Cross-shaped universal shaft hinging device for double-steel-strip press

A technology of cross cardan shaft and double steel belt, which is applied in the direction of press, pivot connection, application, etc., can solve the problems of high cost, high maintenance cost, and low service life of hydraulic cylinders, so as to improve service life and reduce maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

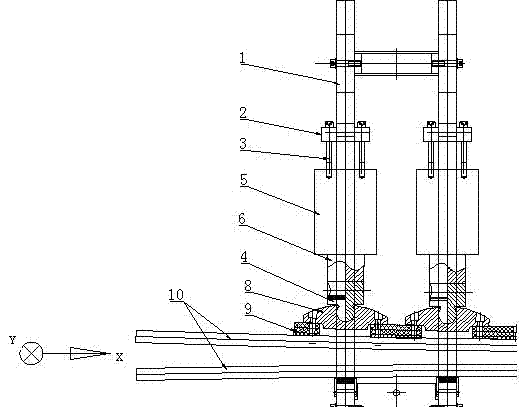

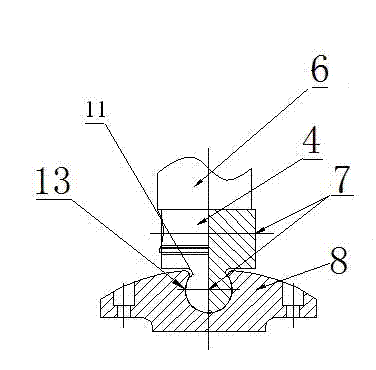

[0020] according to Figure 1~Figure 3 As shown, the cross cardan shaft hinge device for double steel belt presses of the present invention is mainly composed of frame plate 1, pin shaft 2, bolt 3, hydraulic cylinder 5, plunger 6, pressure plate connecting plate 8, heat insulation plate 9, The heat press plate 10 and the hinge device 4 connecting the plunger 6 and the press plate connecting plate 8 etc., wherein, the hinge device 4 has two axes intersecting (the angle between the axes is between 0° and 90°) and has a distance between The half-shaft 7 constitutes the cross cardan shaft mechanism, and the two half-shafts 7 form the shaft groove connection pair 11 with the plunger 6 and the pressure plate connecting plate 8 respectively, and the two half-shafts 7 can be linearly and rotating movement; the pressure plate connecting plate 8 is fixedly connected with the heat insulation plate 9, and pressed tightly on the hot pressing plate 10; the plunger 6 and the hydraulic cylind...

Embodiment 2

[0022] according to figure 2 , image 3 As shown, the included angle between the axes of the two semi-shafts 7 of the cross cardan shaft hinge device 4 for the double steel belt press in embodiment 1 is 90 degrees.

Embodiment 3

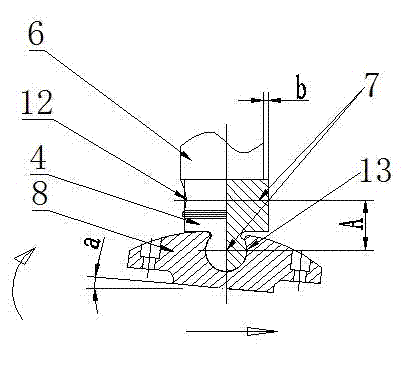

[0024] according to figure 2 , image 3 As shown, the shaft head 12 and notch 13 of the shaft groove connection pair 11 formed by the two half shafts 7 of the cross cardan shaft hinge device 4 for the double steel belt press in embodiment 1, the plunger 6 and the pressure plate connecting plate 8 They are Ω-shaped respectively; the notch 13 and the shaft head 12 of the half shaft 7 are concentrically matched, and can rotate coaxially or move linearly along the axis.

[0025] The working principle of the present invention is as follows:

[0026] In the present invention, the cross cardan shaft hinge device 4 has the function of applying force in both directions, that is, it can apply pressure to the hot pressing plate, see Figure 4 , you can also pull the hot plate in the opposite direction, see Figure 5 .

[0027] When the hot press plate 10 is heated to generate expansion displacement, it will produce expansion displacement along the horizontal plane of the pressing pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axis angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com