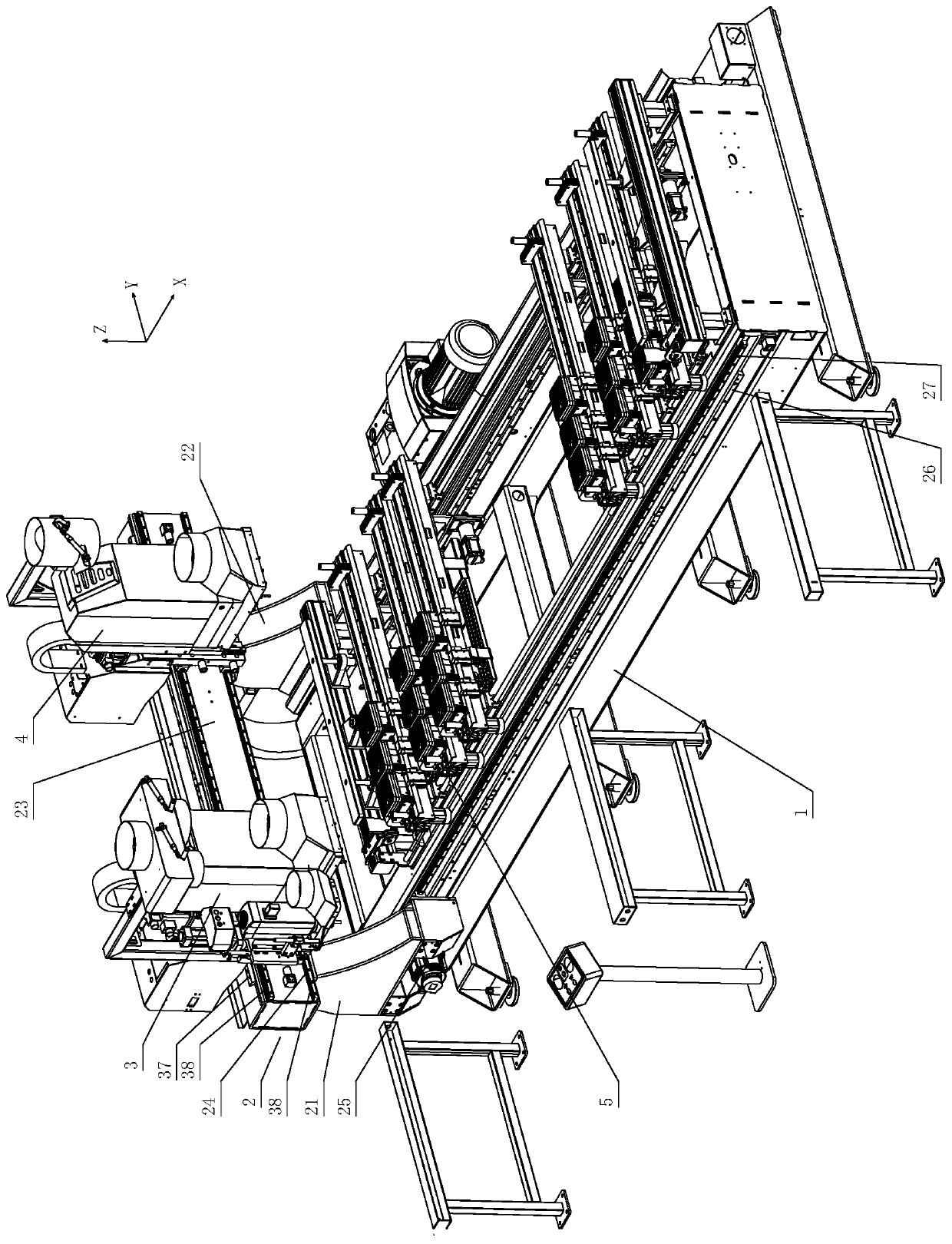

InactiveCN105598781AHigh precisionImprove edging accuracyEdge grinding machinesGrinding drivesProduction lineRemote control

Provided are a special-shaped glass remote control cutting, breaking and grinding integrated processing production line and an operation method thereof. The processes of cutting, edge breaking, edge grinding and the like are integrated to efficiently process all kinds of special-shaped glass in a fully automatic mode at a time, precision, stability and quickness are achieved, waste is treated by itself, and the performance of the whole machine is excellent. Operation is easy, use is safe and convenient, the rate of finished products reaches up to 99.96%, and production quality and efficiency are greatly improved. Energy saving and environment friendliness are achieved, production cost is reduced by 50%, and the requirements of the production processes and the need of a special-shaped glass deep processing production line for fast development and changes are met. The special-shaped glass remote control cutting, breaking and grinding integrated processing production line is composed of a glass GPS positioning and navigation system, a special-shaped glass remote control cutter, a special-shaped glass remote control edge breaking machine, a special-shaped glass remote control edge grinding machine, a glass remote control cleaning machine, a glass control conveying device, a sensing conveying device, a first servo motor, a first ball screw, a cutting linkage mechanical arm, an edge breaking linkage mechanical arm, an edge grinding linkage mechanical arm and the like.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

Automatic seal cover taking control system for nuclear waste steel drum

InactiveCN105129689ASimple structural designReasonable structural designCapsTight-fitting lid removalControl systemWaste treatment

The invention relates to an automatic seal cover taking control system for a nuclear waste steel drum, and belongs to the technical field of nuclear waste treatment. The system comprises an image monitoring unit, a motion control unit, a locating unit and a sensor unit; the motion control unit is used for calculating and processing data and sending a control instruction; the image monitoring unit is connected with the motion control unit and used for monitoring actions of a whole device in the operating process in real time; the locating unit is connected with the motion control unit and used for precisely locating an X axis, a Y axis, a Z axis and a rotary C axis; the sensor unit is connected with the motion control unit and used for detecting the position of the metal drum. The automatic seal cover taking control system for the nuclear waste steel drum is simple and reasonable in structural design, stable and reliable in operation and capable of achieving the functions of grabbing and moving a drum cover, automatically locating the drum cover and the waste drum, locating the position of threaded holes in the drum and the position of screws on the drum cover, placing the drum cover, screwing fastening bolts on the drum cover and the like.

