Ultrasonic wave principle-based measuring point spatial displacement measurement device and method

A space displacement and ultrasonic technology, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as the inability to meet the fire resistance test of building structures and the inability to connect displacement sensors and measuring points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to understand the present invention more clearly, the following detailed description is given in conjunction with the accompanying drawings.

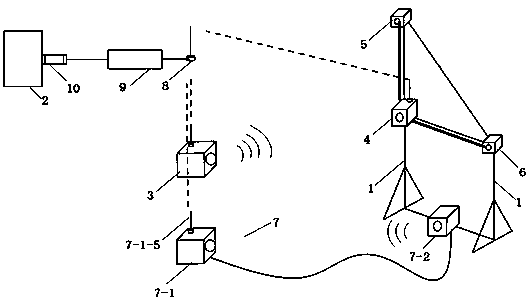

[0051] like Figure 1 to Figure 4 As shown, a measuring point spatial displacement measuring device based on the ultrasonic principle includes a computer 2, a support 1, an ultrasonic spatial displacement measuring part, a wave velocity measuring part and a receiving and converting part.

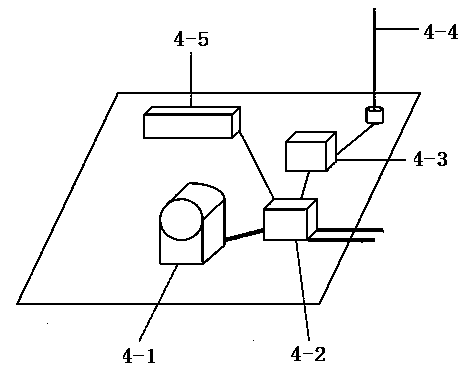

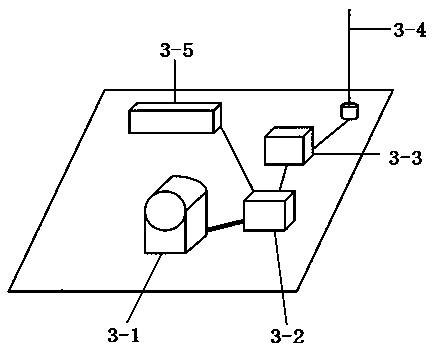

[0052] The ultrasonic spatial displacement measurement part includes an ultrasonic transmitting module 3, an ultrasonic receiving main module 4, an ultrasonic receiver I5, and an ultrasonic receiver III6.

[0053] The wave velocity measurement part includes a wave velocity measurement module 7, and the wave velocity measurement module 7 includes a wave velocity measurement module receiving end 7-1 and a wave velocity measurement module transmitting end 7-2.

[0054] The receiving conversion part includes a data receiver antenna 8 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com