Non-contact visual detection method for Mark positioning of mobile phone touch screen

A non-contact, visual detection technology, applied in the direction of equipment with touch panel/sensor/detector, TV, program control, etc., can solve the problems of detection station change range, low efficiency, inaccurate detection, etc., to achieve automatic Effects of detection, ease of configuration, improved reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 The process of acquiring images

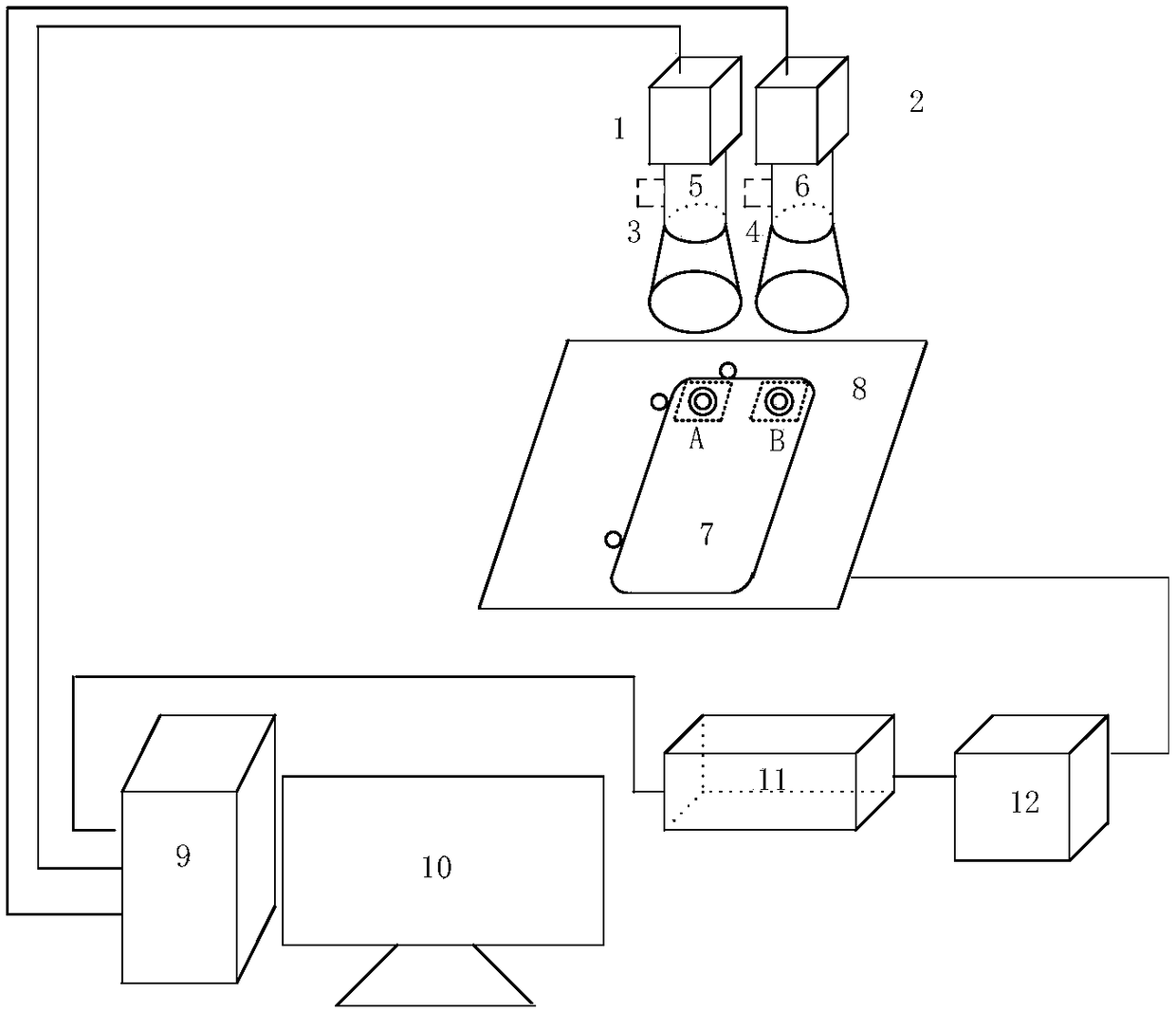

[0024] A mobile phone touch screen Mark positioning non-contact visual detection device, including an image acquisition module, a motion control module, an auxiliary equipment module, a pneumatic valve control module and a host computer module; there are two image acquisition modules, each composed of black and white Composed of industrial camera, telecentric lens, purple coaxial light source and data acquisition card, the telecentric lens is installed on the black and white industrial camera, and the purple coaxial light source is installed inside the telecentric lens; each telecentric lens is at a distance from the Mark mark on the touch screen of the mobile phone Position 1090-1100mm; Two black and white industrial cameras are connected through Gige Ethernet communication and installed in the PCI slot of the industrial control computer Data acquisition card; the motion control module is composed of relay switch, PLC and p...