Owner:CHENGDU UNIV OF INFORMATION TECH

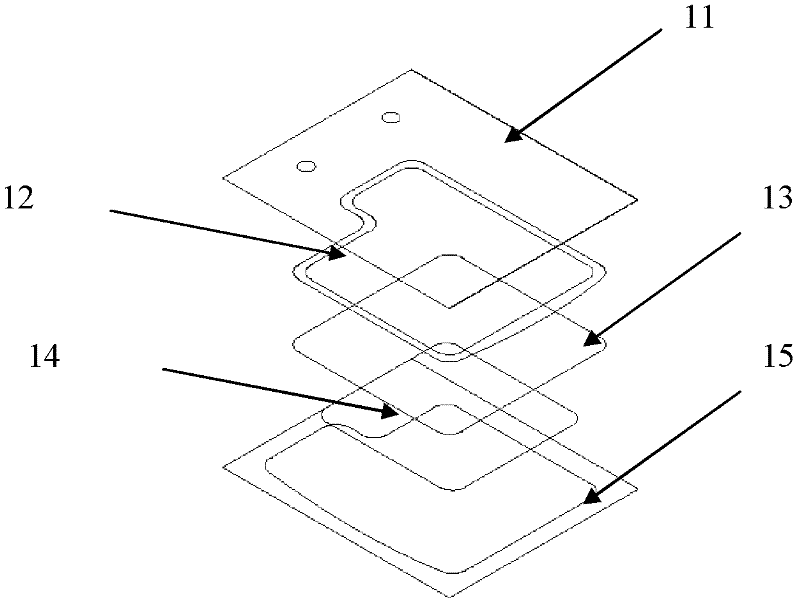

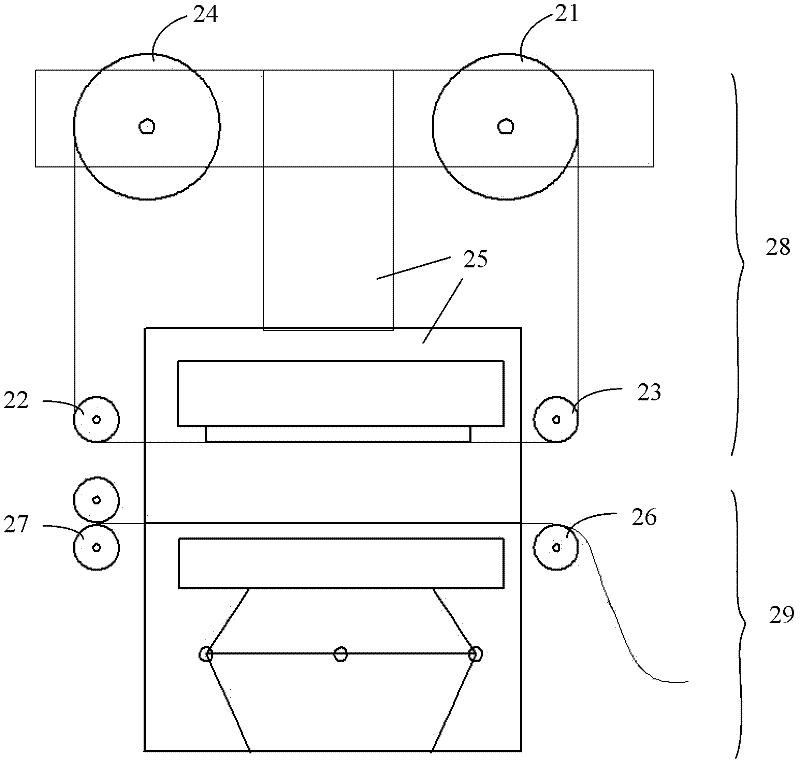

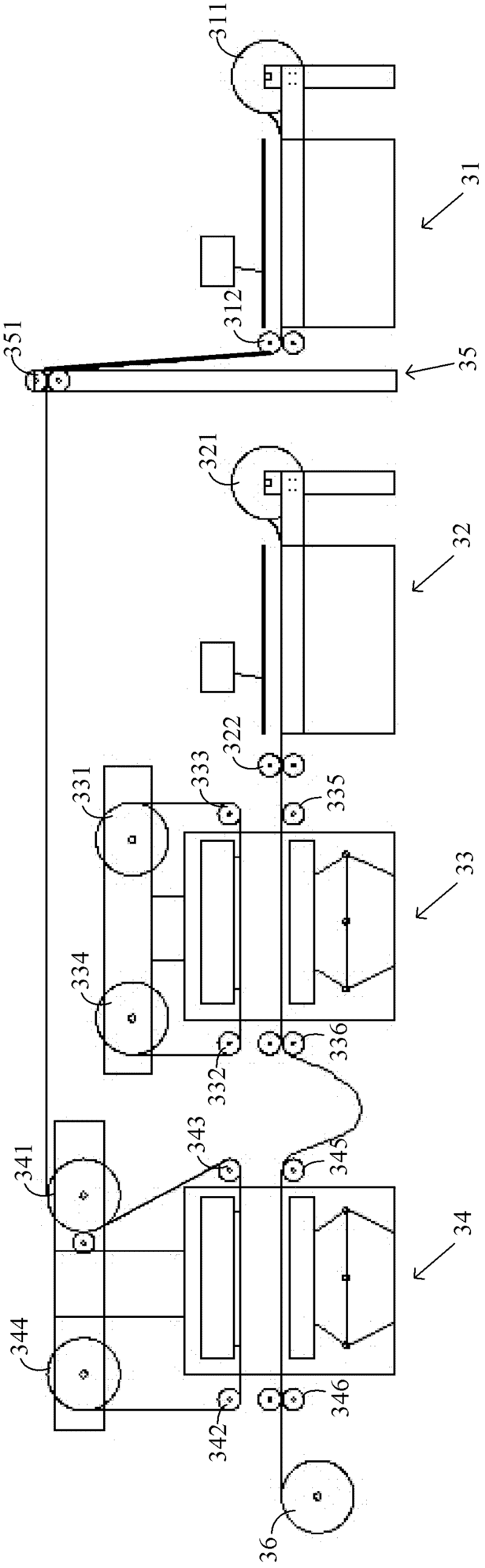

Printing and bonding production line and die cutting equipment thereof

ActiveCN102582211AFacilitate mass productionReduce labor intensityLamination ancillary operationsControlling laminationEngineeringPrinting press

The invention provides a printing and bonding production line and die cutting equipment thereof. The printing and bonding production line comprises one or more pieces of die cutting equipment and one or more size printing machines, wherein each size printing machine comprises a size feeding mechanism controlled by a servo control mechanism; after band-shaped processing materials pass through the size feeding mechanism, electrolytes or size with specified patterns are printed on specified positions of the band-shaped processing materials; and the size feeding servo control mechanism of the size printing machine is synchronously coupled with a first servo control part or a second servo control part of one piece of die cutting equipment, and / or the first servo control part or the second servo control part of one piece of die cutting equipment is synchronously coupled with a first servo control part or a second servo control part of another piece of die cutting equipment. By adopting the printing and bonding production line and the die cutting equipment thereof, large-scale production of printed electronic products can be realized.

Owner:江苏恩福赛柔性电子有限公司

Machine for automatically pasting adhesive tape to refrigerator liner enclosure plates

ActiveCN104192626AIncrease productivityPrecise positioningDomestic cooling apparatusLighting and heating apparatusMechanical engineering

The invention provides a machine for automatically pasting adhesive tape to refrigerator liner enclosure plates. The machine comprises a rectangular machine frame, a main machine frame, an enclosure plate pressing assembly, an adhesive tape pasting assembly and a conveying and positioning part sleeve and is characterized in that the main machine frame is fixedly installed on the rectangular machine frame, the conveying and positioning part sleeve is arranged on the back of the main machine frame, the enclosure plate pressing assembly is arranged under the main machine frame, a rack is arranged on the front face of the main machine frame and meshed with a gear of the adhesive tape pasting assembly, and the adhesive tape pasting assembly is composed of a discharging assembly, floating wheel assemblies, fixed wheel assemblies, a clamping assembly, a shearing assembly and swing wheel assemblies. Through the machine for automatically pasting the adhesive tape to the refrigerator liner enclosure plates, actions required for pasting part of the adhesive tape on the lateral sides of the refrigerator liner enclosure plates can be automatically completed, the machine for automatically pasting the adhesive tape to the refrigerator liner enclosure plates has the advantages of being accurate and reliable in positioning, accurate and stable in adhesive tape position, and firm and reliable in adhesive tape pasting, the adhesive tape is not prone to disengagement, the pasting face is complete, an existing technological mode for manually pasting the adhesive tape to the refrigerator liner enclosure plates can be replaced, and the production efficiency of pasting the adhesive tape to the liner enclosure plates is improved.

Owner:ANHUI KECHANG MACHINERY MFG

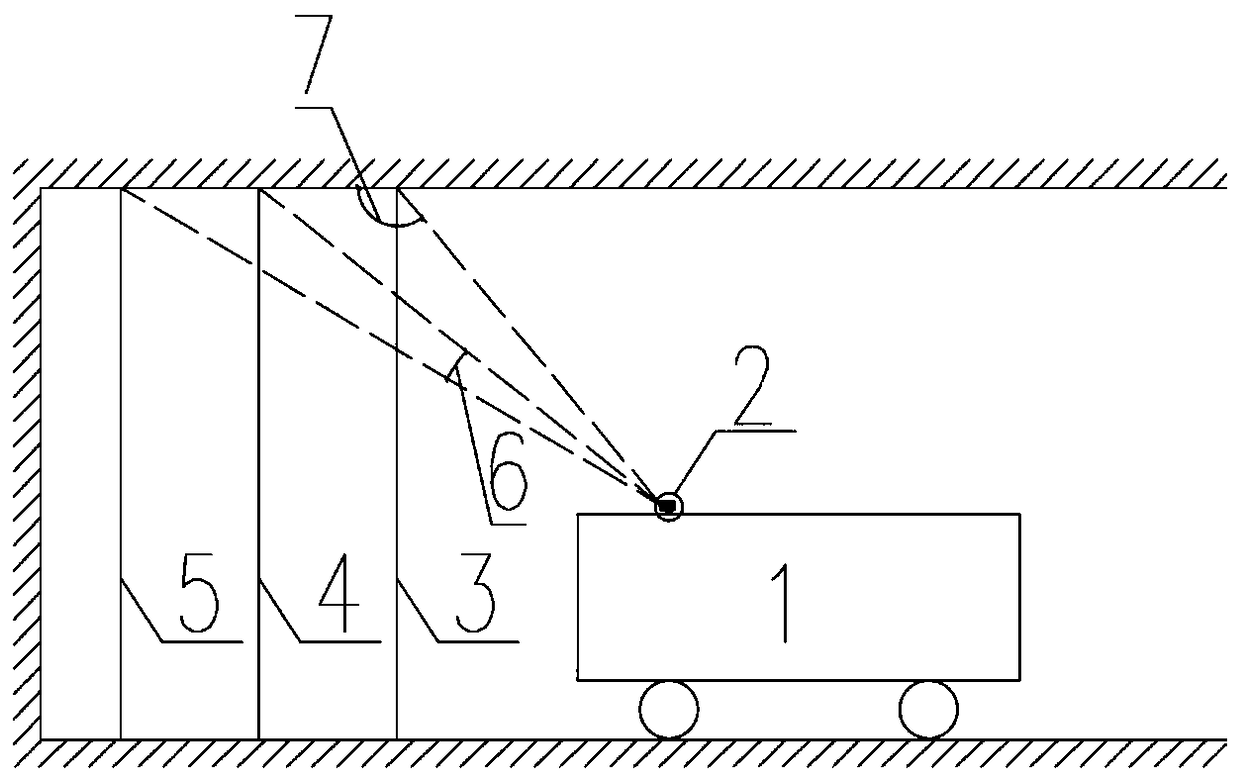

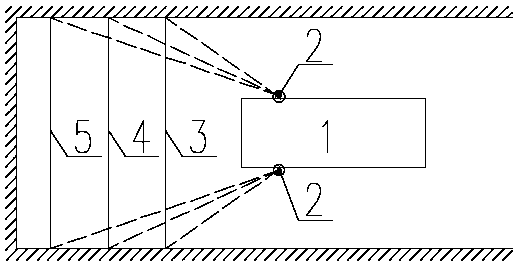

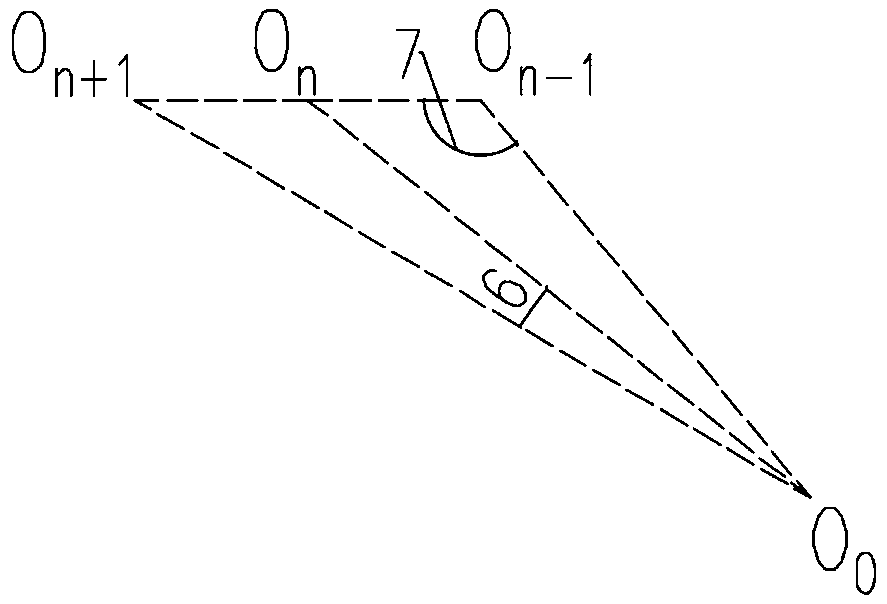

Arch frame positioning system and method based on arch frame installation machine for tunnel construction

ActiveCN109238137ARealize automatic positioningPrecise automatic positioningUsing optical meansLaser rangingRotation function

