Method for automatically positioning cigarettes in mold box of cigarette packaging machine

A technology of automatic positioning and machine mold box, which is applied in the direction of automatic packaging control, packaging, packaging cigarettes, etc., to achieve the effect of improving accuracy, ensuring accuracy, and accurate automatic positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

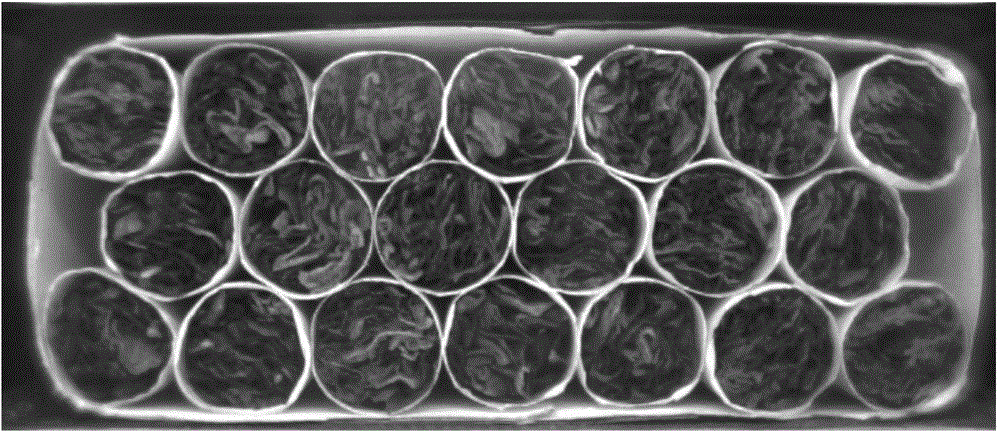

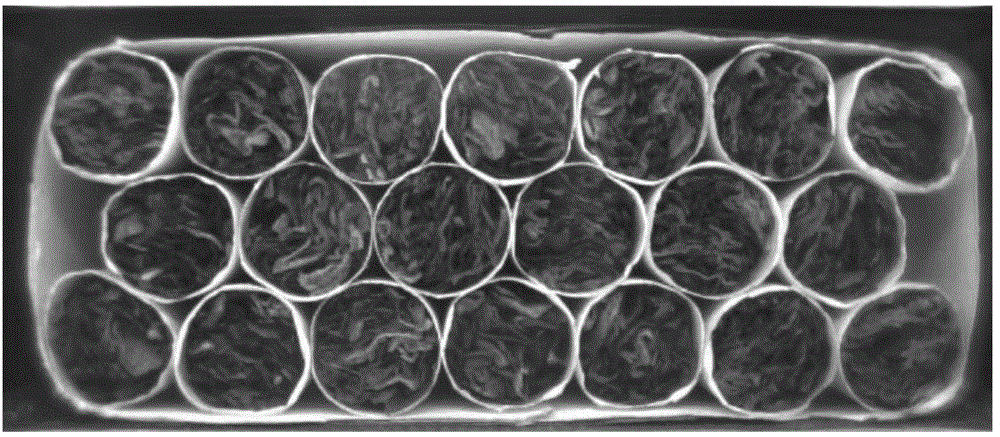

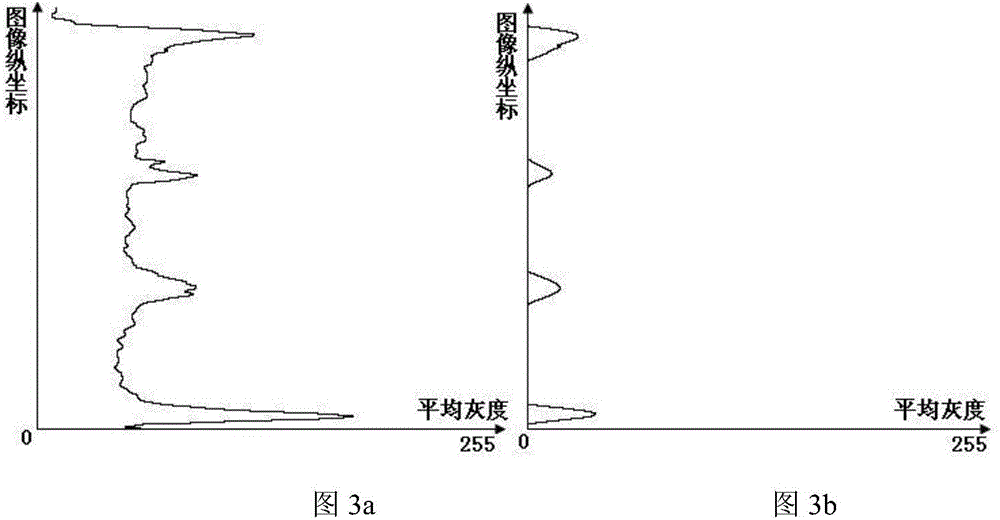

[0019] A method for automatic positioning of cigarettes in the mold box of a cigarette packaging machine. First, grayscale processing is performed on the image of the cut tobacco end surface of the cigarette to be inspected collected by an image sensor, and then horizontal projection is performed using the grayscale value of the image pixel as a projection feature to obtain a horizontal projection. Projection curve. In the horizontal projection curve, the projection value at the boundary of each row of cigarettes will be larger than other surrounding areas, forming a peak. The horizontal projection curve is subjected to special filtering processing to obtain several independent sections corresponding to the number of cigarette rows. Waveform, search and determine the specific position of the peak in each segment of the waveform, and segment the grayscale image according to the position of the peak to obtain the image corresponding to each row of cigarettes;

[0020] In the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com