Embodiment 2

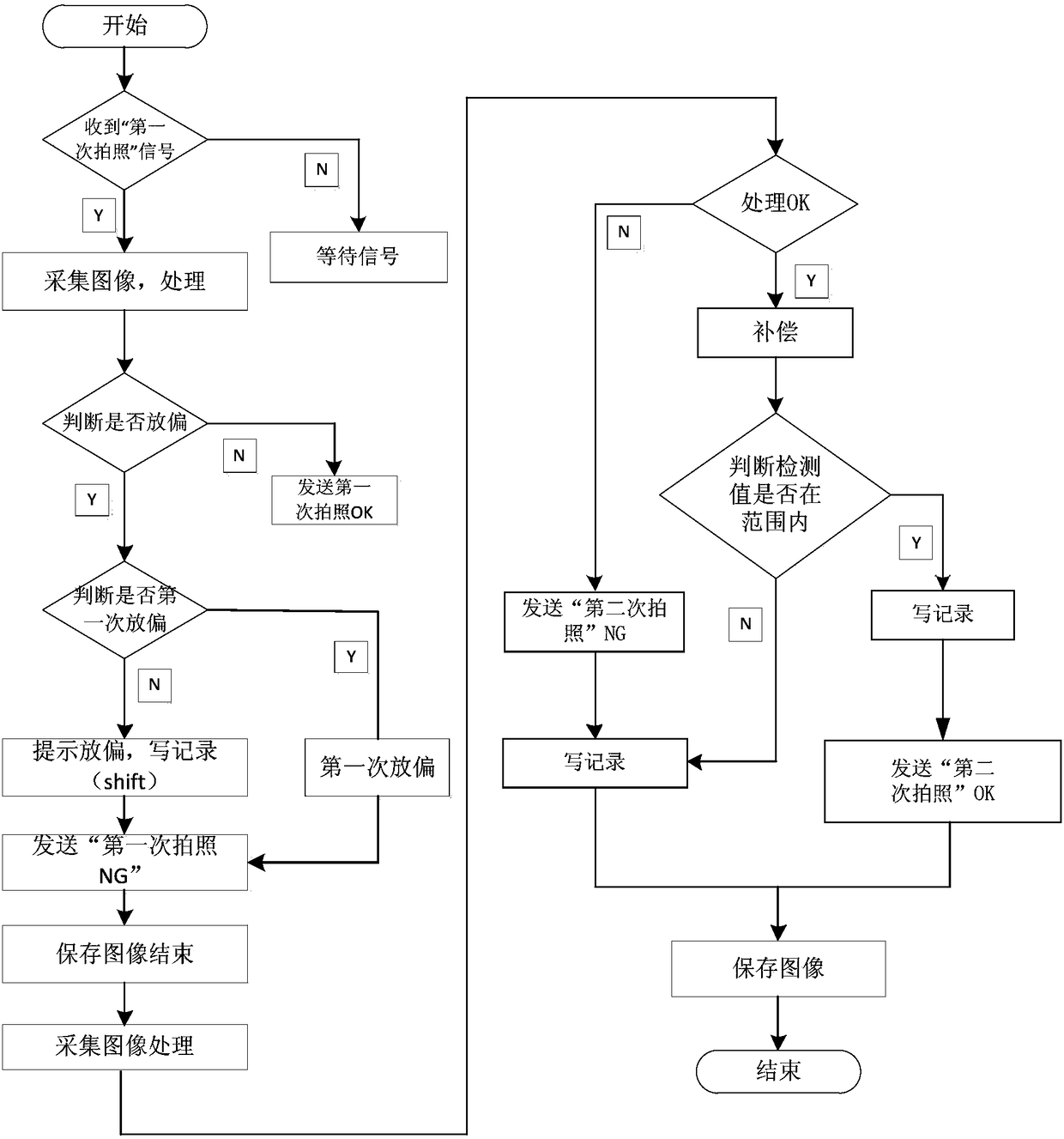

[0026] Example 2 Obtain image post-processing

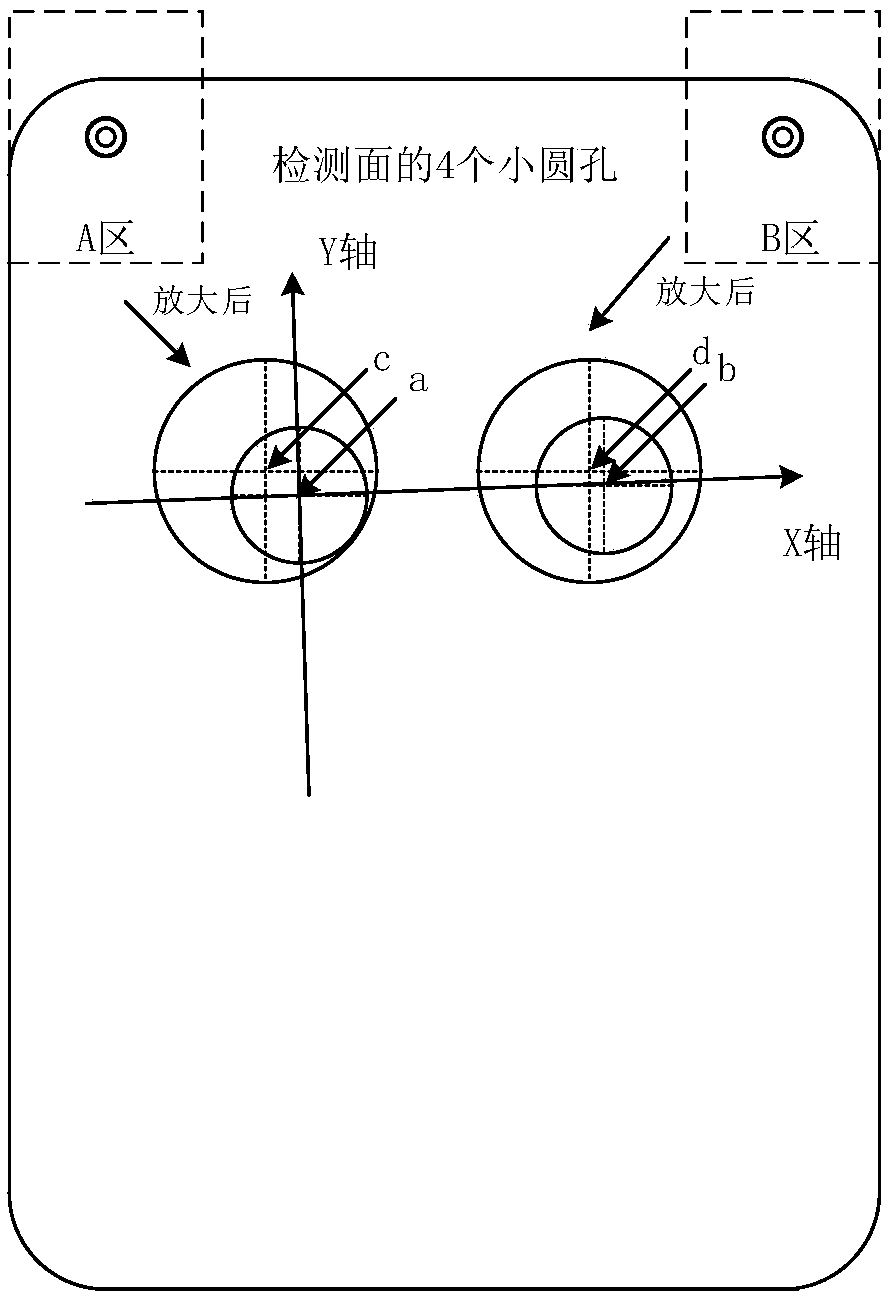

[0027] (1) To calibrate and calibrate the black and white industrial camera image, select a checkerboard calibration plate with a grid of 0.5mm*0.5mm, and use a nonlinear correction mode to correct perspective distortion, radial distortion and plane linear distortion; the specific steps are to place the calibration in reverse board, open the vision software, and open the real-time image modules of the two black and white industrial cameras respectively to perform image capture calibration for this device. After completion, the calibration files of the first black and white industrial camera 1 and the second black and white industrial camera 2 are generated, and the calibration files are respectively loaded into the corresponding host computer module;

[0028] (2) After collecting the image and searching for the template, use the positioning function to train the image features of the rough positioning of the product offline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com