Patents

Literature

39results about How to "Improve edging accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

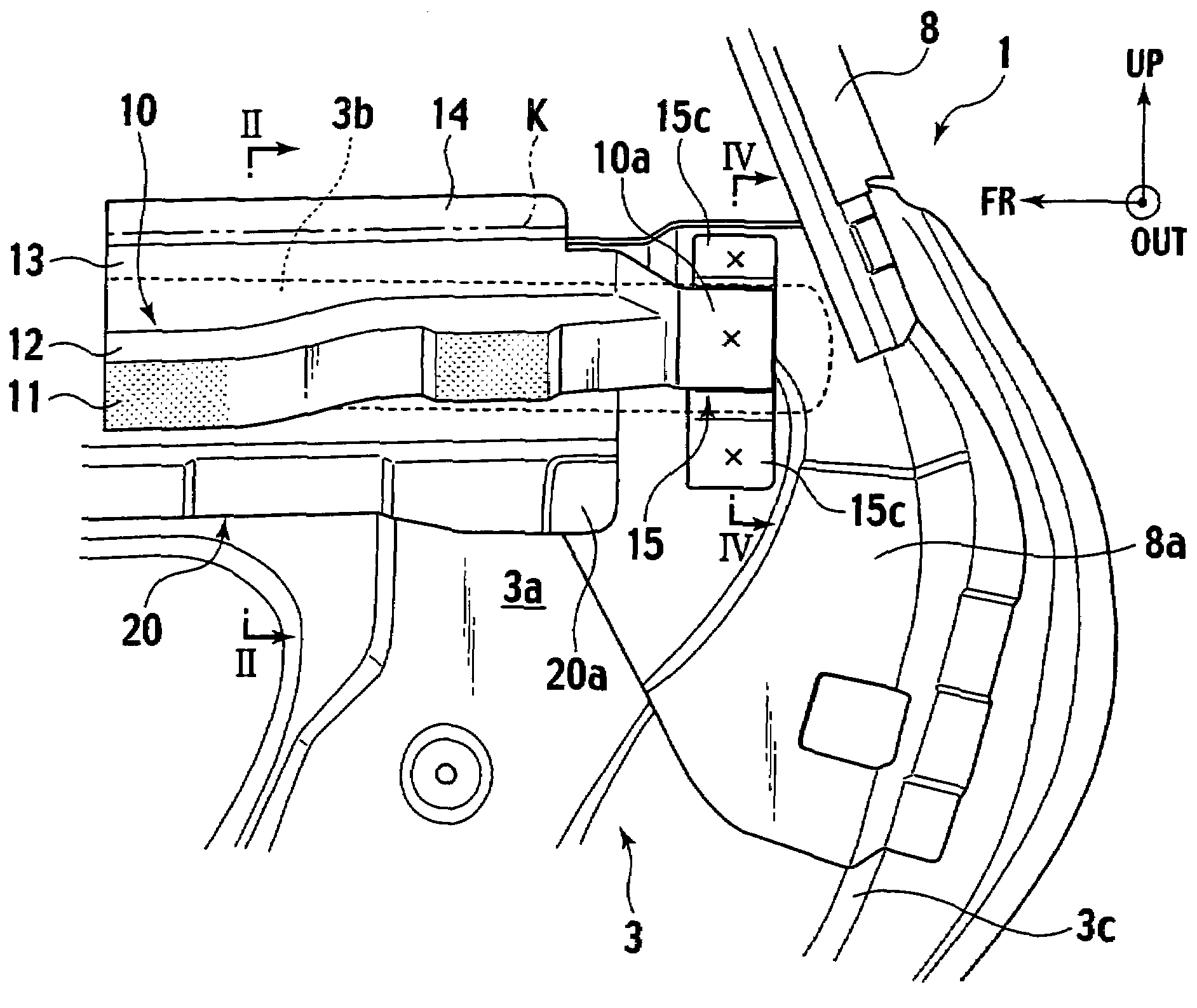

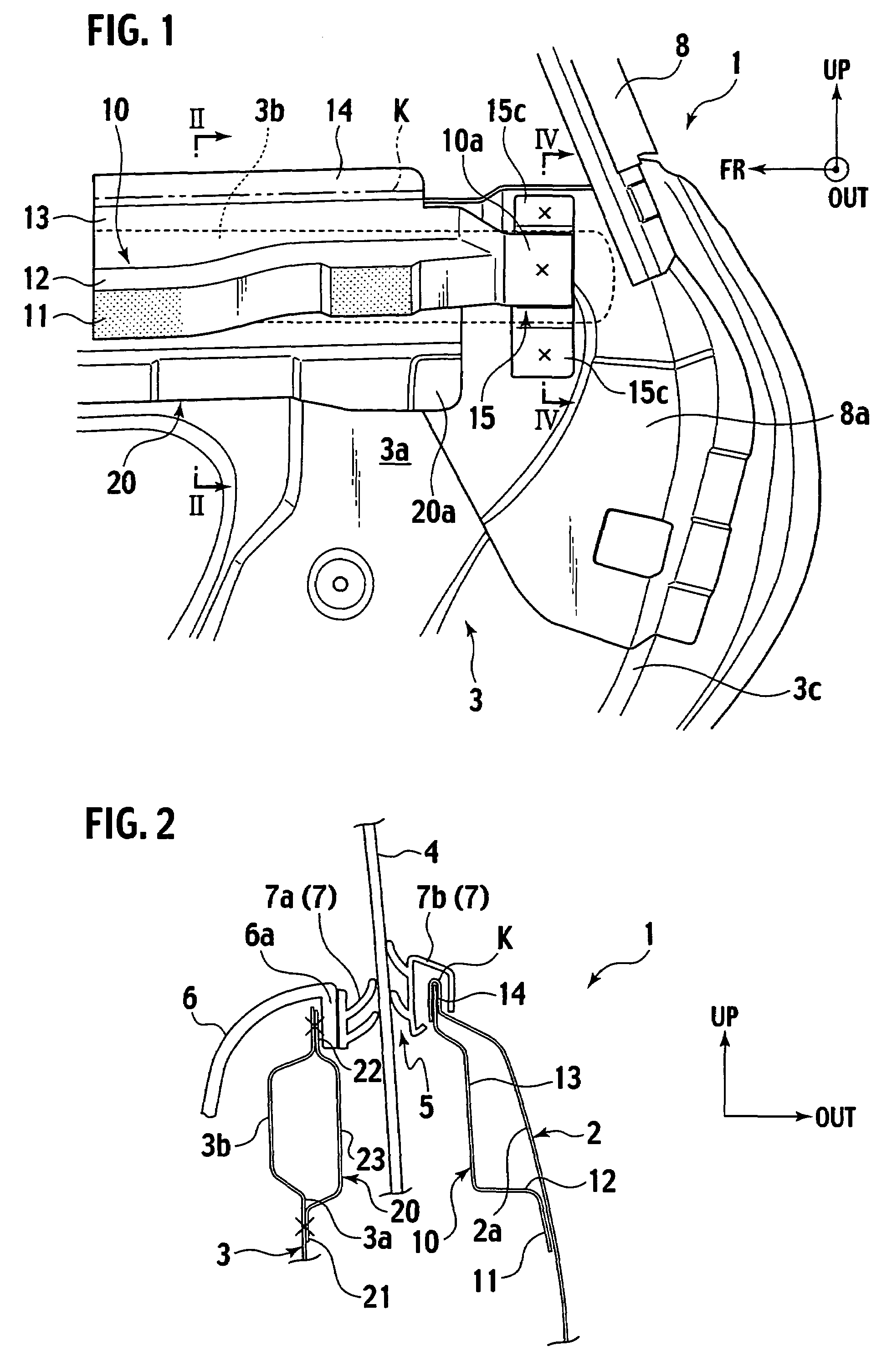

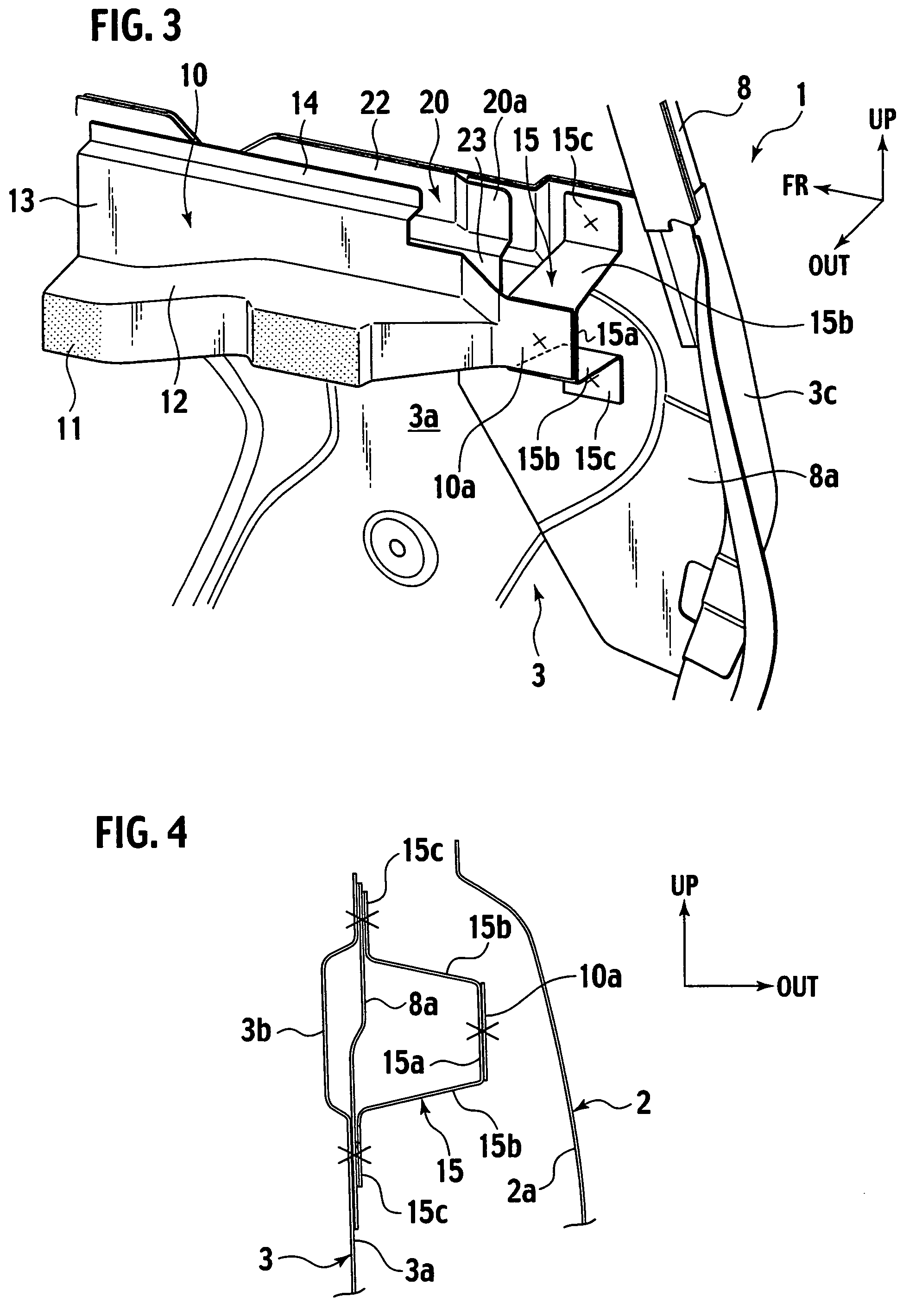

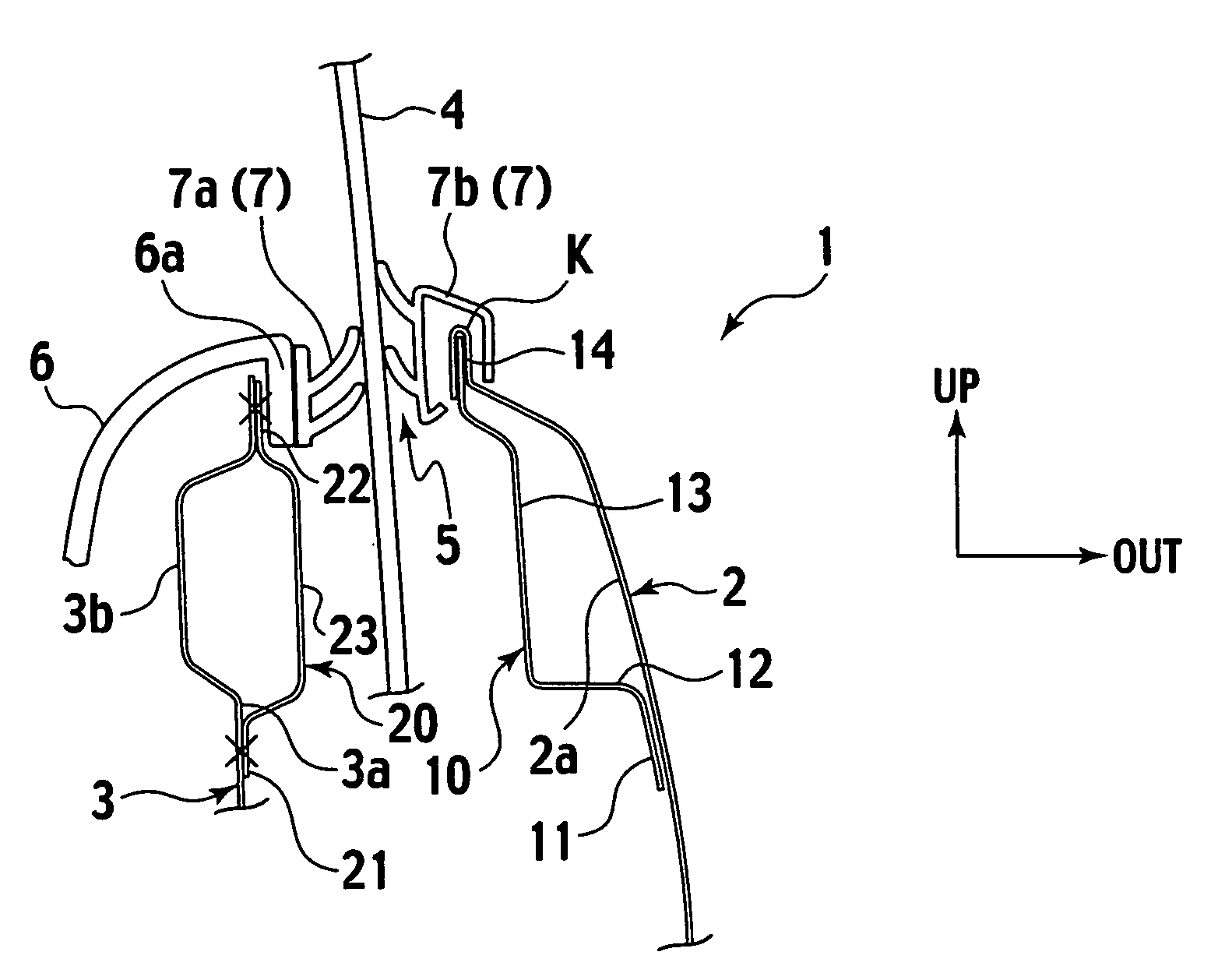

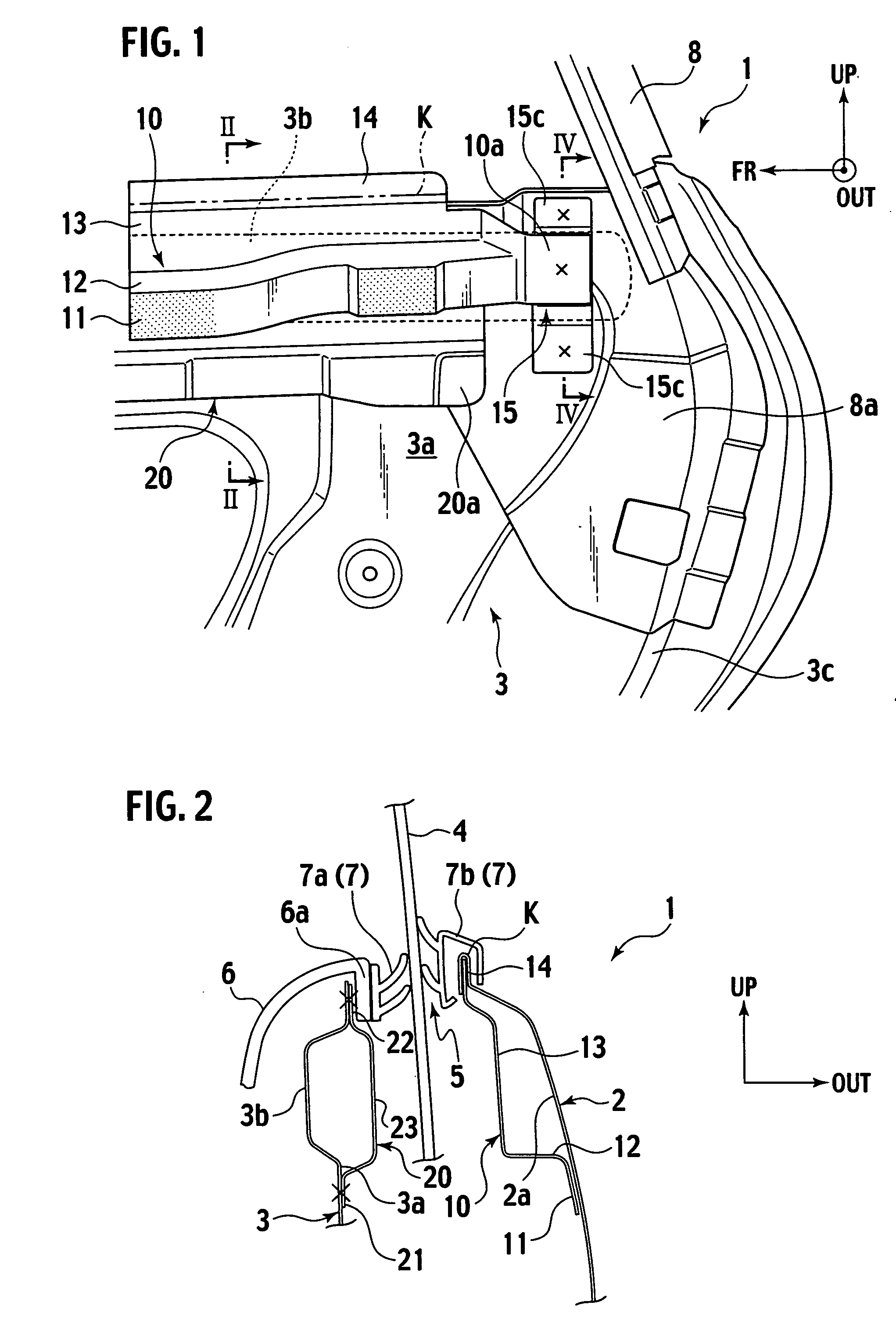

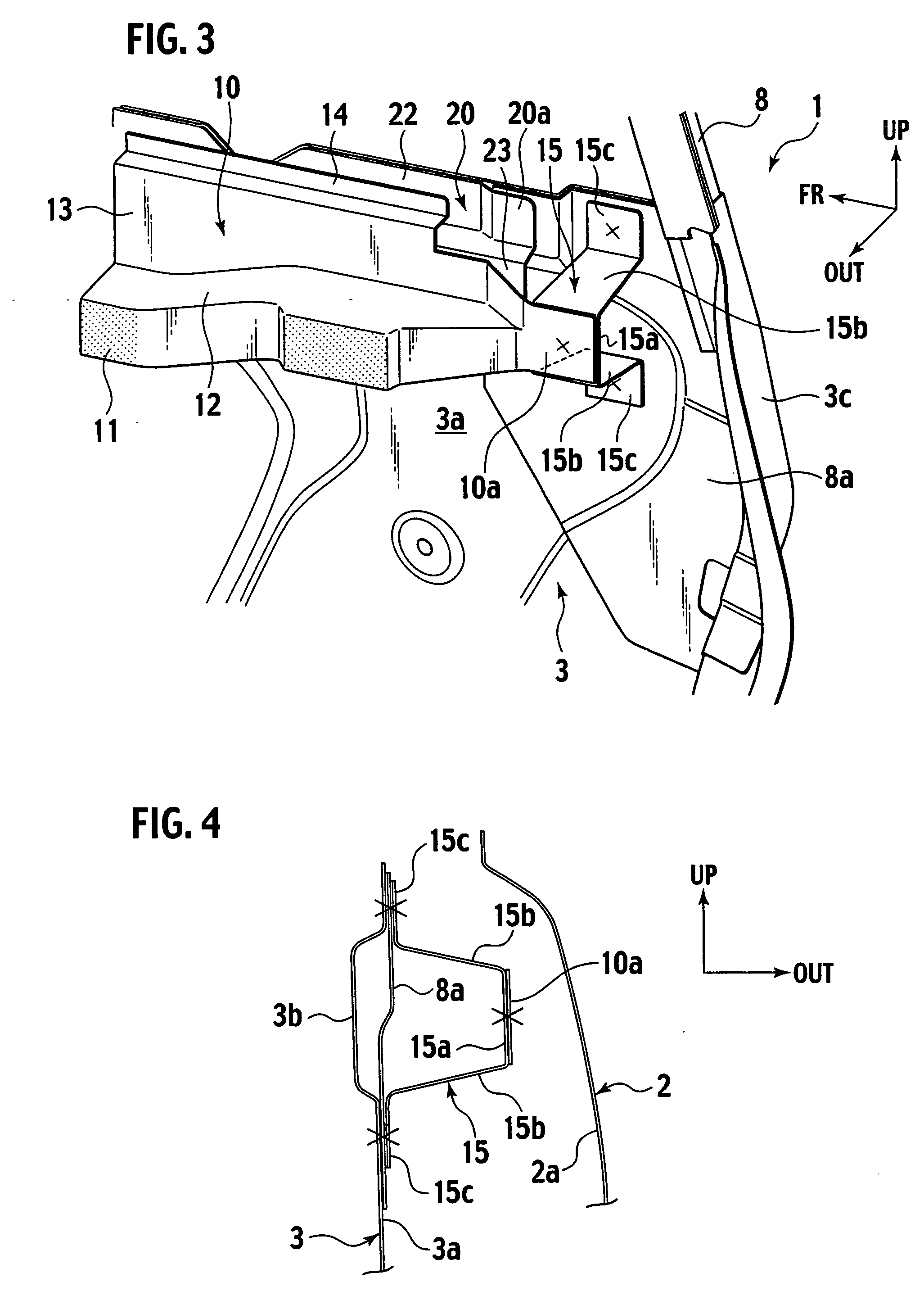

Opening portion structure

Owner:NISSAN MOTOR CO LTD

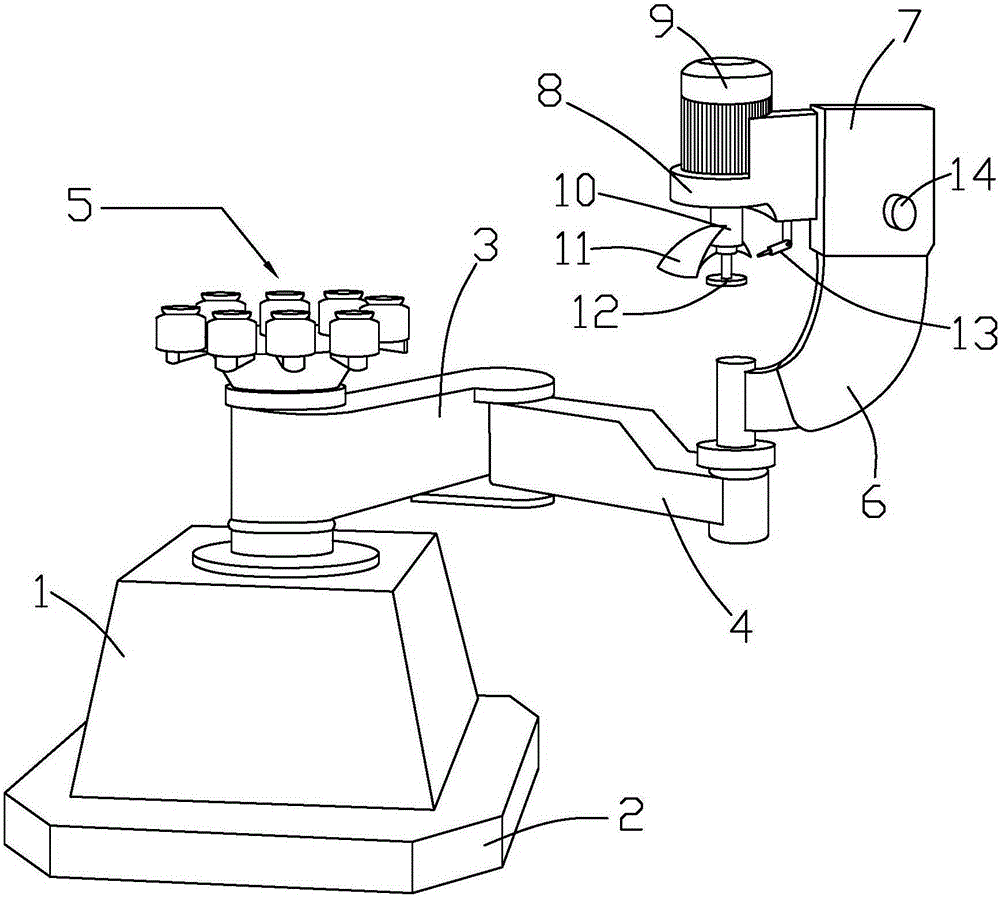

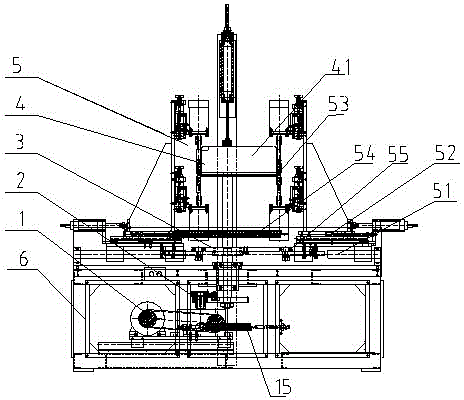

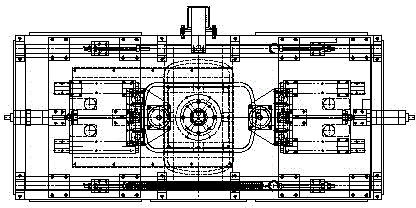

Arc glass edge grinding machine

InactiveCN105171559APrevent splashImprove securityEdge grinding machinesGrinding work supportsFuel tankEngineering

The invention discloses an arc glass edge grinding machine. The arc glass edge grinding machine comprises a box body, positioning suction cups and a grinding mechanism. The positioning suction cups are connected with the box body through a first cantilever. The other end of the first cantilever is connected with a second cantilever in a rotating manner. The end of the second cantilever is connected with a grinding mechanism. The grinding mechanism comprises an arc-shaped supporting frame, a fixed box, a positioning buckle plate and a first motor. The top end of the arc-shaped supporting frame is connected with the fixed box. The positioning buckle plate is arranged on the side face of the fixed box. The first motor is limited by the positioning buckle plate. A second motor, a hydraulic oil tank and a draught fan are arranged in the box body. An air inlet pipe and an air outlet pipe are arranged on the draught fan. The arc glass edge grinding machine is simple in structure and high in practicability, can conduct edge grinding on arc-shaped edges of conventional glass and can conduct arc edge grinding on glass of different sizes as well, the stability of glass during edge grinding is improved, glass uniformly bears force, the service life of the edge grinding machine is prolonged, and economic benefits are remarkable.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

