Rotor production equipment for air suspension centrifugal compressor

A centrifugal compressor and air suspension technology, applied in the field of compressors, can solve the problem of inaccurate installation position of fan blades, achieve the effect of high degree of automation, improve accuracy and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

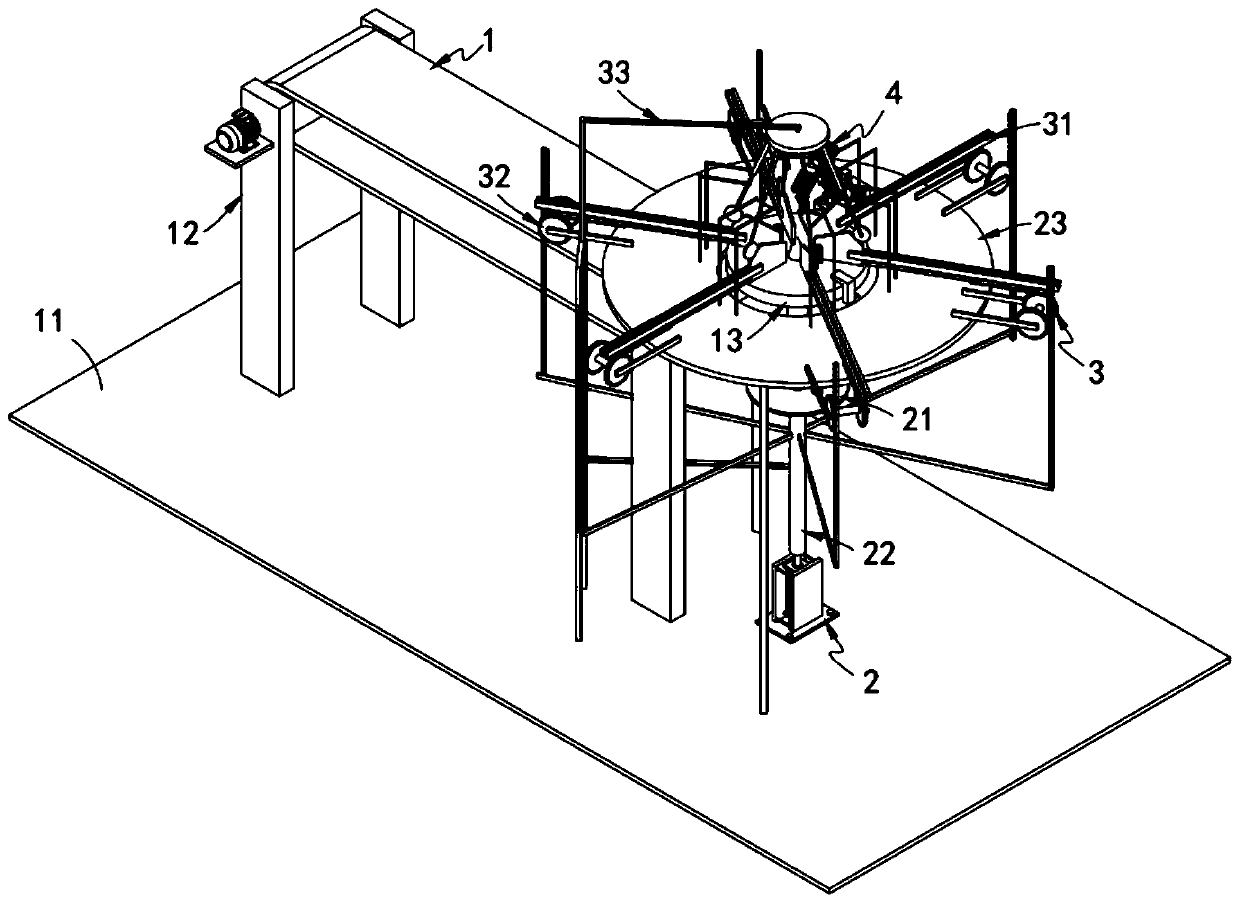

[0070] Such as figure 1 As shown, a rotor production equipment for air suspension centrifugal compressors, including:

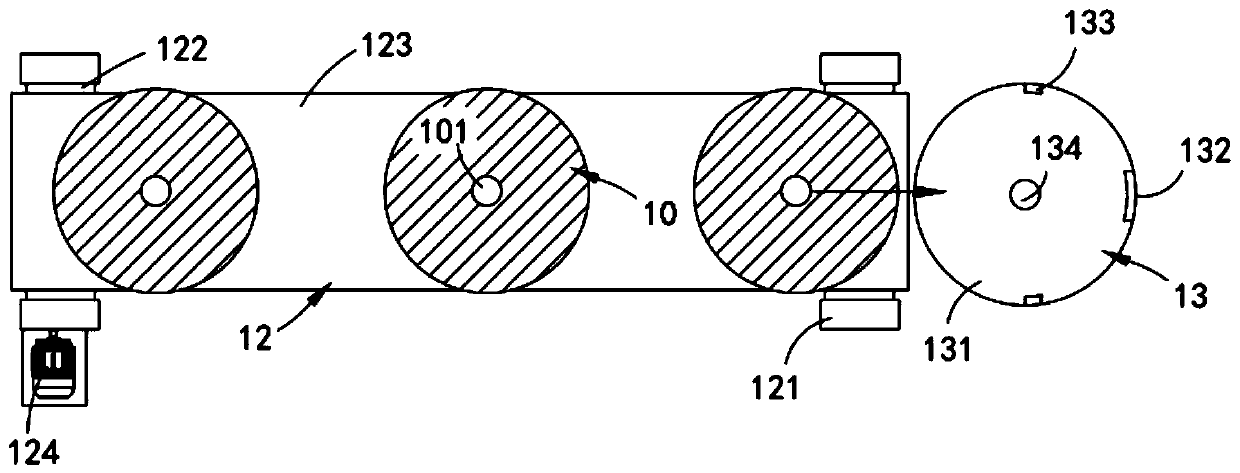

[0071] A disc transport mechanism 1, the disc transport mechanism 1 comprising a base 11, a first conveying assembly 12 disposed on the base 11, and a carrying assembly 13 disposed at the output end of the first conveying assembly 12;

