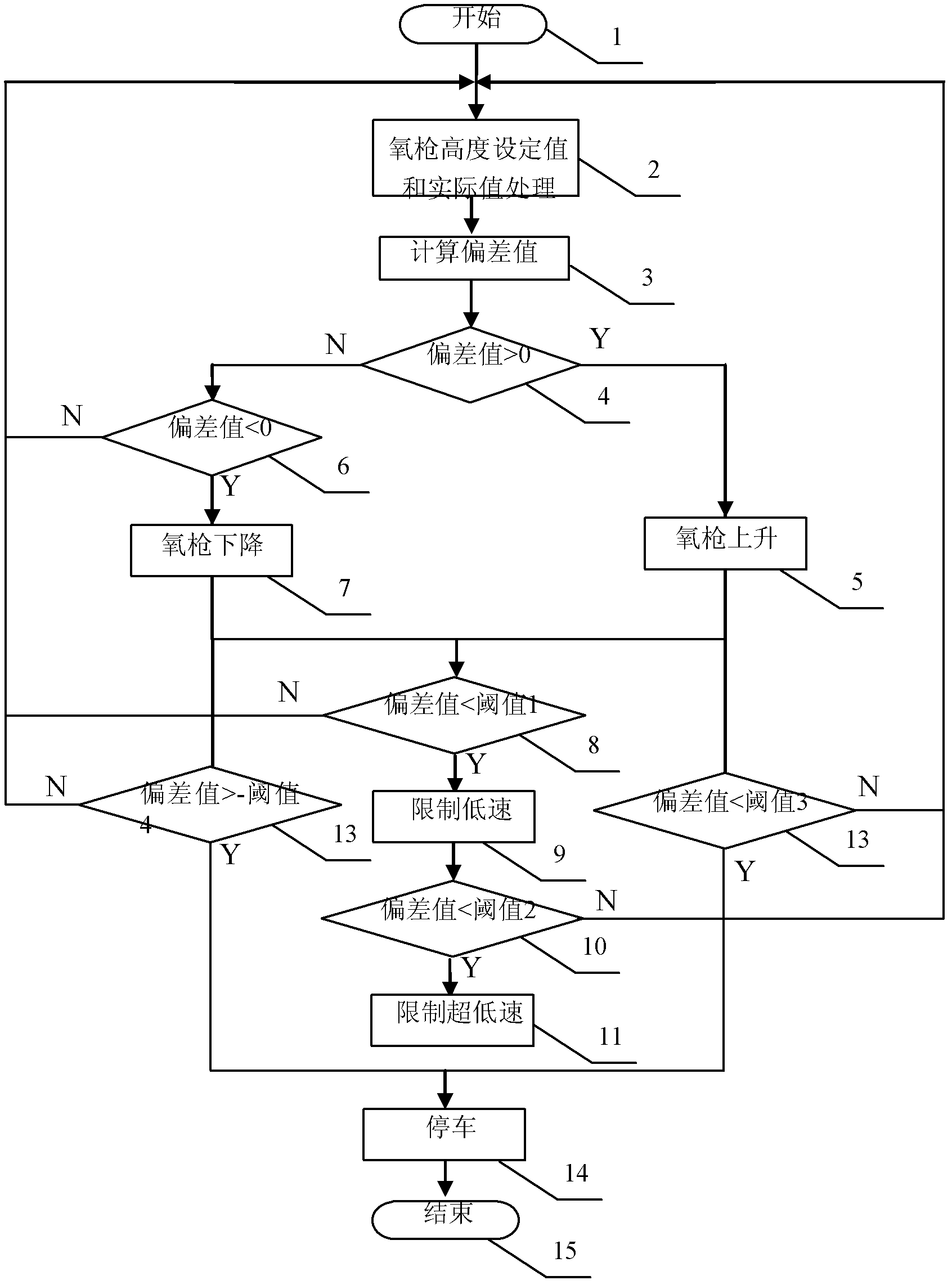

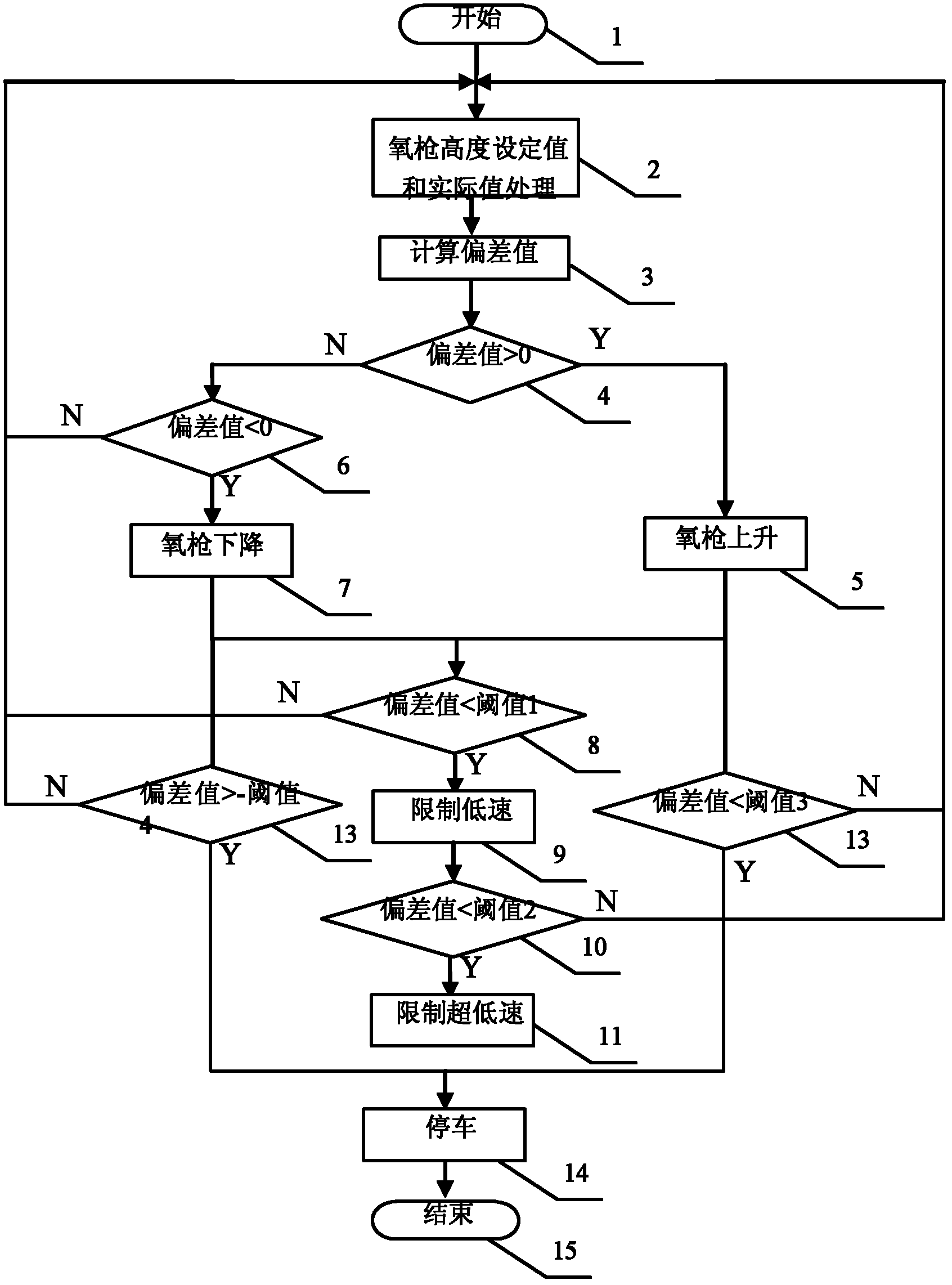

Automatic positioning and controlling method for oxygen lance of converter

An automatic positioning and control method technology, applied in the manufacture of converters, etc., can solve problems such as difficult to balance system speed and control accuracy, overshoot and oscillation, etc., and achieve the effect of easy implementation, simple system and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The hardware equipment involved in this specific embodiment includes: PLC module S7-400, the frequency converter is 6SE70 frequency converter of Siemens Company, and communicates with PLC through Profibus-DP network. An absolute encoder is installed on the drive shaft of the oxygen lance motor to detect the height of the oxygen lance, and the drive shaft of the motor is also equipped with a brake (controlled by a frequency converter). The lifting speed of the oxygen lance involved in this specific embodiment is: high speed 40m / min, low speed 10m / min, ultra-low speed 5m / min. When the oxygen lance is raised and lowered, the acceleration time from V=0m / min to V=40m / min is 5s; the deceleration time from V=40m / min to V=0m / min is 3s.

[0020] The following describes the relative height actual value Hx of the oxygen lance obtained through the detection of the absolute encoder and the corresponding algorithm.

[0021] The absolute value encoder is mounted on the motor drive sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com