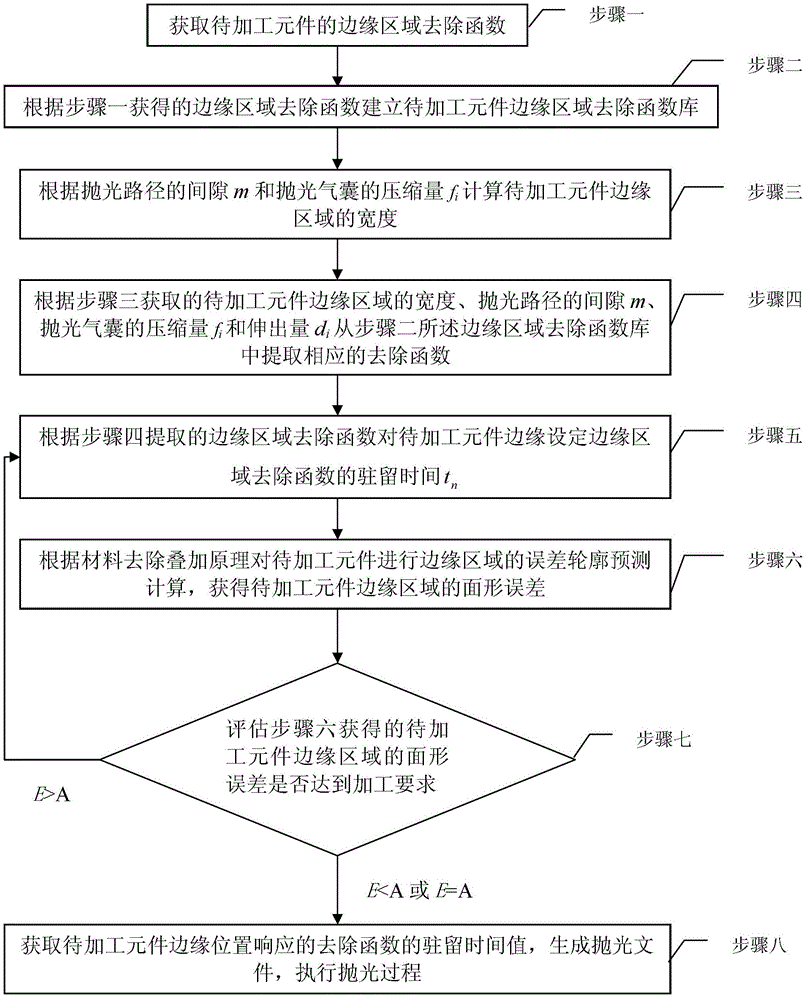

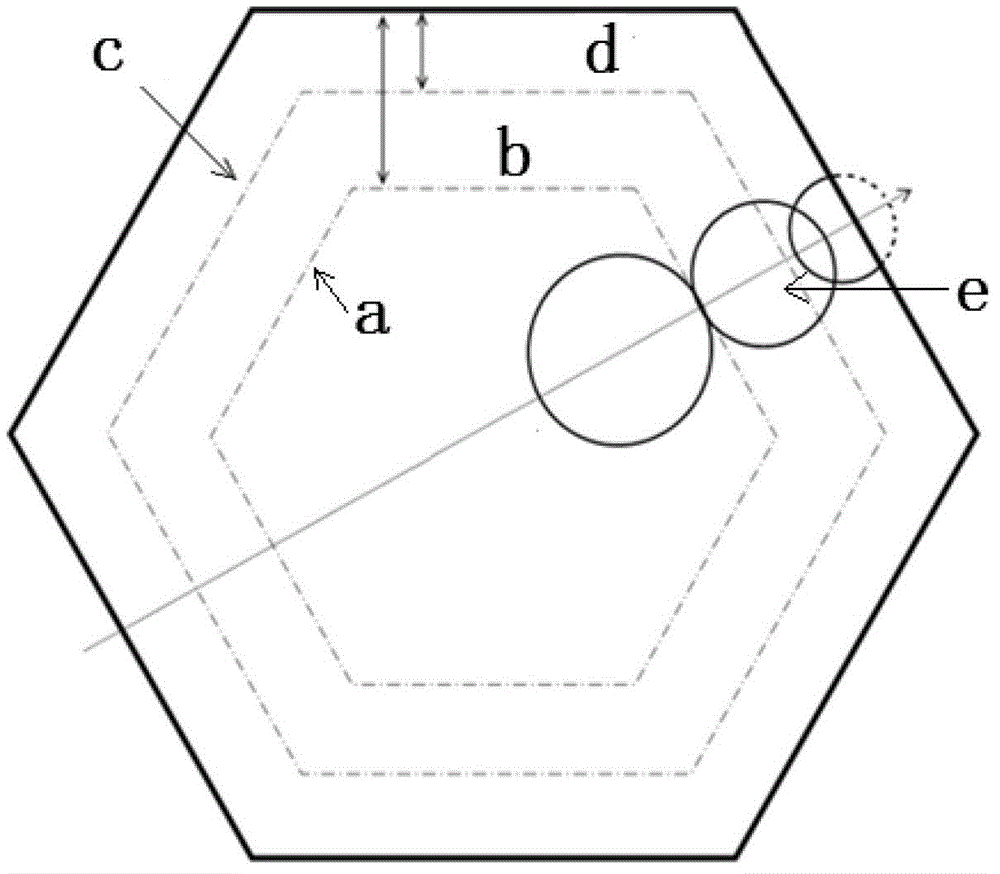

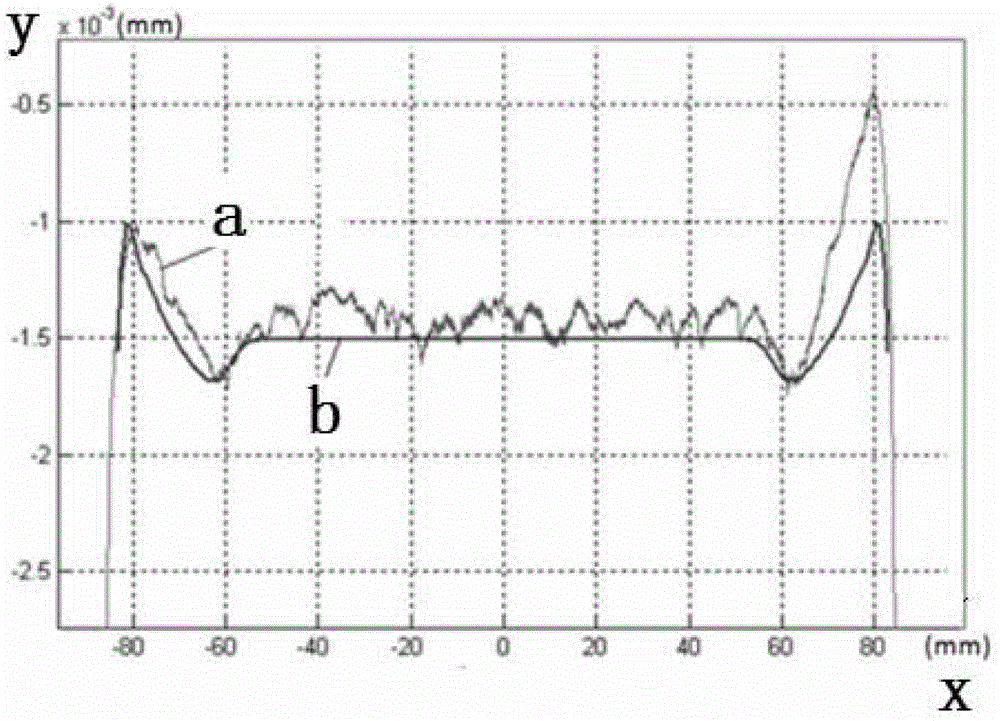

Edge precision control method of large aperture optical element being processed through air bag polishing

ActiveCN103144004AReduce riskPredict and optimize dwell timeOptical surface grinding machinesAutomatic grinding controlEdge effectsOptical processing

The invention discloses an edge precision control method of a large aperture optical element being processed through air bag polishing, and relates to a method for controlling edge precision in an air bag polishing element processing process, belonging to the field of optical processing. With the adoption of the edge precision control method, the problems that in the existing optical element processing process, in order to overcome 'edge effect', the risk of damaging main face precision is high, the cost is high, and the efficiency is low are solved. The method comprises the following steps: acquiring an edge area removing function of materials corresponding to the element to be processed; establishing an edge area removing function library of the element to be processed; calculating the width of an edge area of the element to be processed according to gap m of a polishing path and compression amount fi of a polishing air bag; extracting the corresponding removing function; setting residence time tn of the edge area removing function; carrying out error contour predication calculation on the edge area of the element to be processed, so as to acquire surface-shape error of the edge area of the element to be processed; estimating the surface-shape error; and acquiring a residence time value of the removing function responding to the edge position of the element to be processed, so as to generate a polishing file ,and executing a polishing process. The edge precision control method provided by the invention can be widely applied in the edge precision control processing process of large aperture opt elements.

Owner:HARBIN INST OF TECH

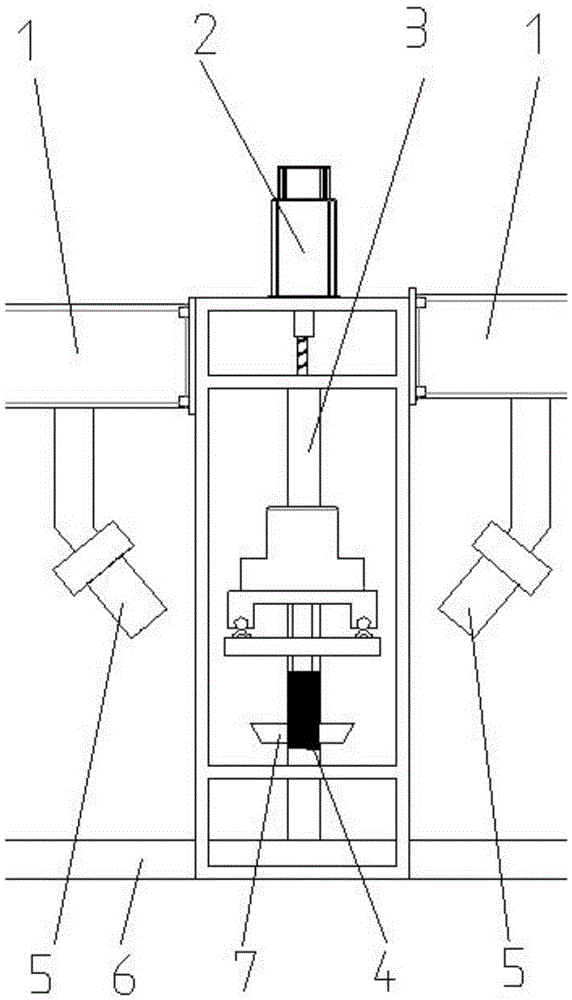

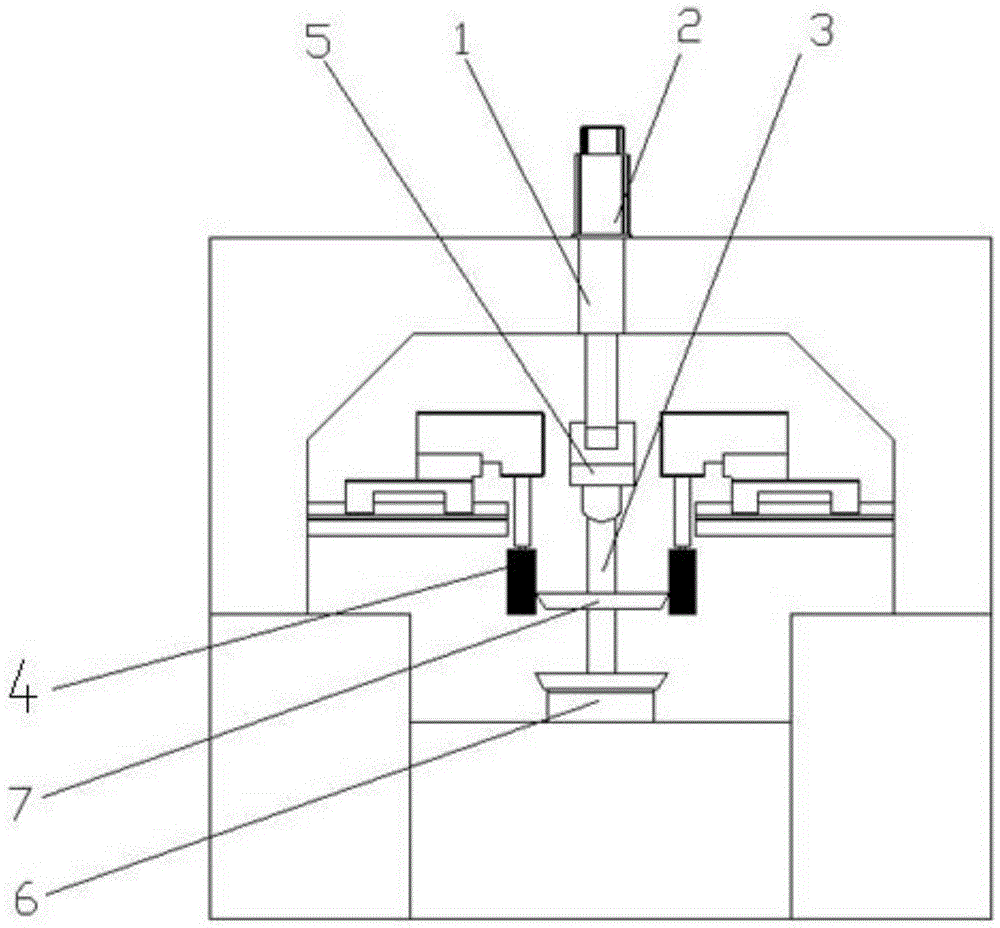

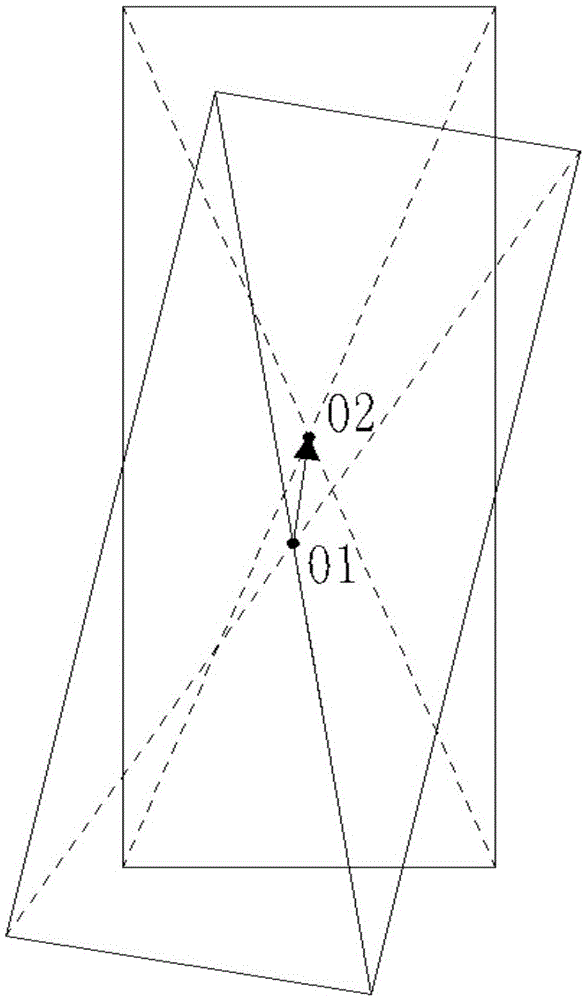

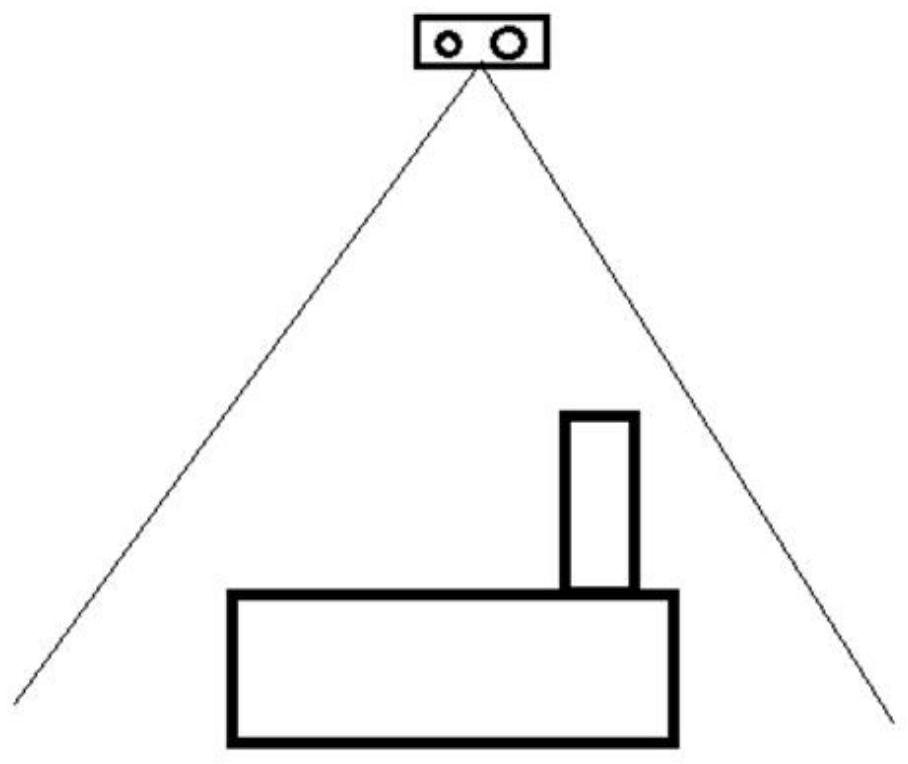

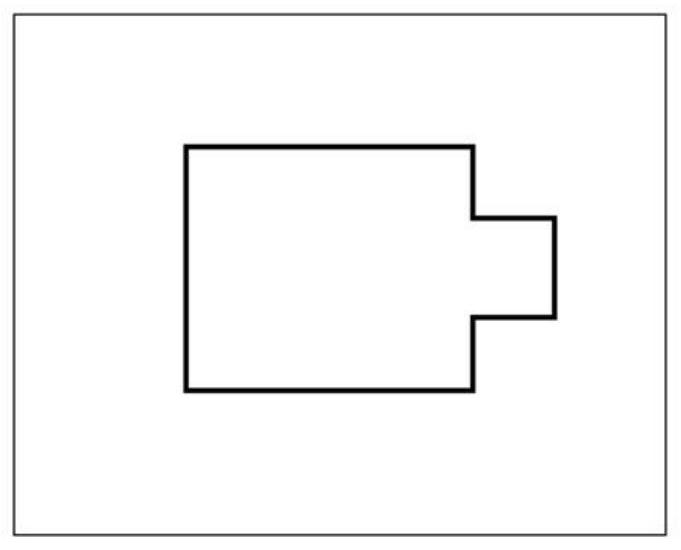

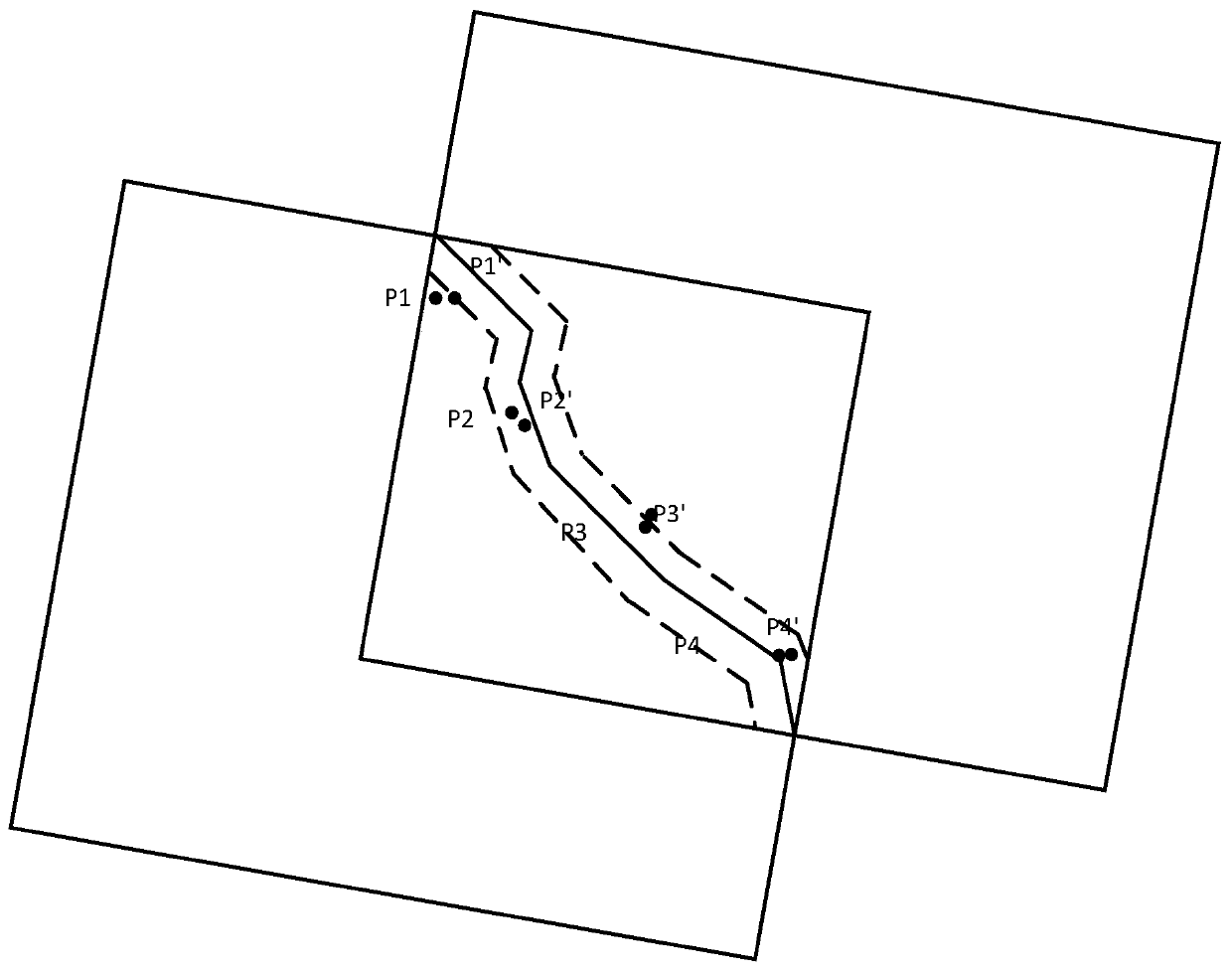

Dinner plate edging method based on vision control

ActiveCN105666274ARealize acquisitionEliminate errorsEdge grinding machinesVision basedPre treatment

The invention discloses a dinner plate edging method based on vision control. The method comprises the following steps: clamping and locating a dinner plate to be edged, and acquiring images of the dinner plate by virtue of two cameras which are symmetrically arranged at the two sides of the dinner plate; integrating the images through pre-treatment, image registration and fusion processing, and then extracting contour features to generate a complete dinner plate contour drawing; comparing the dinner plate contour drawing with a theoretical CAD model of the dinner plate, and obtaining a central position and a deviation angle of the current clamping and locating; and carrying out coordinate offset in a numerical control system according to the central position and the deviation angle, and controlling an edging unit to realize edging for the dinner plate by the numerical control system after the coordinate offset according to G code corresponding to the theoretical CAD model. According to the method disclosed by the invention, the two cameras which are symmetrically distributed at the two sides of the dinner plate are used for carrying out contour acquisition on the edge of the dinner plate, at a machining station, comprehensive acquisition and control for the contour of the dinner plate can be realized, and the G code is finally used for machining; and the method has the advantages of high edging quality, high machining efficiency and the like.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Opening portion structure

ActiveUS20070108794A1Improve edging accuracyVehicle seatsDashboardsExtremity PartMechanical engineering

Owner:NISSAN MOTOR CO LTD

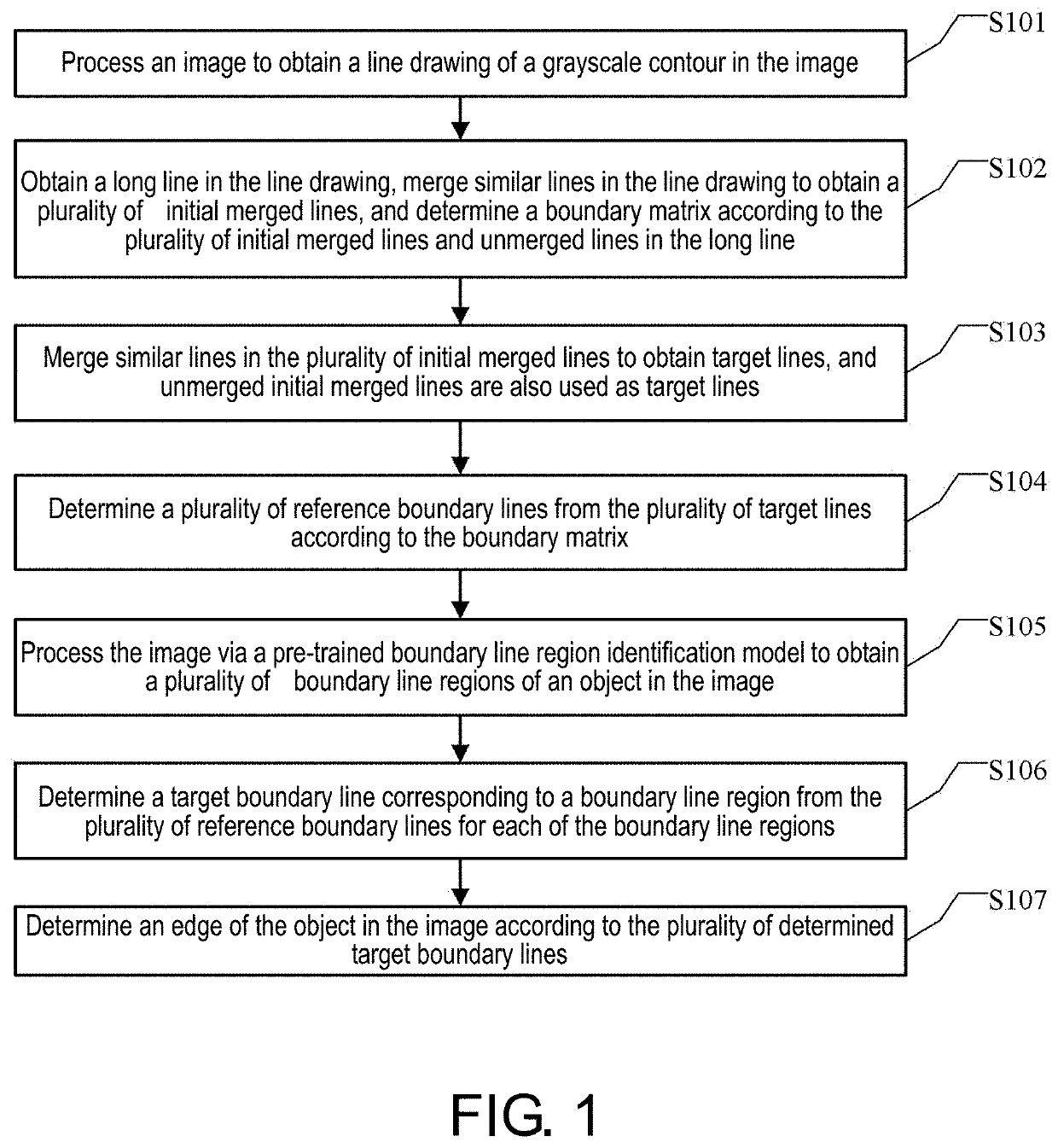

Edge detection method and device, electronic equipment, and computer-readable storage medium

ActiveUS20220215557A1Rapid positioningImprove edging accuracyImage enhancementImage analysisComputer graphics (images)Algorithm

The invention provides an edge detection method and a device of an object in an image, an electronic equipment, and a computer-readable storage medium. The method includes: a line drawing of a grayscale contour in the image is obtained; similar lines in the line drawing are merged to obtain initial merged lines, and a boundary matrix is determined according to the initial merged lines; similar lines in the initial merged lines are merged to obtain target lines, and unmerged initial merged lines are also used as target lines; reference boundary lines are determined from the target lines according to the boundary matrix; boundary line regions of the object in the image are obtained; a target boundary line corresponding to the boundary line region is determined from the reference boundary lines; an edge of the object in the image is determined according to the determined target boundary lines.

Owner:HANGZHOU GLORITY SOFTWARE LTD

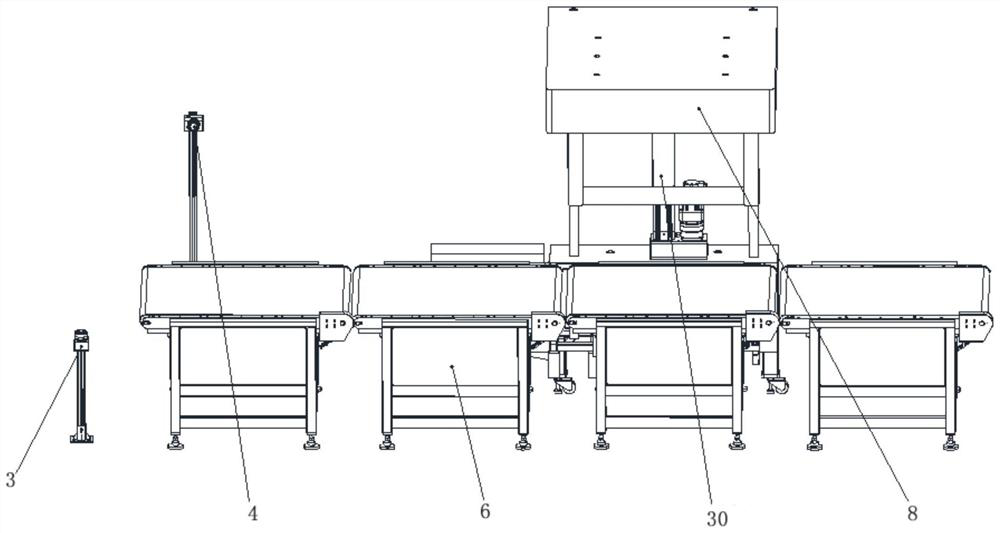

Express full-automatic multi-surface code scanning, weighing and volume measuring system and processing method thereof

ActiveCN112179272AReduce investmentSave operating timeUsing optical meansStacking articlesControl systemEngineering

The invention relates to the field of express full-automatic code scanning and measuring systems, and particularly discloses an express full-automatic multi-surface code scanning, weighing and volumemeasuring system and a processing method thereof, and the system comprises an automatic transportation forklift, multi-axis manipulators, a bottom surface code scanning camera, a side surface code scanning camera, a top surface code scanning and volume measuring camera, a code scanning and weighing conveying line and a control system. The multi-axis manipulators are arranged at the two ends of thecode scanning and weighing conveying line respectively, the automatic transportation forklift is used for conveying stacking trays for stacking express items, the bottom surface code scanning camerais arranged below the working end movement range of the multi-axis manipulators, and the side surface code scanning camera is arranged corresponding to the side edge of the working end movement rangeof the multi-axis manipulators. The top surface code scanning and volume measuring camera is correspondingly arranged above the code scanning and weighing conveying line, the control system controls work and operation of the whole machine, and a gravity sensor is arranged on the code scanning and weighing conveying line. According to the system, a traditional conveying method is changed, automaticexpress item processing such as multi-face code scanning, weighing and volume measuring is achieved, the working efficiency is high, the mechanical structure is compact, and work is stable.

