An arc-shaped air-tight differential electrical connector with elastic contacts

A technology for elastic contacts and electrical connectors, which can be applied to contact parts, two-part connecting devices, fixed/insulated contact members, etc., and can solve the problems of rectangular electrical connector arrangement, large space occupied by shielding layers, and poor electrical continuity. , to achieve the effect of enhanced signal anti-interference performance, improved anti-interference ability and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

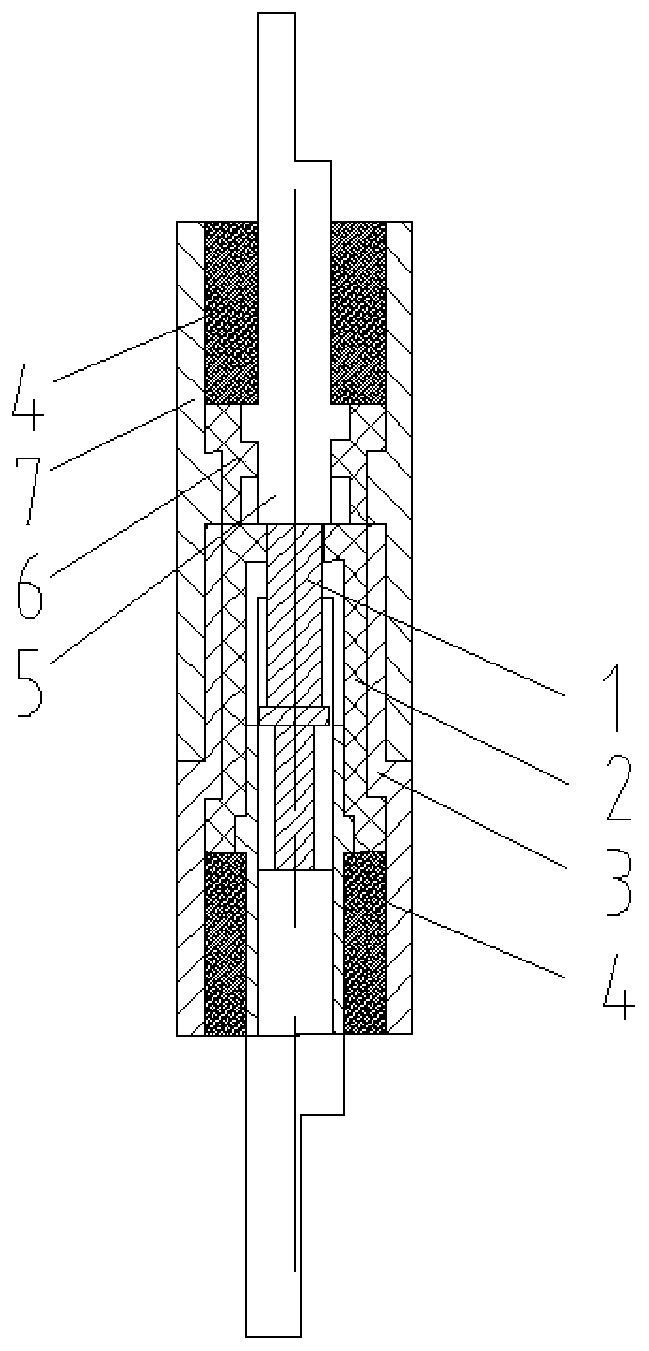

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

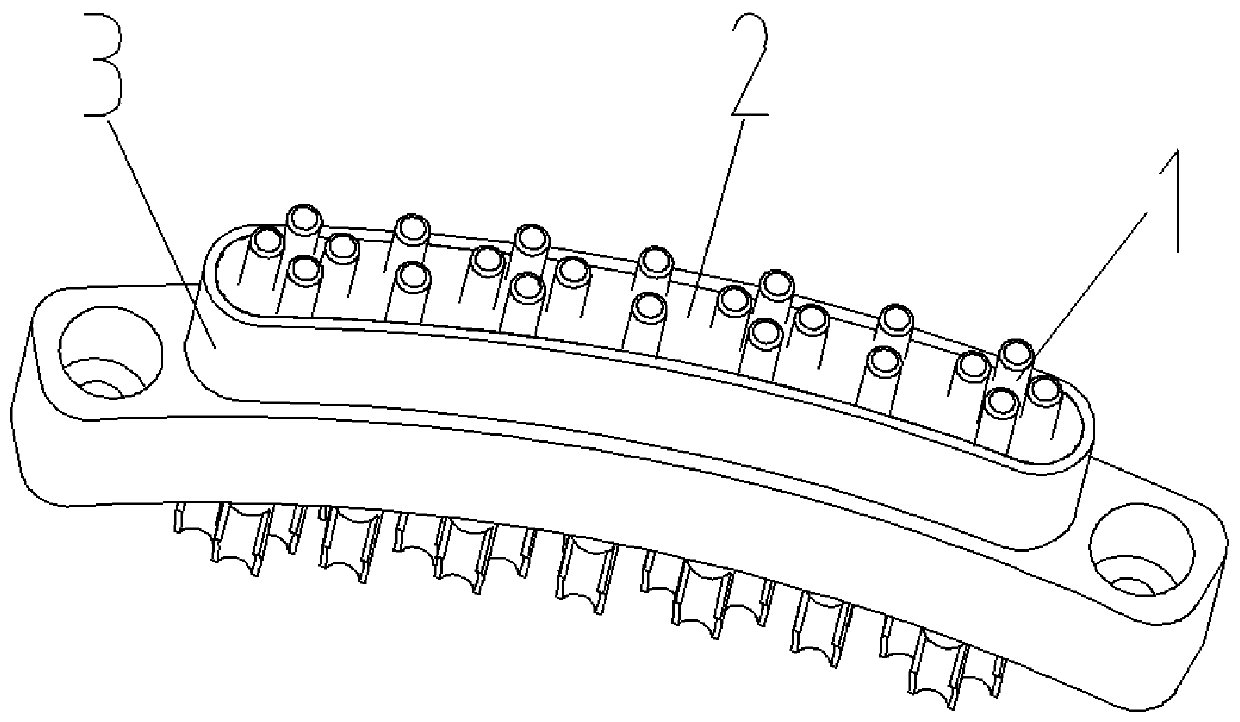

