Pressure increasing type automatic locating steel pipe clamp

A technology of automatic positioning and pipe clamping, which is applied in the direction of pipes/pipe joints/fittings, pipe supports, earth movers/excavators, etc., which can solve the problems of high processing precision, large volume of pipe clamps, and many processing procedures of pipe clamps, etc. problem, to achieve the effect of accurate automatic positioning and good manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

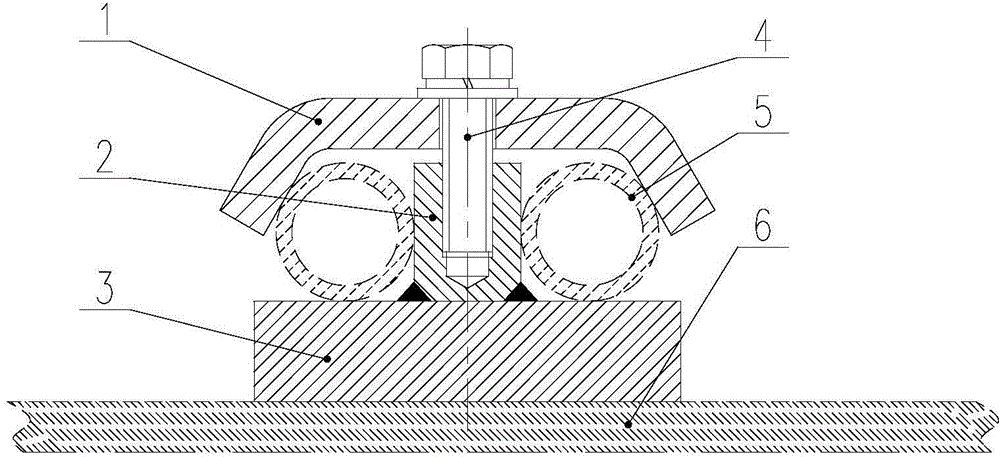

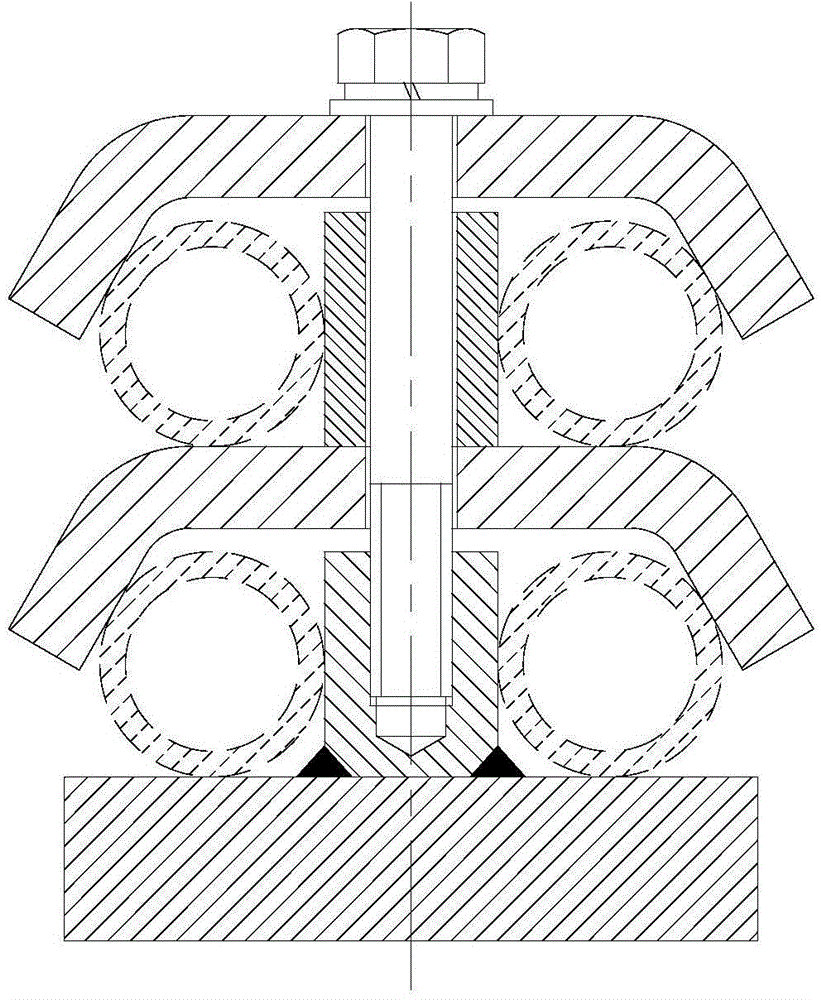

[0023] Such as Figure 1 to Figure 6 As shown, the pressurized automatic positioning steel pipe clamp of the present invention includes an upper pipe clamp 1 , a boss 2 , a bottom plate 3 , a hex head bolt 4 and a fixing plate 6 . The boss 2 and the bottom plate 3 are welded together and fixed on the fixed plate 6 , and the hex head bolt 4 passes through the through hole of the upper pipe clamp 1 and is screwed into the screw hole of the boss 2 .

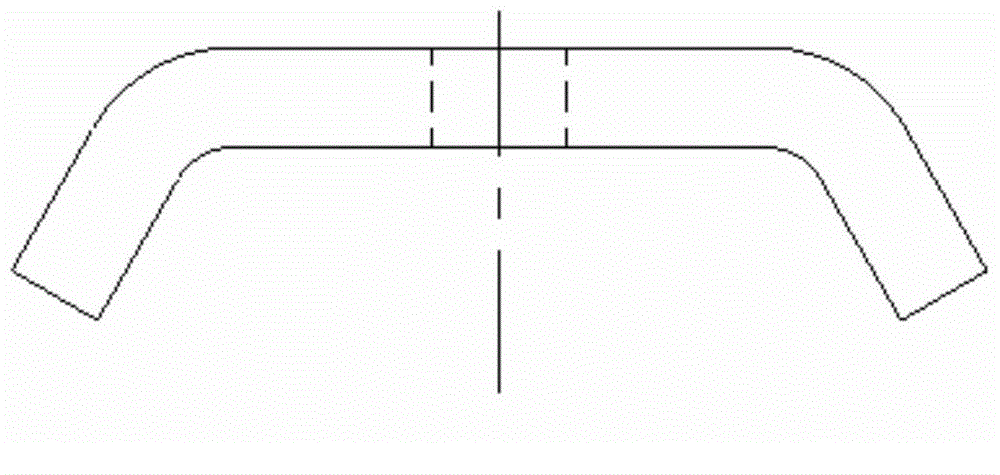

[0024] The two sides of the upper pipe clamp 1 are designed with a wedge-shaped slope. When the upper pipe clamp 1 is pressed on the outside of the steel pipe 5 on both sides of the boss 2, the steel pipe 5 is subjected to oblique pressing force, and the steel pipe 5 can only move toward the middle and Move closer to the bottom, and quickly and automatically locate.

[0025] At least one pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com