Owner:SF TECH +1

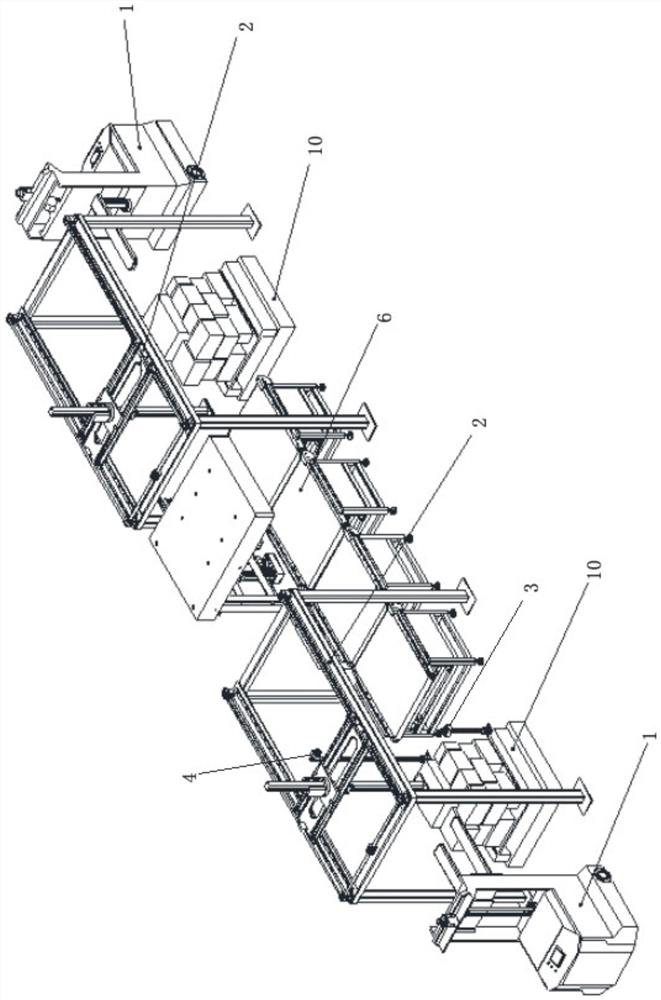

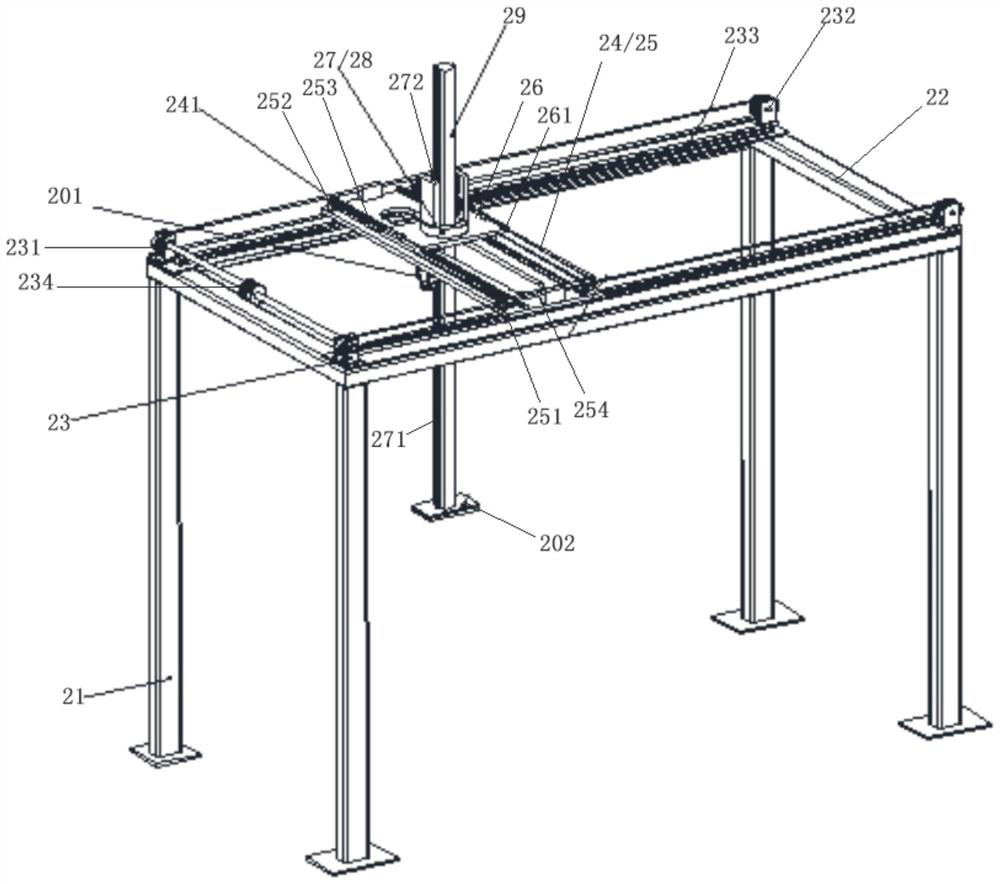

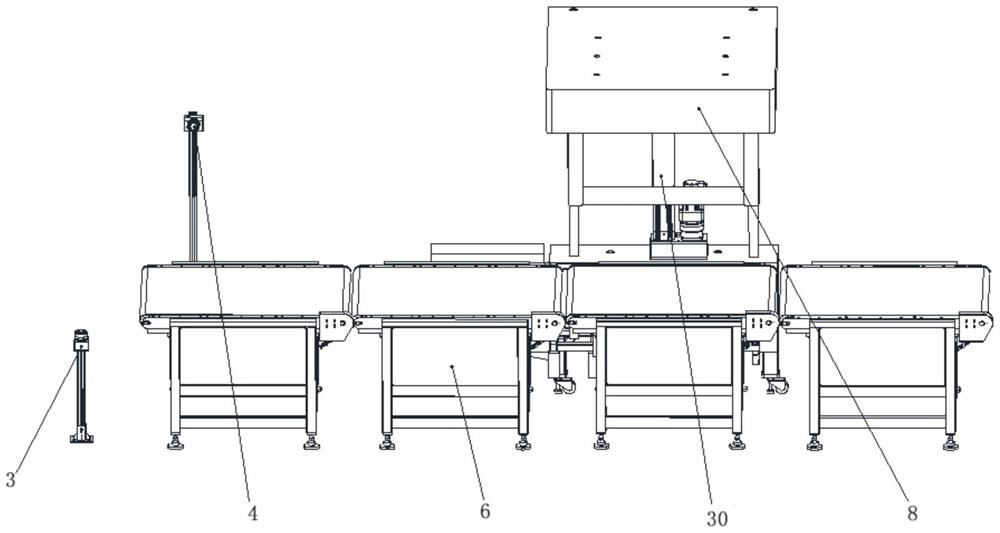

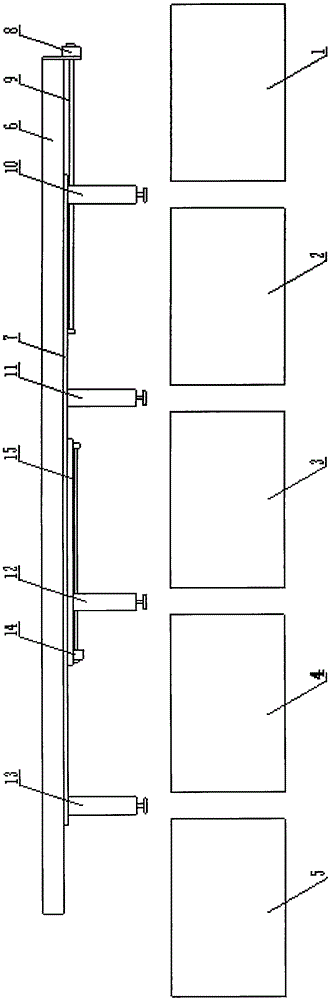

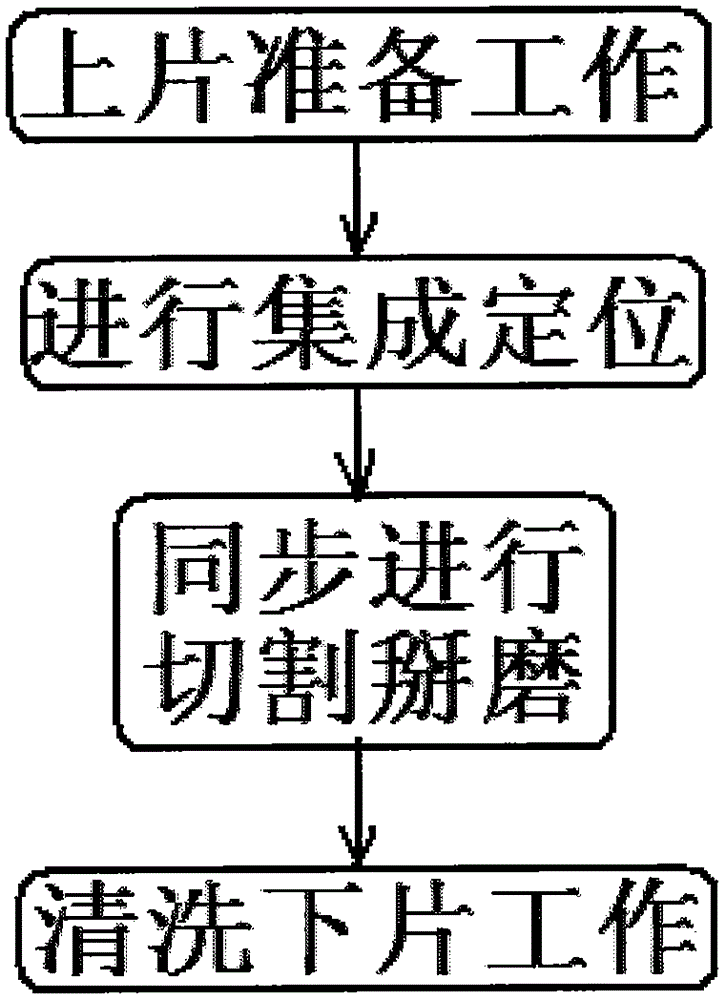

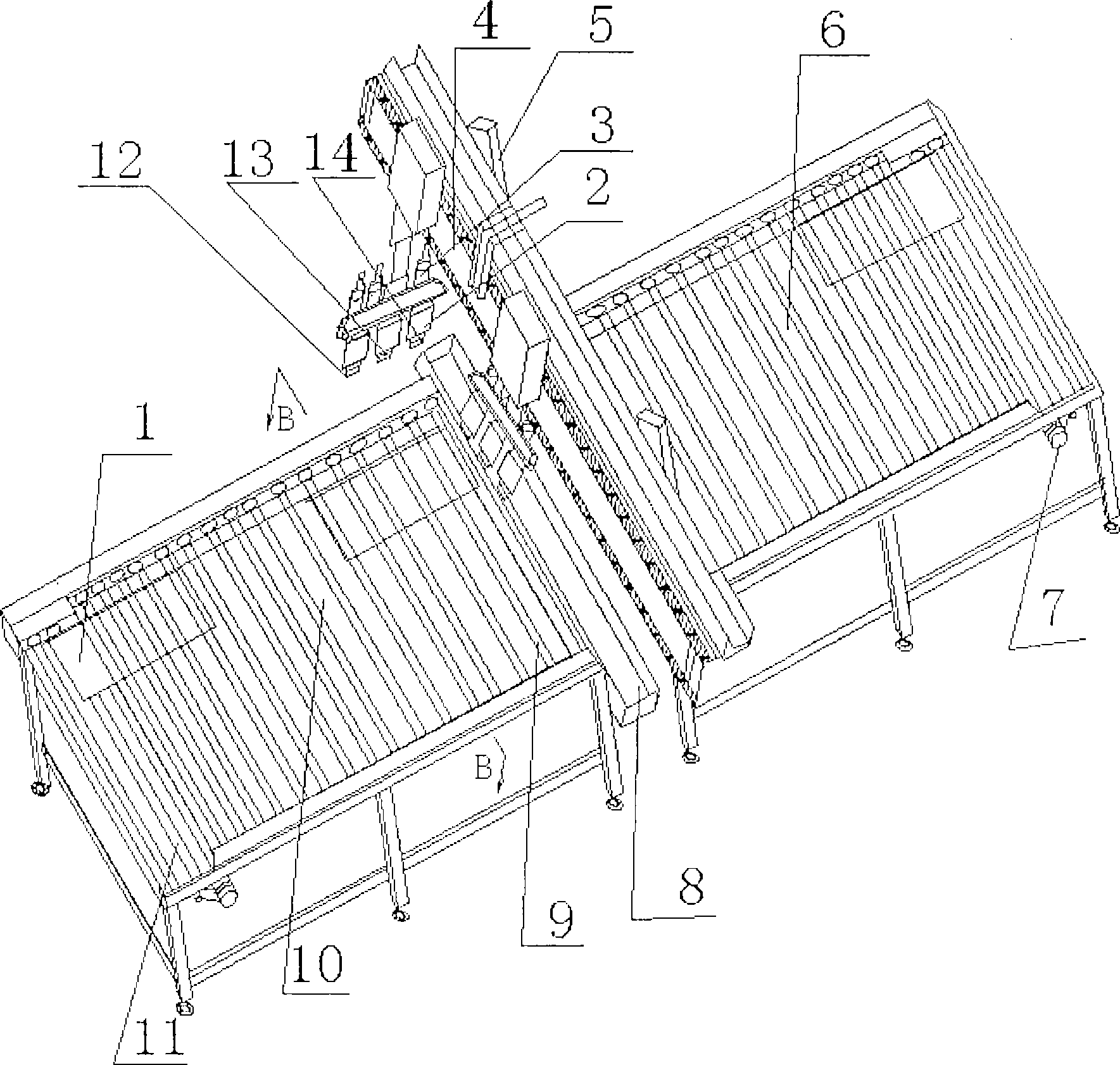

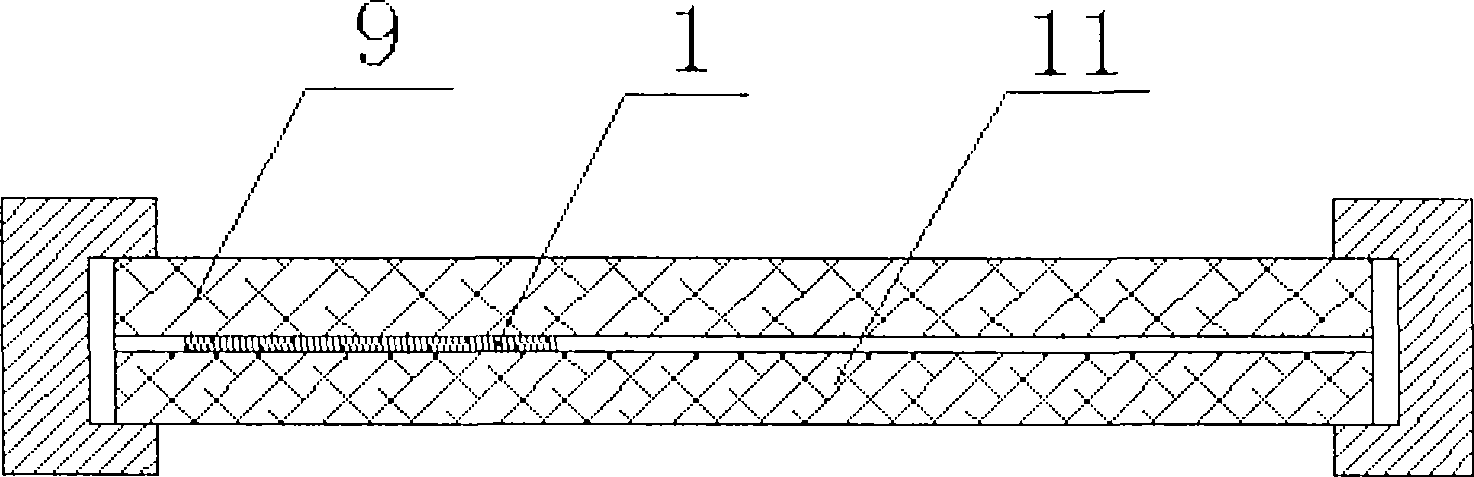

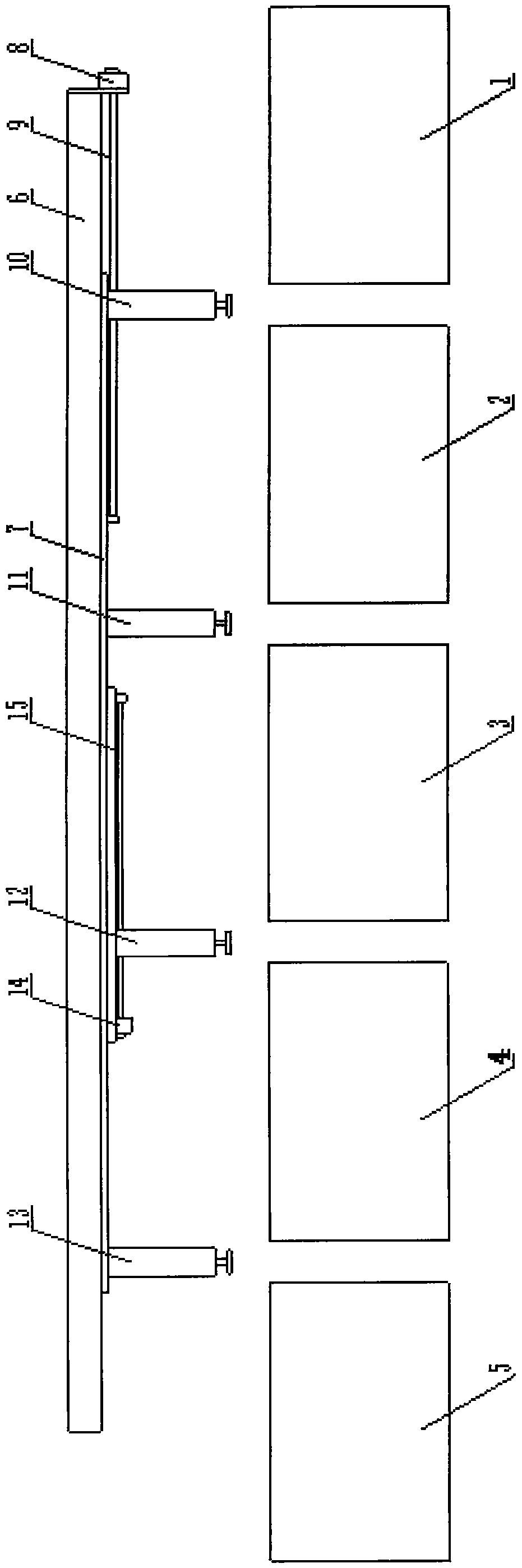

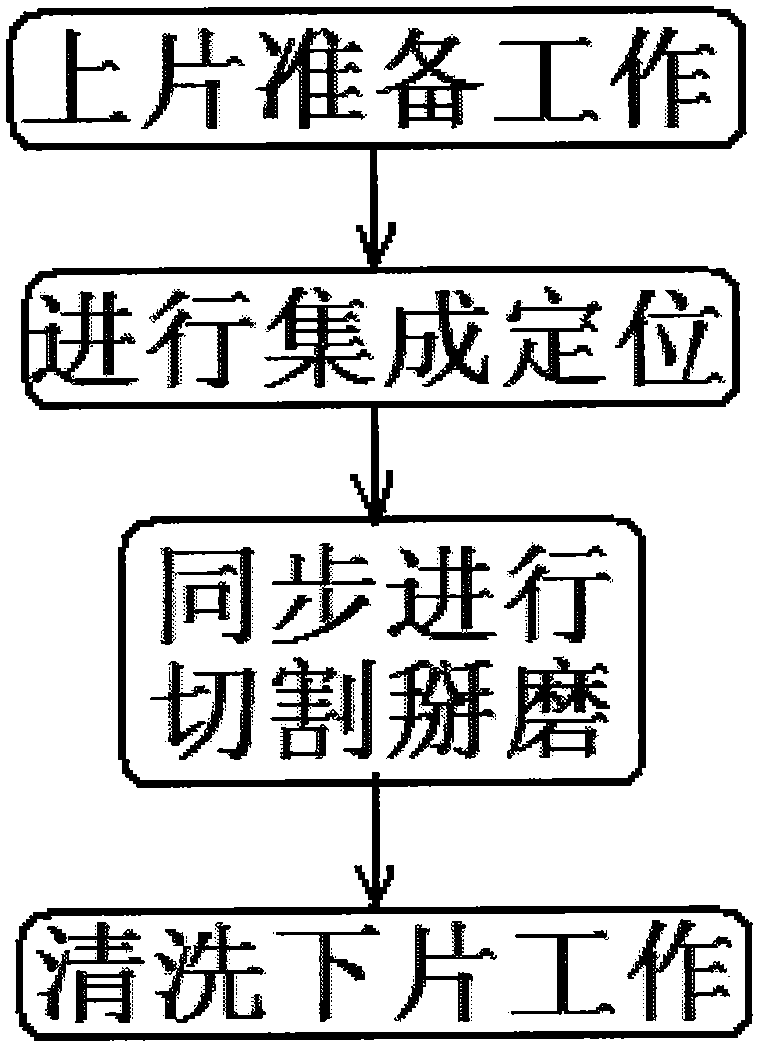

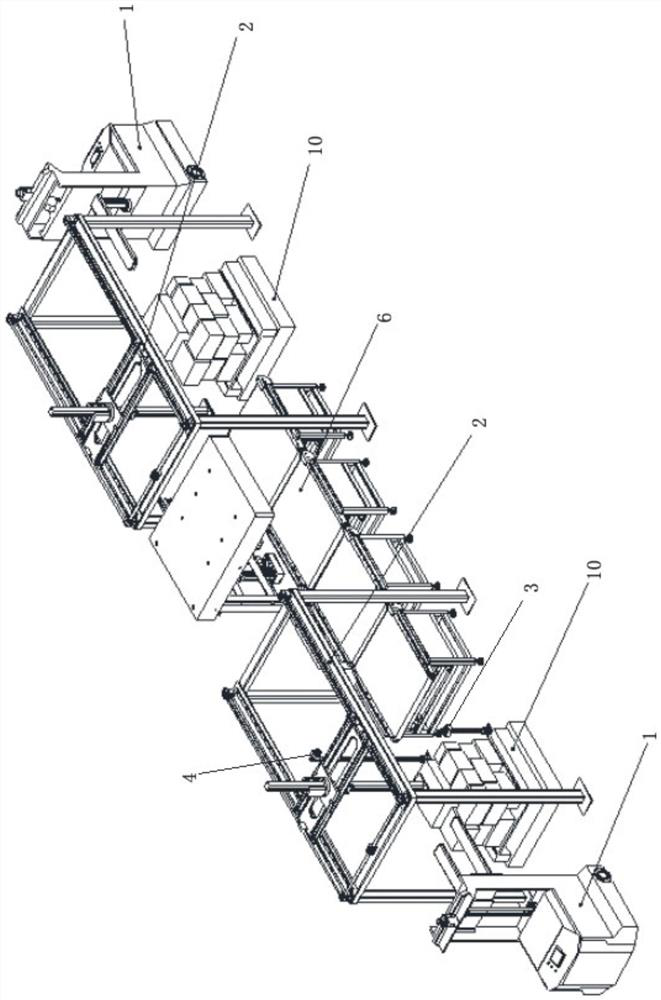

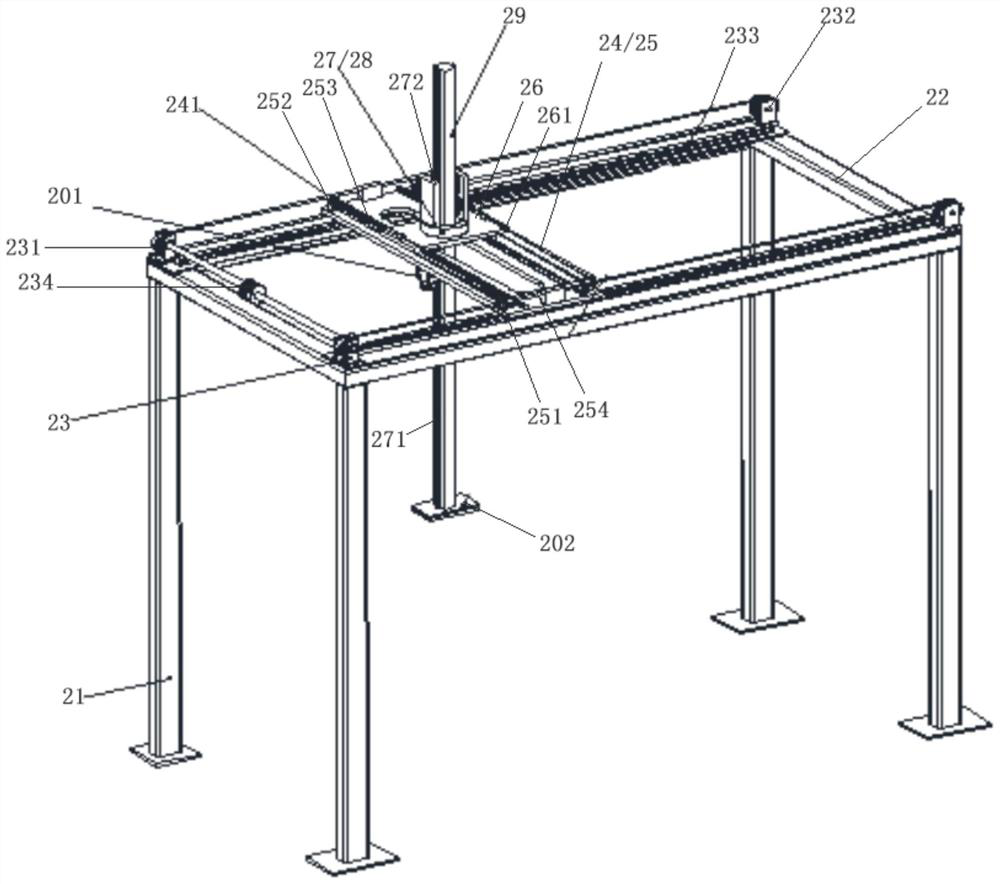

Special-shaped glass remote control cutting, breaking and grinding integrated processing production line and operation method thereof

InactiveCN105598781AHigh precisionImprove edging accuracyEdge grinding machinesGrinding drivesProduction lineRemote control

Provided are a special-shaped glass remote control cutting, breaking and grinding integrated processing production line and an operation method thereof. The processes of cutting, edge breaking, edge grinding and the like are integrated to efficiently process all kinds of special-shaped glass in a fully automatic mode at a time, precision, stability and quickness are achieved, waste is treated by itself, and the performance of the whole machine is excellent. Operation is easy, use is safe and convenient, the rate of finished products reaches up to 99.96%, and production quality and efficiency are greatly improved. Energy saving and environment friendliness are achieved, production cost is reduced by 50%, and the requirements of the production processes and the need of a special-shaped glass deep processing production line for fast development and changes are met. The special-shaped glass remote control cutting, breaking and grinding integrated processing production line is composed of a glass GPS positioning and navigation system, a special-shaped glass remote control cutter, a special-shaped glass remote control edge breaking machine, a special-shaped glass remote control edge grinding machine, a glass remote control cleaning machine, a glass control conveying device, a sensing conveying device, a first servo motor, a first ball screw, a cutting linkage mechanical arm, an edge breaking linkage mechanical arm, an edge grinding linkage mechanical arm and the like.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

