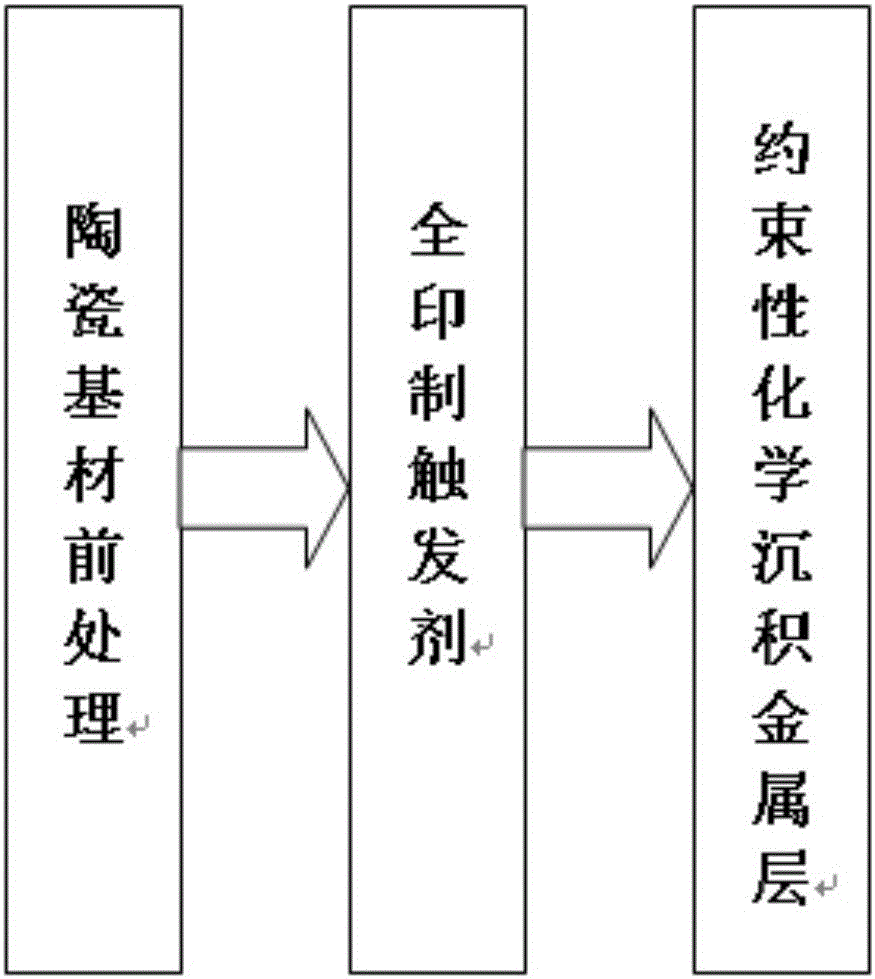

A method for preparing a patterned metal layer on a ceramic surface

A technology of ceramic surface and metal layer, applied in conductive pattern formation and other directions, can solve the problems of reduced reliability of electronic ceramic components, increased process and cost, process chain length, etc., and achieves low production cost, low investment in production equipment, and low cost Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

