Multi-station detecting and packaging device

A packaging equipment and multi-station technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems affecting the overall quality and yield of products, unfavorable production control, and high labor intensity, so as to facilitate production control and save time. and the effect of low manpower and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

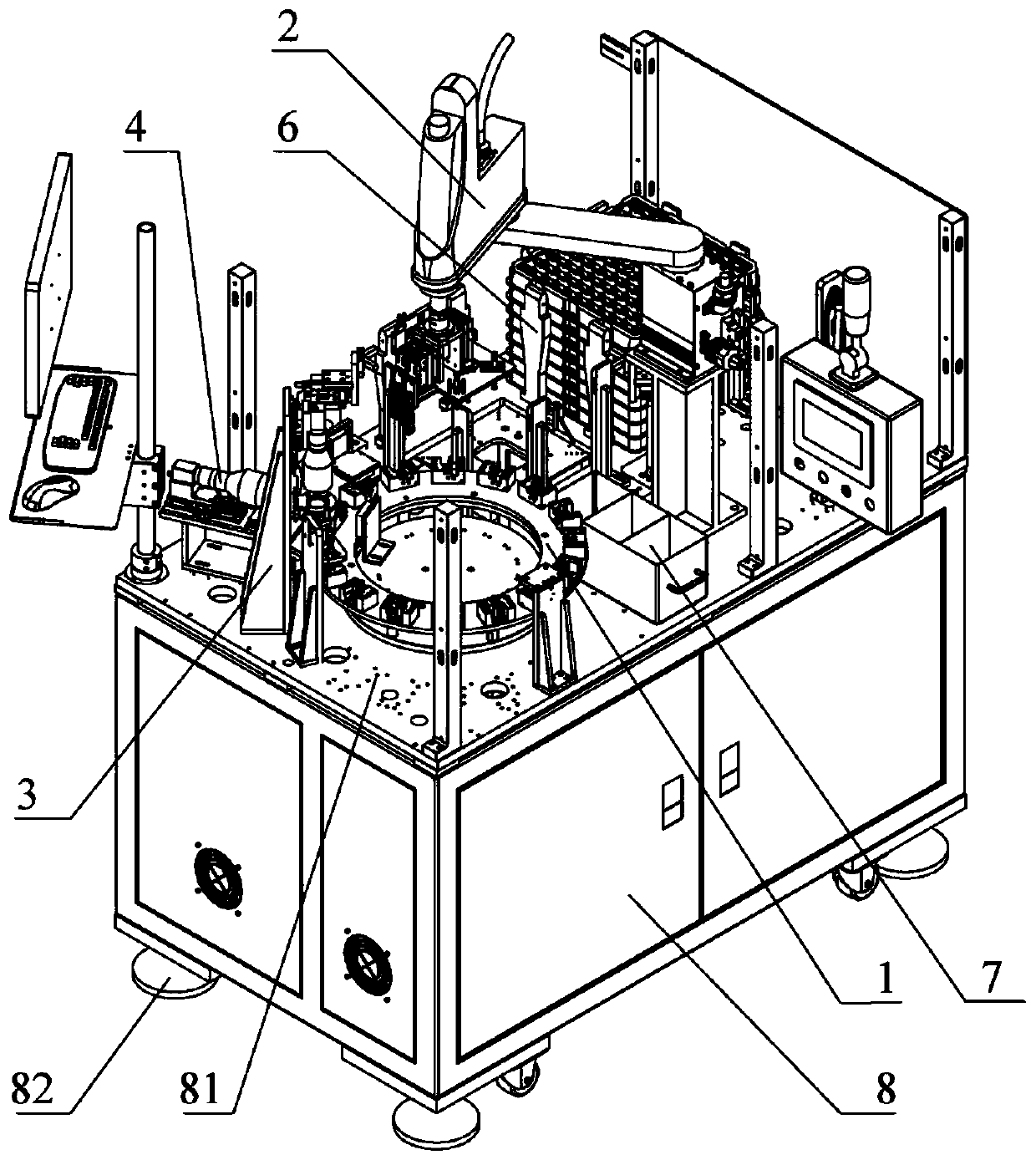

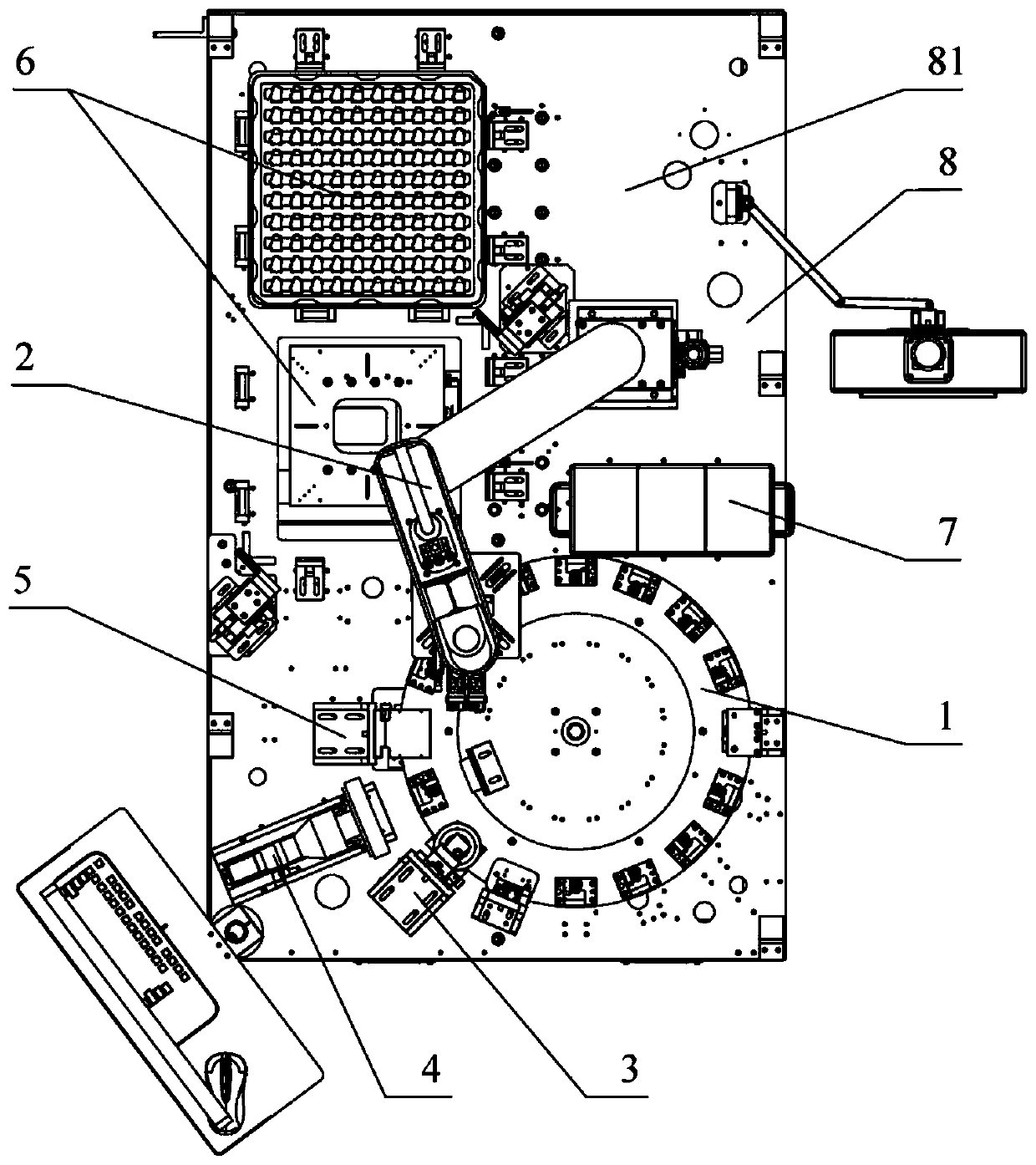

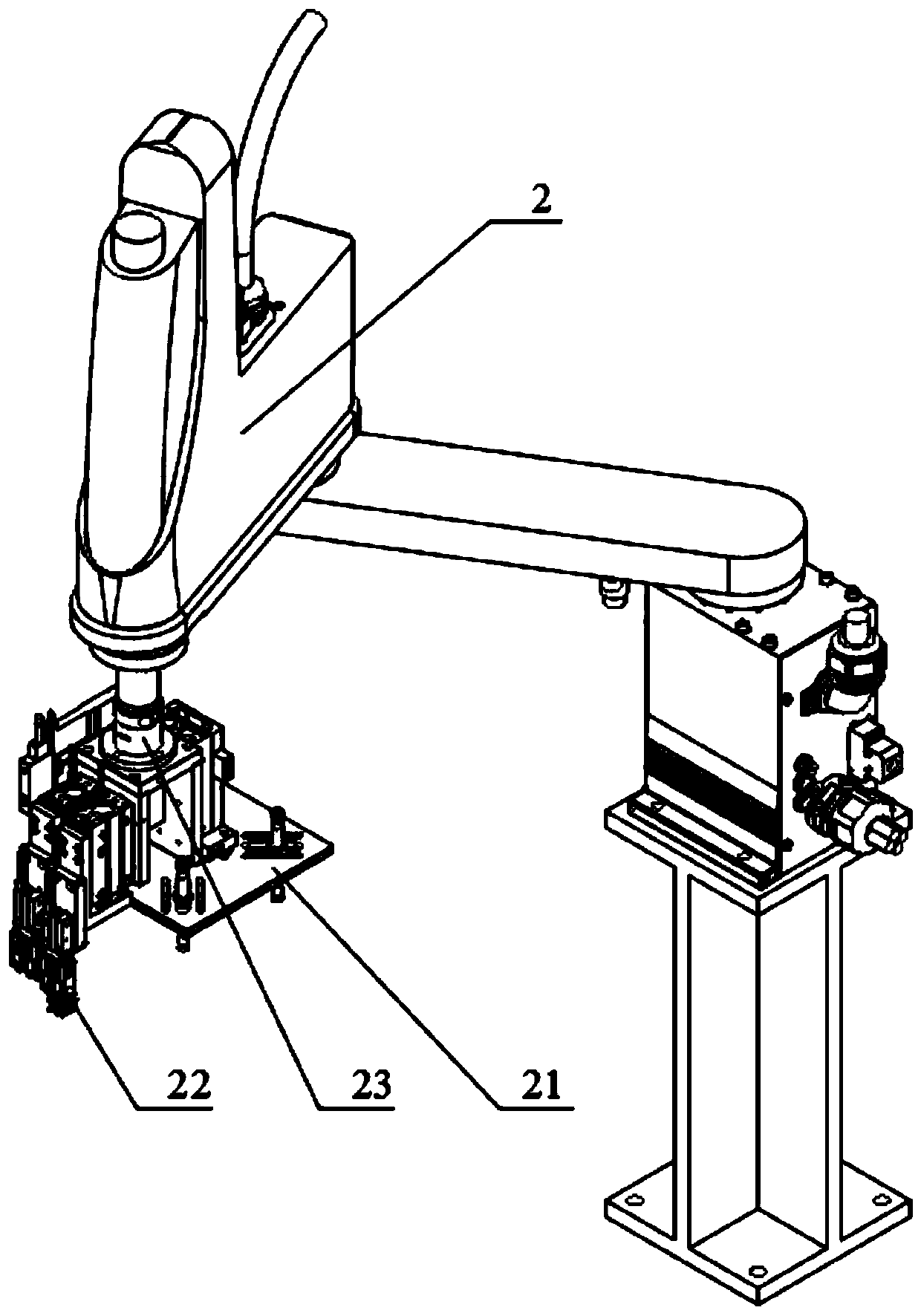

[0039] Such as Figure 1-17 As shown, the multi-station detection and packaging equipment at least includes the multi-station turntable device 1 and the pick-and-place manipulator 2 corresponding to the multi-station turntable device 1, the upper detection device 3, the horizontal detection device 4 and the lower detection device 5 and The bin device 6 and the waste collection box 7 corresponding to the pick-and-place manipulator 2, the multi-station turntable device 1, the pick-and-place manipulator 2, the upper detection device 3, the horizontal detection device 4, the lower detection device 5, and the feed bin The device 6 and the waste collection box 7 are usually arranged on the working base plate 81 of the frame 8. The multi-station turntable device 1 is provided with a positioning jig 11 for placing products. The positioning jig 11 can be one or more than two. The bin device 6 has a first discharge section 601 and a second discharge section 602. The first discharge sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com