Power equipment and transmission line malfunction comprehensive online monitoring system

A line fault and power equipment technology, applied in the field of power system fault online monitoring, can solve the problems of real-time upload function of fault information without automatic fault location function, increase the difficulty and time of fault finding, and leave hidden safety hazards in equipment operation, etc., to achieve Improve the fault detection speed and work efficiency, shorten the troubleshooting time, and have the effect of strong signal anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

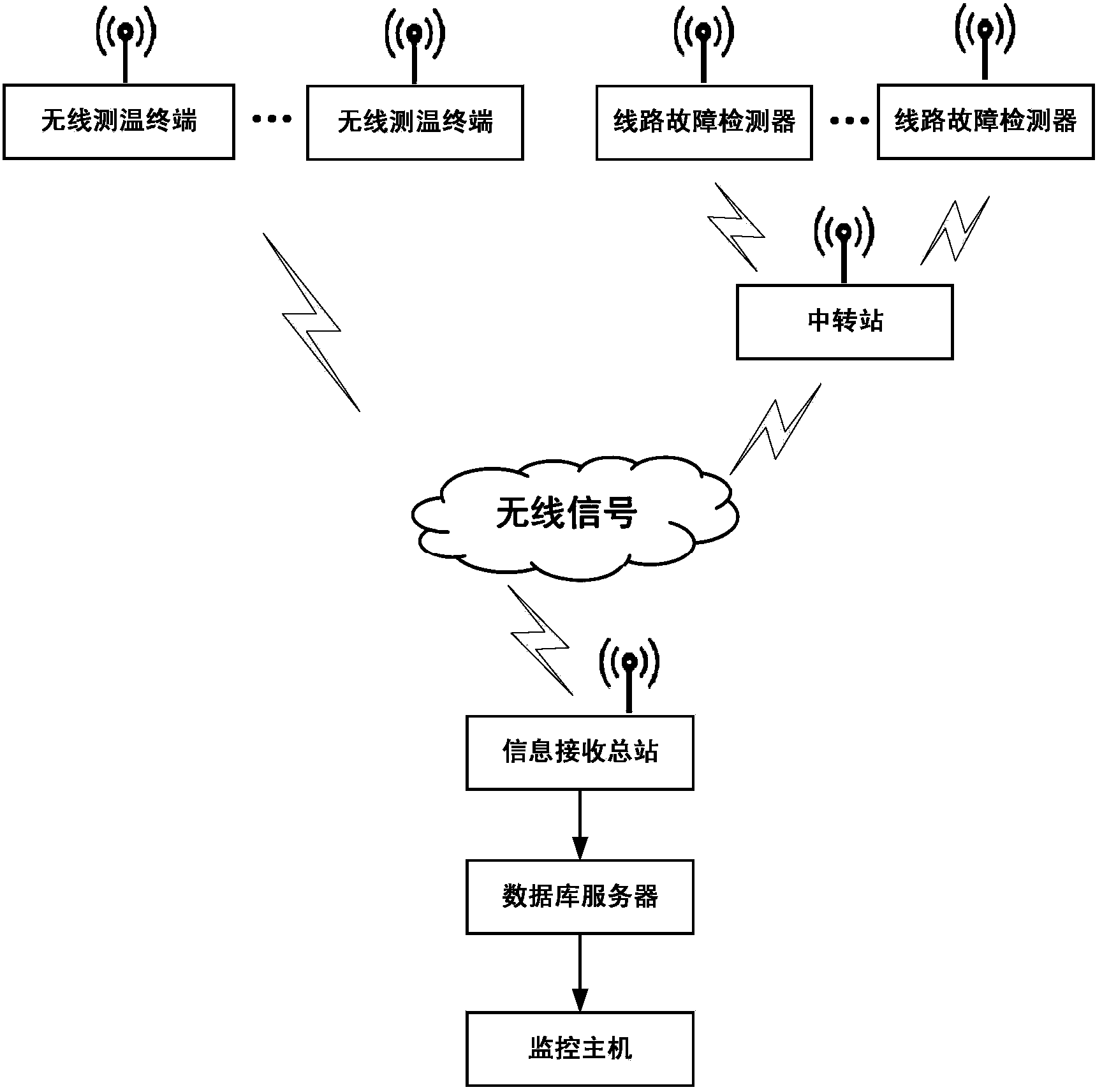

[0030] See figure 1 , a comprehensive online monitoring system for power equipment and transmission line faults, including a wireless