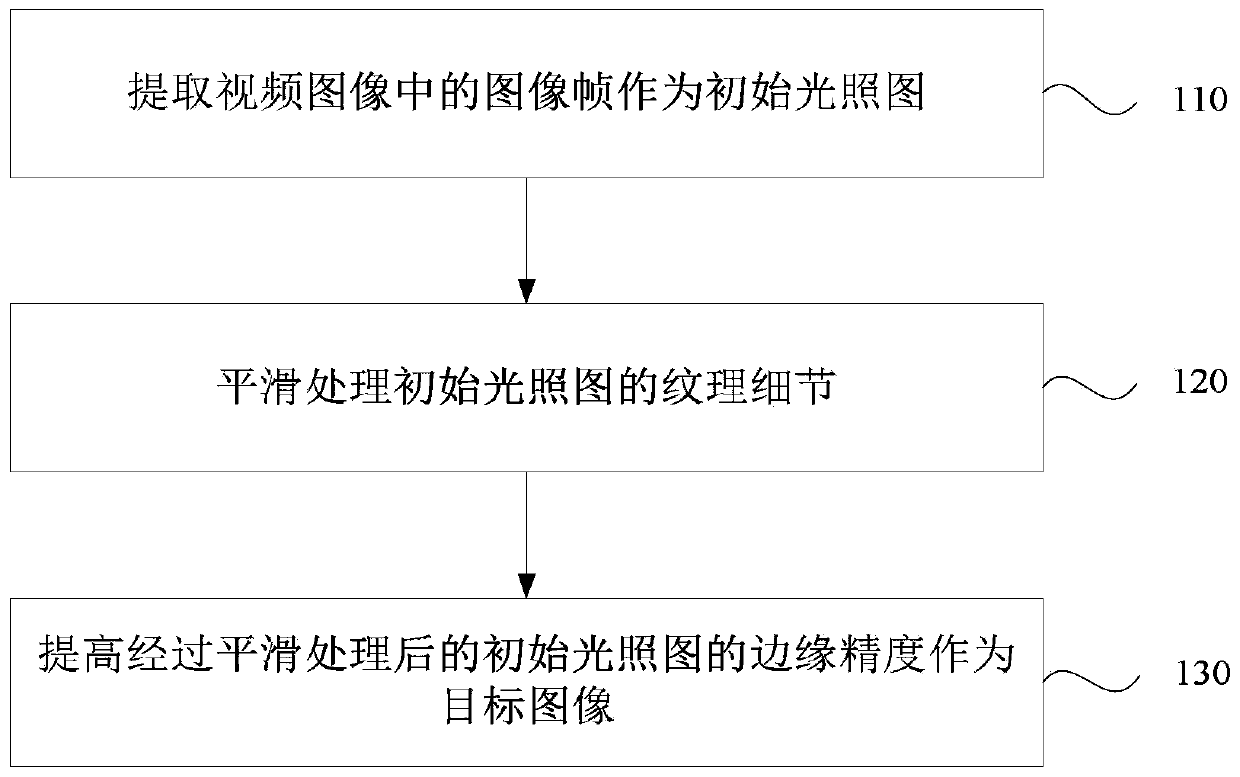

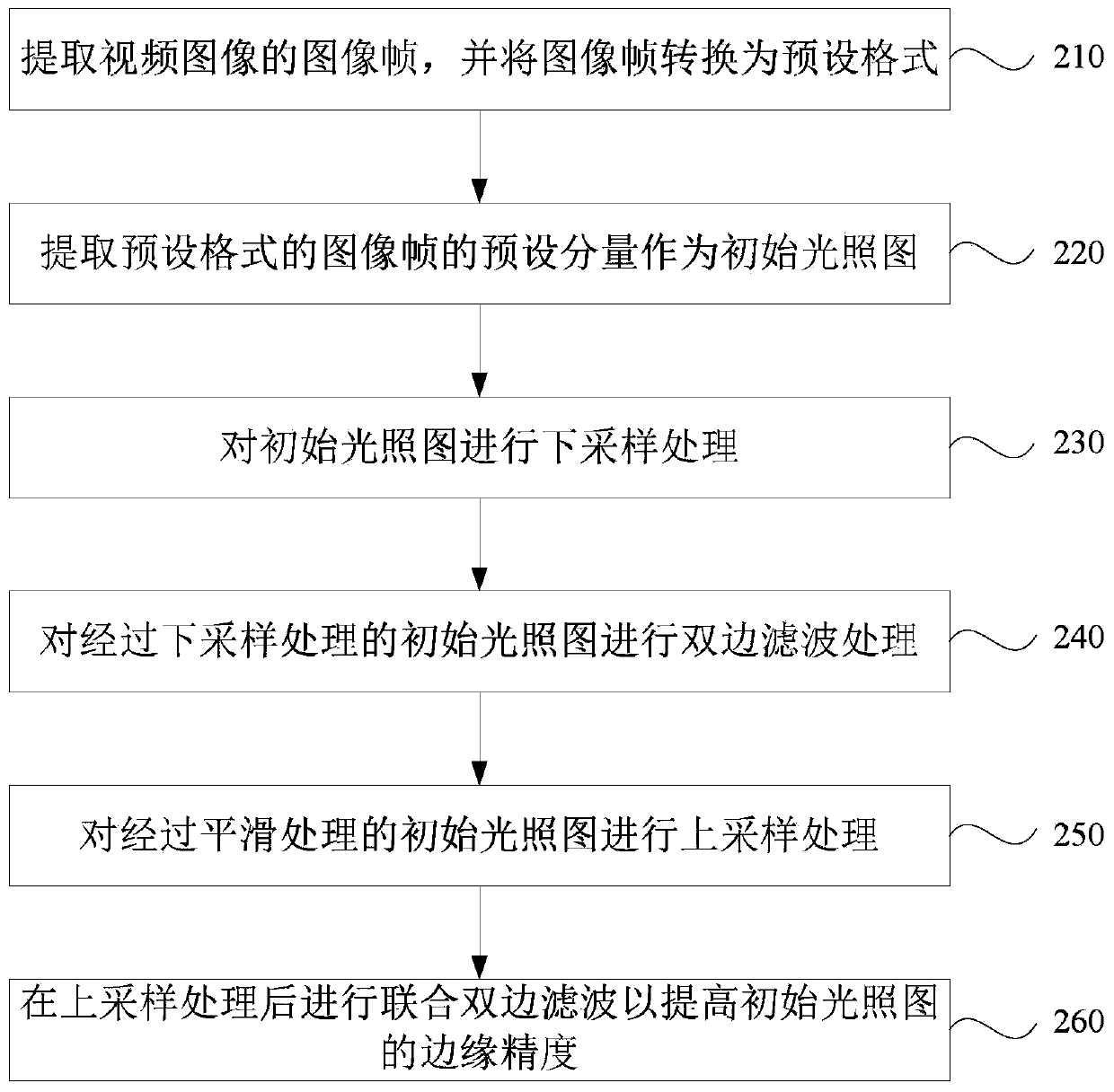

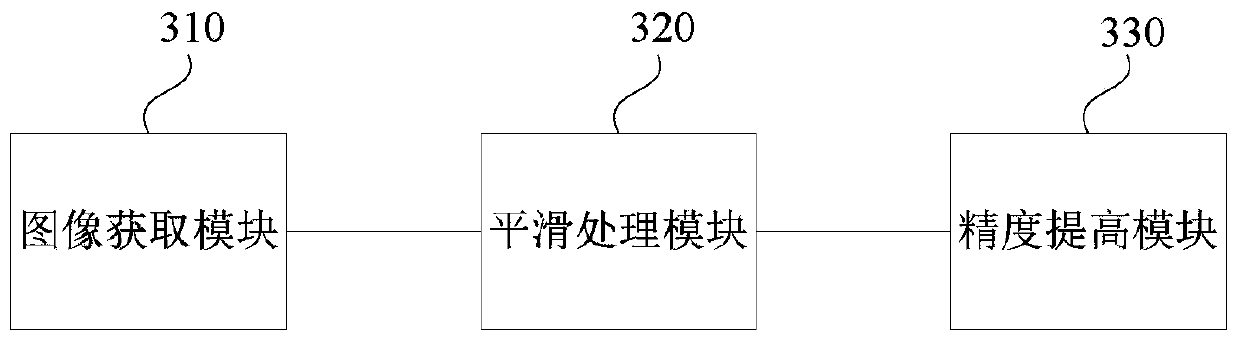

Image processing method, device and equipment and storage medium

PendingCN111353955AMeet the requirements of real-time recordingSave time and costImage enhancementImage analysisImaging processingImaging quality

The invention discloses an image processing method, device and equipment and a storage medium. The method comprises the following steps: extracting an image frame in a video image as an initial illumination image; smoothing texture details of the initial illumination image; and improving the edge precision of the initial illumination image after smoothing processing to serve as a target image. According to the invention, an image frame in a video image is extracted as an initial illumination image; smoothing processing is performed on texture details of the initial illumination image; the image quality is improved, the edge precision is improved, the output target image is enabled to be smooth with excessive texture details, more contour information in the image is reserved, the display effect is improved, rapid processing of the enhanced image in dark light is realized, the time overhead of an image processing process is reduced, the real-time performance of video recording is improved, and the user experience degree is enhanced.

Owner:GUANGZHOU BAIGUOYUAN INFORMATION TECH CO LTD

Full-automatic four-edge linear refining mill for glass

The invention discloses a full-automatic four-edge linear refining mill for glass, which comprises a sheet feeding table and a sheet discharging table, wherein clamping and transmitting devices are arranged on the sheet feeding table and the sheet discharging table respectively; each clamping and transmitting device comprises upper roller ways and lower roller ways; and the glass to be transmitted is positioned between the upper roller ways and the lower roller ways. The refining mill further comprises a bracket, a moving track, milling blade motor sets, coarse-grinding carborundum wheels, medium-grinding carborundum wheels and polishing wheels; each set of the two milling blade motor sets comprises three milling blade motors; the coarse-grinding carborundum wheels, the medium-grinding carborundum wheels and the polishing wheels are respectively mounted on the three milling blade motors. According to the invention, with the upper roller ways and the lower roller ways, the glass fixing strength is strong so as to ensure reliable positioning of the glass from coarse grinding to fine grinding and ensure the edge grinding quality; and with the coarse-grinding carborundum wheels, the medium-grinding carborundum wheels and the polishing wheels, four-edge coarse grinding and fine grinding of the glass can be realized at one time, the production efficiency is high and the edge grinding accuracy is high.

Owner:王世强

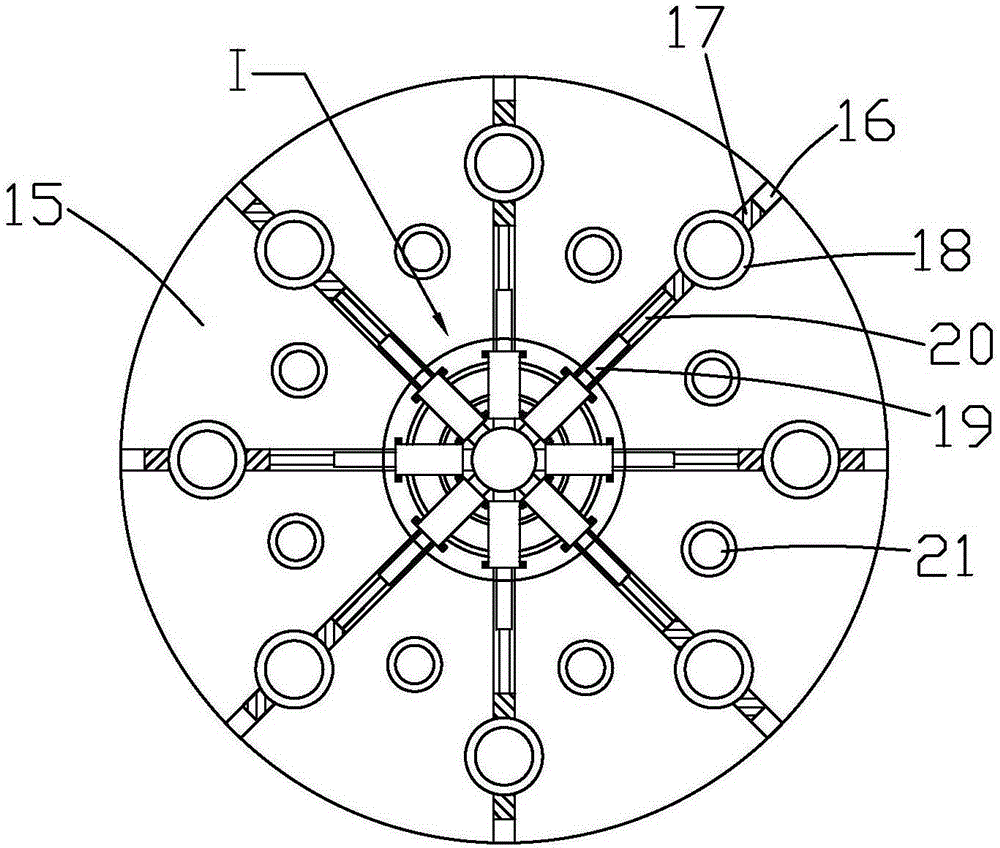

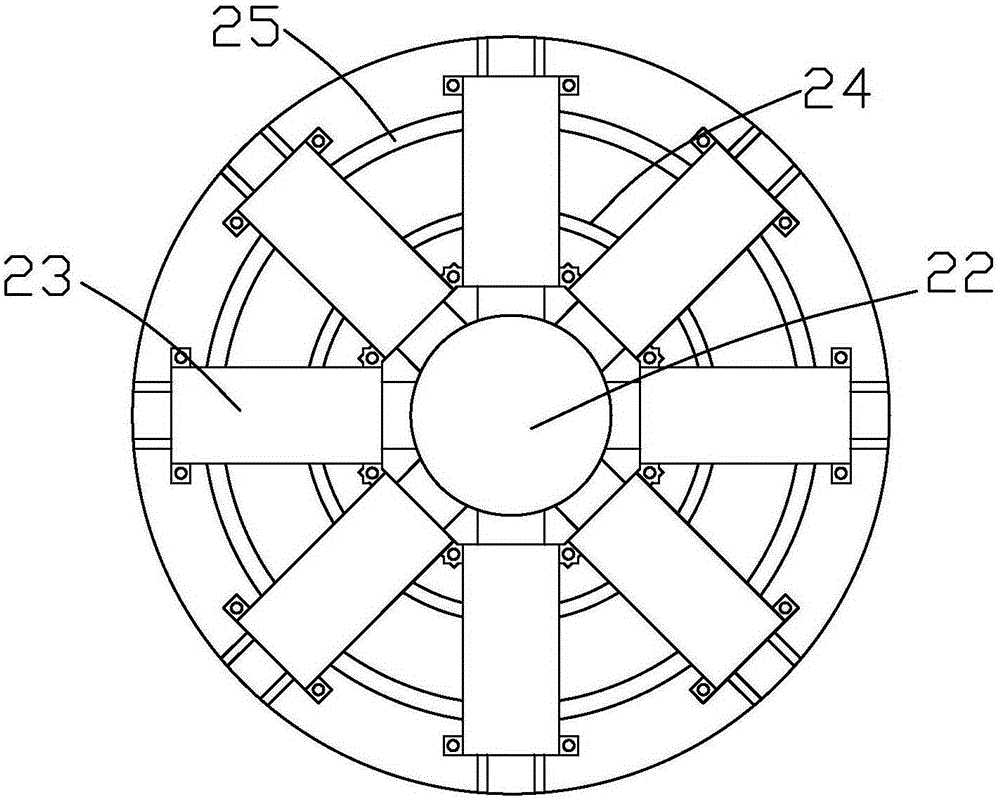

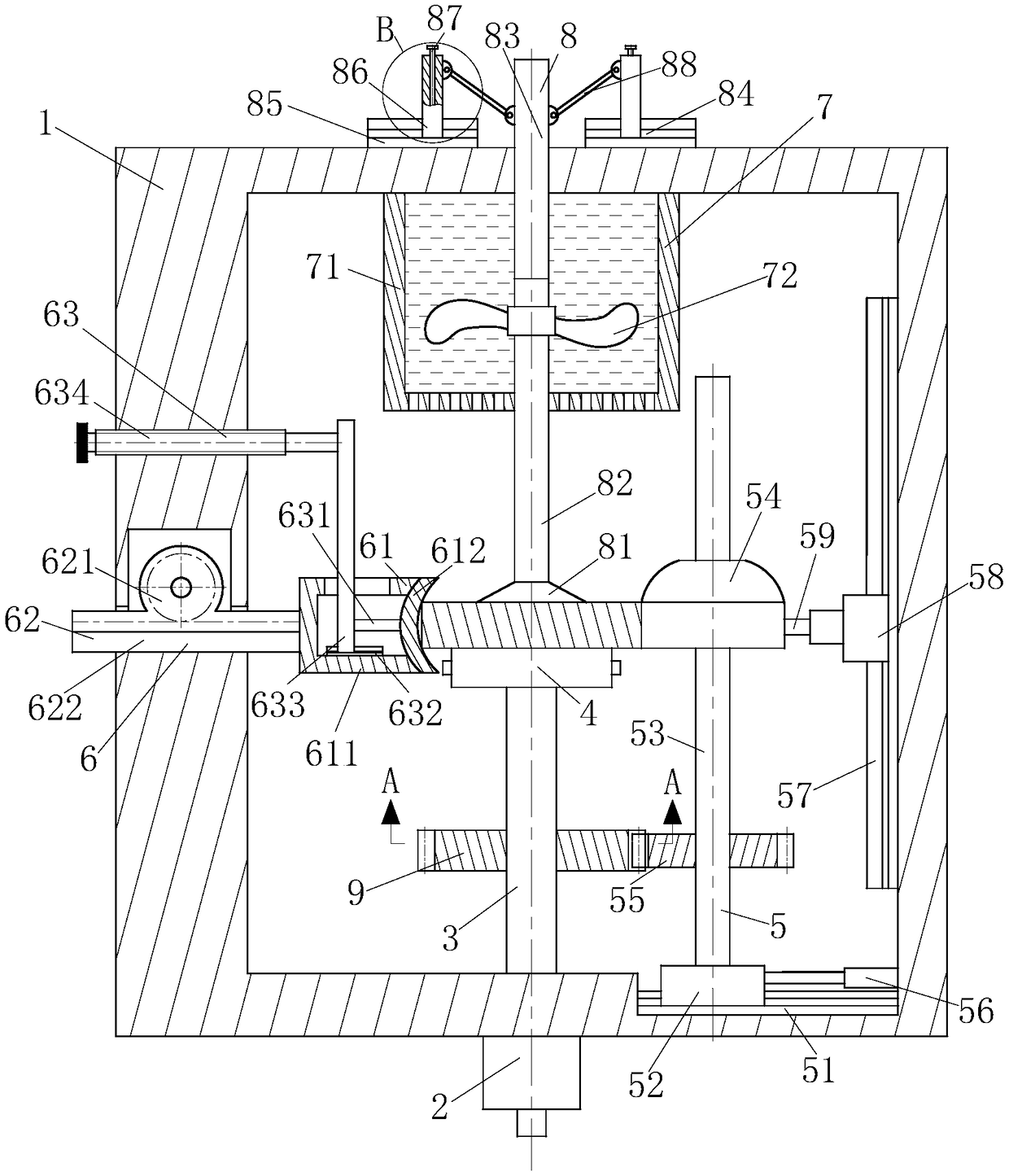

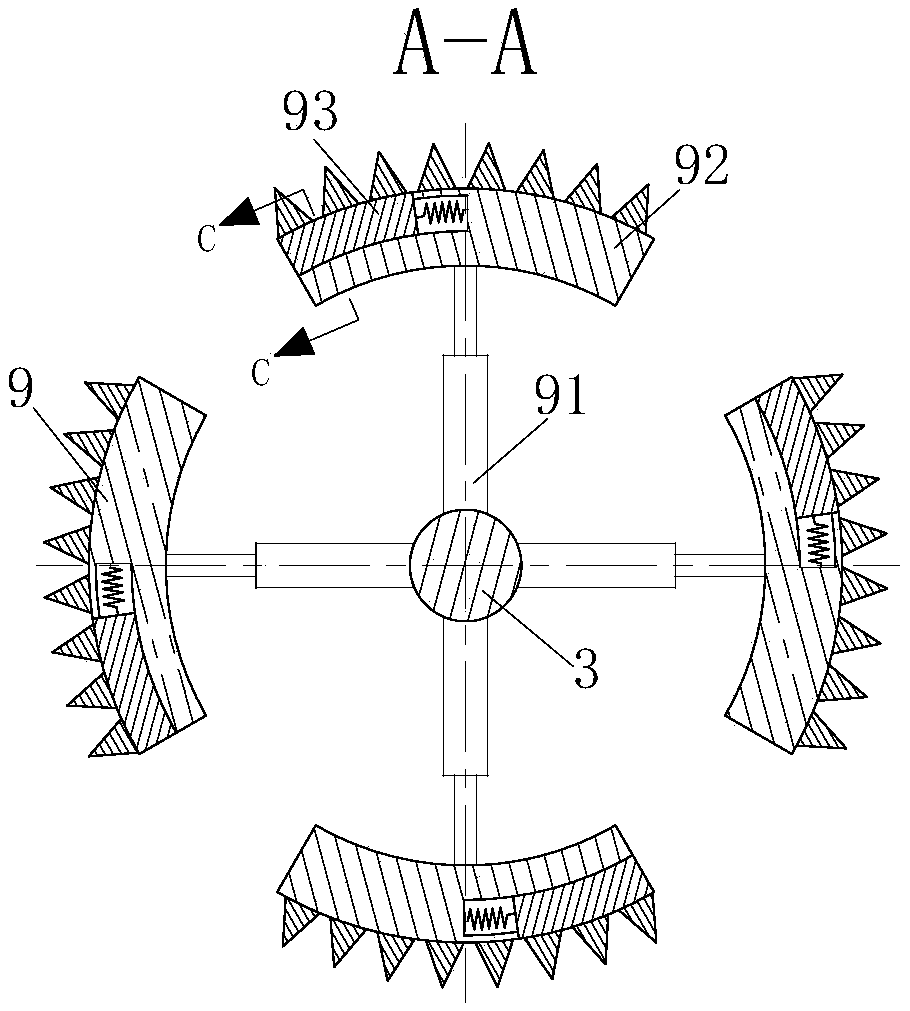

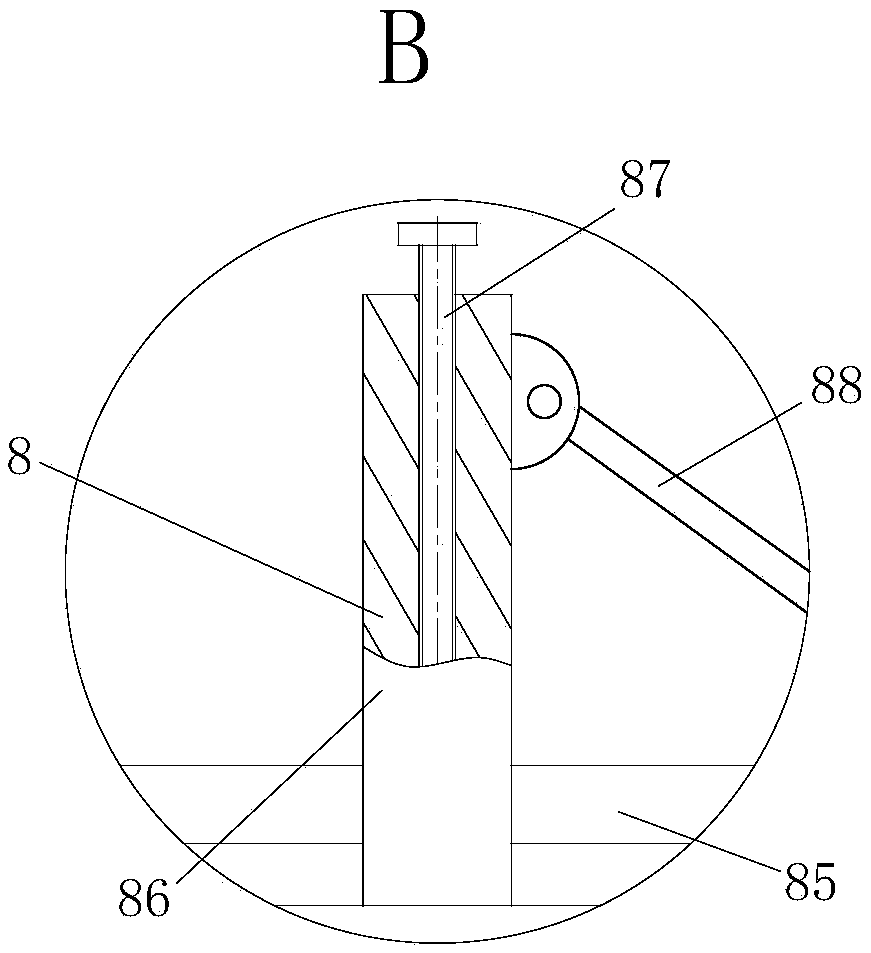

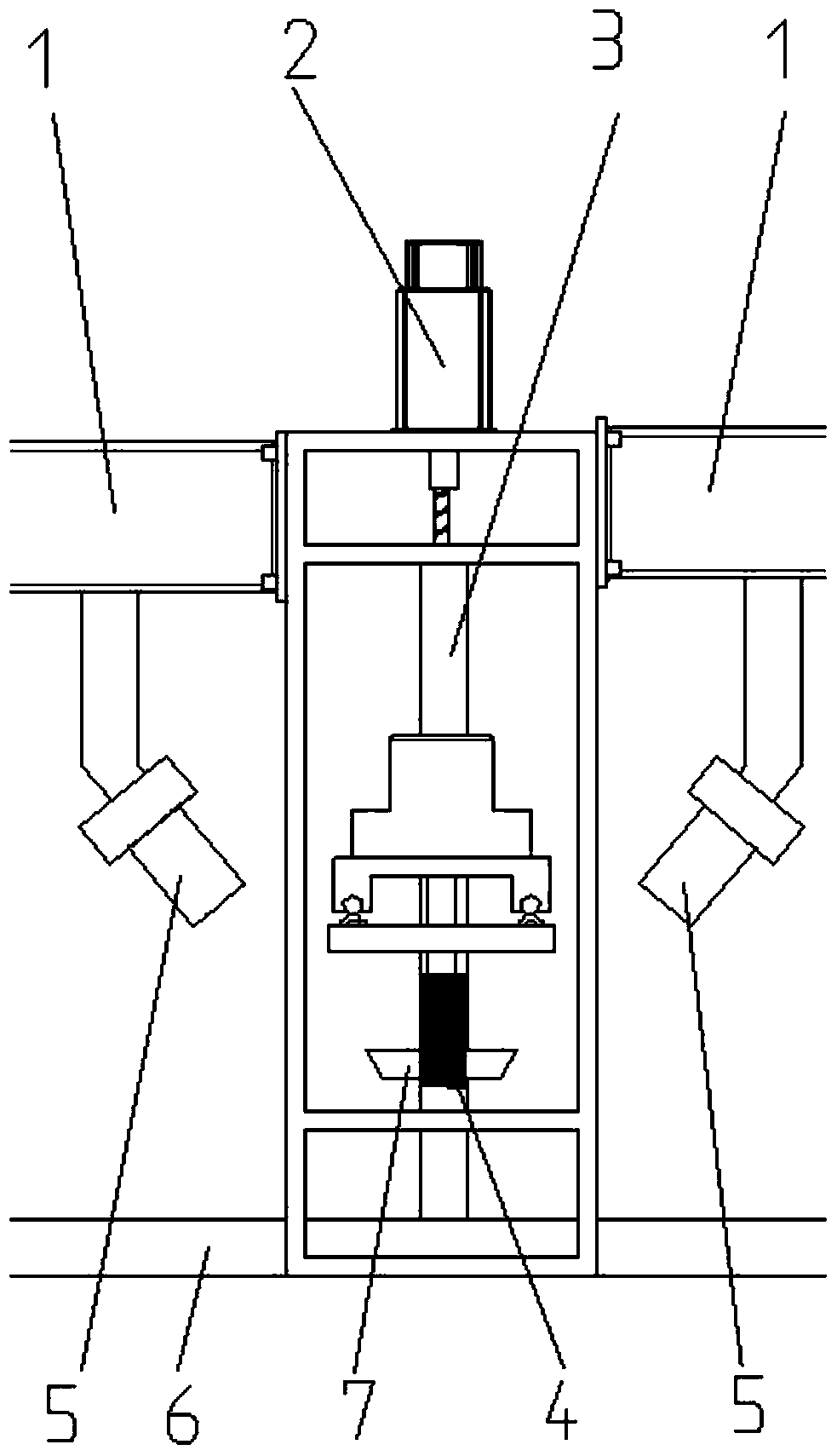

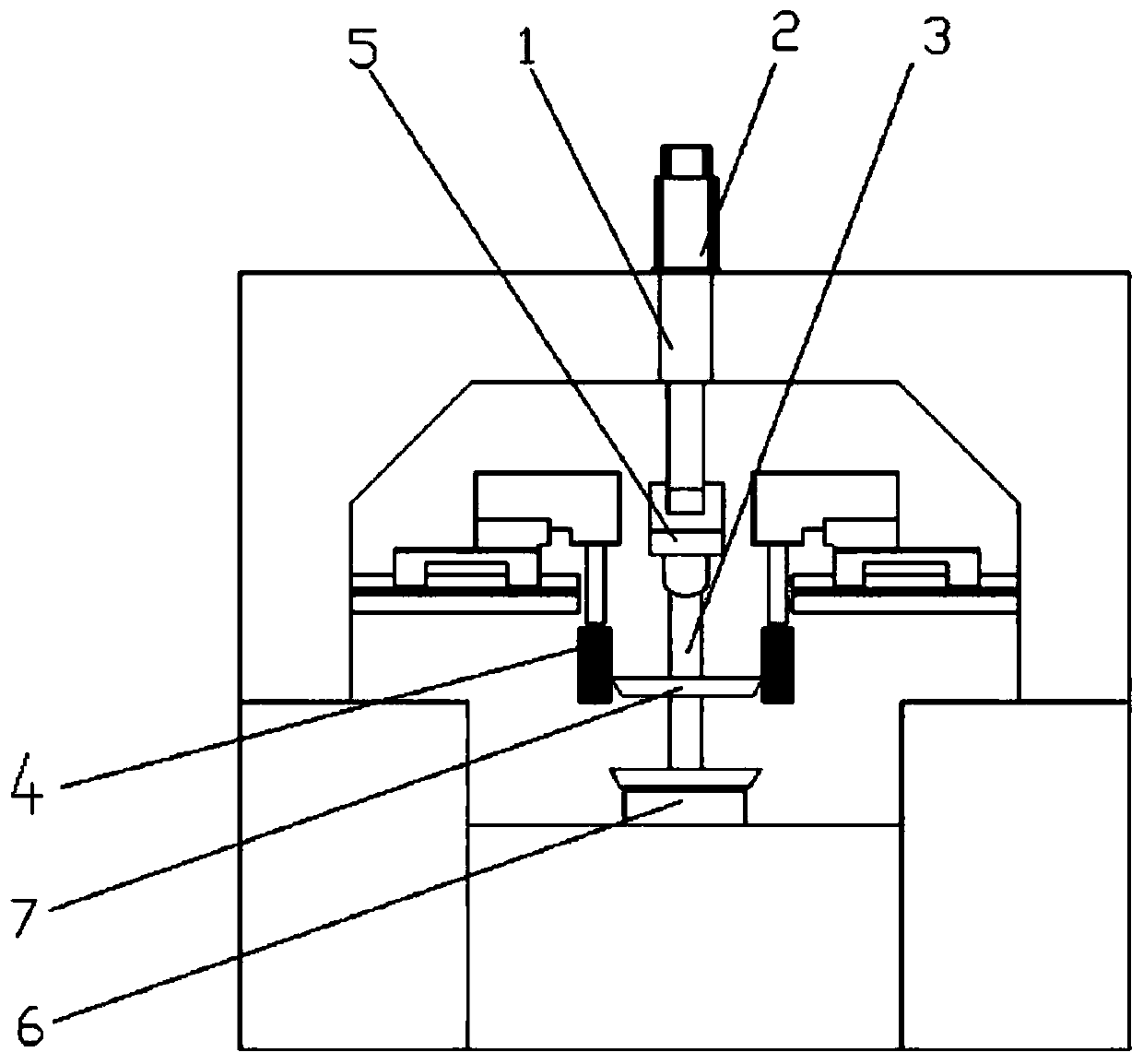

Automatic edge polishing equipment for optical glass

ActiveCN108747683AImprove edging efficiencyImprove cooling effectEdge grinding machinesGrinding/polishing safety devicesEngineeringOptical glass

The invention belongs to the technical field of optical glass production, and particularly relates to automatic edge polishing equipment for optical glass. The automatic edge polishing equipment for the optical glass comprises a tank, a first motor, a first connection shaft, a positioning base, a grinding module, an edge polishing module, a spraying module and a compressing module; the first motoris fixed to the bottom of the tank; the first connection shaft is located inside the tank; the lower end of the first connection shaft is connected with an output shaft of the first motor; the positioning base is located inside the tank and is in a disk shape; the lower surface of the positioning base is connected with the upper end of the first connection shaft; the axis of the positioning baseand the axis of the first connection shaft are located on the same straight line; the grinding module is located on the right side of the positioning base; the edge polishing module is located on theleft side of the positioning base; the spraying module is located above the positioning base and inside the tank; and the compressing module is located above the positioning base and used for compressing the optical glass.

