Numerically-controlled edge grinding machine for irregular glass

A special-shaped glass and edge grinding machine technology, which is applied in the direction of grinding frames, machine tools suitable for grinding workpiece edges, grinding machine parts, etc. requirements and other issues to achieve the effect of realizing three-dimensional displacement and improving edge grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

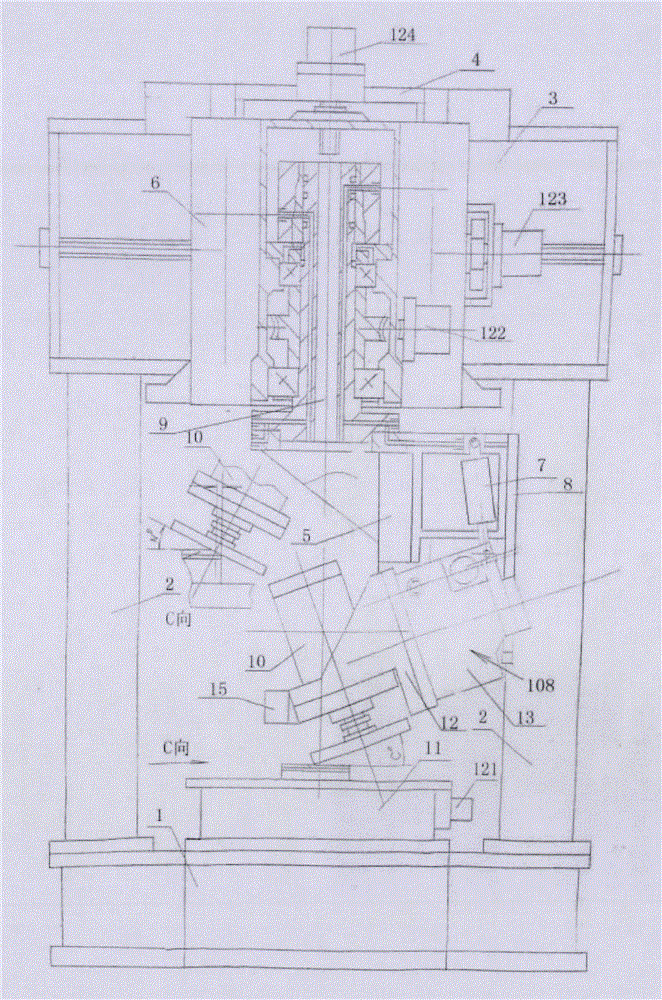

[0019] Such as figure 1 As shown, the present invention provides a CNC special-shaped glass edging machine including a bed 1, a rotary table 11 is arranged above the bed 1, an edging unit 108 is suspended above the rotary table 11, and the edging unit 108 is suspended by the beam 3 and the column 2. Located above the rotary table 11, the column 2 is fixed on both sides of the bed 1, the column 2 is vertically arranged, the beam 3 is fixedly connected between the columns 2 on both sides, and is located above the rotary table 11, and the beam 3 is arranged horizontally.

[0020] As preferably, the transverse slide plate 4 is set on the crossbeam 3, and the third displacement mechanism 123 is arranged on the transverse slide plate 4, and the third displacement mechanism 123 includes a transverse drive mechanism and a transverse transmission mechanism for realizing power transmission between the transverse drive mechanism and the transverse slide plate 4, The crossbeam 3 and the t...

Embodiment 2

[0029] The CNC special-shaped glass edging machine provided by Embodiment 2 of the present invention has basically the same structure as that in Embodiment 1, and the difference lies in:

[0030] As preferred, in this embodiment of the present invention, such as figure 1 As shown, a rectangular slide table 11 is arranged above the bed 1, and the slide table 11 is slidably connected with the bed 1. The rectangular slide table 11 is driven to move back and forth longitudinally by the first displacement mechanism 121. The first displacement mechanism 121 includes a longitudinal displacement drive. mechanism and the longitudinal displacement transmission mechanism that realizes the transmission between the longitudinal displacement drive mechanism and the slide plate workbench 11. Preferably, in this embodiment of the present invention, the slide table 11 and the bed 1 are connected through a ball guide rail or a ball screw, and the longitudinal displacement driving mechanism is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com