The invention relates to an arch frame positioning system and a method based on arch frame installation machines for tunnel construction. The system comprises a laser range finder and a central controller. The laser range finder is installed on the outer part of the arch frame installation machine, has multi-degrees of freedom rotation function, and is used for measuring a distance between a lasersource point and a target point position of two rows of assembled arch frames. The central controller is connected with the laser range finder, is used for receiving distance data acquired by the laser range finder, obtains a distance between the laser source point and a longitudinal corresponding target point of a to-be-assembled arch frame through geometric relationship calculation, so as to calculate an angle value that the laser source point needs when the laser source point directs to the longitudinal corresponding target point, and sends a corresponding angle rotation instruction to thelaser range finder. According to the arch frame positioning system and the method based on arch frame installation machines for tunnel construction, the accurate and automatic position of the longitudinal spacing and a circumferential section joint of the to-be-assembled arch frame can be achieved, so as to effectively ensure the installation precision of the arch frame.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Gantry numerical control machining center and control system and machining method of gantry numerical control machining center

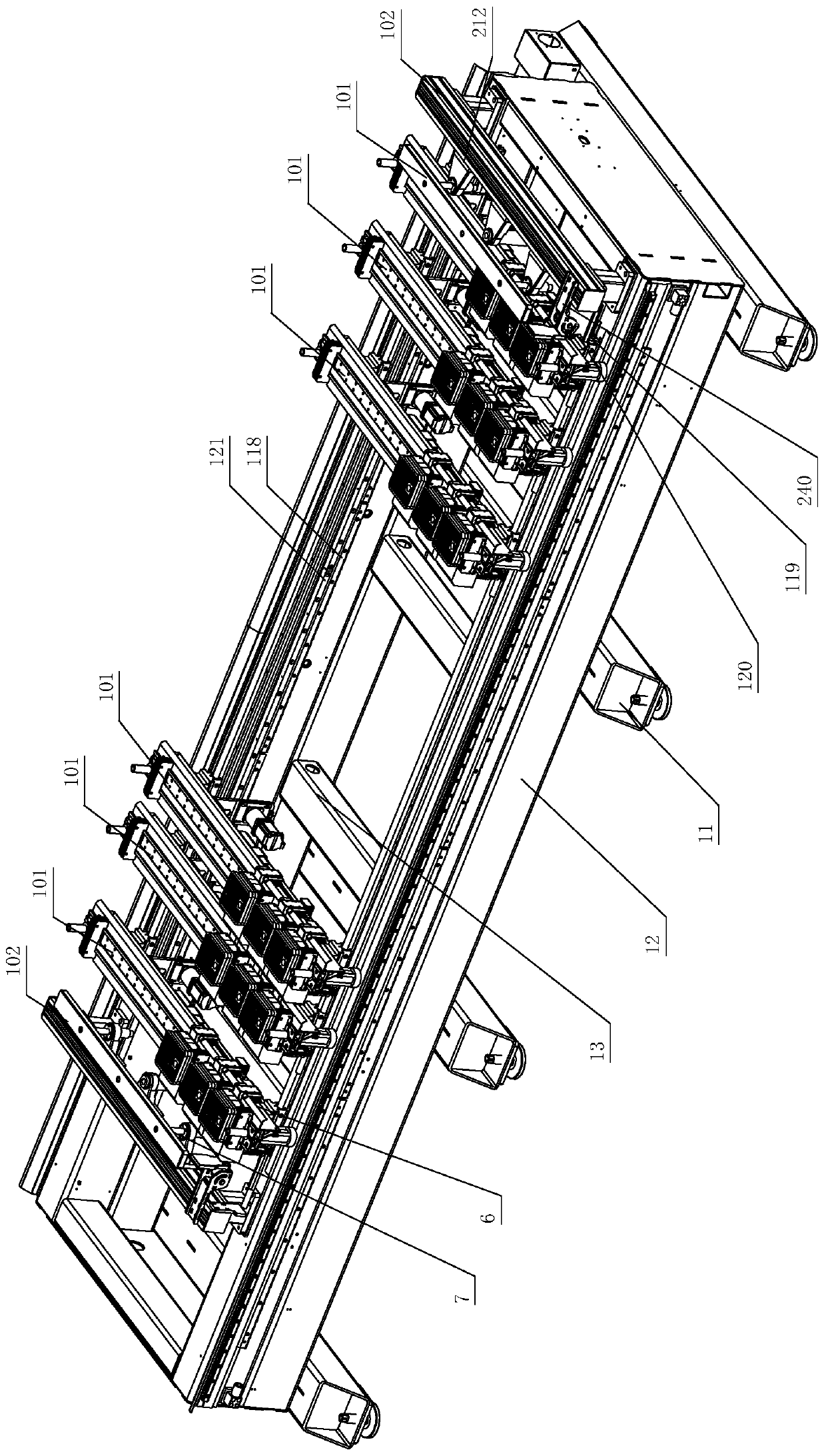

ActiveCN110154168AImprove efficiencyHigh precisionProgramme controlComputer controlNumerical controlControl manner

The invention discloses a gantry numerical control machining center and a control system and a machining method of the gantry numerical control machining center. The gantry numerical control machiningcenter comprises a worktable device. The worktable device comprises multiple sets of automatic positioning moving worktable mechanisms which are arranged in the X direction. The gantry numerical control machining center has the beneficial effects that automatic moving positioning of worktables and suckers can be achieved. The control system comprises a CNC controller, a servo control unit in parallel connection with a bus in a bidirectional control manner, a machine head control unit, a worktable control unit and a vacuum control unit. The worktable control unit comprises multiple sets of automatic positioning moving worktable control units and X-direction positioning control units. Each set of automatic positioning moving worktable control unit comprises a set of worktable X-axis feedingservo system, multiple sets of sucker Y-axis feeding servo systems and a Y-direction positioning control unit. The worktable X-axis feeding servo systems and the sucker Y-axis feeding servo systems are connected with a bus of a PLC in parallel. The control system has the beneficial effects that universality is achieved, compatibility is high, and transportability is high.

Owner:NANXING MACHINERY CO LTD

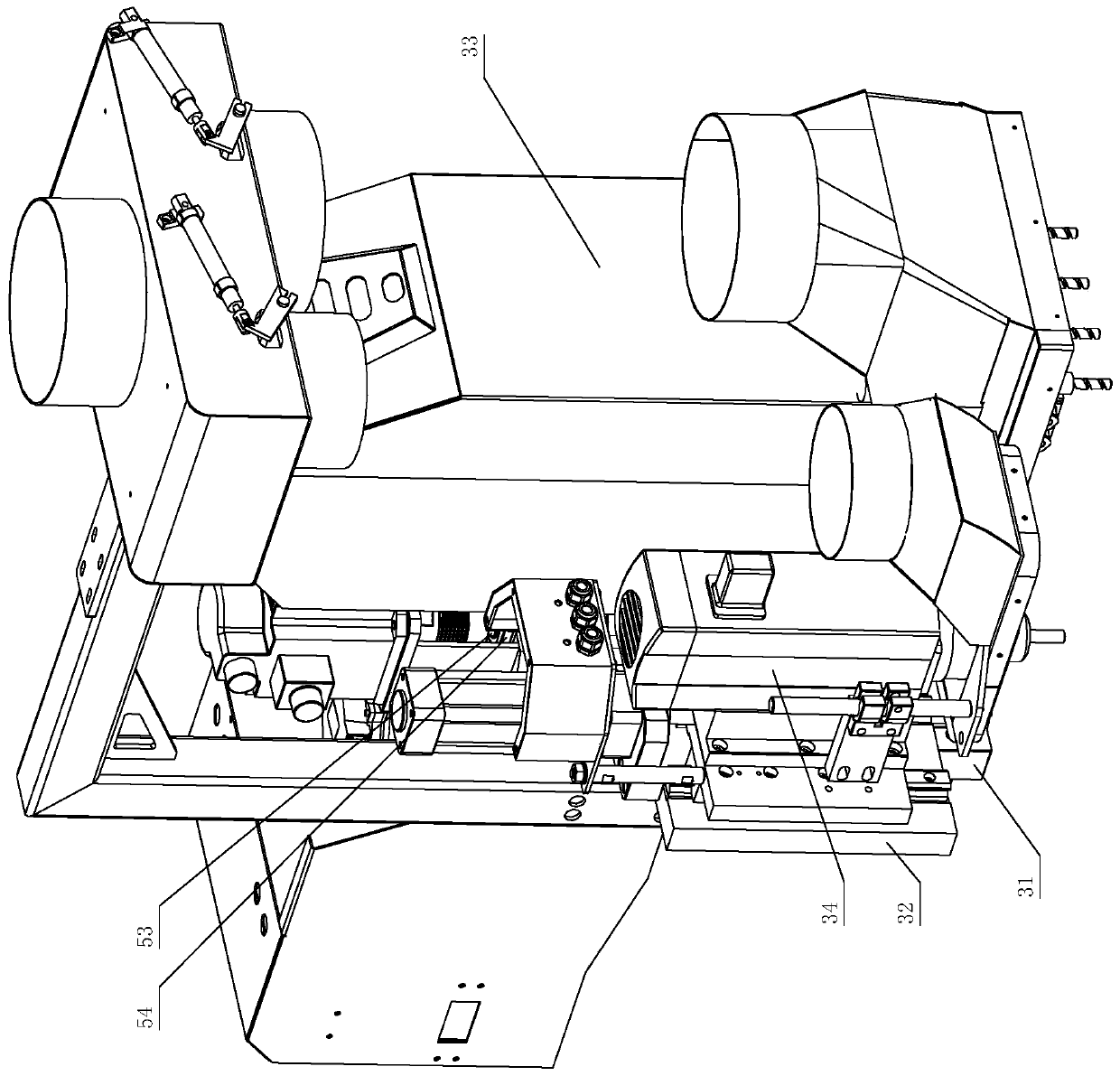

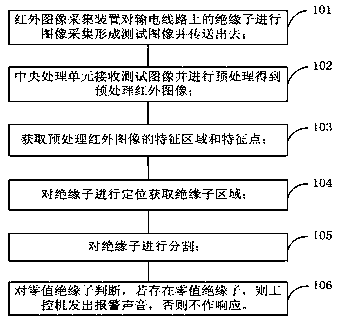

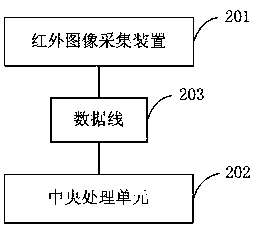

Zero value insulator automatic detection method and apparatus based on infrared image

ActiveCN107833211APrecise automatic positioningImprove accuracyImage enhancementData processing applicationsAcquisition apparatusComputer science

The invention discloses a zero value insulator automatic detection method based on an infrared image. The method comprises the following steps that an infrared image acquisition apparatus carries outimage acquisition on an insulator on a power transmission line so as to form a test image and sends the image to the outside world; a central processing unit receives the test image and carries out preprocessing so as to acquire a preprocessed infrared image; a characteristic area and a characteristic point of the preprocessed infrared image are acquired; the insulator is positioned and an insulator area is acquired; the insulator is segmented; and a zero value insulator is determined, if there is the zero value insulator, an industrial control computer emits an alarm sound, otherwise, there is no response. The invention also provides a zero value insulator automatic detection apparatus based on the infrared image. In the invention, the zero value insulator is determined; the insulator canbe accurately and automatically positioned; and accuracy of zero value insulator detection and determination can be effectively increased.

