Automatic edge grinding device for wood plate materials

A sheet metal, automatic technology, used in grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve problems such as harming workers' health, slow edge grinding, and poor MDF adaptability. , to achieve the effect of reducing dust splash injury, improving product quality, and consistent edging depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

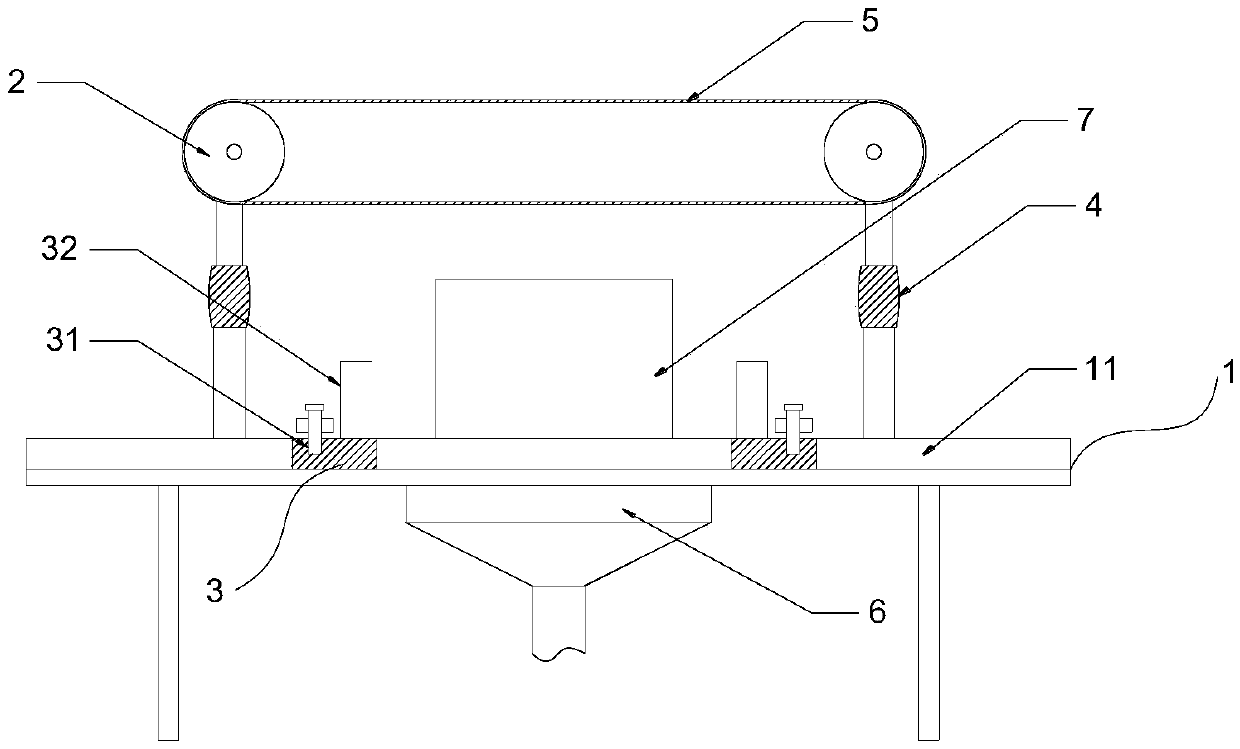

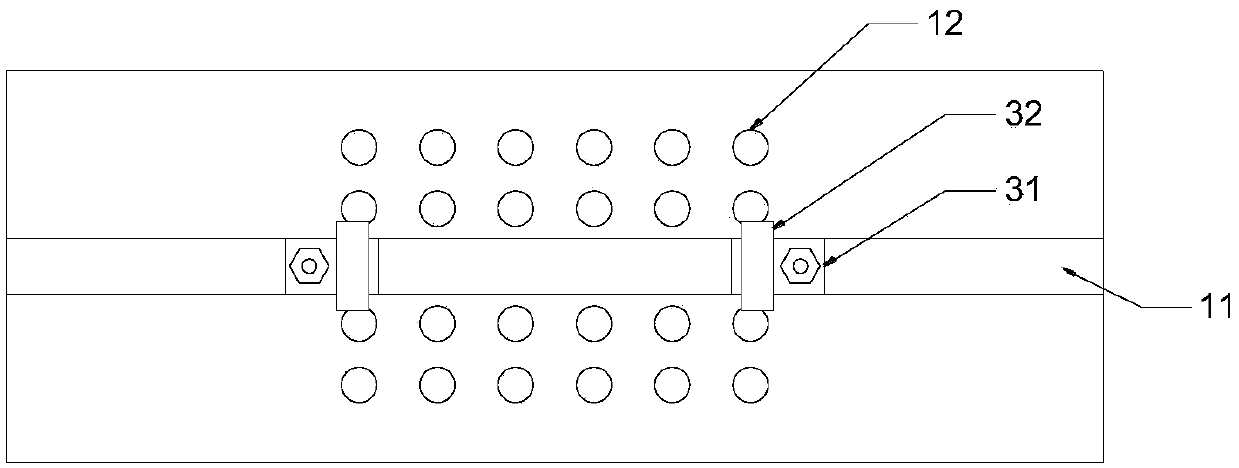

[0026] Such as Figure 1~2 As shown, an automatic edging device for wood panels includes a base 1, a conveyor belt 2 and a clamping assembly 3 for clamping a panel 7 to be ground, and the conveyor belt 2 is installed on the base 1 through a support column 4 , driven by a motor (not shown in the figure), the outer side of the conveyor belt 2 is provided with a coated abrasive 5, when working, the conveyor belt 2 is in contact with the plate to be ground 7, and a chute is provided in the middle of the top of the base 1 11. The clamping assembly 3 is arranged in the sliding groove 11. The motor drives the conveyor belt 2 to rotate, thereby driving the coated abrasive tool 5 to rotate, and to perform surface treatment on the plate 7 to be ground between the conveyor belt 2 and the base 1; the plate 7 to be ground is clamped by the clamping assembly 3, and the conveyor belt 2 Press down on the plate 7 to be ground on the base 1, and fix it horizontally and vertically, effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com