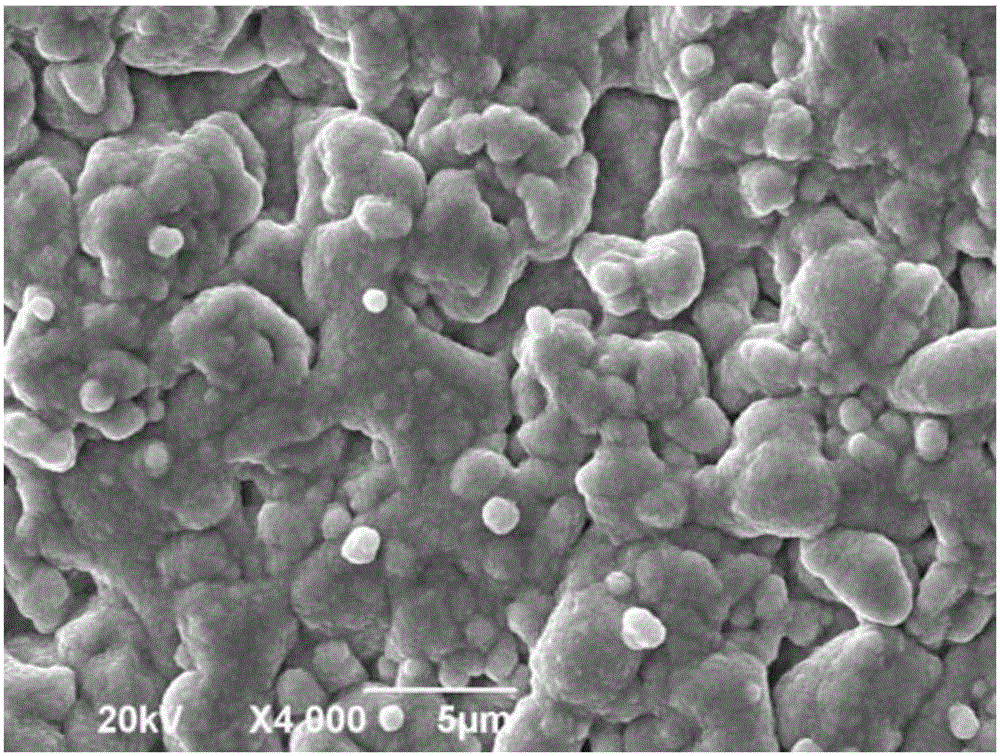

[0038] A metallized silver layer is prepared on the surface of a ceramic substrate. The ceramic substrate undergoes pretreatments such as descaling, roughening, ultrasonic cleaning, and drying in sequence to obtain a ceramic surface state suitable for printing.

[0039] Configuration 100ml solubility is the palladium ion solution of 0.05mol / L, then adds 100ml of A solution, and finally adds ethanol, ethylene glycol, n-propanol to adjust the viscosity of the solution to be 2mPa·s, surface tension 30mN / m, namely A type I trigger is obtained. The configuration method of solution A is as follows: add 0.12mol hydroxyethyl methacrylate, 0.08mol divinylbenzene and 0.024mol azobisisoheptanonitrile to 200ml ethanol, stir well, take out 180ml solution and place it in a constant pressure drop In the funnel, add 180ml of the solution in the constant pressure dropping funnel dropwise to the remaining 20ml of the original solution within 1 hour. During the dropping process, the temperature...

Embodiment 2

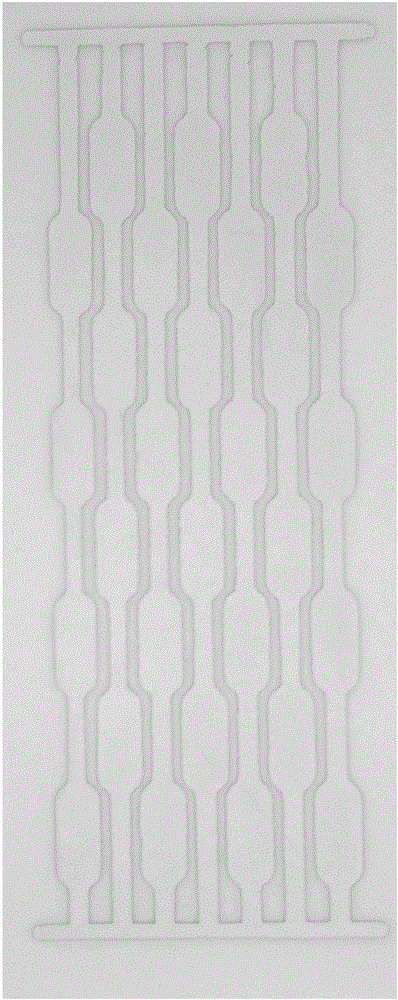

[0042] Prepare the metallization pattern on the surface of capacitor ceramic substrate. The capacitor ceramic substrate undergoes pre-treatments such as descaling, roughening, ultrasonic cleaning, and drying in sequence to obtain a ceramic surface state suitable for printing.

[0043] Configuration 100ml solubility is the palladium ion solution of 0.05mol / L, then adds 10ml of A solution, and finally adds ethanol, ethylene glycol, n-propanol to adjust the viscosity of the solution to be 3mPa·s, and the surface tension is 45mN / m, namely A type I trigger is obtained. The configuration method of solution A is as follows: add 0.12mol hydroxyethyl methacrylate, 0.08mol divinylbenzene and 0.024mol azobisisoheptanonitrile to 200ml ethanol, stir well, take out 180ml solution and place it in a constant pressure drop In the funnel, add 180ml of the solution in the constant pressure dropping funnel dropwise to the remaining 20ml of the original solution within 1 hour. During the dropping...

Embodiment 3

[0046] A metallized nickel layer is prepared on the surface of a ceramic substrate. The ceramic substrate undergoes pretreatments such as descaling, roughening, ultrasonic cleaning, and drying in sequence to obtain a ceramic surface state suitable for printing.

[0047] Dissolve 0.2mol of dimethylaminoborane in 100ml of deionized water, then add ethanol, n-propanol, and isopropanol to adjust the viscosity of the solution to 2.5mPa·s, and the surface tension to 40mN / m, and the trigger type II is obtained. agent. A modified inkjet printer was used to print the trigger agent on the area to be metallized, and then the pattern was cured at 70°C to obtain a patterned trigger layer.

[0048] Put the ceramic substrate printed with the trigger agent into the metal nickel ion solution to carry out constrained chemical deposition of nickel layer. The temperature of the metal nickel ion solution is 40° C., the pH is 9, and the time for constrained chemical deposition is 15 minutes. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com