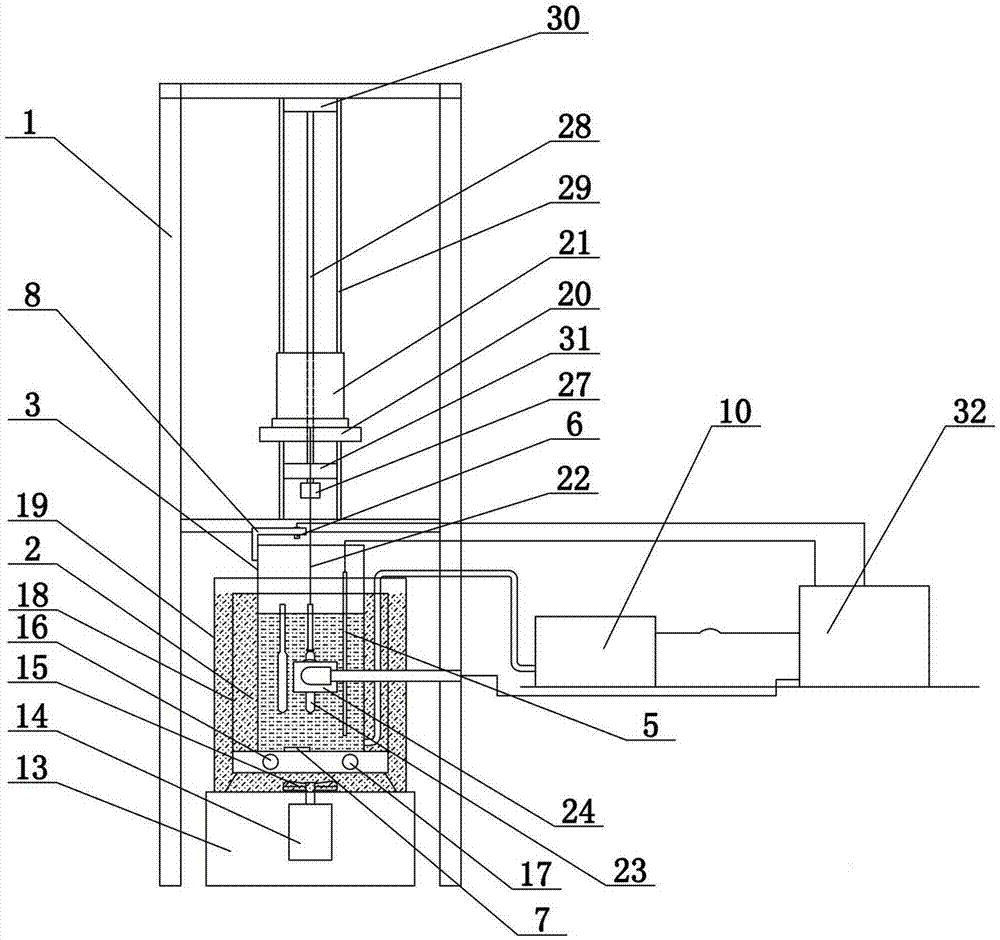

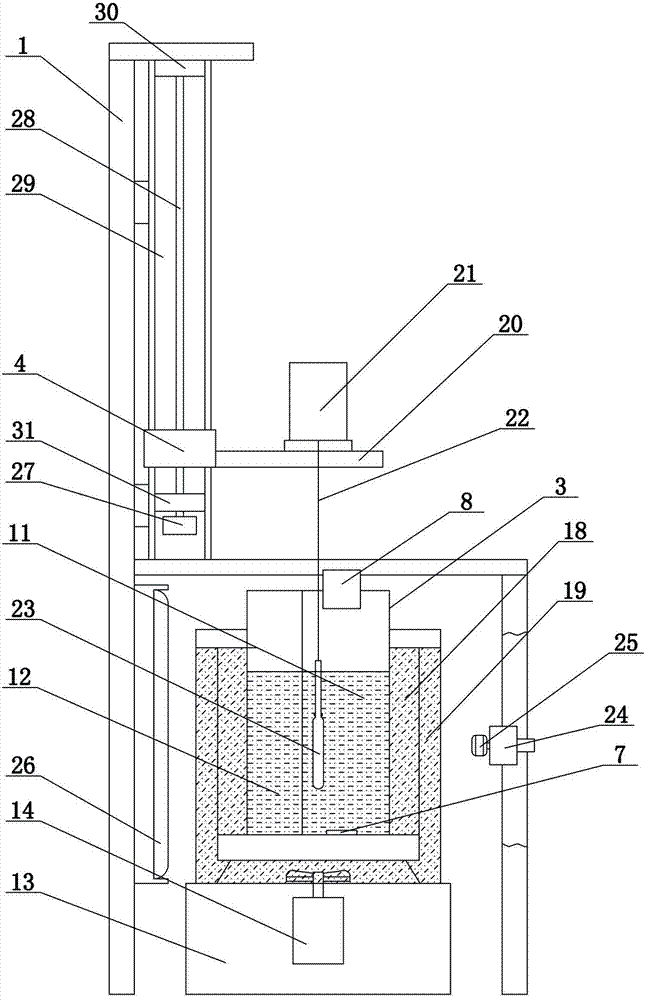

Glass hydrometer detecting/calibrating device

A technology for detecting and calibrating devices and float gauges, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., to achieve the effects of improving the level of uncertainty, increasing the degree of automation, and reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

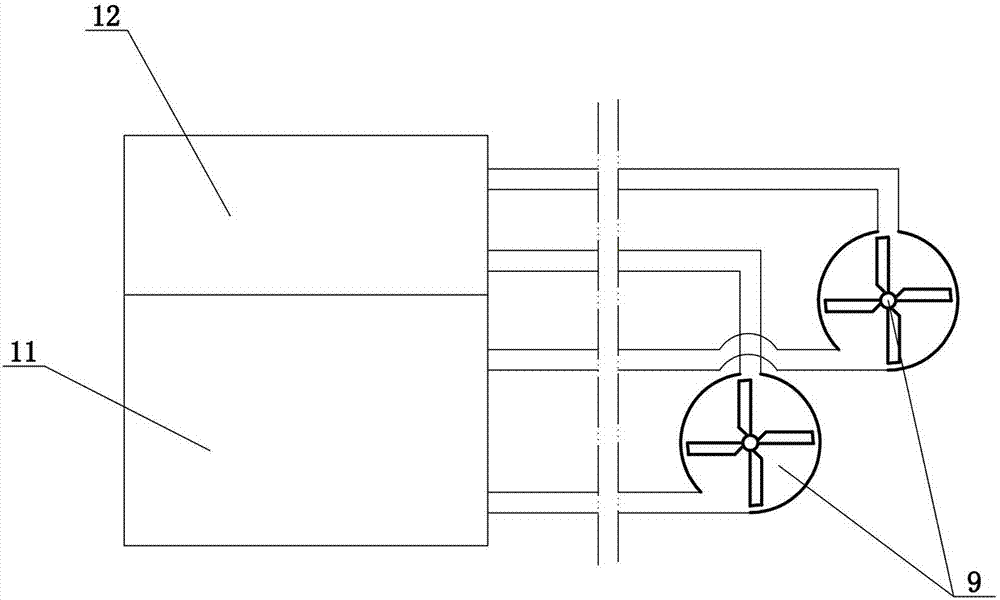

Embodiment Construction

[0036] The fixed frame 1 is provided with a glass float meter scale line recognition device, the glass float meter scale line recognition device is connected to the computer 32 through a data line, and the glass float meter scale line recognition device recognizes that the liquid surface of the glass float meter is in contact with the glass float meter scale line Situation information, and this information is sent to computer 32, and computer 32 controls the glass float gauge positioning device to adjust the contact position of glass float gauge scale line and test liquid liquid level through this information; Described glass float gauge scale line identification device includes industrial Digital camera 24, industrial lens 25 and lighting device 26, industrial digital camera 24 is fixed on the fixed mount 1, the front end of industrial digital camera 24 installs industrial lens 25, industrial digital camera 24 connects computer 32 by data cable, described fixed mount 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com