Probe frame used for automatic water immersion ultrasonic testing of components with complicated surfaces

A water immersion ultrasonic and automatic detection technology, which is applied in the field of probe holders, can solve the problems of low positioning efficiency, difficulty in realizing automatic water immersion ultrasonic detection of complex profile feature components, etc., and achieves the effect of good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

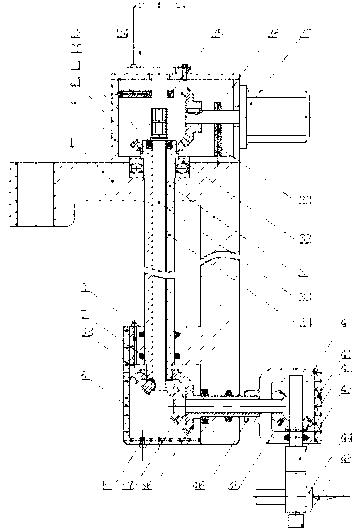

[0020] see figure 2 , the present invention includes an integral bracket 1, a power assembly 2, a motion transmission assembly 3, a probe support assembly 4, an oil discharge screw 5, a transparent sealing cover 6, an O-shaped sealing ring 7, and a lubricating oil hole 8; the power assembly 2 includes a tapered Gear set 21, inner hexagon coupling 22, reset travel switch 23, 28, A-axis servo motor 24, B-axis servo motor 27, reset disc 25, 26; motion transmission assembly 3 includes deep groove ball bearing 31, thrust ball Bearing 32, central transmission shaft, 33, hollow transmission shaft 34, bevel gear set 35, 36, 37, elastic retaining ring 38 for the shaft; the probe support assembly 4 includes a herringbone support sealing cover 41, elastic retaining ring for the shaft 42, probe seat 43, water immersion ultrasonic probe 44, probe fastening screw 45, herringbone support 46.

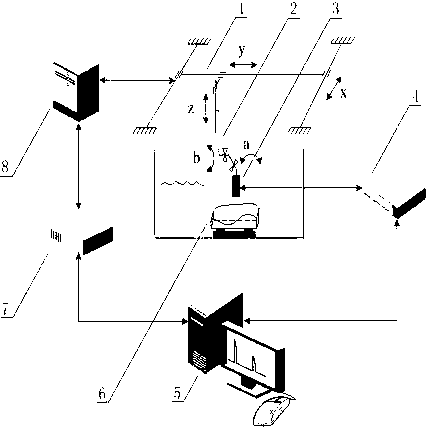

[0021] see image 3 , which describes the flow chart of the positioning of the probe on the A-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com