Owner:TONGXIANG HESHAN CRAFT GLASSWARE FACTORY

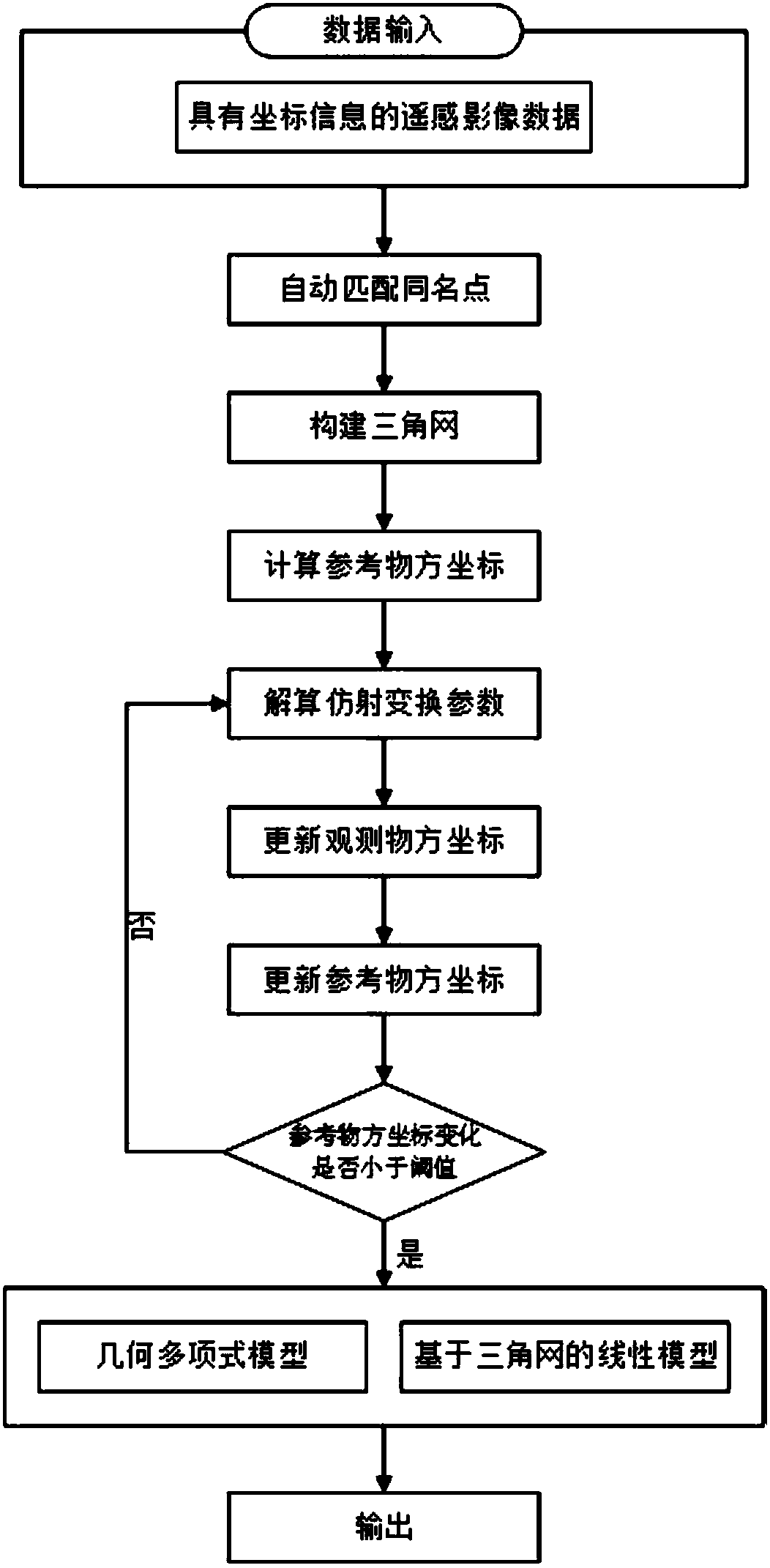

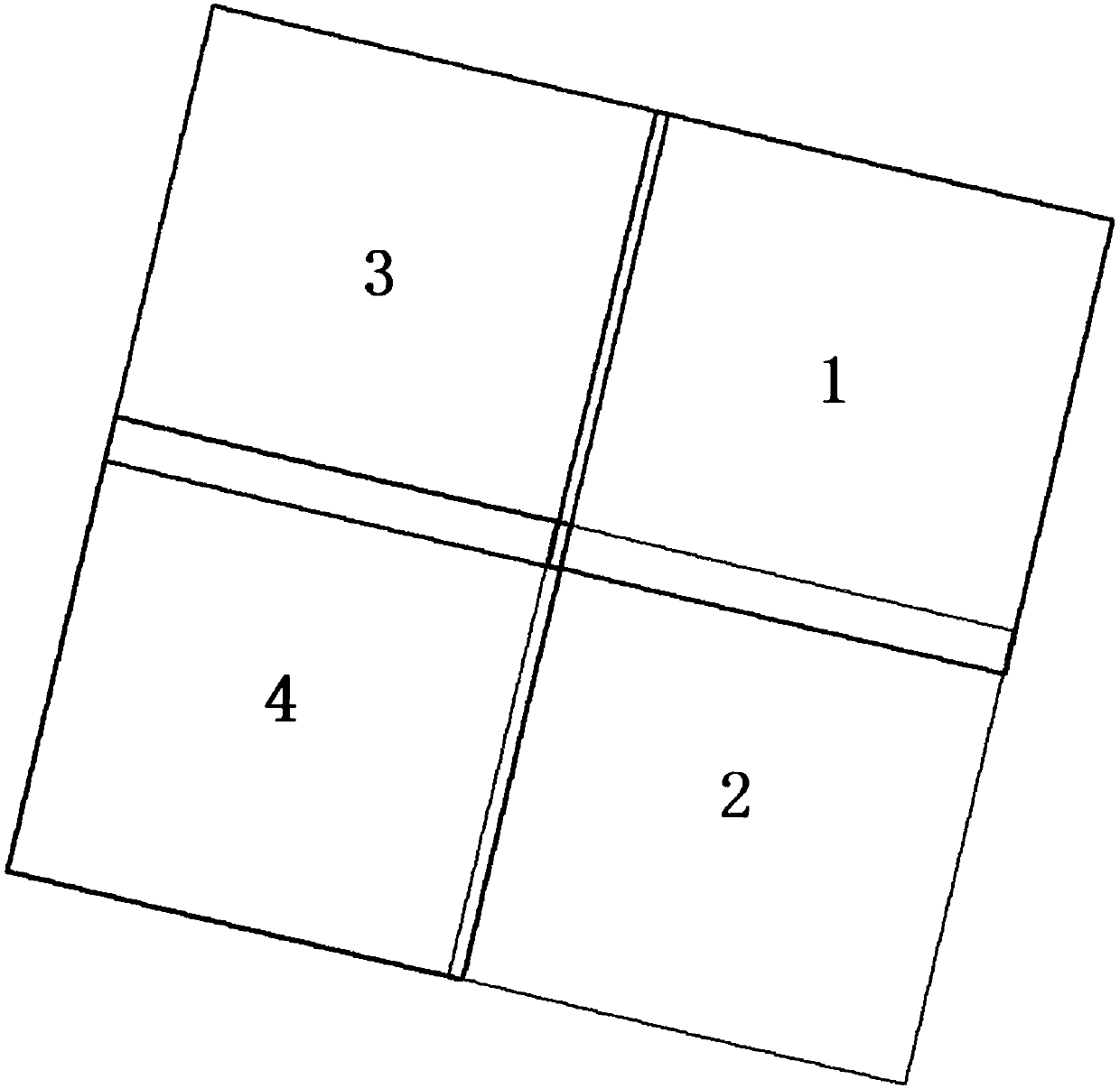

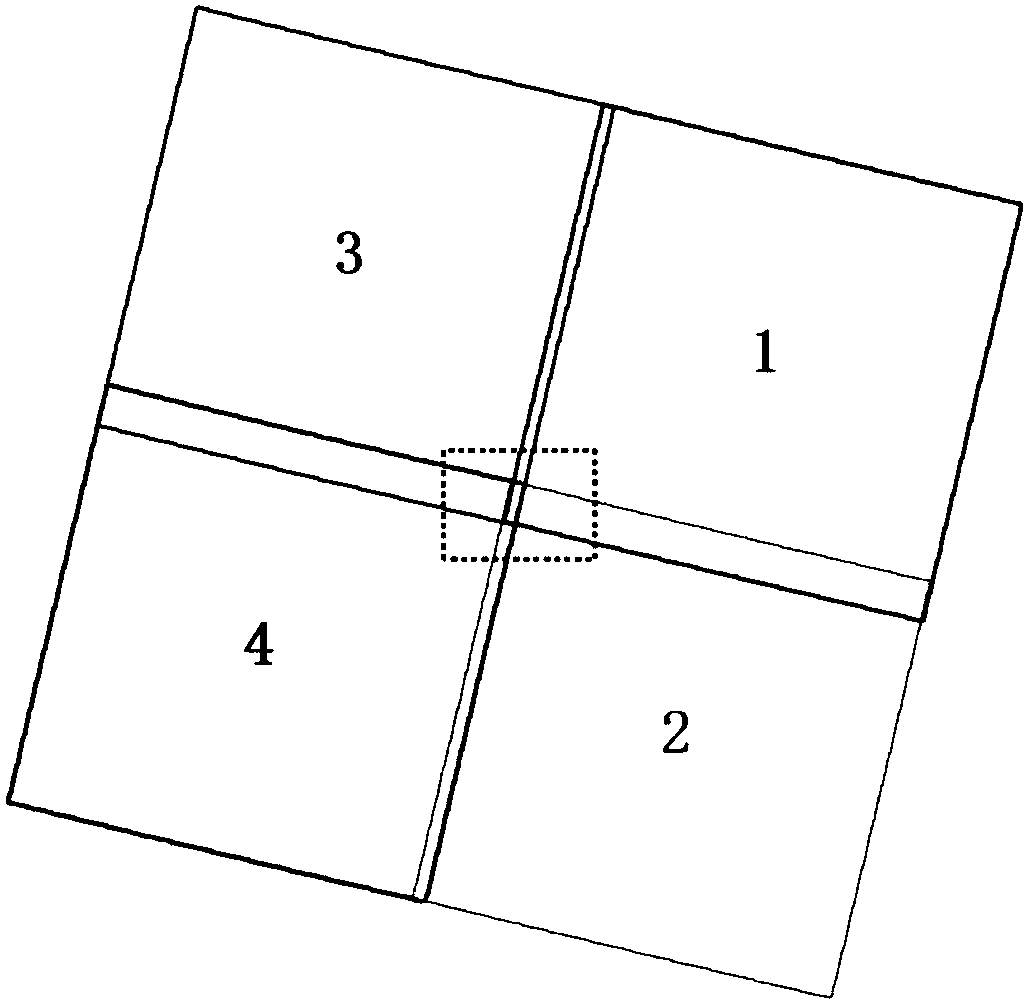

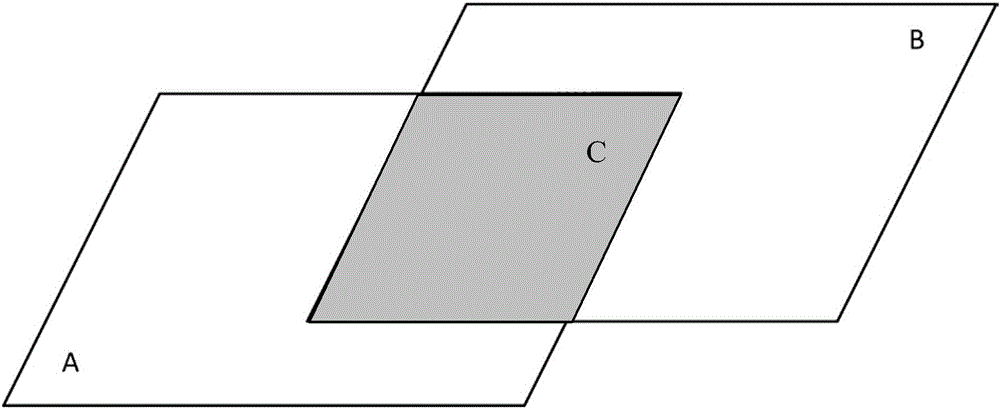

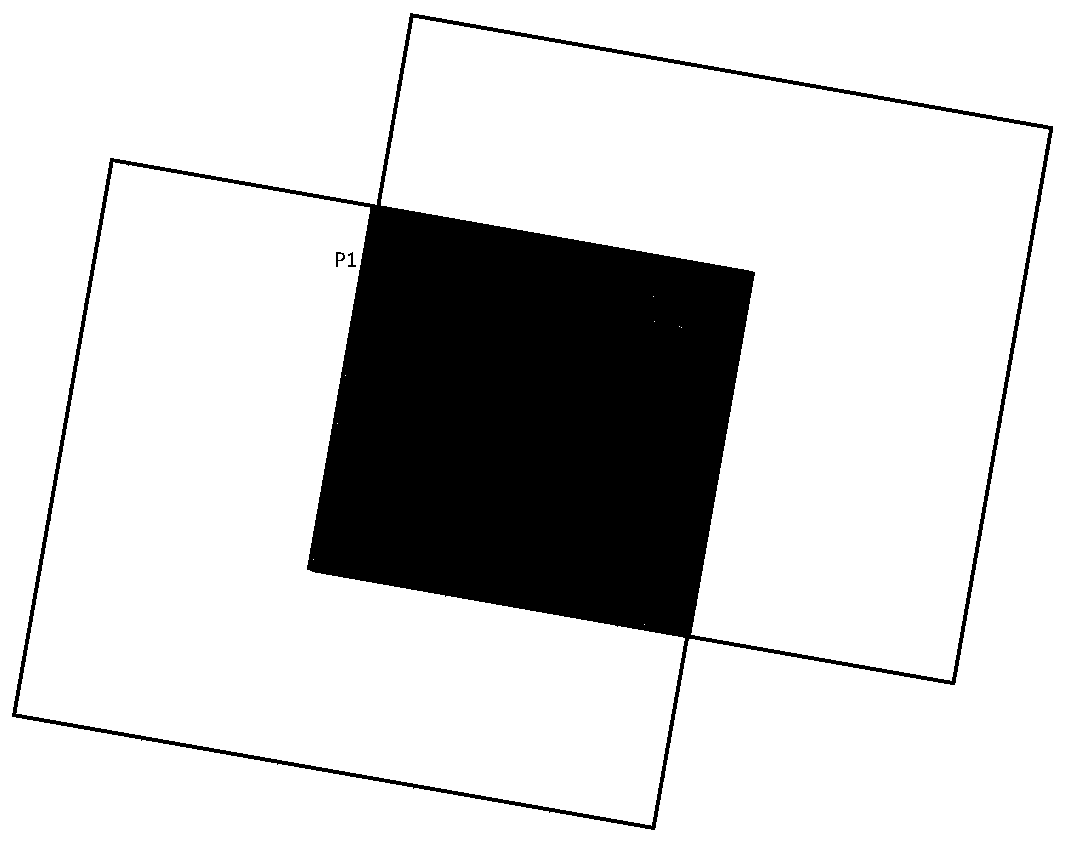

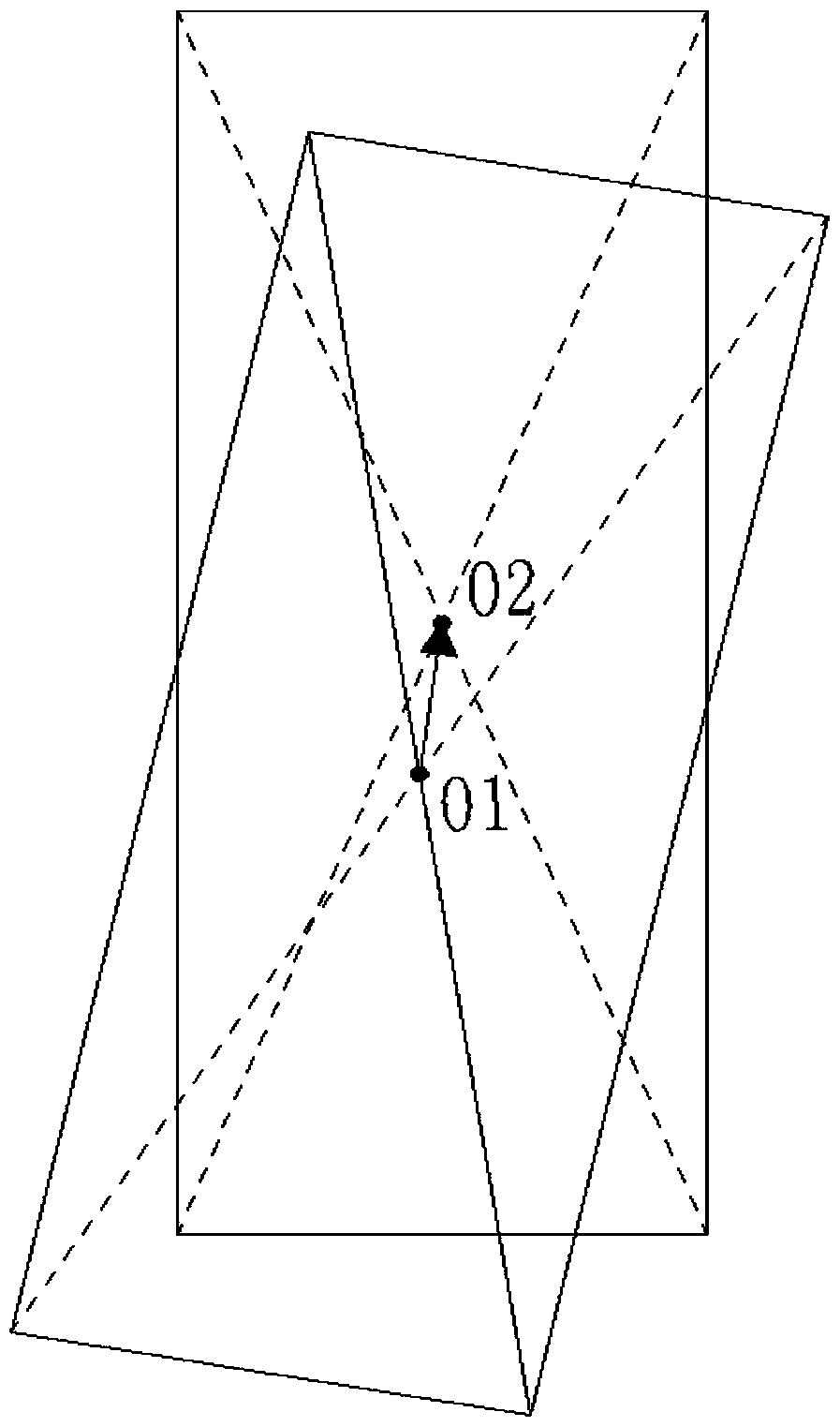

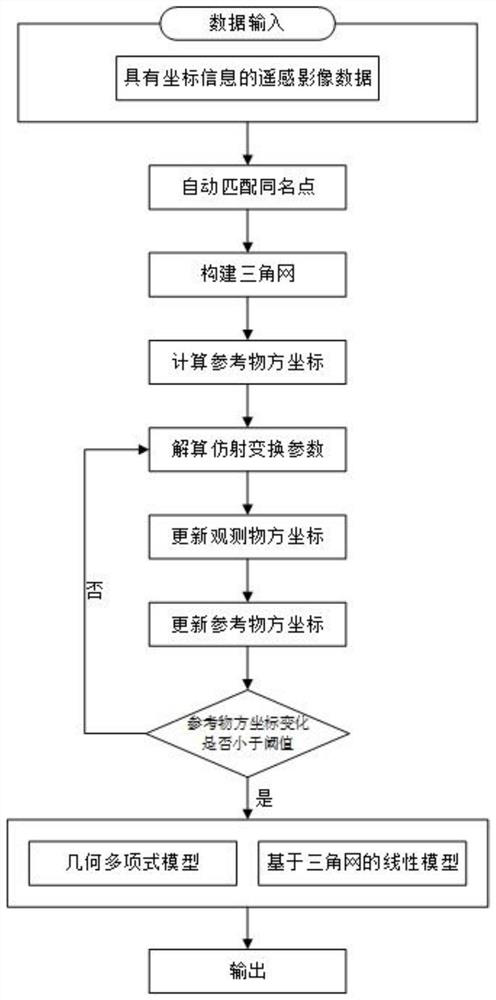

Overlapping area correction method suitable for multiple remote sensing images of large region

ActiveCN107705244AAchieve edge precisionHigh correction accuracyImage enhancementImage analysisCorrection methodPoint match

The invention relates to an overlapping area correction method suitable for multiple remote sensing images of a large region. The method comprises the steps of (1) performing automatic adjacent area homonymy point matching on all images to obtain homonymy points; (2) constructing a triangular net by utilizing existing homonymy points; (3) for each homonymy point, calculating coordinates of a homonymy point reference object space; (4) calculating an affine transformation parameter of each image; (5) for each homonymy point, according to image space coordinates and corresponding affine transformation parameters on different images, resolving new observation object space coordinates of the homonymy point on the corresponding image; (6) repeating the steps (3) to (5) until the coordinate change of the reference object space is smaller than a certain threshold or the reference object space is no longer changed; and (7) correcting the corresponding image by utilizing the affine transformation parameter iterated last time. According to the method provided by the invention, the multiple images of the large region can be subjected to overlapping area correction at the same time; the correction precision is higher; and the problems of deformation unevenness and image over-twisting in a conventional correction method are avoided.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

Numerically-controlled edge grinding machine for irregular glass

InactiveCN106826458ARealize CNC automatic edgingRealize three-dimensional displacementEdge grinding machinesGrinding carriagesEngineeringSlide plate

The invention provides a numerical control special-shaped glass edging machine, which includes a bed, a rotary table is set above the bed, the rotary table is driven by a first displacement mechanism to rotate clockwise or counterclockwise, a beam is set above the bed, and a transverse beam is set on the beam Skateboard, the horizontal slideboard is driven by the third displacement mechanism to move back and forth horizontally; the vertical slideboard is set on the horizontal slideboard, and the vertical slideboard is driven by the vertical up and down displacement mechanism to move vertically up and down; the vertical slideboard is provided with an indexing axis, and the indexing axis passes through the second displacement mechanism Drive to achieve clockwise or counterclockwise rotation, the first displacement mechanism, the second displacement mechanism, the third displacement mechanism and the vertical up and down displacement mechanism realize four-axis linkage under the numerical control, and the large end surface of the indexing axis hangs the edging unit. The technical solution disclosed by the invention not only realizes three-dimensional displacement, but also realizes the precise adjustment of the angle of the edging unit and the precise adjustment of the inclination of the edging, improves the edging precision, and realizes the numerical control automatic edging of special-shaped glass.

