Gantry numerical control machining center and control system and machining method of gantry numerical control machining center

A machining center and gantry technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as safety accidents, complex structures, and damage to suction cup mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

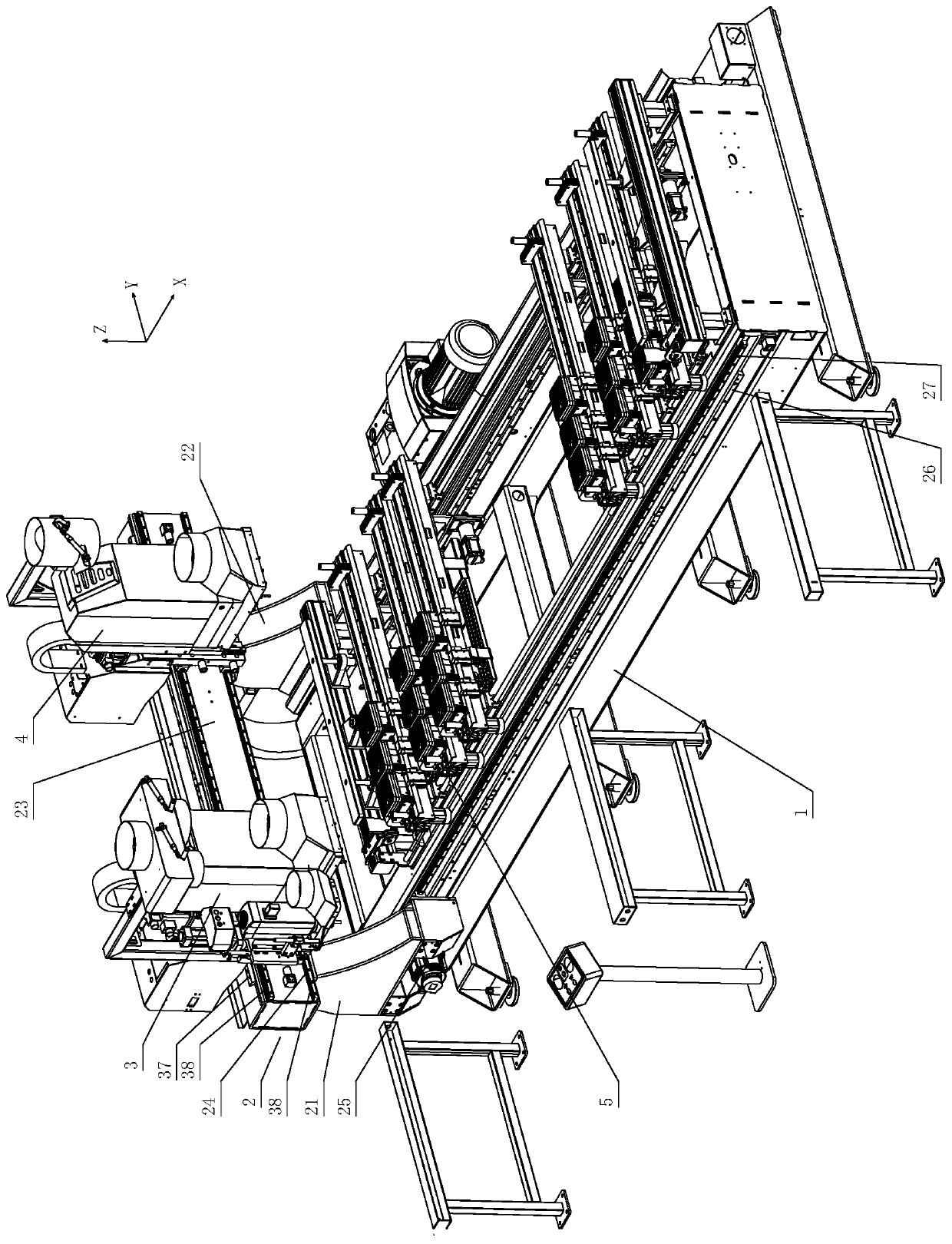

[0146] like figure 1 As shown, a gantry numerical control machining center includes a base 1 , a gantry device 2 , a left machine head 3 , a right machine head 4 , and a workbench device 5 .

[0147] The workbench device 5 is installed on the base 1, and the gantry device 2 is installed together with the base 1 so as to slide back and forth in the X direction; the left machine head 3 and the right machine head 4 are installed on the beam so as to slide back and forth in the Y direction, and are arranged side by side , and placed directly above the workbench device 5 .

