Full-automatic four-edge linear refining mill for glass

A fully automatic, fine grinding machine technology, applied in machine tools, grinders, grinding/polishing equipment suitable for grinding the edge of workpieces, etc., can solve the problems of weak suction cup adsorption, affecting safety, low production efficiency, etc. Strong fixing force, ensure the quality of edging, and the effect of high edging precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

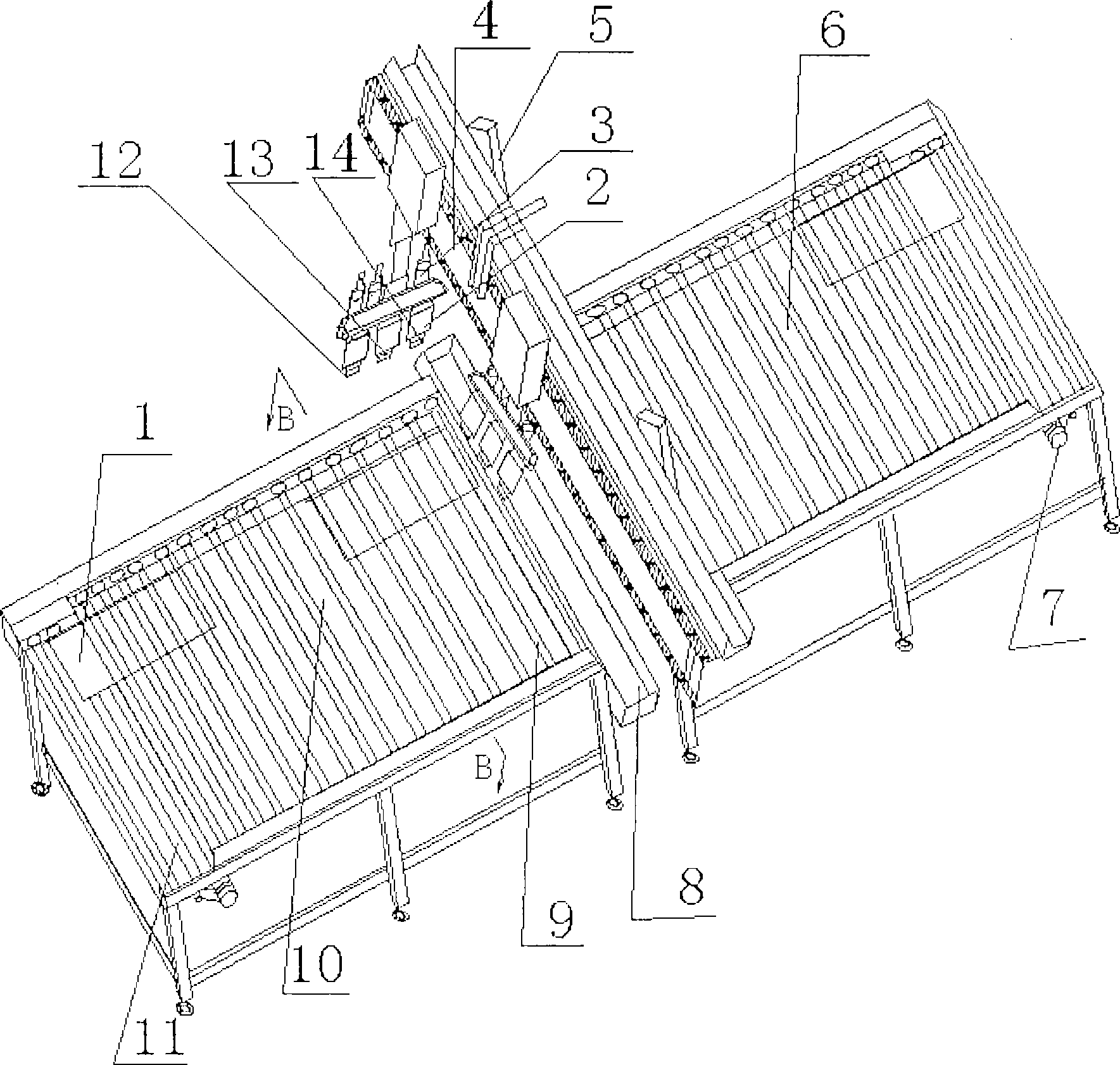

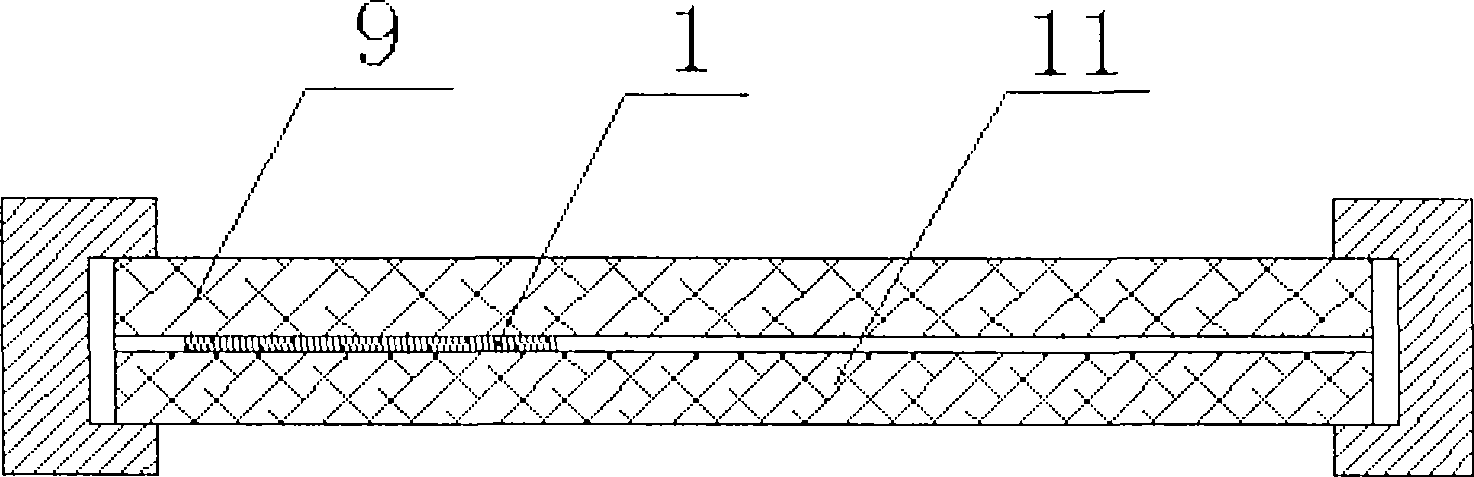

[0013] refer to Figure 1-Figure 2 , the full-automatic four-side linear fine grinding machine for glass of the present embodiment, it comprises film feeding table 10 and unloading table 6, and the gap between film feeding table 10 and unloading table 6 is provided with water receiving tank 8, and described film feeding table 10 and the unloading table 6 are provided with a clamping conveying device, the clamping conveying device includes an upper roller table 9 and a lower roller table 11, and the conveyed glass 1 is located between the upper roller table 9 and the lower roller table 11. The full-automatic four-side linear fine grinding machine for glass also includes a support 5, a moving track 4, a grinding motor unit, a rough grinding emery wheel 12, a medium grinding emery wheel 13 and a polishing wheel 14. The grinding motor unit is provided with two groups, each The group grinding motor unit includes 3 grinding motors 2, and the rough grinding emery wheel 12, the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com