Automatic seal cover taking control system for nuclear waste steel drum

A control system, nuclear waste technology, applied in the direction of closures, nuclear engineering, screw cap disassembly, etc., can solve the problems of effective control, no control system, low operating efficiency, etc., to achieve stable and reliable operation, prevent dust from entering, and structural design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

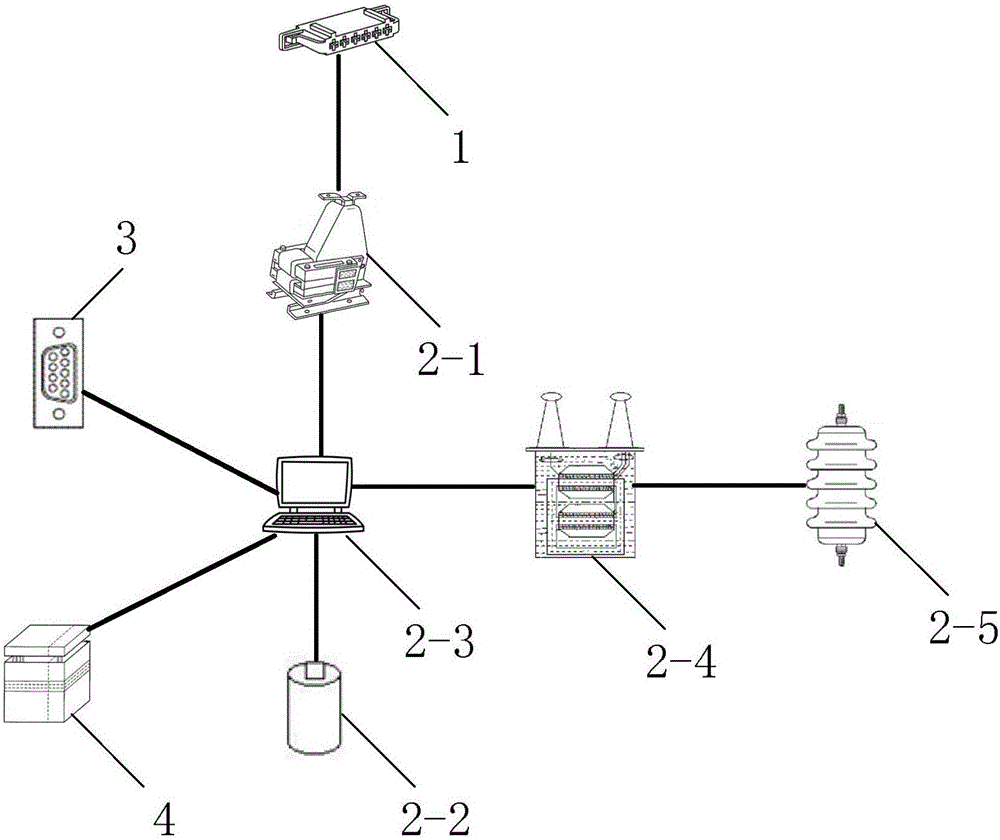

[0029] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

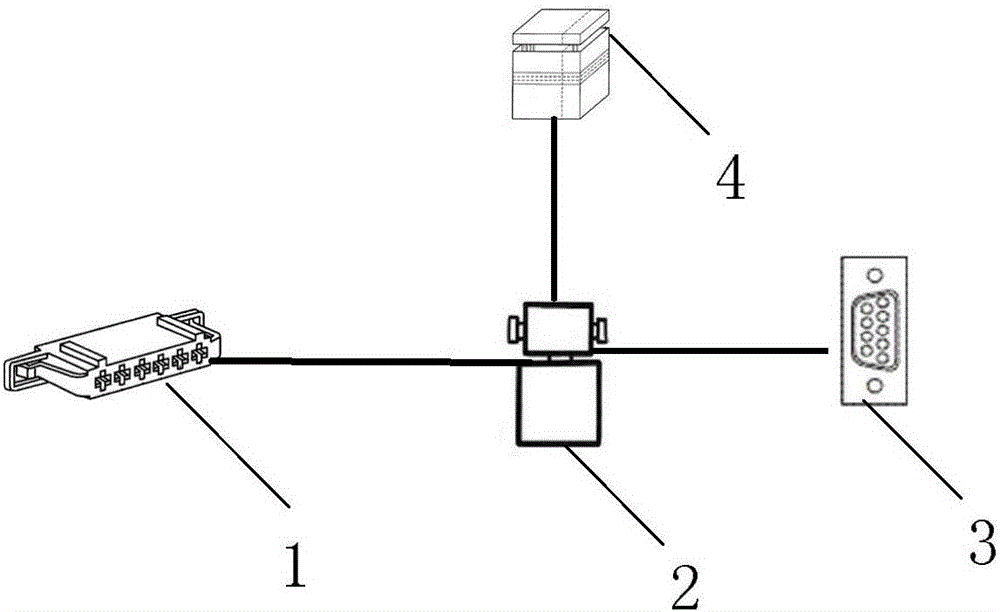

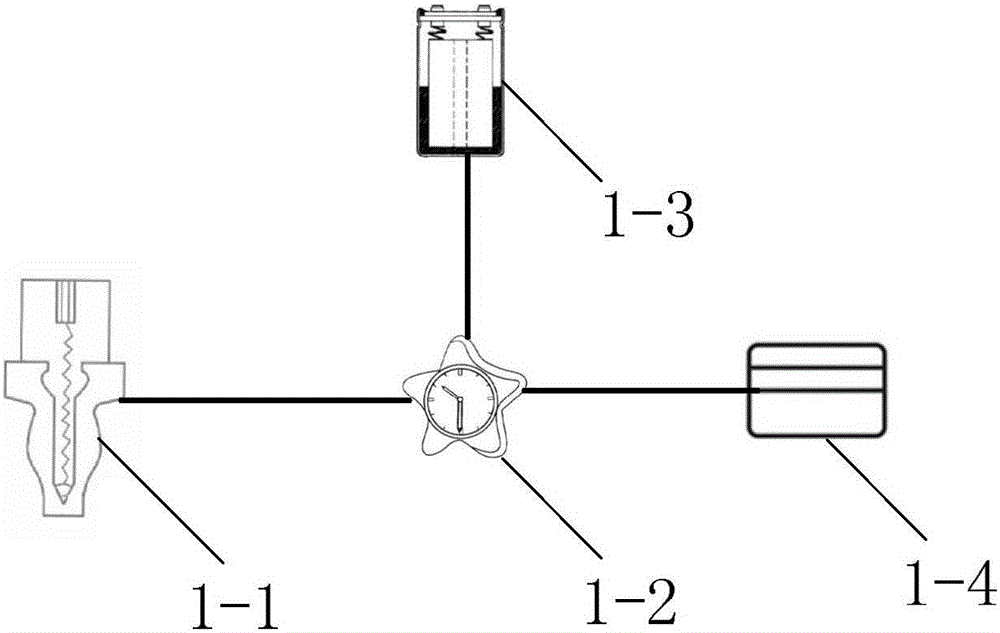

[0030] see Figure 1 to Figure 4 As shown: the nuclear waste steel drum automatic capping control system includes: image monitoring unit 1, motion control unit 2, positioning unit 3, sensor unit 4;

[0031] The motion control unit 2 is used for data calculation and processing, and sends out control commands;

[0032] The image monitoring unit 1 is connected with the motion control unit 2 for real-time monitoring of the actions of the entire device during operation;

[0033] The positioning unit 3 is connected with the motion control unit 2 for precise positioning of the X-axis, Y-axis, Z-axis and rotary C-axis;

[0034] The sensor unit 4 is connected with the motion control unit 2 for detecting the position of the metal bucket.

[0035] The motion control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com