[0029] like figure 1 , figure 2 As shown, the present invention provides an arc-shaped airtight differential electrical connector with elastic contacts, which is composed of a plug and a socket, wherein:

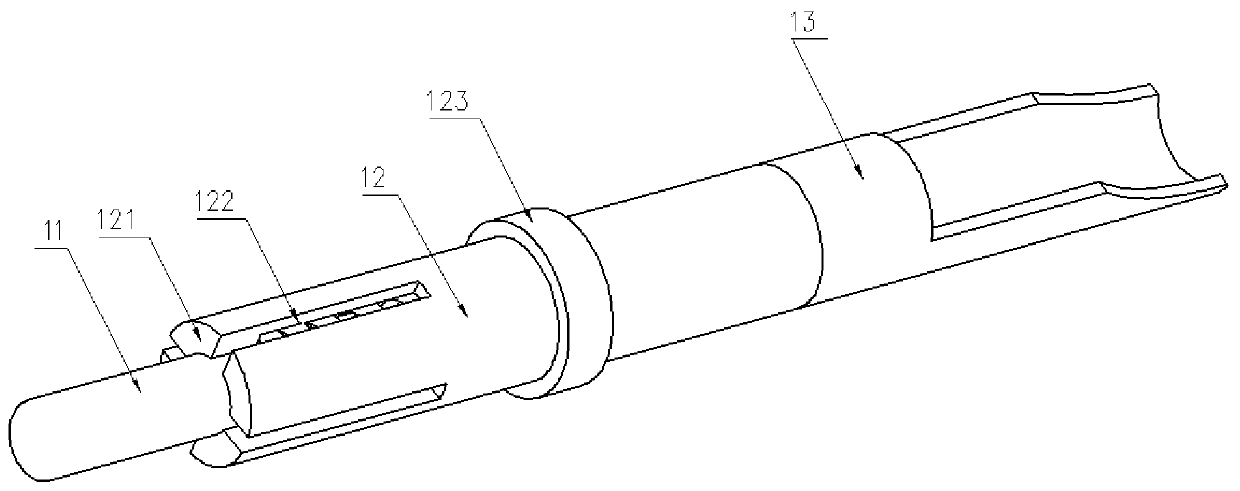

[0030] The plug includes a plurality of elastic contacts 1, a plug base 2, and a plug housing 3. The shape of the plug housing 3 is arc-shaped, and the shape of the plug base 2 is adapted to the shape of the plug housing 3. The plug base can be inserted into the plug housing, and the positioning is realized by the limiting structure, and the elastic contact piece is inserted into the plug base to achieve axial fixation, so that the plurality of elastic contact pieces 1 and the plug base 2 are assembled on the plug base. In the plug housing 3 described above, the tail end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com