Printing and bonding production line and die cutting equipment thereof

A production line and die-punching technology, applied in the field of printing lamination production line and die-cutting equipment, to achieve excellent process flexibility and product adaptability, promote large-scale batch production, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

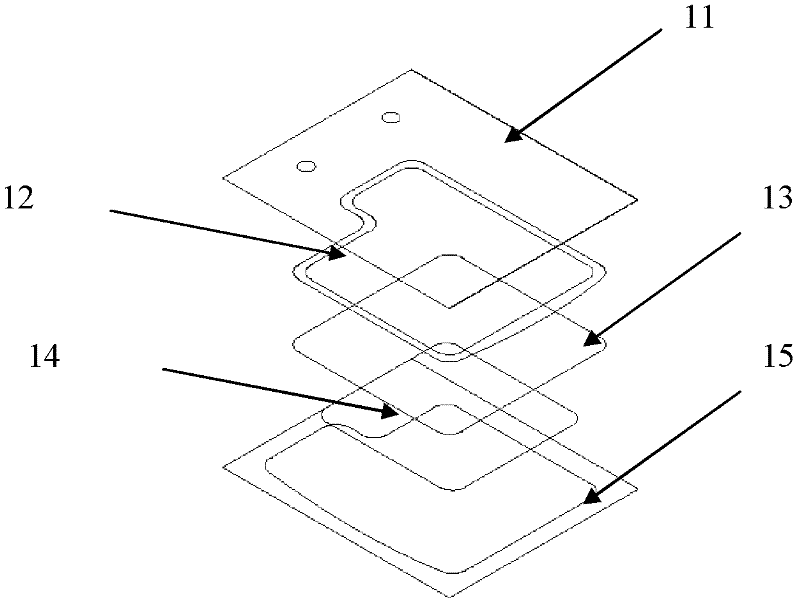

[0036] In the prior art, since printed electronic products have the characteristics of multiple levels and require accurate positioning between levels, there is currently no related equipment for mass production.

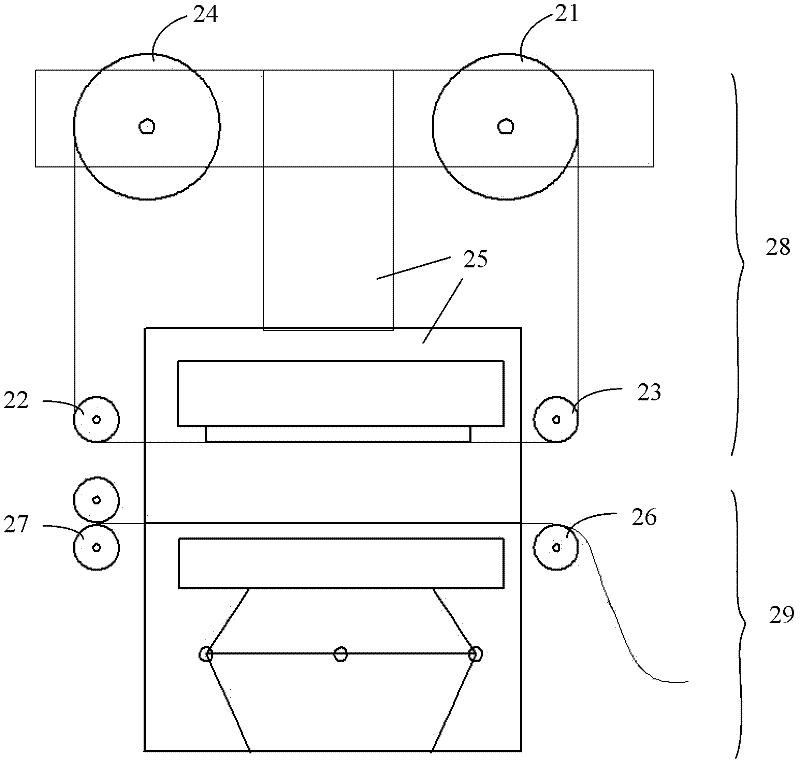

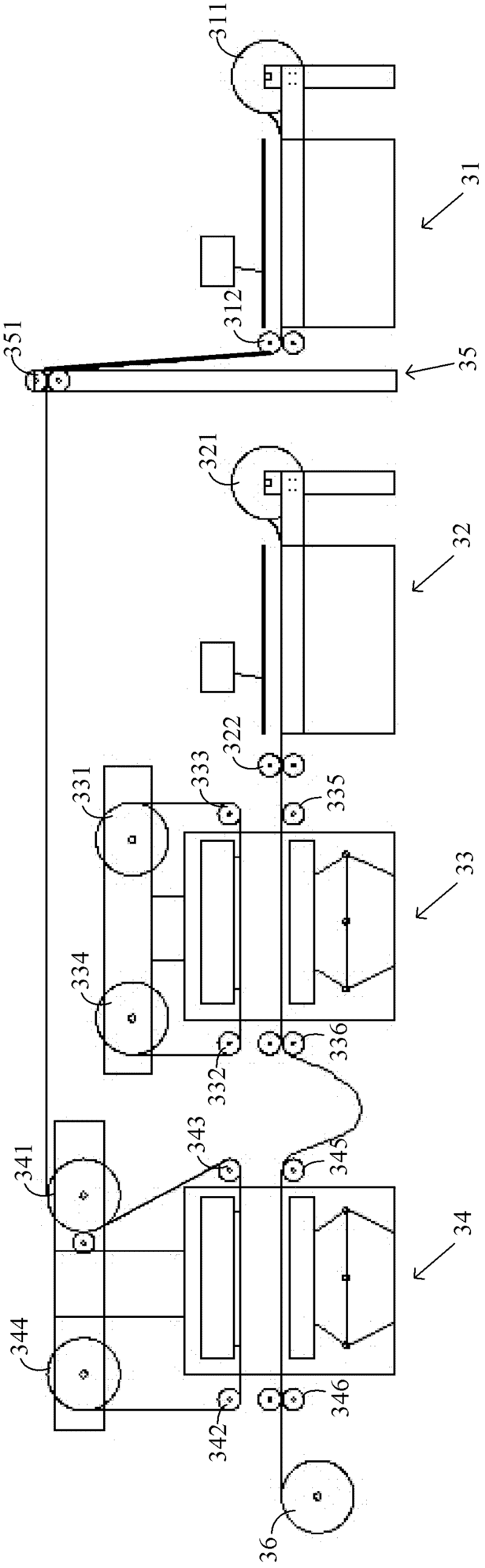

[0037] The die punching equipment of the embodiment of the present invention adopts the first raw material feeding mechanism and the second raw material feeding mechanism to feed the first strip-shaped raw material and the second strip-shaped raw material for punching and bonding, and adopts electronic identification The tracking components respectively track and locate the positioning marks on the first strip-shaped raw material and the second strip-shaped raw material, so that the die-cutting mechanism and the positioning and laminating mechanism can work at a consistent pace, which is beneficial to all levels of printed electronic products. Accurate and automatic positioning.

[0038] The printing and laminating production line of the embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com