Modular battery block structure

A modular battery and group structure technology, which is applied to battery pack parts, structural parts, secondary batteries, etc., can solve the problems of violent internal battery, battery burning, and temperature rise, which is conducive to mass production , low calorific value, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described now in conjunction with accompanying drawing.

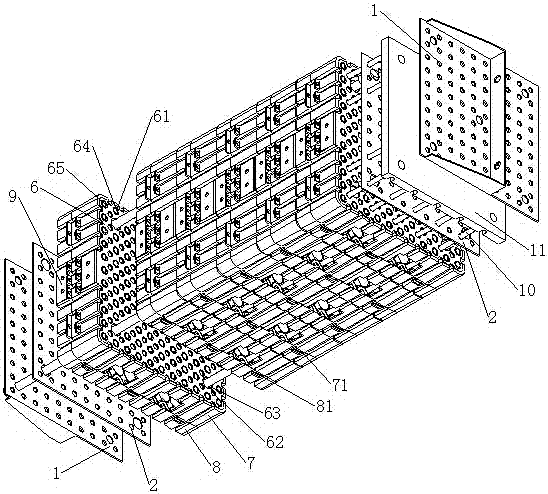

[0027] Such as figure 1 As shown, a modular battery group structure includes a fixed bracket 1, an epoxy board 2, a series module, an epoxy board 2, a heat sink, and a fixed bracket 1 that are sequentially stacked and installed. The modules are stacked and installed in sequence. There are manifolds on both sides of the series modules, and parallel batteries are installed inside. The two ends of the batteries are respectively connected to the manifolds, and the serial modules are connected in series.

[0028] The fixing bracket 1 is located at both ends of the power battery pack, and fixes the power battery pack in the battery box. The epoxy board 2 mainly plays an insulating role, and separates the serial module from the fixed bracket 1 and the heat dissipation device. Secure all parts with long bolts.

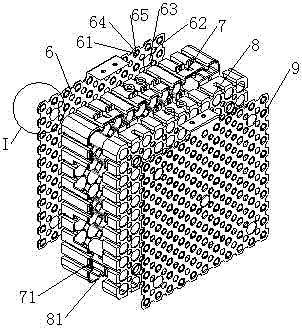

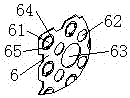

[0029] Such as figure 2 As shown, the series module includes a left...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com