Owner:STATE GRID CORP OF CHINA +3

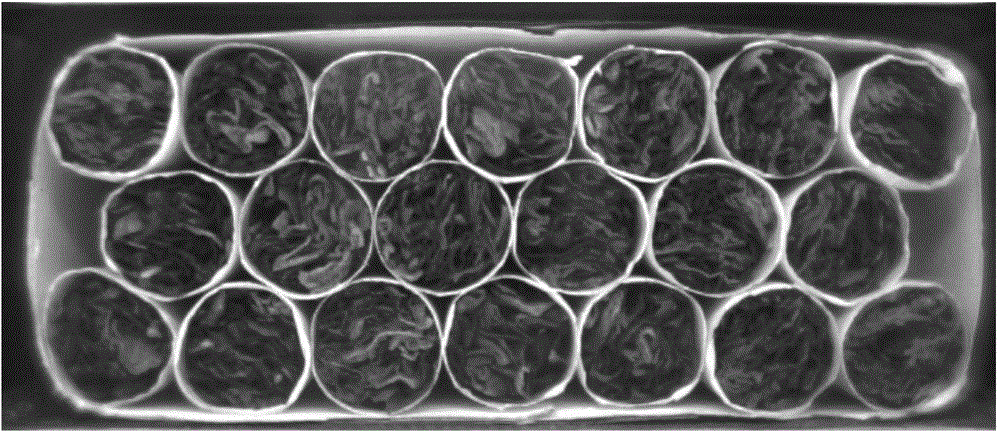

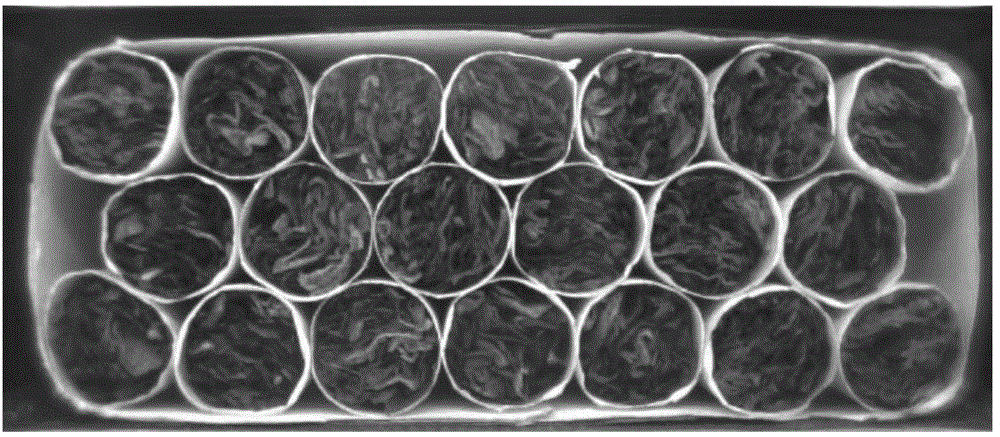

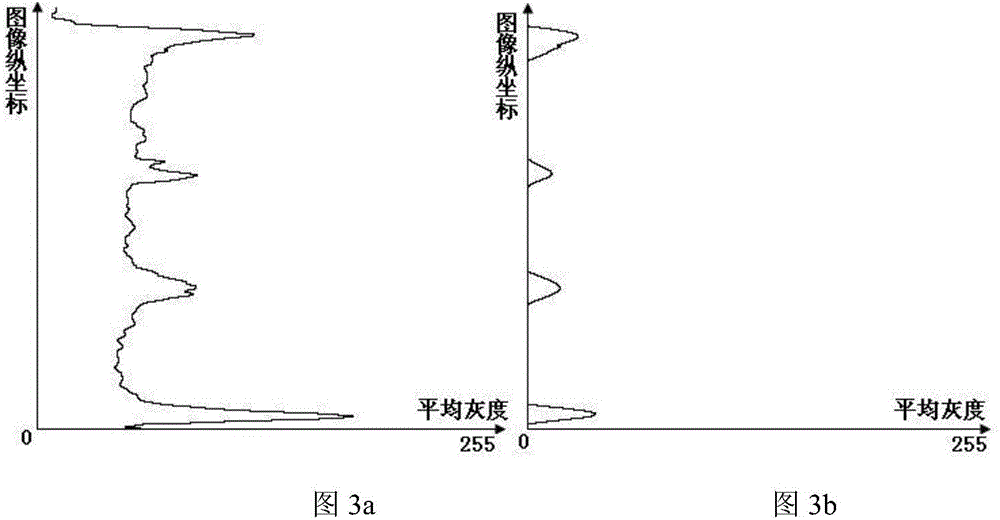

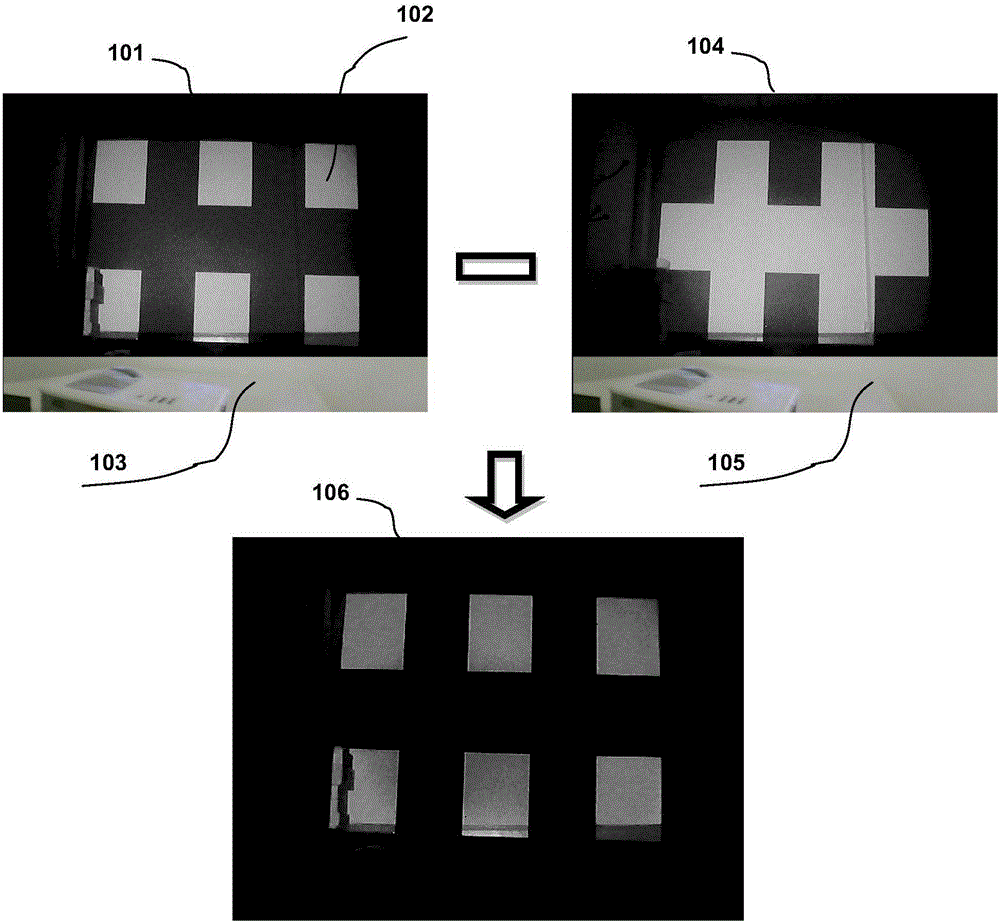

Method for automatically positioning cigarettes in mold box of cigarette packaging machine

ActiveCN104309866AQuick and automatic positioningPrecise automatic positioningPackaging cigarettePackaging cigarsEngineeringColor contrast

The invention discloses a method for automatically positioning cigarettes in a cigarette void end detection process. The method comprises the following steps of accurately positioning cigarettes in a mold box of a cigarette packaging machine, and determining the detection region of each cigarette, thereby ensuring the accuracy of follow-up cigarette void end detection. According to the method, the characteristic that tobacco shreds and coil paper are obvious in color contrast is fully utilized, a direction projection method is adopted to account local slight differences in a certain direction so as to form an obvious characteristic; by virtue of performing special filtering processing to remove interference on a projection curve, traversing and searching the specific position of each wave crest and finally determining the corresponding region of each cigarette, automatic cigarette positioning is realized.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

