Express full-automatic multi-surface code scanning, weighing and volume measuring system and processing method thereof

A fully automatic and express technology, applied in the direction of measuring devices, conveyor objects, object stacking, etc., can solve the problems of equipment debugging, maintenance, troublesome operation, work stability to be improved, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

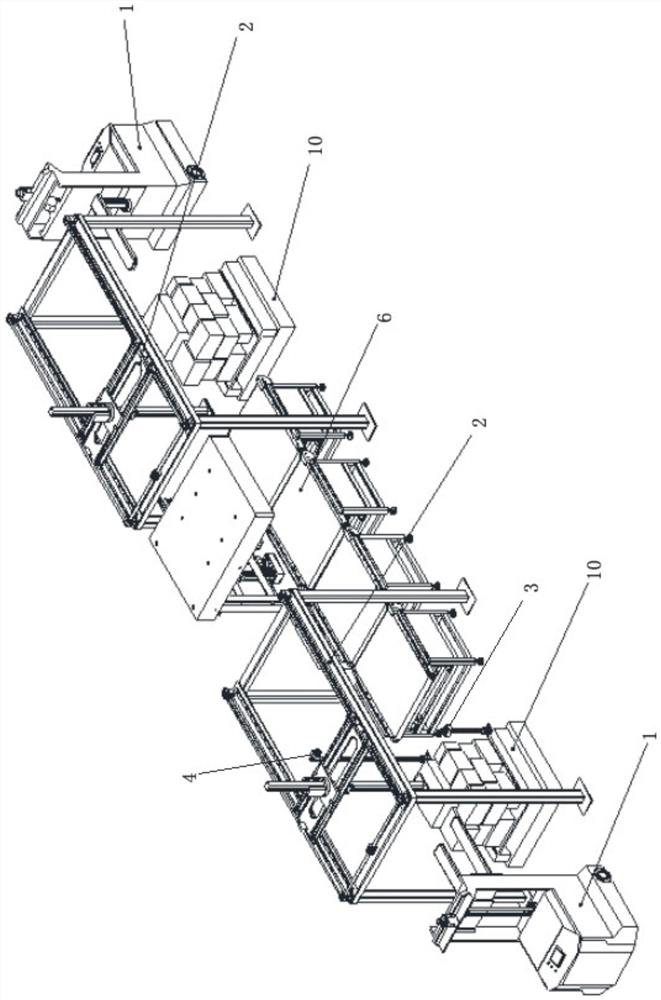

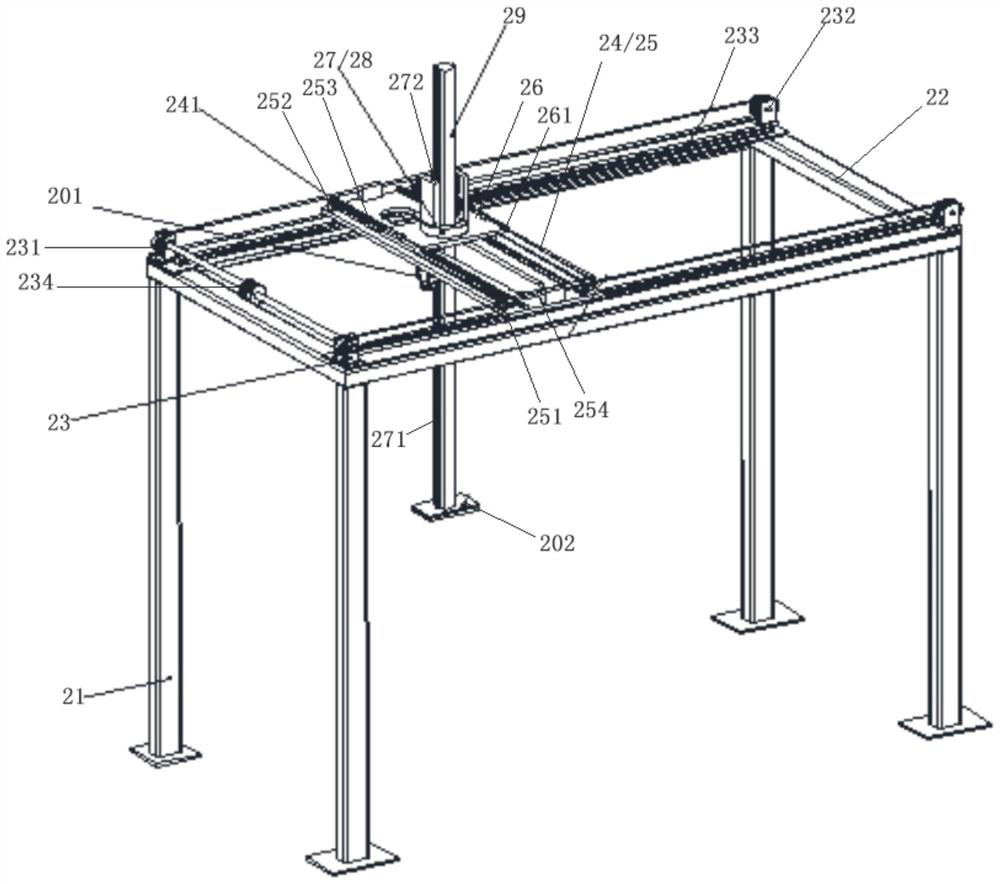

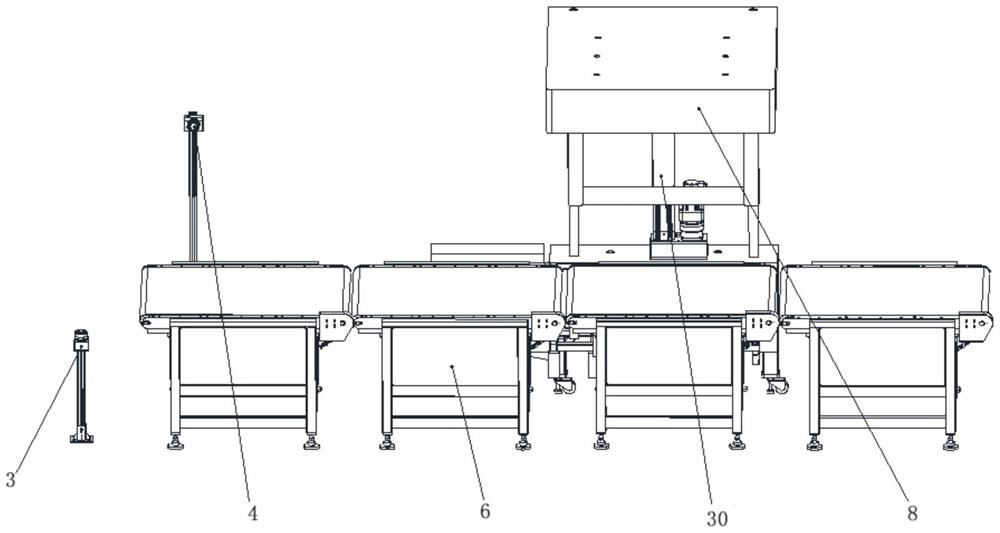

[0063] The present invention discloses a full-automatic multi-faceted code-scanning, weighing, and volume-measuring system for express mail, such as figure 1 , figure 2 , image 3 with Figure 4As shown, it includes an automatic transport forklift 1, a multi-axis manipulator 2, a bottom scanning code camera 3, a side scanning code camera 4, a top surface scanning code measuring volume camera 5, a scanning code weighing conveyor line 6 and a control system (not shown in the figure) output), the multi-axis manipulator 2 is respectively set at both ends of the code scanning and weighing conveying line 6, that is, the input and output of the code scanning and weighing conveying line 6 are both input and output conveyed by the multi-axis manipulator 2, and the multi-axis manipulator Below the working range of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com