Owner:戴巧

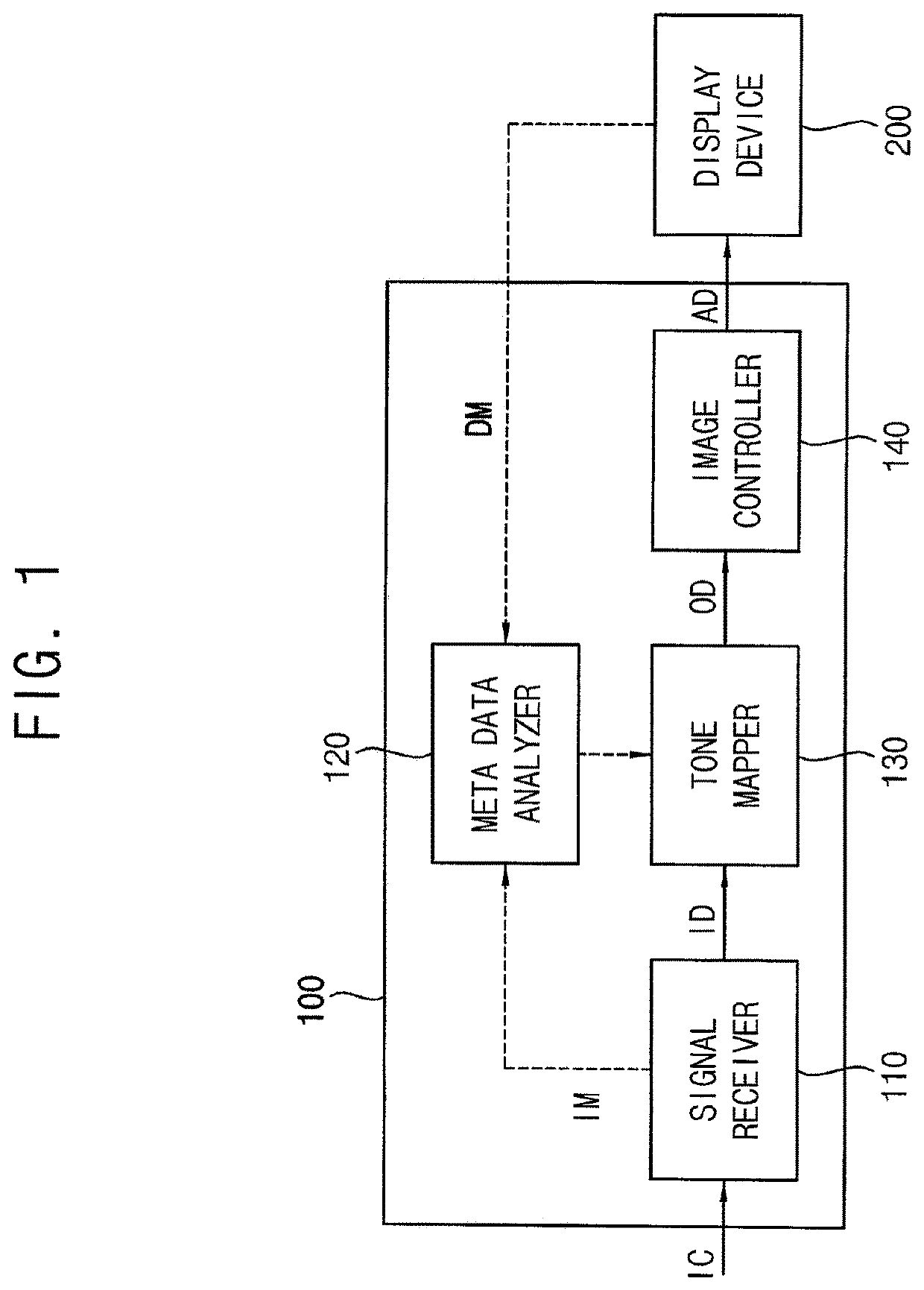

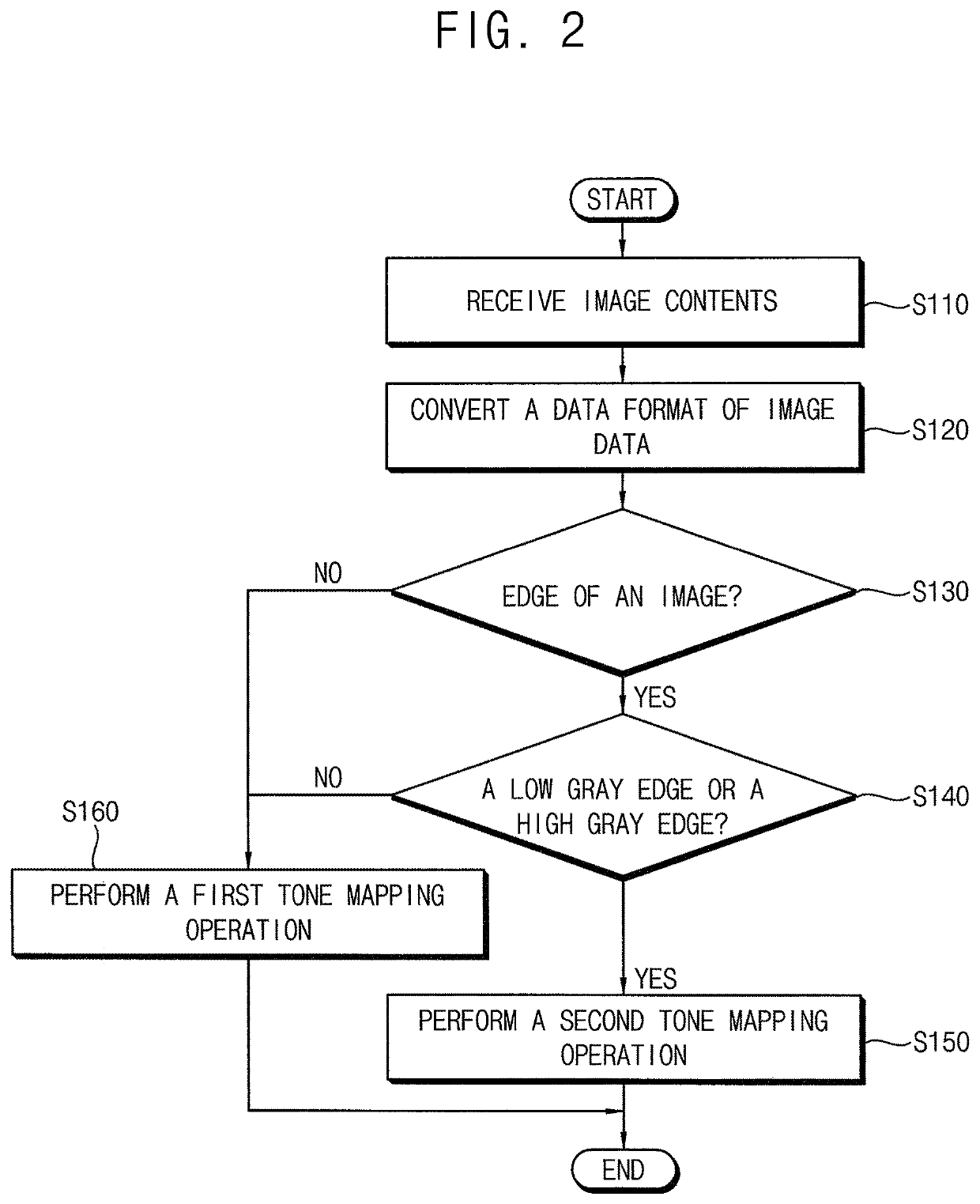

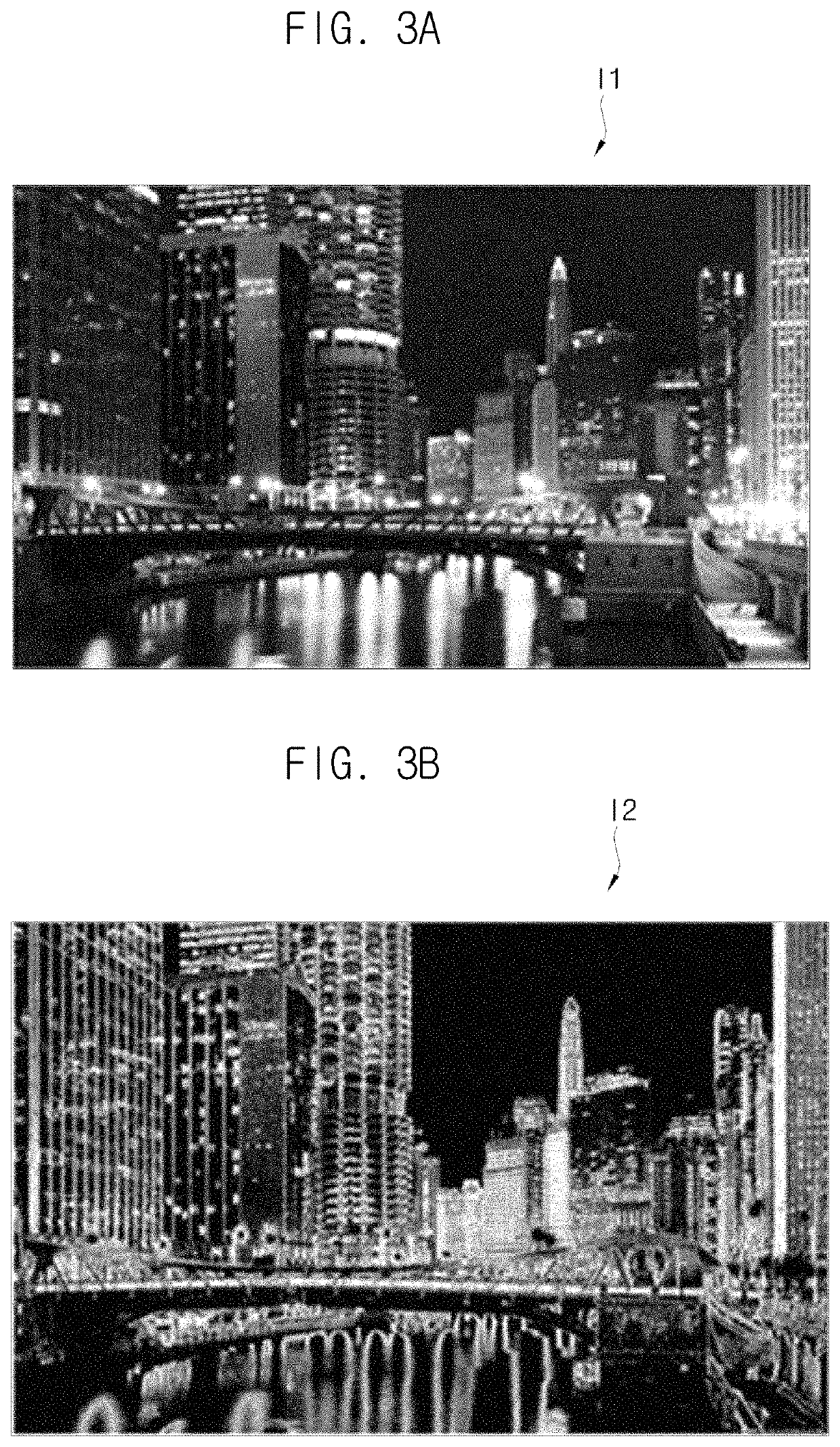

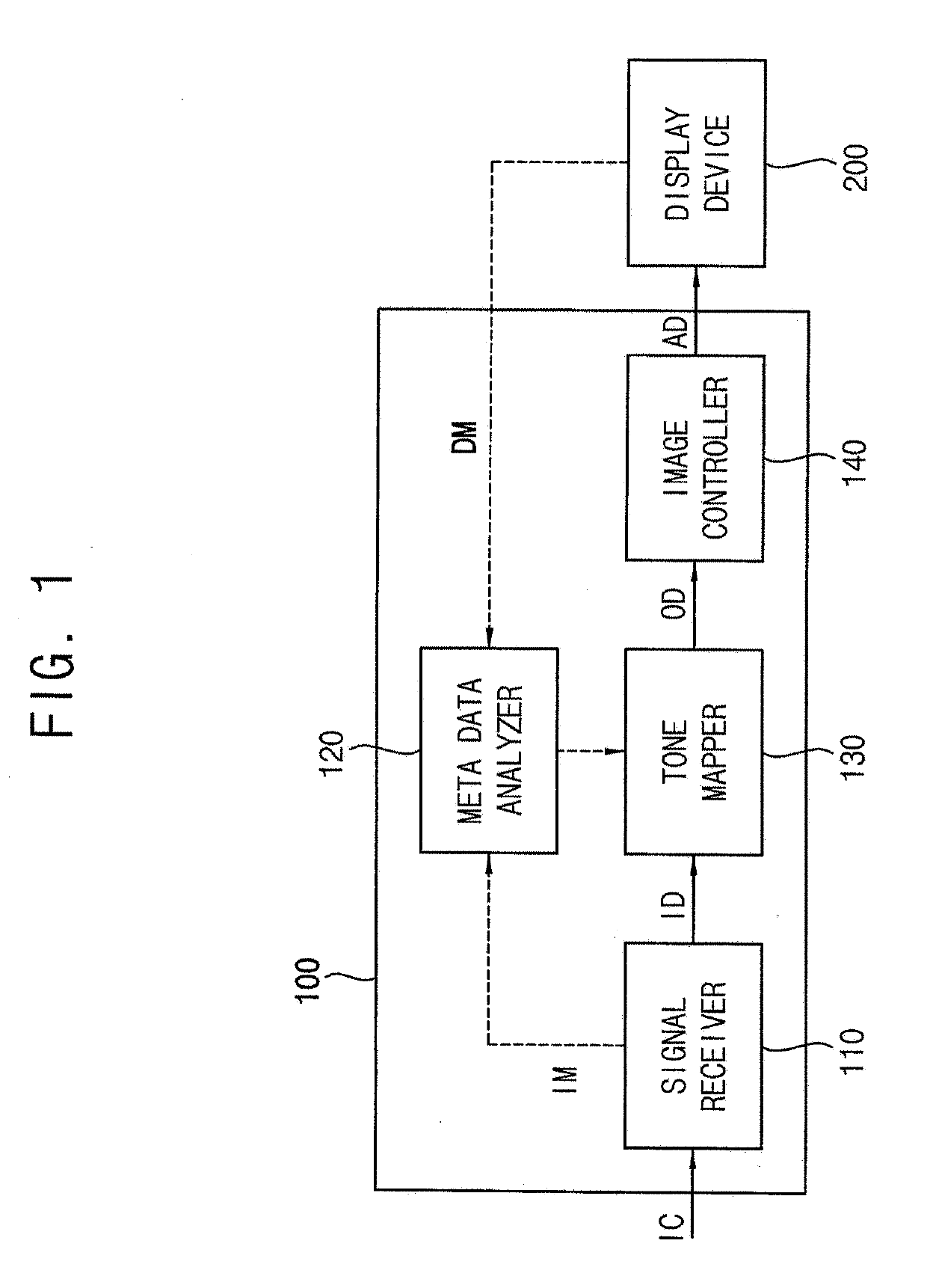

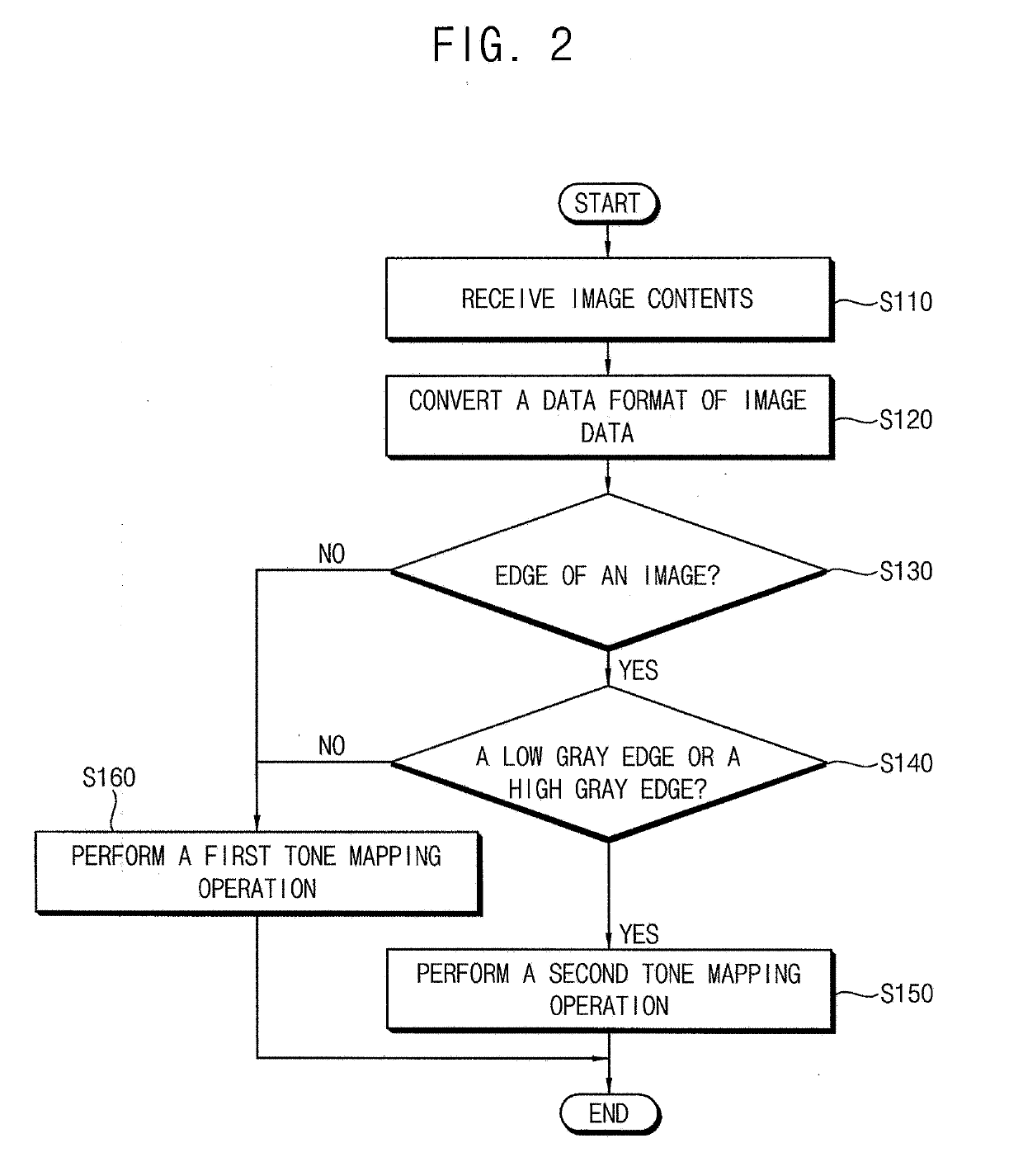

Image processing method and image processor performing the same

ActiveUS10789687B2Improve edging accuracyPrevent a detail loss of an edgeImage enhancementImage analysisImaging processingTone mapping

In an image processing method that converts image data into output data by performing tone mapping, an edge of an image represented by the image data is determined, a first tone mapping operation is performed on first image data included in the image data, where the first image data represent a first portion of the image not including the edge, whether a gray level of second image data is within a predetermined gray range is determined, where the second image data represent a second portion of the image including the edge, a second tone mapping operation is performed on the second image data when the gray level of the second image data is within the gray range, and the first tone mapping operation is performed on the second image data when the gray level of the second image data is not within the gray range.

Owner:SAMSUNG DISPLAY CO LTD

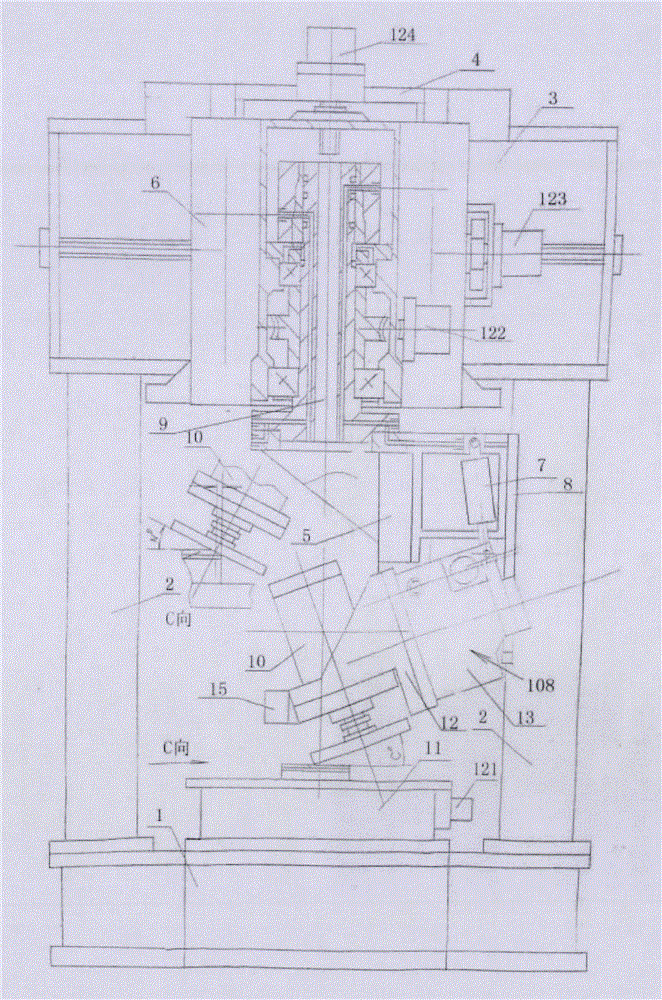

Constant-speed double-surface edge grinding machine for machining special-shaped products

ActiveCN104097123AConsistent thicknessUniform processingEdge grinding machinesGrinding drivesEngineeringMachining

The invention discloses a constant-speed double-surface edge grinding machine for machining special-shaped products. The constant-speed double-surface edge grinding machine comprises a base, wherein a power mechanism, a transmission mechanism, a profiling mechanism, a tool mechanism and a machining mechanism are sequentially arranged on the base from bottom to top; the power mechanism is used for providing driving force and moves along with a curvilinear path of a product; the transmission mechanism is used for transmitting the driving force generated by the power mechanism to the profiling mechanism; the profiling mechanism is used for controlling the machining mechanism to machine the product according to the curvilinear path of the product; and the tool mechanism is used for clamping the product. By the constant-speed double-surface edge grinding machine, power is applied to the curvilinear path of which the shape is the same with that of the special-shaped product, the speed of power drive is consistent with that of the outer edge of the special-shaped production, so that constant-speed machining is realized, and after the edge of the product is ground, the thicknesses of the material of the product are consistent. The constant-speed double-surface edge grinding machine is simple and practical, and is high in profiling effect and high in edge grinding precision.

Owner:ハンツォウトップリフトマシーナリーカンパニーリミテッド

Automatic feeding controlling method for glass edge grinding machine

InactiveCN107877382AImprove edging accuracyNot easy to breakEdge grinding machinesAutomatic grinding controlExecution unitEngineering

The invention discloses an automatic feeding controlling method for a glass edge grinding machine. The automatic feeding controlling method for the glass edge grinding machine comprises the followingsteps that a feeding system is built; the feeding system comprises a clamping unit, a detecting unit, an execution unit, and a controlling unit; the clamping unit, the execution unit, and the controlling unit are electrically connected with the controlling unit. According to the controlling unit controls the clamping unit, the detecting unit, and the execution unit to work, so that the controllingmethod is simple; the edge position of a glass product is detected by four edge detection sensors, so that the precision of glass edge grinding is high; the edges of the glass products are carried out grinding at the same time by four stepping motors and four mobile platforms, so that the efficiency of grinding is high; the glass product is fixed by a vacuum sucker, the glass is not prone to breaking, and the automatic feeding controlling method for the glass edge grinding machine is in favor for being generalized and popularized.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

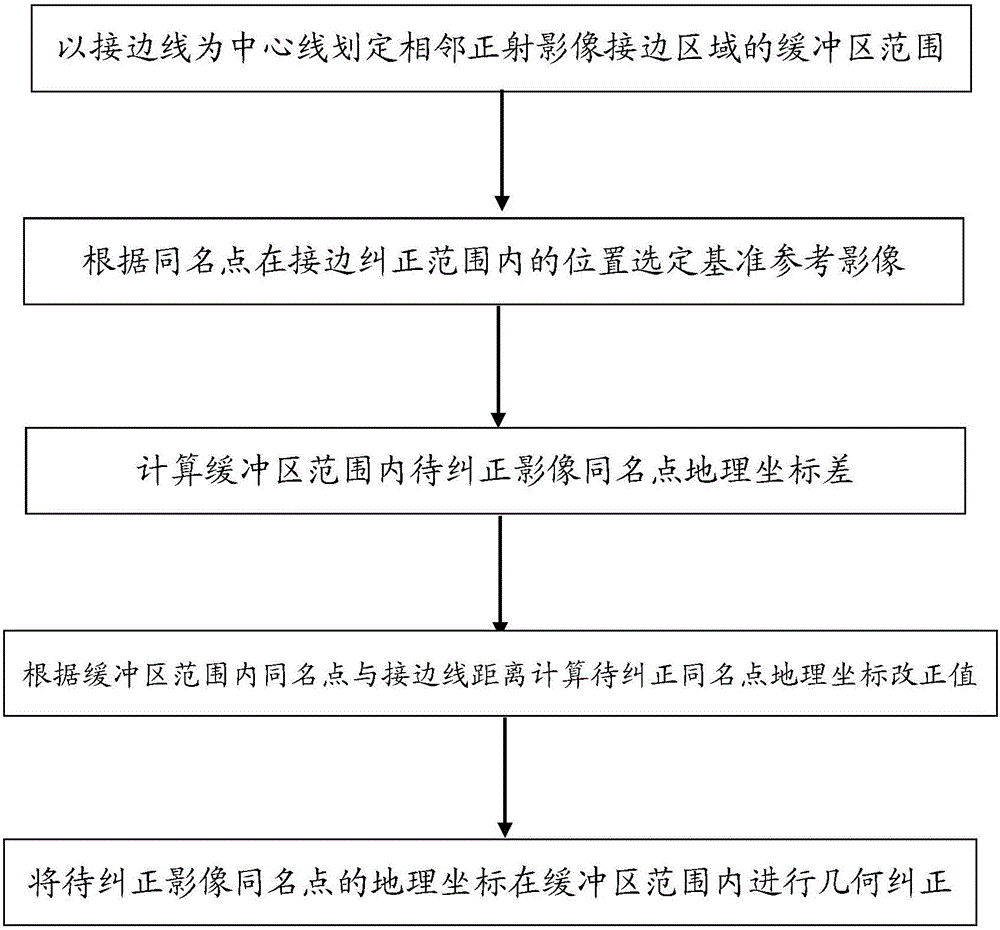

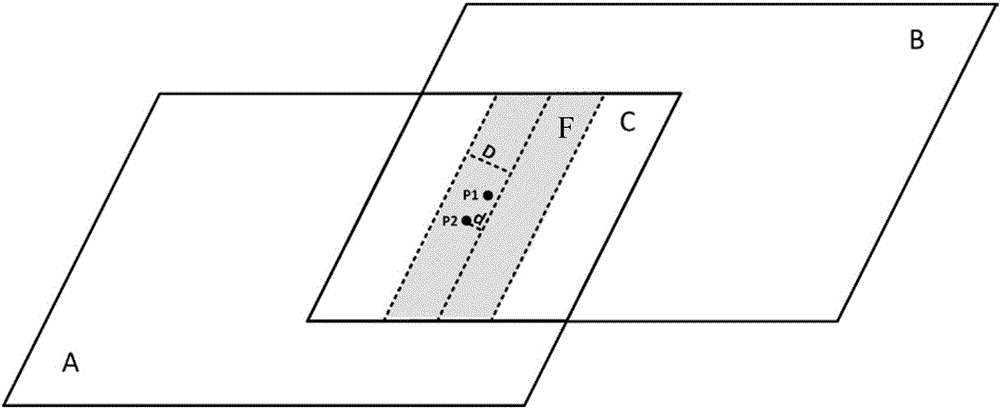

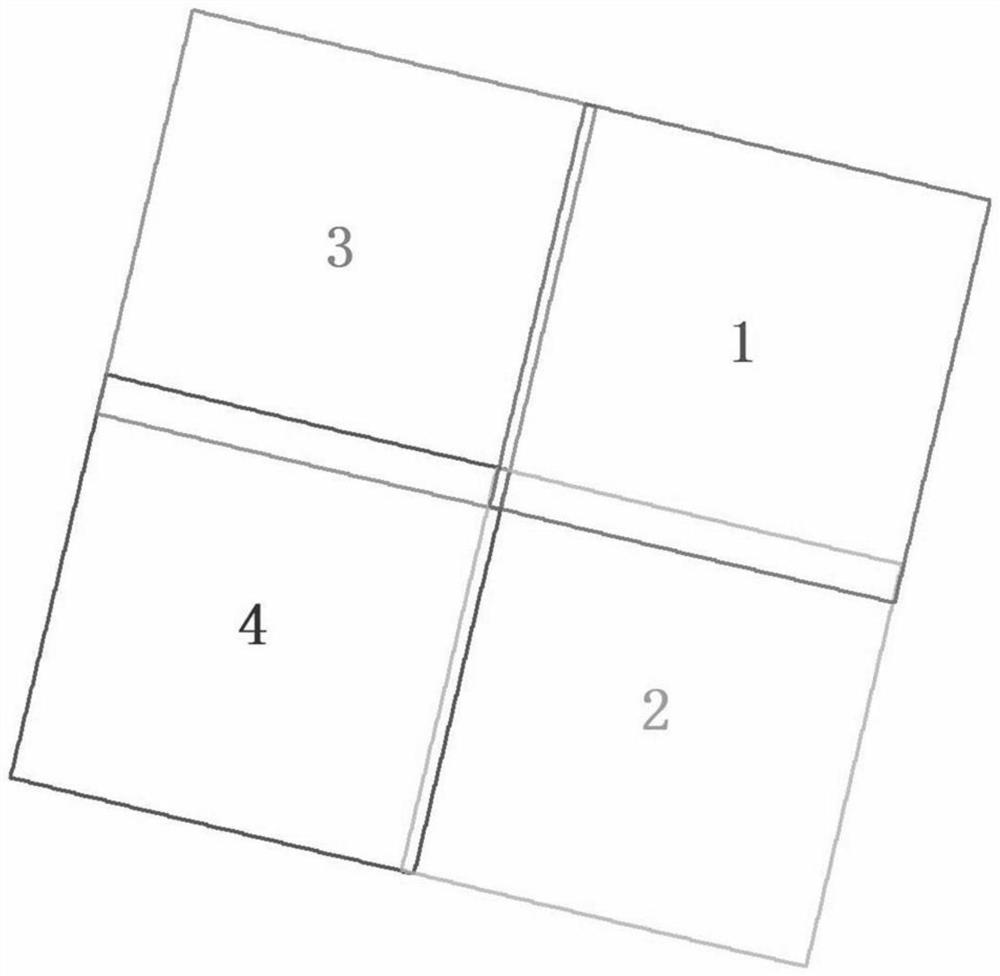

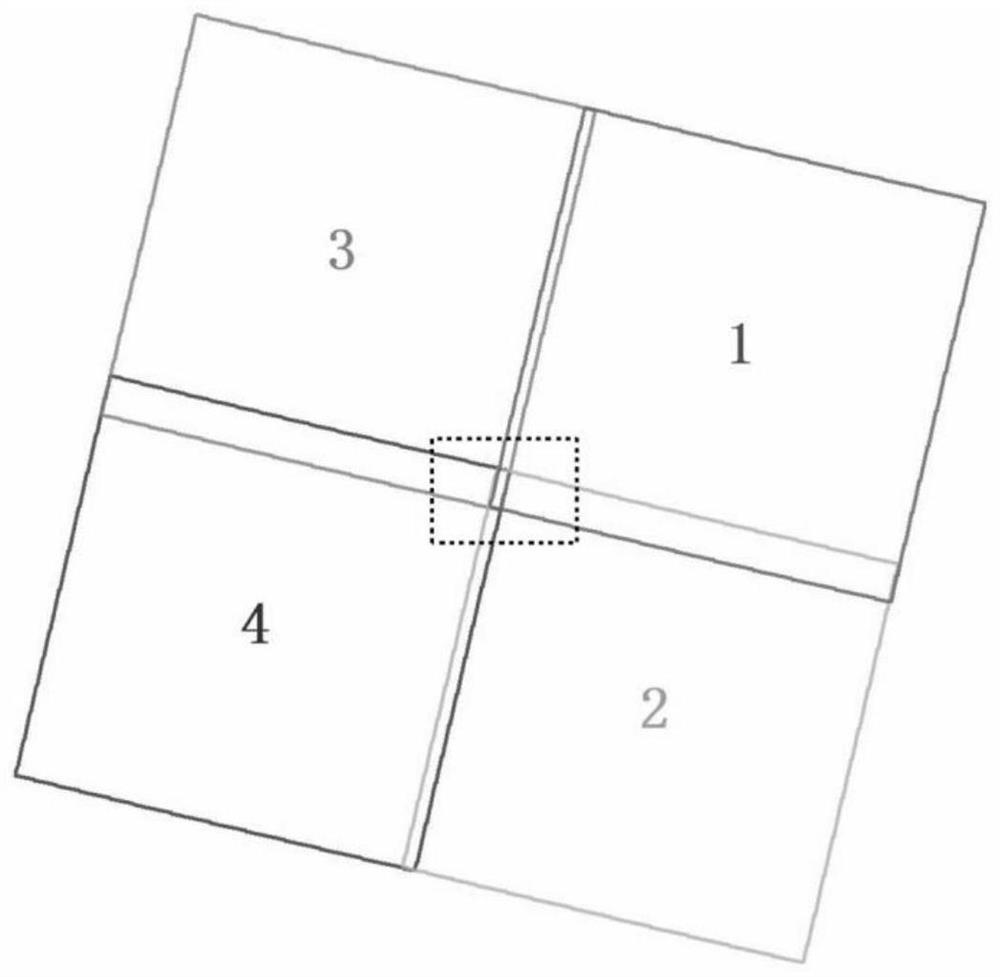

Method for correcting ortho-image mosaic edge matching

ActiveCN106780324AGuaranteed geometric accuracyGuaranteed edge correction accuracyImage enhancementImage analysisReference imageImage correction

The invention provides a method for correcting ortho-image mosaic edge matching. The method comprises the following steps of: determining positions of same-name points in an edge matching are of adjacent ortho-images; demarcating an edge matching correction range in the edge matching area; and selecting a standard reference image according to the positions of the same-name points in the edge matching correction range, and correcting to-be-corrected images of other non-standard reference images onto the standard reference image. According to the method, the aim of correcting ortho-image mosaic edge matching is achieved in a range with a certain distance to an edge matching line, and the image correction is controlled in a certain range when the edge matching correction precision is ensured, so that the edge matching precision of adjacent images is effectively improved, and the integral geometric precision of large-area mosaic images is ensured at the same time.