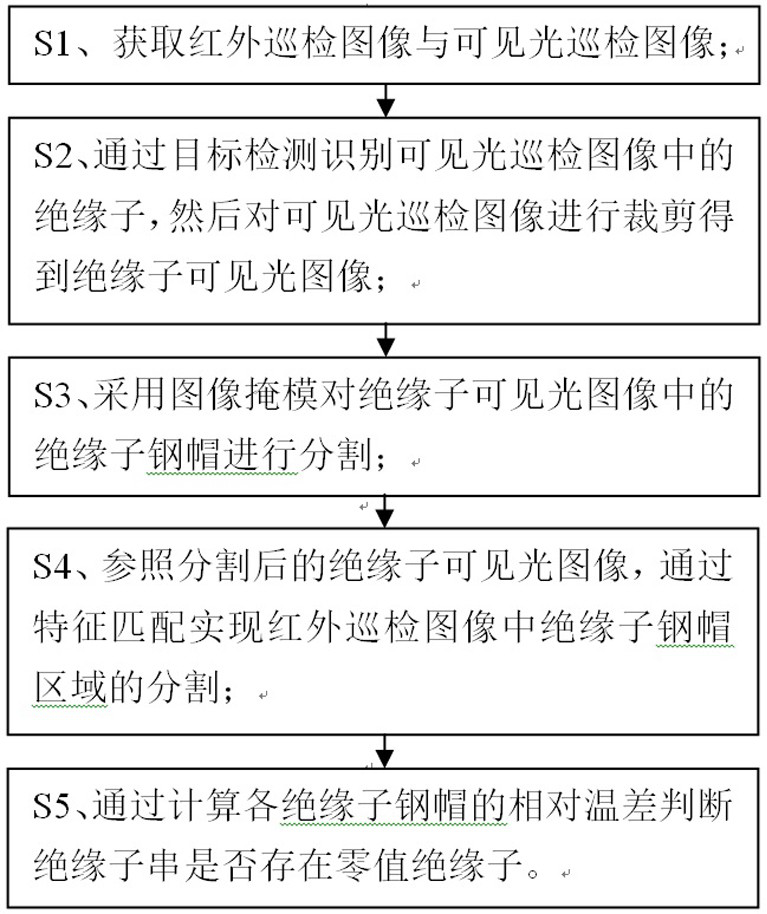

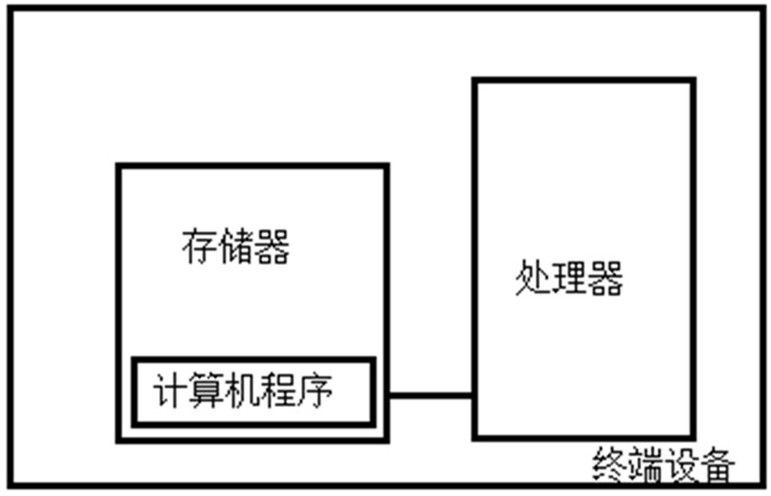

Automatic detection method for zero-value insulator in power transmission line

ActiveCN114724042APrecise automatic positioningImprove accuracyCharacter and pattern recognitionNeural architecturesEngineeringMaterials science

The invention discloses an automatic detection method for a zero-value insulator in a power transmission line. The method comprises the following steps: acquiring an infrared inspection image and a visible light inspection image; identifying an insulator in the visible light inspection image through target detection, and then cutting the visible light inspection image to obtain an insulator visible light image; segmenting the insulator steel cap in the insulator visible light image by using an image mask; according to the segmented insulator visible light image, segmentation of an insulator steel cap area in the infrared inspection image is realized through feature matching; and judging whether the insulator string has a zero-value insulator or not by calculating the relative temperature difference of each insulator steel cap. According to the method, the zero-value insulator is judged, and the insulator can be accurately and automatically positioned, so that the detection accuracy of the zero-value insulator can be effectively improved.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

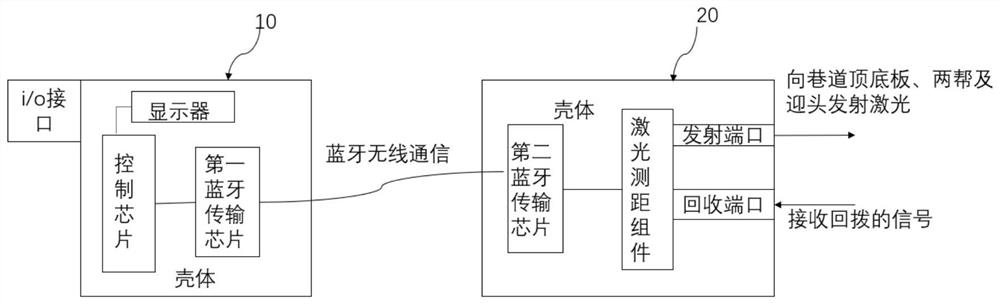

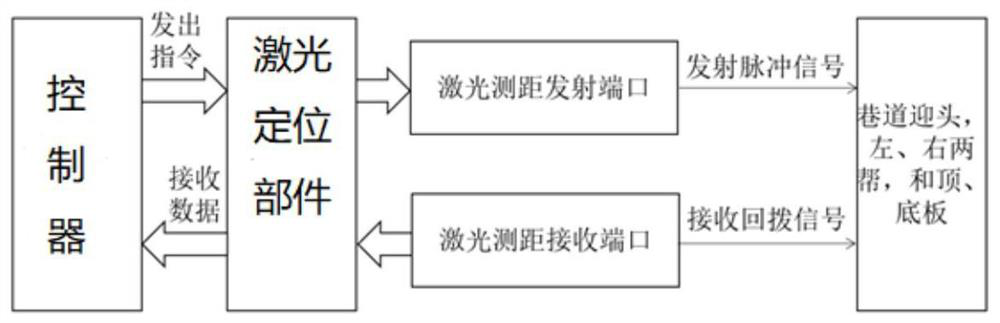

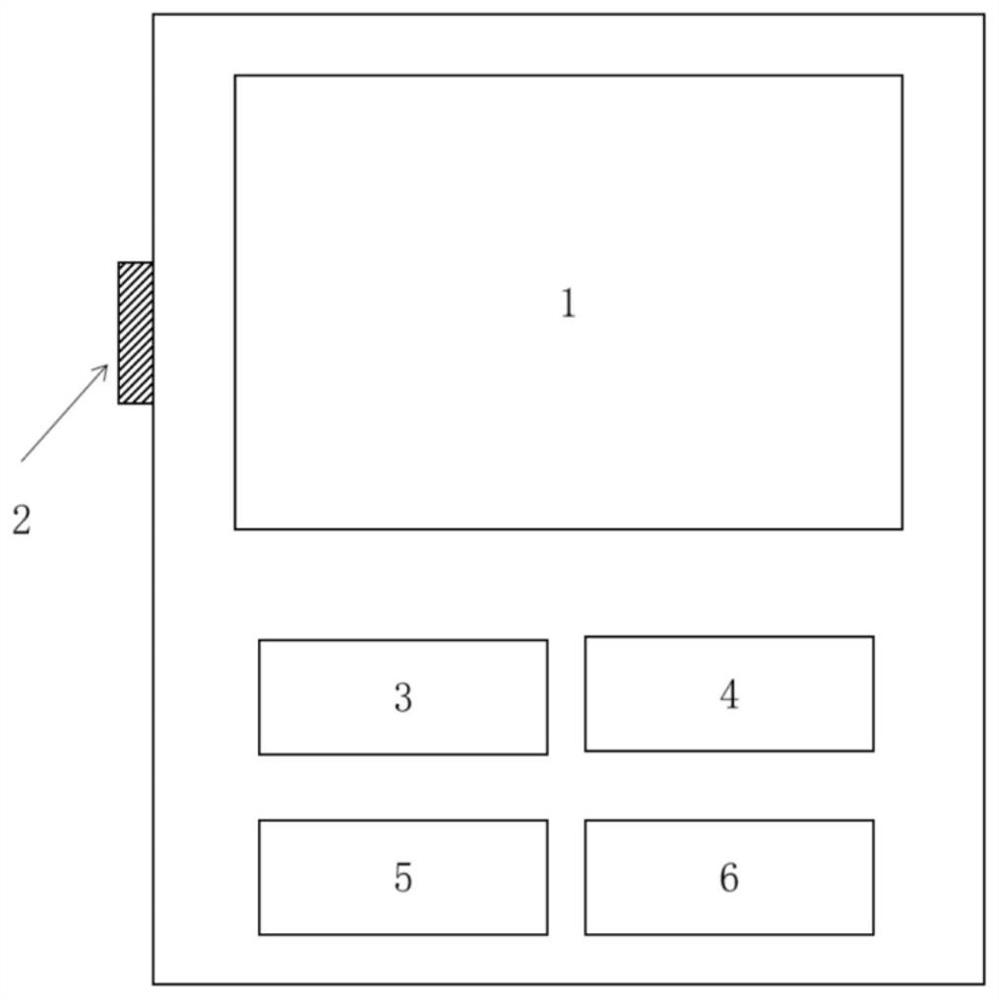

Automatic positioning device for rock roadway blasting holes

PendingCN111878173AImprove construction qualityPrecise automatic positioningMining devicesBlastingLaser rangingControl signal

The embodiment of the invention discloses an automatic positioning device for rock roadway blasting holes, and belongs to the field of coal mine rock roadway blasting. The automatic positioning devicecomprises a controller, a shell, a laser positioning component, and a controller, wherein a control chip and a first Bluetooth transmission chip connected with the control chip are arranged in the shell; the laser positioning component comprises a laser ranging assembly and a second Bluetooth transmission chip in cooperative communication with the first Bluetooth transmission chip; and the controller is mounted on a drilling heading machine, the laser positioning component is hung on a roadway roof and can move in the roadway heading direction, and the controller is used for receiving the distance between the laser positioning component and a roadway head-on, sent by the laser positioning component, and calculating and determining-be-tunneled blast holes and the laser positioning component and a horizontal axis according to the distance, and then sending control signals to control the laser positioning component to emit laser to the roadway head-on according to the included angle so as to realize positioning of the to-be-tunneled blast holes. The difficult problem of inaccurate positioning of the blasting blast holes in actual construction can be solved, so that the construction quality of the blasting blast holes is improved.