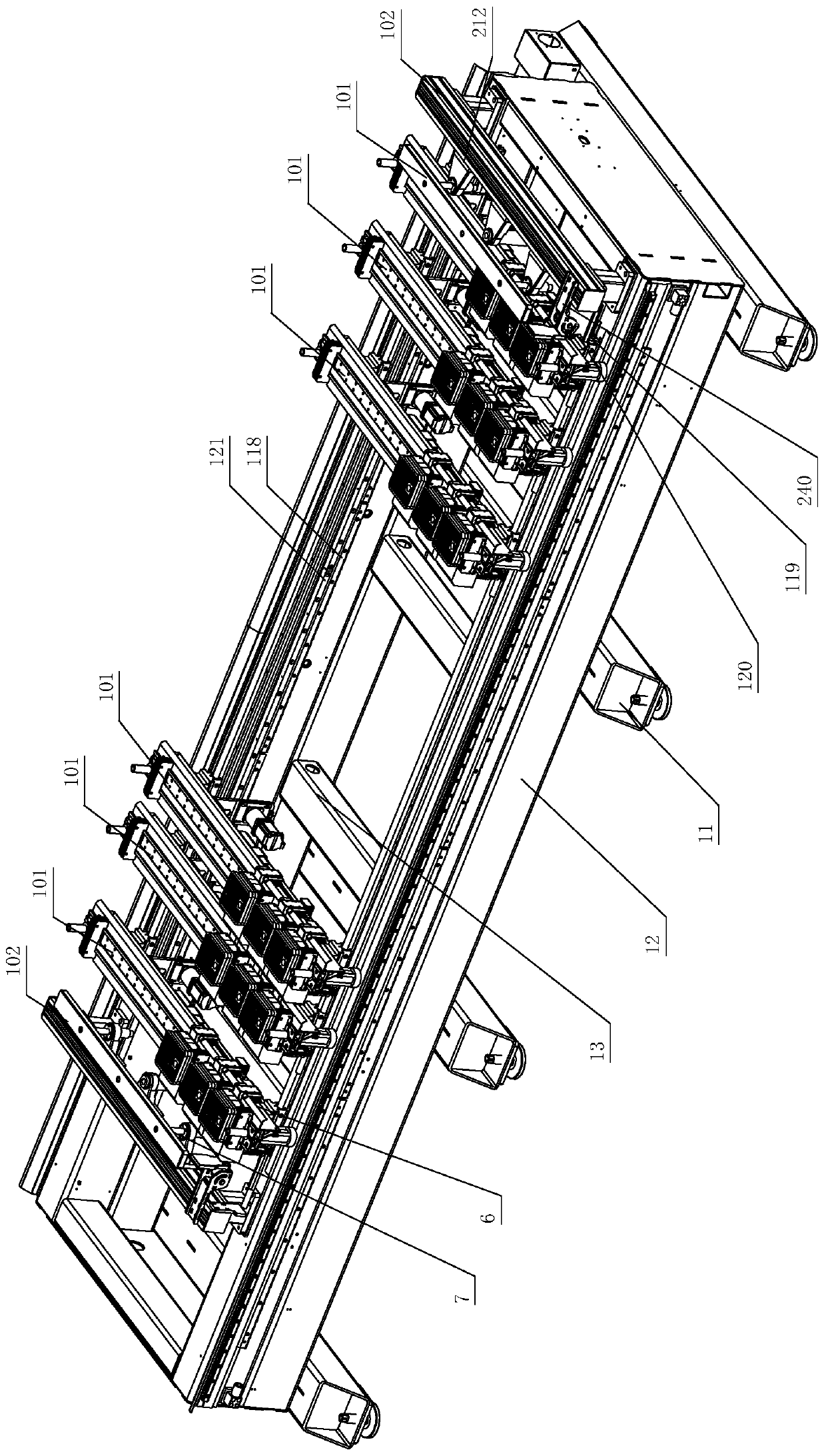

[0148] like figure 2 As shown, the base 1 includes a plurality of square tubes 11 arrayed along the X direction, a square frame-shaped installation frame 12 fixed on the plurality of square tubes 11 , and a Y-direction reinforced square tube 13 fixed inside the installation frame 12 .

[0149] like figure 1 , figure 2 As shown, the gantry device 2 includes a left column 21, a right column 22, and a beam 2...