Owner:BEIJING AEROSPACE TITAN TECH CO LTD

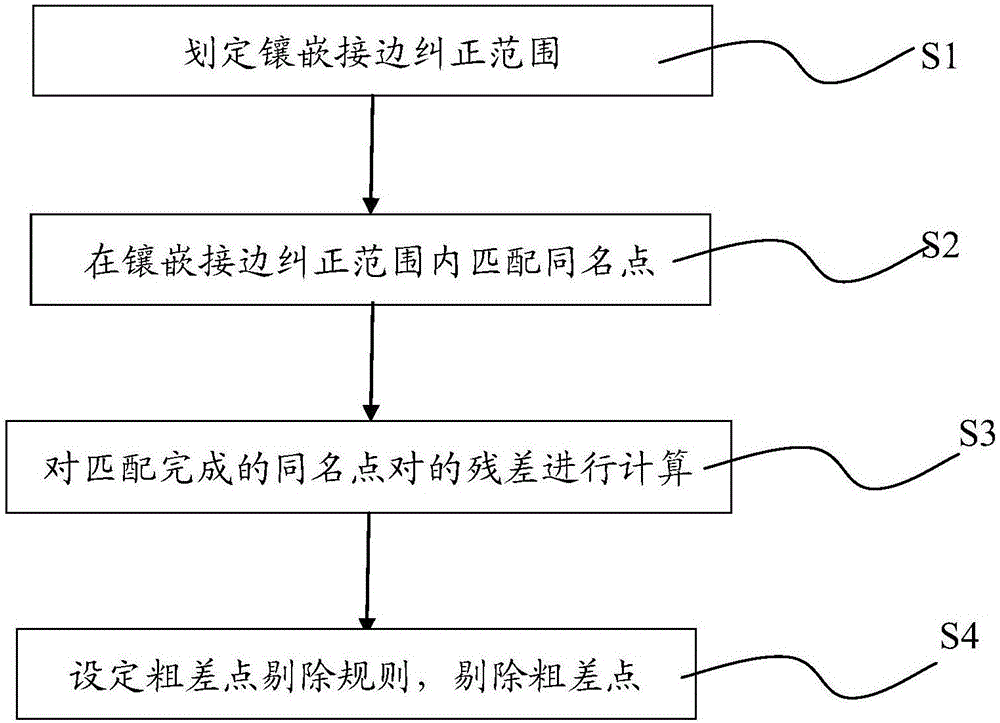

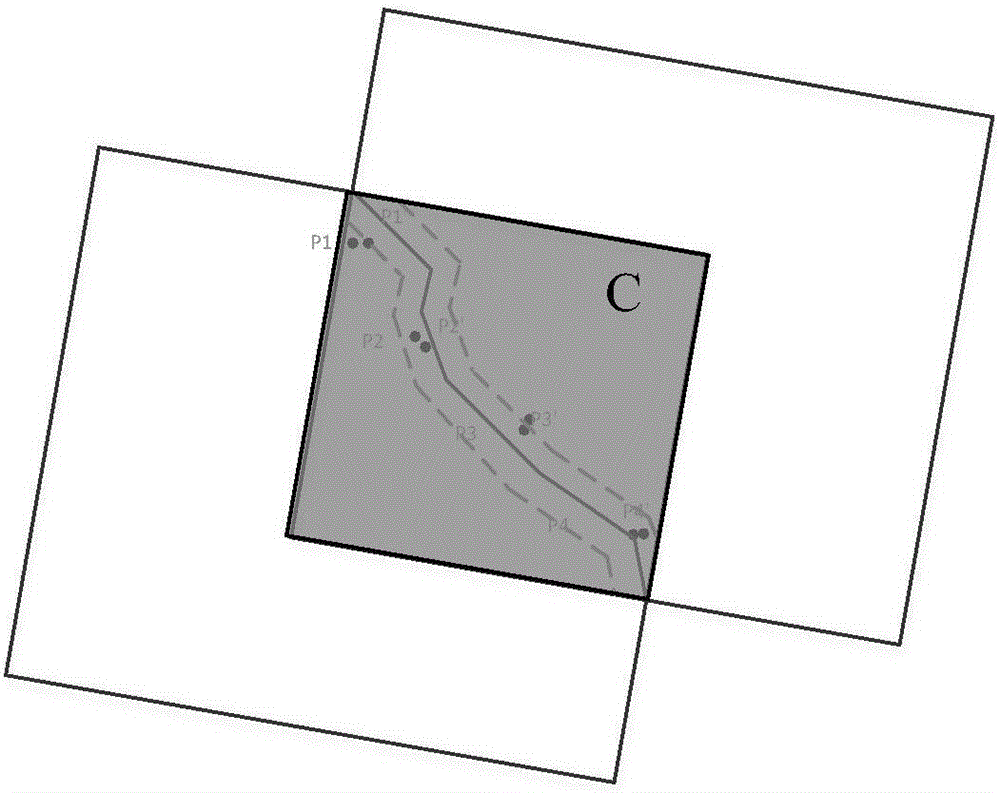

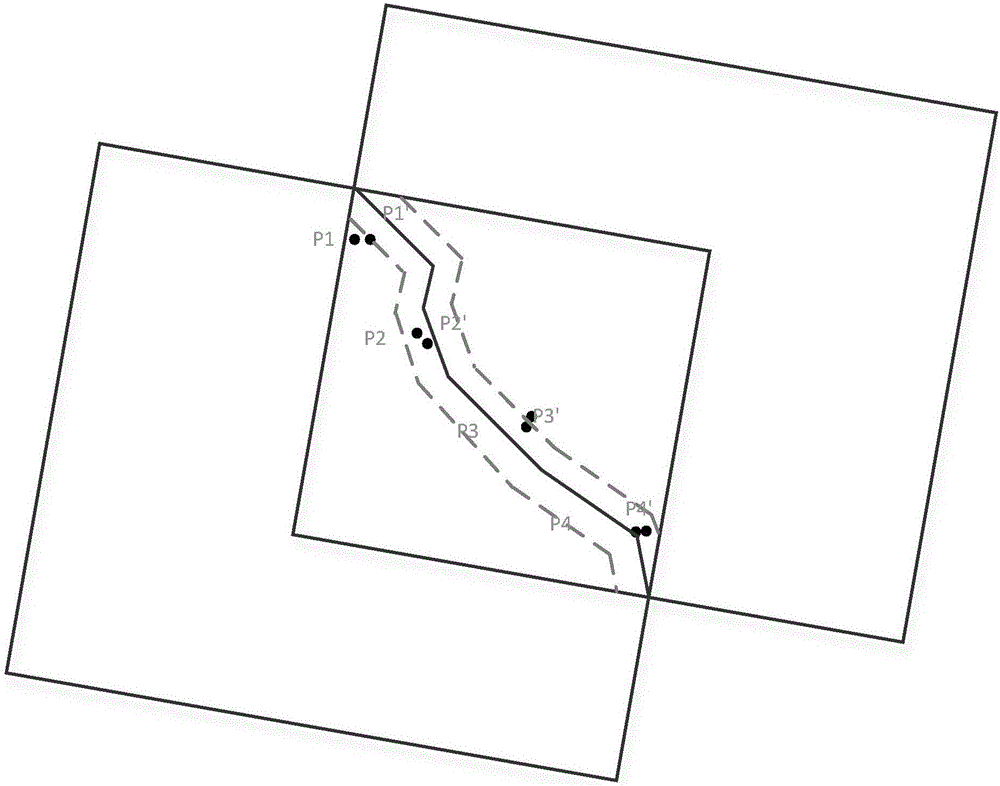

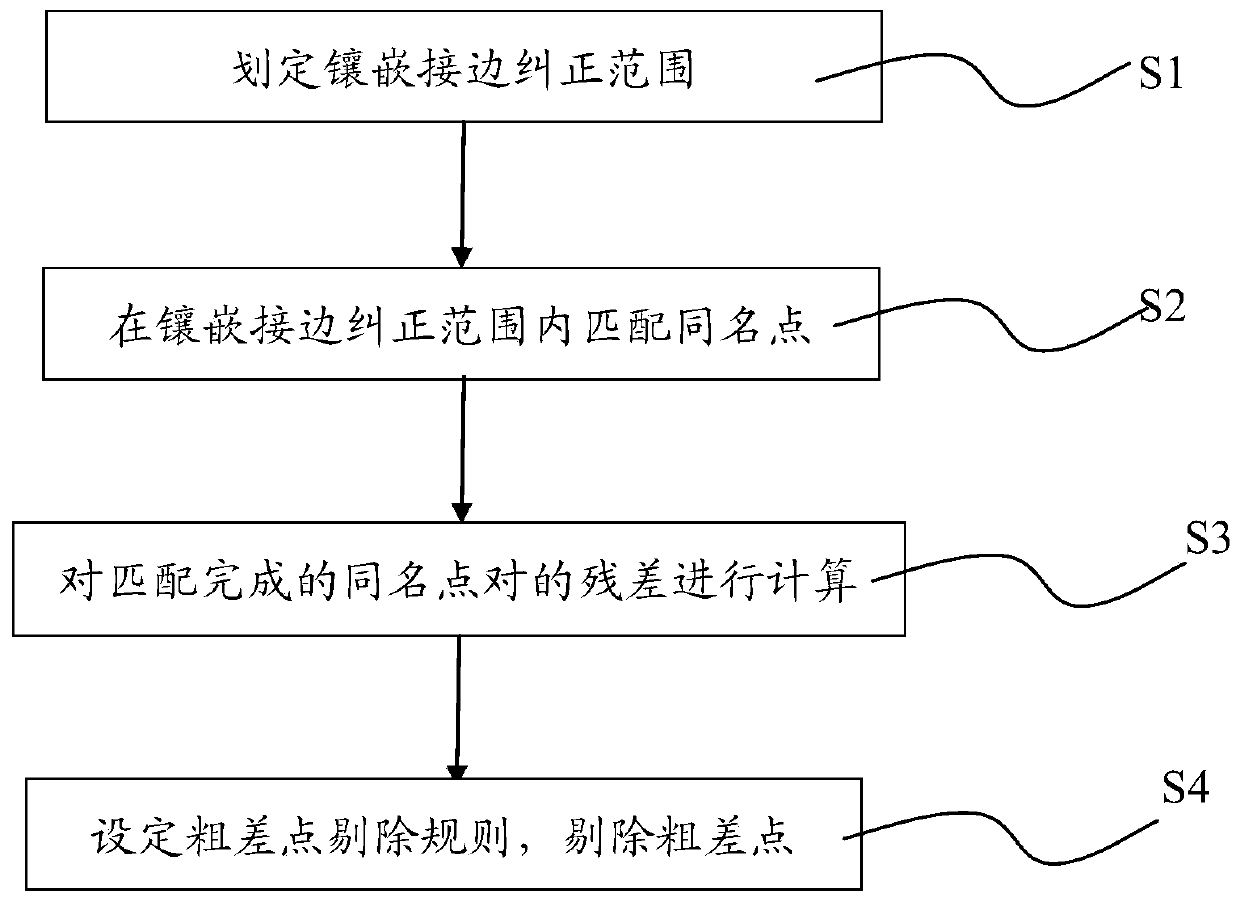

Homonymy point gross error elimination method matched with ortho-image mosaic edge joining

ActiveCN106651927AAchieve the correct tessellationImprove edging accuracyImage enhancementImage analysisAlgorithmModel parameters

The invention discloses a homonymy point gross error elimination method matched with ortho-image mosaic edge joining. The method comprises the following steps: designating a mosaic edge correction range in a mosaic edge region of a to-be-mosaicked ortho-image: matching homonymy points in the mosaic edge correction range; computing the residual error of the completely matched homonymy point pair; setting a gross error elimination rule so as to perform the gross error point elimination on the acquired homonymy point pair according to a gross error elimination rule. By use of the homonymy point gross error elimination method disclosed by the invention, the aims of eliminating the homonymy point and acquiring a precise matching point subset are achieved in a certain range distancing from a mosaic line; and then the precisely matched points are used for computing a conversion model parameter, thereby realizing the correct mosaicking of the image. The edge joining of two adjacent images is effectively improved, and the entire geometric accuracy of the large region mosaic image can be guaranteed at the same time.

Owner:BEIJING AEROSPACE TITAN TECH CO LTD

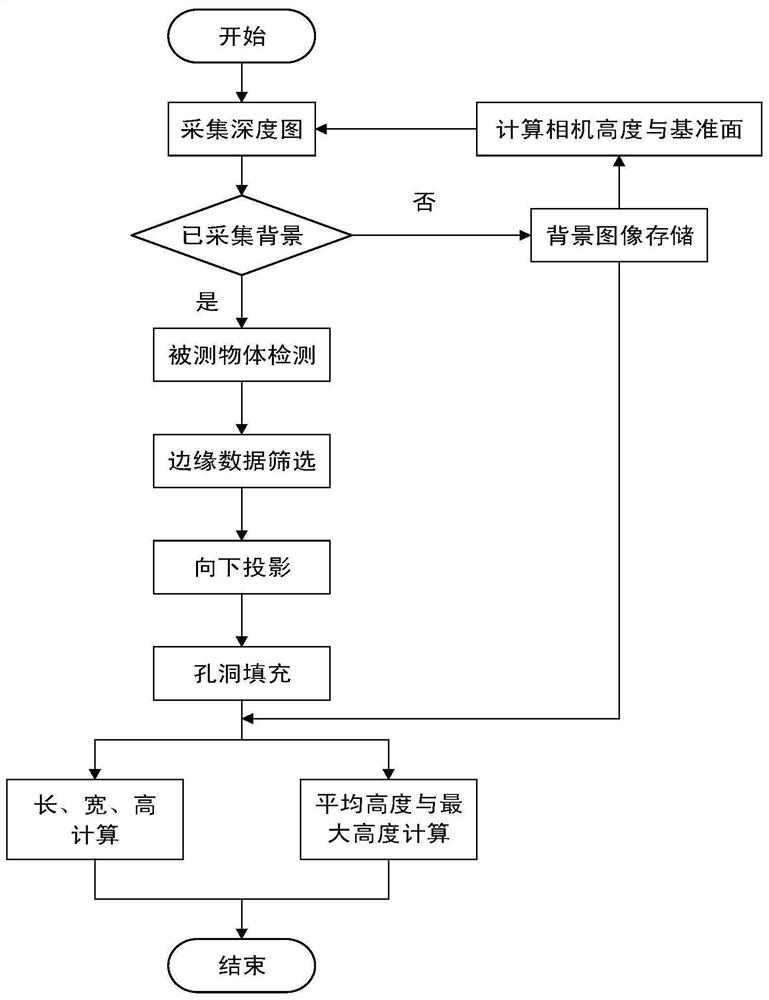

Object size high-precision measurement method based on depth camera

PendingCN112184790AImprove edging accuracyImprove calculation accuracyImage analysisUsing optical meansProjection imageRadiology

The invention relates to the field of methods for automatically measuring the volume of an object, and particularly discloses an object size high-precision measurement method based on a depth camera,which comprises the following steps of: 1) acquiring a depth image of a measurement background in advance, and calculating to obtain a reference plane; 2) acquiring a depth image of the measured object, and positioning the depth image of the measured object to the position of the measured object in the image; 3) removing redundant transition data at the edge to further accurately obtain the position and the size of the measured object in the depth image; 4) projecting to the reference plane to obtain a projection image; 5) performing hole filling on the projection image; and 6) calculating toobtain the average height and the maximum height of the measured object, and converting to obtain the actual size of the measured object. According to the method, the volume of the object measured bythe depth map obtained by the depth camera under the semi-outdoor condition can obtain high-stability measurement precision, and meanwhile, measurement of the irregular object with the fluctuant surface is also supported.

Owner:FUJIAN QUANZHOU HIT RES INSTIUTE OF ENG & TECH +1

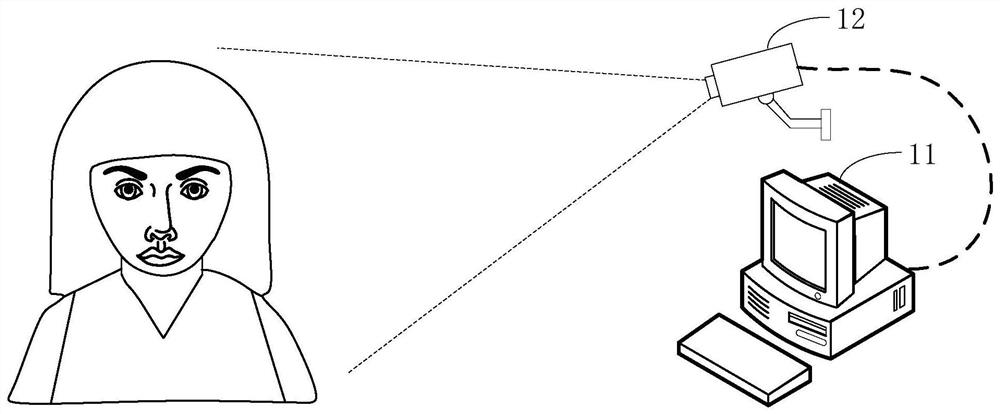

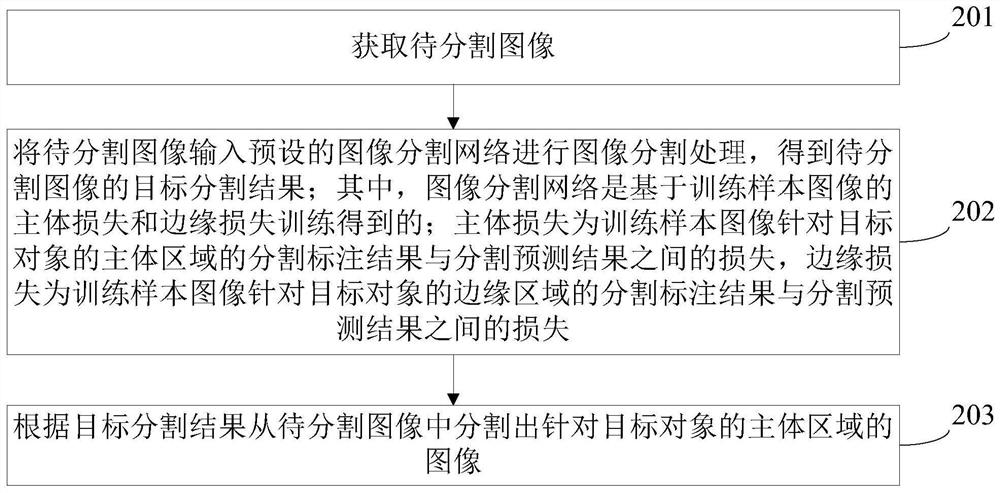

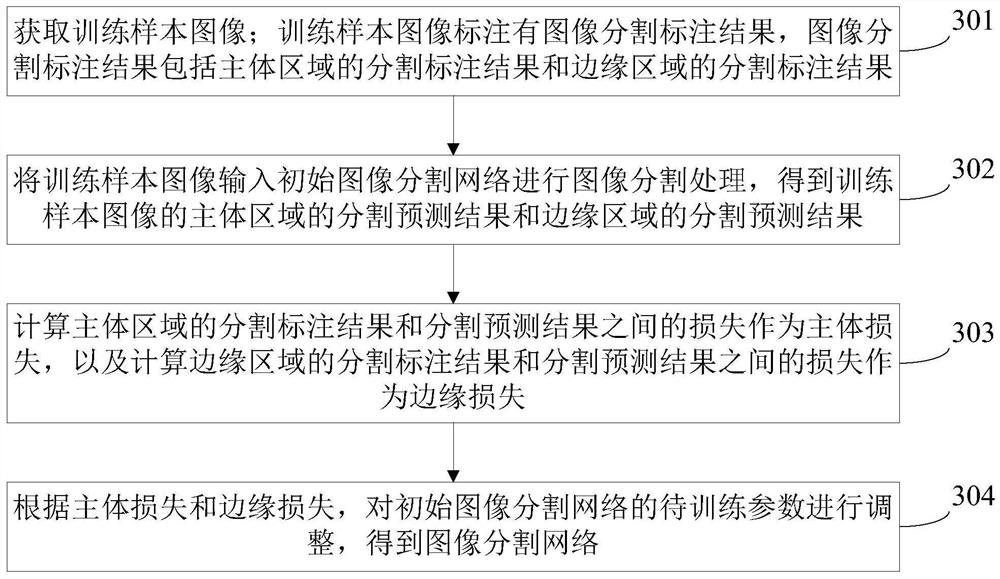

Image segmentation and image segmentation network training method, device and computer equipment

ActiveCN110517278BHigh precisionImprove training efficiency and segmentation accuracyImage enhancementImage analysisSample imageImage segmentation

The present application relates to an image segmentation method, an image segmentation network training method, an image segmentation device, an image segmentation network training device, computer equipment and a readable storage medium. The method includes: acquiring an image to be segmented; inputting the image to be segmented into a preset image segmentation network for image segmentation processing to obtain a target segmentation result of the image to be segmented; wherein the image segmentation network is based on the subject loss and edge loss of the training sample image Obtained by training; the main loss is the loss between the segmentation and prediction results of the training sample image for the main region of the target object and the segmentation prediction result, and the edge loss is the segmentation and prediction results of the training sample image for the edge region of the target object. According to the target segmentation result, the image for the main area of the target object is segmented from the image to be segmented. Using this method can improve the precision of edge segmentation.

Owner:BEIJING KUANGSHI TECH

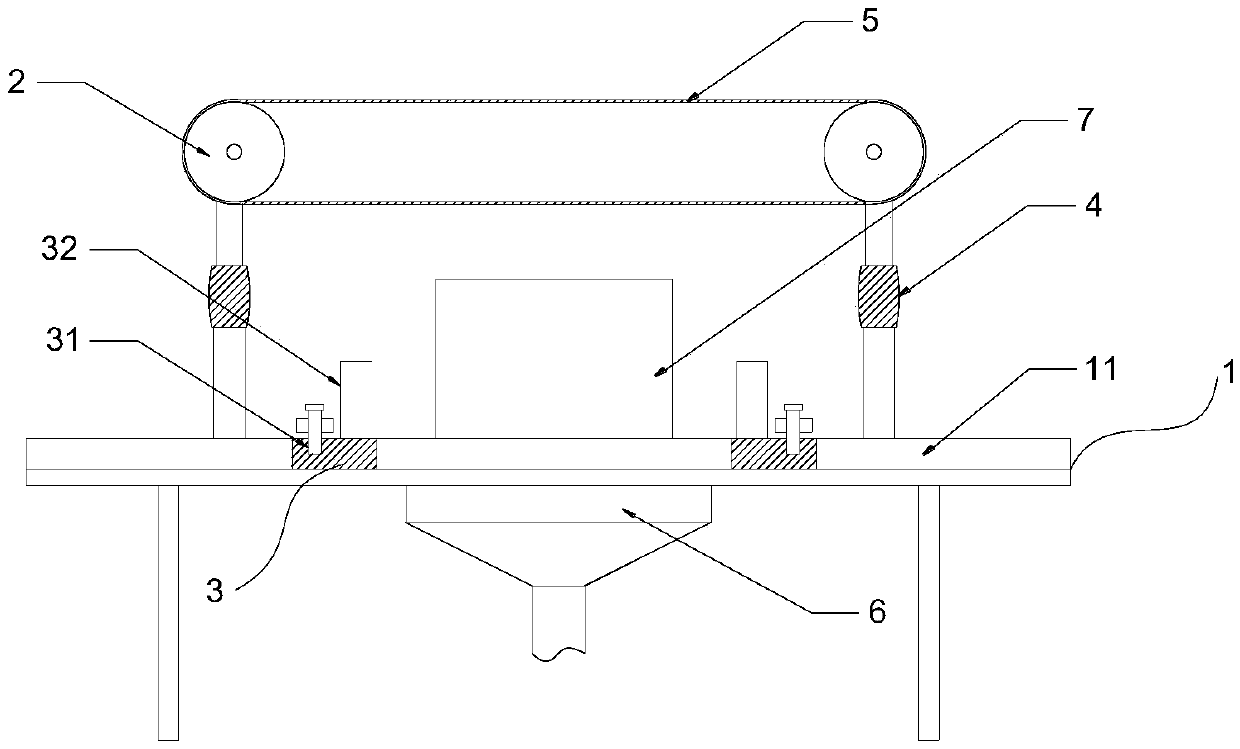

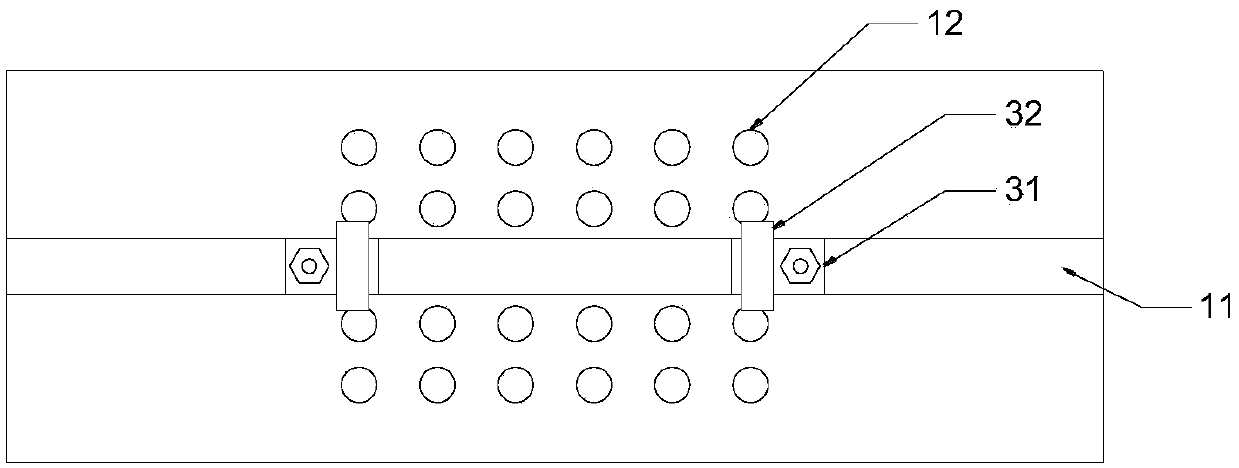

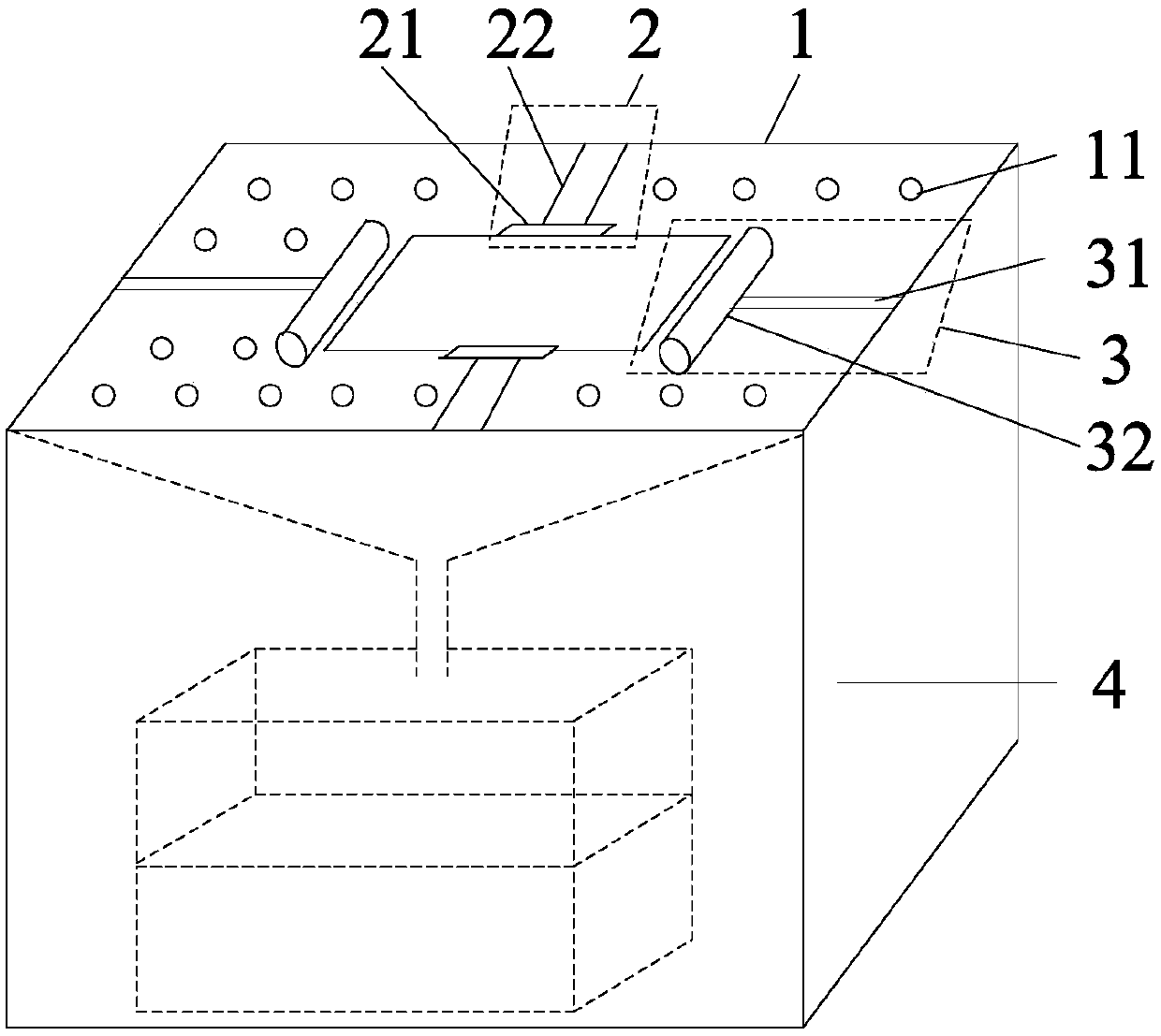

Automatic edge grinding device for wood plate materials

InactiveCN110962007APrevent jumpingReduce splashEdge grinding machinesGrinding feedersElectric machineryWood plank

The invention discloses an automatic edge grinding device for wood plate materials, and belongs to the technical field of wood board processing. The automatic edge grinding device specifically comprises a base, a conveying belt and clamping assemblies used for clamping a to-be-ground plate material; the conveying belt is mounted on the base through supporting columns and is driven by a motor; anda coating grinding tool is arranged on the outer side of the conveying belt, a sliding groove is formed in the middle of the top of the base, and the clamping assemblies are arranged in the sliding groove. According to the automatic edge grinding device, through fixed plates and the conveying belt, the to-be-ground plate material is bidirectionally fixed during grinding, the to-be-ground plate material is effectively prevented from jumping during grinding, the working efficiency is high, and the edge grinding effect is good.

