ITO (indium tin oxide) membrane photoetching automatic recognition positioning method

A technology of automatic identification and positioning method, which is applied in the direction of microlithography exposure equipment, optics, photoplate making process exposure device, etc., which can solve the problems of CCD photosensitive element, such as poor light sensitivity, impact on accuracy, and weak reflection, and achieve clear patterns , improve the processing quality, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

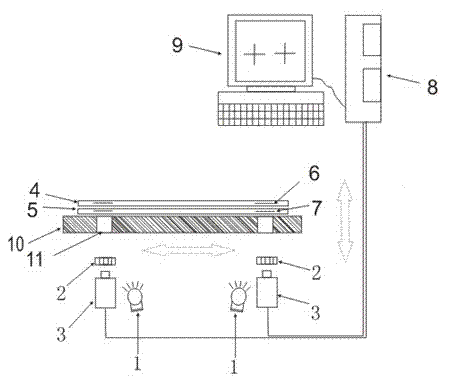

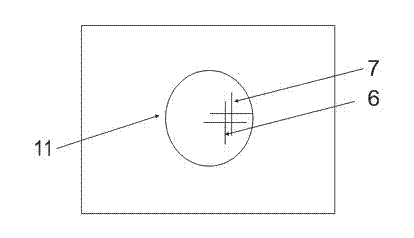

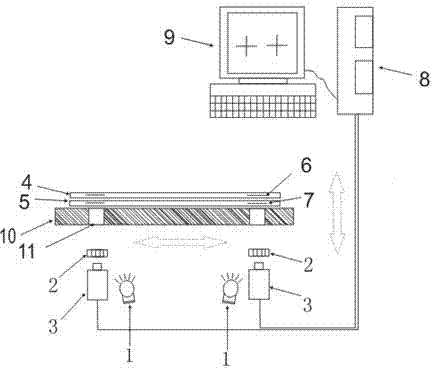

[0013] Such as figure 1 , 2 As shown, a method for automatic identification and positioning of ITO film lithography, which includes the following steps: two UV light sources 1 with a power of 3.5W and a wavelength of 365nM, two sets of CCD imaging equipment 3 and two sets of imaging optical systems 2 Installed under the reticle 4 and the ITO diaphragm 5 covered with photoresist, two sets of CCD imaging equipment 2 capture the reticle alignment mark 6 and the diaphragm alignment mark 7 through two sets of imaging optical systems 3, and the image acquisition The image data is collected by the card 8, input to the computer 9 for processing, positioning and real-time display of the alignment mark image, and adjusting the relative position error of the reticle alignment mark 6 and the diaphragm alignment mark 7 images displayed on the screen of the computer 9 The position of the diaphragm 5, so as to realize automatic and precise alignment between the diaphragm 5 and the reticle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com