Owner:山西华阳集团新能股份有限公司 +2

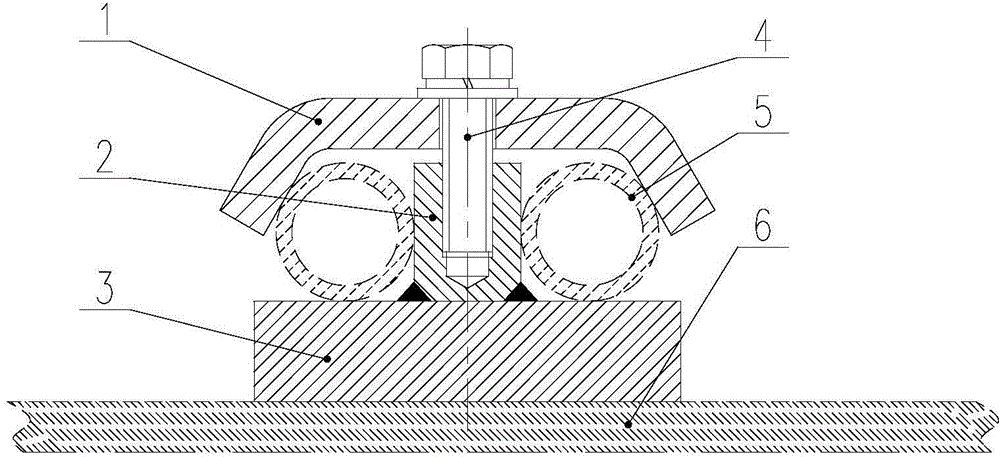

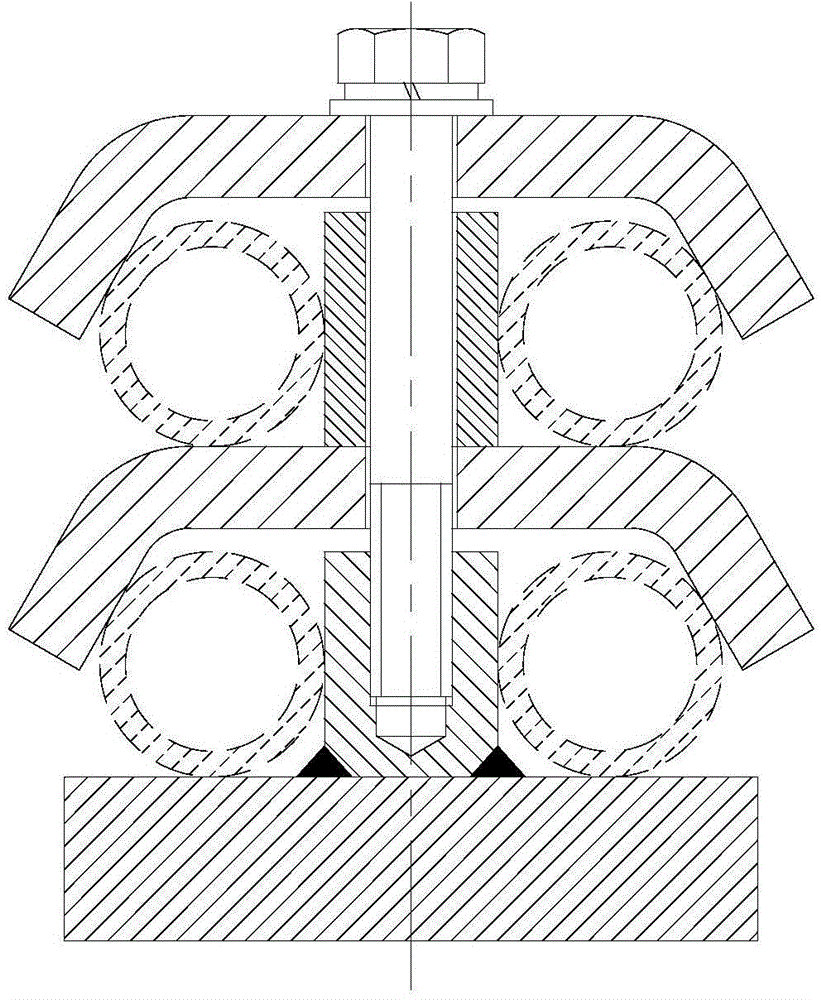

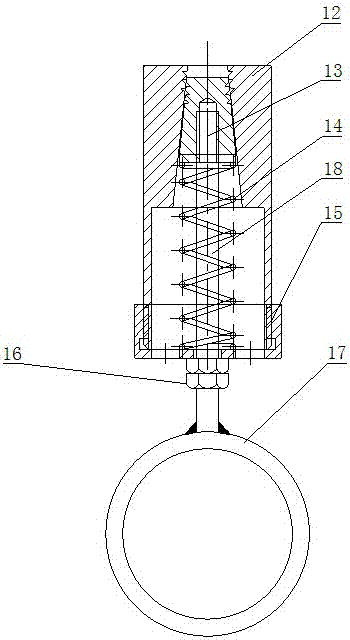

Pressure increasing type automatic locating steel pipe clamp

InactiveCN104878797AGuaranteed accuracySimple manufacturing processPipe supportsSoil-shifting machines/dredgersEngineeringPressure increase

The invention provides a pressure increasing type automatic locating steel pipe clamp. The pressure increasing type automatic locating steel pipe clamp comprises an upper pipe clamp, a boss, a bottom plate, a hexagonal bolt and a fixing plate; according to the specific structure and connection relationship, the boss and the bottom plate are integrally welded and fixed on the fixing plate; the hexagonal bolt passes through a through hole in the upper pipe clamp to be screwed into a screw hole in the boss, thus a steel pipe can be pressed through the upper pipe clamp, and a lateral force is produced when the upper pipe clamp presses the steel pipe, and as a result, the upper pipe clamp can be prevented from being rotated during screwing the bolt. According to the pressure increasing type automatic locating steel pipe clamp, the pipe clamp can be fixed with one bolt, so that the mounting is simple and convenient; the clamping is firm; the outside diameter of the steel pipe is variable; the automatic locating and other functions can be achieved; the generality is high; the adaptability is high.

Owner:GUANGXI YUCHAI HEAVY IND

Anti-interference method for automatic positioning of optical touch screen

ActiveCN106445223APrecise automatic positioningInput/output processes for data processingOphthalmologyTouchscreen

The invention discloses an anti-interference method for the automatic positioning of an optical touch screen. The method comprises a method for enhancing a contrast ratio of an image near a calibration point to a surrounding environment image. The method also comprises the following steps of: 1) enhancing a luminance difference between the image near the calibration point and the surrounding environment image, and 2) enhancing the smooth degree of the edge of the image near the calibration point. By use of the anti-interference method, the anti-ambient light interference ability of the automatic positioning of the optical touch screen is improved.

Owner:南京仁光电子科技有限公司

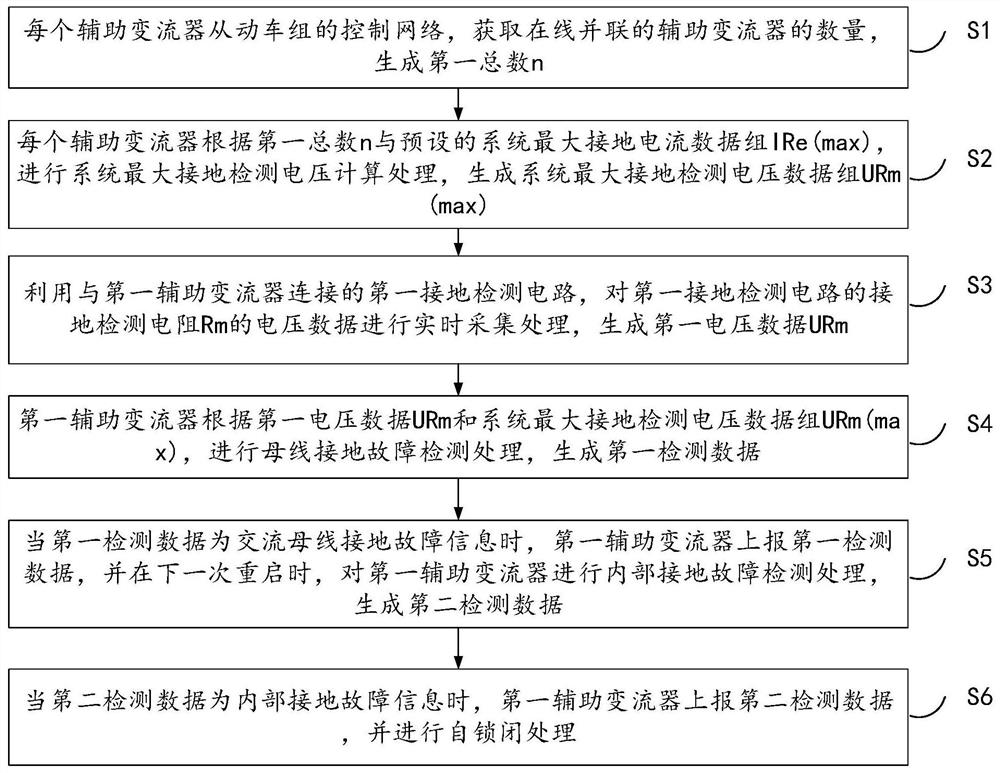

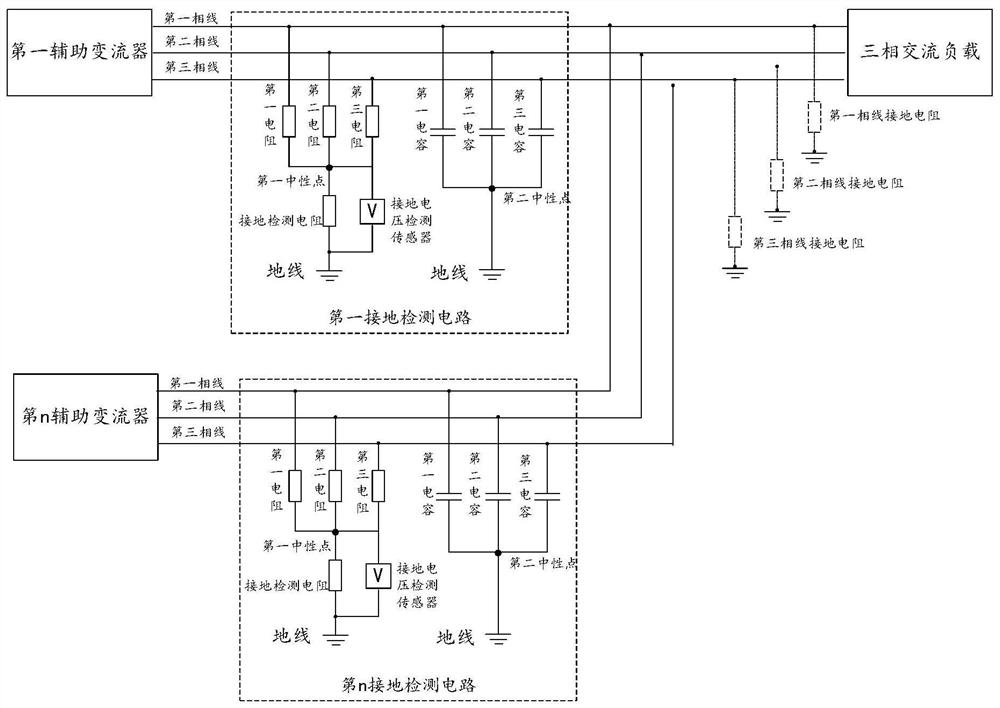

Motor train unit parallel auxiliary converter AC grounding fault detection method