Owner:湖北云艺天木业有限公司

Printed circuit board edge grinding machine

InactiveCN109623540AEasy to fixAvoid displacementEdge grinding machinesGrinding drivesEngineeringPrinted circuit board

The invention provides a printed circuit board edge grinding machine. The printed circuit board edge grinding machine comprises an operating panel, two fixing devices and grinding devices, wherein theoperating panel is of a rectangular structure; the two fixing devices are symmetrically and oppositely fixed to the two side edges of the operating panel, each fixing device comprises a fixing bracket and two or more fixing rods, one ends of the fixing rods are connected with the side edges of the operating panel, the other ends of the fixing rods are connected with the fixing brackets, and a printed circuit board can be clamped and fixed through the two oppositely-arranged fixing brackets; and the grinding devices are symmetrically and oppositely arranged on the another two side edges of theoperating panel and comprise connecting rods and grinding mechanisms, the connecting rods are connected with the side edges of the operating panel, the other ends of the connecting rods are connectedwith the grinding mechanisms, the connecting rods are each of a telescopic structure, and the grinding mechanisms can extend to the edge of the printed circuit board from the side edges of the operating panel through the connecting rods for grinding. According to the printed circuit board edge grinding machine, the edge grinding precision of the printed circuit board can be improved, the grindingefficiency of the printed circuit board is improved, and the machining progress is accelerated.

Owner:赣州科翔电子科技一厂有限公司

A special-shaped glass remote control cutting, breaking and grinding integrated processing production line and its operation method

InactiveCN105598781BHigh precisionImprove edging accuracyEdge grinding machinesGrinding drivesProduction lineRemote control

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

A Method for Removing Homogenous Points in Orthophoto Mosaic and Edge Matching

ActiveCN106651927BAchieve the correct tessellationImprove edging accuracyImage enhancementImage analysisAlgorithmPoint pair

The invention discloses a homonymy point gross error elimination method matched with ortho-image mosaic edge joining. The method comprises the following steps: designating a mosaic edge correction range in a mosaic edge region of a to-be-mosaicked ortho-image: matching homonymy points in the mosaic edge correction range; computing the residual error of the completely matched homonymy point pair; setting a gross error elimination rule so as to perform the gross error point elimination on the acquired homonymy point pair according to a gross error elimination rule. By use of the homonymy point gross error elimination method disclosed by the invention, the aims of eliminating the homonymy point and acquiring a precise matching point subset are achieved in a certain range distancing from a mosaic line; and then the precisely matched points are used for computing a conversion model parameter, thereby realizing the correct mosaicking of the image. The edge joining of two adjacent images is effectively improved, and the entire geometric accuracy of the large region mosaic image can be guaranteed at the same time.

Owner:BEIJING AEROSPACE TITAN TECH CO LTD

A method of edging dinner plate based on vision control

ActiveCN105666274BRealize acquisitionEliminate errorsEdge grinding machinesPre treatmentVisual perception

The invention discloses a dinner plate edging method based on vision control. The method comprises the following steps: clamping and locating a dinner plate to be edged, and acquiring images of the dinner plate by virtue of two cameras which are symmetrically arranged at the two sides of the dinner plate; integrating the images through pre-treatment, image registration and fusion processing, and then extracting contour features to generate a complete dinner plate contour drawing; comparing the dinner plate contour drawing with a theoretical CAD model of the dinner plate, and obtaining a central position and a deviation angle of the current clamping and locating; and carrying out coordinate offset in a numerical control system according to the central position and the deviation angle, and controlling an edging unit to realize edging for the dinner plate by the numerical control system after the coordinate offset according to G code corresponding to the theoretical CAD model. According to the method disclosed by the invention, the two cameras which are symmetrically distributed at the two sides of the dinner plate are used for carrying out contour acquisition on the edge of the dinner plate, at a machining station, comprehensive acquisition and control for the contour of the dinner plate can be realized, and the G code is finally used for machining; and the method has the advantages of high edging quality, high machining efficiency and the like.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A Edge Correction Method Applicable to Multiple Remote Sensing Images in Large Areas

ActiveCN107705244BThe relative relationship remains unchangedImprove edging accuracyImage enhancementImage analysisThresholdingRemote sensing

The invention relates to an edge correction method suitable for multiple remote sensing images in a large area. (1) Automatically match points of the same name in adjacent areas of all images to obtain points of the same name; (2) Use existing points of the same name to construct a triangulation network; (3) For each point with the same name, calculate the reference object coordinates of the point with the same name; (4) Calculate the affine transformation parameters of each image; (5) For each point with the same name, calculate the reference object coordinates of the point on different images and the corresponding Affine transformation parameters are used to calculate the new observed object-space coordinates of the point with the same name on the corresponding image; (6) Repeat (3) to (5) until the change of the reference object-space coordinates is less than a certain threshold or no longer changes; (7) Correct the corresponding image using the affine transformation parameters of the last iteration. The method proposed by the present invention can perform edge correction on multiple images in a large area at the same time; the correction accuracy is higher; and it avoids the problems of uneven deformation and excessive image distortion caused by traditional correction methods.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

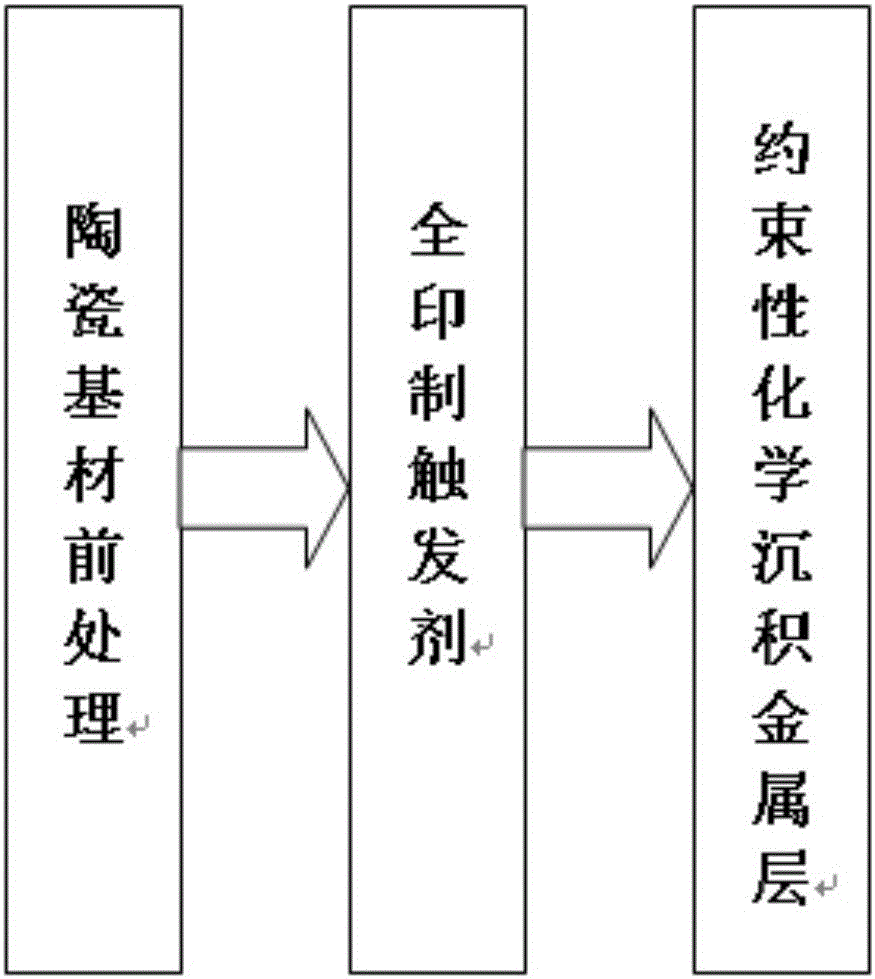

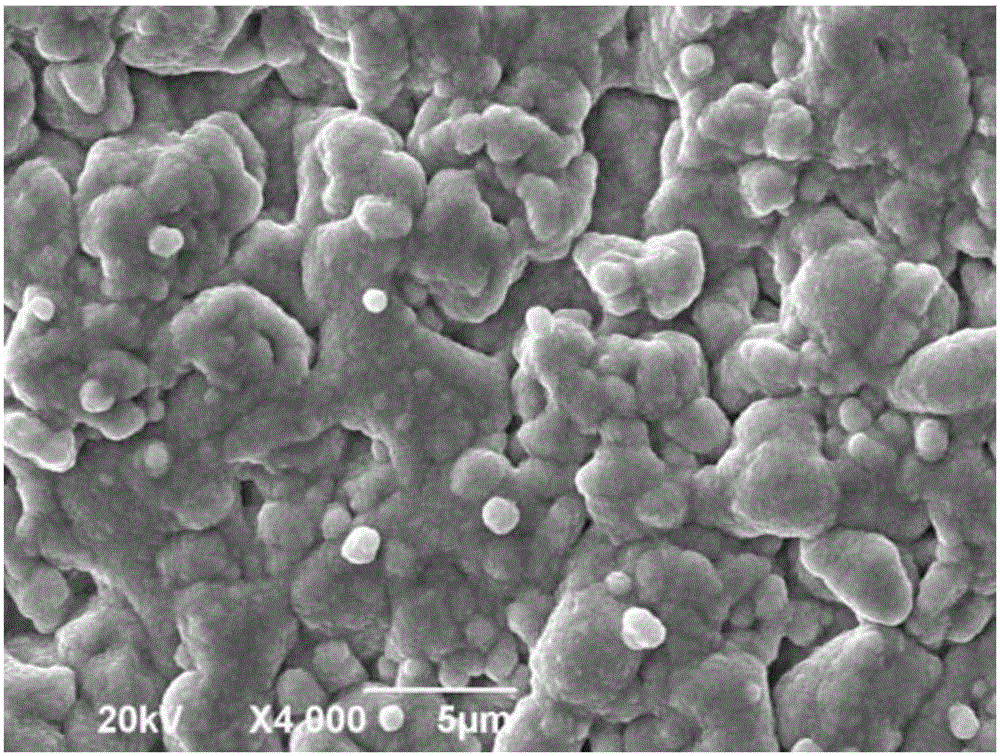

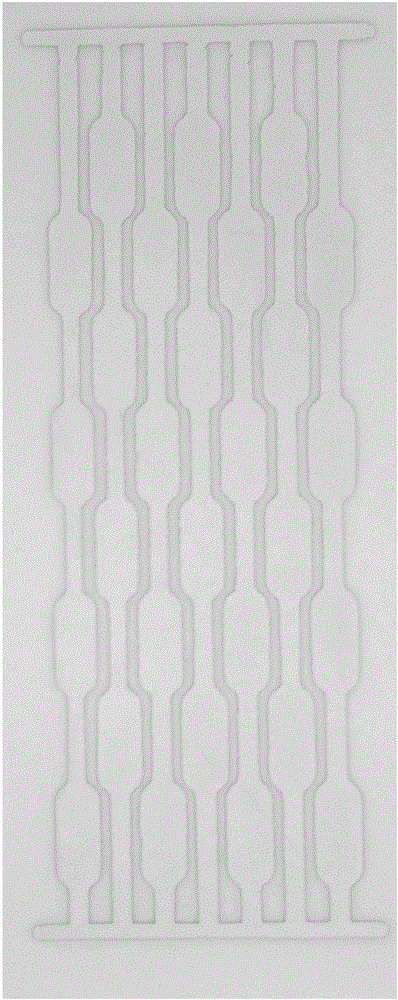

A method for preparing a patterned metal layer on a ceramic surface

ActiveCN104211448BSimple processEase of industrial productionConductive pattern formationGraphicsSurface pattern

The invention discloses a preparation method of a graphical metal layer on a ceramic surface. The preparation method comprises the following steps: sequentially carrying out pre-cleaning, coarsening, post-cleaning, drying, trigger printing, graphical curing, constrained chemical deposition of a metal layer and the like on the surface of a ceramic substrate; and carrying out constrained chemical deposition of conductive graphics of copper, silver, nickel and alloys thereof on the ceramic surface. The graphical metal layer on the ceramic surface prepared by the preparation method disclosed by the invention is uniform and compact, good in adhesive force and easy to weld, and the electrical properties can satisfy the industrial requirements, and meanwhile, the preparation method disclosed by the invention has the characteristics of simple process, low cost, convenience in industrialized production and the like.

Owner:遂宁迪印科技有限公司

Image processing method and image processor performing the same

ActiveUS20190156469A1Avoid image distortionImprove dynamic rangeImage enhancementImage analysisTone mappingImaging processing

In an image processing method that converts image data into output data by performing tone mapping, an edge of an image represented by the image data is determined, a first tone mapping operation is performed on first image data included in the image data, where the first image data represent a first portion of the image not including the edge, whether a gray level of second image data is within a predetermined gray range is determined, where the second image data represent a second portion of the image including the edge, a second tone mapping operation is performed on the second image data when the gray level of the second image data is within the gray range, and the first tone mapping operation is performed on the second image data when the gray level of the second image data is not within the gray range.

Owner:SAMSUNG DISPLAY CO LTD

Full-automatic multi-faceted code scanning, weighing and volume measurement system for express mail and its processing method

ActiveCN112179272BReduce investmentSave operating timeUsing optical meansStacking articlesComputer hardwareFace scanning

The present invention relates to the field of full-automatic code scanning measurement system for express mail, and specifically discloses a full-automatic multi-faceted code scanning, weighing, and volume measurement system for express mail and a processing method thereof, including an automatic transport forklift, a multi-axis manipulator, a bottom-side code-scanning camera, and a side-side code-scanning system. Camera, top scanning code scanning volume measurement camera, scanning code weighing conveyor line and control system, multi-axis manipulators are respectively set at both ends of the code scanning and weighing conveyor line, automatic transport forklifts are used The code camera is set under the working range of the multi-axis manipulator, the side code scanning camera is correspondingly set on the side of the working end range of the multi-axis manipulator, and the top scanning code measuring volume camera is correspondingly set at the side of the code scanning weighing conveyor line Above, the control system controls the operation of the whole machine, and a gravity sensor is installed on the code scanning and weighing conveyor line. This system changes the traditional conveying method, and realizes automatic express processing such as multi-faceted code scanning, weighing, and volume measurement, and has high work efficiency, compact mechanical structure, and stable work.

Owner:SF TECH +1

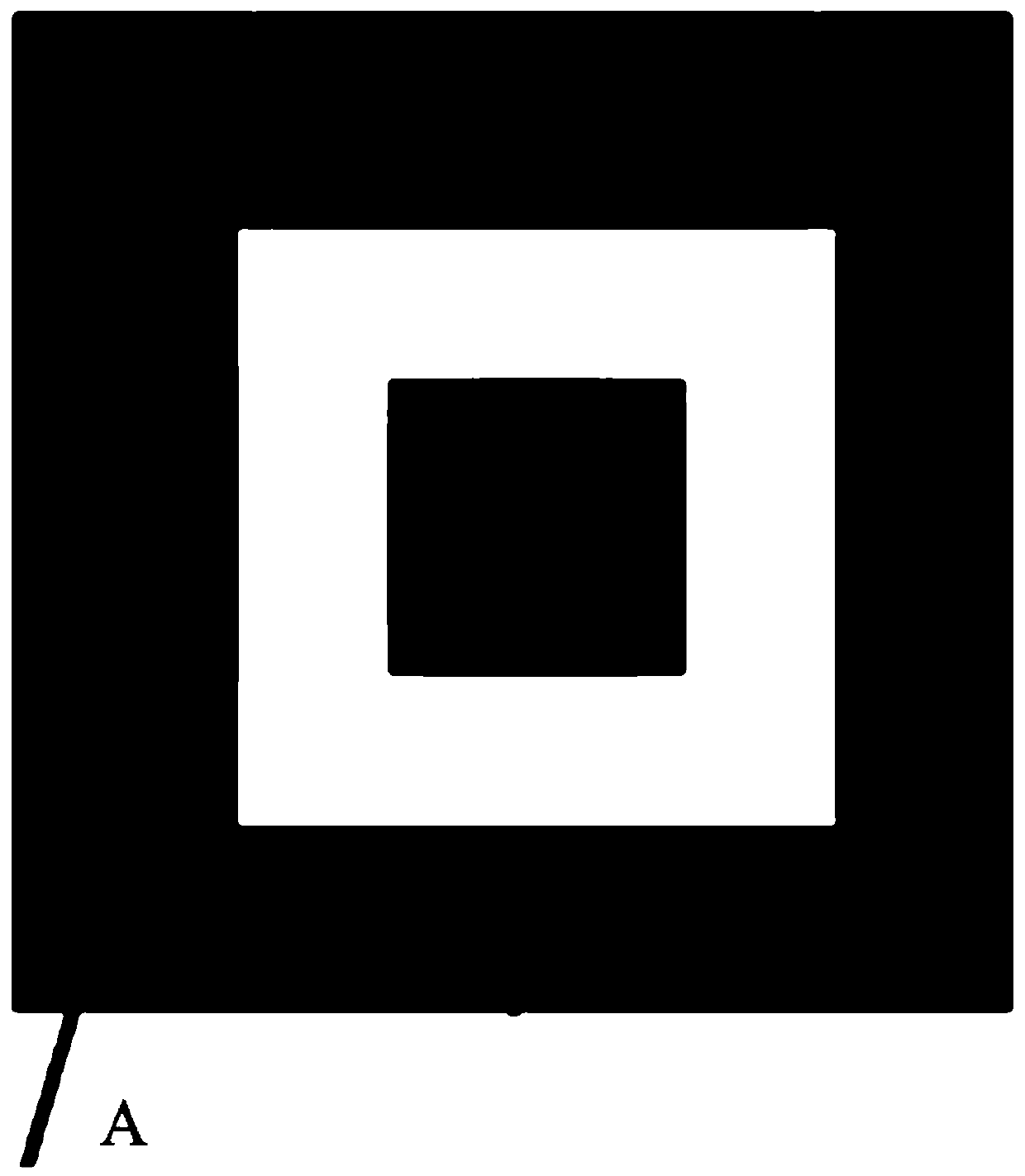

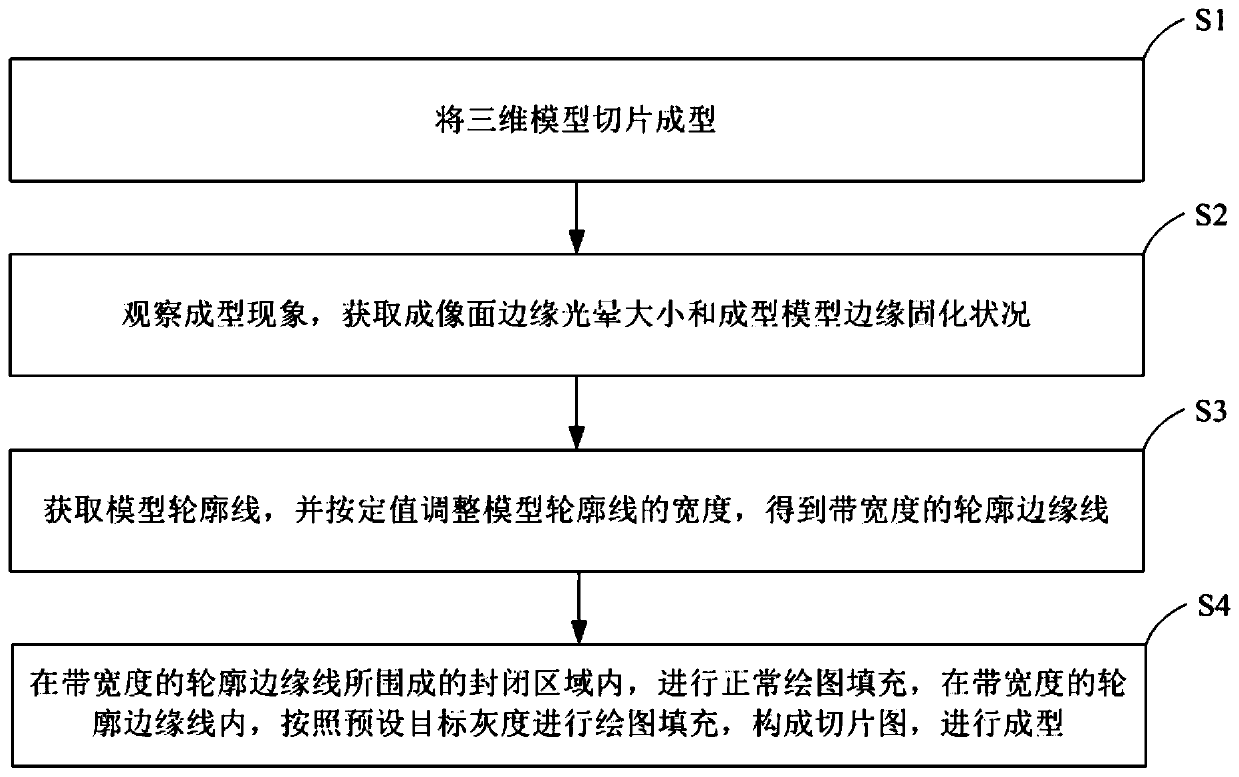

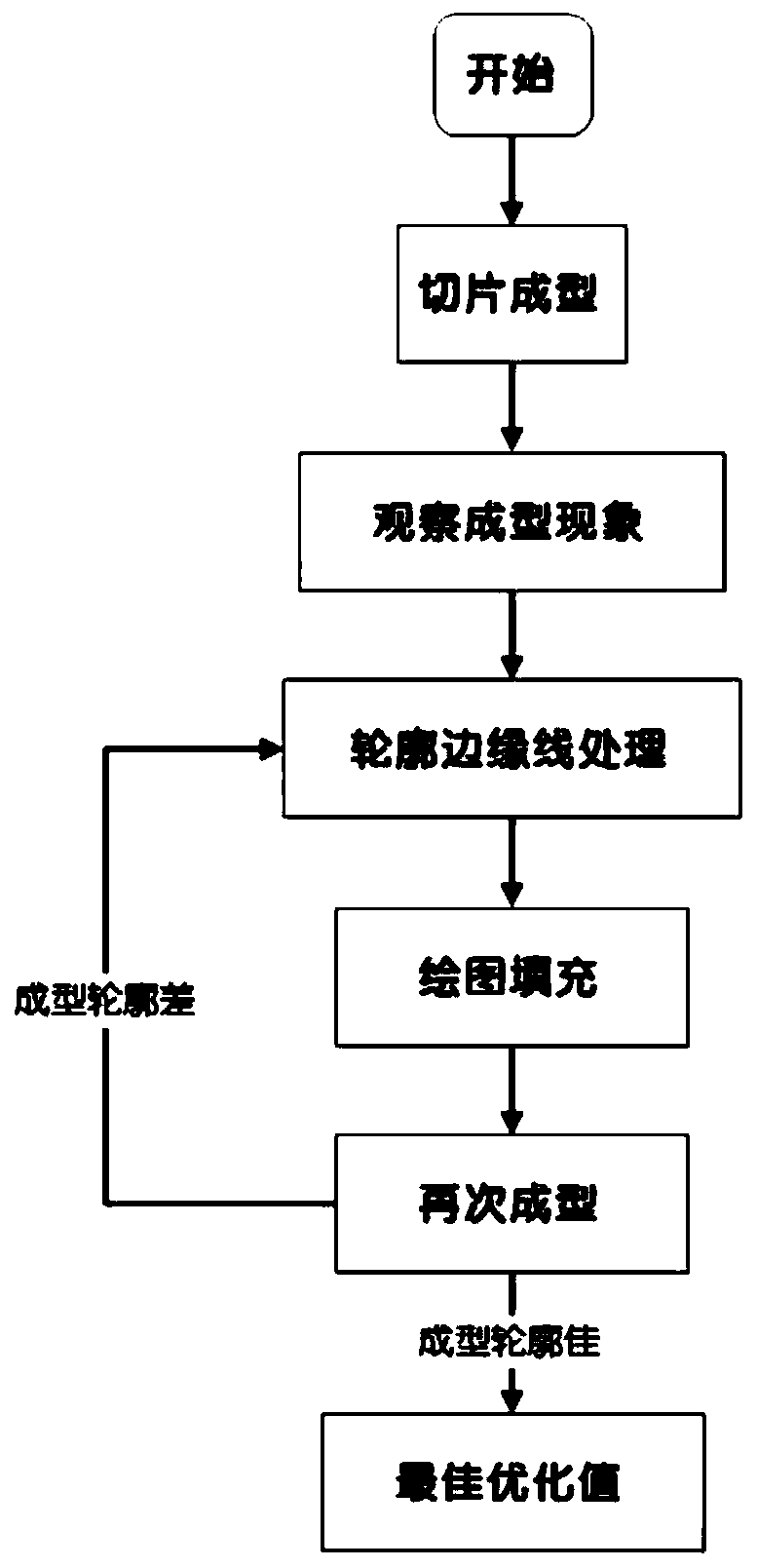

DLP light curing rapid prototyping edge processing method and device

ActiveCN107718535BImprove edging accuracyAdjustable widthAdditive manufacturing apparatus3D object support structuresUV curingRapid prototyping

The invention belongs to the technical field of 3D printing, and provides a DLP UV-curing rapid molding edge processing method and device. The method comprises the steps of slicing and forming 3D models; observing the molding phenomenon, and obtaining the imaging plane edge halo size and the forming model edge curing condition; obtaining the model contour line, and adjusting the width of the modelcontour line according to the definite value to obtain contour edge lines with the width; conducting normal drawing and filling in a closed area defined by the contour edge lines with the width; andconducting drawing and filling in the contour edge lines with the width according to preset target grayscale to form a slice map for molding. According to the DLP UV-curing rapid molding edge processing method and device provided by the invention, curing caused by halo can be avoided effectively, and the curing rapid-molding edge precision is improved; and the molding speed is increased, and the grinding procedure is reduced.

Owner:深圳晗竣雅科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com