Arc glass edge grinding machine

An edge grinding machine and glass technology, which is applied to machine tools, grinders, grinding workpiece supports and other directions suitable for grinding workpiece edges, can solve the problem of not realizing glass arc edge grinding processing, large working space, increasing energy consumption, etc. problems, to reduce pressure, improve safety, and prevent air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

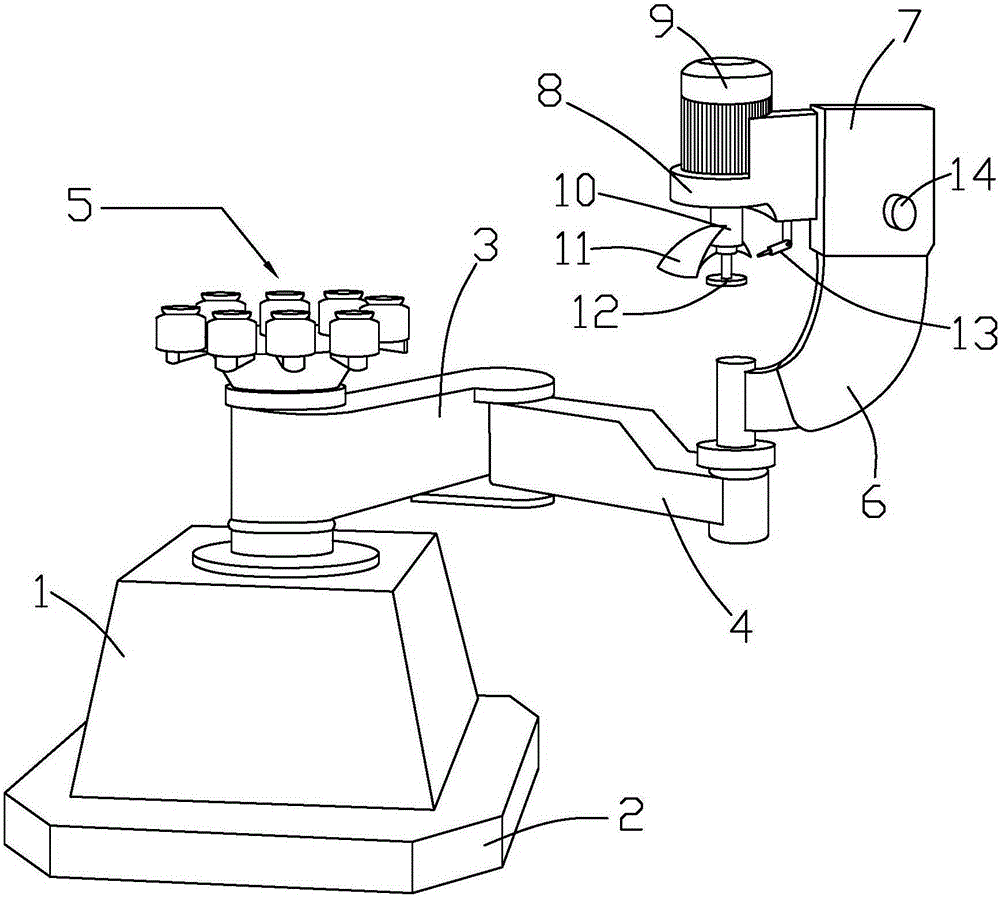

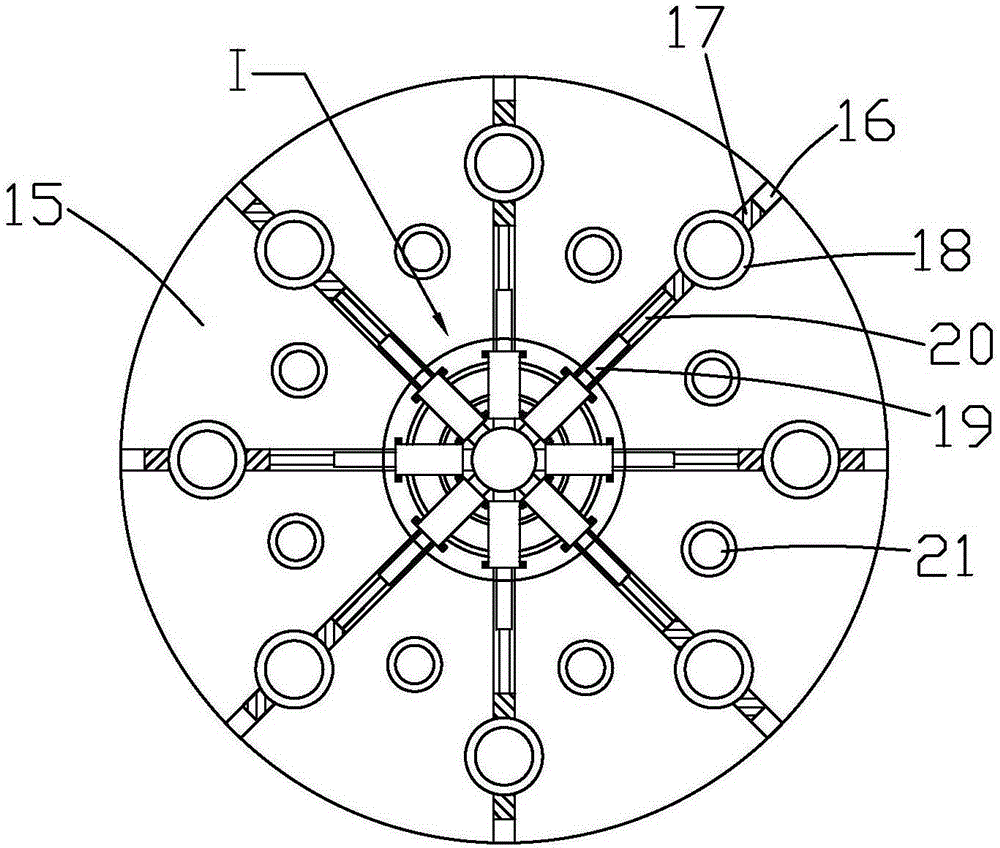

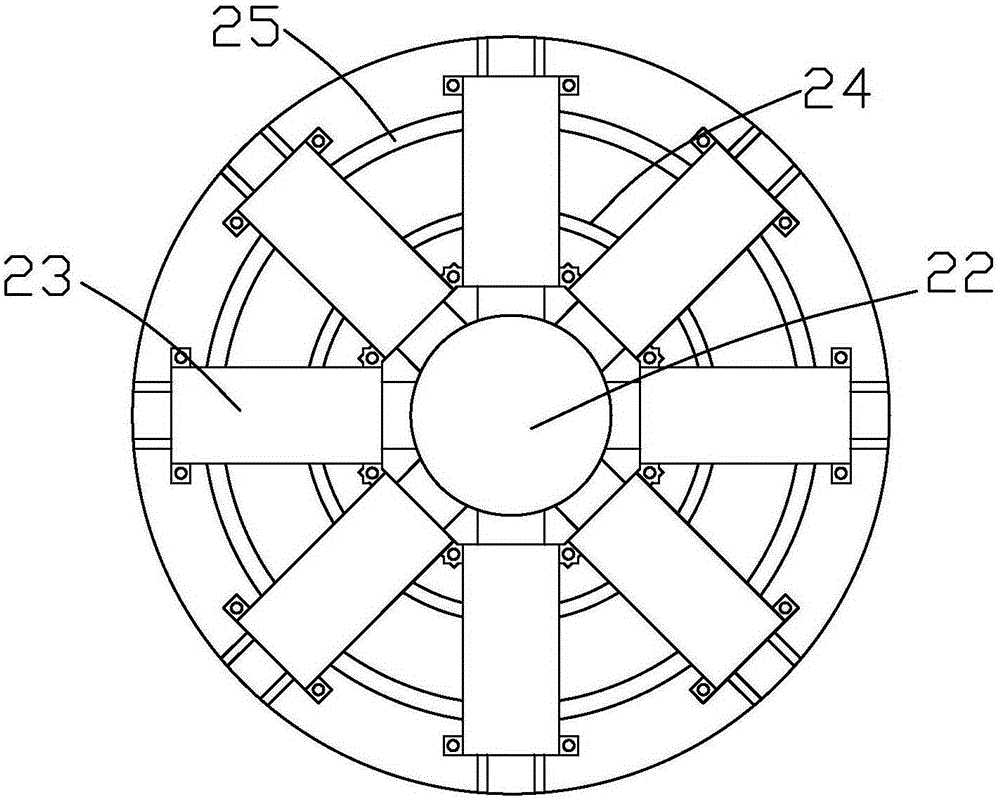

[0032] Such as Figure 1 to Figure 6 As shown, it is an arc glass edging machine of the present invention. The glass edging machine includes a box body 1, a positioning suction cup 5 and a grinding mechanism. Described casing 1, positioning sucker 5 comprise positioning chuck 15, main suction head 18 and auxiliary suction head 21, and the center of positioning chuck 15 is provided with through hole 22, and the periphery of through hole 22 is evenly provided with at least 8 guides. Groove 16, the main suction head 18 is limited in the guide groove 16 by the moving block 17, the top surface of the main suction head 18 is provided with a sealing ring 26, and the inside of the main suction head 18 is provided with a one-way sealing plate 27, adjacent up and down The two one-way sealing plates 27 are arranged in a staggered manner. When the glass is placed on the main suction head 18, the sealing ring 26 can effectively separate the air inside the main suction head 18 from the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com