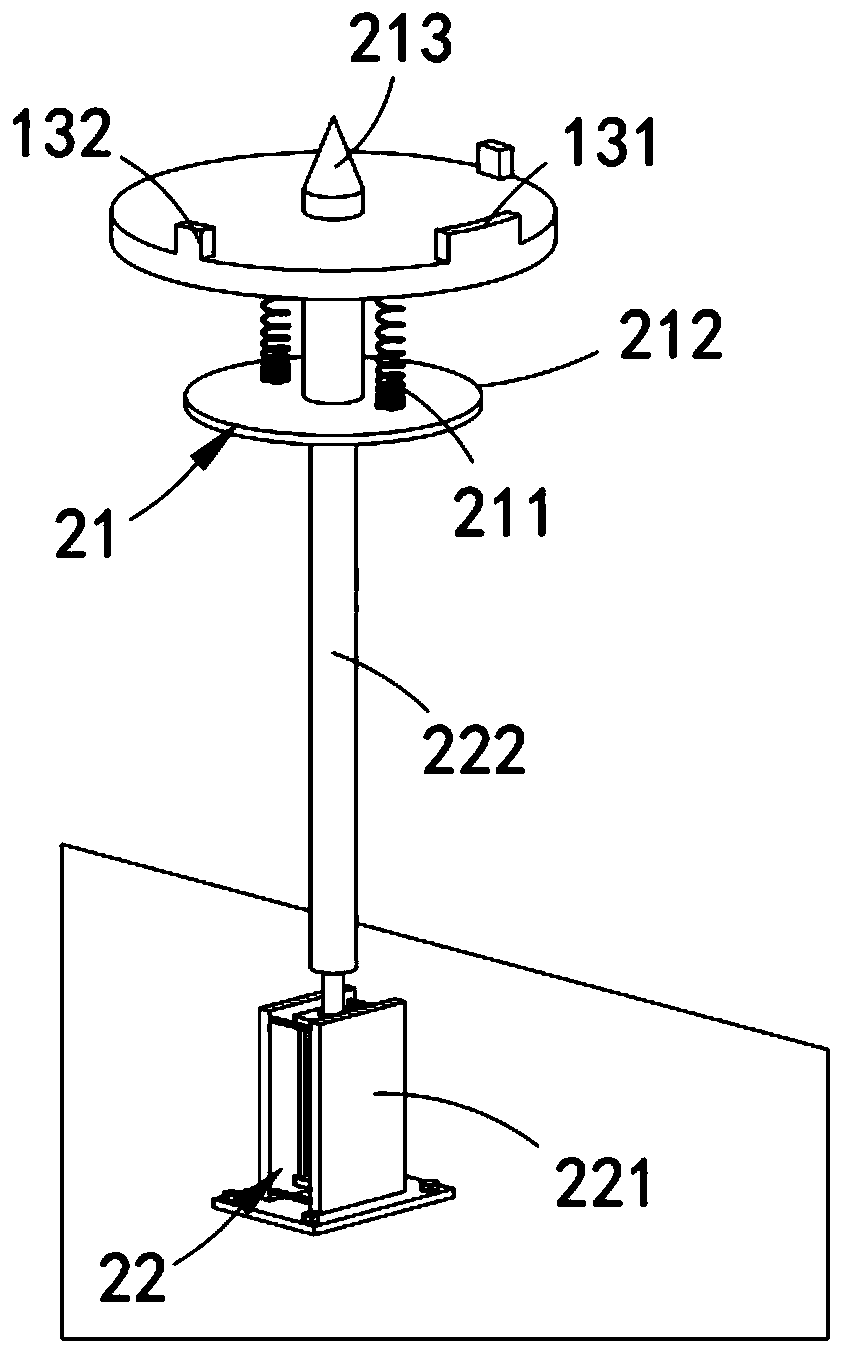

[0072] The precise positioning mechanism 2, the precise positioning mechanism 2 includes a deflection correction component 21 elastically connected to the bearing component 13 and arranged coaxially with it, fixedly connected with the deflection correction component 21 and driving the deflection correction component 21 along the vertical direction The drive assembly 22 moving up and down and the limit assembly 23 located above the bearing assembly 13 and installed on the base 11;

[0073] The blade transmission mechanism 3, the blade transmission mechanism 3 includes a plurality of second transmission components 31 arranged o...

Embodiment 2

[0111] Such as Figure 7 , Figure 13 and Figure 14 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0112] further, such as Figure 7 , Figure 13 and Figure 14 As shown, the tightening assembly 33 includes:

[0113] Lifting member 331, said lifting member 331 includes a pulling plate 3311 located at the upper end of the disc 10 and coaxially arranged with the disc 10 and an intermittent unit 3312 controlling the movement of the pulling plate 3311 up and down; and

[0114] A swing member 332, the swing member 332 includes a mounting frame a3321 installed on the frame b231, a rotating shaft b3322 fixedly arranged on the mounting frame a3321, a transmission rod a3323 rotatingly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com