ActiveCN112098890AEnsure power supply securityPrecise automatic positioningEmergency protective circuit arrangementsShort-circuit testingConvertersAC power

The embodiment of the invention relates to a motor train unit parallel auxiliary converter AC grounding fault detection method. The method comprises the steps of acquiring the first total number n ofonline parallel auxiliary converters; calculating the maximum grounding detection voltage of the system according to the first total number n and the maximum grounding current of the system; obtainingfirst voltage data of a grounding detection resistor by using a grounding detection circuit; performing bus grounding fault detection processing according to the first voltage data and the system maximum grounding detection voltage to generate first detection data; when the first detection data is AC bus grounding fault information, reporting the first detection data, and performing internal grounding fault detection processing to generate second detection data during next restart; and when the second detection data is the internal grounding fault information, reporting the second detection data, and performing self-locking processing. According to the embodiment of the invention, the real-time ground fault detection problem of the parallel auxiliary converter AC power supply system is solved, and the ground fault detection accuracy is improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

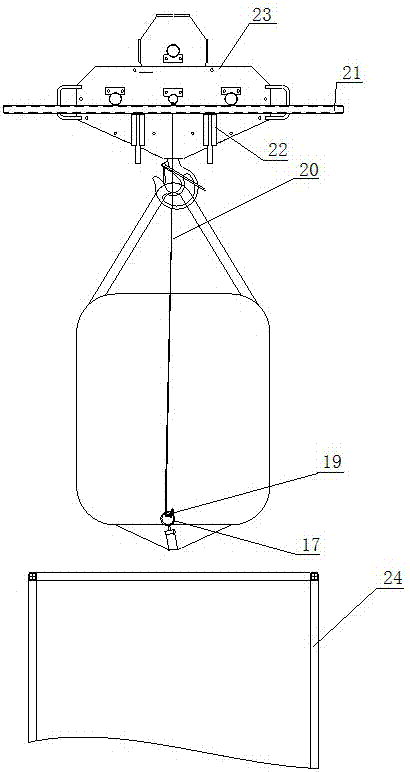

Integrated and automatic sand unloading device for petroleum well site fracturing construction and working method of integrated and automatic sand unloading device

ActiveCN107381380ASmall footprintReliable structural designCranesLoad-engaging elementsControl systemFrequency conversion

The invention belongs to the field of petroleum machinery, and provides an integrated and automatic sand unloading device for petroleum well site fracturing construction and a working method of the integrated and automatic sand unloading device. The integrated and automatic sand unloading device comprises a hoist, sand storage tanks, a lifting mechanism, a swing mechanism, a trolleying mechanism, a programmed frequency conversion control system, sandbag untying devices and sandbag tying devices. According to the working method, one-key hoist positioning including one-key positioning of an empty hook and one-key positioning of a large hoisting hook are realized through parameters of the programmed frequency conversion control system. The integrated and automatic sand unloading device for petroleum well site fracturing construction is simple in structure, convenient to operate, high in automation degree, capable of increasing sand transporting efficiency and low in transportation and maintenance cost.

Owner:HUBEI JOINHAND CONSTR MACHINERY

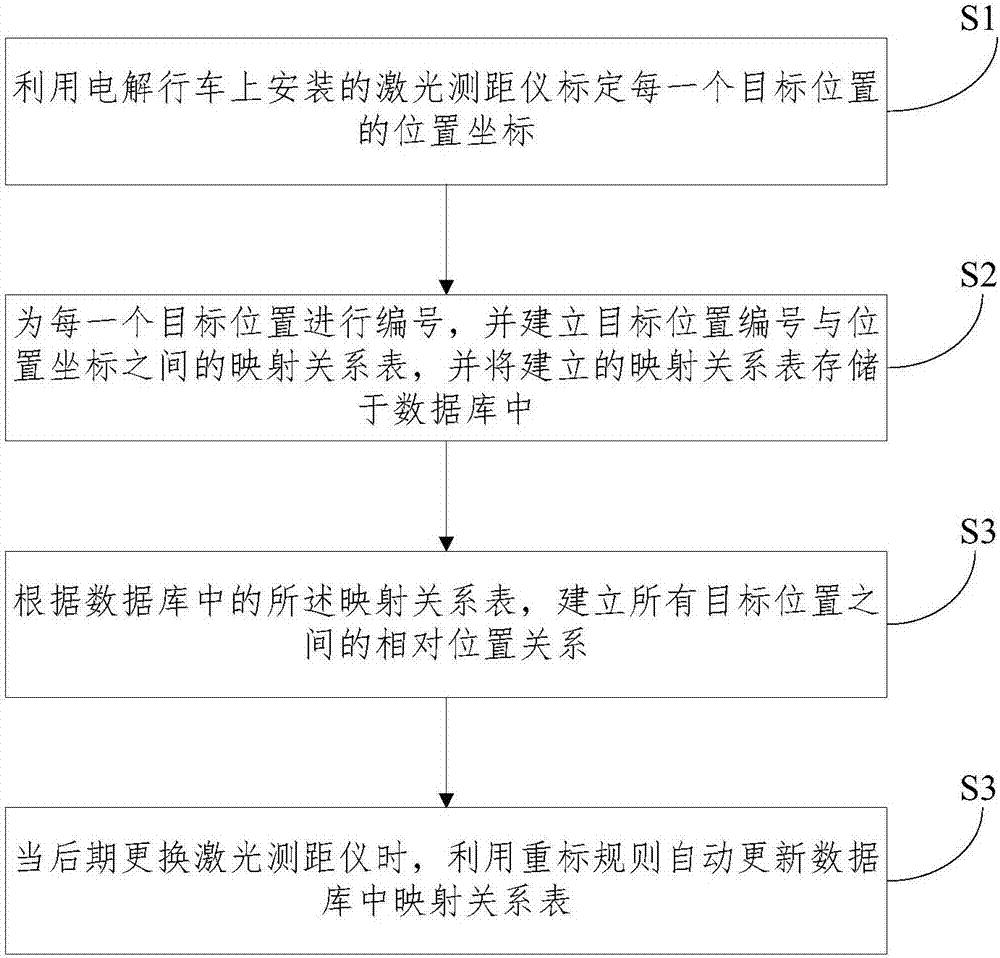

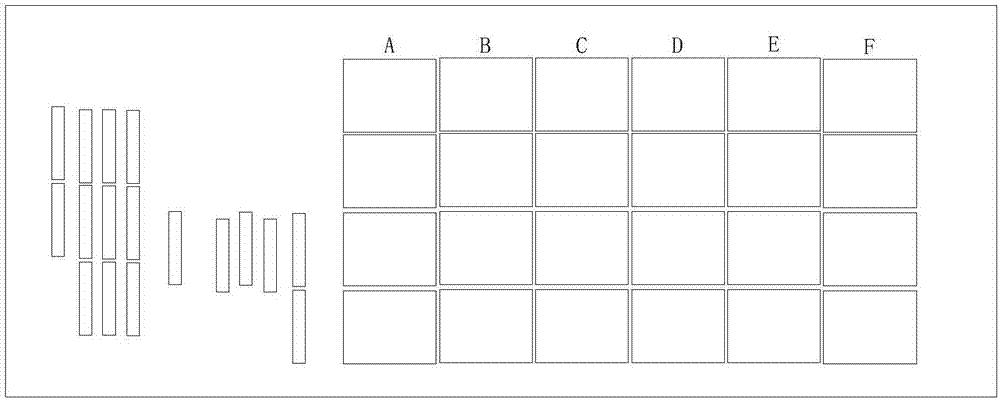

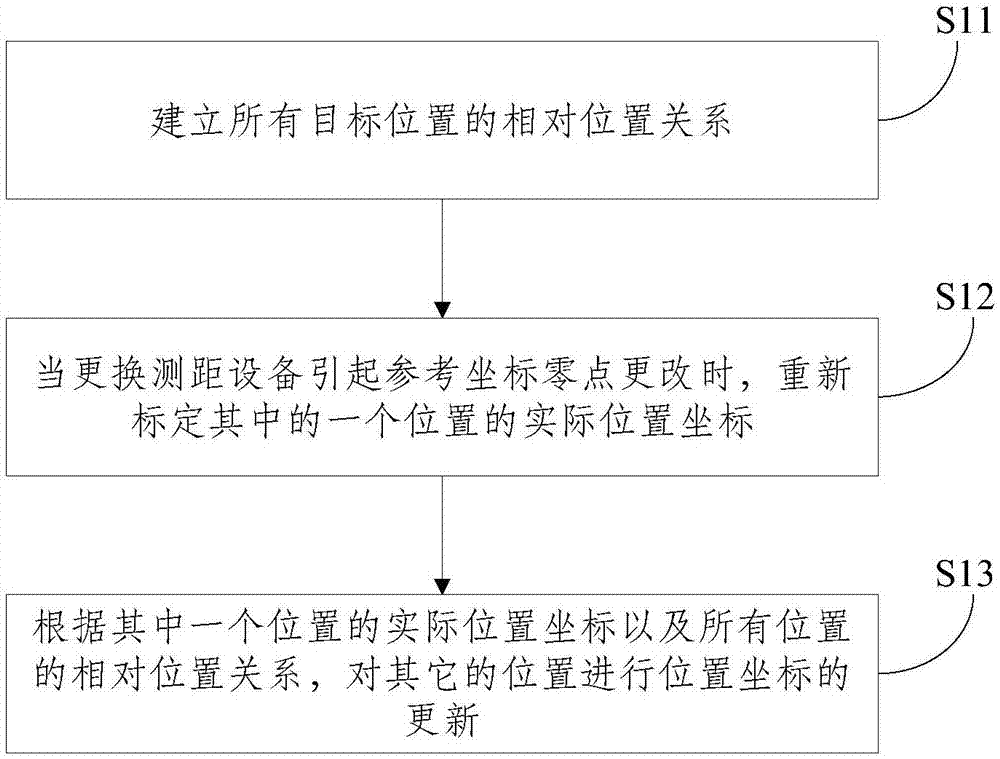

Electrolytic workshop position information management and distance measurement data processing method

