Automatic detection, trimming and sorting device and method for large-array resistance type strain gauges

An automatic detection device, resistive strain technology, applied in measurement devices, sorting, instruments, etc., can solve the problems of large output of strain gauges, manual testing of strain gauges, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

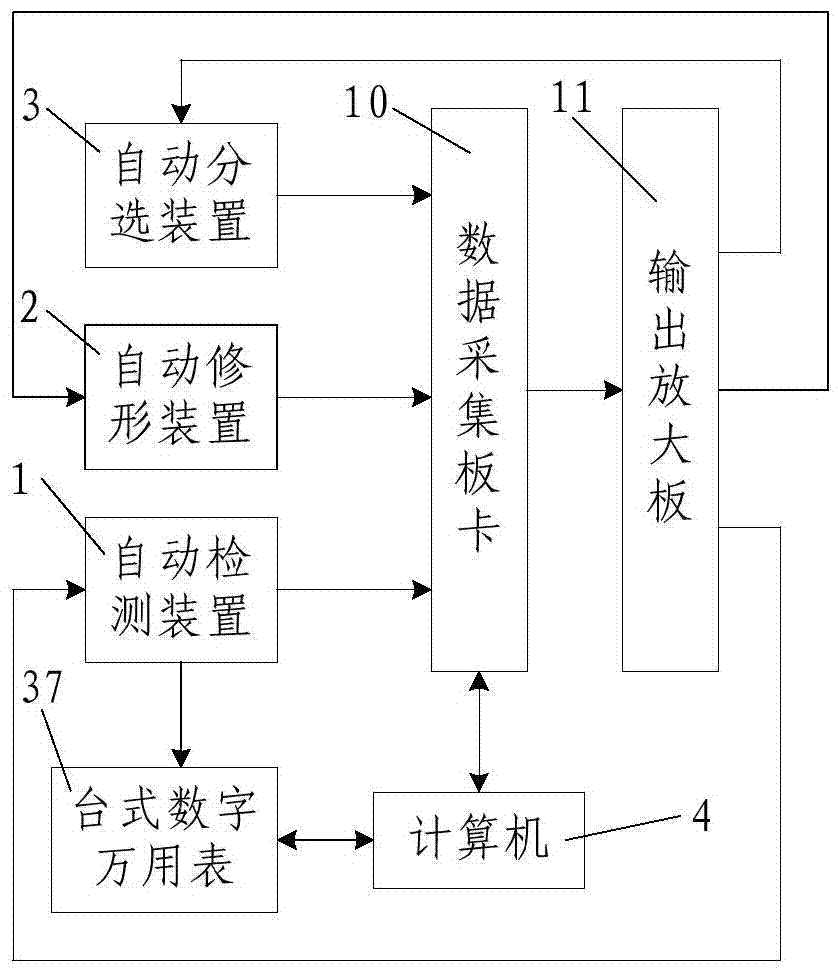

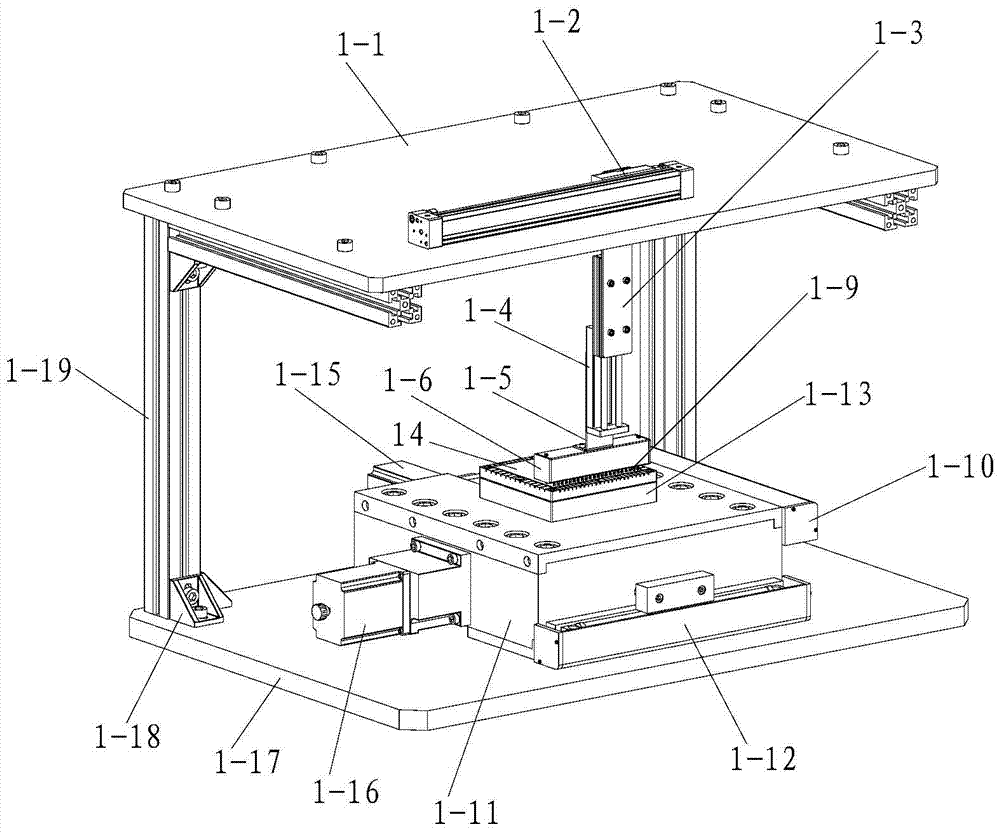

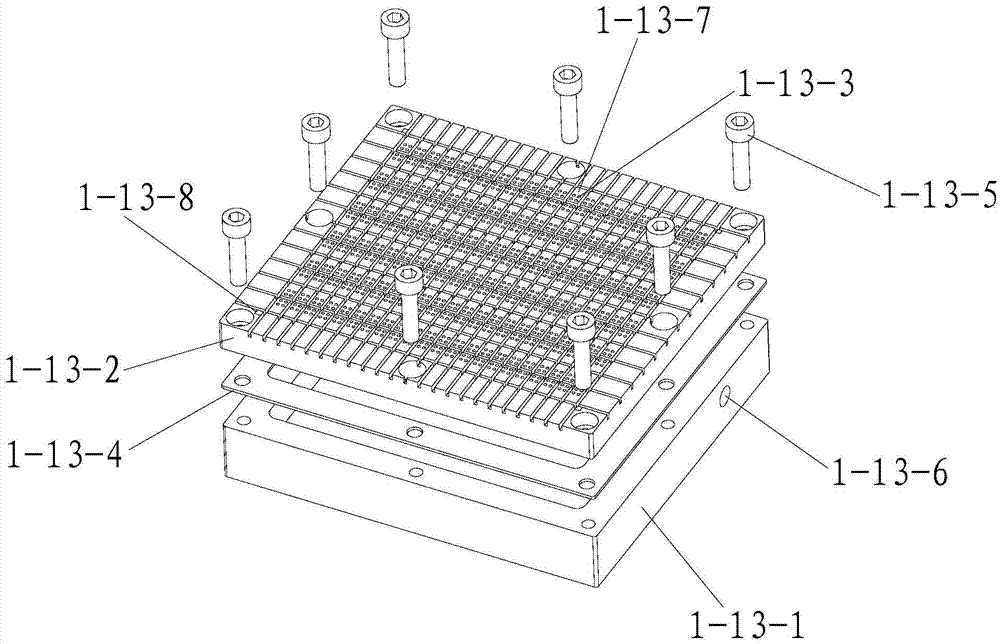

[0127] Such as figure 1 and Figure 20 As shown, the large array resistive strain gauge automatic detection, modification and sorting device of the present invention includes an automatic detection device 1, an automatic modification device 2, an automatic sorting device 3 and a computer 4, and the automatic detection device 1 includes Detection frame, detection positioning fixing mechanism and detection mechanism, described automatic shape modification device 2 comprises shape modification frame, shape modification positioning fixing mechanism and shape modification mechanism, and described automatic sorting device 3 comprises sorting frame, sorting Positioning and fixing mechanism, adsorption sorting mechanism and positioning and sorting mechanism, the computer 4 is connected with a data acquisition board 10 and a desktop digital multimeter 37, and the signal output terminal of the data acquisition board 10 is connected with an output amplifier 11;

[0128] combine figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com