Embodiment 2

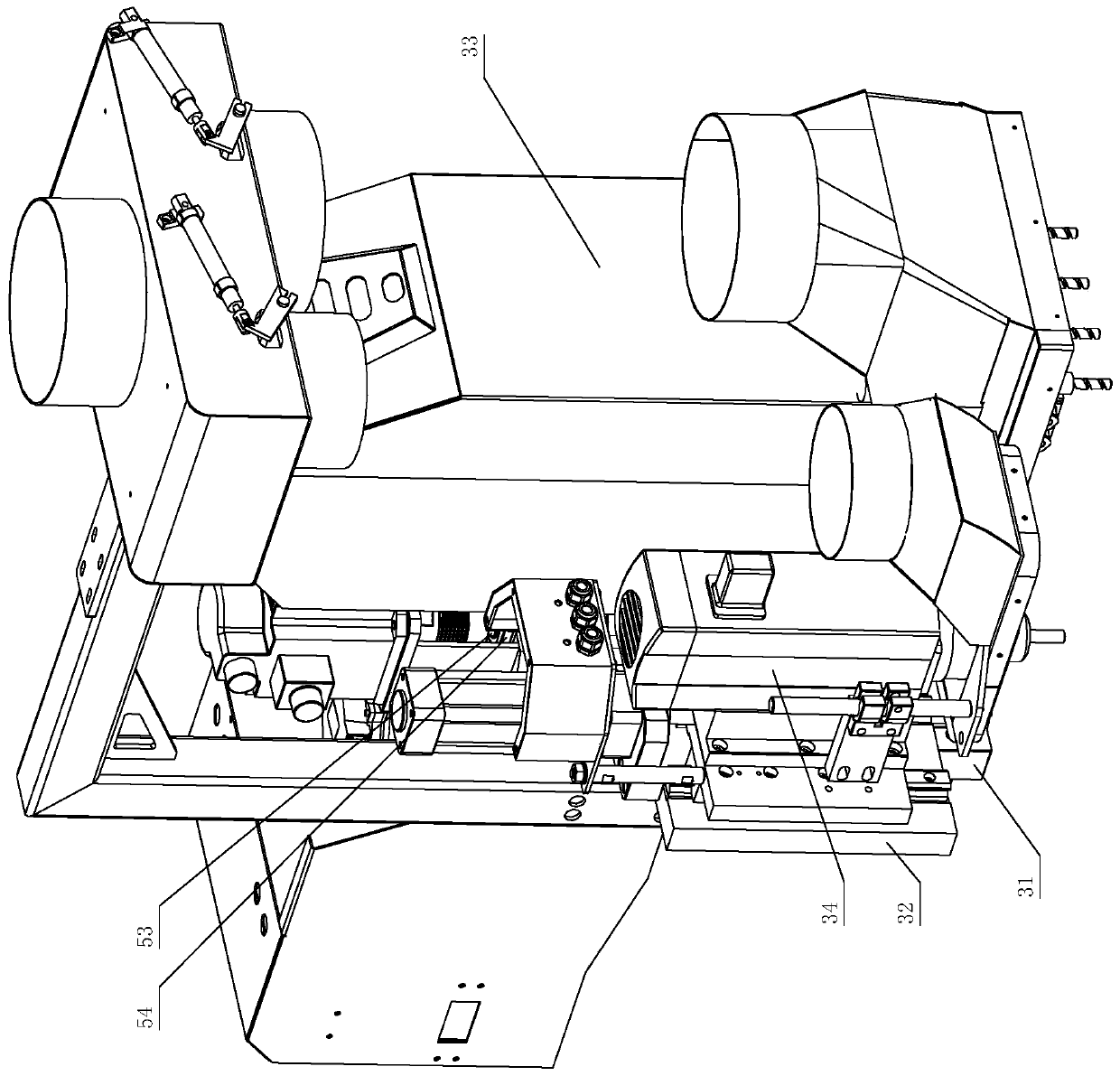

[0221] like Figure 11 As shown, the difference from Embodiment 1 is that each suction cup mechanism includes a suction cup 301, and the vacuum pipeline follows the moving assembly 302.

[0222] The suction cup movement and positioning mechanism utilizes the self-locking function of the suction cup Y-axis feed servo mechanism and the suction cup Y-axis feed transmission mechanism, and can realize the automatic positioning of the suction cup without the air lock component, and can also realize the automatic movement of the suction cup, which not only greatly simplifies structure, but also greatly improved the degree of automation.

Embodiment 3

[0224] like Figure 12 As shown, a control system of a numerical control machining center includes a CNC controller, a data bus, a control bus, and an address bus connected to the CNC controller, a bidirectional control servo control unit connected in parallel to the data bus, the control bus, and the address bus, Left machine head control unit, right machine head control unit, workbench control unit, vacuum control unit, strong and weak current control unit, man-machine dialogue interface unit, communication unit.

[0225] There are multiple standardized CNC controller interfaces on the CNC controller; servo control unit, left machine head control unit, right machine head control unit, workbench control unit, vacuum control unit, strong and weak current control unit, man-machine dialogue The interface unit and communication unit are modules composed of open and modular structures; they have standardized connectors that cooperate with the CNC controller interface, and can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com