ActiveCN107064951AIncrease productivityImprove informatizationDatabase updatingGeographical information databasesLaser rangingMeasuring instrument

The invention provides an electrolytic workshop position information management and distance measurement data processing method, which comprises the steps of calibrating position coordinates of each target position by using a laser distance measuring instrument installed on an electrolytic travelling crane; numbering each target position, building a mapping relation table between target position numbers and position coordinates, and storing the built mapping relation table into a database; building a relative position relation of all target positions according to the mapping relation table in the database; and automatically updating the mapping relation table in the database by using a re-calibration rule when the laser distance measuring instrument is replaced in a later period. According to the invention, all target positions can be updated by using the re-calibration rule according to the relative position relation of all target positions in an electrolytic workshop, distance measuring data after laser distance measuring signals are lost is speculated according to historical movement data of the electrolytic traveling crane, and a problem of distance measuring signal loss in the high-speed operating process of the electrolytic travelling crane is avoided.

Owner:CENT SOUTH UNIV

A power quality disturbance source location system and location method

ActiveCN104635114BSimple structurePrecise automatic positioningFault locationPower qualityStart time

The invention relates to a positioning system and a positioning method of a power quality disturbance source. The positioning system includes a power quality management master station and an online power quality monitoring device connected to the master station through Ethernet. Each monitoring point of the line is equipped with a power quality online monitoring device, and the power quality online monitoring devices are connected through Ethernet; when an actual disturbance event occurs in the system, the power quality online monitoring device will record the disturbance event after detecting the disturbance event. The time when the disturbance source occurs, and broadcast to other power quality online monitoring devices in the network via Ethernet to start the disturbance recording system based on this time, and record the sampling data of N cycles before and after N cycles , and send it to the power quality management master station in real time, and establish the system coverage matrix and system direction matrix through the mutual cooperation between various power quality online monitoring devices, and then locate the disturbance source.

Owner:JIANGSU ELECTRIC POWER CO +2

Rotor production equipment for air suspension centrifugal compressor

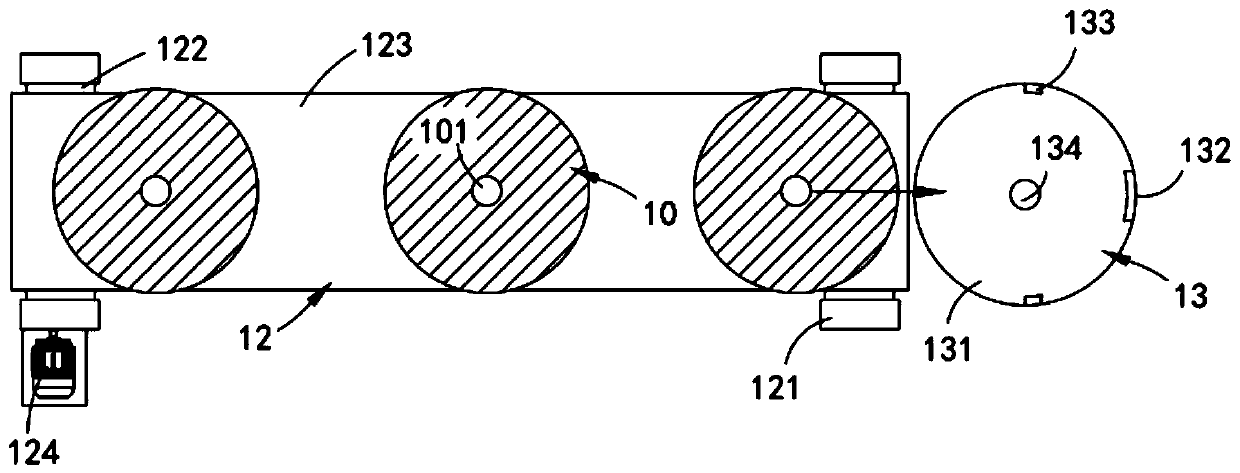

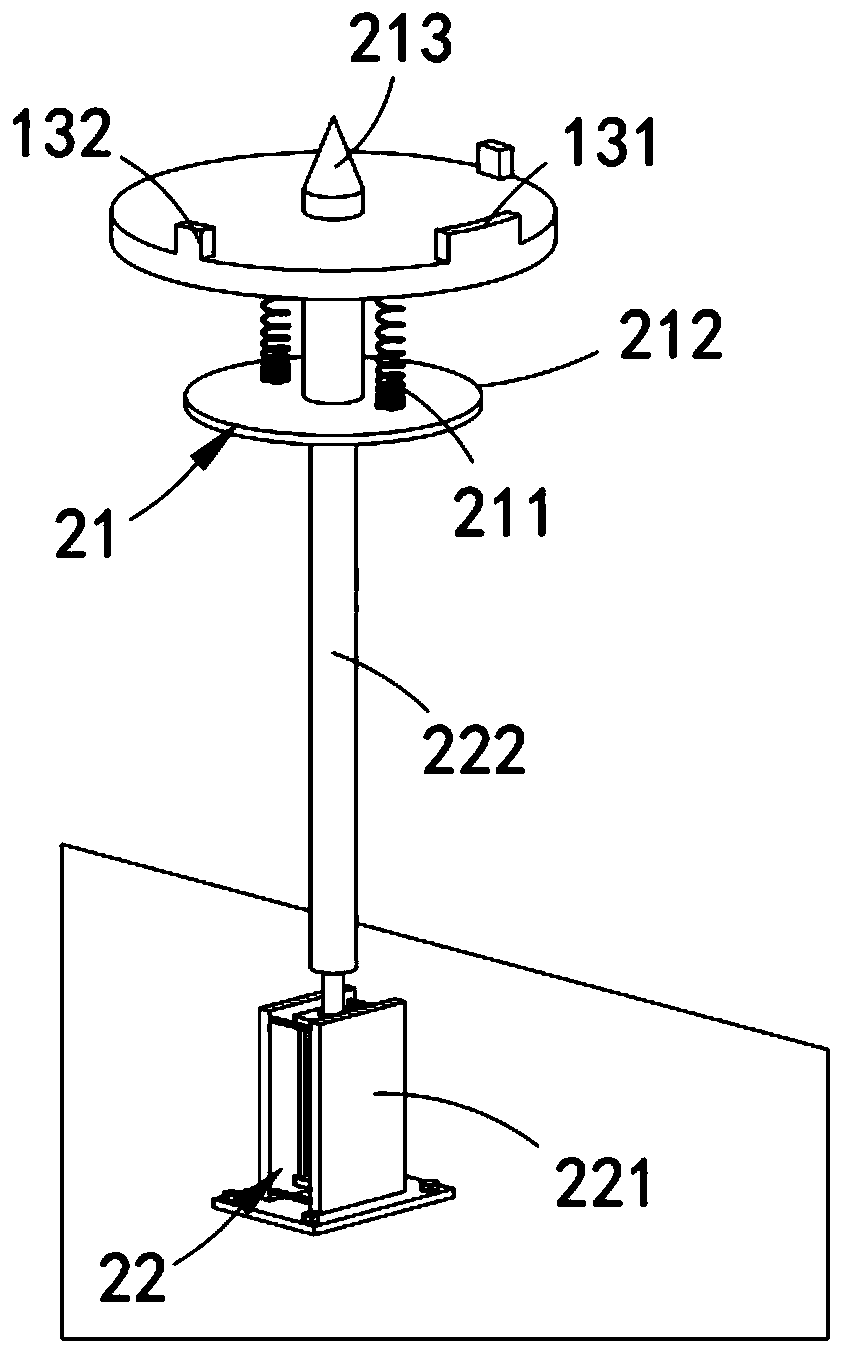

ActiveCN110900029AHigh degree of automationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCircular discEngineering

The invention relates to rotor production equipment for an air suspension centrifugal compressor. The rotor production equipment comprises a disc conveying mechanism, a precise positioning mechanism,a blade conveying mechanism and a welding robot; the disc conveying mechanism comprises a machine seat, a first conveying assembly and a bearing assembly; the precise positioning mechanism comprises adeviation rectifying assembly, a driving assembly fixedly connected with the deviation rectifying assembly and driving the deviation rectifying assembly to move up and down in the vertical directionand a limiting assembly positioned above the bearing assembly and mounted on the machine seat; the blade conveying mechanism comprises a plurality of groups of second conveying assemblies arranged onthe limiting assembly and arrayed in the circumferential direction of a disc, pushing assemblies in one-to-one correspondence with the input ends of the second conveying assemblies and working synchronously with the driving assembly as well as hooping assemblies arranged above the second conveying assemblies and in synchronous action with the driving assembly; and the welding robot is used for carrying out one-by-one welding and assembling of a plurality of groups of blades accurately positioned on the disc. According to the rotor production equipment for the air suspension centrifugal compressor, the technical problem of inaccurate precision in the installation position during assembling of the blades of a fan can be solved.

Owner:HUZHOU TEACHERS COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com