temperature measurement terminal, a line fault detector, a transfer station, an information receiving general station, a database server, and a monitoring host. The wireless temperature measurement terminal is wirelessly connected to the information receiving terminal through the built-in wireless communication module, and the line fault detector is wirelessly connected to the transfer station and the information receiving terminal through the built-in wireless communication module, and the information receiving terminal is connected to the database server , the database server is connected to the monitoring host.

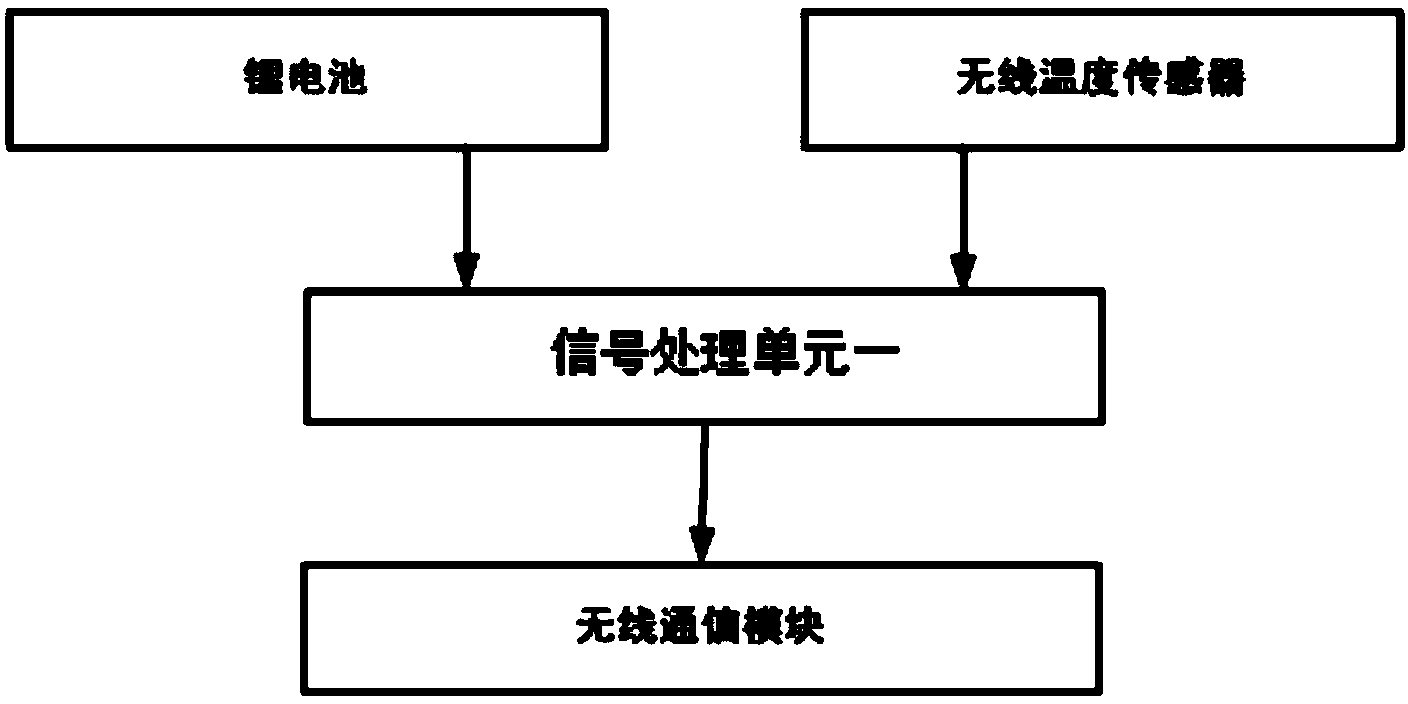

[0031] See figure 2 , one of the wireless temperature measurement terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com